Studies on the influences of forging processes on the microstructures and properties of TA15 rods

-

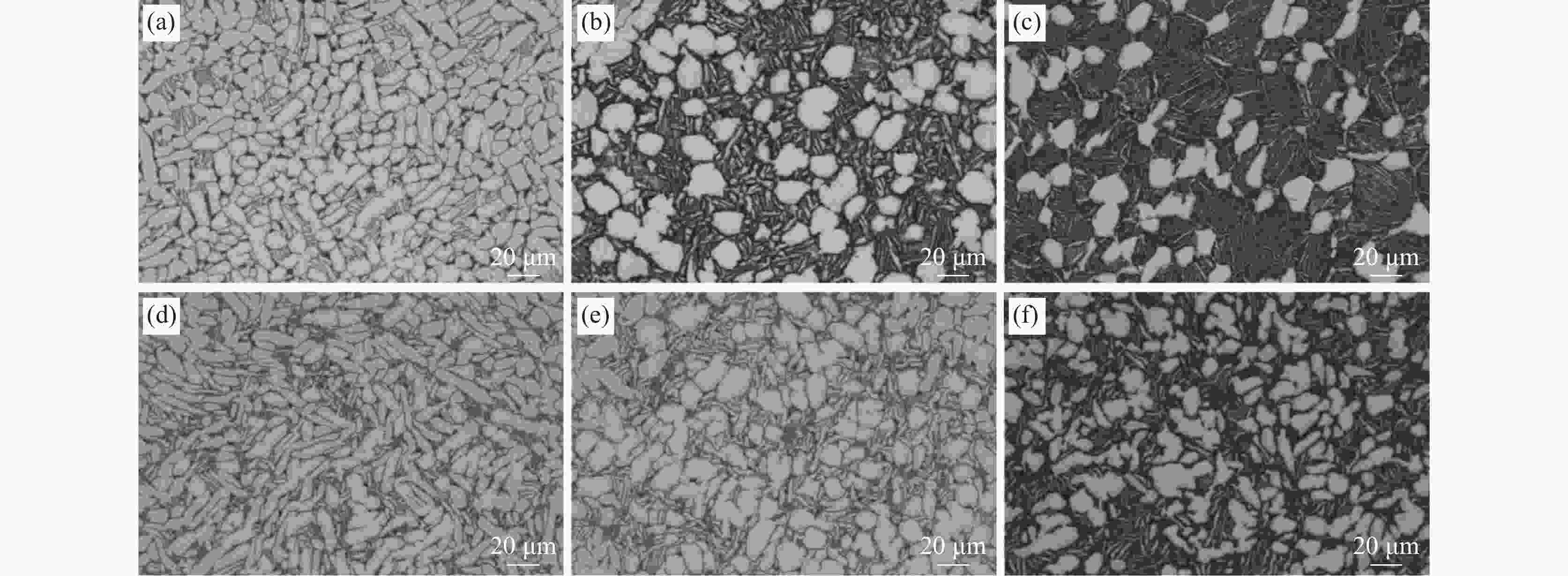

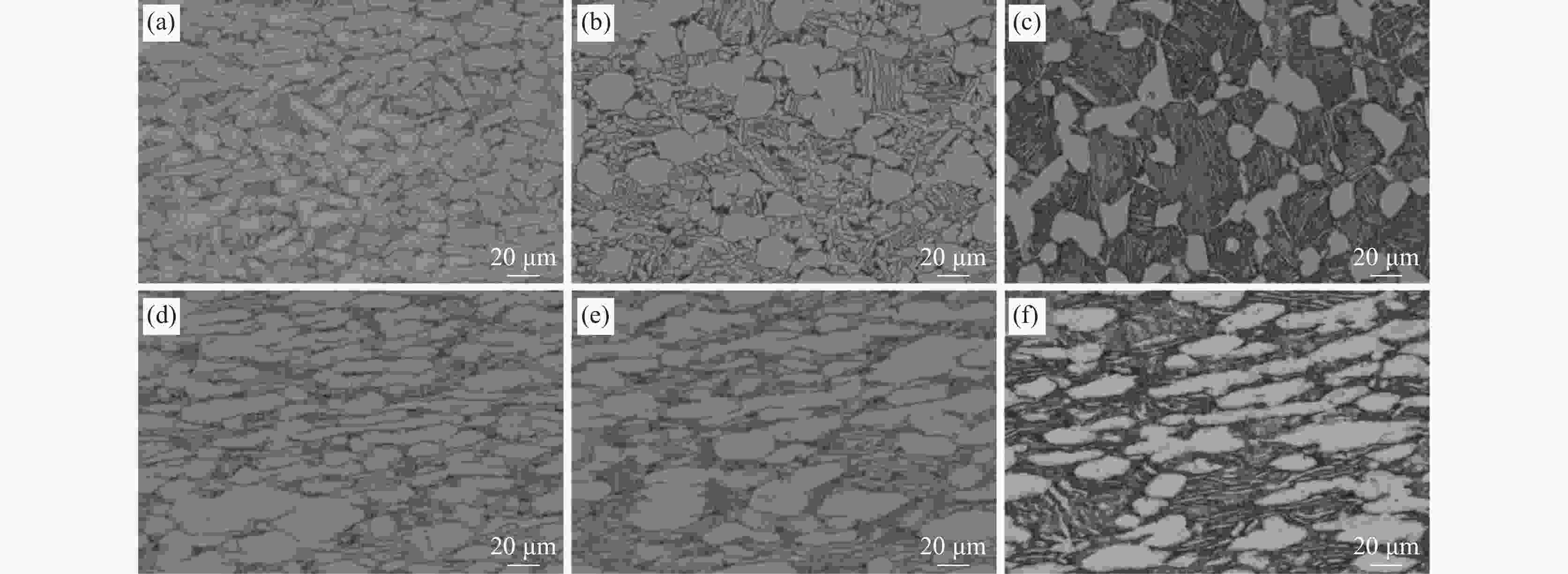

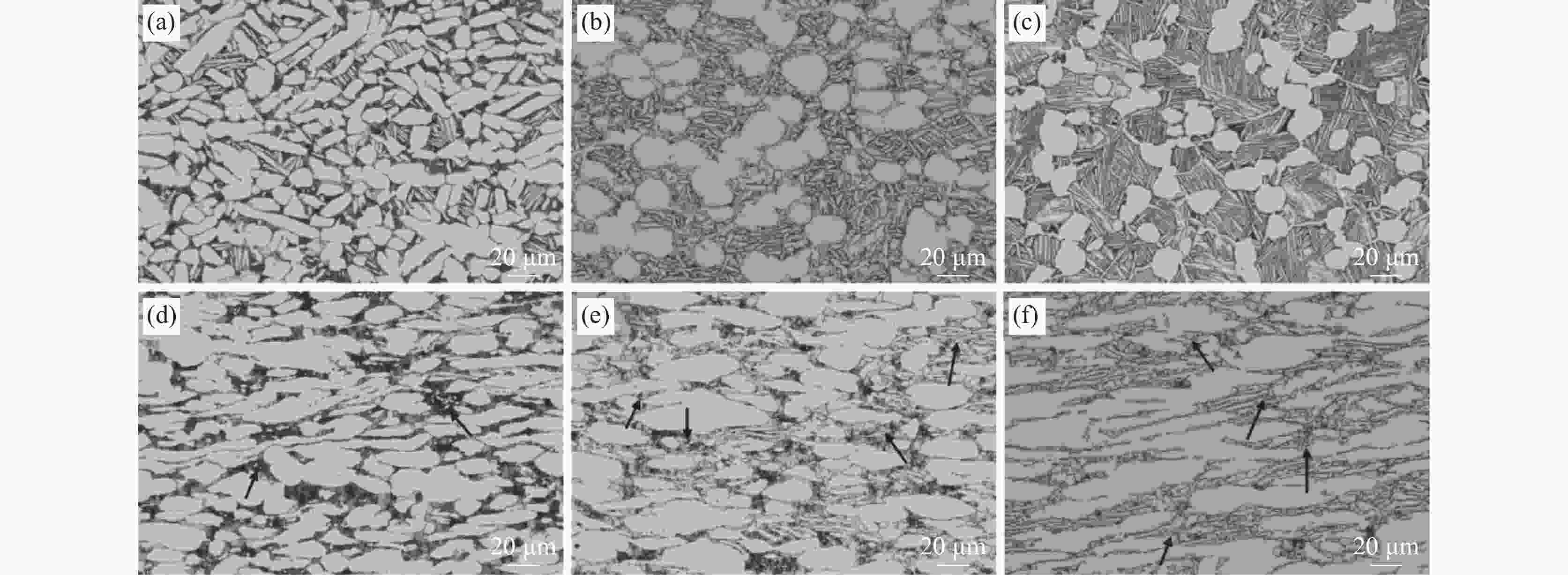

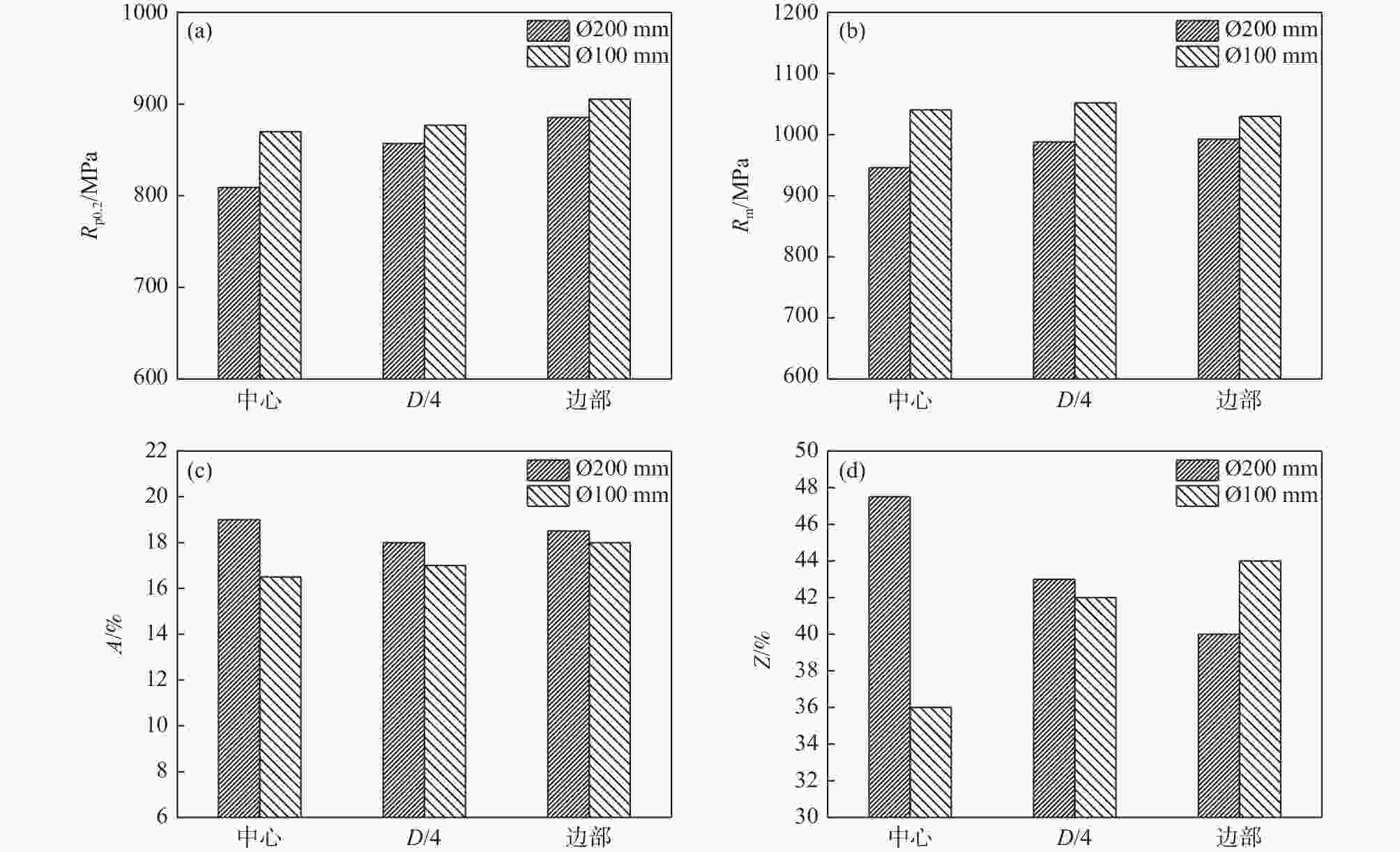

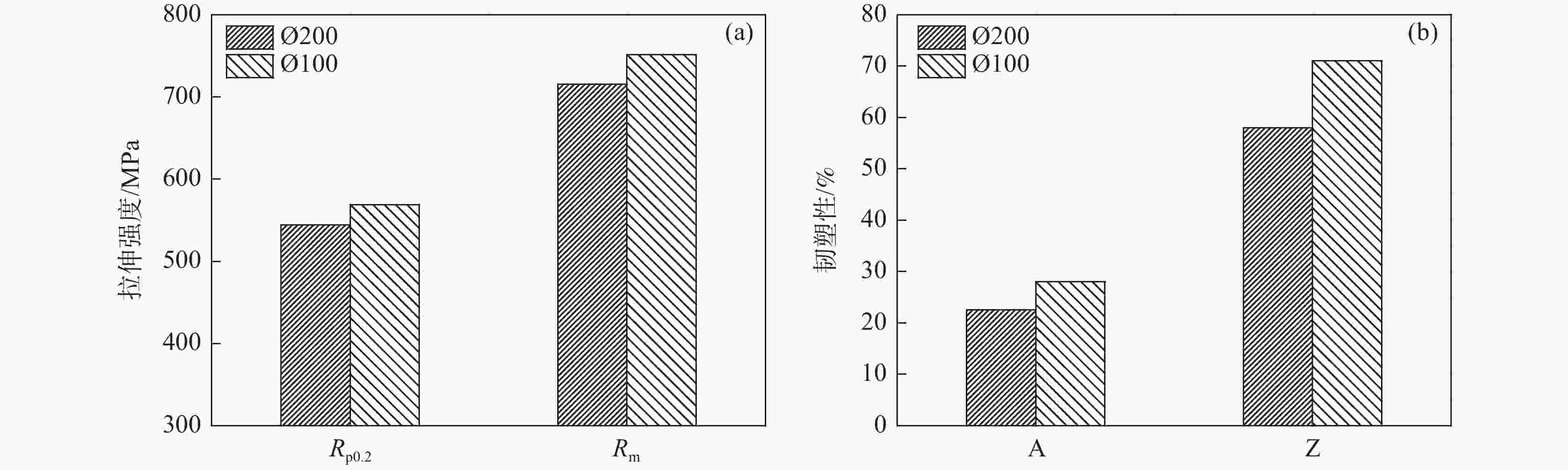

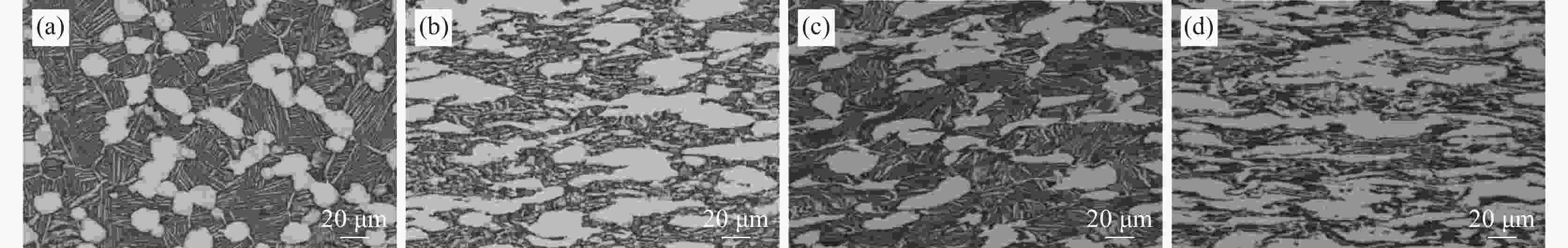

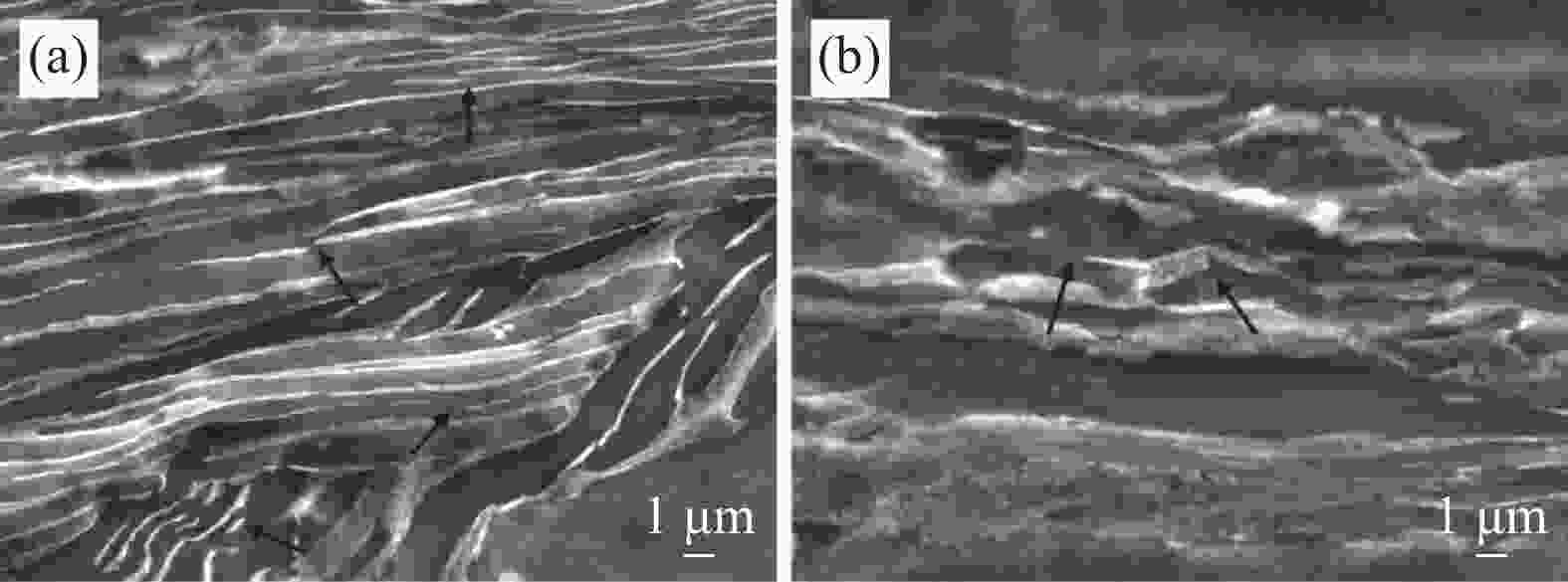

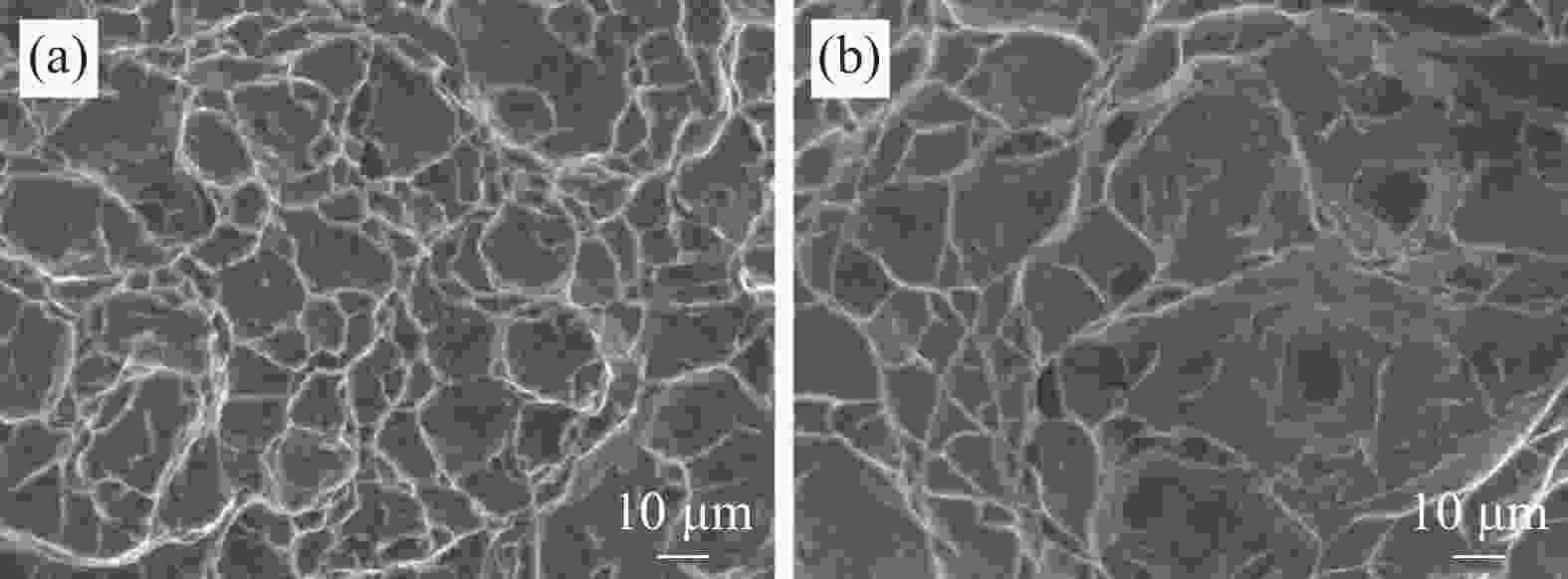

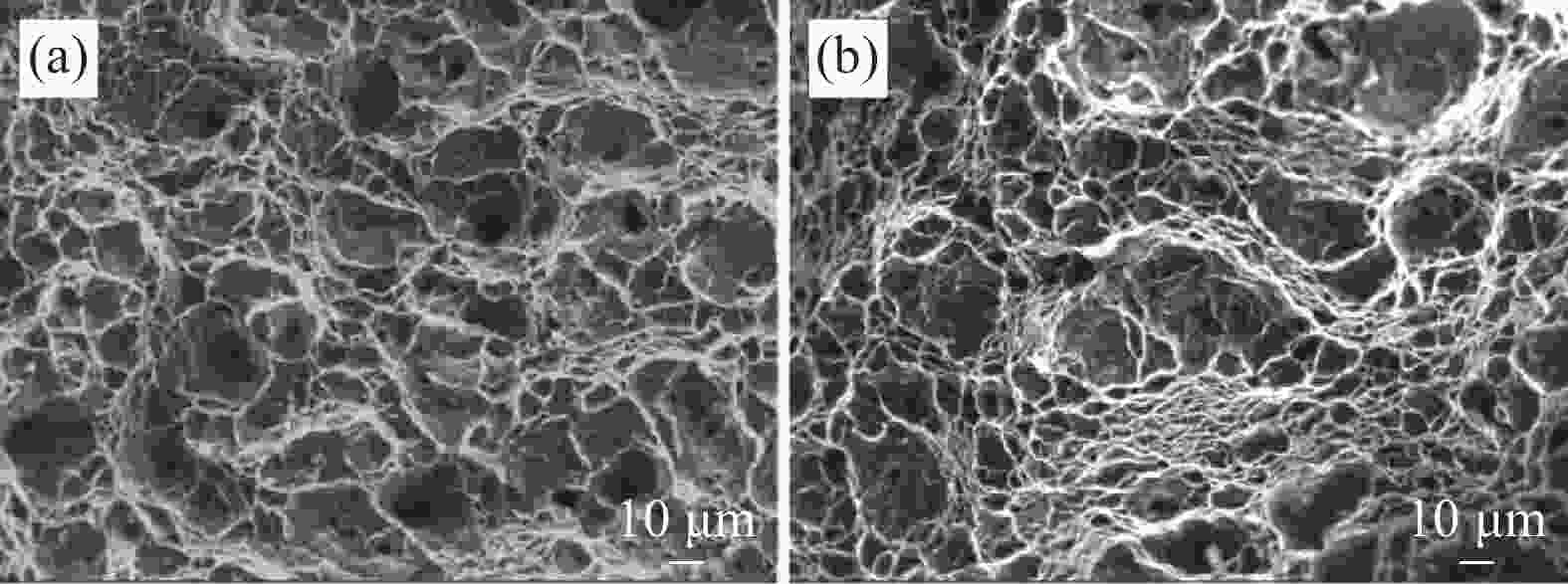

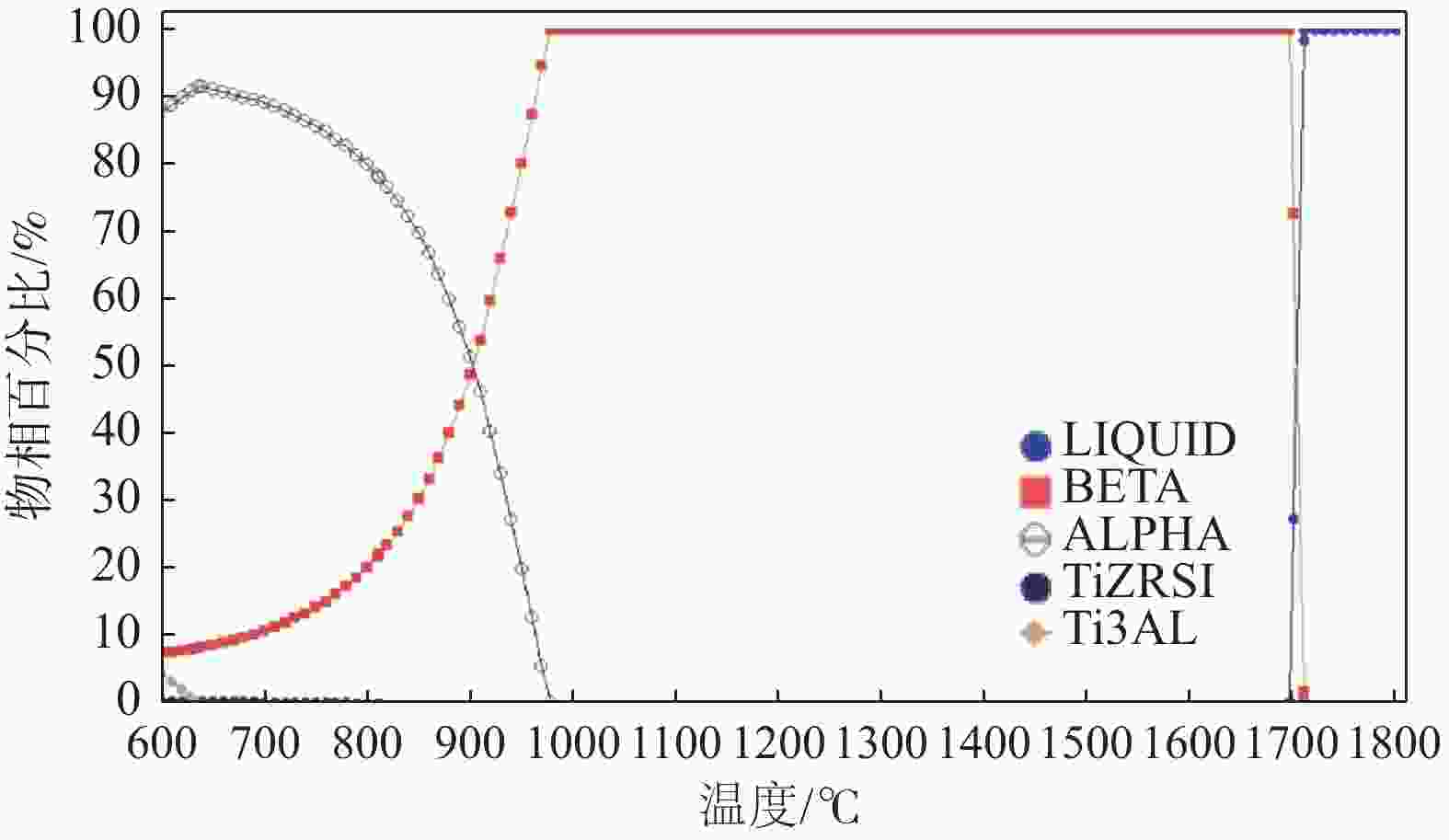

摘要: 采用自由锻和径锻工艺,分别制备出直径Ø200 mm和Ø100 mm的两支TA15钛合金锻棒,研究了锻造工艺对TA15锻棒组织和力学性能的影响。结果表明,两种TA15锻棒不同位置的金相组织有明显差异,径锻棒心部初生α相占比高,初生及次生α相均呈现不规则变形组织形貌,说明Ø100 mm锻棒中心发生变形。两支锻棒的α相含量从心部到边部逐渐减少,β转变组织含量逐渐增多。退火后径锻棒的组织内存在大量块状α相和细小再结晶晶粒,而自由锻锻棒组织无明显变化。经过径锻变形后,锻棒的边部室温抗拉强度、面缩和冲击性能提升。细长的片层状组织提供了更多α/β相界面,促进了高温扩散,使得自由锻锻棒的高温力学性能低于径锻棒。Abstract: TA15 rods with the diameter of 100 mm and 200 mm were produced by free forging and radial forging respectively. In this study, the effects on the microstructures and mechanical properties of TA15 rods were investigated. It is shown that there are dramatic differences in the microstructures at different positions of two rods. Deformation occurs in the center of the radial forged rods with a considerable amount of primary α phase in the microstructure, ascertained by the irregular and deformed appearance of the primary and secondary α phases. The content of α phase in two rods is lowered from the center to the edge, while the amount of β transformation phases increase. The phase morphology change in the free forged rod is negligible after annealing. However, a great quantity of blocky α phase and tiny recrystallized grains appear in the microstructure of radial forged rod after annealing. The tensile strength, area reduction and impact energy of the rod are increased by radial forging. The long and thin lamellar structures provide more interfaces of α/β phases, promoting fast diffusion at high temperature and leading to the results that the high-temperature properties of free forged rod are worse compared to that of the radial forged rod.

-

Key words:

- TA15 /

- free forging /

- radial forging /

- microstructure /

- mechanical properties

-

表 1 TA15钛合金铸锭化学成分

Table 1. Chemical composition of TA15 ingot

% Al Mo V Zr O Fe Ti 6.50 1.72 2.41 2.03 0.12 0.21 Bal. 表 2 TA15锻棒高温持久性能

Table 2. High-temperature durability of TA15 rods

锻棒尺寸

/mm高温持久(500 ℃,470 MPa)

/hØ200 164.5,199.6 Ø100 218.8,255.4 -

[1] Zhao Yongqing, Ge Peng, Xin Shewei. Progresses of R&D on Ti-alloy materials in recent 5 years[J]. Materials China, 2020,39(7-8):527−534. (赵永庆, 葛鹏, 辛社伟. 近五年钛合金材料研发进展[J]. 中国材料进展, 2020,39(7-8):527−534.Zhao Yongqing, Ge Peng, Xin Shewei. Progresses of R&D on Ti-alloy materials in recent 5 years [J]. Materials China, 2020, 39(7-8): 527-534. [2] Wu Bin, Tang Dingcheng, He Xiaofan, et al. Fatigue bahavior of laser metal deposition TA15 titanium alloy universal beam[J]. Chinese Journal of Rare Metals, 2022,46(5):545−553. (吴斌, 唐鼎承, 贺小帆, 等. 激光金属沉积TA15钛合金工字梁疲劳性能研究[J]. 稀有金属, 2022,46(5):545−553.Wu Bin, Tang Dingcheng, He Xiaofan, et al. Fatigue bahavior of laser metal deposition TA15 titanium alloy universal beam [J]. Chinese Journal of Rare Metals, 2022, 46(5) : 545-553. [3] Cao Jingxia, Fang Bo, Huang Xu, et al. Effects of microstructure on properties of TA15 titanium alloy[J]. Chinese Journal of Rare Metals, 2004,28(2):362−364. (曹京霞, 方波, 黄旭, 等. 微观组织对TA15钛合金力学性能的影响[J]. 稀有金属, 2004,28(2):362−364.Cao Jingxia, Fang Bo, Huang Xu, et al. Effects of microstructure on properties of TA15 titanium alloy [J]. Chinese Journal of Rare Metals, 2004, 28(2): 362-364. [4] He Fei, Chen Haifeng, Wang Yuhui. Effect of microstructure on high temperature tensile properties of TA15 titanium alloy[J]. Journal of Materials Engineering, 2012,(2):13−15. (贺飞, 陈海峰, 王玉会. 显微组织对TA15合金高温拉伸性能的影响[J]. 材料工程, 2012,(2):13−15.He Fei, Chen Haifeng, Wang Yuhui. Effect of microstructure on high temperature tensile properties of TA15 titanium alloy [J]. Journal of Materials Engineering, 2012, (2): 13-15. [5] 郭威威. TA15钛合金等温多向锻造组织演化行为及力学性能研究[D]. 合肥: 合肥工业大学, 2019.Guo Weiwei. Microstructure evolution behaviors and mechanical properties of TA15 alloy by isothermal multi-directional forging [D]. Hefei: Hefei University of Technology, 2019. [6] Xie Li, Yu Zhongliang, Wang Yuan, et al. Effect of forging process on microstructure and mechanical properties of lager diameter TA15 titanium alloy bar[J]. Heat Treatment of Metals, 2016,41(2):181−182. (谢力, 虞忠良, 王媛, 等. 锻造工艺对TA15钛合金大直径棒材的组织与性能影响[J]. 金属热处理, 2016,41(2):181−182.Xie Li, Yu Zhonglang, Wang Yuan, et al. Effect of forging process on microstructure and mechanical properties of lager diameter TA15 titanium alloy bar [J]. Heat Treatment of Metals, 2016, 41(2): 181-182. [7] Wang Fuqiang, Yang Lixin, Wang Deyong, et al. Research on technology and microstructure and properties of TA15 titanium alloy large-size forging billet[J]. Hot Working Technology, 2020,49(13):19−23. (王富强, 杨立新, 王德勇, 等. TA15钛合金大型锻坯工艺及组织与性能研究[J]. 热加工工艺, 2020,49(13):19−23.Wang Fuqiang, Yang Lixin, Wang Deyong, et al. Research on technology and microstructure and properties of TA15 titanium alloy large-size forging billet [J]. Hot Working Technology, 2020, 49(13): 19-23. [8] Min Xinhua, Ji Renfeng. Effect of forging process on microstructure and mechanical properties of TA15 titanium alloy slab[J]. Titanium Industry Process, 2016,33(6):36−39. (闵新华, 纪仁峰. 锻造工艺对TA15钛合金扁坯组织和力学性能的影响[J]. 钛工业进展, 2016,33(6):36−39.Min Xinhua, Ji Renfeng. Effect of forging process on microstructure and mechanical properties of TA15 titanium alloy slab[J]. Titanium Industry Process, 2016, 33(6): 36-39. [9] Wang Zhe, He Jian, Zhang Shuai, et al. Influence of forging equipment on microstructure and mechanical properties of TA15 titanium alloy[J]. Iron Steel Vanadium Titanium, 2022,43(1):80−84. (王哲, 何健, 张帅, 等. 锻造设备对TA15钛合金显微组织及性能的影响研究[J]. 钢铁钒钛, 2022,43(1):80−84.Wang Zhe, He Jian, Zhang Shuai, et al. Influence of forging equipment on microstructure and mechanical properties of TA15 titanium alloy[J]. Iron Steel Vanadium Titanium, 2022, 43(1): 80-84. [10] Zuo Zheng, Zou Junjie, Jiang Jiajun, et al. Dynamic globularization behavior of lamellar α phase in TC21 titanium alloy during hot deformation[J]. Journal of Netshape Forming Engineering, 2023,15(2):60−67. (左正, 邹俊杰, 蒋佳君, 等. TC21钛合金热变形过程中片层α相动态球化行为研究[J]. 精密成形工程, 2023,15(2):60−67.Zuo Zheng, Zou Junjie, Jiang Jiajun, et al. Dynamic globularization behavior of lamellar α phase in TC21 titanium alloy during hot deformation [J]. Journal of Netshape Forming Engineering, 2023, 15(2) : 60-67. [11] 董显娟. 片状组织TA15钛合金α+β相区塑性变形特性及等轴化行为研究[D]. 南京: 南京航空航天大学, 2011.Dong Xianjuan. Research on plastic deformation characterisitics and globularization behavior of TA15 titanium alloy with lamellar microstructure in alpha and beta phase field[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2011. [12] Li Ping, Gan Guoqiang, Xue Kemin. Modeling of phase transformation and DRX in TA15 alloy during the isothermal hot compression[J]. Rare Metal Materials and Engineering, 2012,41(S2):343−347. (李萍, 甘国强, 薛克敏. TA15合金等温热压缩过程中相变和再结晶模型的建立(英文)[J]. 稀有金属材料与工程, 2012,41(S2):343−347.Li Ping, Gan Guoqiang, Xue Kemin. Modeling of phase transformation and DRX in TA15 alloy during the isothermal hot compression[J]. Rare Metal Materials and Engineering, 2012, 41(S2): 343-347. [13] Han Yunfei, Yuan Bingbing, Sun Bing, et al. Microstructure and properties of ZTA15 titanium alloy in different states[J]. Foundry Technology, 2022,43(8):694−697. (韩云飞, 袁兵兵, 孙冰, 等. ZTA15钛合金在不同状态下的组织和性能[J]. 铸造技术, 2022,43(8):694−697.Han Yunfei, Yuan Bingbing, Sun Bing, et al. Microstructure and properties of ZTA 15 titanium alloy in different states[J]. Foundry Technology, 2022, 43(8): 694-697. [14] Lu Jing, Wang Yuhui, Zhang Wangfeng. Effect of microstructure on tensile properties of near-alpha TA15 titanium alloy[J]. Heat Treatment of Metals, 2011,36(6):25−28. (鹿靖, 王玉会, 张旺峰. 组织形态对近α型TA15钛合金拉伸性能的影响[J]. 金属热处理, 2011,36(6):25−28.Lu Jing, Wang Yuhui, Zhang Wangfeng. Effect of microstructure on tensile properties of near-alpha TA15 titanium alloy[J]. Heat Treatment of Metals, 2011, 36(6): 25-28. [15] Wang Zhe, Ran Xing, Liu Chengcheng, et al. Influence of forging temperature on microstructure and tensile strength aeolotropy of TA15 titanium alloy[J]. Materials for Mechanical Engineering, 2022,46(7):6−10. (王哲, 冉兴, 刘程程, 等. 锻造温度对TA15钛合金显微组织及抗拉强度各向异性的影响[J]. 机械工程材料, 2022,46(7):6−10.Wang Zhe, Ran Xing, Liu Chengcheng, et al. Influence of forging temperature on microstructure and tensile strength aeolotropy of TA15 titanium alloy[J]. Materials for Mechanical Engineering, 2022, 46(7): 6-10. [16] Wang Yun, Luo Dengchao, Wang Sha, et al. Effects of heat treatment on mechanical properties and microstructure of Ti80 cold-rolled tubes[J]. Hot Working Technology, 2019,48(10):200−202. (王云, 罗登超, 王莎, 等. 热处理对Ti80冷轧管材力学性能和组织的影响[J]. 热加工工艺, 2019,48(10):200−202.Wang Yun, Luo Dengchao, Wang Sha, et al. Effects of heat treatment on mechanical properties and microstructure of Ti80 cold-rolled tubes[J]. Hot Working Technology, 2019, 48(10): 200-202. [17] Luo Dengchao, Wang Yun, Li Wei. Manufacture of TA15 titanium alloy pipes by different processes[J]. Forging & Stamping Technology, 2022,47(8):118−122. (罗登超, 王云, 李维. 不同工艺制备TA15钛合金管材[J]. 锻压技术, 2022,47(8):118−122.Luo Dengchao, Wang Yun, Li Wei. Manufacture of TA15 titanium alloy pipes by different processes[J]. Forging & Stamping Technology, 2022, 47(8): 118-122. [18] Zhang Mingyu, Yun Xinbing, Fu Hongwang. Effect of different heat treatment process on microstructure and properties of TC10 titanium alloy[J]. Journal of Plasticity Engineering, 2021,28(12):237−245. (张明玉, 运新兵, 伏洪旺. 不同热处理工艺对TC10钛合金组织及性能的影响[J]. 塑性工程学报, 2021,28(12):237−245.Zhang Minyu, Yun Xinbing, Fu Hongwang. Effect of different heat treatment process on microstructure and properties of TC10 titanium alloy [J]. Journal of Plasticity Engineering, 2021, 28(12): 237-245. [19] Meng Yan, Huang Dong, Feng Zhenyong, et al. Finite element modeling and study on the propagation rules of microcracks in TA15 titanium alloy with different microstructures during isothermal tension[J]. Journal of Plasticity Engineering, 2017,24(2):160−167. (孟岩, 黄栋, 冯振勇, 等. 不同组织TA15钛合金等温拉伸微裂纹扩展规律的有限元建模研究[J]. 塑性工程学报, 2017,24(2):160−167.Meng Yan, Huang Dong, Feng Zhenyong, et al. Finite element modeling and study on the propagation rules of microcracks in TA15 titanium alloy with different microstructures during isothermal tension[J]. Journal of Plasticity Engineering, 2017, 24(2): 160-167. [20] Zhang Qi, Yang Na, Zhang Mingyu, et al. The effect of forging process on the structrure and properties of Ti-662 titanium alloy bars[J]. Metal Working, 2023,(5):104−107. (张起, 杨娜, 张明玉, 等. 锻造工艺对Ti-662钛合金棒材组织和性能的影响[J]. 金属加工(热加工), 2023,(5):104−107.Zhang Qi, Yang Na, Yang Mingyu, et al. The effect of forging process on the structrure and properties of Ti-662 titanium alloy bars[J]. Metal Working, 2023 (5): 104-107. [21] Sha Aixue, Li Xingwu, Wang Qingru, et al. Influence of hot deformation temperature on microstructure and mechanical properties of TC18 alloy[J]. The Chinese Journal of Nonferrous Metals, 2005,15(8):1167−1172. (沙爱学, 李兴无, 王庆如, 等. 热变形温度对TC18钛合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2005,15(8):1167−1172.Sha Aixue, Li Xingwu, Wang Qingru, et al. Influence of hot deformation temperature on microstructure and mechanical properties of TC18 alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1167-1172. [22] Yao Zekun, Guo Hongzhen, Su Zuwu, et al. Effect of microstructure and recrystallization and mechanical properties of two phase (α+β) Ti alloy[J]. Rare Metal Materials and Engineering, 2000,29(5):340−343. (姚泽坤, 郭鸿镇, 苏祖武, 等. 热力参数对α+β两相钛合金再结晶百分数和力学性能的影响[J]. 稀有金属材料与工程, 2000,29(5):340−343.Yao Zekun, Guo Hongzhen, Su Zuwu, et al. Effect of microstructure and recrystallization and mechanical properties of two phase (α+β) Ti alloy[J]. Rare Metal Materials and Engineering, 2000, 29(5): 340-343. [23] Hou Yanrong, Lai Yunjin, Du Yuxuan, et al. Effect of heat treatment process on impact property of TA15 alloy[J]. Material and Heat Treatment, 2011,40(2):182−183. (侯艳荣, 赖运金, 杜予晅, 等. 热处理对TA15钛合金棒材冲击性能的影响[J]. 热加工工艺, 2011,40(2):182−183.Hou Yanrong, Lai Yunjin, Du Yuxuan, et al. Effect of heat treatment process on impact property of TA15 alloy[J]. Material and Heat Treatment, 2011, 40(2): 182-183. [24] Li Mingbing, Wang Xinnan, Shang Guoqiang, et al. High temperature mechanical properties of near α, (α+β) and near β type titanium alloy[J]. Heat Treatment of Metals, 2022,47(11):199−205. (李明兵, 王新南, 商国强, 等. 近α型、(α+β)型和近β型钛合金的高温力学性能[J]. 金属热处理, 2022,47(11):199−205.Li Mingbing, Wang Xinnan, Shang Guoqiang, et al. High temperature mechanical properties of near α, (α+β) and near β type titanium alloy[J]. Heat Treatment of Metals, 2022, 47(11): 199-205. -

下载:

下载: