Preparation of electrically conductive carbon fiber-cement mortars with carbonized titanium-bearing blast furnace slag as an aggregate

-

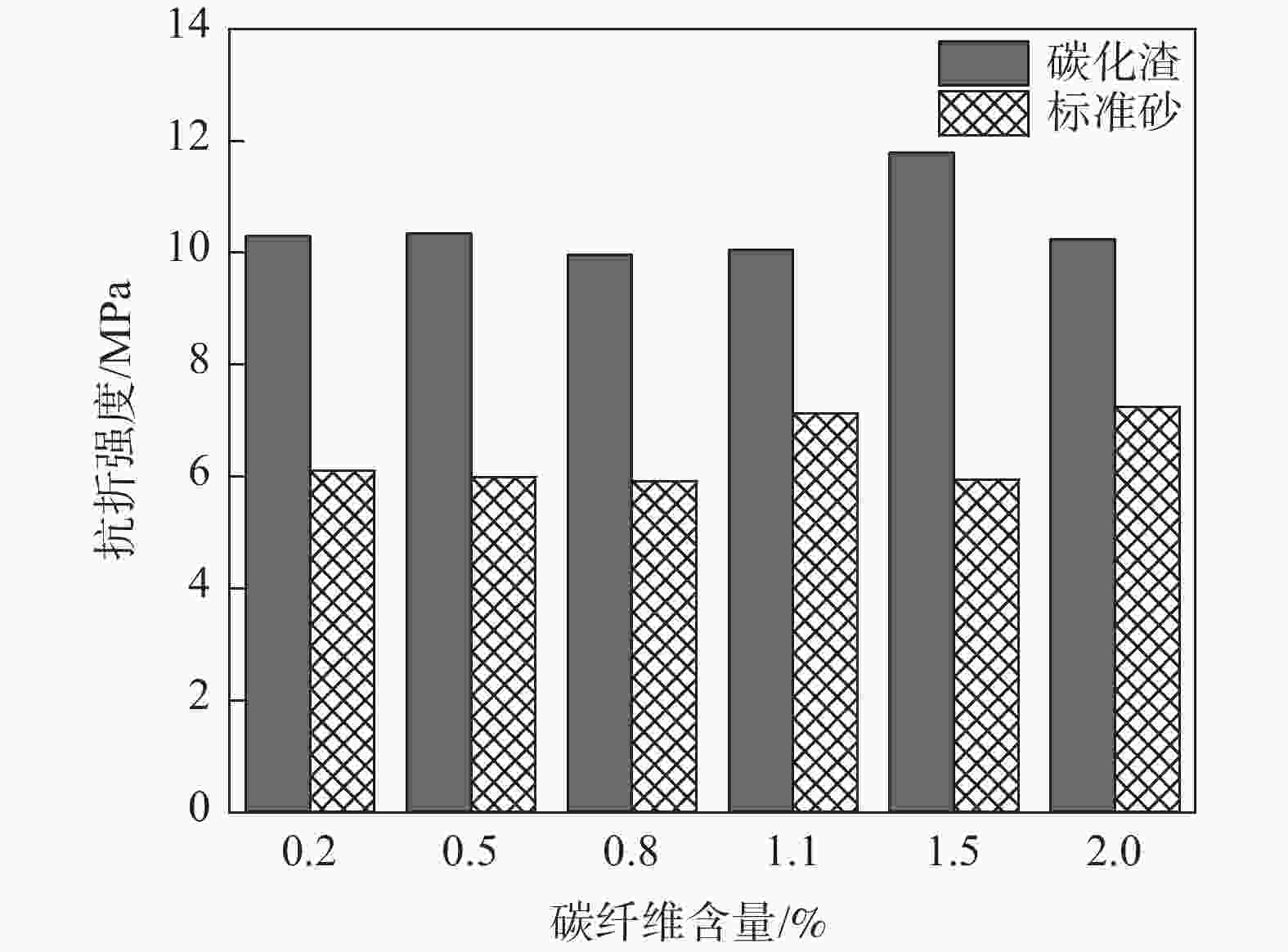

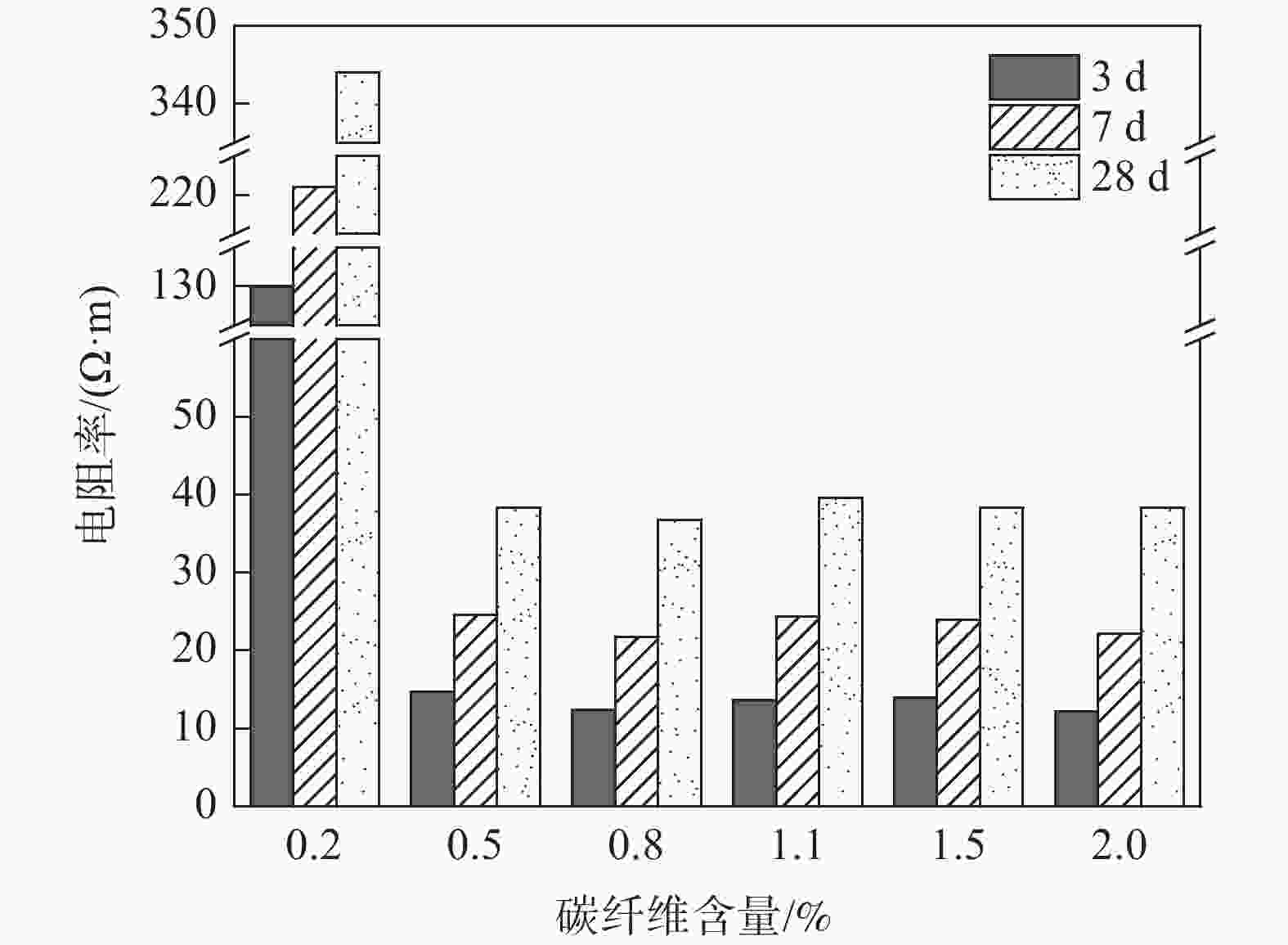

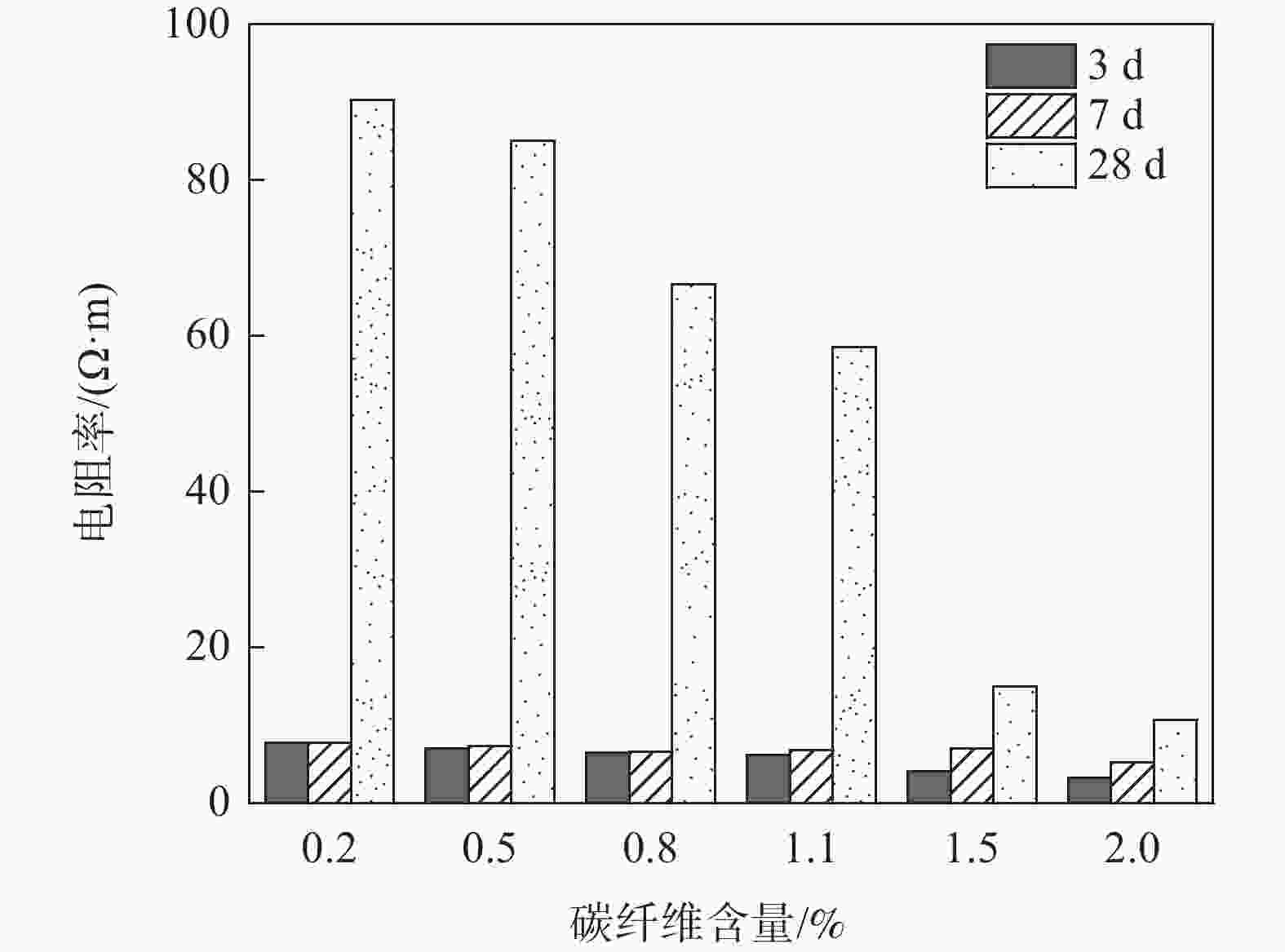

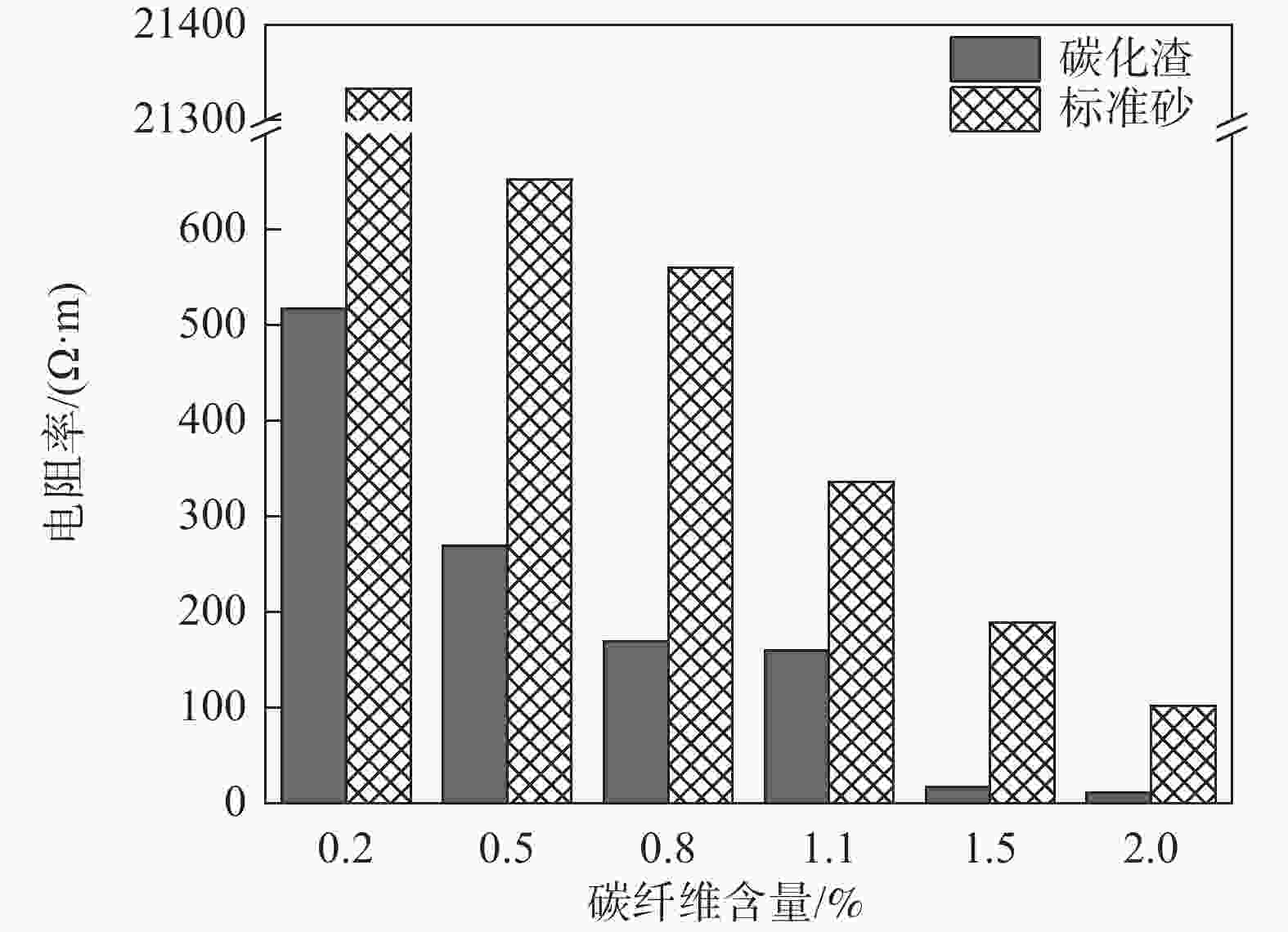

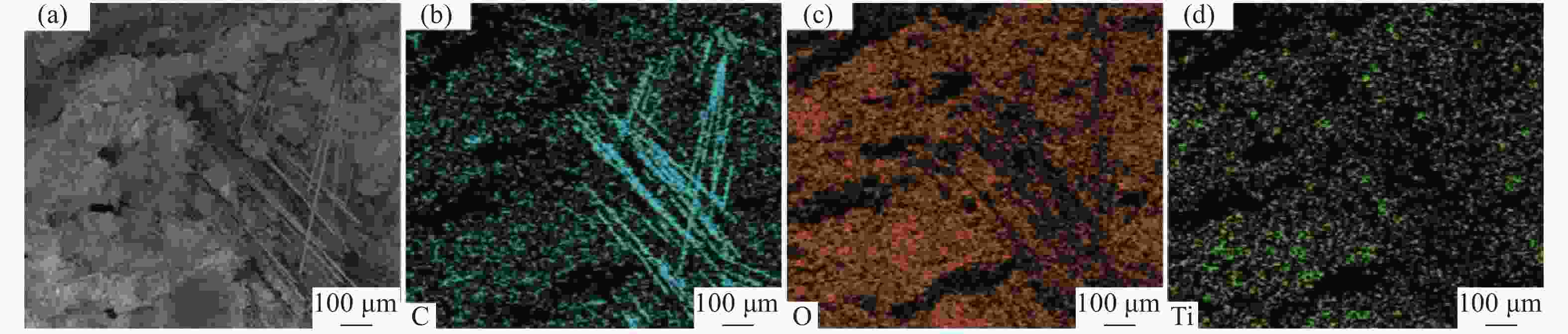

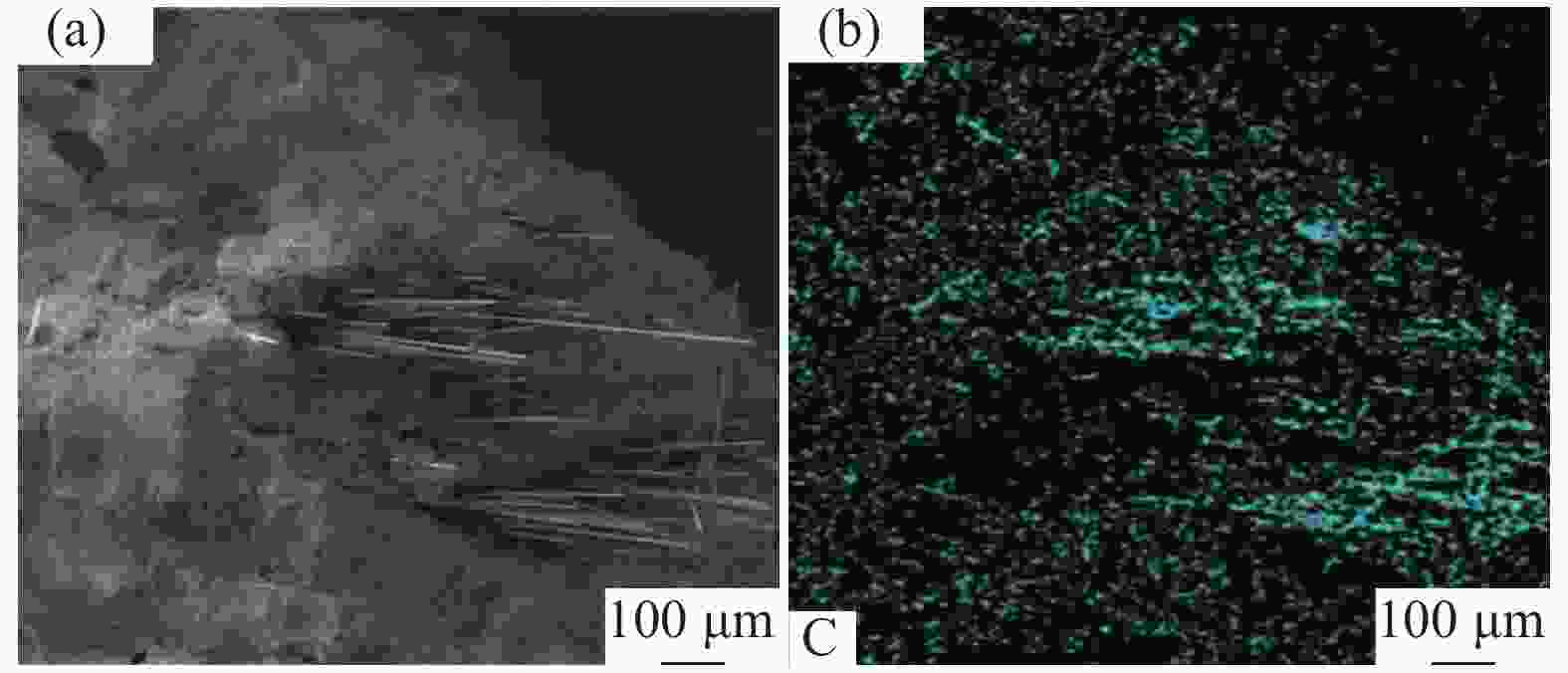

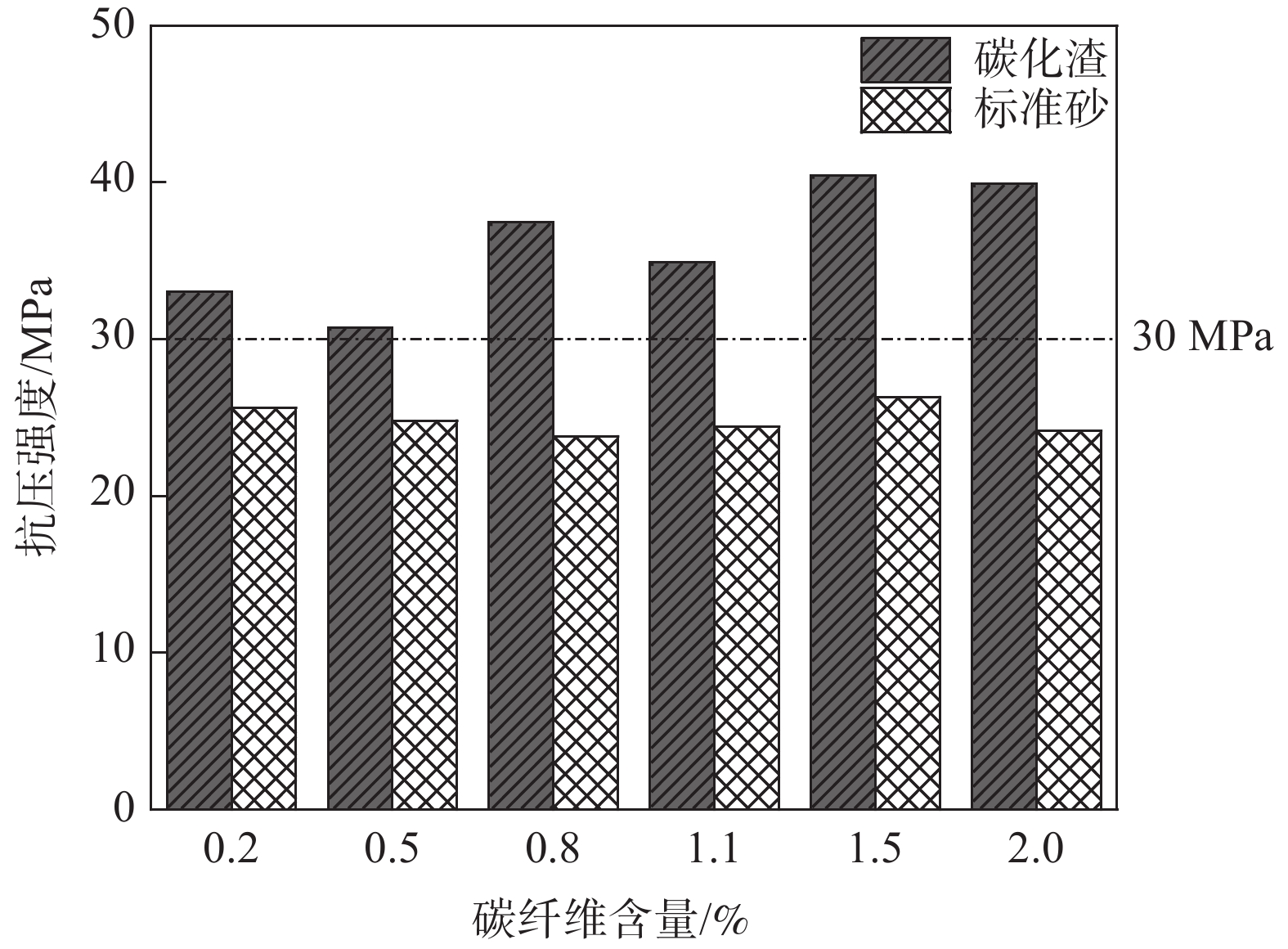

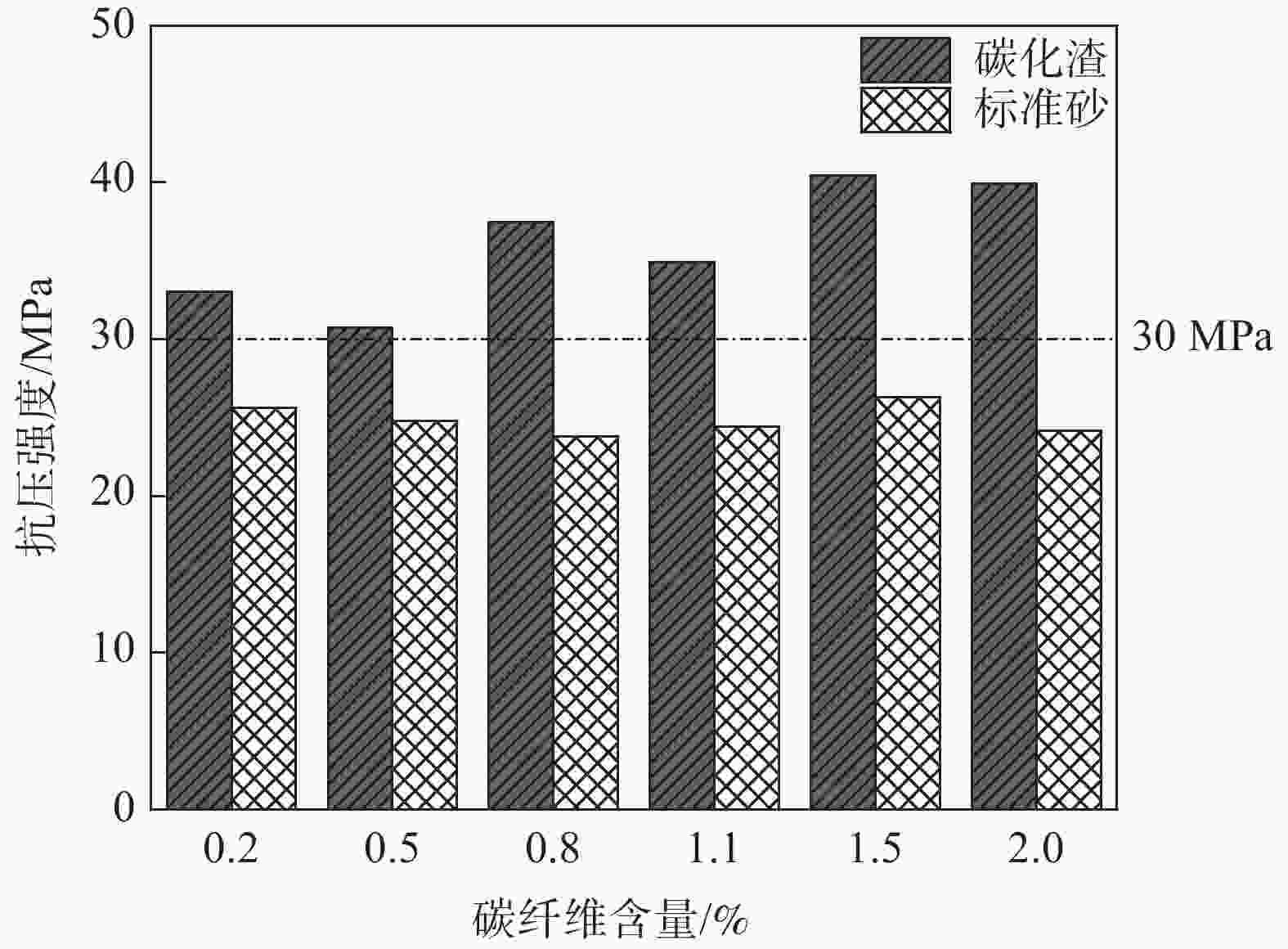

摘要: 以含钛高炉渣的碳化产物(含钛碳化渣)为集料,以碳纤维为导电相,制备了导电水泥砂浆。测试了含钛碳化渣-碳纤维水泥砂浆在不同碳纤维含量下的抗折、抗压强度和电阻率,并与标准砂-碳纤维水泥砂浆进行了性能比较。结果显示,以含钛碳化渣替代标准砂作为集料,不仅能显著提升碳纤维水泥砂浆的抗压和抗折强度,使其满足建筑水泥砂浆的要求,还将导电水泥砂浆的渗流阈值从0.5 %降低至0.2 %。当碳纤维含量为2.0 %时,以含钛碳化渣作为集料的水泥砂浆表现出优异的性能:28 d抗压和抗折强度分别为39.9 MPa和10.2 MPa,湿润条件下电阻率为10.7 Ω·m,干燥条件下电阻率为10.9 Ω·m。该研究既为含钛高炉渣的再利用提供了一种新思路,也为导电水泥基复合材料的制备提供了新选择。Abstract: Electrically conductive cement mortars were prepared by using carbon fiber as a conductive phase and carbonized titanium-bearing blast furnace slag (CTBFS) as an aggregate. The content of carbon fiber on the rupture strength, compressive strength, and electrical resistivity of the as-prepared cement mortar was investigated and compared with those with standard sand as an aggregate. The results show that the replacement of standard sand with CTBFS as the aggregate not only significantly improved the rupture and compressive strength of carbon fiber cement mortar, making it meet the requirements of building cement mortar, but also reduced the threshold of conductive cement mortar from 0.5% to 0.2%. With a carbon fiber content of 2.0%, the as-prepared cement mortar with CTBFS as the aggregate showed excellent performance with 28 d compression and rupture strength of 39.9 MPa and 10.2 MPa, respectively, as well as electrical resistance of 10.7 Ω·m in wet state and 10.9 Ω·m in dry state, respectively. The investigation provides a new way for the reuse of titanium-bearing blast furnace slag and the preparation of conductive cement-based composites.

-

表 1 短切碳纤维性质

Table 1. Properties of chopped carbon fibers

长度/

mm碳含量/

%抗拉强度/

GPa密度/

(g·cm−3)体积电阻率/

(Ω·cm)6 ≥ 95 3.8 1.76 1.5×10−3 表 2 碳纤维水泥砂浆的配合比

Table 2. Mix proportion of carbon fiber cement mortar

编号 碳纤维含量/% 材料配比/g 水泥 碳化渣 标准砂 水 短切碳纤维 1 0.2 450 1350 0 225 0.90 2 0.5 450 1350 0 225 2.25 3 0.8 450 1350 0 225 3.60 4 1.1 450 1350 0 225 4.95 5 1.5 450 1350 0 225 6.75 6 2.0 450 1350 0 225 9.00 7 0.2 450 0 1350 225 0.90 8 0.5 450 0 1350 225 2.25 9 0.8 450 0 1350 225 3.60 10 1.1 450 0 1350 225 4.95 11 1.5 450 0 1350 225 6.75 12 2.0 450 0 1350 225 9.00 -

[1] Zhu Fuxing, Jiao Yu, Li Liang, et al. The status and trends of material processing technology for vanadic titanomagnetite in Panxi area[J]. Mining and Metallurgy, 2021,30(4):26−32. (朱福兴, 焦钰, 李亮, 等. 攀西钒钛磁铁矿的选矿技术现状及发展趋势[J]. 矿冶, 2021,30(4):26−32. doi: 10.3969/j.issn.1005-7854.2021.04.005 [2] Ou Yang, Sun Yongsheng, Yu Jianwen, et al. Research status and development prospect of utilization of vanadium-titanium magnetitie[J]. Journal of Iron and Steel Research, 2021,33(4):267−278. (欧杨, 孙永升, 余建文, 等. 钒钛磁铁矿加工利用研究现状及发展趋势[J]. 钢铁研究学报, 2021,33(4):267−278. [3] Xu Ying, Li Dandan, Yang Shanshan, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021,(1):23−31. (许莹, 李单单, 杨姗姗, 等. 含钛高炉渣综合利用研究进展[J]. 矿产综合利用, 2021,(1):23−31. doi: 10.3969/j.issn.1000-6532.2021.01.004 [4] Hao Baichuan, Li Ziyue, Jia Dongfang, et al. Comprehensive utilization of blast furnace slag containing titanium[J]. Multipurpose Utilization of Mineral Resources, 2020,(6):1−6. (郝百川, 李子越, 贾东方, 等. 含钛高炉渣的综合利用[J]. 矿产综合利用, 2020,(6):1−6. doi: 10.3969/j.issn.1000-6532.2020.06.001 [5] Fan G, Wang M, Dang J, et al. A novel recycling approach for efficient extraction of titanium from high-titanium-bearing blast furnace slag[J]. Waste Manage, 2021,120:626−634. doi: 10.1016/j.wasman.2020.10.024 [6] Han Jiqing, Zhang Jing, Zhang Jiahao, et al. Recovery of Fe, V, and Ti in modified Ti-bearing blast furnace slag[J]. Transactions of Nonferrous Metals Society of China, 2022,32(1):333−344. (韩吉庆, 张晶, 张加豪, 等. 改性含钛高炉渣中铁、钒和钛的回收[J]. 中国有色金属学报: 英文版, 2022,32(1):333−344. [7] Zhang Yue, Wang Sijia, Xue Xiangxing. Recovery of titanium dioxide from titanium-bearing solution by using ammonium as precipitant[J]. CIESC Journal, 2012,63(10):3345−3349. (张悦, 王思佳, 薛向欣. 氨水沉淀法由含钛滤液提取二氧化钛[J]. 化工学报, 2012,63(10):3345−3349. doi: 10.3969/j.issn.0438-1157.2012.10.048 [8] Zheng F, Guo Y, Qiu G, et al. A novel process for preparation of titanium dioxide from Ti-bearing electric furnace slag: NH4HF2-HF leaching and hydrolyzing process[J]. J. Hazard. Mater., 2018,344:490−498. doi: 10.1016/j.jhazmat.2017.10.042 [9] Xue T, Wang L, Qi T, et al. Decomposition kinetics of titanium slag in sodium hydroxide system[J]. Hydrometallurgy, 2009, 95(1–2): 22-27. [10] Zhang Suxin, Yang Yangjun, Lu Ping, et al. Study on preparation of TiCl4 using titanium-containing carbonized blast furnace slag as raw material[J]. Iron Steel Vanadium Titanium, 2016,37(6):24−28. (张苏新, 杨仰军, 陆平, 等. 含钛碳化高炉渣为原料制备TiCl4试验研究[J]. 钢铁钒钛, 2016,37(6):24−28. doi: 10.7513/j.issn.1004-7638.2016.06.005 [11] Gao Qirui, Song Bo, Yang Zhanbing, et al. Carbonization of blast furnace slag bearing titanium and separation of TiC phase by super gravity[J]. Nonferrous Metals Science and Engineering, 2017,8(2):1−7. (高启瑞, 宋波, 杨占兵, 等. 含钛高炉渣碳化及超重力分离碳化钛的研究[J]. 有色金属科学与工程, 2017,8(2):1−7. [12] Li Z, Lei Y, Ma W, et al. Preparation of high-purity TiSi2 and eutectic Si–Ti alloy by separation of Si–Ti alloy for clean utilization of Ti-bearing blast furnace slag[J]. Sep. Purif. Technol., 2021,265:118473. doi: 10.1016/j.seppur.2021.118473 [13] Zhang Z, Lv H, Li X, et al. Conversion of CaTi1–xMnxO3–δ-based photocatalyst for photocatalytic reduction of NO via structure-reforming of Ti-bearing blast furnace slag[J]. ACS Sustain. Chem. Eng., 2019,7:10299−10309. doi: 10.1021/acssuschemeng.9b00097 [14] Qiu Shengtao, Zhang Mingbo, Li Jianxin, et al. Recent progress and prospective of comprehensive utilization of Ti-bearing blast furnace slag[J]. Iron & Steel, 2016,51(7):1−8. (仇圣桃, 张明博, 李建新, 等. 含钛高炉渣资源化综合利用研究现状与展望[J]. 钢铁, 2016,51(7):1−8. [15] Frac M, Pichor W, Szoldra P, et al. Cement composites with expanded graphite/paraffin as storage heater[J]. Constr Build Mater., 2021,275:122126. doi: 10.1016/j.conbuildmat.2020.122126 [16] Yuan T F, Choi J S, Hong S H, et al. Enhancing the electromagnetic shielding and impact resistance of a reinforced concrete wall for protective structures[J]. Cem Concr Compos., 2021,122:104148. doi: 10.1016/j.cemconcomp.2021.104148 [17] Monteiro A O, Costa P M F J D, Oeser M, et al. Dynamic sensing properties of a multifunctional cement composite with carbon black for traffic monitoring[J]. Smart Mater Struct., 2020,29:025023. doi: 10.1088/1361-665X/ab62e2 [18] Wang H, Shi F, Shen J, et al. Research on the self-sensing and mechanical properties of aligned stainless steel fiber-reinforced reactive powder concrete[J]. Cem Concr Compos., 2021,119:104001. doi: 10.1016/j.cemconcomp.2021.104001 [19] Ma Shining, Liu Xiaojun, Zhang Yuanlong, et al. Application study on snow-ice melting for airport carbon fiber conductive concrete pavement[J]. Subgrade Engineering, 2011,(3):182−184. (马世宁, 刘晓军, 张元龙. 碳纤维导电混凝土道面机场除冰雪的应用研究[J]. 路基工程, 2011,(3):182−184. doi: 10.3969/j.issn.1003-8825.2011.03.053 [20] Zhang Yiming, Yu Lehua. Smart properties of steel fiber and carbon nano tube reinforced conductive concrete during flexural process[J]. Concrete, 2017,(9):49−52. (张苡铭, 俞乐华. 钢纤维-碳纳米管导电混凝土的受弯机敏性试验研究[J]. 混凝土, 2017,(9):49−52. [21] 丁益林. 钢纤维锈蚀对砂浆力学及物质传输性能影响的试验研究[D]. 大连: 大连理工大学, 2021.Ding Yilin. Experiment study on the influence of steel fiber corrosion on mechanical and mass transport properties of mortar [D]. Dalian: Dalian University of Technology, 2021. [22] Guo Chuanhui, Tang Wuan, Liu Shuhua. Properties and microstructure of conductive concrete containing graphite powder[J]. Bulletin of the Chinese Ceramic Society, 2017,36(9):3174−3179. (郭传慧, 汤婉, 刘数华. 石墨粉导电混凝土的性能与微结构[J]. 硅酸盐通报, 2017,36(9):3174−3179. doi: 10.16552/j.cnki.issn1001-1625.2017.09.052 [23] 崔素萍, 刘永肖, 兰明章, 等. 石墨-水泥基复合材料的制备与性能[J]. 硅酸盐学报, 2007, 35: 91-95.Cui Suping, Liu Yongxiao, Lan Mingzhang, et al. Preparation and properties of graphite-cement based composites[J]. Journal of the Chinese Ceramic Society, 2007, 35: 91-95. [24] Fang Zhenggang, Huang Peng, Xue Feng, et al. Effects of the mixing amount of graphite and carbon fiber on macro properties of concrete[J]. Building Structure, 2017,47(21):59−62. (房正刚, 黄彭, 薛峰, 等. 石墨和碳纤维掺量对混凝土宏观性能的影响[J]. 建筑结构, 2017,47(21):59−62. doi: 10.19701/j.jzjg.2017.21.011 [25] Ge Yuchuan, Liu Shuhua. Research progress on characteristics of carbon fiber conductive concrete[J]. Bulletin of the Chinese Ceramic Society, 2019,38(8):2442−2447. (葛宇川, 刘数华. 碳纤维导电混凝土特性研究进展[J]. 硅酸盐通报, 2019,38(8):2442−2447. [26] 邓宵. 掺铁导电集料及其水泥基导电复合材料的制备与性能研究[D]. 武汉: 武汉理工大学, 2011.Deng Xiao. Preparation and performance investigation of iron containing aggregate and its cement-based conductive composites [D]. Wuhan: Wuhan University of Technology, 2011. [27] Lamastra F R, Chougan M, Marotta E, et al. Toward a better understanding of multifunctional cement-based materials: The impact of graphite nanoplatelets (GNPs)[J]. Ceram Int, 2021,47(14):20019−20031. doi: 10.1016/j.ceramint.2021.04.012 [28] Dong W, Guo Y, Sun Z, et al. Development of piezoresistive cement-based sensor using recycled waste glass cullets coated with carbon nanotubes[J]. J Clean Prod, 2021,314:127968. doi: 10.1016/j.jclepro.2021.127968 [29] Dong Q, Wang G, Chen X, et al. Recycling of steel slag aggregate in Portland cement concrete: An overview[J]. J Clean Prod, 2021,282:124447. doi: 10.1016/j.jclepro.2020.124447 [30] Ozturk M, Akgol O, Sevim U K, et al. Experimental work on mechanical, electromagnetic and microwave shielding effectiveness properties of mortar containing electric arc furnace slag[J]. Constr Build Mater, 2018,165:58−63. doi: 10.1016/j.conbuildmat.2018.01.031 [31] Tang Chenjun, Xuan Ming, Ding Xiang, et al. Effects of carbonized titanium-bearing blast furnace slag on the compressive strength and electrical resistivity of cement mortar[J]. The Chinese Journal of Process Engineering, 2022,(4):499−505. (唐晨钧, 宣明, 丁祥, 等. 含钛高炉渣的碳化产物对水泥砂浆强度及电阻率的影响[J]. 过程工程学报, 2022,(4):499−505. doi: 10.12034/j.issn.11009-12606X.221095 [32] Doo-Yeol Y, You I, Seung-Jung L. Electrical properties of cement-based composites with carbon nanotubes, graphene, and graphite nanofibers[J]. Sensors, 2017,17(5):1064−1076. doi: 10.3390/s17051064 -

下载:

下载: