Effect of final cooling temperature on the microstructure and DWTT of thick X80 linepipe steel strip

-

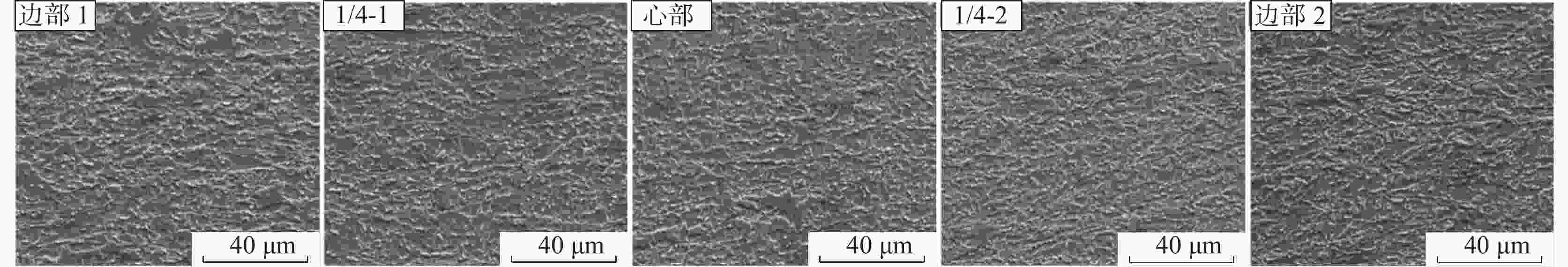

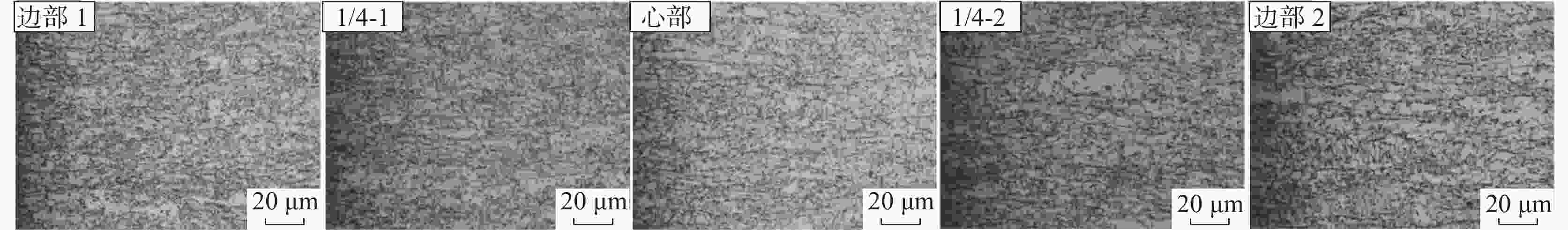

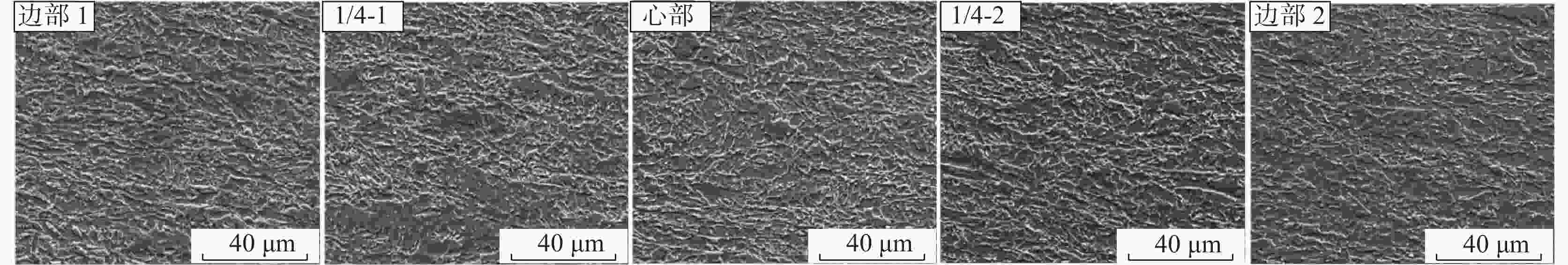

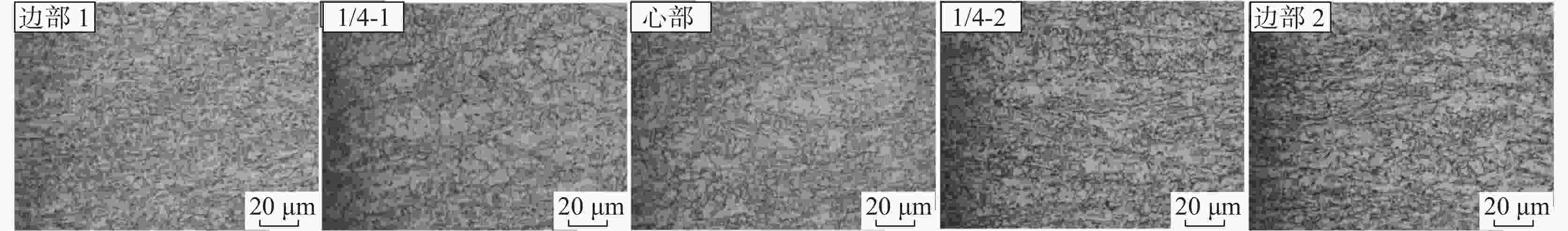

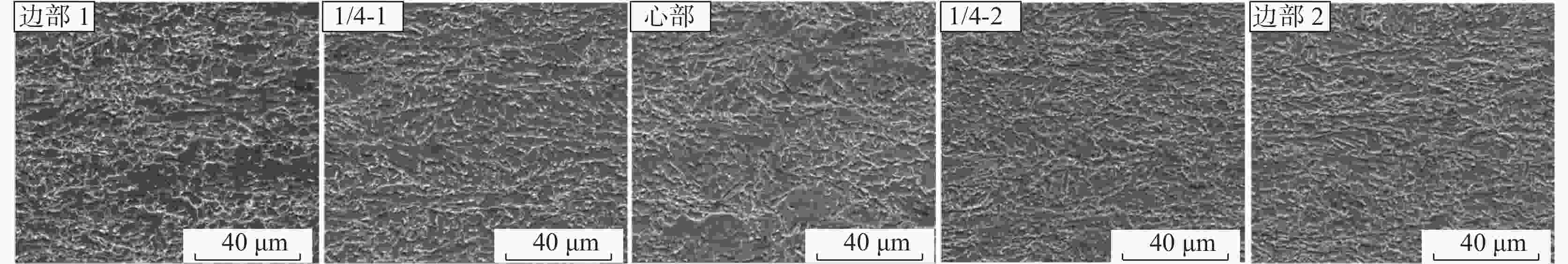

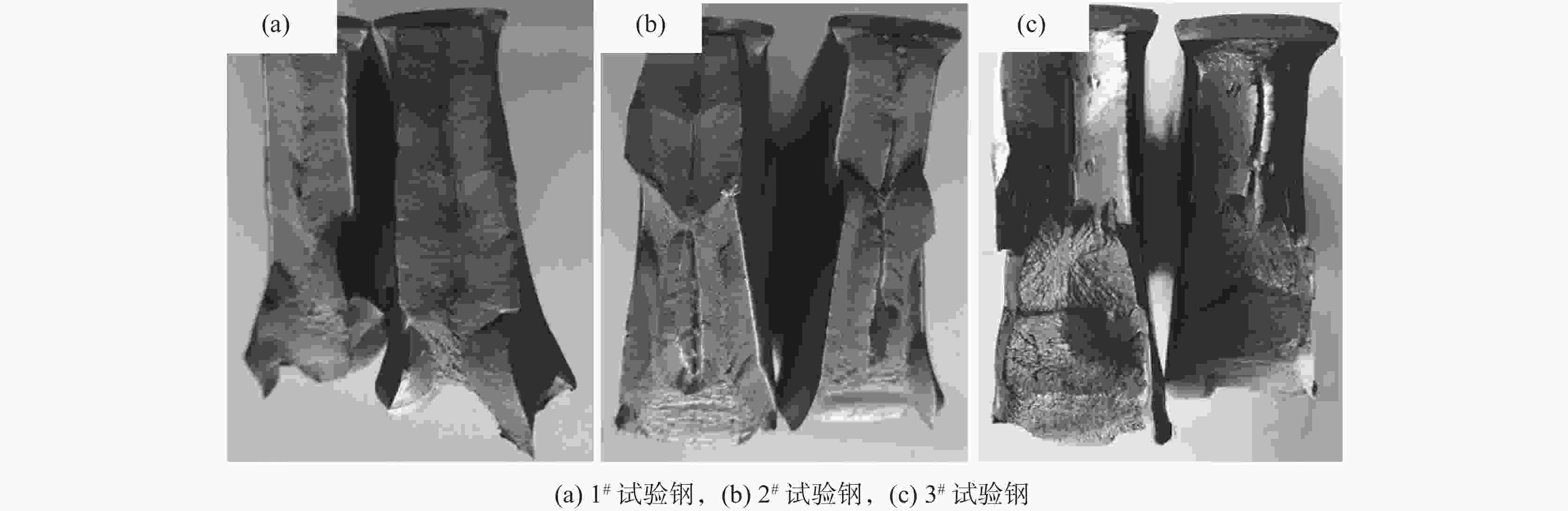

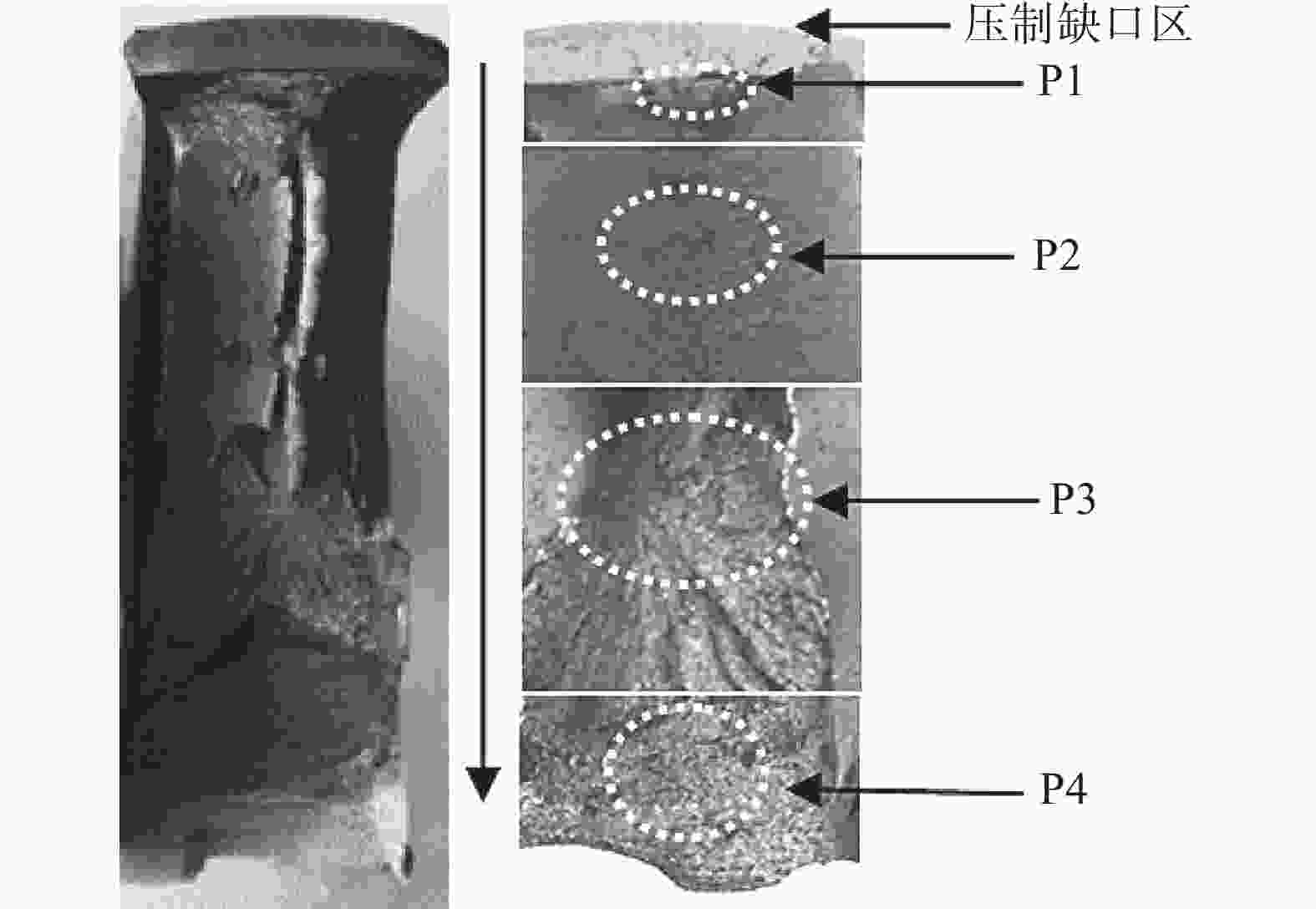

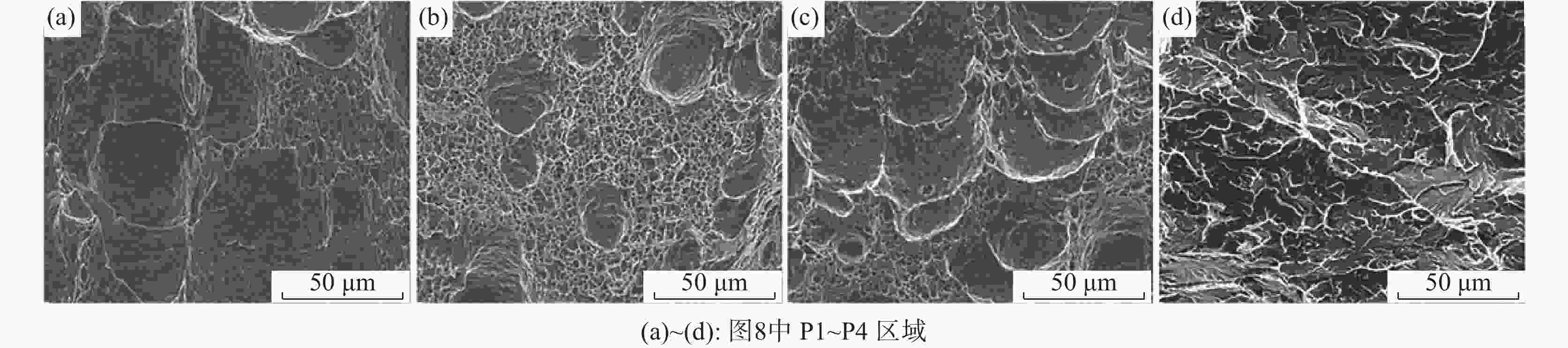

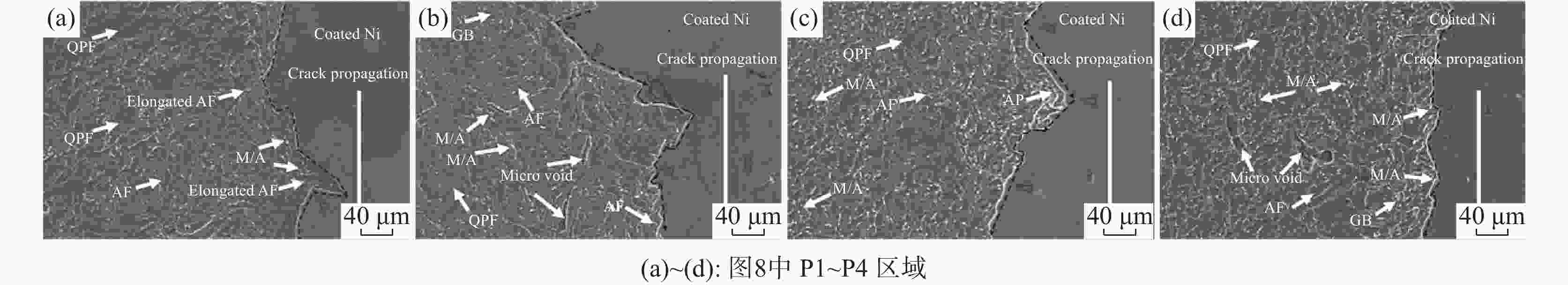

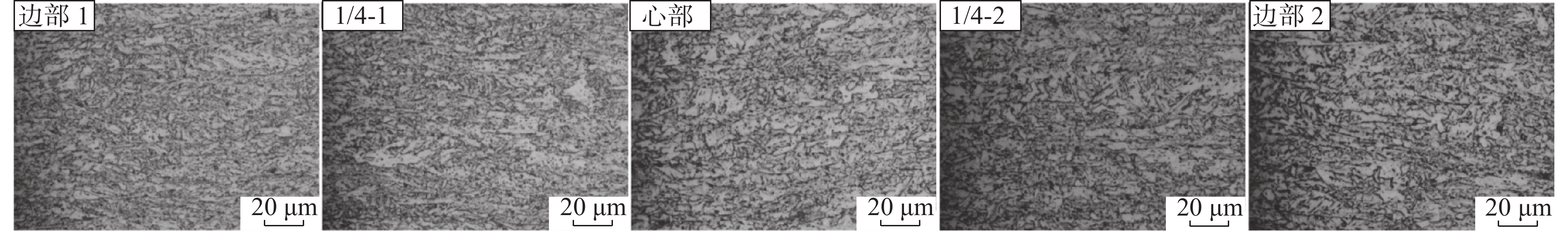

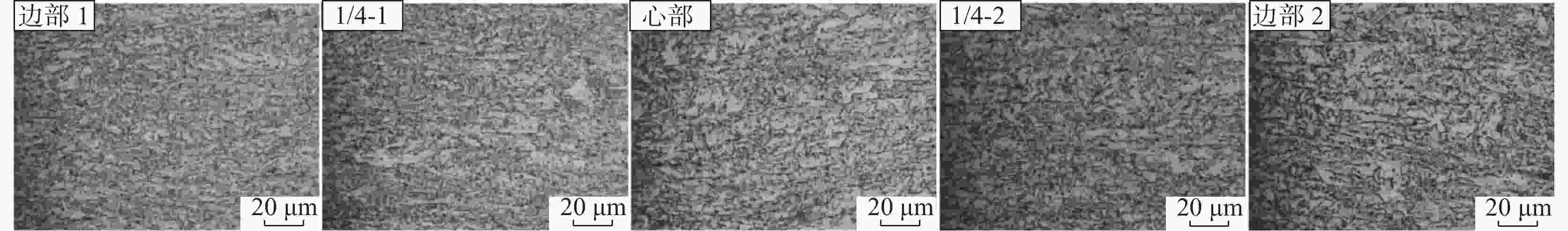

摘要: 通过显微组织和落锤试样的断裂路径表征,研究了不同终冷温度对21.4 mm厚X80组织和落锤性能的影响,分析了不同组织对裂纹扩展路径的影响。试验结果表明,当终冷温度为480 ℃时,其组织为粒状贝氏体+细小的准多边形铁素体,当终冷温度提高到510 ℃时,在心部出现大尺寸的多边形铁素体,随着终冷温度提高,大尺寸的多边形铁素体含量增加。当终冷温度从480 ℃提高到550 ℃时,整个断面的组织由全针状铁素体组织向边部针状铁素体组织+心部大尺寸多边形铁素体组织转变,心部的大尺寸多边形铁素体组织不能有效阻止裂纹的扩展,落锤剪切面积从100%降低到72%。Abstract: The effects of different final cooling temperatures on the microstructure and drop weight properties of 21.4 mm thick X80 linepipe steel strip were studied, and the effect of different microstructure on crack propagation path was discussed. When the final cooling temperature is 480 ℃, the microstructure of the resulted steel strip is composed of granular bainite + fine quasi-polygonal ferrite. When the final cooling temperature is increased to 510 ℃, large-size polygonal ferrite appears in the core of strip sample. As the final cooling temperature further increases, the volume fraction of large-size polygonal ferrite increases. When the final cooling temperature is increased from 480 ℃ to 550 ℃, the microrstructure across cross section transforms from fully acicular ferrite to acicular ferrite in the edge + large-size polygonal ferrite in the core. Since the large-size polygonal ferrite in the core cannot restrain crack propagation effectively, the drop weight shear area of tested steel decreases from 100% to 72% with cooling temperature increasing from 480 ℃ to 550 ℃.

-

Key words:

- X80 pipeline steel /

- final cooling temperature /

- ferrite /

- DWTT /

- crack flaw

-

表 1 试验用钢的化学成分设计

Table 1. Chemical composition of test steel

% C Si Mn P S Nb Cr Mo 0.05 0.23 1.76 0.011 0.002 0.07 0.24 0.22 表 2 不同终冷温度对比试验方案

Table 2. Comparison test schemes designed to investigate the effect of different final cooling temperatures

编号 终冷温度/℃ 卷取温度/℃ 是否表面积水 1# 480 322 否 2# 510 325 否 3# 550 330 否 表 3 不同试验钢的落锤剪切面积

Table 3. Drop weight shear area of tested steel obtained under different cooling scheme indicated in table 2

编号 −20 ℃DWTT落锤剪切面积比/% 1# 100 2# 92 3# 72 技术条件要求值 ≥85 -

[1] Koo J Y, Luton M J,Bangaru N V, et al. Metallurgical design of ultra-high strength steels for gas pipelines[C]//The 13th (2003) International Offshore and Polar Engineering Conference. 2003, Honolulu. [2] Schwinn V. Production and progress work of plates for pipes with strength level of X80 and above[C]// International Conference on Application and Evaluation of High Grade Linepipes in Hostile Environments. 2002, Tokyo. [3] Zhang Xixi, Wang Feng, Fan Yuran. Current crack arrest technologies for high-grade steel long-distance gas pipeline[J]. Oil & Gas Storage and Transportation, 2014,33(8):819−824. (张希悉, 汪凤, 范玉然. 高钢级天然气长输管道止裂控制技术现状[J]. 油气储运, 2014,33(8):819−824.Zhang Xixi, Wang Feng, Fan Yuran . Current crack arrest technologies for high-grade steel long-distance gas pipeline[J]. Oil & Gas Storage and Transportation. 2014, 33(8): 819-824. [4] Zhang Weiwei, Li He, Chi Qiang, et al. Technical specifications of the X80 large OD 1422 mm line pipes and the corresponding product development[J]. Natural Gas Industry, 2016,36(6):84−91. (张伟卫, 李鹤, 池强, 等. 外径 1 422 mm 的 X80 钢级管材技术条件研究及产品开发[J]. 天然气工业, 2016,36(6):84−91. doi: 10.3787/j.issn.1000-0976.2016.06.013Zhang Weiwei, Li He, Chi Qiang, et al. Technical specifications of the X80 large OD 1422 mm line pipes and the corresponding product development[J]. Natural Gas Industry, 2016, 36(6﹚: 84-91. doi: 10.3787/j.issn.1000-0976.2016.06.013 [5] Huo Chunyong, Li He, Zhang Weiwei, et al. Fracture control technology for the X80 large OD 1422 mm line pipes[J]. Natural Gas Industry, 2016,36(6﹚:78−83. (霍春勇, 李鹤, 张伟卫, 等. X80 钢级 1422 mm 大口径管道断裂控制技术[J]. 天然气工业, 2016,36(6﹚:78−83. doi: 10.3787/j.issn.1000-0976.2016.06.012Huo Chunyong, Li He, Zhang Weiwei, et al. Fracture control technology for the X80 large OD 1422 mm line pipes[J]. Natural Gas Industry, 2016, 36(6﹚: 78-83. doi: 10.3787/j.issn.1000-0976.2016.06.012 [6] Yu Qingbo. Effect of the yolume fraction and grain size of polygonal ferrite on the fracture properties of drop weight tear test of pipeline steel[J]. Journal of Mechanical Engineering, 2011,47(24):44−49. (于庆波. 多边形铁素体的体积分数和大小对管线钢落锤撕裂性能的影响[J]. 机械工程学报, 2011,47(24):44−49. doi: 10.3901/JME.2011.24.044Yu Qingbo. Effect of the Volume Fraction and Grain Size of Polygonal Ferrite on the Fracture Properties of Drop Weight Tear Test of Pipeline Steel[J]. Journal of Mechanical Engineering, 2011, 47(24): 44-49. doi: 10.3901/JME.2011.24.044 [7] (美)布鲁克斯.有色合金的热处理、组织与性能[M]. 北京: 冶金工业出版社, 1988.Brooks C R . Heat treatment, structure and properties of non-ferrous alloys[M]. Beijing: Metallurgical Industry Press, 1988. [8] Zhou Min, Du Linxiu, Yi Hailong, et al. Factors affecting DWTT property of X80 pipeline steel[J]. Journal of Iron and Steel Research, 2009,21(9):33−36. [9] 刘宗昌. 贝氏体与贝氏体相变[M]. 北京: 冶金工业出版社, 2009: 21−23.Liu Zongchang. Bainite and bainite transformation[M]. Beijing: Metallurgical Industry Press,2009:21-23. -

下载:

下载: