Solidification process simulation and process optimization of high strength steel slab

-

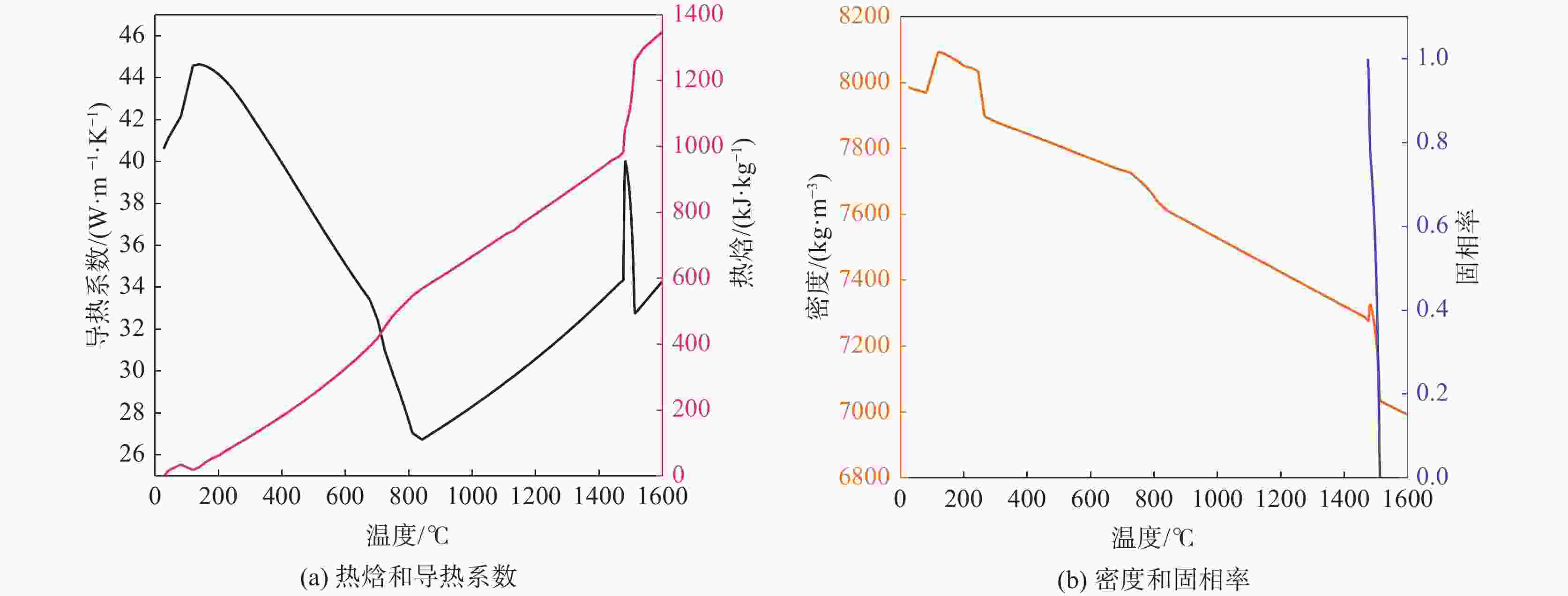

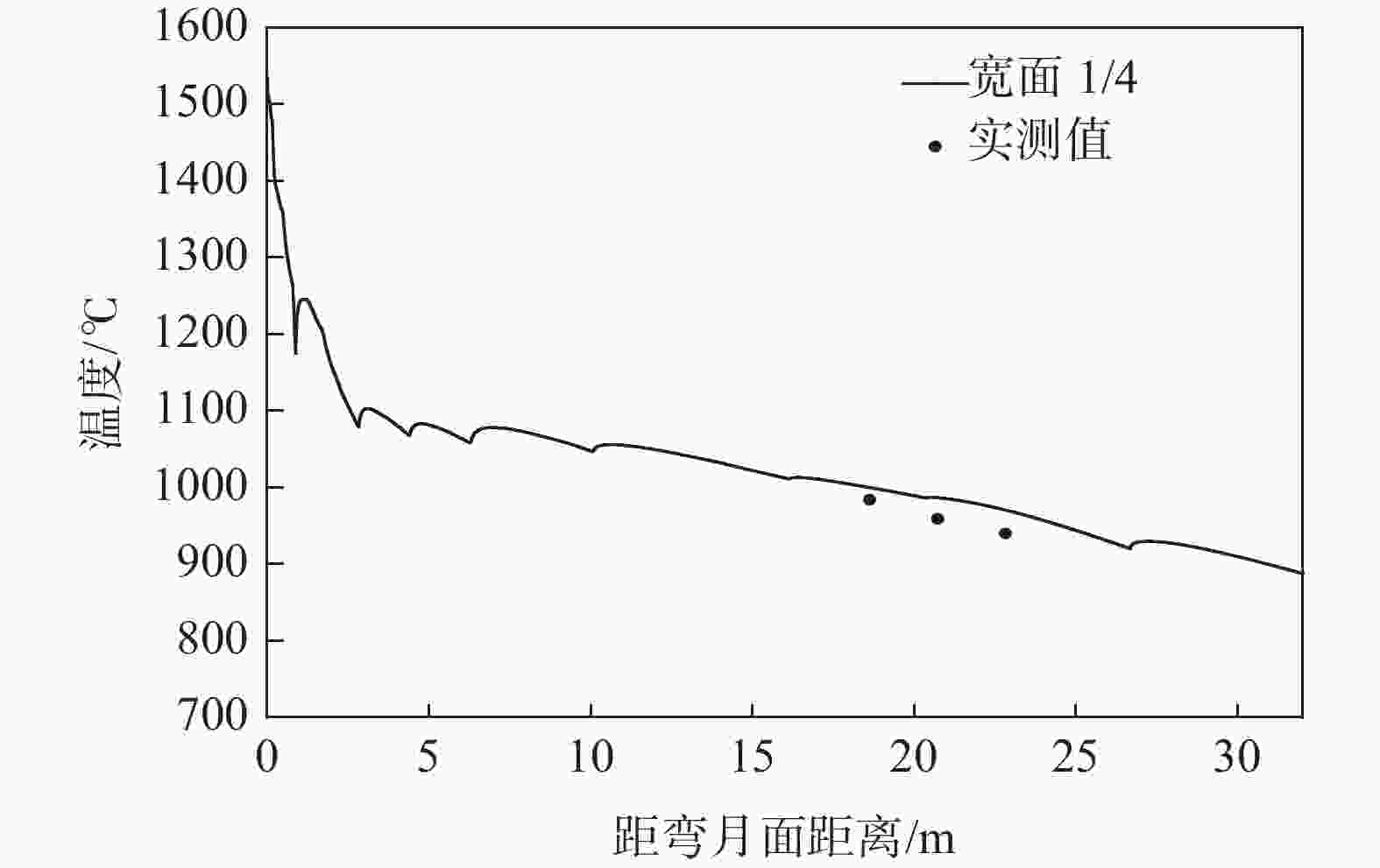

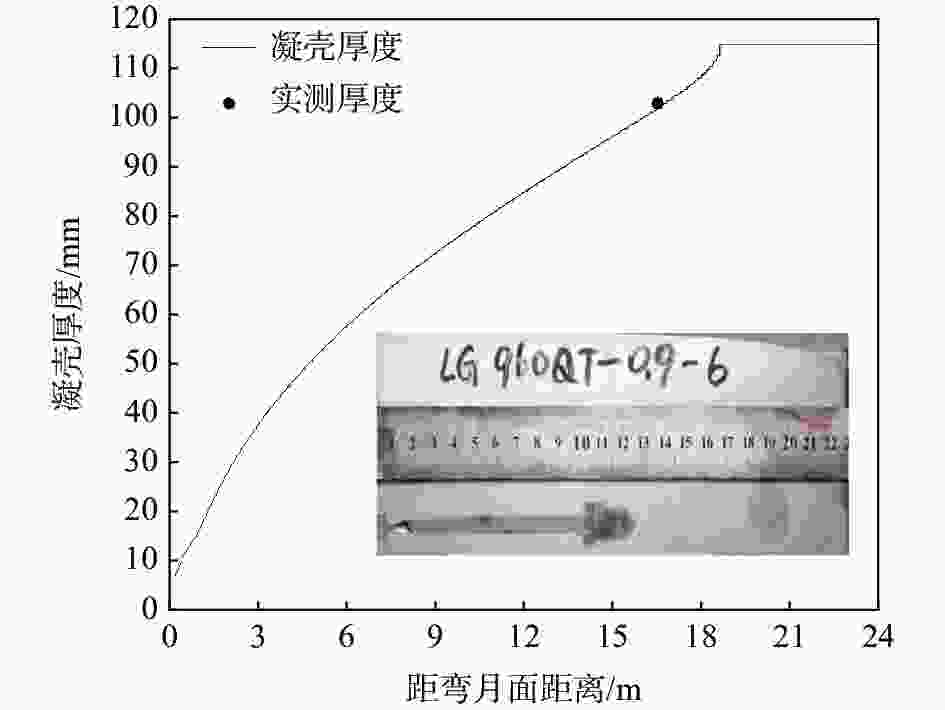

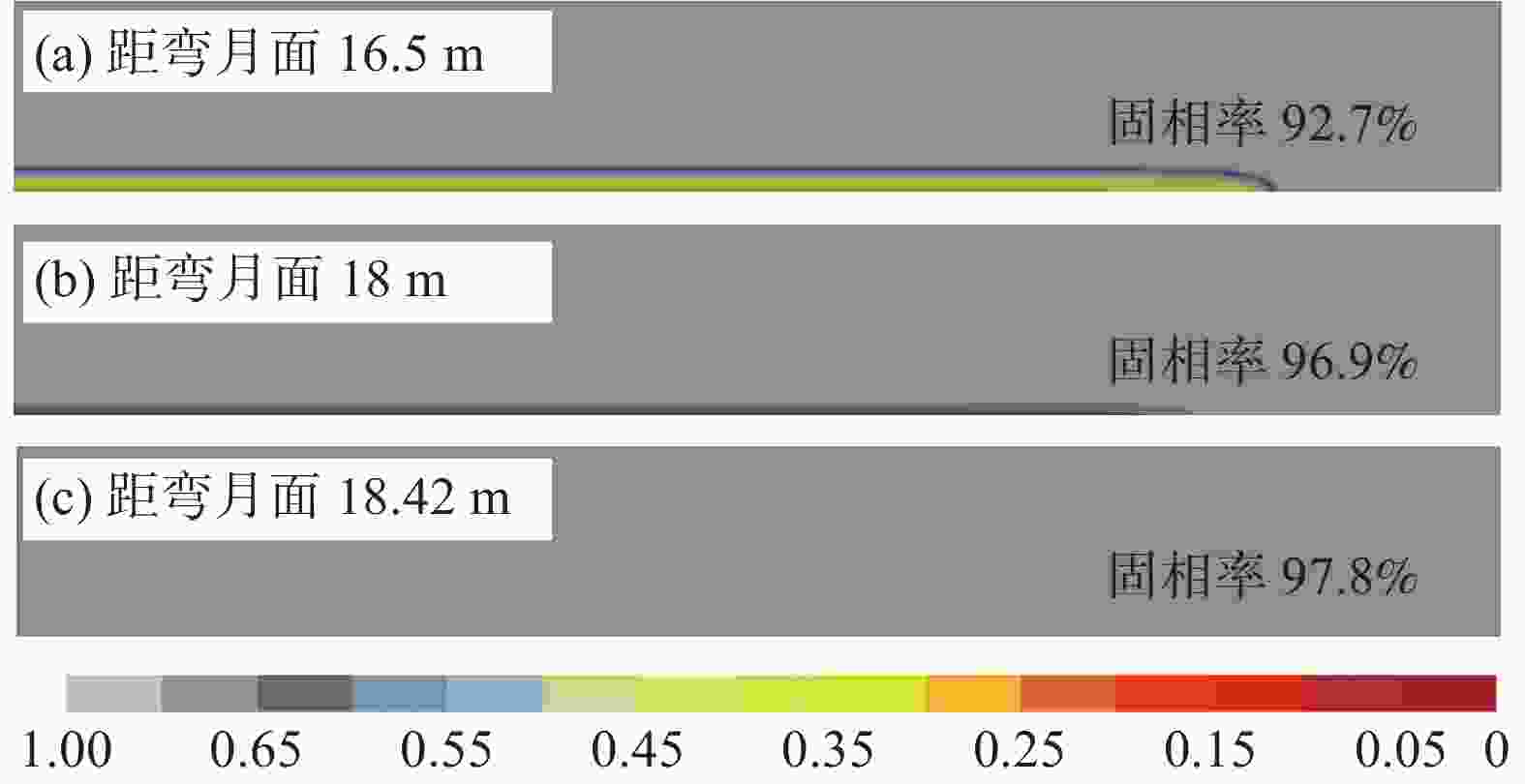

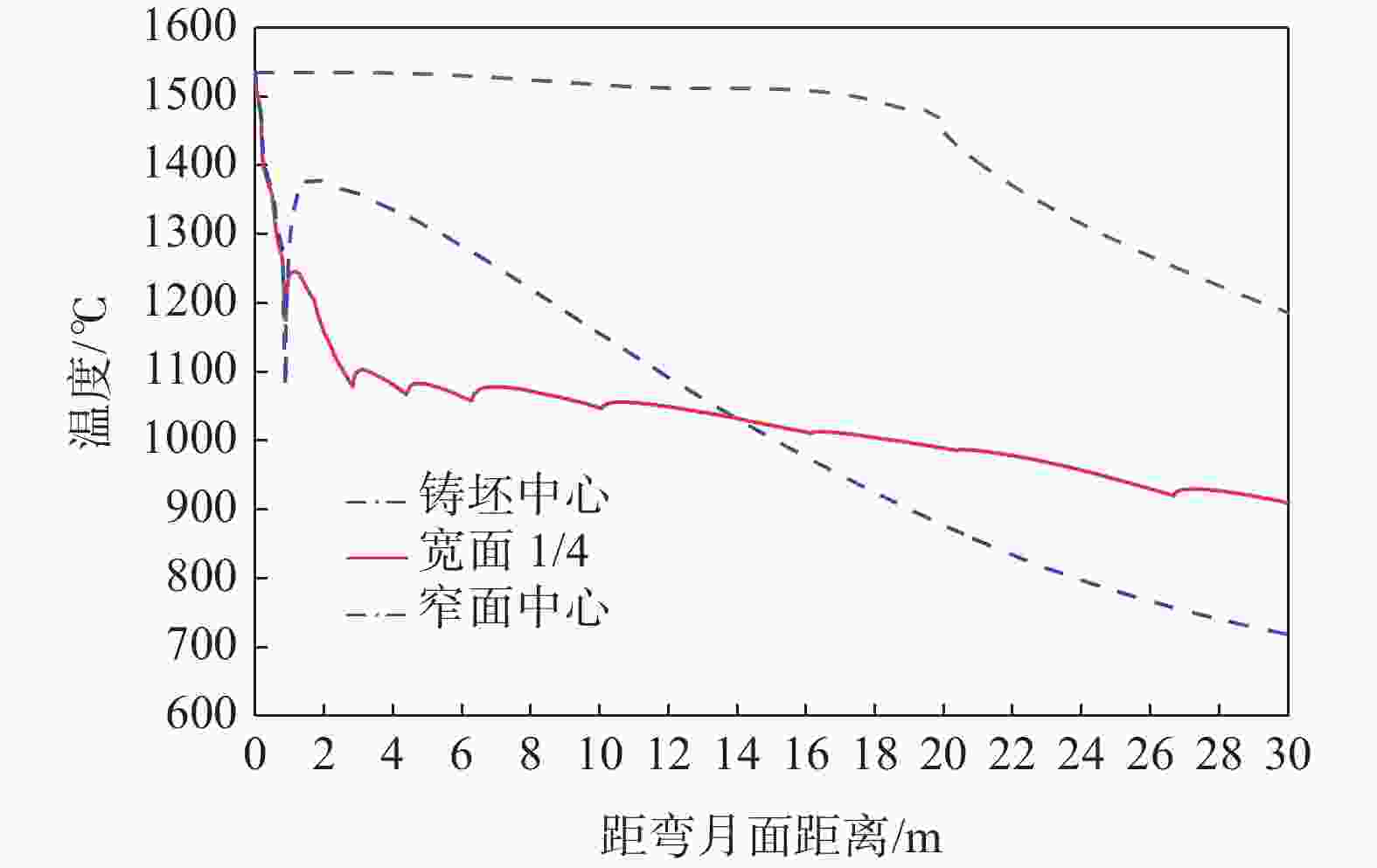

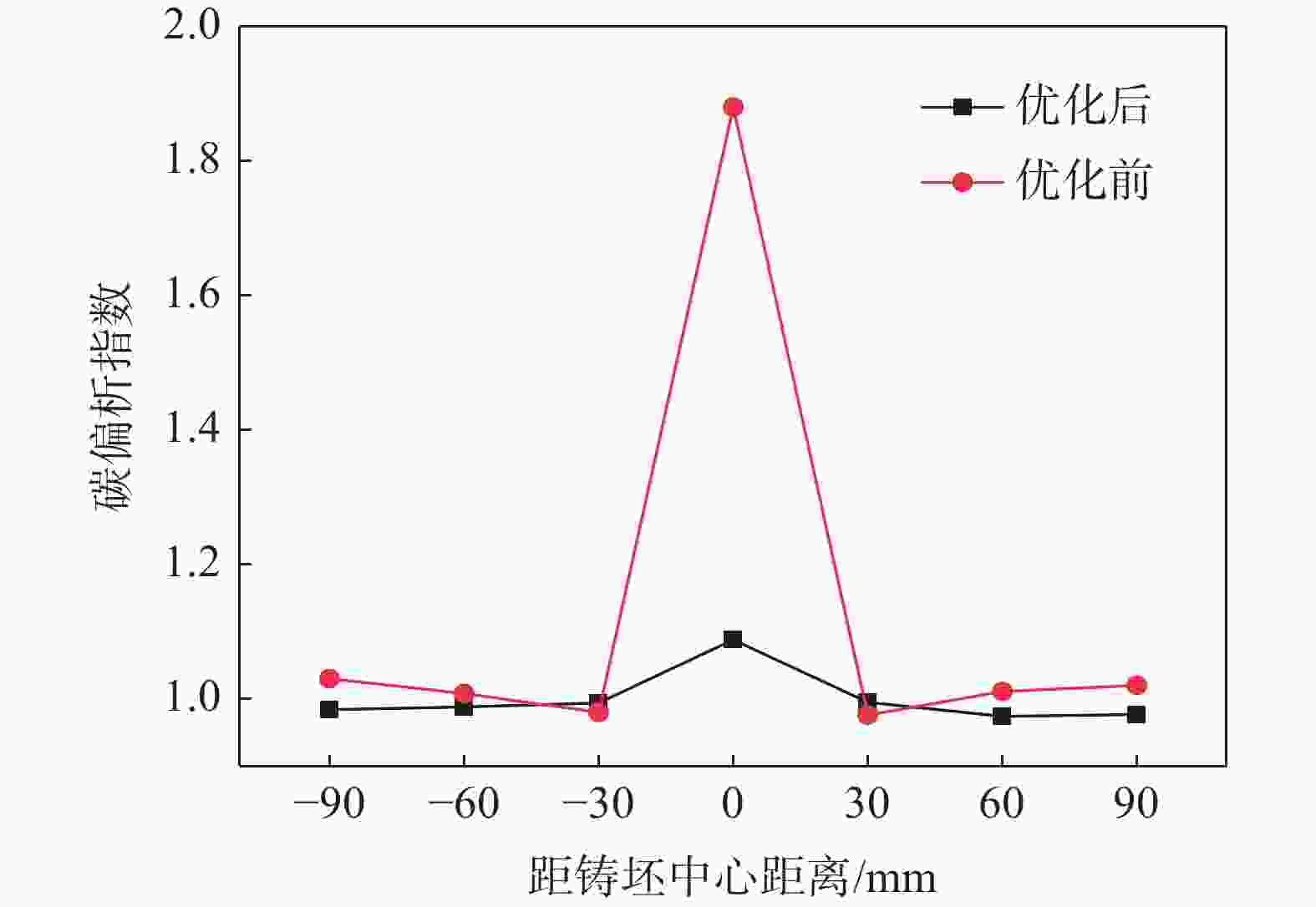

摘要: 以凝固参数测定和铸坯表面温度测量结果为验证边界条件,应用ProCAST软件对960QT钢板坯连铸过程中的传热和凝固过程进行了模拟,分析了拉速、过热度对铸坯温度场、液芯长度的影响,得出在拉速为0.9 m/min,过热度为23 ℃工况下,960QT板坯的凝固终点位置距离弯月面18.43 m;在浇注温度为1535 ℃时,拉速每增加0.1 m/min,凝固末端位置向后移动2.7 m左右;在拉速为0.9 m/min时,过热度每增加10 ℃,凝固末端位置向后移动0.4 m左右。此外,对轻压下系统的压下位置和压下量进行了优化,由3个扇形段压下改为2个扇形段压下,6、7段压下量改为2.0、2.5 mm。工艺优化后,铸坯中心偏析和中心疏松得到明显改善,中心碳偏析指数由1.85降至1.09。Abstract: Using solidification parameters and surface temperature measurements as boundary conditions, ProCAST software was applied to simulate the heat transfer and solidification process of 960QT steel slab during continuous casting. The effects of casting speed and superheat on the temperature fields of slab and liquid core length at the outlet of the copper mold were analyzed. It is concluded that under the conditions of the casting speed of 0.9 m/min and superheat of 23 ℃, the solidification end point is 18.43 m away from the meniscus. When the casting temperature is 1535 ℃, the position of solidification end moves forward about 2.7 m when the casting speed increases by 0.1 m/min. When the pulling speed is 0.9 m/min, the position of the solidification end moves back about 0.4 m with every 10 ℃ increase of superheat. In addition, the reduction position and amount of the soft reduction system were optimized, from 3 segments to 2 segments, and the reduction of sections 6 and 7 was changed to 2.0 and 2.5 mm respectively. After the process optimization, the central segregation and central porosity of slab were significantly improved, and the carbon segregation index at the slab center decreased from 1.85 to 1.09.

-

Key words:

- continuous casting /

- 960QT /

- ProCAST /

- superheat /

- end of solidification /

- shell thickness /

- centerline segregation

-

表 1 试验钢种的主要化学成分

Table 1. Main chemical composition of the steel

% C Si Mn P S Al Ca Ti 0.16 0.25 1.23 0.0094 0.0027 0.0329 0.0015 0.019 表 2 二冷区参数

Table 2. Parameters of secondary cooling zone

冷却区 起始位置/cm 结束位置/cm L1(宽面) 80 88 L2(窄面) 80 88 L3 88 174 L4 174 283 L5 283 440 L6 440 629 L7 629 1008 L8 1008 1616 L9 1616 2038 L10 2038 2668 L11 2668 3298 表 3 二冷区冷却水量

Table 3. Cooling water quantity in secondary cooling zone

L/min L1 L2 L3 L4 L5 L6 L7 L8 L9 L10 L11 72 78 258 208 194 160 189 166 83 17 4 表 4 温度测量值与模拟值对比

Table 4. Comparison of the measured and simulated temperature values

拉速/(m·min−1) 位置/m 计算宽面中心温度/℃ 实测宽面温度/℃ 计算误差率/% 0.9 18.63 1000 984 1.6 0.9 20.73 987 959 2.9 0.9 22.83 970 940 3.2 表 5 960QT钢凝固计算实测结果对比

Table 5. Comparison of solidification calculation and measured results of 960QT steel

拉速/(m·min−1) 距弯月面距离/m 计算凝固厚度/mm 凝固层厚度/mm 计算误差率/% 0.9 16.5 100 102.5 2.4 表 6 优化前后的轻压下参数对比

Table 6. Comparison of soft reduction parameters before and after optimization

压下位置 距结晶器

距离/m优化前压下

量/mm优化后压下

量/mm5段 12.37~14.43 1.6 0 6段 14.43~16.5 1.6 2.0 7段 16.5~18.63 1.6 2.5 -

[1] Mu P, Nadot Y, Nadot-Martin C, et al. Influence of casting defects on the fatigue behavior of cast aluminum AS7G06-T6[J]. International Journal of Fatigue, 2014,63:97−109. doi: 10.1016/j.ijfatigue.2014.01.011 [2] Pascon F, Habraken A M. Finite element study of the effect of some local defects on the risk of transverse cracking incontinuous casting of steel slabs[J]. Computer Methods in Applied Mechanics and Engineering, 2007,196(21-24):2285−2299. doi: 10.1016/j.cma.2006.07.017 [3] Petr Haušild, Clotilde Berdin, Philippe Bompard, et al. Ductile fracture of duplex stainless steel with casting defects[J]. International Journal of Pressure Vessels and Piping, 2001,78(9):607−616. doi: 10.1016/S0308-0161(01)00069-2 [4] Cenanovic M B, Maureira H A, Ng M K C, et al. Electromagnetic technology for continuous casting in the steel industry[J]. Direct Rolling and Hot Charging of Strand Cast Billets, 1989:139−148. [5] Guo Liangliang, Tian Yong, Yao Man, et al. Temperature distribution and dynamic control of secondary cooling in slab continuous casting[J]. International Journal of Minerals, Metallurgy and Materials, 2009,16(6):626−631. [6] Chen Yong, Xiao Mingfu, Wu Guorong. Dynamic soft reduction technology for bloom casting[J]. Journal of Iron and Steel Research, International, 2010,17(6):1−5. doi: 10.1016/S1006-706X(10)60104-5 [7] 蔡开科. 浇注与凝固[M]. 北京: 冶金工业出版社, 1987: 83-106.Cai Kaike. Pouring and solidification[M]. Beijing: Metallurgical Industry Press, 1987: 83-106. [8] Li Jinghong, Jia Hongming, Li Xiaowei, et al. Determination of solidified shell thinkness of continuous casting slab at Angang[J]. Steelmaking, 2008,24(6):17−18,21. (李惊鸿, 贾洪明, 李晓伟, 等. 鞍钢厚板坯凝固坯壳厚度的测定[J]. 炼钢, 2008,24(6):17−18,21. [9] Li Pengfei, Wang Minglin, Zhang Zhenxue, et al. Reaserch on measurement of Q550D steel solidified slab shell thickness[J]. Hot Working Technology, 2019,48(1):98−102. (李鹏飞, 王明林, 张振学, 等. Q550D凝固坯壳厚度测定研究[J]. 热加工工艺, 2019,48(1):98−102. [10] Ruan Xibao, Tian Yushi, Xu Lijun, et al. Effect of continuous casting technological parameters on solidification end point of slab[J]. Continuous Casting, 2016,41(5):5−10. (阮细保, 田玉石, 徐李军, 等. 连铸工艺参数对板坯凝固终点的影响[J]. 连铸, 2016,41(5):5−10. doi: 10.13228/j.boyuan.issn1005-4006.20160073 [11] Xie Guiqiang, Xu Lijun, Zou Jinzhong, et al. Application of nail-shooting technique in forecasting model of slab solidification end point[J]. China Metallurgy, 2016,26(3):42−46. (谢桂强, 徐李军, 邹锦忠, 等. 射钉法在铸坯凝固终点预报模型中的应用[J]. 中国冶金, 2016,26(3):42−46. doi: 10.13228/j.boyuan.issn1006-9356.20150142 [12] Xu Lijun, Qiu Shengtao, Zhang Xingzhong. Solidification parameters measurement and soft reduction process optimization of slab[J]. Continuous Casting, 2014,(4):1−8. (徐李军, 仇圣桃, 张兴中. 板坯凝固参数测定及轻压下工艺优化[J]. 连铸, 2014,(4):1−8. doi: 10.13228/j.boyuan.issn1005-4006.2014.04.001 [13] 李杰. 连铸坯凝固组织的模拟[D]. 沈阳: 东北大学, 2010.Li Jie. Simulation of solidification structure in continuous casting billet[D]. Shenyang: Northeastern University, 2010. [14] Savage J, Pritchard W H. The problem of rupture of the billet in the continuous casting of steel[J]. Iron Steel Inst. , London, 1954,178(3):269−277. [15] 黄燕. 立式半连铸特厚板坯凝固过程的模拟分析[D]. 武汉: 武汉科技大学, 2014.Huang Yan. Modeling of solidification process of extra thick plate slab in vertical semi-continuous casting[D]. Wuhan: Wuhan University of Science and Technology, 2014. [16] 曹广畴. 现代板胚连铸[M]. 北京: 冶金工业出版社, 1994.Cao Guangchou. Modern slab continuous casting[M]. Beijing: Metallurgical Industry Press, 1994. -

下载:

下载: