Comparative study on arc characteristics of hollow and solid electrode electric furnace melting titanium slag

-

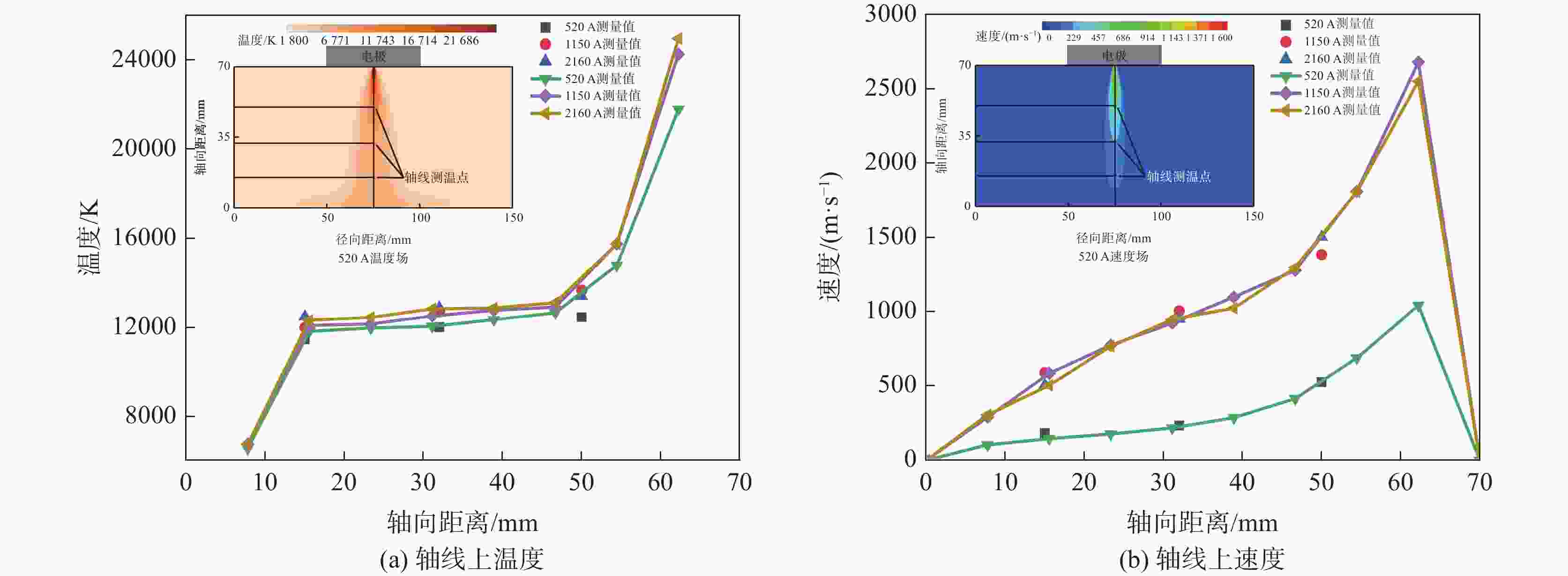

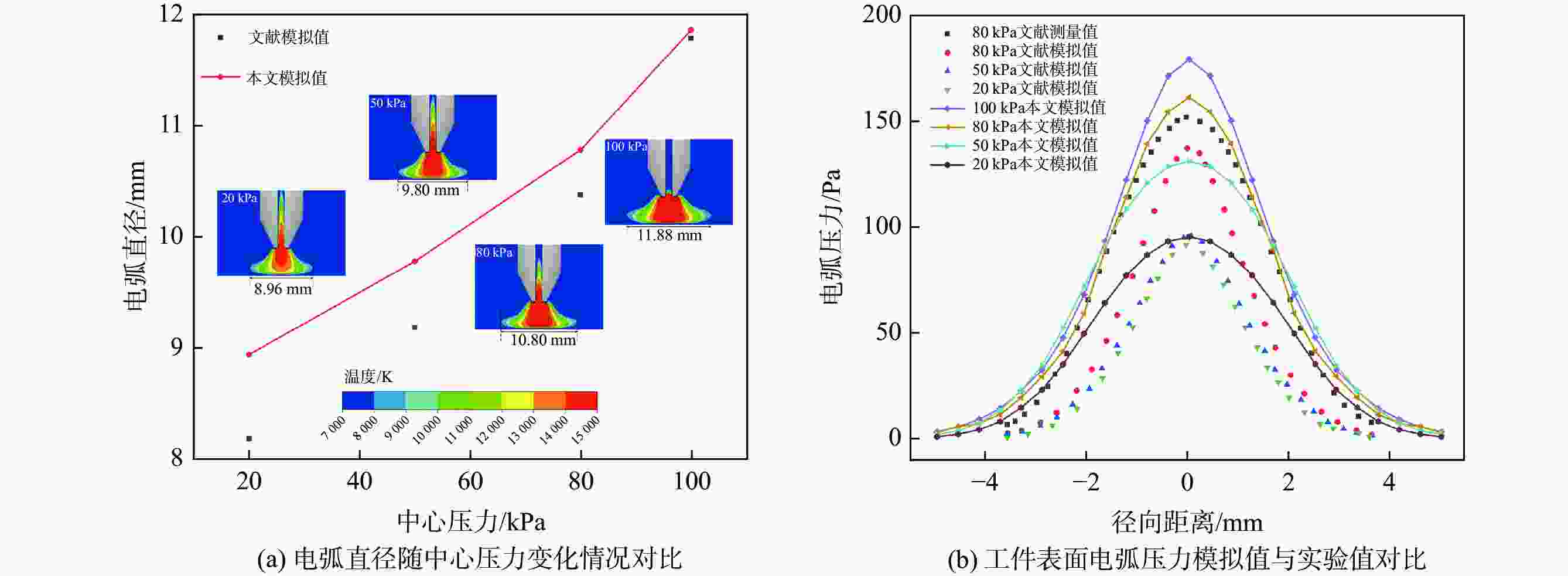

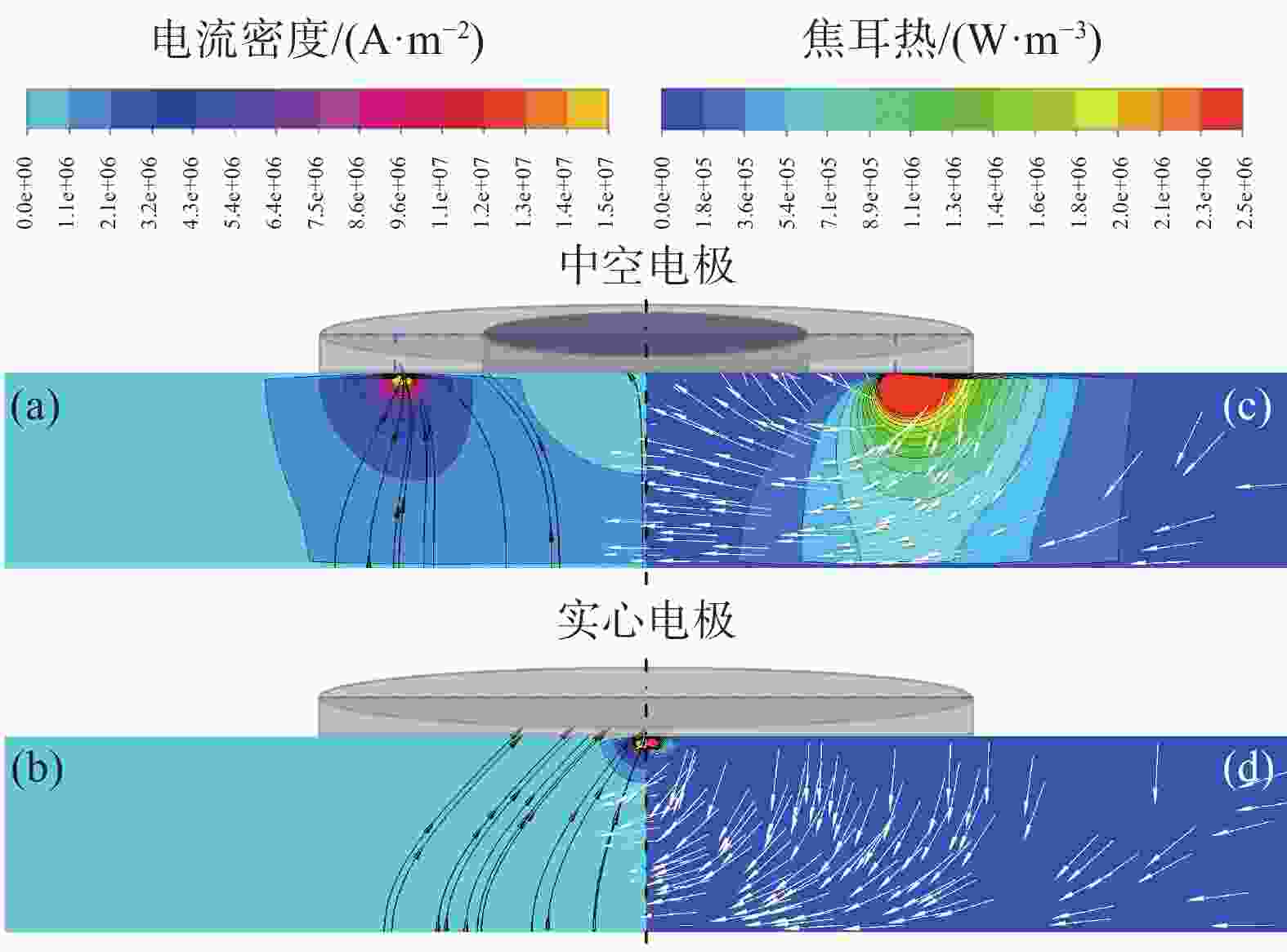

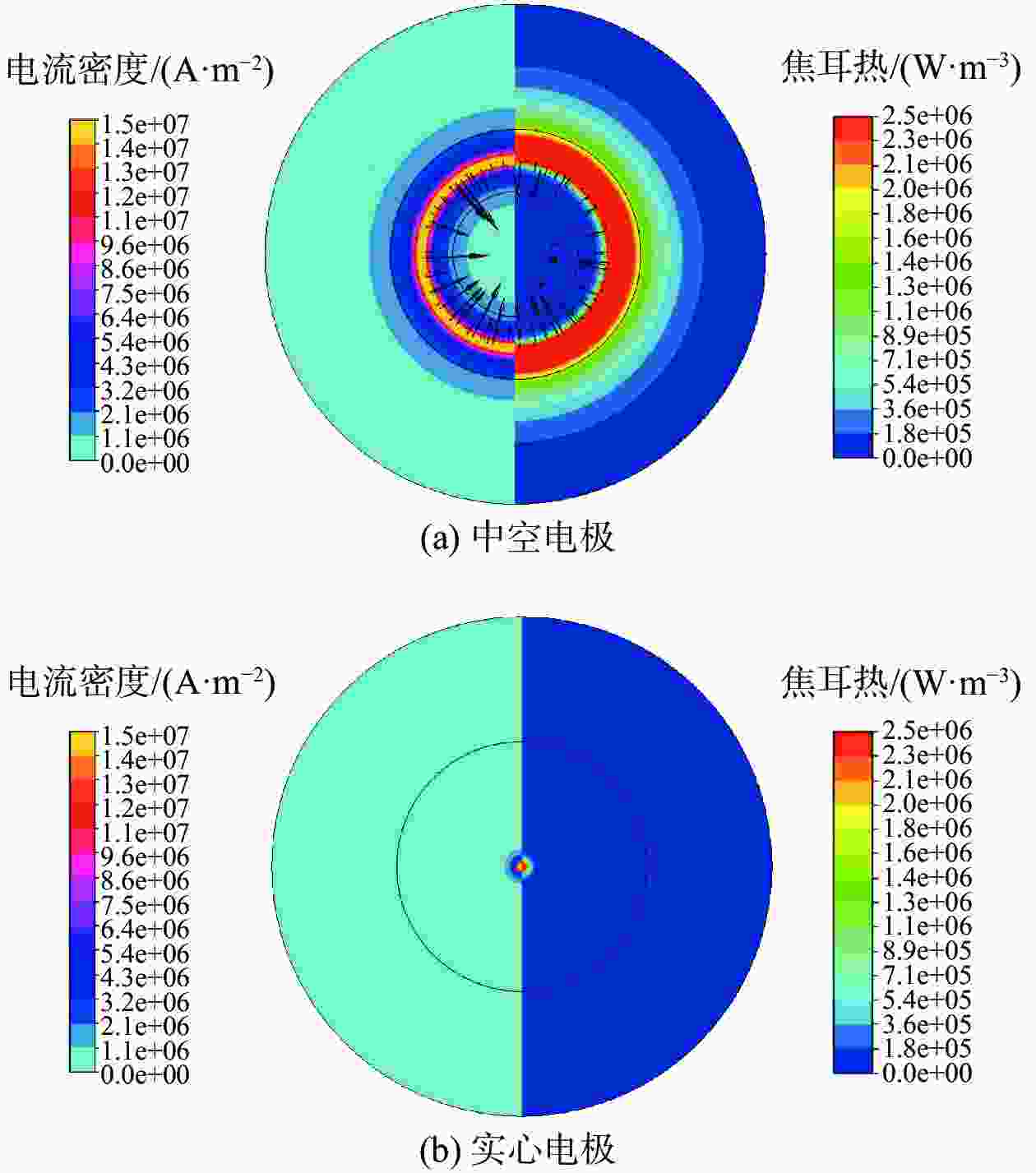

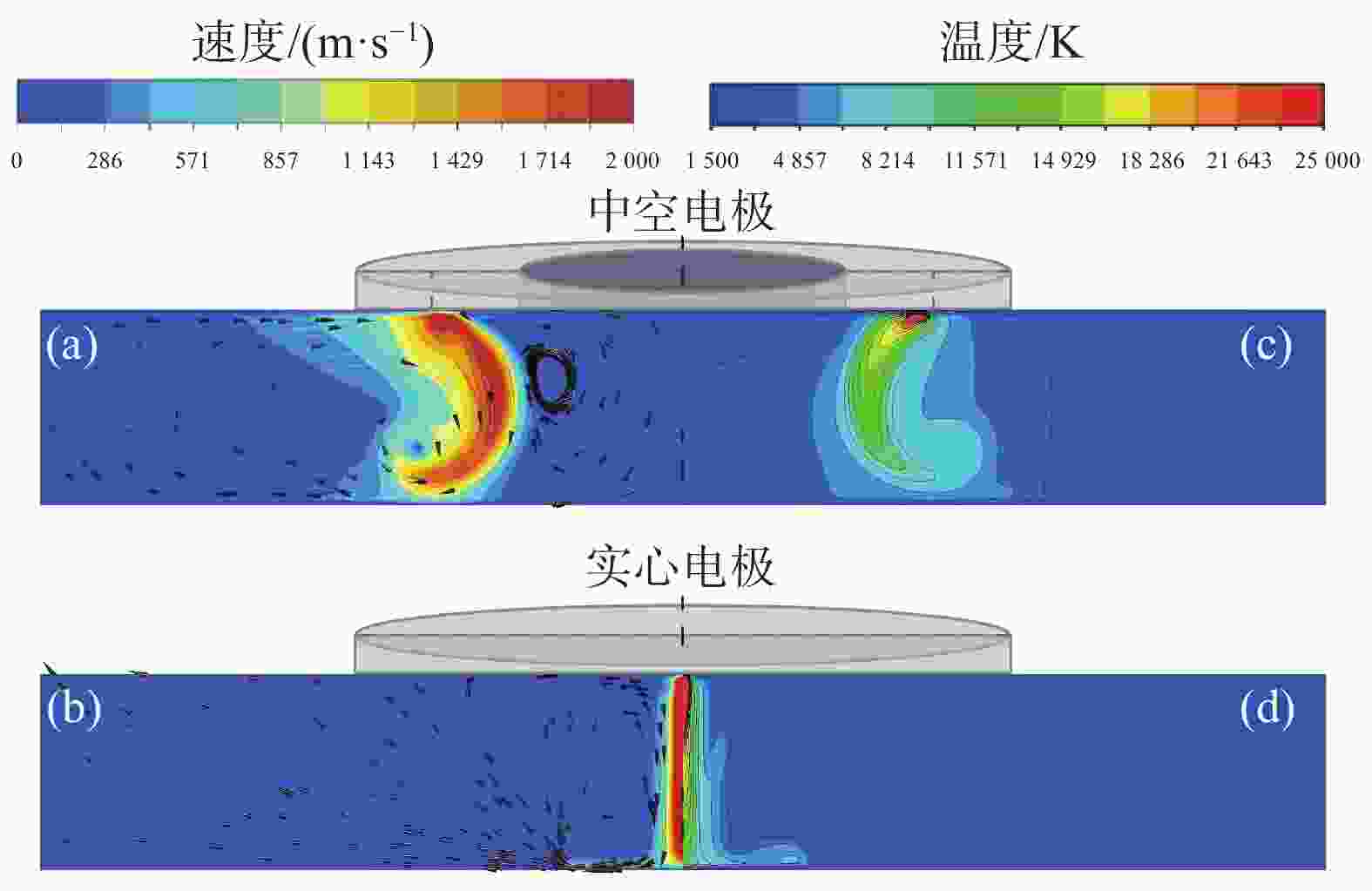

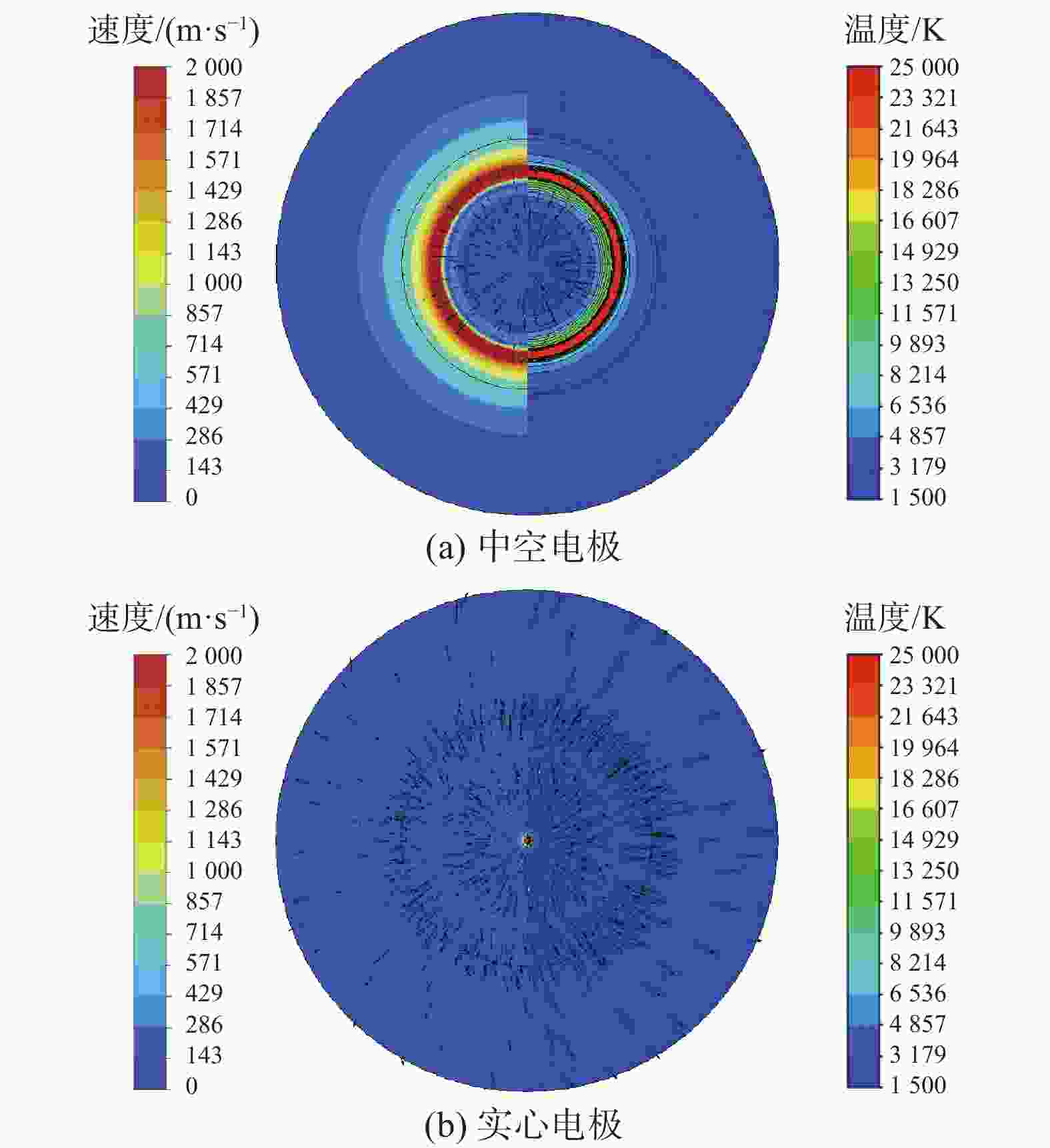

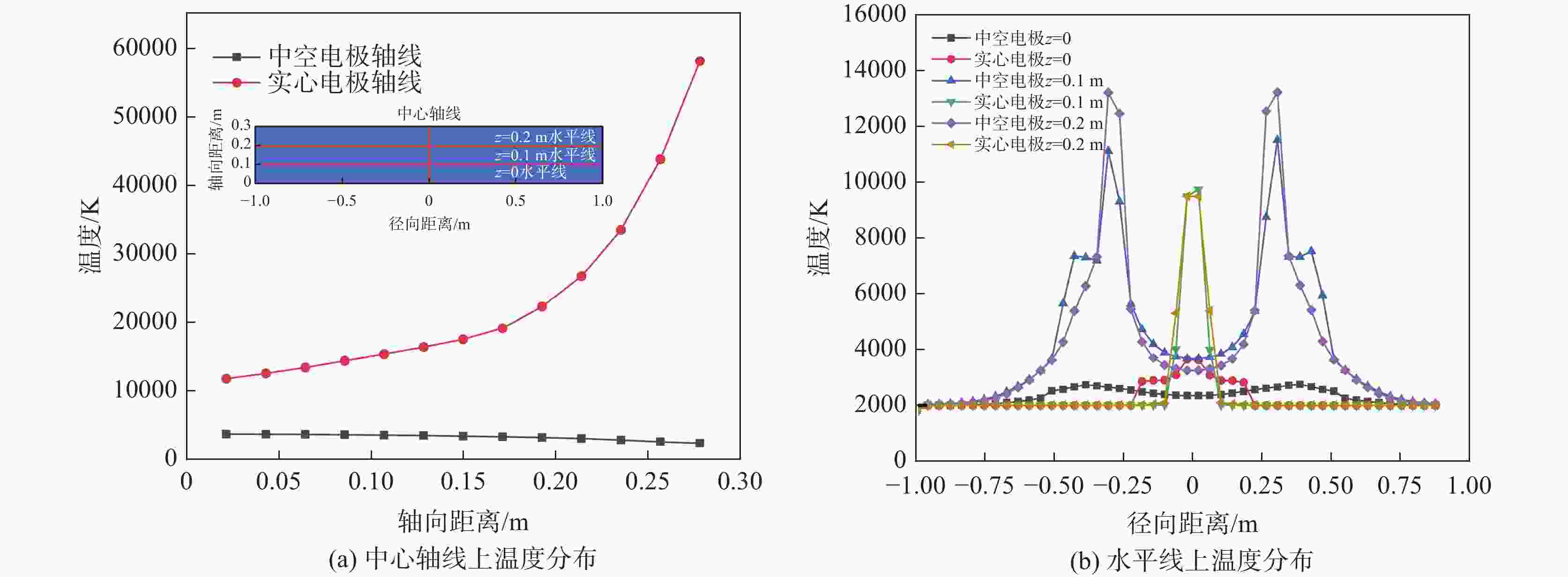

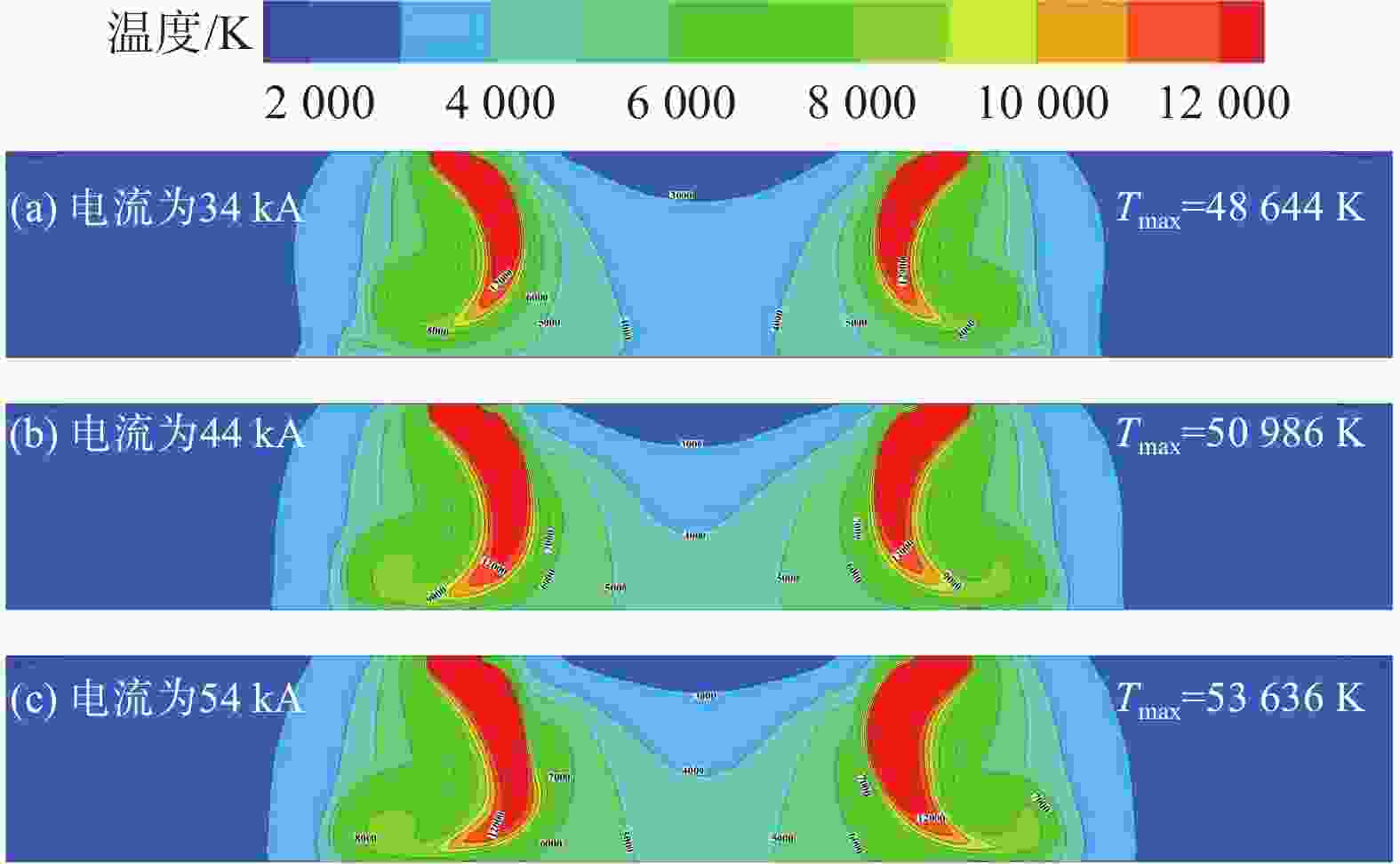

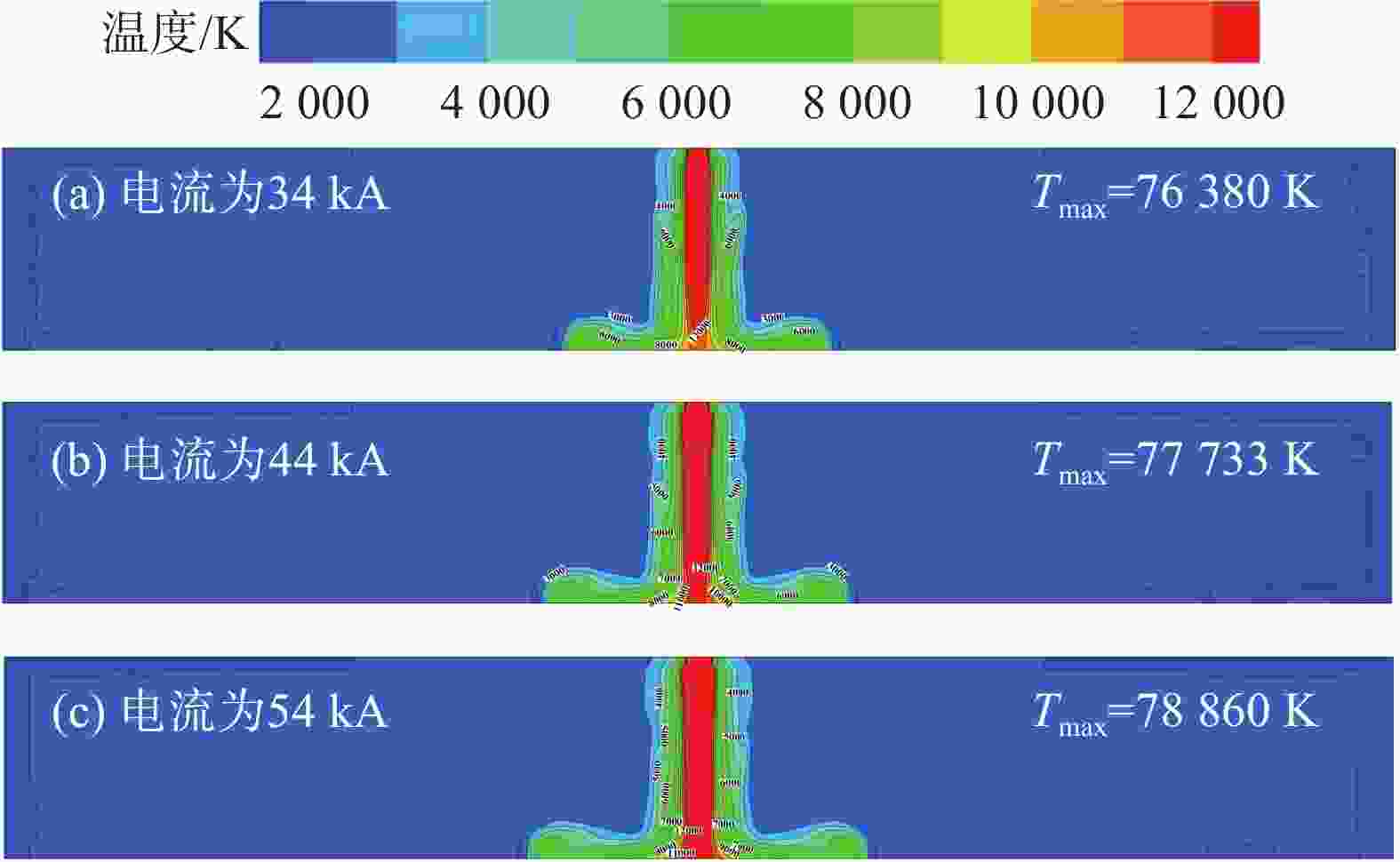

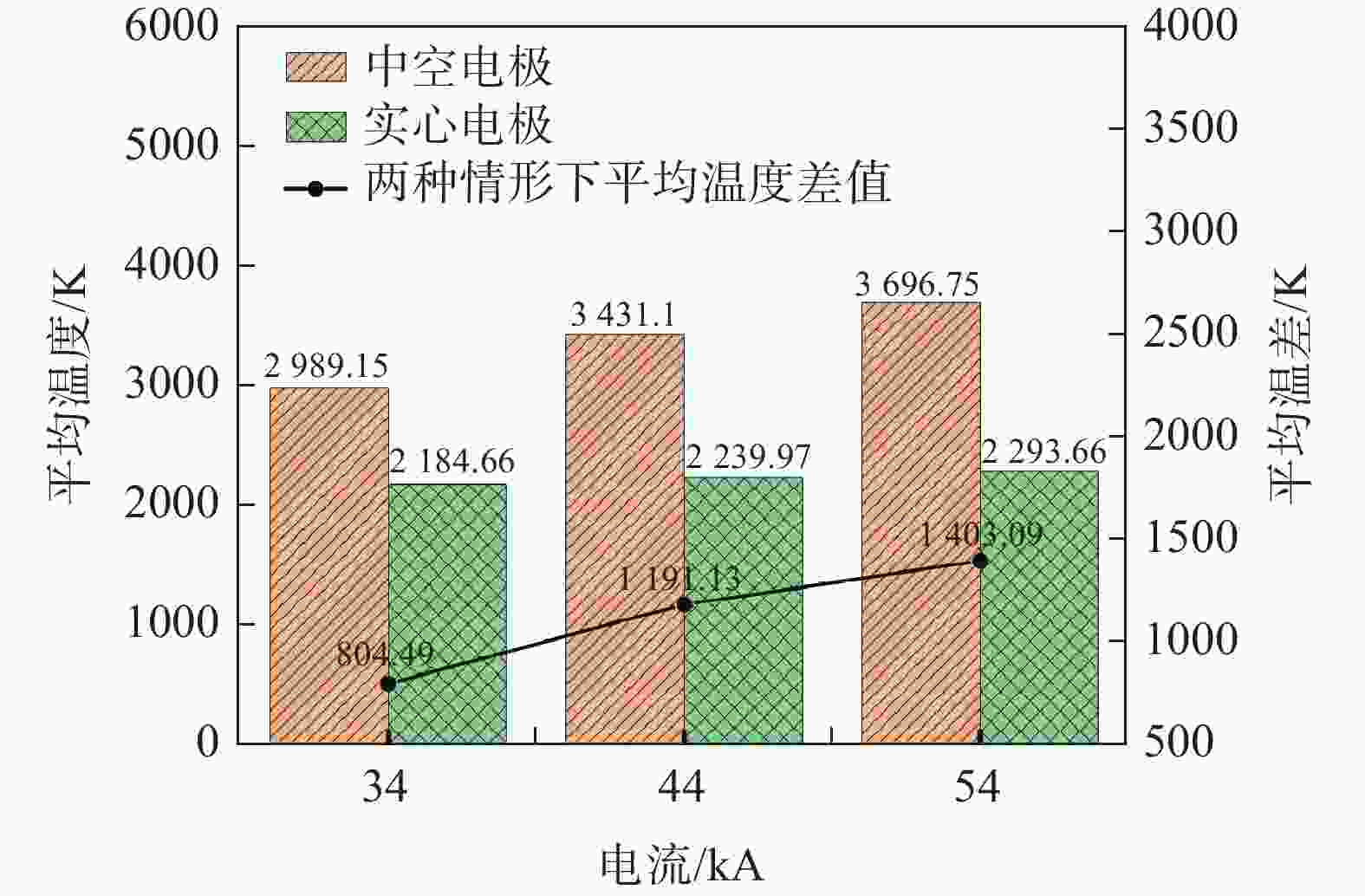

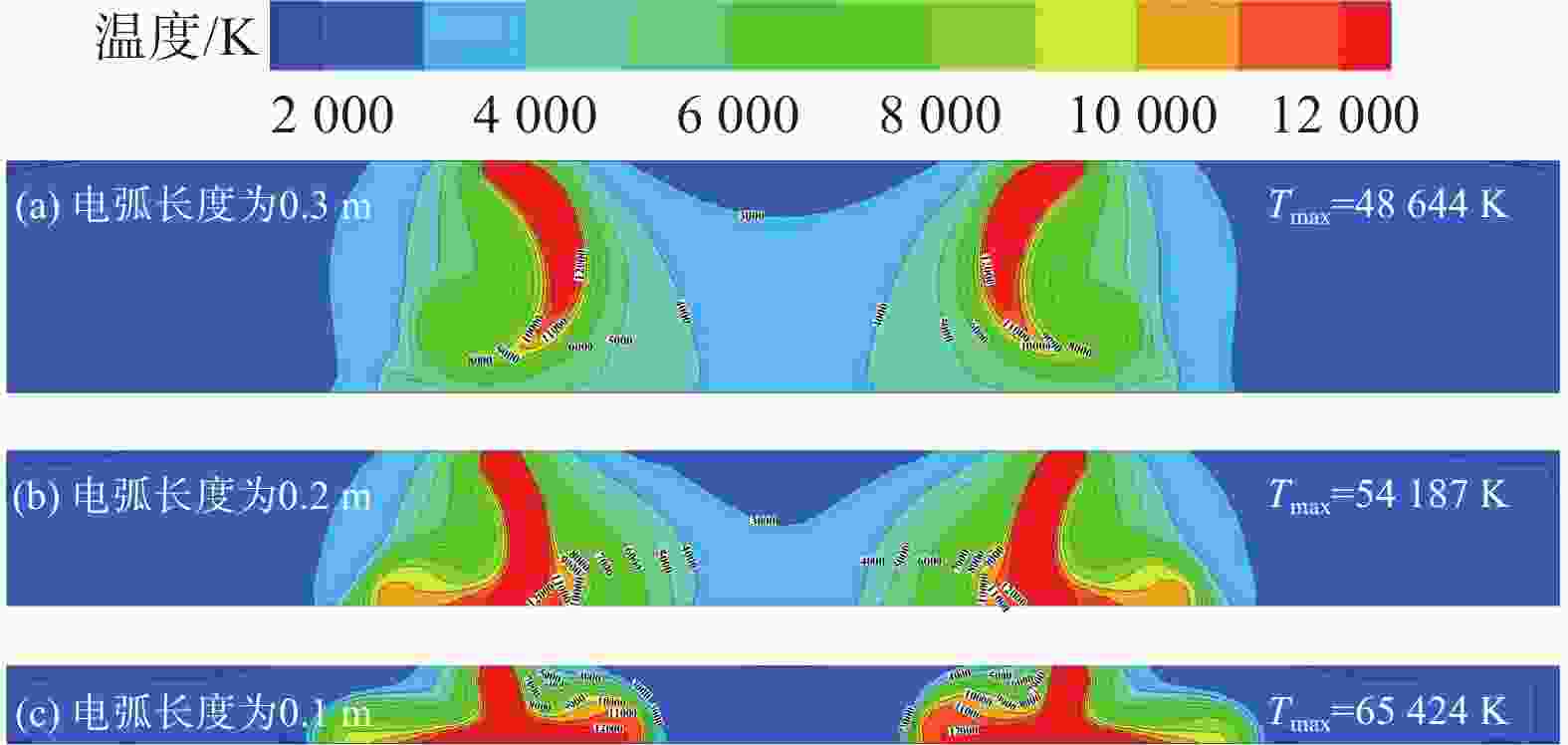

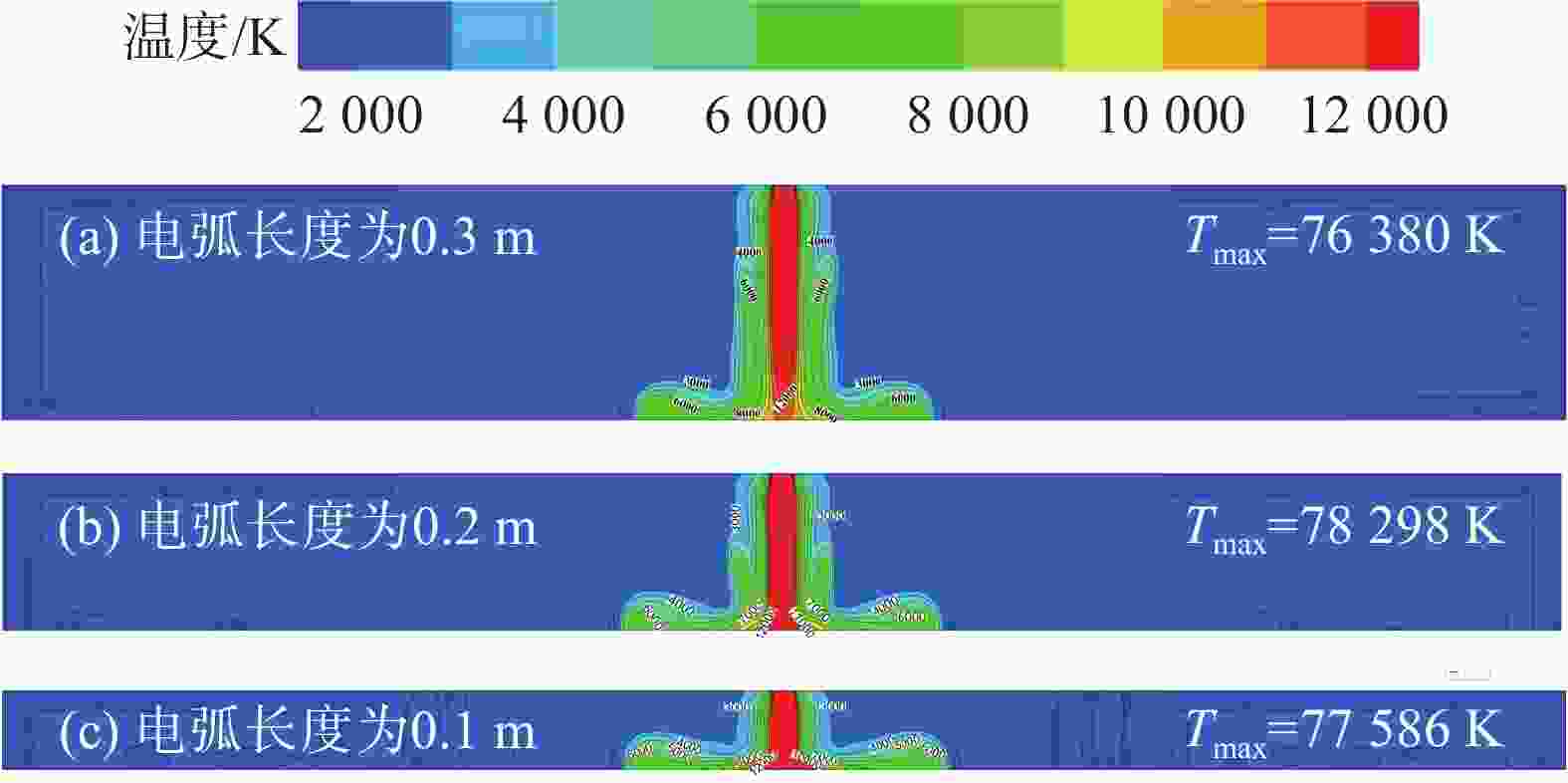

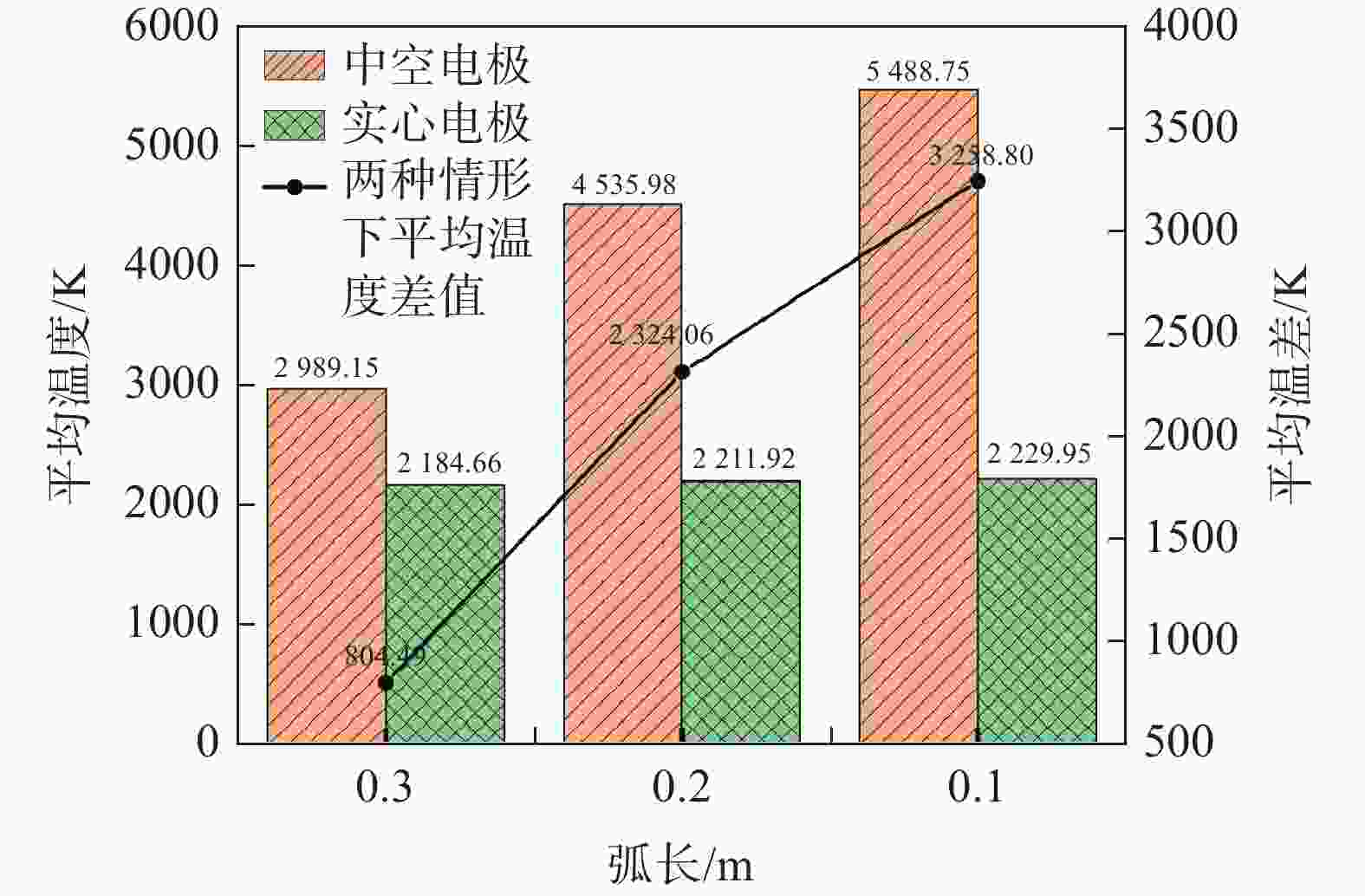

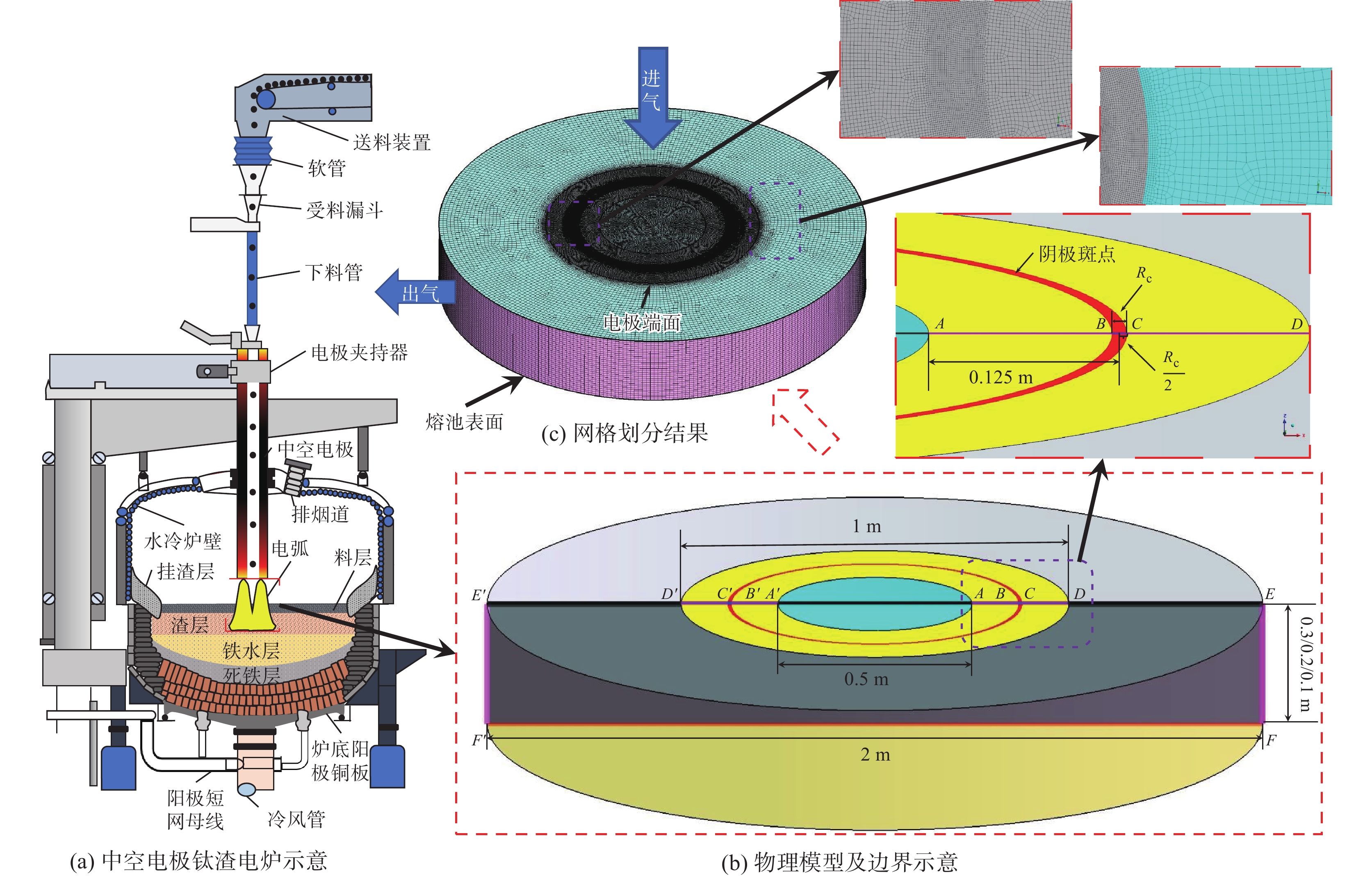

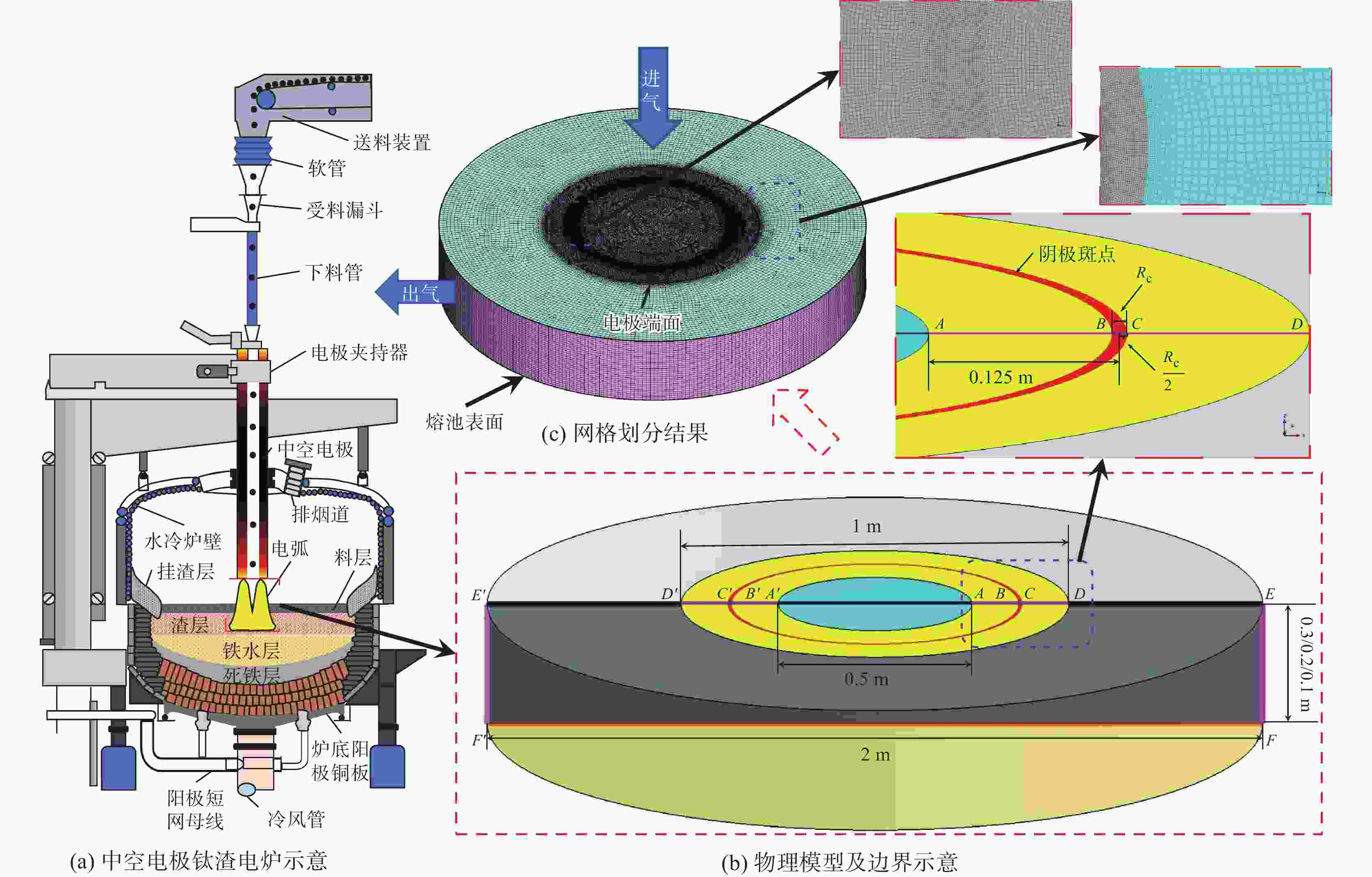

摘要: 为了深入探究中空电极技术在钛渣电炉冶炼工艺中的优势所在,以25.5 MW钛渣电炉实际电极尺寸为基础,分别建立了中空和实心电极电弧的数学模型,模拟得到中空、实心电极电弧的电磁场、温度场和流场分布特性,研究了电流大小和电弧长度对熔池表面温度分布的影响规律。结果表明,电弧内电流密度、焦耳热值、速度和温度的较大值位于阴极斑点附近,中空电极是内外径中心线下方区域,实心电极是中心轴线附近区域。采用中空电极时,周围的电弧会向中轴线汇聚,该现象有利于提高电弧加热物料的效率。当电流值由34 kA增大到54 kA,两种情形下的熔池表面平均温度分别提升了708 K和109 K。当电弧长度由0.3 m缩短到0.1 m,两种情形下的熔池表面平均温度分别提升了2500 K和46 K。相比于实心电极,中空电极更适合采用大电流和短弧长的运行方式,且合理控制弧长对提高中空电极电弧加热效率的效果更显著。Abstract: In order to further explore the advantages of hollow electrode technology in titanium slag electric furnace smelting process, based on the actual electrode size of 25.5 MW titanium slag electric furnace, the mathematical models of hollow and solid electrode arc were established, and the distribution characteristics of electromagnetic field, temperature field and flow field of hollow and solid electrode arc were simulated. The effects of current magnitude and arc length on the surface temperature distribution of molten pool were studied. The results show that the larger values of current density, joule heating value, velocity, and temperature in the arc are located near the cathode spot. In the situation of hollow electrode, the area is below the centerline of the inner and outer diameters. And in the situation of solid electrode, the area is near the central axis. When using hollow electrode, the surrounding arc will converge towards the central axis, which is beneficial for improving the efficiency of arc heating materials. When the current value increases from 34 kA to 54 kA, the average surface temperature of the molten pool in both cases increases by 708 K and 109 K, respectively. When the arc length was reduced from 0.3 m to 0.1 m, the average surface temperature of the molten pool in both cases increased by 2500 K and 46 K, respectively. Compared to solid electrode, the hollow electrode is more suitable for using the operation mode of high current and short arc length, and the reasonable control of arc length has a more significant effect on improving the heating efficiency of hollow electrode arc.

-

表 1 中空电极电弧模拟边界条件

Table 1. Boundary conditions of the hollow electrode arc simulation

边界 温度/K 压力/Pa $ \varphi $ $ \vec{A} $ $ {A}{{A}}' $ 1000 101325 $ \dfrac{\partial \varphi }{\partial z}=0 $ $ \dfrac{\partial \vec{A}}{\partial n}=0 $ $ {A}{B}/{{A}}'{{B}}' $ 2000 $ \dfrac{\partial P}{\partial z}=0 $ $ \dfrac{\partial \varphi }{\partial z}=0 $ $ \dfrac{\partial \vec{A}}{\partial n}=0 $ $ {B}{C}/{{B}}'{{C}}' $ 4130 $ \dfrac{\partial P}{\partial z}=0 $ $ \dfrac{\partial \varphi }{\partial z}=-\dfrac{{J}_{\mathrm{h}\mathrm{o}\mathrm{l}\mathrm{l}\mathrm{o}\mathrm{w}}}{\sigma } $ $ \dfrac{\partial \vec{A}}{\partial n}=0 $ $ {C}{D}/{{C}}'{{D}}' $ 2000 $ \dfrac{\partial P}{\partial z}=0 $ $ \dfrac{\partial \varphi }{\partial z}=0 $ $ \dfrac{\partial \vec{A}}{\partial n}=0 $ $ {D}{E}/{{D}}'{{E}}' $ 1000 101325 $ \dfrac{\partial \varphi }{\partial z}=0 $ $ \dfrac{\partial \vec{A}}{\partial n}=0 $ $ {E}{F}/{{E}}'{{F}}' $ 1000 101325 $ \dfrac{\partial \varphi }{\partial x}=\dfrac{\partial \varphi }{\partial y}=0 $ 0 $ {F}{{F}}' $ 1800 $ \dfrac{\partial P}{\partial z}=0 $ 0 $ \dfrac{\partial \vec{A}}{\partial n}=0 $ -

[1] 杨绍利, 盛继孚. 钛铁矿熔炼钛渣与生铁技术[M]. 北京: 冶金工业出版社, 2006.Yang Shaoli, Sheng Jifu. Titanium slag and pig iron smelting technology of ilmenite[M]. Beijing: Metallurgical Industry Press, 2006. [2] Yu Jiahua, Liu Honggui. The current status and development trend of titanium ore and titanium rich materials production at home and abroad[J]. World Nonferrous Metals, 2003,(6):4−8. (余家华, 刘洪贵. 国内外钛矿和富钛料生产现状及发展趋势[J]. 世界有色金属, 2003,(6):4−8.Yu Jiahua, Liu Honggui. The current status and development trend of titanium ore and titanium rich materials production at home and abroad[J]. World Nonferrous Metals, 2003(6): 4-8. [3] Sheng Jifu. Analysis of some characteristics of titanium slag melted in DC hollow electrode electric furnace[J]. Titanium Industry Progress, 2003,21(1):27−32. (盛继孚. 直流—空心电极电炉熔炼钛渣的某些特性浅析[J]. 钛工业进展, 2003,21(1):27−32. doi: 10.3969/j.issn.1009-9964.2003.01.006Sheng Jifu. Analysis of some characteristics of titanium slag melted in DC hollow electrode electric furnace[J]. Titanium Industry Progress, 2003, 21(1): 27-32. doi: 10.3969/j.issn.1009-9964.2003.01.006 [4] Mckelliget J W, Szekely J. A mathematical model of the cathode region of a high intensity carbon arc[J]. Journal of Physics D:Applied Physics, 1983,16:1007−1022. doi: 10.1088/0022-3727/16/6/010 [5] Hsu K S, Etemadi K, Pfender E. Study of the free‐burning high‐intensity argon arc[J]. Journal of Applied Physics, 1983,54(3):1293−1301. doi: 10.1063/1.332195 [6] Qian F, Farouk B, Mutharasan R. Modeling of fluid flow and heat transfer in the plasma region of the dc electric arc furnace[J]. Metallurgical & Materials Transactions B, 1995,26(5):1057−1067. [7] Bowman B. Measurements of plasma velocity distributions in free-burning DC arcs up to 2160 A[J]. Journal of Physics D Applied Physics, 1972,5(8):1422−1432. doi: 10.1088/0022-3727/5/8/309 [8] Lowke J J, Morrow R, Haidar J. A simplified unified theory of arcs and their electrodes[J]. Journal of Physics D:Applied Physics, 1997,30:2033−2042. doi: 10.1088/0022-3727/30/14/011 [9] Ramírez M, Alexis J, Trapaga G, et al. Modeling of a DC electric arc furnace—mixing in the bath[J]. ISIJ International, 2001,41(10):1146−1155. doi: 10.2355/isijinternational.41.1146 [10] Li Heping, Chen Xi. Numerical simulation of heat transfer and flow in a free burning arc[J]. Journal of Engineering Thermophysics, 2001,22(1):78−81. (李和平, 陈熙. 自由燃烧电弧中传热与流动的数值模拟[J]. 工程热物理学报, 2001,22(1):78−81. doi: 10.3321/j.issn:0253-231X.2001.01.022Li Heping, Chen Xi. Numerical simulation of heat transfer and flow in a free burning arc[J]. Journal of Engineering Thermophysics, 2001, 22(1): 78-81. doi: 10.3321/j.issn:0253-231X.2001.01.022 [11] 王丰华. 电弧炉建模研究及其应用[D]. 上海: 上海交通大学, 2006.Wang Fenghua. Research and application of electric arc furnace modeling[D]. Shanghai: Shanghai Jiaotong University, 2006. [12] 刘立超. 耦合熔池的直流电弧物理特性数值研究[D]. 沈阳: 东北大学, 2016.Liu Lichao. Numerical study on physical characteristics of DC arc in coupled molten pool[D]. Shenyang: Northeast University, 2016. [13] Reynolds Q G. Influence of the power supply on the behaviour of DC plasma arcs - a modelling study[J]. Journal of the Southern African Institute of Mining and Metallurgy, 2018,118:655−660. [14] Yao Conglin, Zhu Hongchun, Jiang Zhouhua, et al. Numerical simulation of long arc plasma in electric arc furnace[J]. Journal of Engineering Science, 2020,42(S1):60−67. (姚聪林, 朱红春, 姜周华, 等. 电弧炉内长电弧等离子体的数值模拟[J]. 工程科学学报, 2020,42(S1):60−67.Yao Conglin, Zhu Hongchun, Jiang Zhouhua, et al. Numerical simulation of long arc plasma in electric arc furnace[J]. Journal of Engineering Science, 2020, 42(S1): 60-67. [15] Makgoale T, Bogaers A, Zietsman J, et al. Momentum transfer from arc to slag bath in a DC ilmenite smelting furnace: A computational analysis[J]. JOM, 2021,73(9):2682−2697. doi: 10.1007/s11837-021-04792-x [16] Chen Y C, Ryan S, Silaen A K, et al. Numerical investigation of AC electric arc plasma heat dissipation in EAF[J]. Ironmaking & Steelmaking, 2022,49(3):255−267. [17] Huang P C, Pfender E. Study of a transferred-arc plasma reactor with a converging wall and flow through a hollow cathode[J]. Plasma Chemistry and Plasma Processing, 1991,11(1):129−150. doi: 10.1007/BF01447037 [18] Tashiro C S, Tanaka M, Nakatani M, et al. Numerical analysis of energy source properties of hollow cathode arc[J]. Surface & Coatings Technology, 2007,201:5431−5434. [19] Chen Shujun, Sheng Shan, Jiang Fan, et al. Physical properties of negative pressure arc at the center of hollow tungsten electrode[J]. Journal of Welding, 2017,38(12):1−4. (陈树君, 盛珊, 蒋凡, 等. 空心钨极中心负压电弧的物理性能[J]. 焊接学报, 2017,38(12):1−4. doi: 10.12073/j.hjxb.20171230Chen Shujun, Sheng Shan, Jiang Fan, et al. Physical properties of negative pressure arc at the center of hollow tungsten electrode[J]. Journal of Welding, 2017, 38(12): 1-4. doi: 10.12073/j.hjxb.20171230 [20] Angola A D, Colonna G, Gorse C, et al. Thermodynamic and transport properties in equilibrium air plasmas in a wide pressure and temperature range[J]. The European Physical Journal D, 2008,46(1):129−150. doi: 10.1140/epjd/e2007-00305-4 [21] Rao Z H, Liao S M, Tsai H L. Effects of shielding gas compositions on arc plasma and metal transfer in gas metal arc welding[J]. Journal of Applied Physics, 2010,107(4):044902. doi: 10.1063/1.3291121 [22] Naghizadeh-Kashani Y, Cressault Y, Gleizes A. Net emission coefficient of air thermal plasmas[J]. Journal of Physics D:Applied Physics, 2002,35(22):2925−2934. doi: 10.1088/0022-3727/35/22/306 -

下载:

下载: