Effect of sintering temperature on microstructure and properties of porous Ti-15Al alloy

-

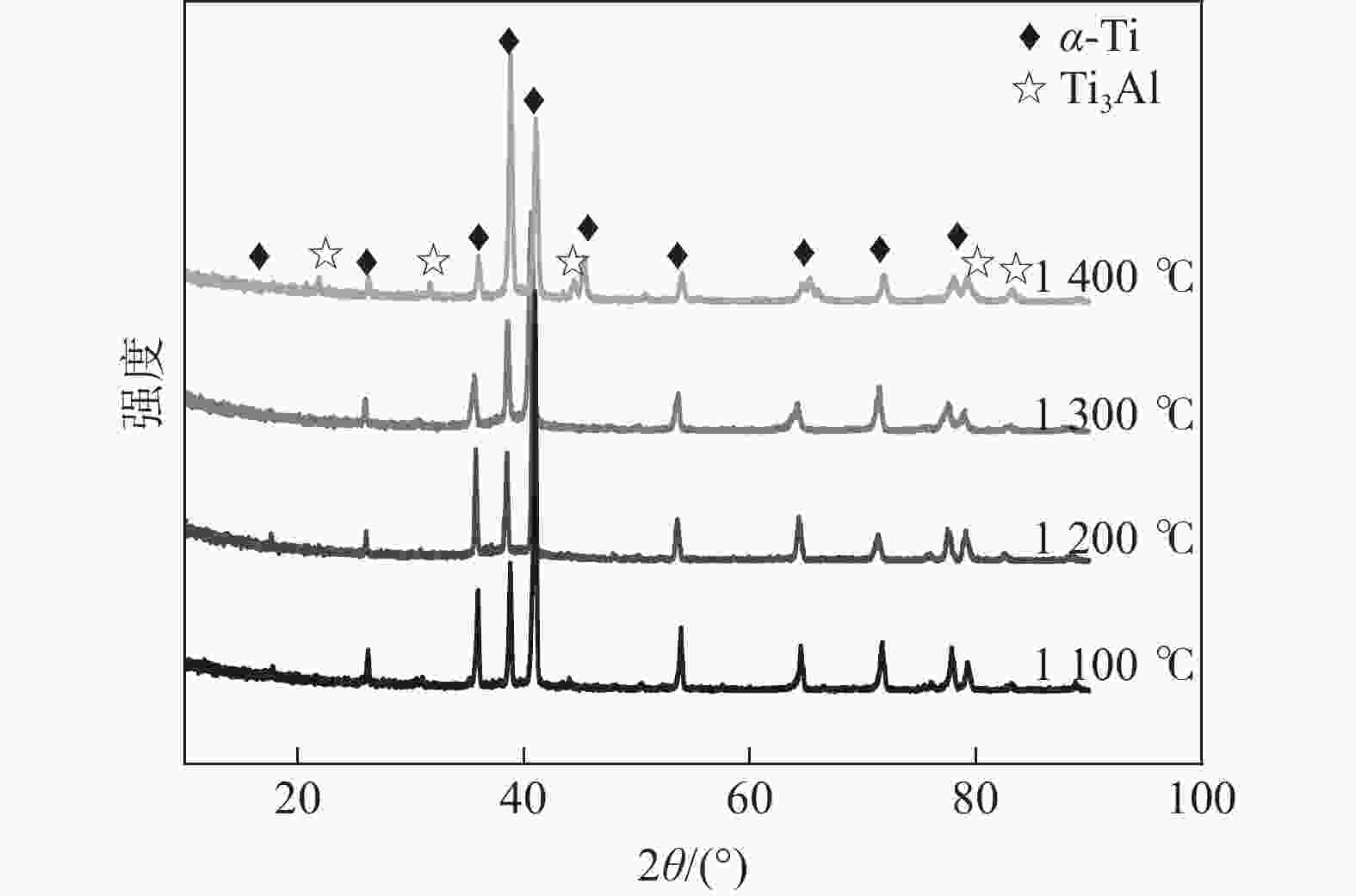

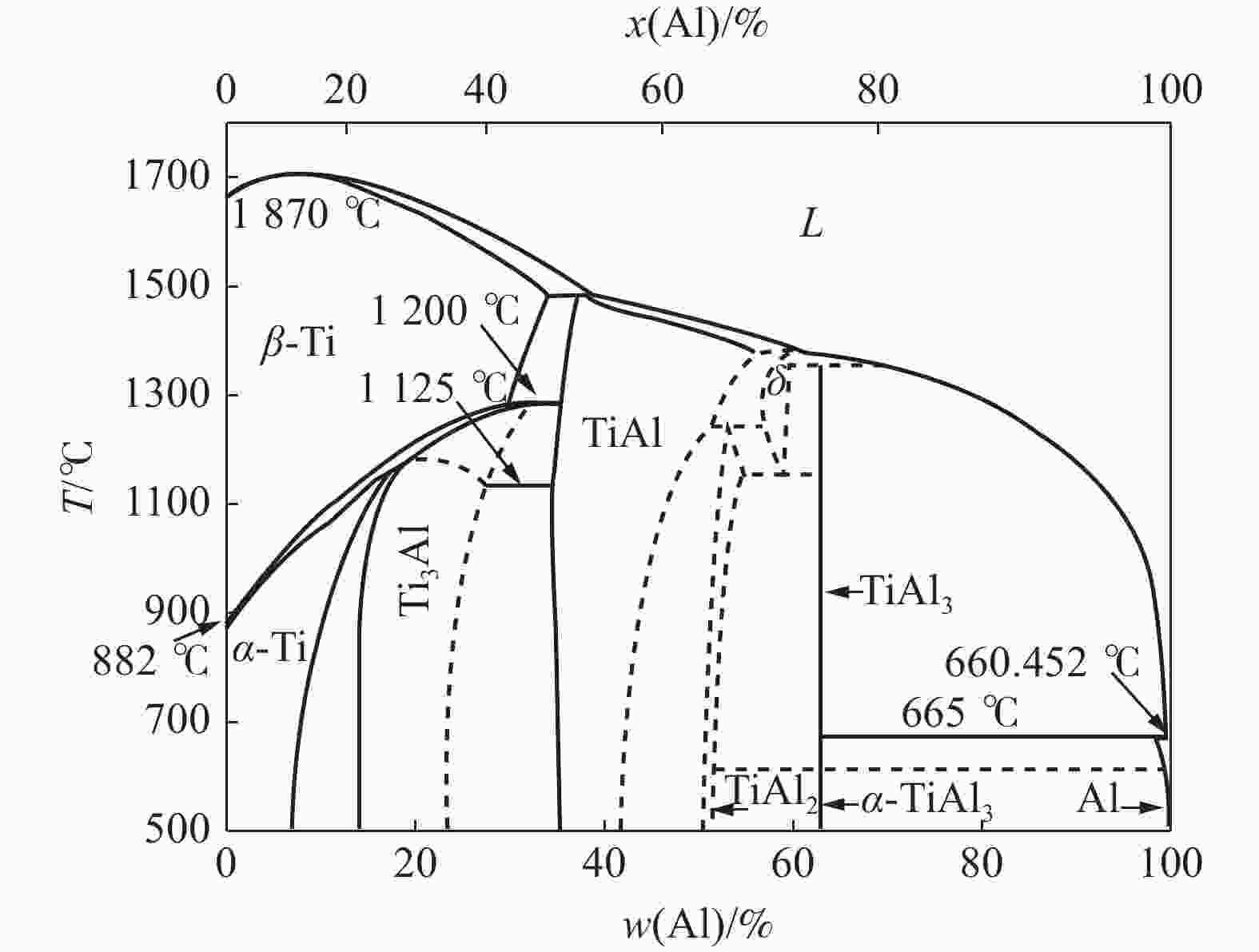

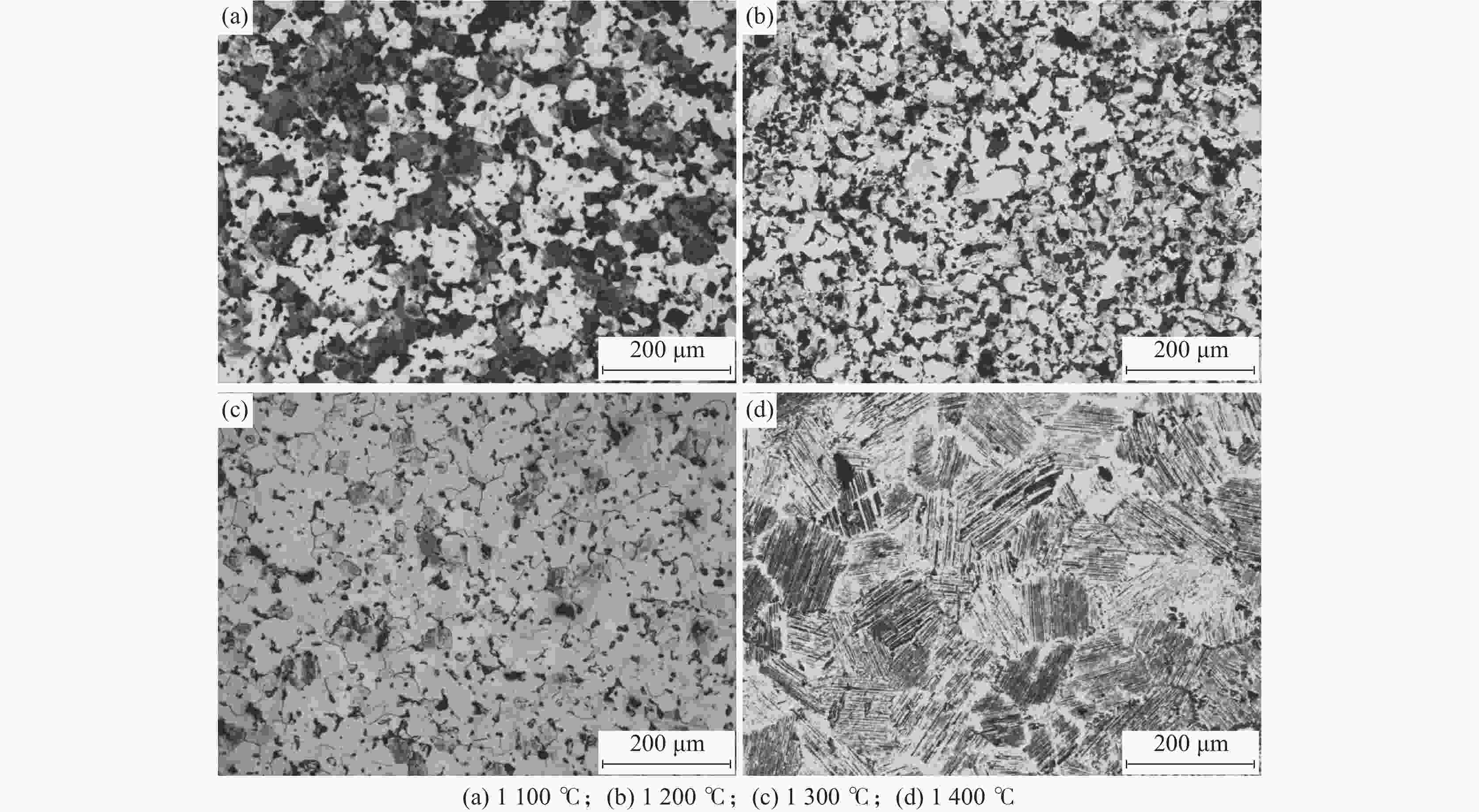

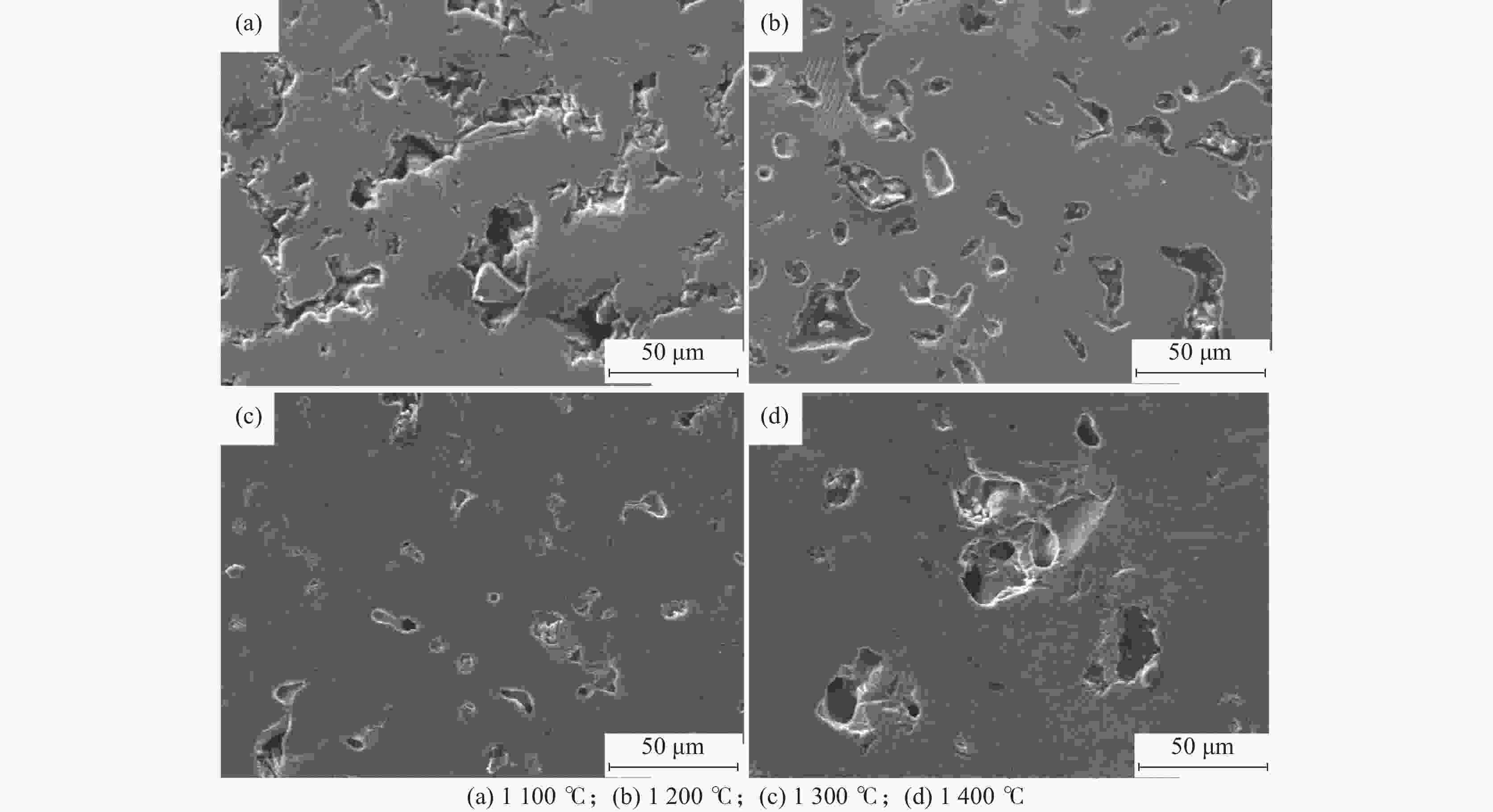

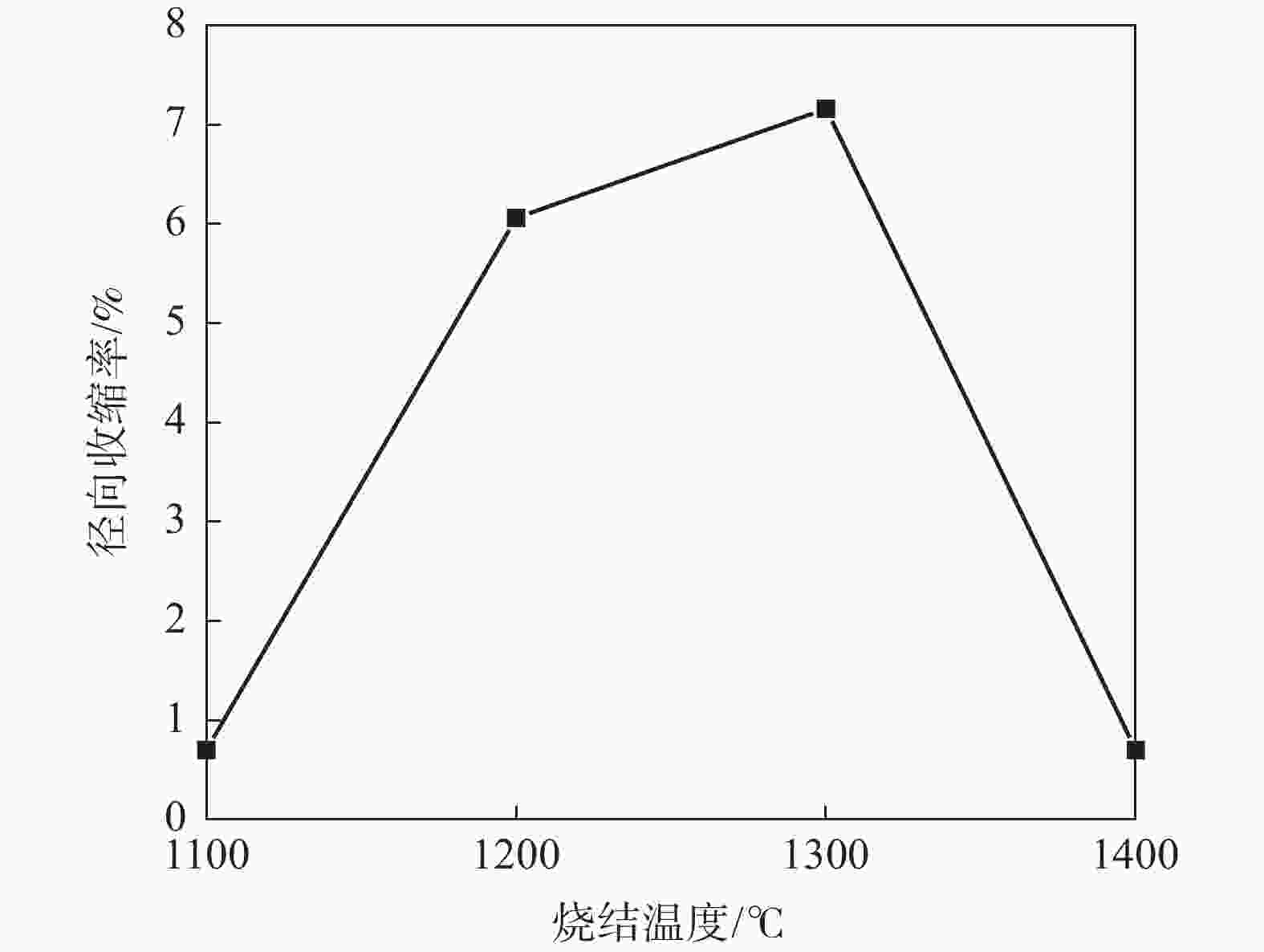

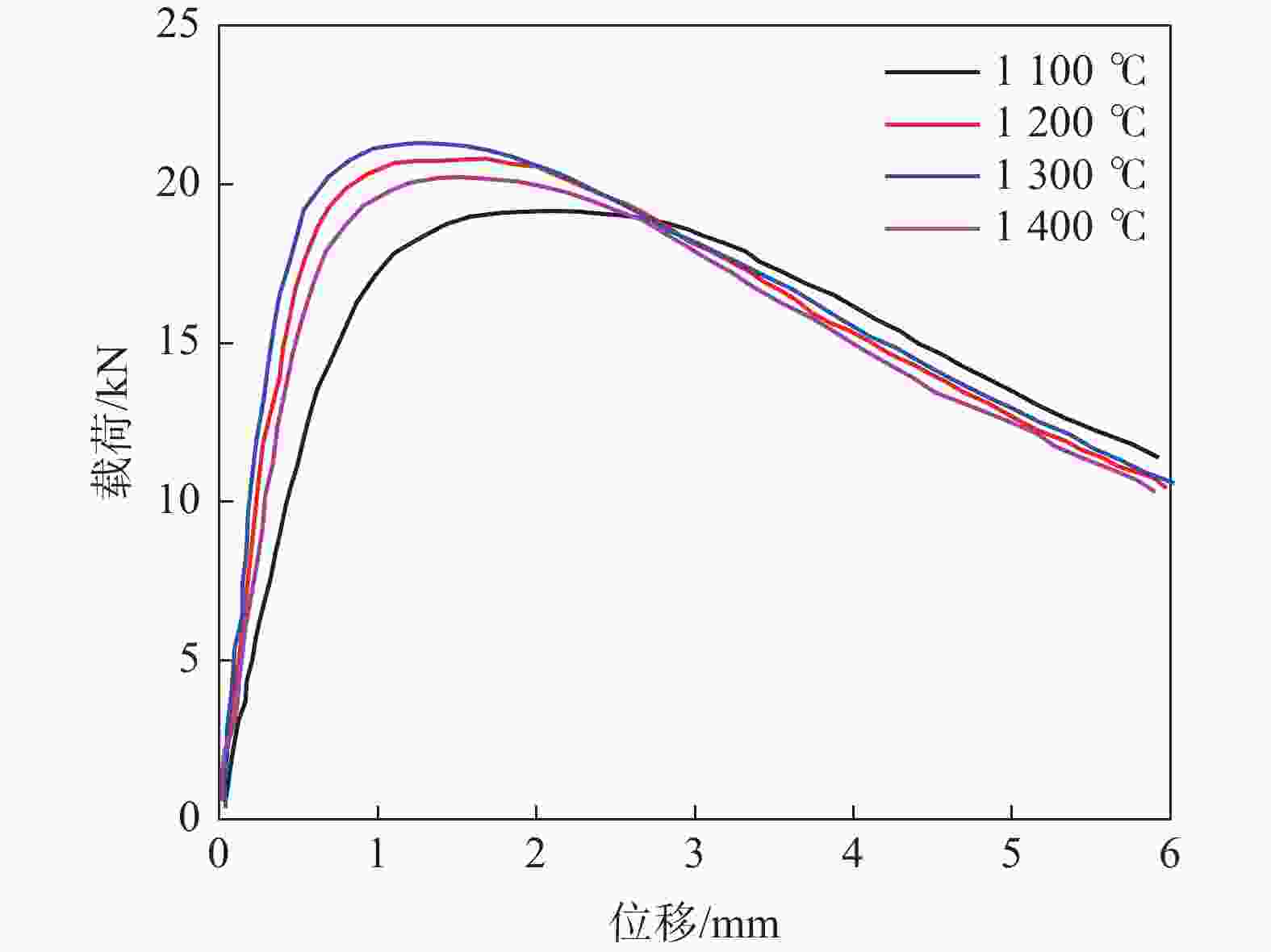

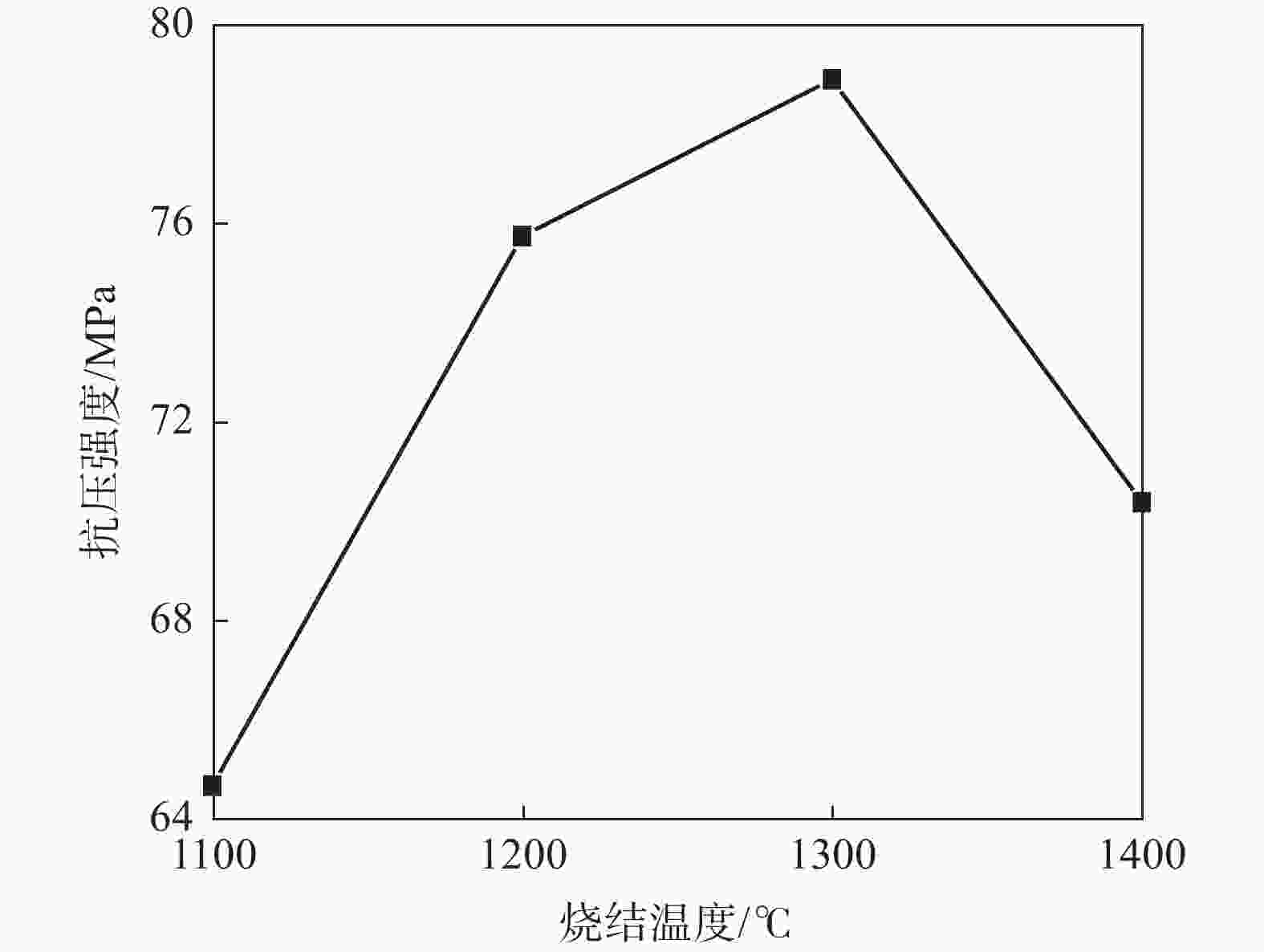

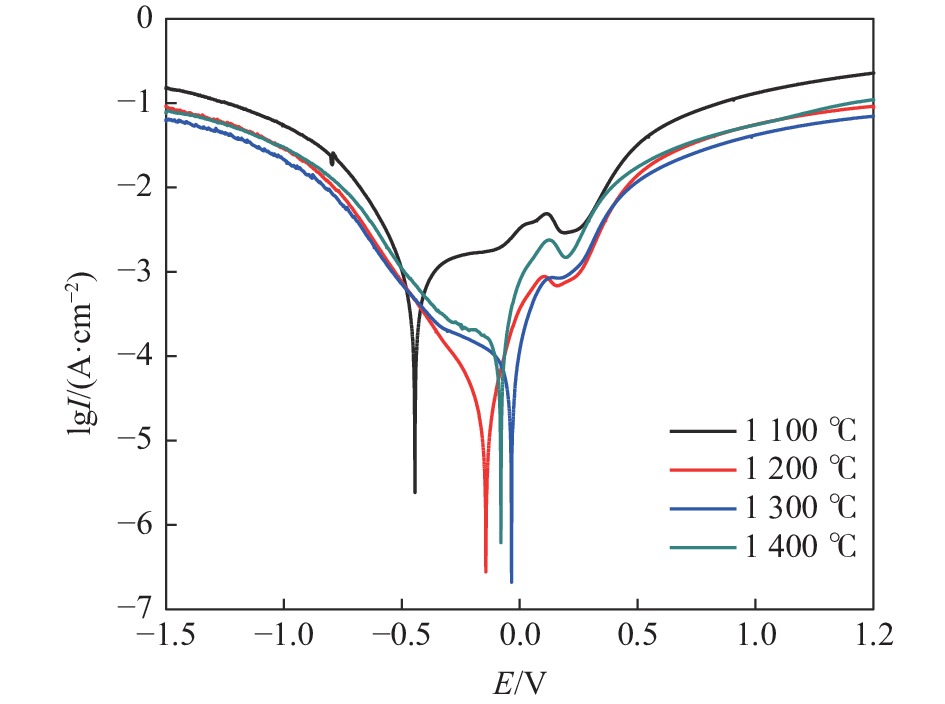

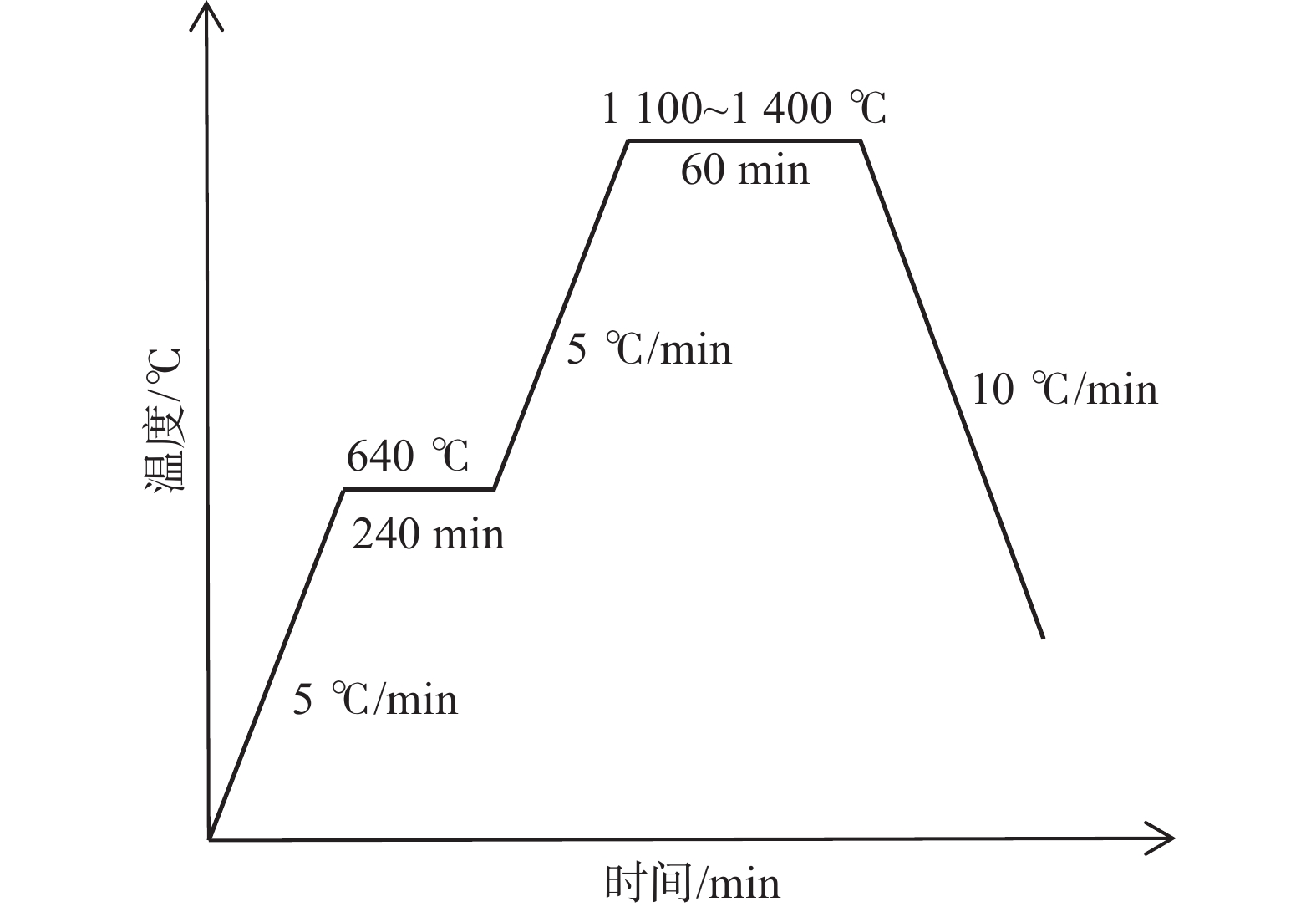

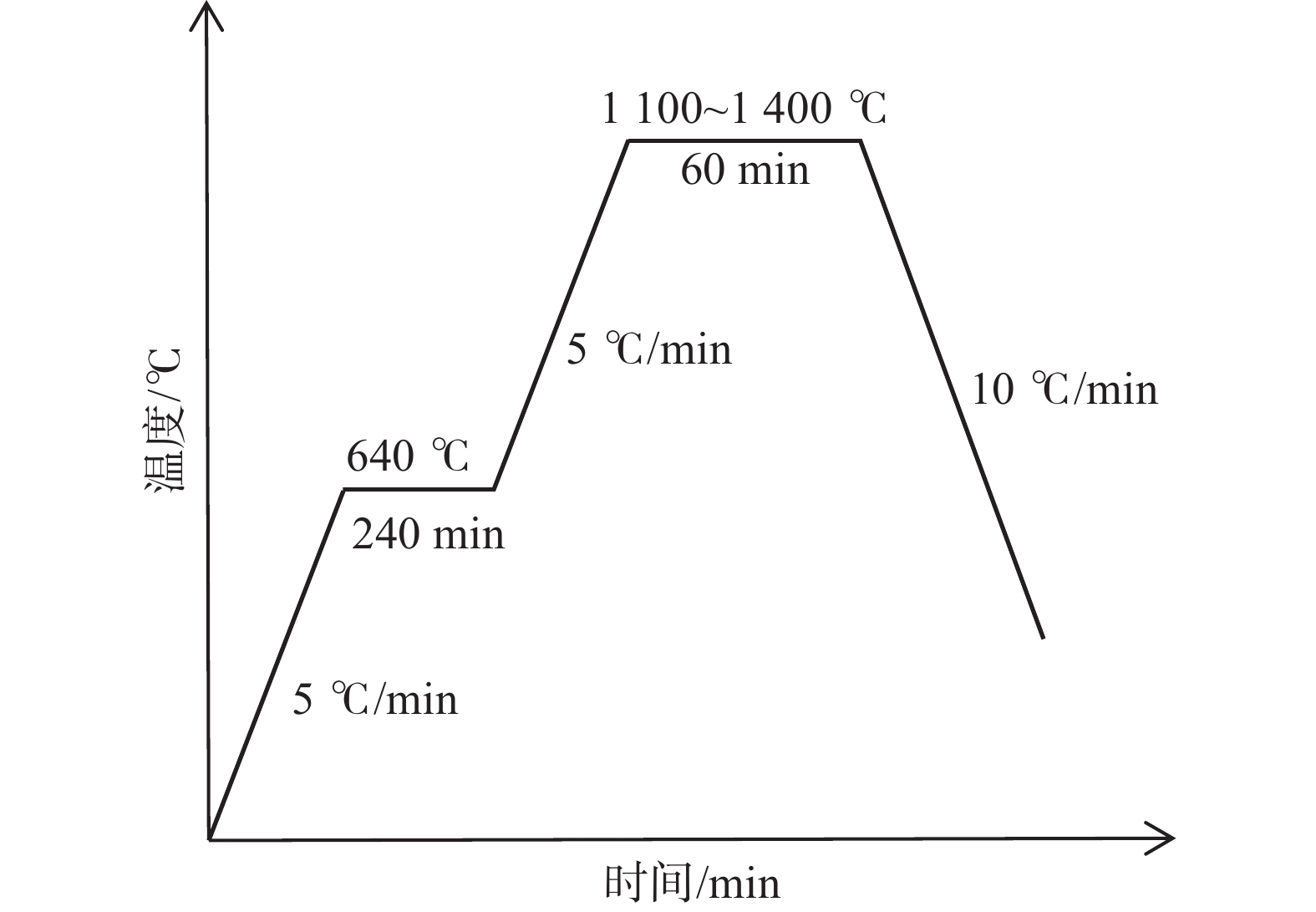

摘要: 以金属Ti粉和Al粉为原料,采用粉末冶金法制备多孔Ti-15Al合金材料,并研究不同的烧结温度对其物相成分、微观孔隙结构、抗压性能和耐腐蚀性能的影响。结果表明:多孔Ti-15Al合金在高温烧结后,因金属Ti和Al之间发生偏扩散和固相反应而形成了α-Ti和Ti3Al的平衡相,随着烧结温度的升高,合金中孔隙结构逐渐由长条状的贯通孔向近似球状的封闭孔转变,且孔隙率和平均孔径尺寸均呈先增大后减小的变化,在1300 ℃烧结后的孔隙率和孔径尺寸最小,最小值分别为11.6%和13.8 μm;因材料孔隙结构的转变,导致多孔Ti-15Al合金的抗压强度和耐腐蚀性能均随烧结温度的升高先增大后减小,烧结温度为1300 ℃时的抗压强度和耐腐蚀性能最好,最大抗压强度为79 MPa,最小腐蚀电流密度为2.05×10−7 A/cm2。Abstract: The porous Ti-15Al alloy materials were prepared by powder metallurgy with Ti and Al powder as raw materials. The effects of different sintering temperatures on the phase composition, micropore structure, compressive and corrosion resistance were studied. The results show that the equilibrium phase of α-Ti and Ti3Al is formed due to partial diffusion and solid-phase reaction between metal Ti and Al after the porous Ti-15Al alloy sintered at high temperature. With the increase of sintering temperature, the structure gradually changes from elongated through-holes to nearly spherical closed pores, and the porosity and average pore size both increases first and then decreases. The porosity and pore size after sintering at 1 300 ℃ reach the minimum, with values of 11.6% and 13.8 μm, respectively. Due to the change of pore structure, the compressive strength and corrosion resistance of porous Ti-15Al alloy increase first and then decrease with the increase of sintering temperature. The compressive strength and corrosion resistance of porous Ti-15Al alloy are the best when the sintering temperature is 1 300 ℃, the maximum compressive strength is 79 MPa, and the minimum corrosion current density is 2.05×10−7 A/cm2.

-

图 3 Ti-Al二元合金相图[1]

Figure 3. Binary phase diagram of Ti-Al alloy

表 1 Ti粉的化学成分

Table 1. Chemical composition of Ti powder

% C H O N Fe Mn Mg Si Ti 0.013 0.022 0.28 0.009 0.028 <0.01 <0.01 0.02 Bal. 表 2 Al粉的化学成分

Table 2. Chemical composition of Al powder

% Si Fe Cu Zn Ti Mn Mg Si Al 0.45 0.5 0.05 0.009 0.028 <0.01 <0.01 0.02 Bal. 表 3 多孔Ti-15Al合金的孔隙率和平均孔径

Table 3. Porosity and average pore size of the porous Ti-15Al alloys

烧结温度/℃ 孔隙率/% 平均孔径/μm 1100 22.2 25.1 1200 19.1 16.5 1300 11.6 13.8 1400 14.3 25.8 表 4 多孔Ti-15Al合金的自腐蚀电位和自腐蚀电流密度

Table 4. Self-corrosion potential and current density of the porous Ti-15Al alloys

烧结温度/℃ 腐蚀电位/V 电流密度/(A·cm−2) 1100 −0.44 2.38×10−6 1200 −0.14 2.73×10−7 1300 −0.04 2.05×10−7 1400 −0.08 6.04×10−7 -

[1] Li Tingting, Peng Chaoqun, Wang Richu, et al. Research progress in porous Fe-Al, Ti-Al and Ni-Al intermetallic compound porous materials[J]. The Chinese Journal of Nonferrous Metals, 2011,21(4):784−795. (李婷婷, 彭超群, 王日初, 等. Fe-Al、Ti-Al和Ni-Al系金属间化合物多孔材料的研究进展[J]. 中国有色金属学报, 2011,21(4):784−795. doi: 10.1016/S1003-6326(11)60781-4Li Tingting, Peng Chaoqun, Wang Richu, et al. Research progress in porous Fe-Al, Ti-Al and Ni-Al intermetallic compound porous materials[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 784-795. doi: 10.1016/S1003-6326(11)60781-4 [2] Jiang Yao, He Yuehui, Huang Baiyun, et al. Progress in research on Ti-Al intermetallic compound porous material[J]. Materials China, 2010,29(3):18−22. (江垚, 贺跃辉, 黄伯云, 等. Ti-Al金属间化合物多孔材料的研究进展[J]. 中国材料进展, 2010,29(3):18−22.Jiang Yao, He Yuehui, Huang Baiyun, et al. Progress in research on Ti-Al intermetallic compound porous material[J]. Materials China, 2010, 29(3): 18-22. [3] Feng Peizhong, Su Jian, Zhou Yaguo, et al. Microstructure and formation mechanism of porous Ti-Al intermetallics prepared by pressureless sintering[J]. Rare Metal Materials and Engineering, 2015,44(11):2721−2727. (冯培忠, 苏健, 周亚国, 等. 无压烧结Ti-Al多孔材料的组织结构与反应机制[J]. 稀有金属材料与工程, 2015,44(11):2721−2727.Feng Peizhong, Su Jian, Zhou Yaguo, et al. Microstructure and formation mechanism of porous Ti-Al intermetallics prepared by pressureless sintering[J]. Rare Metal Materials and Engineering, 2015, 44(11): 2721-2727. [4] Liu Yanan, Jiao Xinyang, Feng Peizhong. Research progress of intermetallic compounds porous materials[J]. Materials China, 2017,36(7):532−540,565. (刘亚南, 焦欣洋, 冯培忠, 等. 含Al金属间化合物多孔材料的研究进展[J]. 中国材料进展, 2017,36(7):532−540,565.Liu Yanan, Jiao Xinyang, Feng Peizhong. Research progress of intermetallic compounds porous materials[J]. Materials China, 2017, 36 (7): 532-540, 565. [5] Liu Yuzuo, Li Xide, Li Juying, et al. Effect of pore-forming agent (NH4)2CO3 and urea on properties of porous TiAl intermetallics[J]. Materials Science and Engineering of Powder Metallurgy, 2019,24(3):255−260. (刘羽祚, 李喜德, 李菊英, 等. 造孔剂(NH4)2CO3和尿素含量对TiAl多孔材料性能的影响[J]. 粉末冶金材料科学与工程, 2019,24(3):255−260. doi: 10.3969/j.issn.1673-0224.2019.03.008Liu Yuzuo, Li Xide, Li Juying, et al. Effect of pore-forming agent (NH4)2CO3 and urea on properties of porous TiAl intermetallics[J]. Materials Science and Engineering of Powder Metallurgy, 2019, 24(3): 255-260. doi: 10.3969/j.issn.1673-0224.2019.03.008 [6] Li Daren, Cui Liqun, Cai Yixiang. Research on structure property of TiAl-based porous material prepared by titanium hydride foaming[J]. Powder Metallurgy Technology, 2014,32(2):96−99. (李达人, 崔利群, 蔡一湘. TiH2发泡制备TiAl基多孔材料及其组织性能研究[J]. 粉末冶金技术, 2014,32(2):96−99.Li Daren, Cui Liqun, Cai Yixiang. Research on structure property of TiAl-based porous material prepared by titanium hydride foaming[J]. Powder Metallurgy Technology, 2014, 32(2): 96-99. [7] Zhang Meili, Luo Shushu, Dai Weili, et al. Preparation and properties of porous Ti-Al alloy[J]. Iron Steel Vanadium Titanium, 2020,41(4):48−53,59. (张美丽, 罗姝淑, 代卫丽, 等. 多孔 Ti-Al 合金材料的制备与性能研究[J]. 钢铁钒钛, 2020,41(4):48−53,59.Zhang Meili, Luo Shushu, Dai Weili, et al. Preparation and properties of porous Ti-Al alloy[J]. Iron Steel Vanadium Titanium, 2020, 41(4): 48-53, 59. [8] Chen Yuyong, Su Yongjun, Kong Fantao. Research progress in preparation of TiAl interemetallic based compound[J]. Rare Metal Materials and Engineering, 2014,43(3):757−762. (陈玉勇, 苏勇君, 孔凡涛. TiAl金属间化合物制备技术的研究进展[J]. 稀有金属材料与工程, 2014,43(3):757−762.Chen Yuyong, Su Yongjun, Kong Fantao. Research progress in preparation of TiAl interemetallic based compound[J]. Rare Metal Materials and Engineering, 2014, 43(3): 757-762. [9] Chen Murong, Jiang Yao, Tian Li, et al. Effect of molding parameters on pore structure Ti-35%Al porous material[J]. Journal of Xiangtan University(Natural Science Edition), 2013,35(2):70−74. (陈慕容, 江垚, 田俐, 等. 成型参数对Ti-35%Al多孔材料孔结构的影响[J]. 湘潭大学学报(自然科学版), 2013,35(2):70−74. doi: 10.3969/j.issn.1000-5900.2013.02.014Chen Murong, Jiang Yao, Tian Li, et al. Effect of molding parameters on pore structure Ti-35%Al porous material[J]. Natural Science Journal of Xiangtan University, 2013, 35(2): 70-74. doi: 10.3969/j.issn.1000-5900.2013.02.014 [10] Zou Liming, Yang Chao, Li Yuanyuan. Research progress on preparing Ti-based biomedical materials by powder metallurgy[J]. Materials Review, 2011,25(15):82−85. (邹黎明, 杨超, 李元元. 粉末冶金法制备钛基生物医学材料的研究进展[J]. 材料导报, 2011,25(15):82−85.Zou Liming, Yang Chao, Li Yuanyuan. Research progress on preparing Ti-based biomedical materials by powder metallurgy[J]. Materials Review, 2011, 25(15): 82-85. [11] Qiao Jichao, Xi Zhengping, Tang Huiping, et al. Current status of metal porous materials by powder metallurgy technology[J]. Rare Metal Materials and Engineering, 2008,37(11):2054−2058. (乔吉超, 奚正平, 汤慧萍, 等. 粉末冶金技术制备金属多孔材料研究进展[J]. 稀有金属材料与工程, 2008,37(11):2054−2058. doi: 10.3321/j.issn:1002-185X.2008.11.040Qiao Jichao, Xi Zhengping, Tang Huiping, et al. Current status of metal porous materials by powder metallurgy technology[J]. Rare Metal Materials and Engineering, 2008, 37(11): 2054-2058. doi: 10.3321/j.issn:1002-185X.2008.11.040 [12] Li Jing, Yang Hailin, Jie Yunfeng, et al. Effect of sintering temperature on microstructure and mechanical properties of TiNi alloy[J]. Journal of Functional Materials, 2013,44(6):897−901. (李婧, 杨海林, 节云峰, 等. 烧结温度对多孔TiNi合金微观结构和力学性能的影响[J]. 功能材料, 2013,44(6):897−901. doi: 10.3969/j.issn.1001-9731.2013.06.033Li Jing, Yang Hailin, Jie Yunfeng, et al. Effect of sintering temperature on microstructure and mechanical properties of TiNi alloy[J]. Journal of Functional Materials, 2013, 44(6): 897-901. doi: 10.3969/j.issn.1001-9731.2013.06.033 [13] Li Shitong, Zhu Ruifu, Zhen Liang, et al. Effect of sintering temperature on microstructure and properties of porous titanium[J]. Transactions of Materials and Heat Treatment, 2009,30(2):93−95. (李士同, 朱瑞富, 甄良, 等. 烧结温度对多孔钛组织结构与性能的影响[J]. 材料热处理学报, 2009,30(2):93−95.Li Shitong, Zhu Ruifu, Zhen Liang, et al. Effect of sintering temperature on microstructure and properties of porous titanium[J]. Transactions of Materials and Heat Treatment, 2009, 30(2): 93-95. [14] Liu Peisheng. Determining methods for porosity of porous materials[J]. Titanium Industry Progress, 2005,22(6):34−36. (刘培生. 多孔材料孔率的测定方法[J]. 钛工业进展, 2005,22(6):34−36. doi: 10.3969/j.issn.1009-9964.2005.06.008Liu Peisheng. Determining methods for porosity of porous materials [J]. Titanium Industry Progress, 2005, 22(6): 34-36. doi: 10.3969/j.issn.1009-9964.2005.06.008 [15] Zhang Junhong, Cao Qincun. Preparation of sub-microstructure powder metallurgical titanium aluminide[J]. Materials Science and Engineering of Powder Metallurgy, 2013,18(5):687−692. (张俊红, 曹钦存. 细晶粉末冶金TiAl合金的制备[J]. 粉末冶金材料科学与工程, 2013,18(5):687−692. doi: 10.3969/j.issn.1673-0224.2013.05.011Zhang Junhong, Cao Qincun. Preparation of sub-microstructure powder metallurgical titanium aluminide[J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(5): 687-692. doi: 10.3969/j.issn.1673-0224.2013.05.011 -

下载:

下载: