Effect of intermediate pass annealing on the microstructures and properties of Ti-3Al-2.5V tubes

-

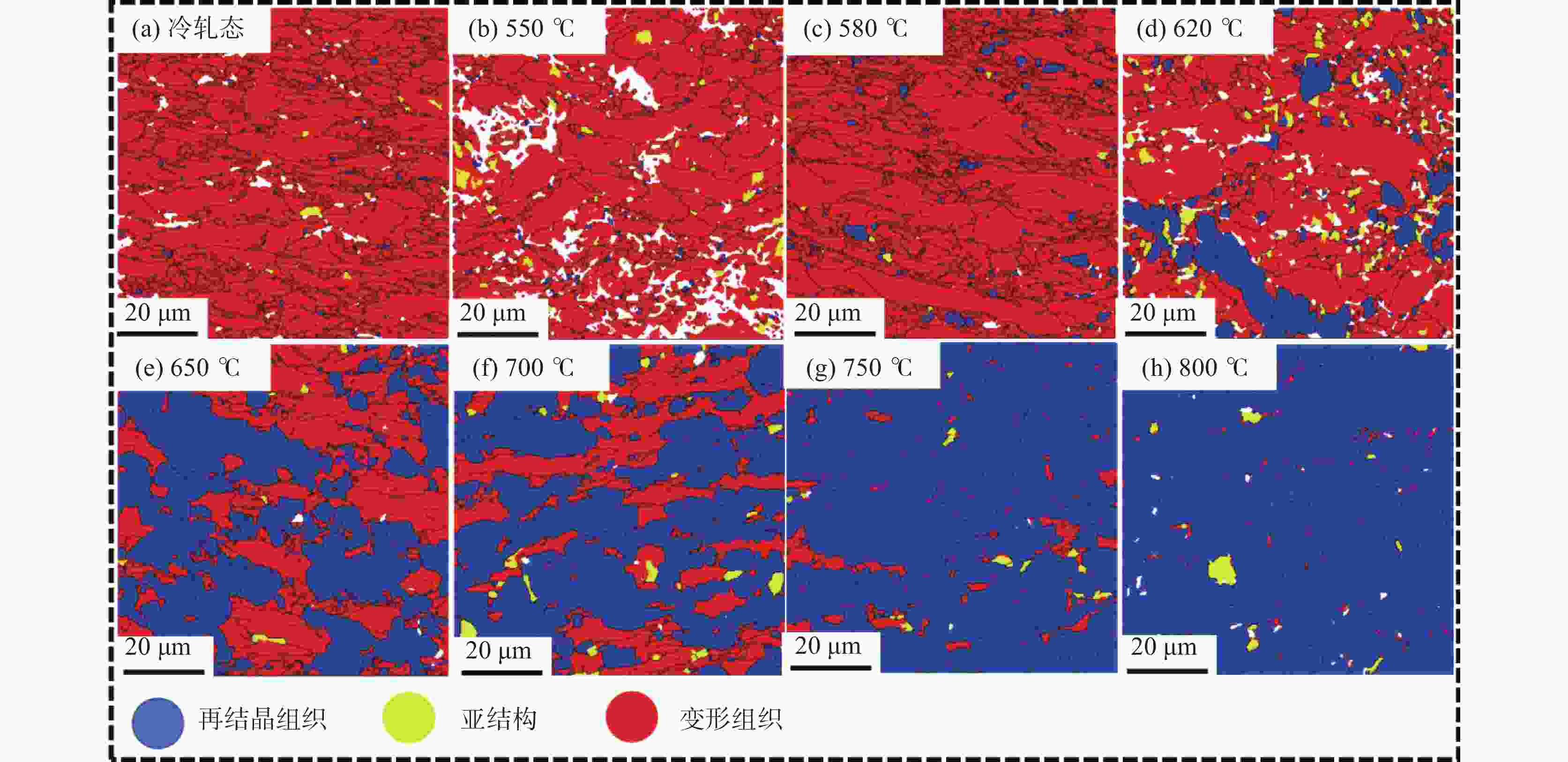

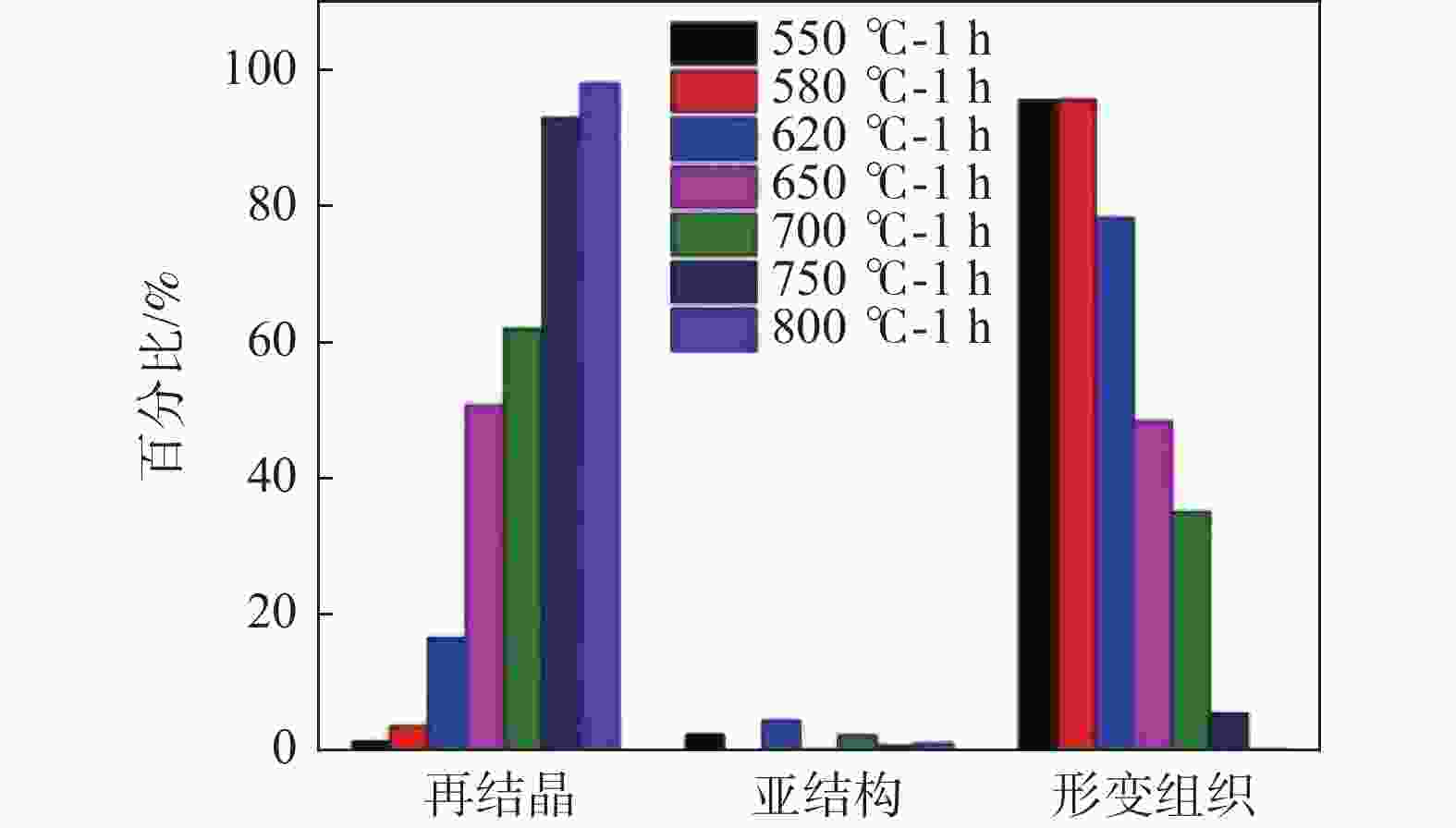

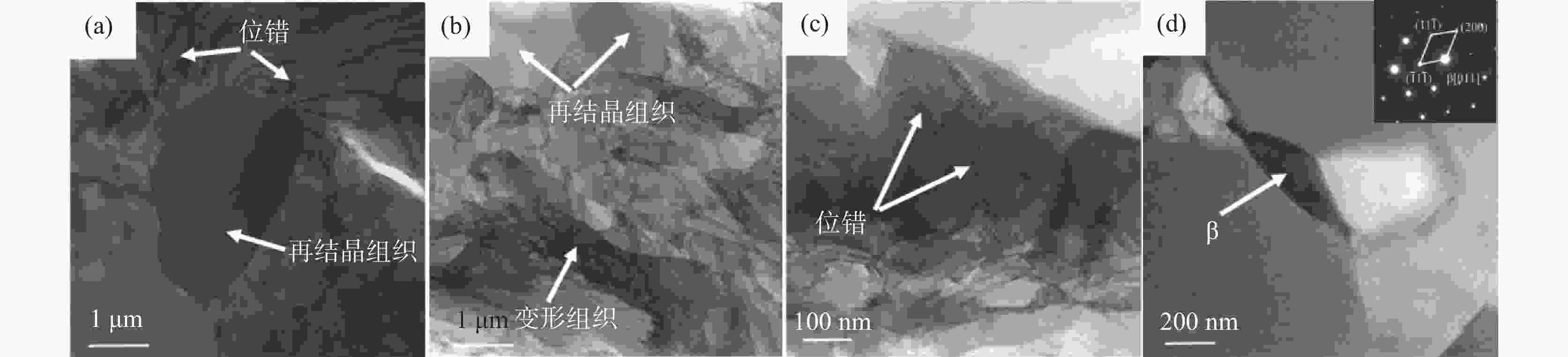

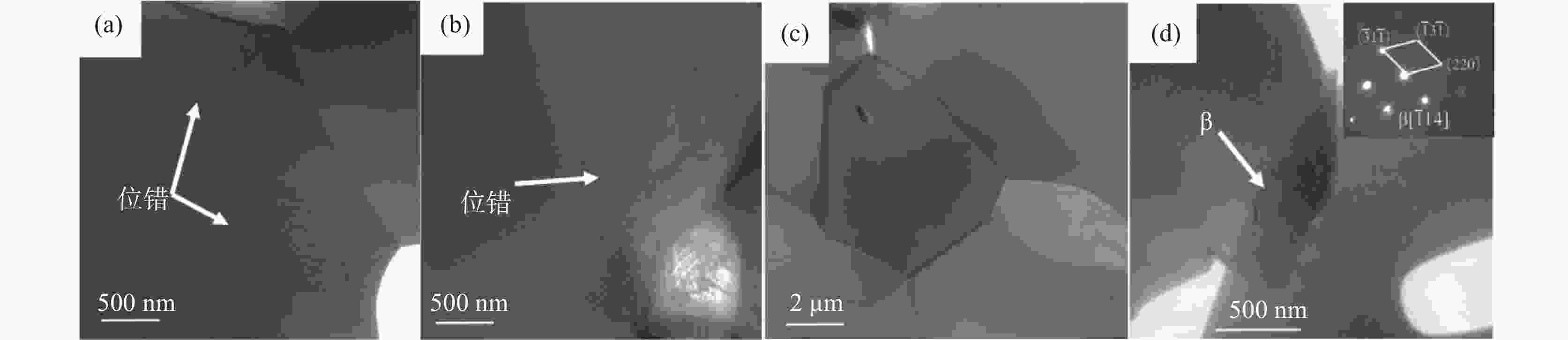

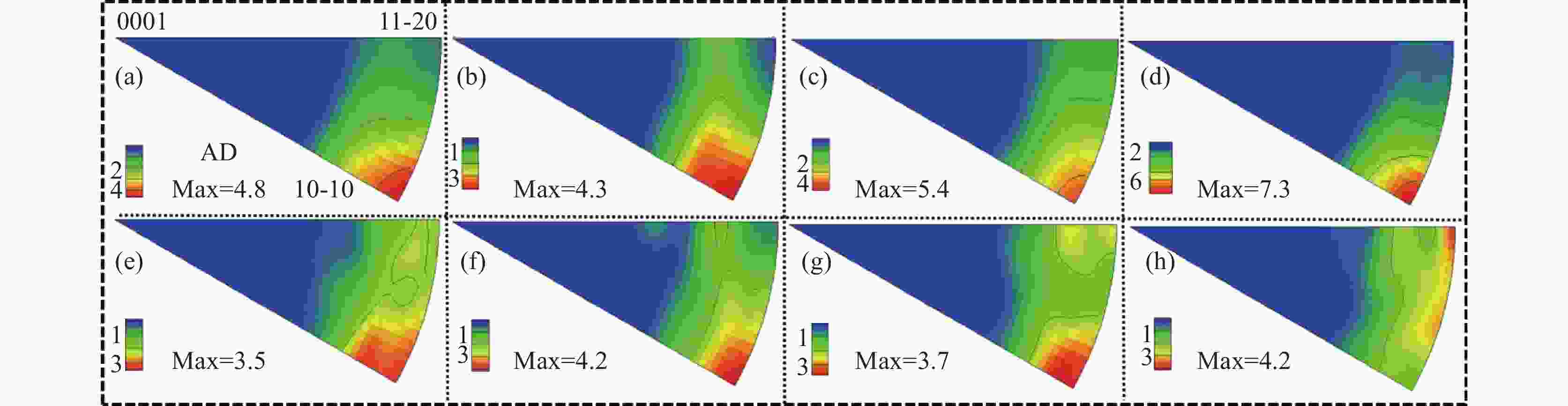

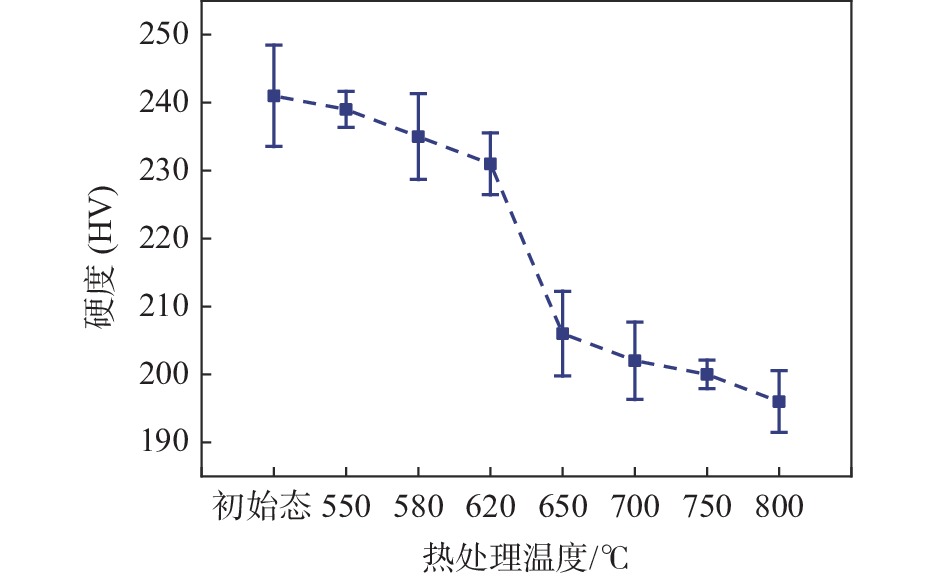

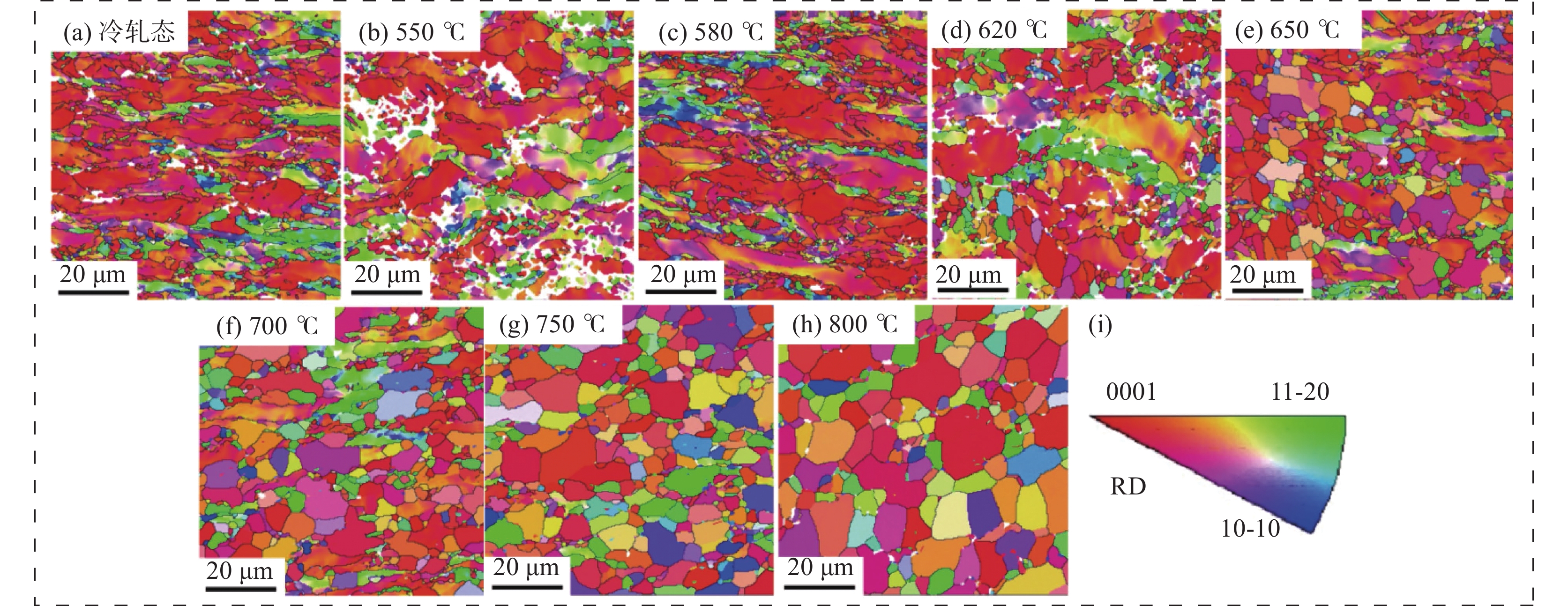

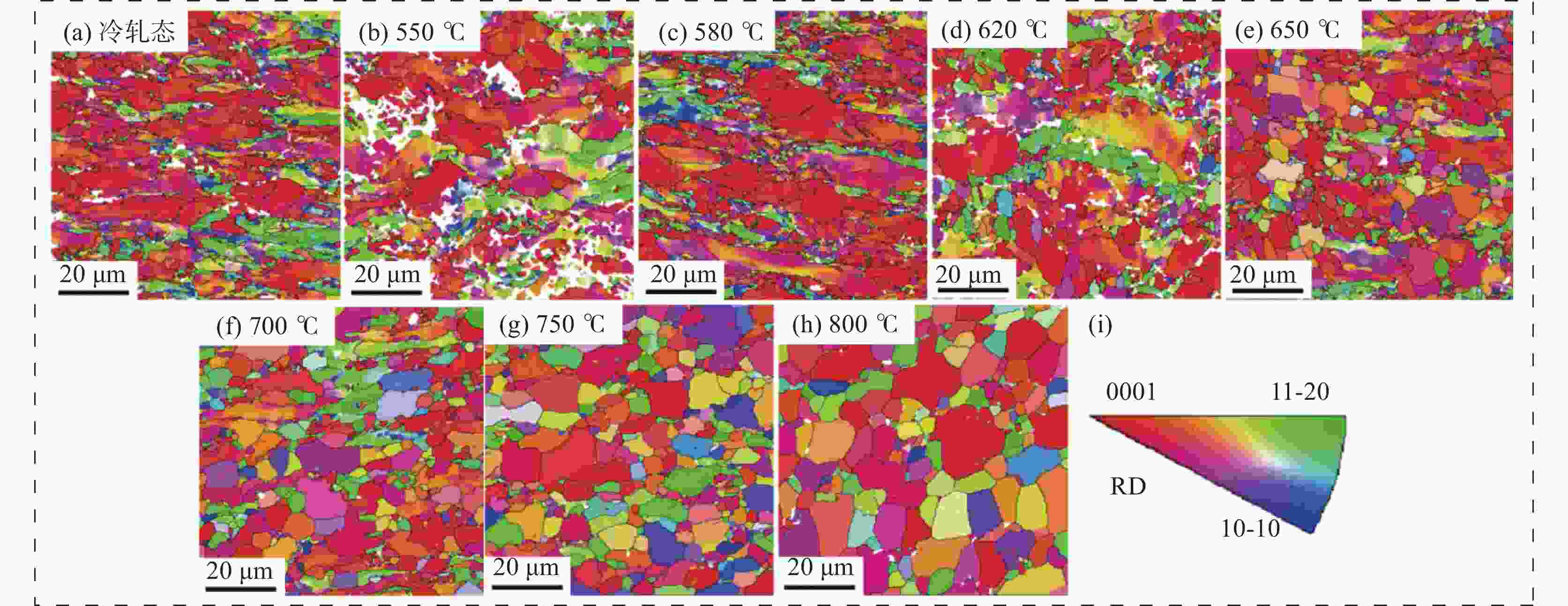

摘要: 冷轧态及退火态样品的微观组织采用EBSD和TEM进行表征,进而探究Ti-3Al-2.5V管材在热处理过程中的再结晶过程,通过极图和反极图分析了不同热处理过程中织构的变化。试验结果表明,在低于580 ℃热处理时,此阶段冷轧管材主要发生回复,微观组织以变形组织为主,管材完全再结晶过程在750 ℃热处理时才会出现。分析表明,管材冷轧形成了沿周向(TD)方向倾斜的基面双峰织构,随热处理温度升高,基面双峰织构类型并未改变,而再结晶织构<

$ { 11{\bar 2}0 }$ >//AD逐渐取代<$ {10{\bar 1}0} $ >//AD形变织构。合金管材在620~650 ℃温度范围内退火时,力学性能发生明显变化,这主要归因于在此温度敏感区间内,随着温度升高再结晶程度急剧增大。-

关键词:

- Ti-3Al-2.5V合金 /

- 中间道次退火 /

- 再结晶 /

- 织构

Abstract: By using EBSD and TEM techniques, the microstructures of the deformation and annealed samples were characterized. After that, the recrystallization process of the tubes during the heat treatments was examined, and the changes in the texture during the various heat treatments were analyzed using polar and inverse polar figures. The experimental results show that when the heat treatment temperature is below 580 ℃, the tube mainly recovers and the microstructure is mainly consisted of the deformed grains. The complete recrystallization process of the tube will occur only when the heat treatment is conducted at 750 ℃. The research demonstrates that the cold-rolled tubes produce a basal bimodal texture with a circumferential (TD) tilt, and that the type of basal bimodal texture produced remains constant as the heat treatment temperature rises, while the recrystallization texture <${11{\bar 2}0 }$ >//AD gradually replaced the deformation texture <${10{\bar 1}0}$ >//AD. The mechanical properties of the alloy tubes after annealing at 620 ~ 650 ℃ change obviously, which is ascribed to the sharp increase in the recrystallization ratio with the rise in temperature.-

Key words:

- Ti-3Al-2.5V alloy /

- intermediate pass annealing /

- recrystallization /

- texture

-

表 1 TA18管材化学成分

Table 1. Chemical composition of TA18 tubes

% Al V Fe C N O H Ti 2.5~3.5 2.0~3.0 0.30 0.05 0.025 0.12 0.015 余量 -

[1] Meng Qinglan, Guan Shumin, Li Zhong. Current situation and development trend of world aviation titanium market[J]. Progress of Titanium Industry, 2011,28(2):1−3. (孟庆兰, 关淑敏, 李中. 世界航空钛市场现状及发展趋势[J]. 钛工业进展, 2011,28(2):1−3. doi: 10.3969/j.issn.1009-9964.2011.02.001Meng Qinglan, Guan Shumin, Li Zhong. Current situation and development trend of world aviation titanium market [J]. Progress of Titanium Industry, 2011, 28 (2): 1-3. doi: 10.3969/j.issn.1009-9964.2011.02.001 [2] Yang Lei, Hui Songxiao, Ye Wenjun, et al. Texture testing and EBSD analysis of TA18 titanium alloy pipes[J]. Rare Metals, 2011,35(6):928−933. (杨磊, 惠松骁, 叶文君, 等. TA18 钛合金管材织构的测试与EBSD分析[J]. 稀有金属, 2011,35(6):928−933. doi: 10.3969/j.issn.0258-7076.2011.06.024Yang Lei, Hui Songxiao, Ye Wenjun, et al. Texture testing and EBSD analysis of TA18 titanium alloy pipes[J]. Rare Metals, 2011, 35 (6): 928-933. doi: 10.3969/j.issn.0258-7076.2011.06.024 [3] Murty K L, Charit I. Texture development and anisotropic deformation of zircaloys[J]. Progress in Nuclear Energy, 2006,48:325−359. doi: 10.1016/j.pnucene.2005.09.011 [4] 齐元昊, 杨亚社, 南莉, 等. 高强Ti-3Al-2.5V合金管材的组织与性能[J]. 特种铸造及有色合金, 2011, 31(11): 1062-1065.Qi Yuanhao, Yang Yashe, Nan Li, et al. Microstructure and properties of high strength Ti-3Al-2.5V alloy pipes [J]. Special Casting and Nonferrous Alloys, 2011, 31 (11): 1062-1065. [5] Luo Dengchao, Nan Li, Yang Yashe, et al. Effect of annealing temperature on properties and microstructure of TA18 pipe[J]. Hot Working Process, 2012,41(20):206−208. (罗登超, 南莉, 杨亚社, 等. 退火温度对TA18管材性能和组织的影响[J]. 热加工工艺, 2012,41(20):206−208. doi: 10.14158/j.cnki.1001-3814.2012.20.061Luo Dengchao, Nan Li, Yang Yashe, et al. Effect of annealing temperature on properties and microstructure of ta18 pipe [J]. Hot Working Process, 2012, 41 (20): 206-208. doi: 10.14158/j.cnki.1001-3814.2012.20.061 [6] Wei Yaqiu, Ma Ding, Wu Anliang, et al. Effect of cold rolling deformation on microstructure and tensile properties of Ti-3Al-2.5V titanium alloy tube[J]. Journal of Nanchang Aeronautical University:Natural Science Edition, 2017,31(4):61−65. (魏亚秋, 马丁, 毋安良, 等. 冷轧变形量对Ti-3Al-2.5V钛合金管微观结构及拉伸性能的影响[J]. 南昌航空大学学报:自然科学版, 2017,31(4):61−65.Wei Yaqiu, Ma Din, Wu Anliang, et al. Effect of cold rolling deformation on Microstructure and tensile properties of Ti-3 Al-2.5 V titanium alloy tube [J]. Journal of Nanchang Aeronautical University: Natural Science Edition, 2017, 31(4): 61-65. [7] Zhou Dadi, Zeng Weidong, Xu Jianwei, et al. Microstructure and texture evolution of cold rolled titanium tubes during annealing[J]. Rare Metals, 2019,43(5):470−475. (周大地, 曾卫东, 徐建伟, 等. 冷轧钛管在退火过程中的显微组织与织构演变[J]. 稀有金属, 2019,43(5):470−475. doi: 10.13373/j.cnki.cjrm.xy18060001Zhou Dadi, Zeng Weidong, Xu Jianwei, et al. Microstructure and texture evolution of cold rolled titanium tubes during annealing [J]. Rare Metals, 2019, 43 (05): 470-475. doi: 10.13373/j.cnki.cjrm.xy18060001 [8] Li H, Wei D, Zhang H Q, et al. Texture evolution and controlling of high-strength titanium alloy tube in cold pilgering for properties tailoring[J]. Journal of Materials Processing Tech, 2020,279:116520. doi: 10.1016/j.jmatprotec.2019.116520 [9] Li Z, Mei Z, Guo K, et al. Texture development of Ti-3Al-2.5V titanium alloy tubes[J]. Rare Metal Materials and Engineering, 2017,46(11):3169−3175. doi: 10.1016/S1875-5372(18)30023-7 [10] Liao Qiang, Qu Henglei, Yang Yashe, et al. Effect of cold rolling pass deformation rate on microstructure and tensile properties of TA18 titanium alloy pipe[J]. Progress of Titanium Industry, 2012,29(1):26−28. (廖强, 曲恒磊, 杨亚社, 等. 冷轧道次变形率对TA18钛合金管材组织与拉伸性能的影响[J]. 钛工业进展, 2012,29(1):26−28. doi: 10.3969/j.issn.1009-9964.2012.01.007Liao Qiang, Qu Henglei, Yang Yashe, et al. Effect of cold rolling pass deformation rate on Microstructure and tensile properties of ta18 titanium alloy pipe [J]. Progress of Titanium Industry, 2012, 29 (1): 26-28. doi: 10.3969/j.issn.1009-9964.2012.01.007 [11] 崔忠圻, 覃耀春. 金属学与热处理[M].北京: 机械工业出版社, 2007.Cui Zhongqi, Qin Yaochun. Metalology and heat treatment [M]: China Machine Press, 2007. [12] Tenckhoff E. The development of the deformation texture in zirconium during rolling in sequential passes[J]. Metallurgical Transactions A, 1978,9A:1401−1412. [13] Ballinger R G, Lucas G E, Pelloux R M. The effect of plastic strain on the evolution of crystallographic texture in Zircaloy-2[J]. Journal of Nuclear Materials, 1984,126:53−69. doi: 10.1016/0022-3115(84)90532-4 [14] Inoue H, Inakazu N. Deformation and recrystallization textures in cold rolled titanium [C]//Proceedings of the Eighth International Conference on Textures of Materials. 1987: 997-1004. [15] Jiang Xianfeng, Xiang Shunhua, Chen Nailu. Effect of annealing process on recrystallization texture of cold rolled pure titanium strip[J]. Hot Working Process, 2011,18:167−169. (江先锋, 向顺华, 陈乃录. 退火工艺对冷轧纯钛带再结晶织构的影响[J]. 热加工工艺, 2011,18:167−169. doi: 10.3969/j.issn.1001-3814.2011.02.048Jiang Xianfeng, Xiang Shunhua, Chen Nailu. Effect of annealing process on recrystallization texture of cold rolled pure titanium strip [J]. Hot Working Process, 2011, 18: 167-169. doi: 10.3969/j.issn.1001-3814.2011.02.048 [16] Zhu Zhishou, Gu Jialin, Chen Nanping. Effect of cold rolling deformation on recrystallization texture formation of titanium sheet[J]. Materials Science and Technology, 1995,3(2):49−52. (朱知寿, 顾家琳, 陈南平. 冷轧形变量对钛板材再结晶织构形成的影响[J]. 材料科学与工艺, 1995,3(2):49−52.Zhu Zhishou, Gu Jialin, Chen Nanping. Effect of cold rolling deformation on recrystallization texture formation of titanium sheet [J]. Materials Science and Technology, 1995, 3 (2): 49-52. [17] Zhu Zhishou, Gu Jialin, Chen Nanping, et al. Study on anisotropy relationship between texture and mechanical properties of titanium[J]. Mechanical Engineering Materials, 1994,18(2):23−26. (朱知寿, 顾家琳, 陈南平, 等. 钛的织构与力学性能各向异性关系研究[J]. 机械工程材料, 1994,18(2):23−26.Zhu Zhishou, Gu Jialin, Chen Nanping, et al. Study on anisotropy relationship between texture and mechanical properties of titanium [J]. Mechanical Engineering Materials, 1994, 18 (2): 23-26. [18] Wagner F, Bozzolo N, Landuyt O V, et al. Evolution of recrystallisation texture and microstructure in low alloyed titanium sheets[J]. Acta Materialia, 2002,50:1245−1259. doi: 10.1016/S1359-6454(01)00427-X [19] Bozzolo N, Dewobroto N, Grosdidier T, et al. Texture evolution during grain growth in recrystallized commercially pure titanium[J]. Materials Science and Engineering A, 2005,397:346−355. doi: 10.1016/j.msea.2005.02.049 [20] Tenckhoff E, Rittenhouse P L. Annealing textures in zircaloy tubing[J]. Journal of Nuclear Materials, 1970,35:14−23. doi: 10.1016/0022-3115(70)90022-X -

下载:

下载: