Progress of anti-oxidation protection technology in titanium alloy welding process

-

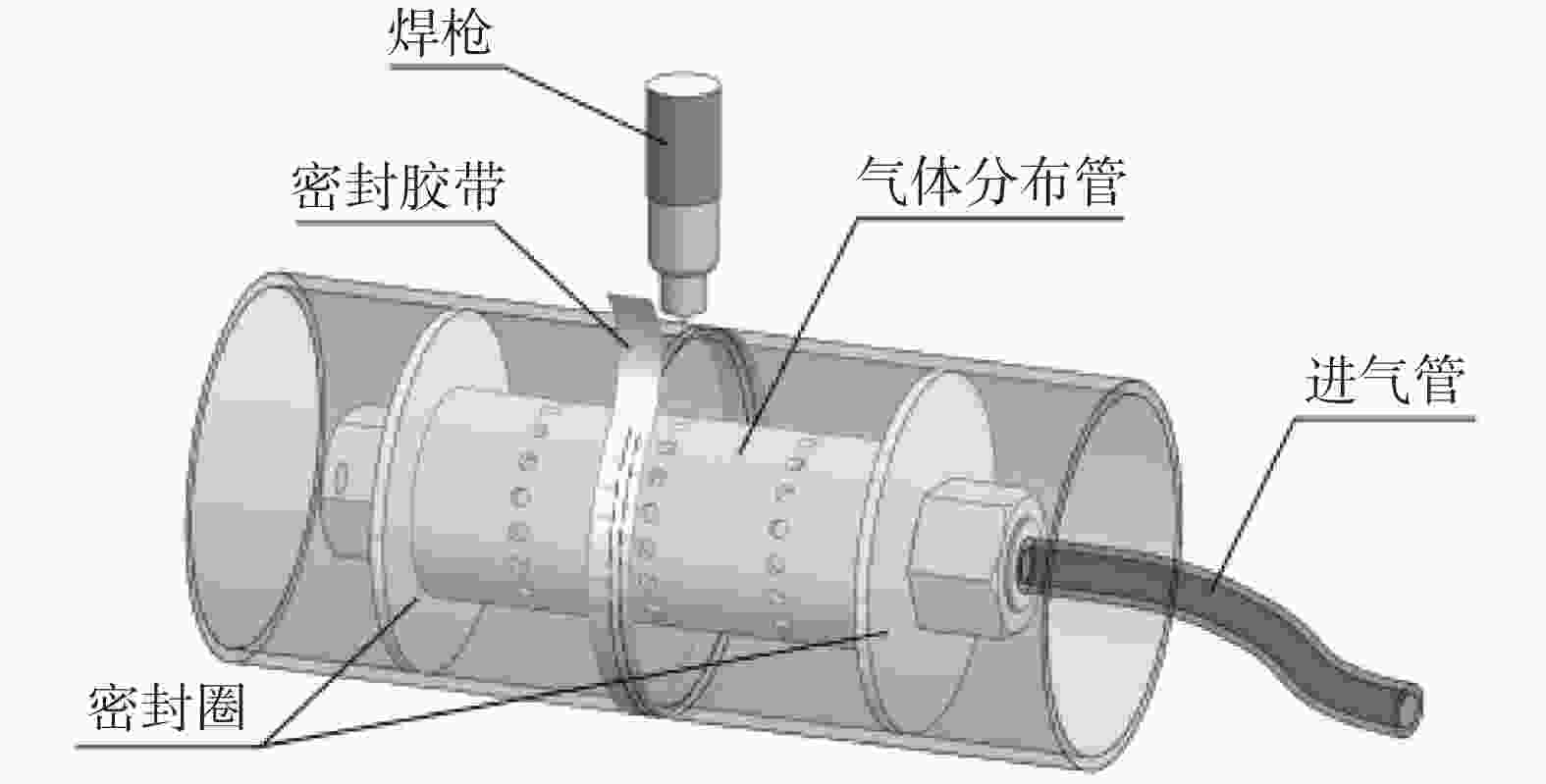

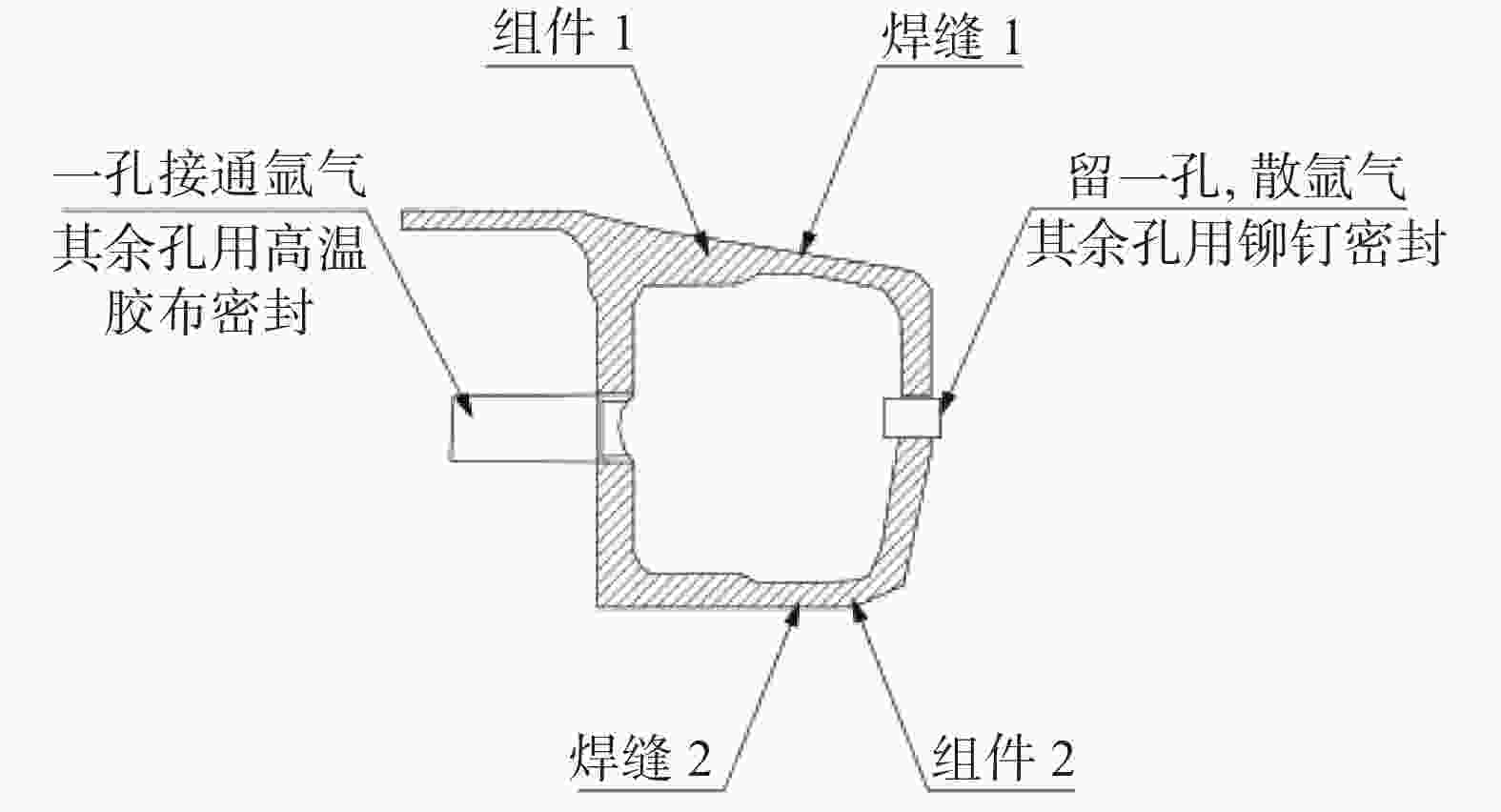

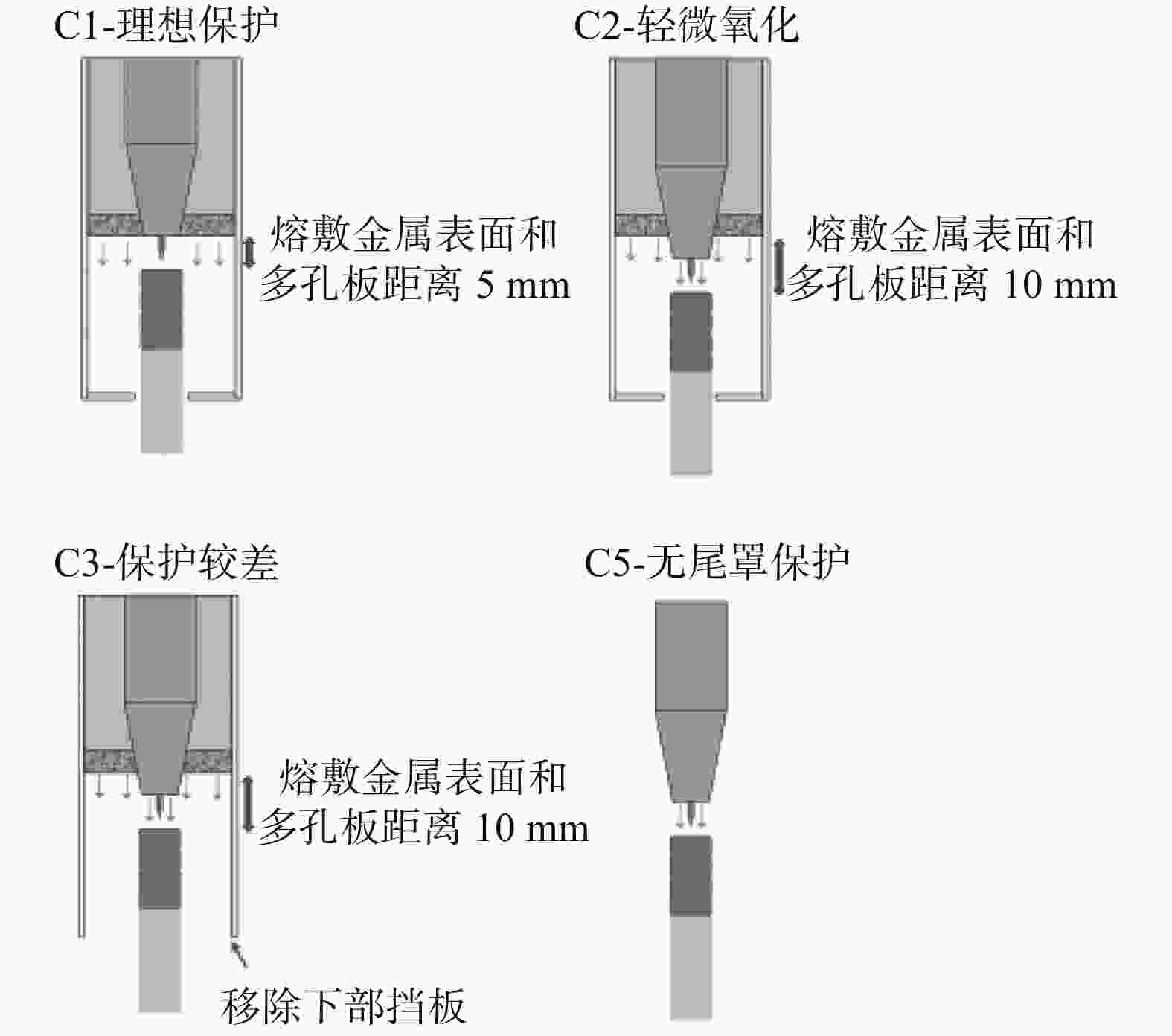

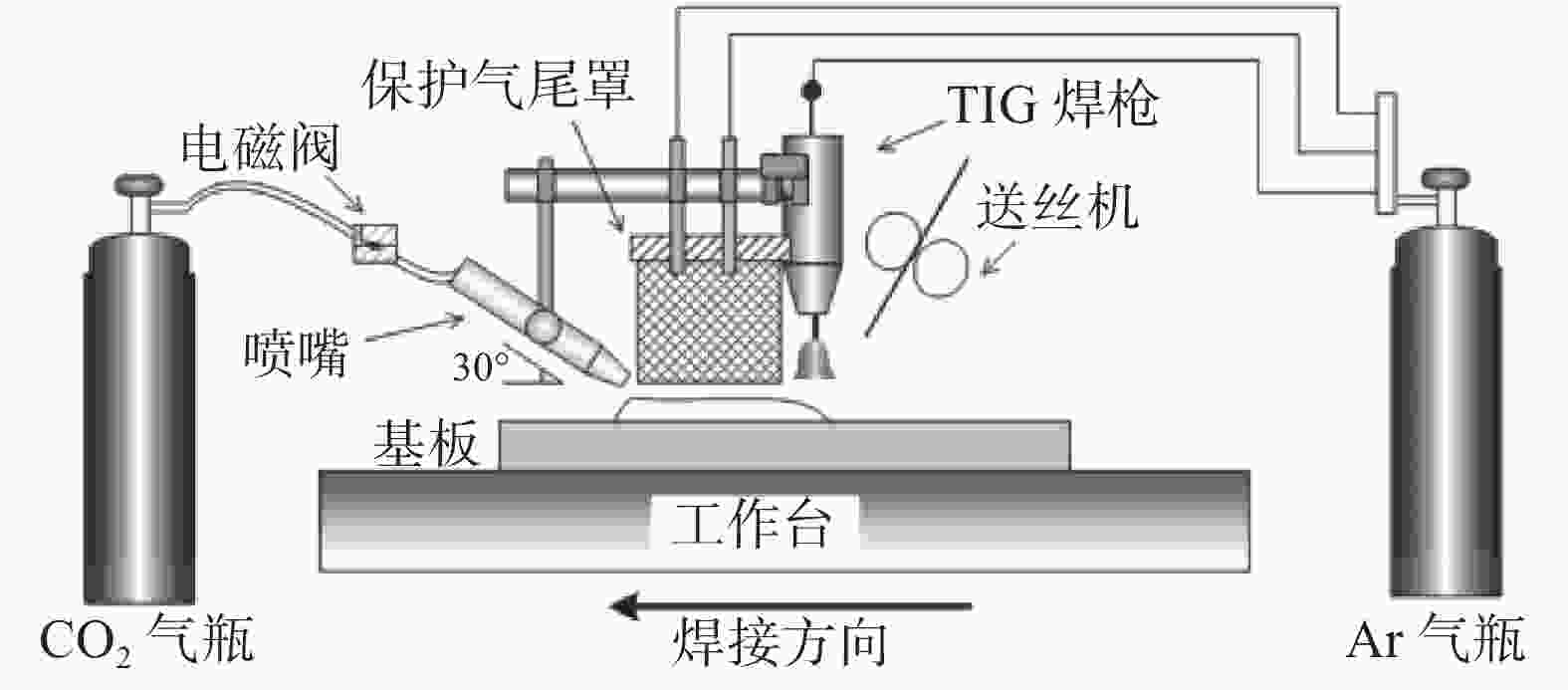

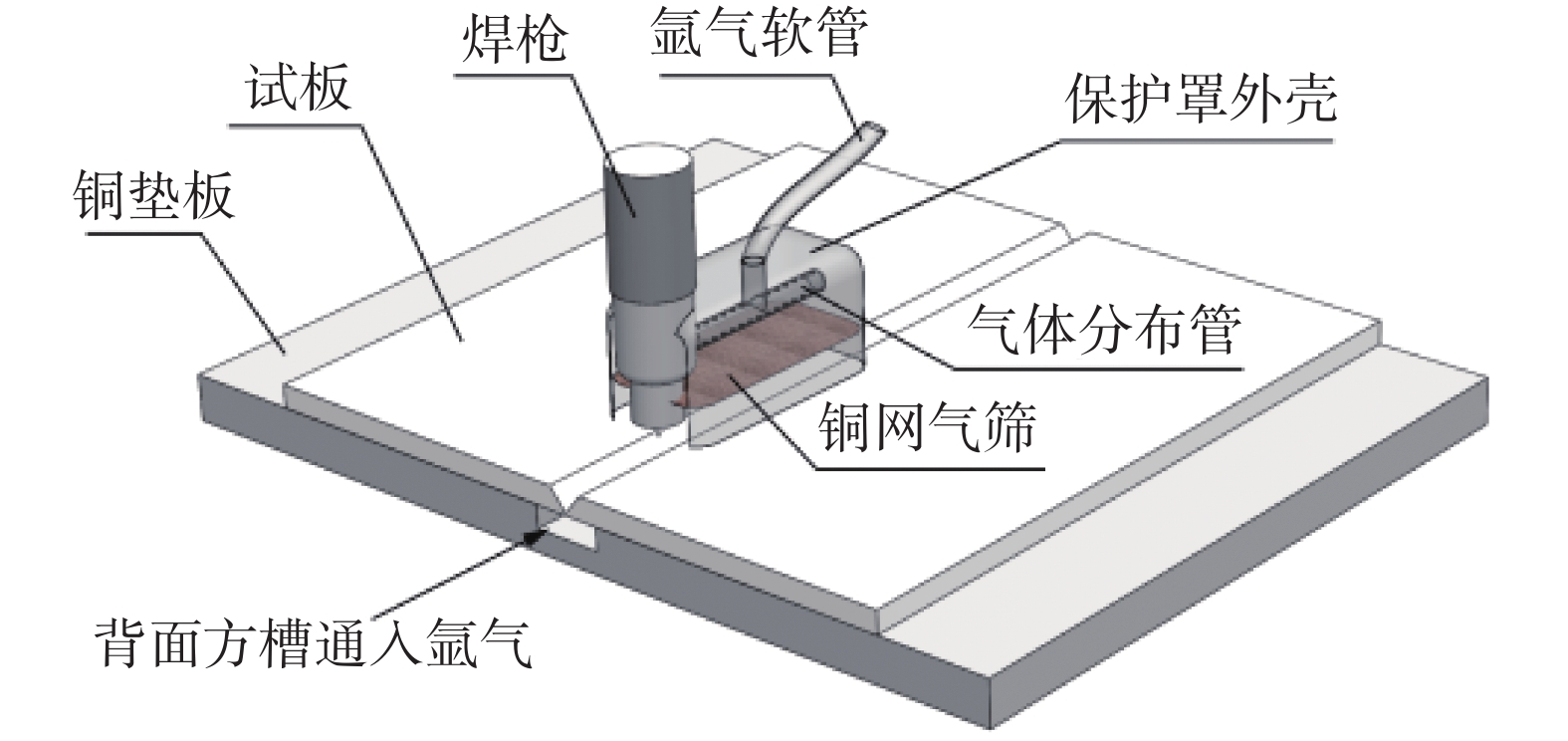

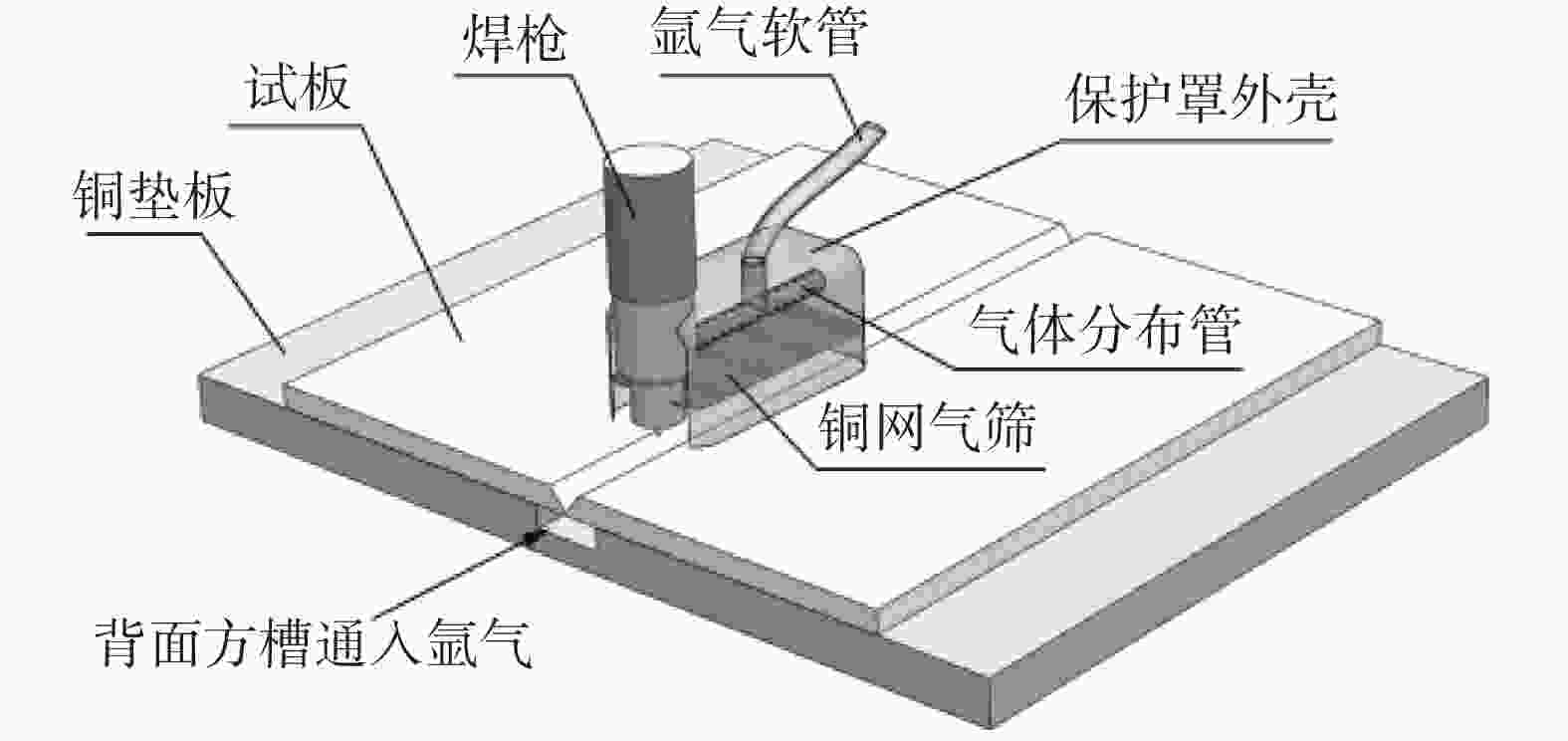

摘要: 钛及钛合金综合性能优异,但由于高温活性强导致焊接氧化问题严重,特别是在很低的固态温度下仍然吸收气体影响焊接接头质量,因此需要严格的焊接保护措施。在分析了钛合金的氧化机理及特性的基础上,系统总结了焊接过程中的各种防氧化保护措施和具体技术。详细介绍了钛合金长直焊缝、环形焊缝、空间不规则焊缝以及增材制造四种典型过程的防氧化保护问题,主要的防护措施有保护拖罩、封闭式充氩环境以及强制冷却三大类。针对钛合金长直焊缝局部气体保护,一般形式为保护拖罩结合背面保护气槽以及水冷措施;对于环形焊缝的背面保护方式,可以采用背面拖罩或者整体充氩保护的方法,其正面保护采用弧形拖罩即可;而不规则焊缝受限于空间形状,焊接拖罩的方法不再适用,小尺寸构件可采用简易充氩保护箱,大尺寸构件保护问题亟待解决;增材制造过程中的热积累问题也对其保护形式提出了更高的要求,目前采用具有一定气体挺度的层流惰性气体和CO2跟随强制冷却的方式取得了较好的效果。Abstract: Titanium and titanium alloys have excellent comprehensive properties, but the welding oxidation problem is serious due to the strong high-temperature activity. Especially the problem of absorbing gas at solid-state temperature is significant, which affects the quality of the welding joint. Therefore, strict welding protection measures are needed. Based on the analyses of oxidation mechanism and characteristics of titanium alloy, various anti-oxidation protection measures and specific technologies in welding process are summarized systematically in this paper. Anti-oxidation protection of titanium alloy in four typical processes of long straight weld, circular weld, space irregular weld and additive manufacturing is introduced in detail. The main protective measures include welding gas shielding trailing, closed argon-filled environment and forced cooling. For local gas protection of long straight weld of titanium alloy, the general form is welding gas shielding trailing combined with back protective gas groove and water cooling measures. For the back protection of the circular weld, the back gas shielding or the whole argon filled protection method can be adopted, and the front protection can use the welding gas shielding trailing. However, due to the limitation of the shape of the irregular weld, the method of welding gas shielding trailing is no longer applicable. The simple argon-filled protective box can be used for small size components, while the protection problem of large size components needs to be solved urgently. The heat accumulation in the additive manufacturing process also increases requirements for its protection form. At present, good results have been achieved by the laminar inert gas and followed by forced CO2 cooling process.

-

Key words:

- titanium alloy /

- welding /

- oxidation /

- local shielding

-

表 1 固态氧化试验结果[9]

Table 1. Results of solid oxidation experiment

加热温度/℃ 保温时间/min 接头颜色 弯曲角/(°) 测量值 平均值 400 30 黄 100~129 113 500 30 紫 90~112 97 600 30 蓝 102~110 106 700 30 灰红 94~116 107 800 30 灰白(浅) 88~118 99 900 30 灰白(深) 87~109 104 表 2 钛焊缝表面不同氧化颜色的情况对比[11]

Table 2. Comparison of different oxidation colors on titanium weld surface

焊缝表面颜色 污染程度 对接头质量影响 处理措施 银白色 几乎不存在有害气体的污染 无影响 浅黄、金黄色 轻微污染 对接头机械性能影响不大 淡蓝 一般性污染 略有影响 不锈钢丝纶刷除 紫蓝、深蓝色 污染较严重 接头弯曲角下降 去除焊道及邻近金属,重新焊接 灰色或黄色粉末 严重污染 焊接区脆化 完全去除焊道和热影响区,检查保护、供气系统,试验测试后重新焊接 -

[1] Li Xingyu, Li Fang, Mou Gang, et al. Welding of titanium and titanium alloy[J]. Electric Welding Machine, 2017,47(4):67−70. (李兴宇, 李芳, 牟刚, 等. 钛及钛合金的焊接[J]. 电焊机, 2017,47(4):67−70. [2] Cui C, Hu B, Zhao L, et al. Titanium alloy production technology, market prospects and industry development[J]. Materials & Design, 2011,32(3):1684−1691. [3] Choi B H, Choi B K. The effect of welding conditions according to mechanical properties of pure titanium[J]. Journal of Materials Processing Technology, 2008,201(1):526−530. [4] Costa A, Miranda R, Quintino L, et al. Analysis of beam material interaction in welding of titanium with fiber lasers[J]. Materials and Manufacturing Processes, 2007,22(7):798−803. [5] Liu Shunhong, Peng Shande, Xiang Fan. Research on laser lap welding of TC4 titanium alloy[J]. Electric Welding Machine, 2006,(6):24−29. (刘顺洪, 彭善德, 项凡. TC4钛合金激光搭接焊的研究[J]. 电焊机, 2006,(6):24−29. doi: 10.3969/j.issn.1001-2303.2006.06.010 [6] Chen Sijie, Zhu Chunli. Research on advanced connecting technology of titanium and titanium alloy[J]. Hot Working Process, 2015,44(3):18−21. (陈思杰, 朱春莉. 钛及钛合金先进连接技术研究[J]. 热加工工艺, 2015,44(3):18−21. [7] Chen Guangfeng, Guo Fenying. Development and application of inert gas integral protective welding equipment[J]. Welding, 2000,(9):20−22. (陈光锋, 郭奋颖. 惰性气体整体保护焊接设备的研制及应用[J]. 焊接, 2000,(9):20−22. doi: 10.3969/j.issn.1001-1382.2000.09.005 [8] 罗辉, 郝丽萍, 魏祚伟. 钛合金氧化性能研究[C]//第九次全国焊接会议. 天津: 中国机械工程学会焊接分会, 1999.Luo Hui, Hao Liping, Wei Zuowei. Study on oxidation properties of titanium alloys [C]//The 9th National Welding Conference. Tianjing: Welding Branch of China Society of Mechanical Engineering, 1999. [9] Room 23, 621 Research Institute. Research on welding oxidation of titanium alloy[J]. Aviation Technology, 1997,(7):3−7. (六二一研究所二十三室. 钛合金焊接氧化问题的研究[J]. 航空工艺技术, 1997,(7):3−7. [10] Jia Zhiqiang, Zeng Weidong, Zhang Yaowu, et al. Effect of oxidation treatment on oxidation color and mechanical properties of TC21 titanium alloy[J]. Rare Metal Materials and Engineering, 2013,42(1):49−53. (贾志强, 曾卫东, 张尧武, 等. 氧化处理对TC21钛合金氧化色及力学性能的影响[J]. 稀有金属材料与工程, 2013,42(1):49−53. doi: 10.3969/j.issn.1002-185X.2013.01.010 [11] Ting Wang. Welding problems and countermeasures of marine titanium and titanium alloy[J]. Ship Science and Technology, 2011,33(6):113−116. (汀 汪. 船用钛及钛合金的焊接问题及对策[J]. 舰船科学技术, 2011,33(6):113−116. doi: 10.3404/j.issn.1672-7649.2011.06.026 [12] Zou Shuai. Patent analysis of gas protection technology for titanium alloy welding[J]. Chemical Industry Management, 2018,(19):23−25. (邹帅. 钛合金焊接气体保护技术的专利分析[J]. 化工管理, 2018,(19):23−25. doi: 10.3969/j.issn.1008-4800.2018.19.015 [13] Zhang Yong, Yang Jianguo, Liu Xuesong, et al. Design of jet protection welding tooling for TIG welding of thin plate[J]. Welding & Joining, 2009,(10):46−49. (张勇, 杨建国, 刘雪松, 等. TC4薄板TIG焊喷流保护焊接工装的设计[J]. 焊接, 2009,(10):46−49. doi: 10.3969/j.issn.1001-1382.2009.10.010 [14] Shi J, Song G, Chi J. Effect of active gas on weld appearance and performance in laser-TIG hybrid welded titanium alloy[J]. International Journal of Lightweight Materials and Manufacture, 2018,1:47−53. doi: 10.1016/j.ijlmm.2018.03.002 [15] Bendikiene R, Baskutis S, Baskutiene J, et al. Comparative study of TIG welded commercially pure titanium[J]. Journal of Manufacturing Processes, 2018,36:155−163. doi: 10.1016/j.jmapro.2018.10.007 [16] Hu Xukun, Ma Anguo, Zhang Pengfei, et al. Improvement and application of inert gas protection devices for welding zirconium alloy plates[J]. Metal World, 2019,(4):64−66. (胡旭坤, 马安国, 张鹏飞, 等. 锆合金板材焊接惰性气体保护装置的改进和应用[J]. 金属世界, 2019,(4):64−66. doi: 10.3969/j.issn.1000-6826.2019.04.016 [17] Shi Fangle, Huang Lei. Design of Ti and Ti-alloy tube TIG arc welding protective cover[J]. Mechanical and Electrical Equipment, 2019,36(1):36−38. (施方乐, 黄雷. 钛及钛合金管氩弧焊焊接保护罩设计[J]. 机电设备, 2019,36(1):36−38. [18] Yang Qinghua. Improve the welding quality of titanium tube with self-made argon-filled protective cover[J]. Install, 2002,(1):20−21. (杨庆华. 利用自制充氩保护罩提高钛管焊接质量[J]. 安装, 2002,(1):20−21. doi: 10.3969/j.issn.1002-3607.2002.01.011 [19] Bin Gao, Deng Qilin, Zhou Chunyan. Research on gas protection in laser welding of titanium alloy[J]. Electrical Machining and Die, 2009,(5):44−49. (宾 高, 邓琦林, 周春燕. 钛合金激光焊接过程中气体保护问题的研究[J]. 电加工与模具, 2009,(5):44−49. doi: 10.3969/j.issn.1009-279X.2009.05.011 [20] 刘帛炎. 钛合金管道全位置等离子弧焊焊缝成形及组织性能研究 [D]. 沈阳: 沈阳工业大学, 2019.Liu Boyan. Research on welding seam forming and microstructure performance by full-position plasma arc welding of titanium alloy pipeline [D]. Shenyang : Shenyang University of Technology, 2019. [21] Guo Chunfu, Liu Boyan, Sun Weiqiang, et al. All-position plasma arc automatic welding equipment for pipelines[J]. Research and Application of Materials, 2017,11:251−255. (郭春富, 刘帛炎, 孙伟强, 等. 管道全位置等离子弧自动焊接设备[J]. 材料研究与应用, 2017,11:251−255. doi: 10.3969/j.issn.1673-9981.2017.04.009 [22] Guo Chunfu, Liu Boyan, Dong Chunlin, et al. TC4 Full-position PAW technology and joint performance analysis[J]. Journal of Welding, 2019,40:121−126. (郭春富, 刘帛炎, 董春林, 等. TC4厚壁管全位置PAW工艺及接头性能分析[J]. 焊接学报, 2019,40:121−126. doi: 10.12073/j.hjxb.2019400193 [23] 李小书. 钛合金导管焊接保护研究[C]//第二届中国北方焊接学术会议. 西安: 中国机械工程学会焊接分会, 2001.Li Xiaoshu. Research on titanium alloy pipe welding protection [C]//The Second North China Welding Academic Conference. Xi’an: Welding Branch of China Society of Mechanical Engineering, 2001. [24] Zhang Junling, Shi Xiaogang, Wang Xiaoyun. Argon shielding for welding of high alloy stainless steel and heat resisting steel tube[J]. Petrochemical Equipment, 2012,41:70−72. (张俊玲, 石小刚, 王孝云. 高合金不锈钢和耐热钢管焊接氩气保护罩[J]. 石油化工设备, 2012,41:70−72. doi: 10.3969/j.issn.1000-7466.2012.01.018 [25] 司松社. 某机钛合金熔焊缝防表面氧化工艺研究[C]//中国航空学会学术年会. 深圳: 中国航空学会, 2007.Si Songshe. Research on anti-surface oxidation technology of titanium alloy fusion welding joint of a machine [C]//The Annual Academic Conference of The Aviation Society of China. Shenzhen: The Aviation Society of China, 2007. [26] Bermingham M J, Thomson-larkins J, St John D H, et al. Sensitivity of Ti-6Al-4V components to oxidation during out of chamber wire+arc additive manufacturing[J]. Journal of Materials Processing Technology, 2018,258:29−37. doi: 10.1016/j.jmatprotec.2018.03.014 [27] Ding J, Colegrove P, Martina F, et al. Development of a laminar flow local shielding device for wire + arc additive manufacture[J]. Journal of Materials Processing Technology, 2015,226:99−105. doi: 10.1016/j.jmatprotec.2015.07.005 [28] Wu B, Pan Z, Ding D, et al. The effects of forced interpass cooling on the material properties of wire arc additively manufactured Ti6Al4V alloy[J]. Journal of Materials Processing Technology, 2018,258:97−105. doi: 10.1016/j.jmatprotec.2018.03.024 [29] Wu B, Pan Z, Chen G, et al. Mitigation of thermal distortion in wire arc additively manufactured Ti6Al4V part using active interpass cooling[J]. Science and Technology of Welding and Joining, 2019,24:484−494. doi: 10.1080/13621718.2019.1580439 [30] Ding Donghong, Pan Zengxi, Qiu Zhijun, et al. Wire arc additive manufacturing of Ti6Al4V using active interpass cooling[J]. Materials and Manufacturing Processes, 2020,35(7):845−851. doi: 10.1080/10426914.2020.1732414 -

下载:

下载: