Research on TIG welding process of high strength titanium alloy

-

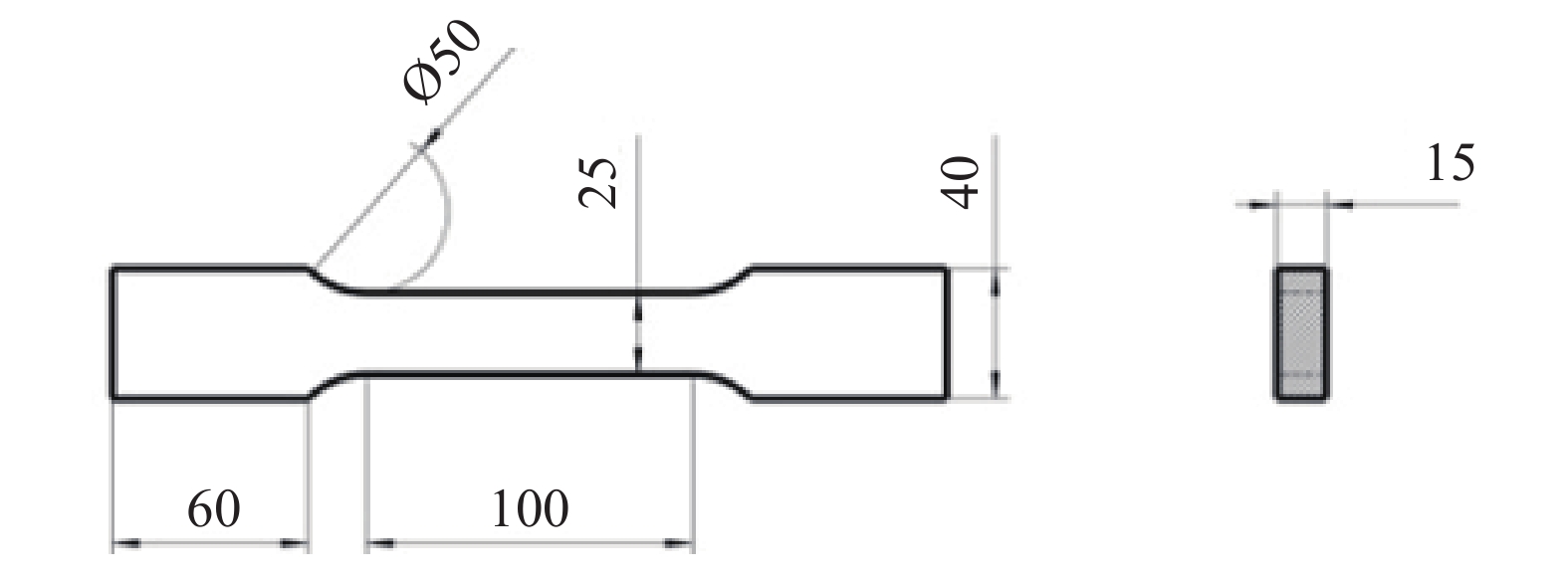

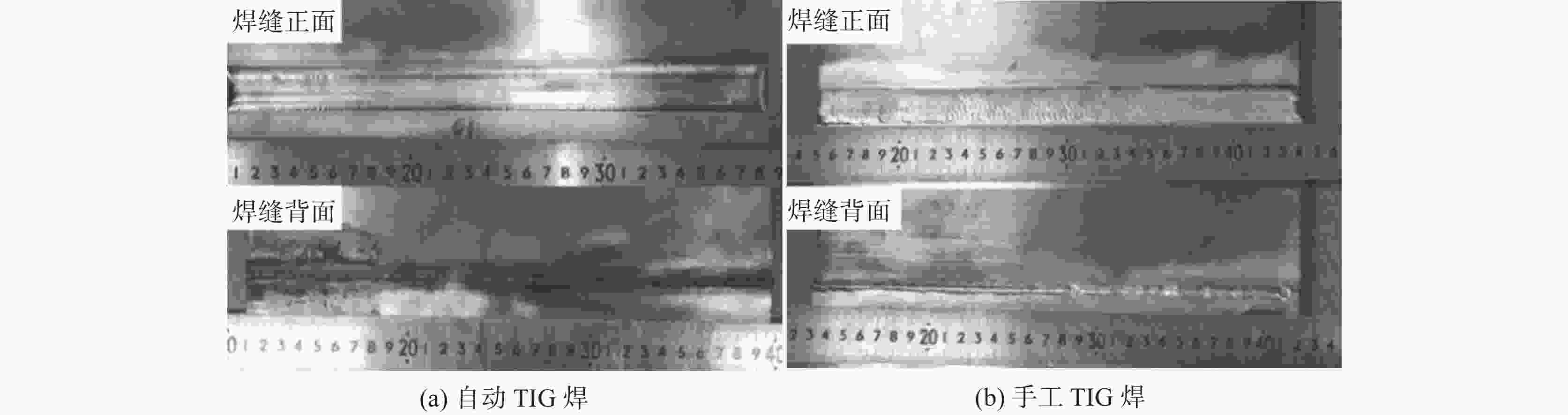

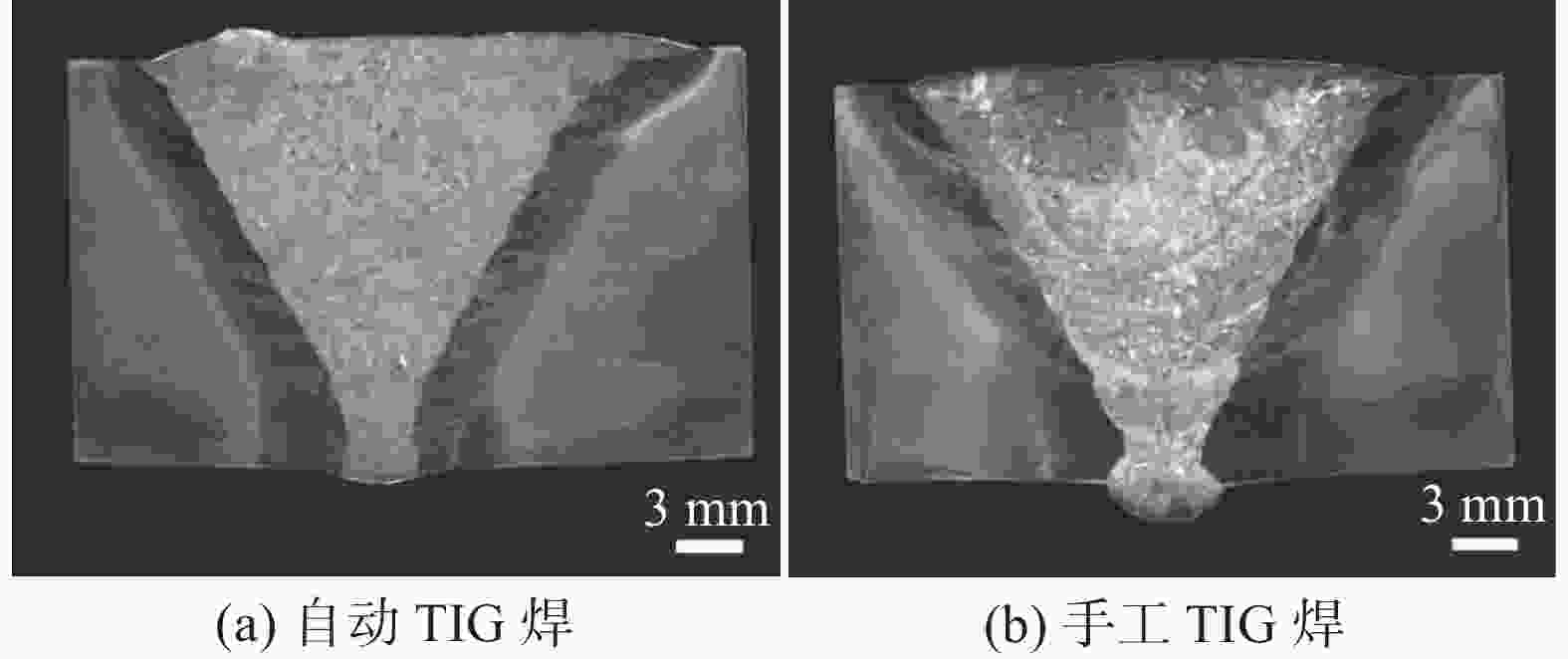

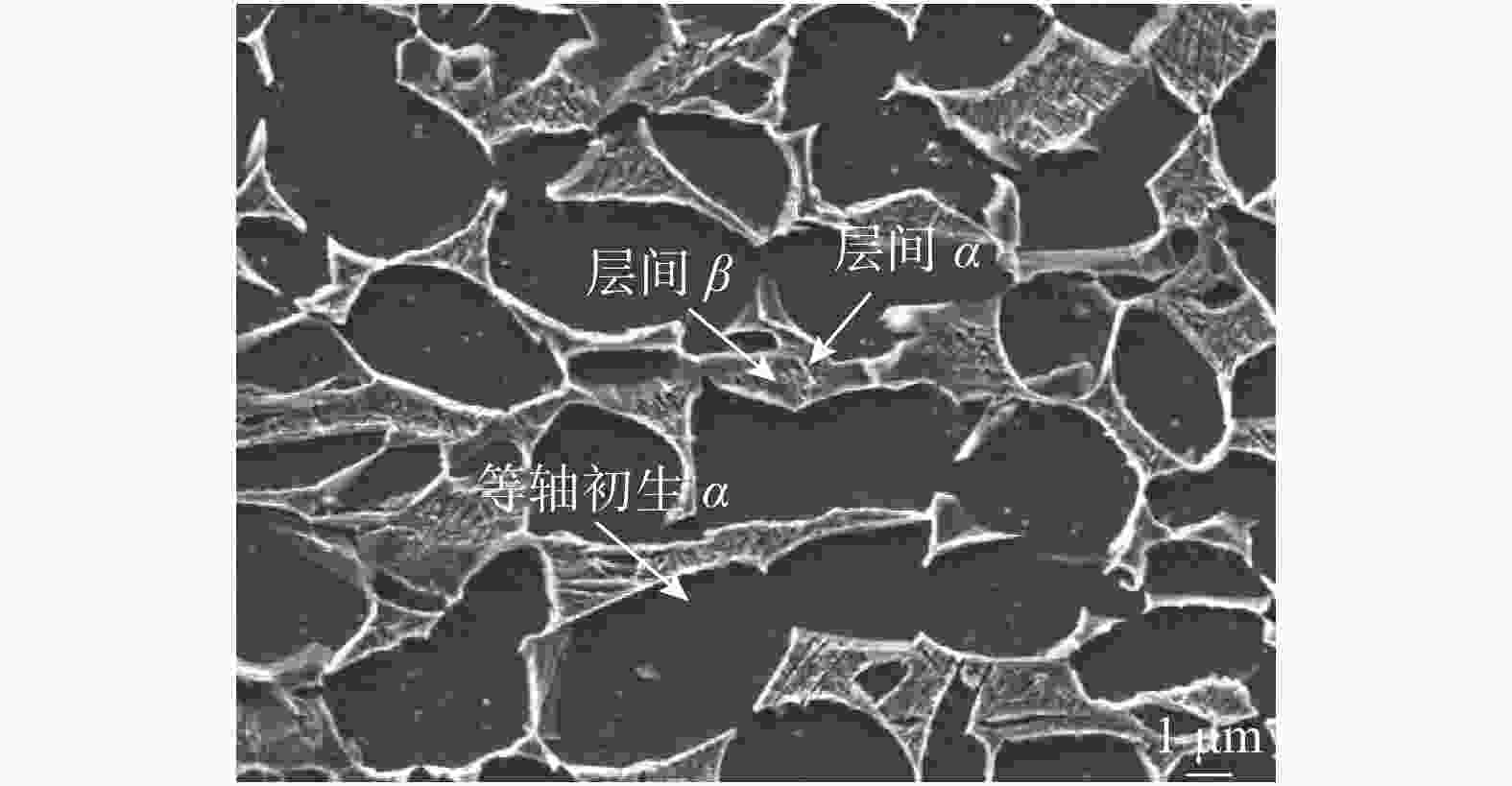

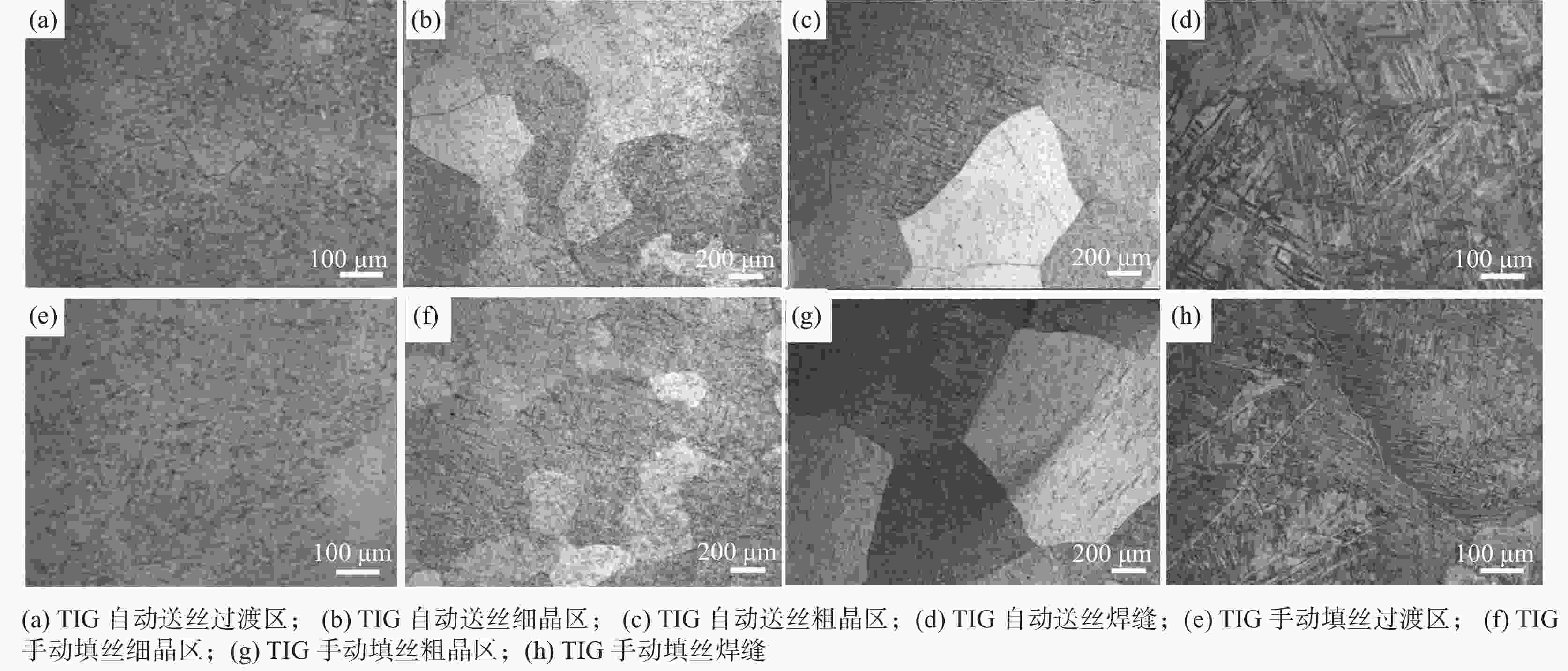

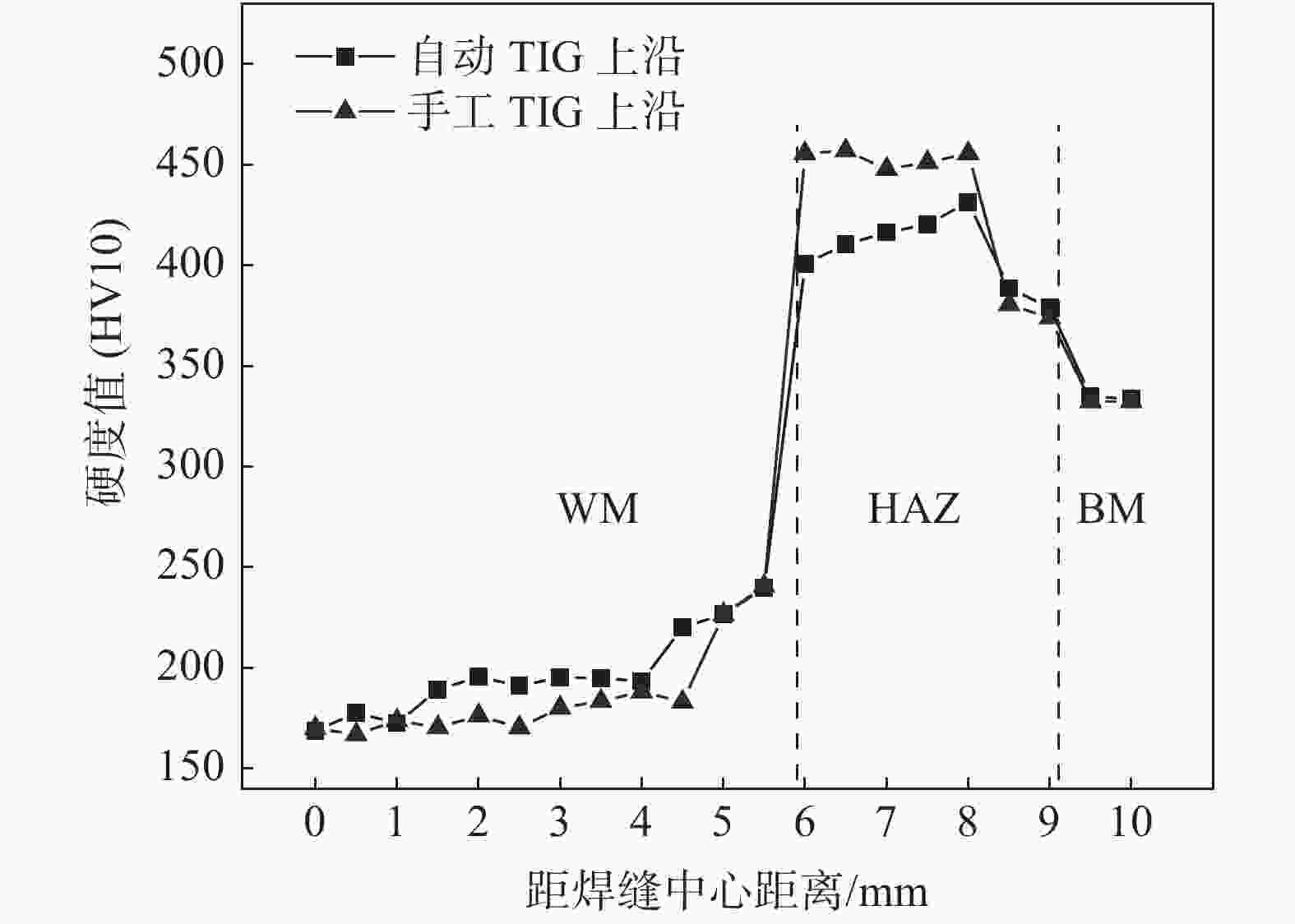

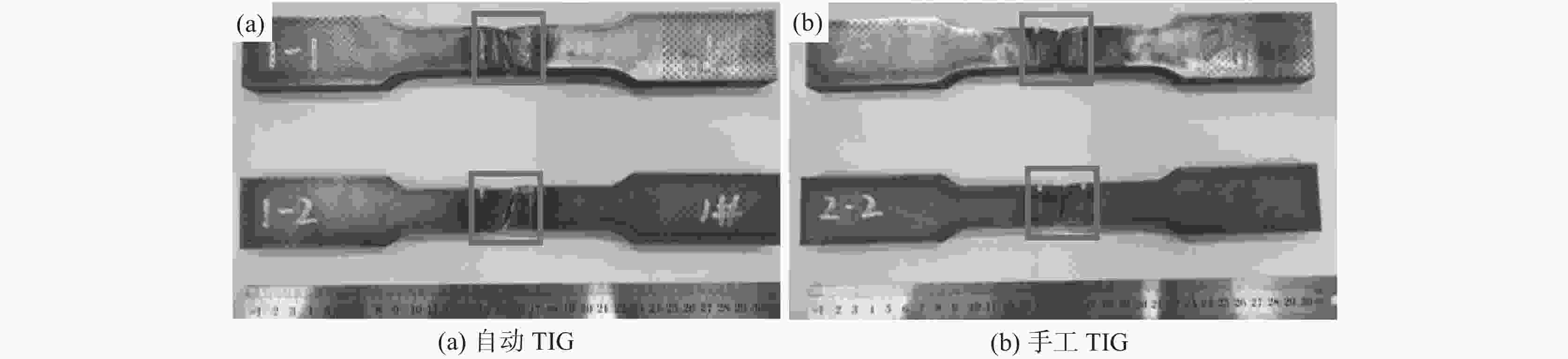

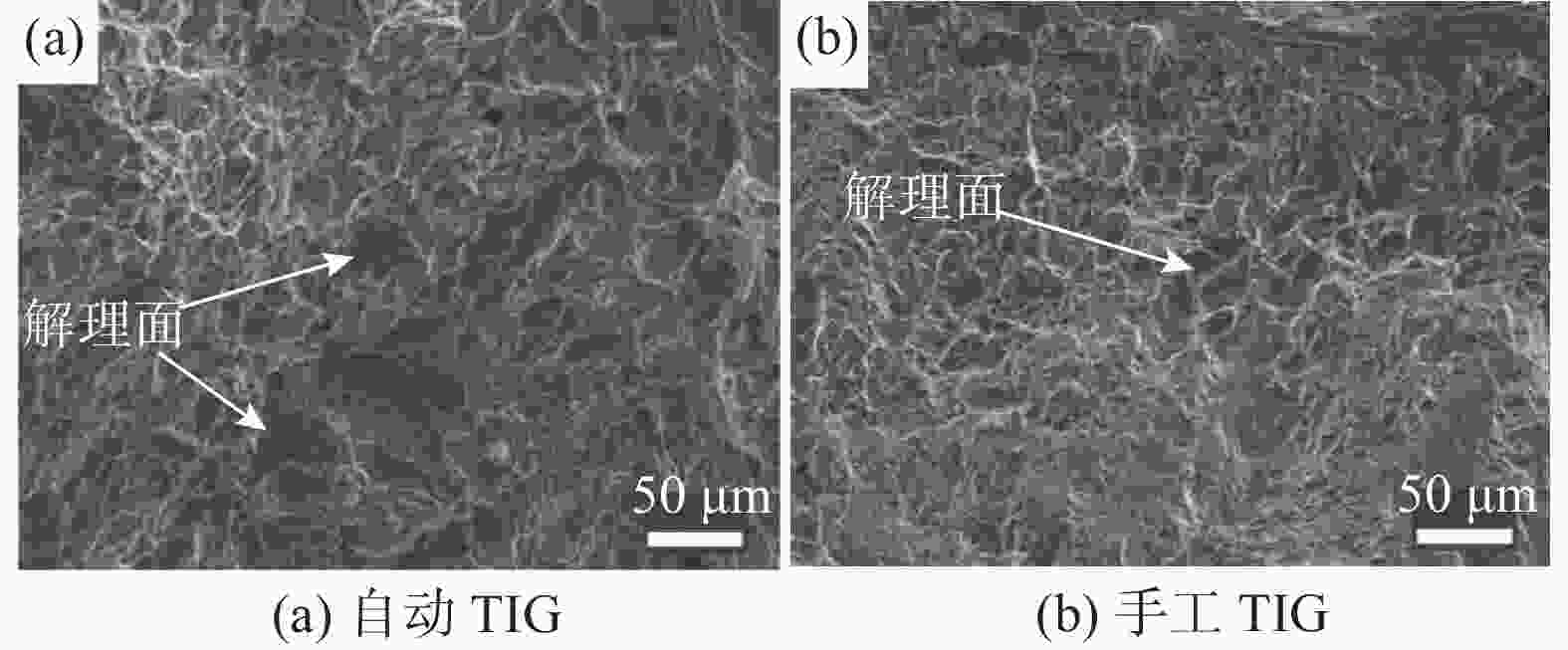

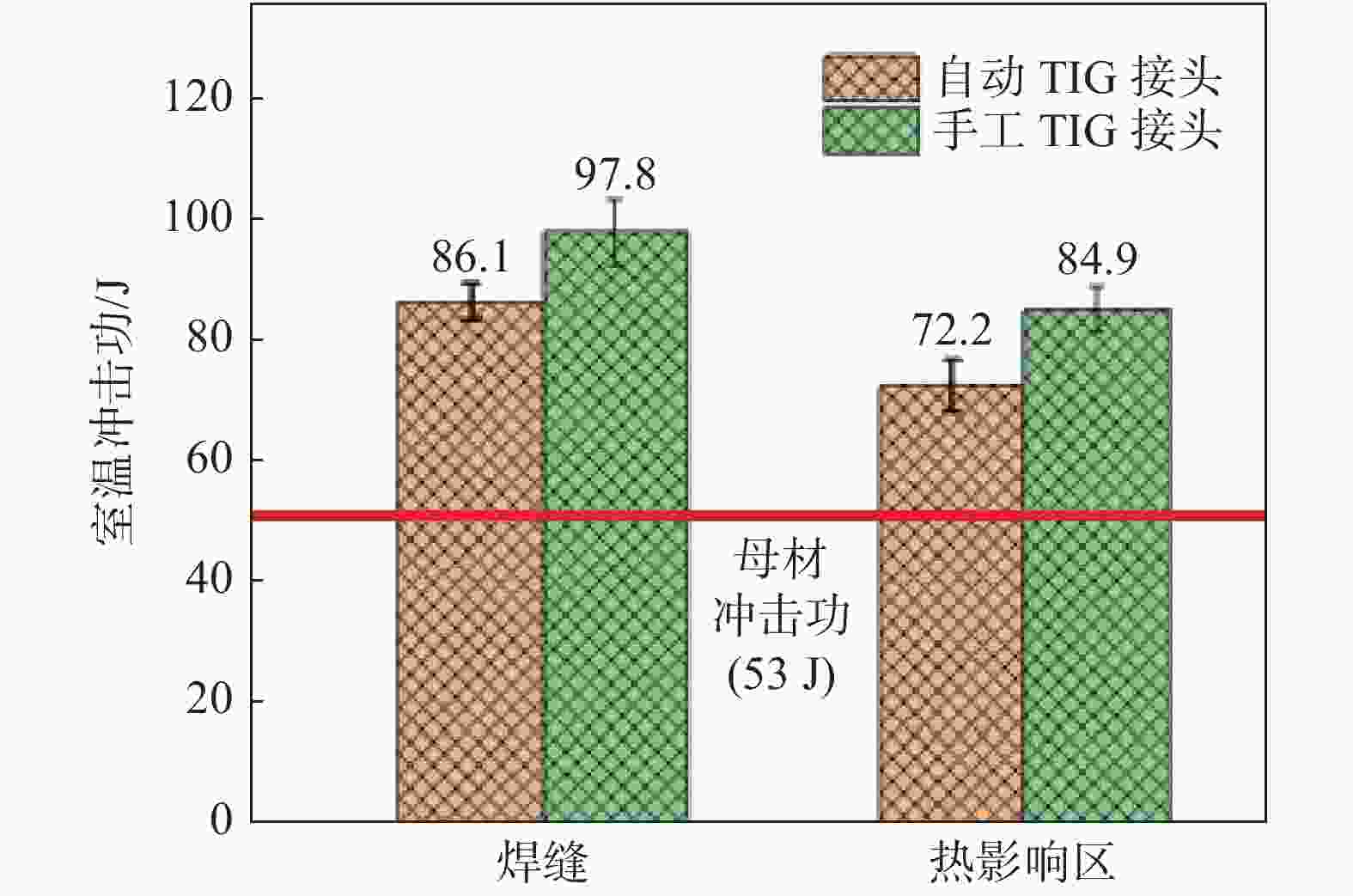

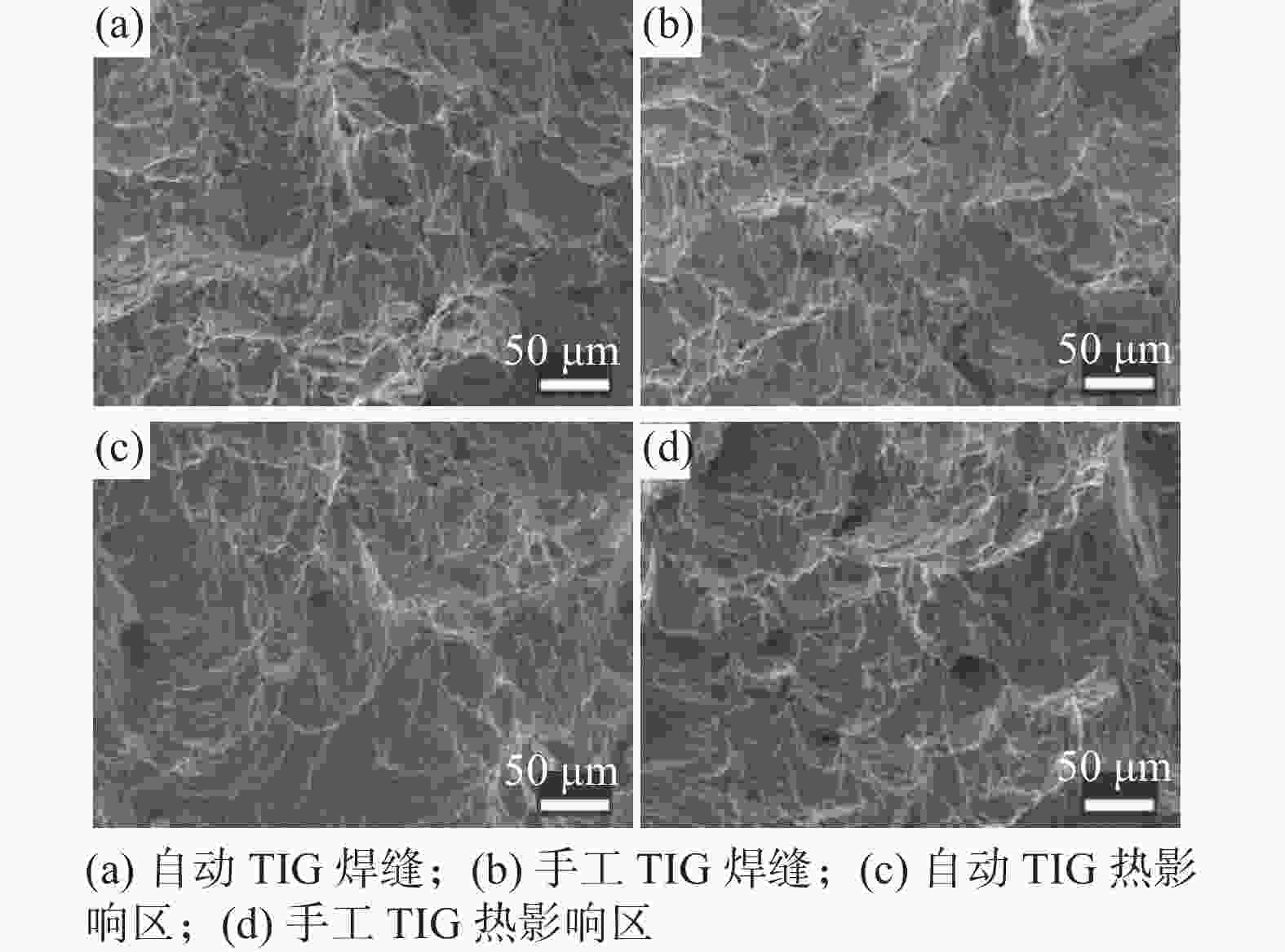

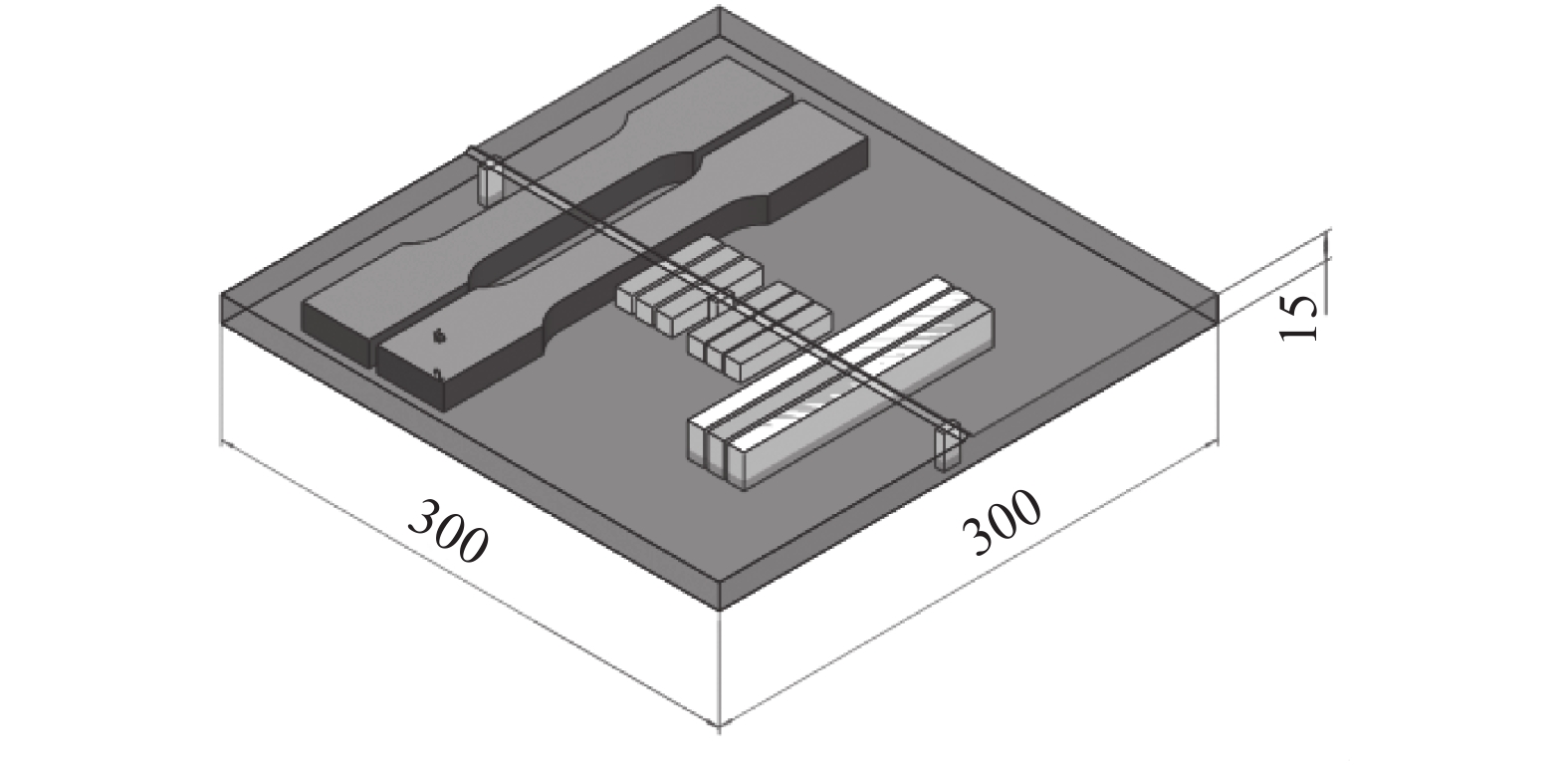

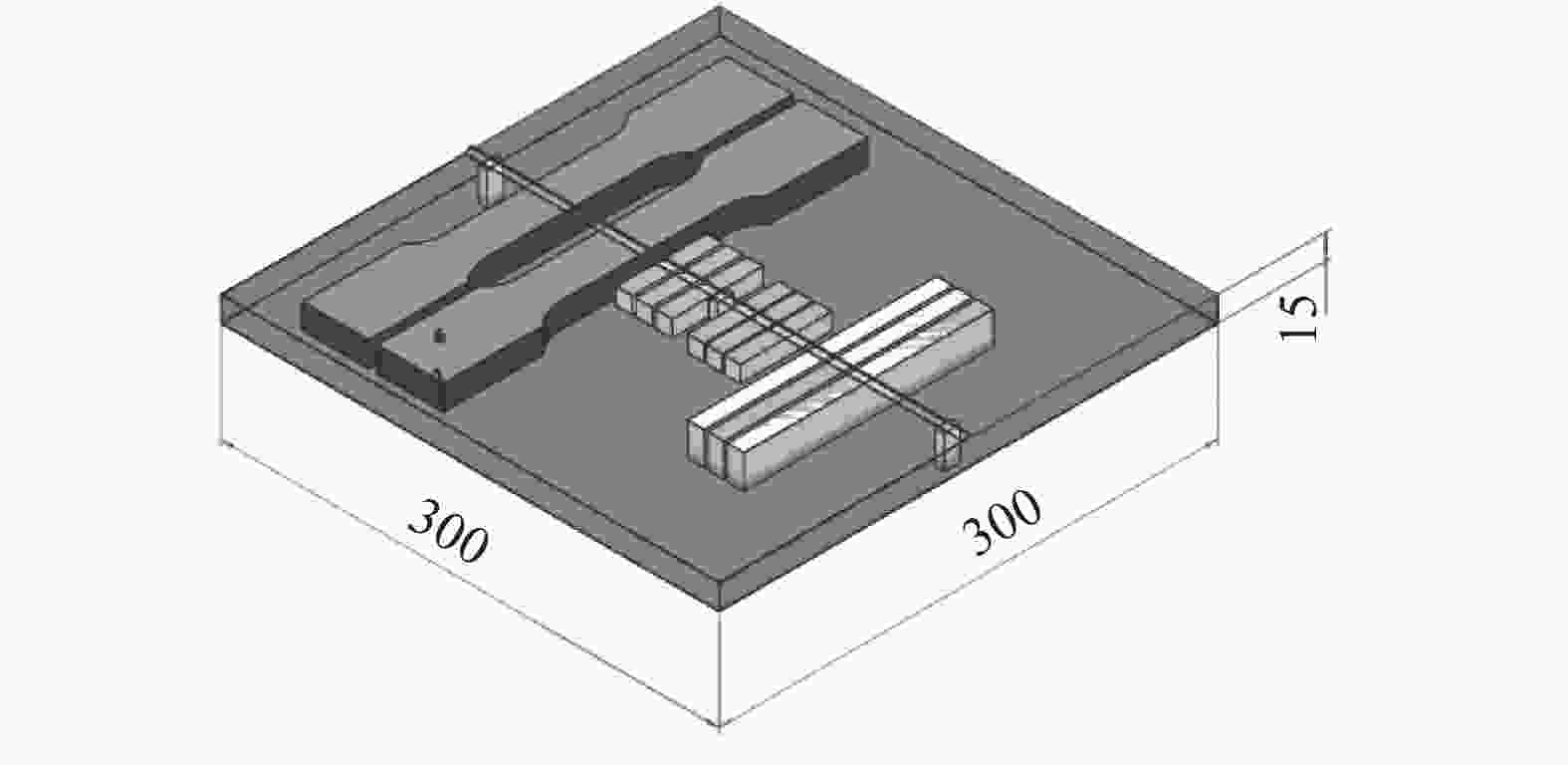

摘要: 采用一种新型Ti-V-Mo系高强钛合金,通过TIG自动送丝和手动填丝两种方式进行了焊接工艺试验,对焊接接头的成形、组织和力学性能进行了分析测试。结果表明:两种焊接方式下的焊缝外观成形都很美观,没有飞溅和咬边等缺陷,焊道表面呈银白色;母材是一种等轴α相含量较高的双态组织,热影响区晶粒十分粗大,内部主要是针状α'相,焊缝区晶粒也十分粗大,主要由层片α相转变组织构成,含有少量针状α'相;自动送丝TIG和手动填丝TIG的接头抗拉强度分别为822 MPa和612 MPa,热影响区的冲击吸收功分别达到了72.2 J和84.9 J,表明该钛合金在TIG焊接工艺下,热影响区具有良好的韧性特征。Abstract: A new type of high strength Ti-V-Mo titanium alloy was used as raw material. Welding test was carried out respectively by TIG automatic wire feeding and manual wire filling. The microstructure, forming, and mechanical properties of the joint were analyzed. The results show that the weld appearance shape is very smooth with no splash and edge defects. The base material has a duplex microstructure with higher content of equiaxed α phase. The grain size of the heat affected zone of Ti-V-Mo titanium alloy is very rough with needlelike α' phase inside the alloy. The grain size of weld area is very bulky, made up of a large number of layer α transitional phase structure and a small amount of needlelike α' phase structure. The tensile strength of the joint by TIG automatic and manual wire filling is 822 MPa and 612 MPa, respectively. And the impact absorbing energy of heat affected zone by TIG automatic and manual wire filling is 72.2 J and 84.9 J respectively. It shows good toughness characteristics in heat affected zone through the TIG welding process.

-

表 1 两种TIG方式下焊接参数

Table 1. Welding parameters of two TIG methods

I/A U/V vf/(m·min−1) vw/(m·min−1) 自动TIG 122 9.6 0.36 0.26 手工TIG 80~110 9.6 表 2 自动TIG和手工TIG焊拉伸性能

Table 2. Tensile properties of automatic TIG and manual TIG welding

编号 抗拉强度/MPa 平均值/MPa ZD-TIG-1 728 822 ZD-TIG-2 916 SG-TIG-1 599 612 SG-TIG-2 625 -

[1] Zhu Zhishou. Recent research and development of titanium alloys for aviation application in China[J]. Journal of Aeronautical Materials, 2014,34(4):44−50. (朱知寿. 我国航空用钛合金技术研究现状及发展[J]. 航空材料学报, 2014,34(4):44−50. doi: 10.11868/j.issn.1005-5053.2014.4.004 [2] Li Yi, Zhao Yongqing, Zeng Weidong, et al. Application and development of aerial titanium alloys[J]. Materials Report, 2020,34(S1):280−282. (李毅, 赵永庆, 曾卫东. 航空钛合金的应用及发展趋势[J]. 材料导报, 2020,34(S1):280−282. [3] Jia Haitao, Zhang Ruiwei. Analysis and application of welding titanium and titanium alloy[J]. Welding Technology, 2020,49(1):55−60. (贾海涛, 张睿伟. 钛及钛合金的焊接性分析与应用[J]. 焊接技术, 2020,49(1):55−60. [4] Luo Sheji, Li Dan, Li Ning. Research status of thermal oxidation behavior of titanium and titanium alloy[J]. Hot Working Technology, 2021,50(10):17−21. (雒设计, 李丹, 李宁. 钛及钛合金热氧化行为的研究现状[J]. 热加工工艺, 2021,50(10):17−21. [5] Guo Li, He Weixia, Zhou Peng, et al. Research status and development prospect of titanium and titanium alloy products in China[J]. Hot Working Technology, 2020,49(22):22−28. (郭鲤, 何伟霞, 周鹏, 等. 我国钛及钛合金产品的研究现状及发展前景[J]. 热加工工艺, 2020,49(22):22−28. [6] Li Yulong, Yang Jin, Yu Yexiao. Characteristic and current status of titanium and its alloys[J]. Hot Working Technology, 2011,40(9):130−133. (李玉龙, 杨瑾, 禹业晓. 钛及钛合金钎焊特点及现状[J]. 热加工工艺, 2011,40(9):130−133. doi: 10.3969/j.issn.1001-3814.2011.09.041 [7] Yu Deshui, Zhang Yan, Zhou Jianping, et al. Research status titanium alloy and dissimilar metal welding of aluminum[J]. Welding & Joining, 2020,(11):37−45, 63. (于得水, 张岩, 周建平, 等. 钛合金与铝合金异种金属焊接的研究现状[J]. 焊接, 2020,(11):37−45, 63. [8] Huang Jiuling, Kong Liang, Wang Min, et al. Welding of titanium and titanium alloy sheet[J]. Welding Technology, 2018,47(11):1−5. (黄九龄, 孔谅, 王敏, 等. 钛及钛合金薄板的焊接[J]. 焊接技术, 2018,47(11):1−5. [9] Gao Fuyang, Liao Zhiqian, Li Wenya. Welding method and research of titanium and titanium alloy[J]. Aeronautical Manufacturing Technology, 2012,(Z2):86−90. (高福洋, 廖志谦, 李文亚. 钛及钛合金焊接方法与研究现状[J]. 航空制造技术, 2012,(Z2):86−90. [10] 郑成博. TA2钛合金熔丝钨极氩弧焊工艺研究[D]. 沈阳: 沈阳理工大学, 2020.Zheng Chengbo. Research on molten wire tungsten inert gas welding process of TA2 titanium alloy[J]. Shenyang: Shenyang Ligong University, 2020. [11] Mou Gang, Hua Xueming, Xu Xiaobo, et al. Comparative study on TIG and MIG welding process and performance of 8 mm thick TC4 titanium alloy[J]. Electric Welding Machine, 2020,50(4):70−74, 138. (牟刚, 华学明, 徐小波, 等. 8 mm厚TC4钛合金TIG、MIG焊接工艺及性能对比研究[J]. 电焊机, 2020,50(4):70−74, 138. -

下载:

下载: