Research progress of micro-arc oxidation technology of titanium alloys

-

摘要: 目前国内已建成世界上规模最大的钛工业体系,专注深化钛及钛合金的应用和使役行为探究,大力开发表面处理新技术提高使用寿命,其中,微弧氧化是最具代表性的表面改性技术,以其绿色环保的特点贯彻可持续发展战略。总结了国内外钛合金微弧氧化技术的研究成果,阐述了微弧氧化原理,综述了电解液、电参数和添加剂对钛合金微弧氧化的影响,以及钛合金微弧氧化陶瓷膜的耐腐蚀性、耐磨性及结合强度的研究进展,认为钛合金微弧氧化技术下一步研究重点需要加快研发节能电源装置,实现工件批量化生产,继续强化微弧氧化机理研究和工艺系统化设计,构建一个完整的技术库。Abstract: China has developed the largest titanium industry system at present in the world, focusing on deepening the application and service behavior of titanium and titanium alloys, and vigorously developing new surface treatment technologies to improve the life of materials. Among them, micro-arc oxidation is the most representative surface modification technology, which is environmentally friendly and implements the sustainable development strategy. Therefore, the research achievement of titanium and titanium alloys micro-arc oxidation technology at home and abroad are summarized. The technological principle of micro-arc oxidation is described, and the influence of electrolyte, electrical parameters and additives on titanium and titanium alloys micro-arc oxidation is expounds. The investigate progress of corrosion resistance, wear resistance and bonding strength of titanium alloys micro-arc oxidation ceramic films is also reviewed. Finally, the next research focus of titanium alloy micro-arc oxidation technology is prospected. It is necessary to accelerate the research and development of energy-saving power supply devices to realize batch production of workpieces, continue to strengthen the research on micro-arc oxidation mechanism and systematic design of process, and build a complete technology library.

-

Key words:

- titanium alloys /

- surface modification /

- micro-arc oxidation /

- ceramic films /

- property

-

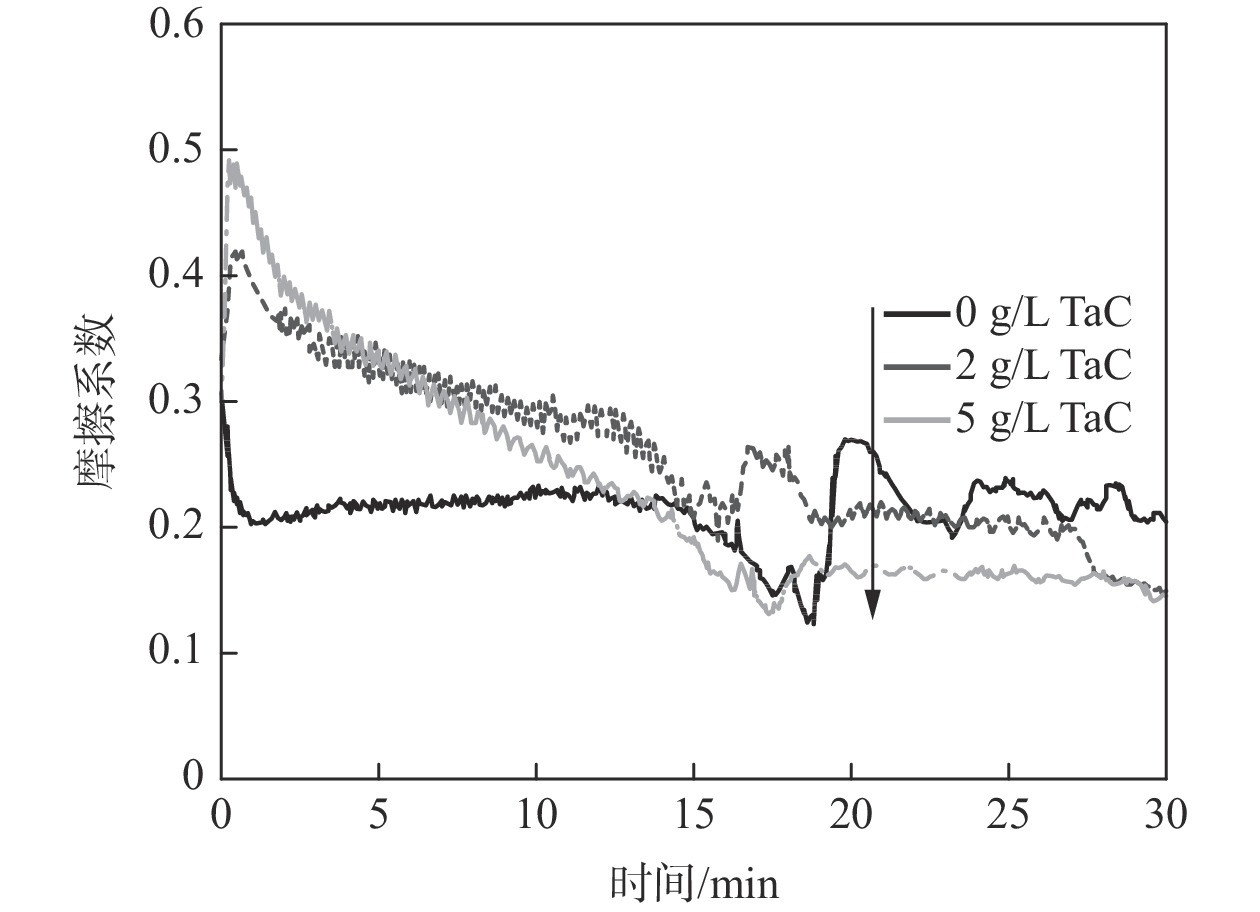

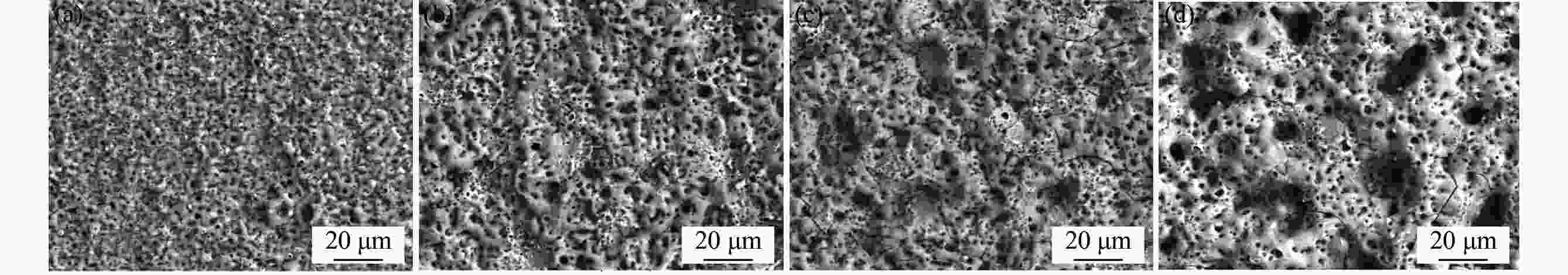

图 1 钛合金微弧氧化后的表面形貌[33]

(a) 420 V; (b) 450 V; (c) 480 V; (d) 510 V

Figure 1. Surface morphology of titanium alloy after MAO treatment

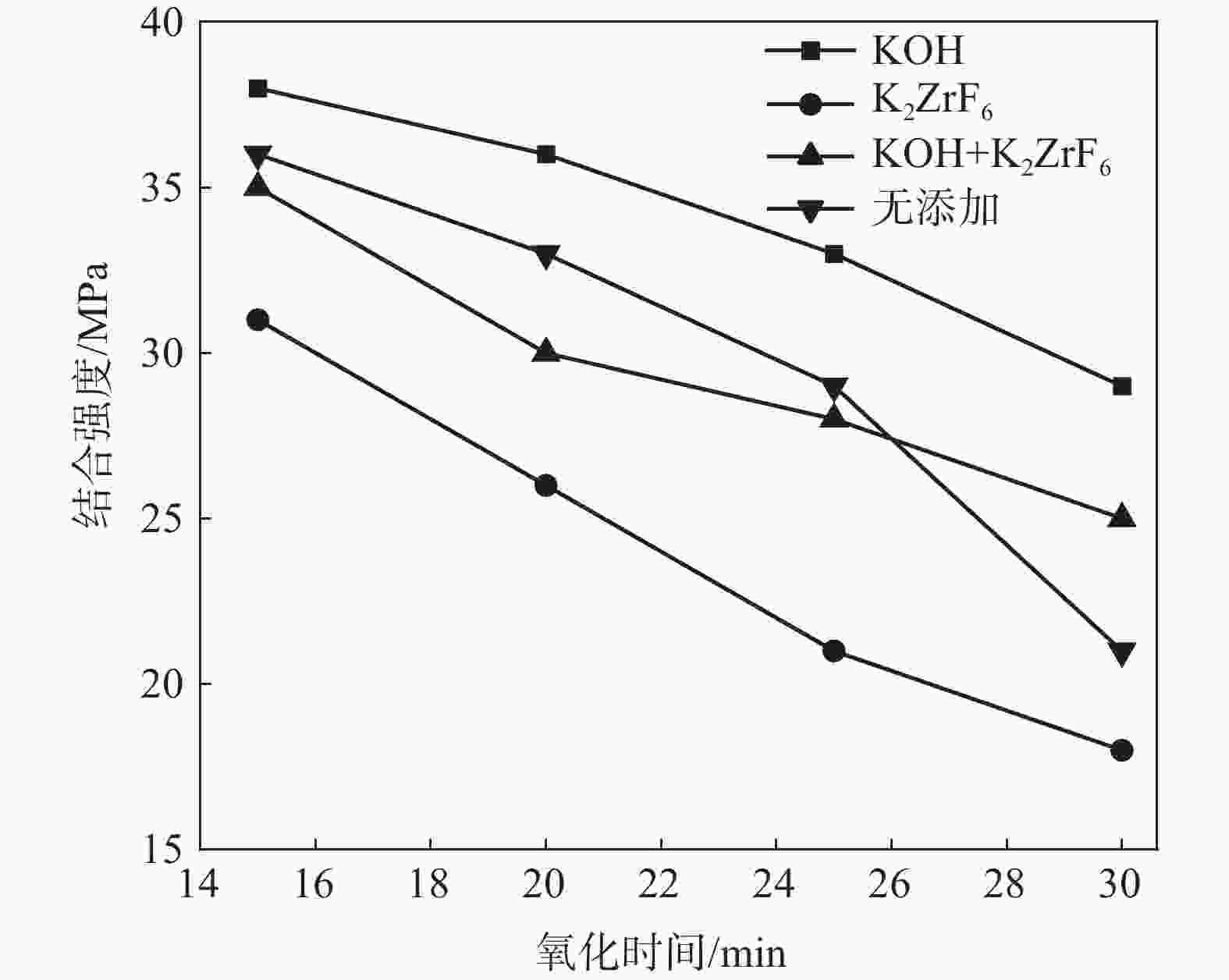

图 2 微弧氧化陶瓷膜模拟海水中的摩擦曲线[46]

Figure 2. Friction curves of MAO ceramic coatings in simulated seawater

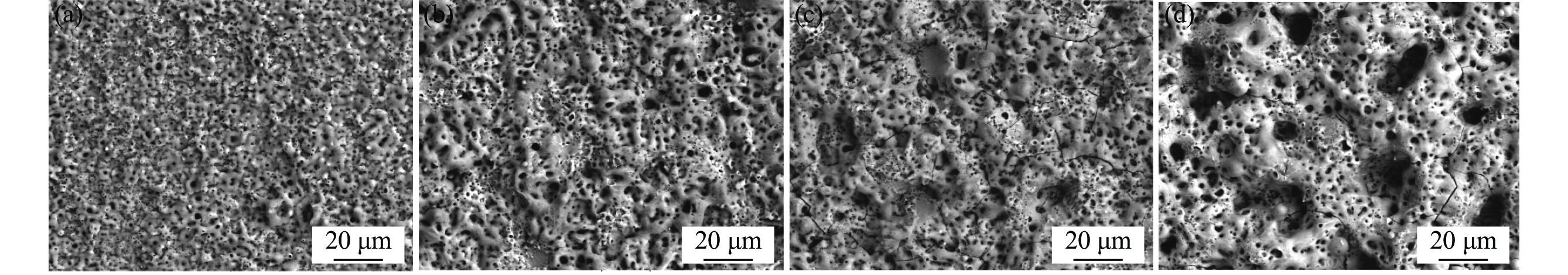

图 3 不同添加剂条件下结合强度对比[48]

Figure 3. Comparison of bonding strength with different additives

表 1 微弧氧化与阳极氧化性能指标对比[16]

Table 1. Properties comparison of MAO and anodic oxidation

类型 电压/ V 最大厚度/ μm 氧化时间/ min 硬度(HV) 抗热震性/ ℃ 孔隙率/ % 盐雾试验/ h 膜层电阻/ MΩ 工作温度/ ℃ 微弧氧化 ≤ 750 300 10~30 ≤ 3000 2500 0~40 > 1000 ≥ 100 < 50 阳极氧化 13~22 < 40 30~60 > 40 < 300 13~26 表 2 试样的硬度和弹性模量[39]

Table 2. Hardness and elastic modulus of samples

占空比/ % 硬度/ GPa 弹性模量/ GPa 50 5.08 259.2 40 4.82 185.4 30 3.91 119.2 Ti-Cu alloy 2.73 118.2 表 3 不同氧化时间在3.5%氯化钠溶液中的腐蚀参数[43]

Table 3. Corrosion parameters in 3.5% NaCl solution with different oxidation time

试样 氧化时

间/minEcorr/ V Icorr×10−9/

( A·cm−2)Rp×106/

( Ω·cm2)钛合金 0 –0.497 52.8 1.07 MAO-10 10 –0.231 9.39 5.86 MAO-30 30 0.175 7.86 13.2 MAO-50 50 0.108 6.39 13.5 -

[1] Lei Ting. Titanium and titanium alloys[M]. Beijing: Metallurgical Industry Press, 2018. (雷霆. 钛及钛合金[M]. 北京: 冶金工业出版社, 2018.Lei Ting. Titanium and titanium alloys[M]. Beijing: Metallurgical Industry Press, 2018. [2] Yang Biao, Wang Ping, Gong Yunbai, et al. Progress in manufacturing and application research of titanium alloy oil country tubular goods for petroleum and natural gas industry[J]. Transactions of Materials and Heat Treatment, 2021,42(9):12−21. (杨彪, 王平, 龚云柏, 等. 油气行业用钛合金油井管生产与研究应用进展[J]. 材料热处理学报, 2021,42(9):12−21. Yang Biao, Wang Ping, Gong Yunbai, et al . Progress in manufacturing and application research of titanium alloy oil country tubular goods for petroleum and natural gas industry[J]. Transactions of Materials and Heat Treatment,2021 ,42 (9 ):12 −21 .[3] Zhao Qinyang, Sun Qiaoyan, Xin Shewei, et al. High-strength titanium alloys for aerospace engineering applications: A review on melting-forging process[J]. Materials Science and Engineering:A, 2022,845:143260. doi: 10.1016/j.msea.2022.143260 [4] Li Yonghua, Zhang Wenxu, Chen Xiaolong, et al. Research and application status of titanium alloys for marine engineering[J]. Titanium Industry Progress, 2022,39(1):43−48. (李永华, 张文旭, 陈小龙, 等. 海洋工程用钛合金研究与应用现状[J]. 钛工业进展, 2022,39(1):43−48. Li Yonghua, Zhang Wenxu, Chen Xiaolong, et al . Research and application status of titanium alloys for marine engineering[J]. Titanium Industry Progress,2022 ,39 (1 ):43 −48 .[5] Héctor Guerra-Yánez, Néstor Rubén Florido-Suárez, Ionelia Voiculescu, et al. Corrosion behavior of new titanium alloys for medical applications[J]. Materials Today:Proceedings, 2022,72(2):533−537. [6] An Zhongsheng, Chen Yan, Zhao Wei. Report on China titanium industry in 2022[J]. Iron Steel Vanadium Titanium, 2023,44(3):1−8. (安仲生, 陈岩, 赵巍. 2022年中国钛工业发展报告[J]. 钢铁钒钛, 2023,44(3):1−8. An Zhongsheng, Chen Yan, Zhao Wei . Report on China titanium industry in 2022[J]. Iron Steel Vanadium Titanium,2023 ,44 (3 ):1 −8 .[7] Xin Shewei, Zhou Wei, Li Qian, et al. A new type extra-high strength and medium toughness titanium alloy of Ti-1500[J]. Materials China, 2021,40(6):441−445. (辛社伟, 周伟, 李倩, 等. 1500 MPa级新型超高强中韧钛合金[J]. 中国材料进展, 2021,40(6):441−445. Xin Shewei, Zhou Wei, Li Qian, et al . A new type extra-high strength and medium toughness titanium alloy of Ti-1500[J]. Materials China,2021 ,40 (6 ):441 −445 .[8] Xakimov Anvarjon, Xakimov K A. Effect of heat treatment process on mechanical properties of titanium alloy[J]. Journal of Pharmaceutical Negative Results, 2022,13:282−290. [9] Di Jing , Yao Jiani , Li Meng, et al. Research status of laser cladding material system on titanium alloy[J]. Journal of Physics: Conference Series, 2022, 2256: 012021. [10] Jiang Dongxue, Fu Ying, Zhang Junwei, et al. Preparation and properties of alumina ceramic film on Ti-alloy surface[J]. Journal of Chinese Society for Corrosion and Protection, 2019,39(6):469−476. (姜冬雪, 付颖, 张峻巍, 等. 钛合金表面Al2O3陶瓷膜制备及性能研究[J]. 中国腐蚀与防护学报, 2019,39(6):469−476. Jiang Dongxue, Fu Ying, Zhang Junwei, et al . Preparation and properties of alumina ceramic film on Ti-alloy surface[J]. Journal of Chinese Society for Corrosion and Protection,2019 ,39 (6 ):469 −476 .[11] Trevor William Clyne, Samuel Christopher Troughton. A review of recent work on discharge characteristics during plasma electrolytic oxidation of various metals[J]. International Materials Reviews, 2019,64(3):127−162. doi: 10.1080/09506608.2018.1466492 [12] Wang Yaming, Zou Yongchun, Wang Shuqi, et al. Design, fabrication and performance of multifuctional ceramic coatings formed by microarc oxidation on metals: a critial review[J]. China Surface Engineering, 2018,31(4):20−45. (王亚明, 邹永纯, 王树棋, 等. 金属微弧氧化功能陶瓷涂层设计制备与使役性能研究进展[J]. 中国表面工程, 2018,31(4):20−45. Wang Yaming, Zou Yongchun, Wang Shuqi, et al . Design, fabrication and performance of multifuctional ceramic coatings formed by microarc oxidation on metals: a critial review[J]. China Surface Engineering,2018 ,31 (4 ):20 −45 .[13] Mosab Kaseem, Siti Fatimah, Nisa Nashrah, et al. Recent progress in surface modification of metals coated by plasma electrolytic oxidation: Principle, structure, and performance[J]. Progress in Materials Science, 2021,117:100735. doi: 10.1016/j.pmatsci.2020.100735 [14] Yerokhin A L, Nie X, Leyland A, et al. Plasma electrolysis for surface engineering[J]. Surface and Coatings Technology, 1999,122(2-3):73−93. doi: 10.1016/S0257-8972(99)00441-7 [15] Jiang Bailing, Wang Yaming. Plasma electrolytic oxidation treatment of aluminium and titanium alloys[M]. Cambridge: Woodhead Publishing, 2010: 110-154. [16] Song Renguo. Development and applications of micro-arc oxidation technology[J]. Journal of Materials Engineering, 2019,47(3):50−62. (宋仁国. 微弧氧化技术的发展及其应用[J]. 材料工程, 2019,47(3):50−62. Song Renguo . Development and applications of micro-arc oxidation technology[J]. Journal of Materials Engineering,2019 ,47 (3 ):50 −62 .[17] Ikonopisov S. Theory of electrical breakdown during formation of barrier anodic films[J]. Electrochimica Acta, 1977,22(10):1077−1082. doi: 10.1016/0013-4686(77)80042-X [18] Yahalom J, Zahavi J. Electrolytic breakdown crystallization of anodic oxide films on Al, Ta and Ti[J]. Electrochimica Acta, 1970,15(9):1429. doi: 10.1016/0013-4686(70)80064-0 [19] Ashok K Vijh. Sparking voltages and side reactions during anodization of valve metals in terms of electron tunnelling[J]. Corrosion Science, 1971,11(6):411−417. doi: 10.1016/S0010-938X(71)80125-7 [20] O’Dwyer J J. The theory of avalanche breakdown in solid dielectrics[J]. Journal of Physics and Chemistry of Solids, 1967,28(7):1137−1144. doi: 10.1016/0022-3697(67)90057-1 [21] Yerokhin A L, Snizhko L O, Gurevina N L, et al. Discharge characterization in plasma electrolytic oxidation of aluminium[J]. Journal of Physics D:Applied Physics, 2003,36(17):2110. doi: 10.1088/0022-3727/36/17/314 [22] Qi Yuming, Peng Zhenjun, Liu Baixing, et al. Fabrication and wear resistance of hard micro arc oxidation coatings on Ti alloys[J]. Surface Technology, 2019,48(7):81−88. (齐玉明, 彭振军, 刘百幸, 等. 钛合金表面高硬度微弧氧化膜的制备和耐磨性研究[J]. 表面技术, 2019,48(7):81−88. Qi Yuming, Peng Zhenjun, Liu Baixing, et al . Fabrication and wear resistance of hard micro arc oxidation coatings on Ti alloys[J]. Surface Technology,2019 ,48 (7 ):81 −88 .[23] Li Xuewei, Zhu Zhizhong, Tian Hong, et al. Effect of phosphate concentration on high temperature oxidation resistance of titanium alloy MAO ceramic coatings[J]. Journal of Heilongjiang University of Science and Technology, 2019,29(2):205−209. (李学伟, 朱志众, 田宏, 等. 磷酸盐对钛合金MAO陶瓷涂层抗高温氧化性能的影响[J]. 黑龙江科技大学学报, 2019,29(2):205−209. Li Xuewei, Zhu Zhizhong, Tian Hong, et al . Effect of phosphate concentration on high temperature oxidation resistance of titanium alloy MAO ceramic coatings[J]. Journal of Heilongjiang University of Science and Technology,2019 ,29 (2 ):205 −209 .[24] Wu Ting, Blawert C, Serdechnova M, et al. Role of phosphate, silicate and aluminate in the electrolytes on PEO coating formation and properties of coated Ti6Al4V alloy[J]. Applied Surface Science, 2022,595:153523. doi: 10.1016/j.apsusc.2022.153523 [25] Liang Haicheng, Tian Zhiyu, Wang Jinchuan, et al. Effect of electrolyte system on microstructure and properties of titanium alloy micro-arc oxidation coating[J]. Journal of Shenyang Ligong University, 2019,38(3):16−20. (梁海成, 田志宇, 王金川, 等. 电解液体系对钛合金微弧氧化陶瓷膜层组织及性能的影响[J]. 沈阳理工大学学报, 2019,38(3):16−20. Liang Haicheng, Tian Zhiyu, Wang Jinchuan, et al . Effect of electrolyte system on microstructure and properties of titanium alloy micro-arc oxidation coating[J]. Journal of Shenyang Ligong University,2019 ,38 (3 ):16 −20 .[26] Qin Y K, Xiong D S, Li J L, et al. Compositions and tribological properties of PEO coatings on Ti6Al4V alloy[J]. Surface Engineering, 2017,33(12):895−902. [27] Zhai Dajun, Tao Qiu, Jun Shen, et al. Growth kinetics and mechanism of microarc oxidation coating on Ti-6Al-4V alloy in phosphate/silicate electrolyte[J]. International Journal of Minerals Metallurgy and Materials, 2022,29(11):1991−1999. doi: 10.1007/s12613-022-2413-8 [28] Yang Mei, Tang Ning, Chen Jin, et al. Effect of current density on micro-arc oxidation properties of TC11 titanium alloy[J]. Rare Metal Materials and Engineering, 2020,49(2):404−411. (杨眉, 唐宁, 陈劲, 等. 电流密度对TC11钛合金微弧氧化性能的影响[J]. 稀有金属材料与工程, 2020,49(2):404−411. Yang Mei, Tang Ning, Chen Jin, et al . Effect of current density on micro-arc oxidation properties of TC11 titanium alloy[J]. Rare Metal Materials and Engineering,2020 ,49 (2 ):404 −411 .[29] Kang Jia, Wang Shuaixing, Shao Zhisong, et al. Influence of negative current on bioactivity coating prepared by micro-arc oxidation on TC4 alloy[J]. Surface Technology, 2018,47(8):64−70. (康佳, 王帅星, 邵志松, 等. 负向电流对钛合金微弧氧化形成生物陶瓷膜的影响[J]. 表面技术, 2018,47(8):64−70. Kang Jia, Wang Shuaixing, Shao Zhisong, et al . Influence of negative current on bioactivity coating prepared by micro-arc oxidation on TC4 alloy[J]. Surface Technology,2018 ,47 (8 ):64 −70 .[30] Li Mingzhe, Niu Zongwei. Electrochemical corrosion behavior of TC4 titanium alloy micro-arc oxidation film prepared at different current density[J]. Electroplating and Pollution Control, 2015,35(2):31−34. (李明哲, 牛宗伟. 不同电流密度下TC4钛合金微弧氧化膜的电化学腐蚀行为[J]. 电镀与环保, 2015,35(2):31−34. Li Mingzhe, Niu Zongwei . Electrochemical corrosion behavior of TC4 titanium alloy micro-arc oxidation film prepared at different current density[J]. Electroplating and Pollution Control,2015 ,35 (2 ):31 −34 .[31] Tsao L C. Effects of applied voltage on the microstructure and properties of hydroxyapatite bioceramic coatings formed on Ti7Cu5Sn titanium alloy by micro-arc oxidation[J]. Corrosion Engineering Science and Technology, 2018,53(8):582−590. doi: 10.1080/1478422X.2018.1513619 [32] Gao Guangrui, Li Ying, Hu Dan, et al. Effect of voltage on infrared emissivity of MAO coatings on TC4 titanium alloys[J]. Titanium Industry Progress, 2018,35(1):32−37. (高广睿, 厉英, 呼丹, 等. 电压对TC4钛合金表面微弧氧化陶瓷膜层红外发射率的影响[J]. 钛工业进展, 2018,35(1):32−37. Gao Guangrui, Li Ying, Hu Dan, et al . Effect of voltage on infrared emissivity of MAO coatings on TC4 titanium alloys[J]. Titanium Industry Progress,2018 ,35 (1 ):32 −37 .[33] Cui Wei, Hu Dan, Gao Guangrui, et al. Effect of voltage on properties of micro-arc oxidation film on TC4 alloy prepared in K2ZrF6–Na2SiO3–(NaPO3)6[J]. Electroplating and Finishing, 2019,38(1):23−28. (崔嵬, 呼丹, 高广睿, 等. 电压对TC4合金K2ZrF6–Na2SiO3–(NaPO3)6体系微弧氧化膜性能的影响[J]. 电镀与涂饰, 2019,38(1):23−28. Cui Wei, Hu Dan, Gao Guangrui, et al . Effect of voltage on properties of micro-arc oxidation film on TC4 alloy prepared in K2ZrF6–Na2SiO3–(NaPO3)6[J]. Electroplating and Finishing,2019 ,38 (1 ):23 −28 .[34] Yu Jing, Wu Lianbo, Ma Weihong. Effect of impulse frequency on microstructure and properties of MAO coatings of biomedical titanium alloy[J]. Rare Metal Materials and Engineering, 2015,44(3):692−696. (于晶, 吴连波, 马维红. 脉冲频率对医用钛合金微弧氧化膜微观结构和性能的影响[J]. 稀有金属材料与工程, 2015,44(3):692−696. Yu Jing, Wu Lianbo, Ma Weihong . Effect of impulse frequency on microstructure and properties of MAO coatings of biomedical titanium alloy[J]. Rare Metal Materials and Engineering,2015 ,44 (3 ):692 −696 .[35] Alexander Sobolev, Alexey Kossenko, Konstantin Borodianskiy. Study of the effect of current pulse frequency on Ti-6Al-4V alloy coating formation by micro arc oxidation[J]. Materials, 2019,12(23):3983. doi: 10.3390/ma12233983 [36] Li Xingzhao, Wu Lianbo. Effect of pulse frequency on the properties of microarc oxidation coating formed on titanium alloy[J]. Journal of Changchun University of Technology, 2016,37(5):449−453. (李兴照, 吴连波. 脉冲频率对钛合金微弧氧化陶瓷膜层性能的影响[J]. 长春工业大学学报, 2016,37(5):449−453. Li Xingzhao, Wu Lianbo . Effect of pulse frequency on the properties of microarc oxidation coating formed on titanium alloy[J]. Journal of Changchun University of Technology,2016 ,37 (5 ):449 −453 .[37] Hao Guodong, Luo Liyan, Su Shuangyue, et al. Research on preparation and properties of micro-arc bipolar oxide coating of titanium alloy[J]. Contemporary Chemical Industry, 2020,49(11):2383−2387. (郝国栋, 罗丽妍, 苏爽月, 等. 钛合金双极微弧氧化陶瓷膜层抗高温氧化性能[J]. 当代化工, 2020,49(11):2383−2387. Hao Guodong, Luo Liyan, Su Shuangyue, et al . Research on preparation and properties of micro-arc bipolar oxide coating of titanium alloy[J]. Contemporary Chemical Industry,2020 ,49 (11 ):2383 −2387 .[38] Du Yong, Lin Xiuzhou, Cui Xuejun, et al. Effect of negative duty cycle on micro-arc oxidation coating of titanium alloy[J]. Materials Science Forum, 2016,852(1):1050−1054. [39] Hao Xin, Wang Hefeng, Yu Feifei, et al. Effect of duty cycle on microstructure and mechanical properties of microarc oxidation coatings of Ti-Cu alloys[J]. Hot Working Technology, 2020,49(20):92−95,101. (郝鑫, 王鹤峰, 于菲菲, 等. 占空比对Ti-Cu合金的微弧氧化陶瓷膜层组织及其力学性能的影响[J]. 热加工工艺, 2020,49(20):92−95,101. Hao Xin, Wang Hefeng, Yu Feifei, et al . Effect of duty cycle on microstructure and mechanical properties of microarc oxidation coatings of Ti-Cu alloys[J]. Hot Working Technology,2020 ,49 (20 ):92 −95,101 .[40] Wang Zhuo, Zhang Weiyi, Zhang Yunlong, et al. Effect of Nd(NO3)3 on wettability and corrosion resistance of TC4 MAO coating[J]. Chinese Rare Earths, 2021,42(2):48−55. (王卓, 张唯一, 张云龙, 等. Nd(NO3)3的添加对TC4 MAO涂层润湿性和耐蚀性的影响[J]. 稀土, 2021,42(2):48−55. Wang Zhuo, Zhang Weiyi, Zhang Yunlong, et al . Effect of Nd(NO3)3 on wettability and corrosion resistance of TC4 MAO coating[J]. Chinese Rare Earths,2021 ,42 (2 ):48 −55 .[41] Khorasanian M, Dehghan A, Shariat M H, et al. Microstructure and wear resistance of oxide coatings on Ti–6Al–4V produced by plasma electrolytic oxidation in an inexpensive electrolyte[J]. Surface and Coatings Technology, 2011,206(6):1495−1502. doi: 10.1016/j.surfcoat.2011.09.038 [42] Shin Kin Ryong, Kim Yeon Sung, Kim Gye Won, et al. Effects of concentration of Ag nanoparticles on surface structure and in vitro biological responses of oxide layer on pure titanium via plasma electrolytic oxidation[J]. Applied Surface Science, 2015,347:574−582. doi: 10.1016/j.apsusc.2015.04.161 [43] Zhou Ke, Wang Shuqi, Lou Xia, et al. Preparation and galvanic corrosion resistance of microarc oxidation ceramic coatings on TA15 alloy[J]. Surface Technology, 2019,48(7):72−80. (周科, 王树棋, 娄霞, 等. TA15合金微弧氧化陶瓷涂层制备与电偶腐蚀性能[J]. 表面技术, 2019,48(7):72−80. Zhou Ke, Wang Shuqi, Lou Xia, et al . Preparation and galvanic corrosion resistance of microarc oxidation ceramic coatings on TA15 alloy[J]. Surface Technology,2019 ,48 (7 ):72 −80 .[44] Zhang Ruifang, Kai Lv, Du Zhaoxin, et al. Effects of graphene on the wear and corrosion resistance of micro-arc oxidation coating on a titanium alloy[J]. Metals, 2022,12(70):70. [45] Zhang Yunlong, Li Qirong, Niu Guangjin, et al. Effect of Er(NO3)3 doping on wear resistance of TC4 MAO coating in calcium acetate-sodium hexametaphosphate system[J]. Chinese Journal of Stereology and Image Analysis, 2022,27(1):9−17. (张云龙, 李启荣, 牛广津, 等. Er(NO3)3掺杂对乙酸钙-六偏磷酸钠体系下TC4 MAO涂层耐磨性能的影响[J]. 中国体视学与图像分析, 2022,27(1):9−17. Zhang Yunlong, Li Qirong, Niu Guangjin, et al . Effect of Er(NO3)3 doping on wear resistance of TC4 MAO coating in calcium acetate-sodium hexametaphosphate system[J]. Chinese Journal of Stereology and Image Analysis,2022 ,27 (1 ):9 −17 .[46] Ding Zhisong, Gao Wei, Wei Jingpeng, et al. Effects of TaC microparticles on structure and properties of micro-arc oxidation coating on Ti-6Al-4V alloy[J]. Acta Physica Sinica, 2022,71(2):324−332. (丁智松, 高巍, 魏敬鹏, 等. TaC微粒对Ti6Al4V合金微弧氧化层结构和性能的影响[J]. 物理学报, 2022,71(2):324−332. Ding Zhisong, Gao Wei, Wei Jingpeng, et al . Effects of TaC microparticles on structure and properties of micro-arc oxidation coating on Ti-6Al-4V alloy[J]. Acta Physica Sinica,2022 ,71 (2 ):324 −332 .[47] He Daihua, Zhu Wei, Liu Xiang, et al. Effects of calcium silicate and sodium silicate concentrations on bioactive coating on titanium alloy[J]. Journal of Materials Engineering, 2020,48(10):148−156. (何代华, 朱威, 刘翔, 等. 硅酸钙及硅酸钠浓度对钛合金表面生物活性涂层的影响[J]. 材料工程, 2020,48(10):148−156. He Daihua, Zhu Wei, Liu Xiang, et al . Effects of calcium silicate and sodium silicate concentrations on bioactive coating on titanium alloy[J]. Journal of Materials Engineering,2020 ,48 (10 ):148 −156 .[48] Li De, Zhang Lihua, Wen Kang, et al. Effect of KOH/K2ZrF6 on the structure and bonding strength of micro-arc oxide film of TC4 titanium alloy[J]. Materials Science and Technology, 2021,29(1):30−37. (李德, 张立华, 文康, 等. KOH/K2ZrF6对TC4钛合金微弧氧化陶瓷膜形貌和结合强度的影响[J]. 材料科学与工艺, 2021,29(1):30−37. Li De, Zhang Lihua, Wen Kang, et al . Effect of KOH/K2ZrF6 on the structure and bonding strength of micro-arc oxide film of TC4 titanium alloy[J]. Materials Science and Technology,2021 ,29 (1 ):30 −37 . -

下载:

下载: