Adiabatic shear sensitivity performance of Ti-1023 alloys at different heat treatment regimes

-

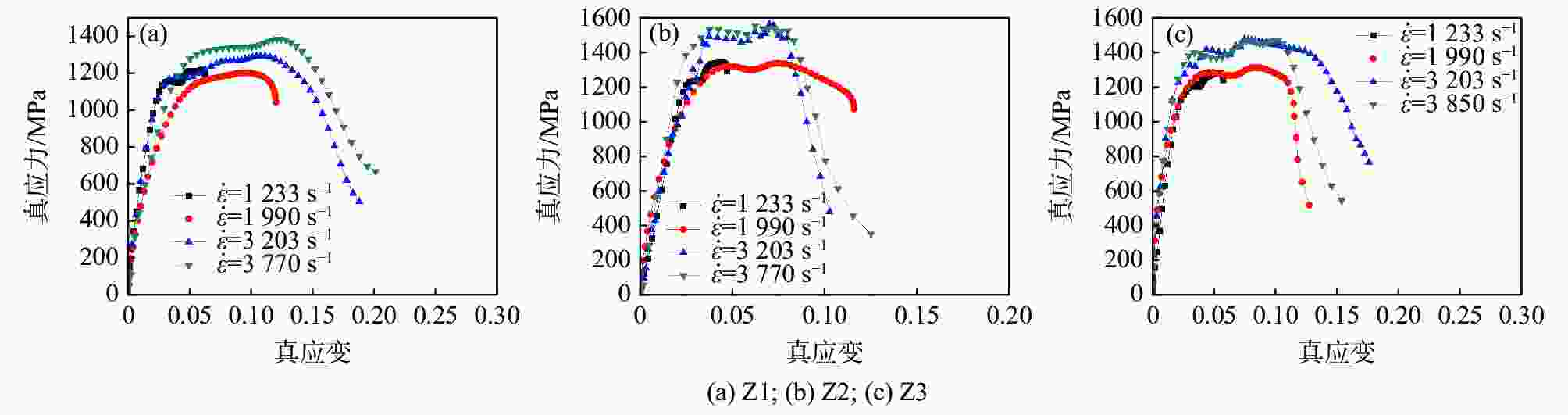

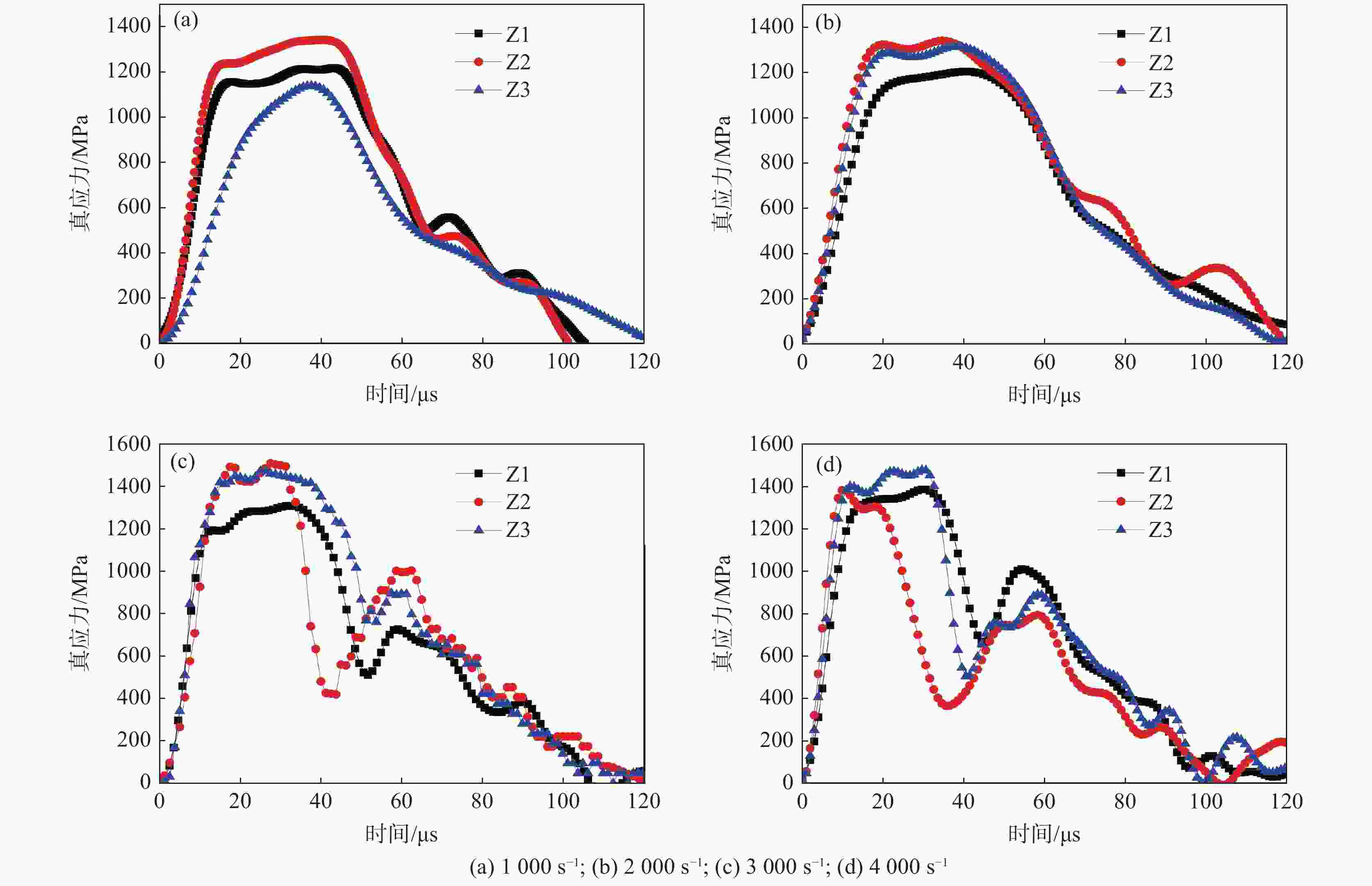

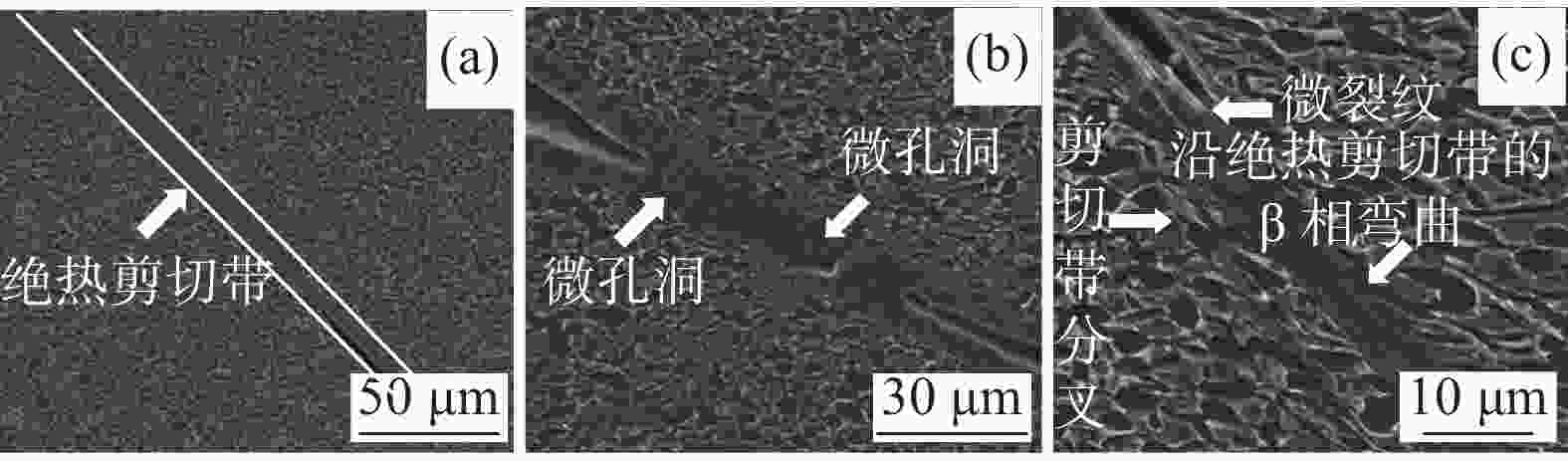

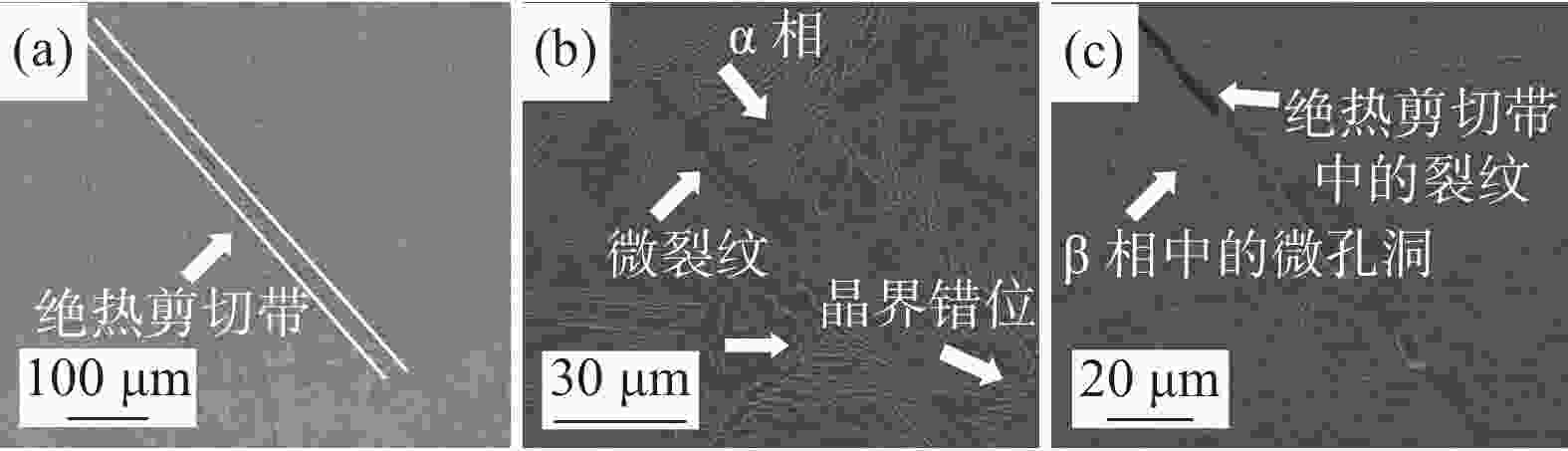

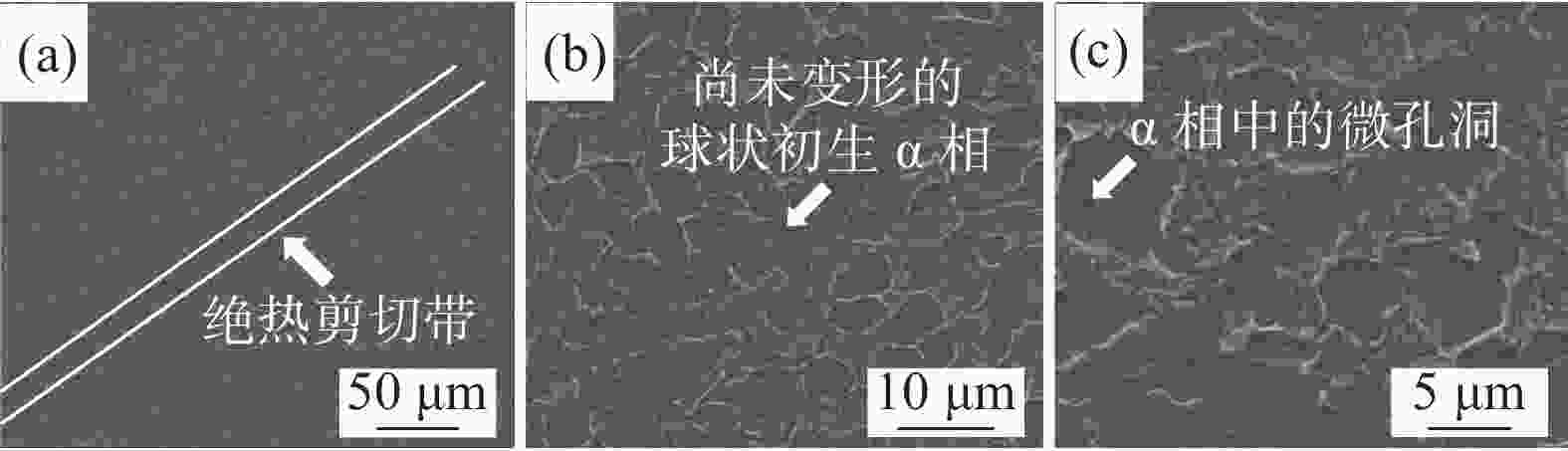

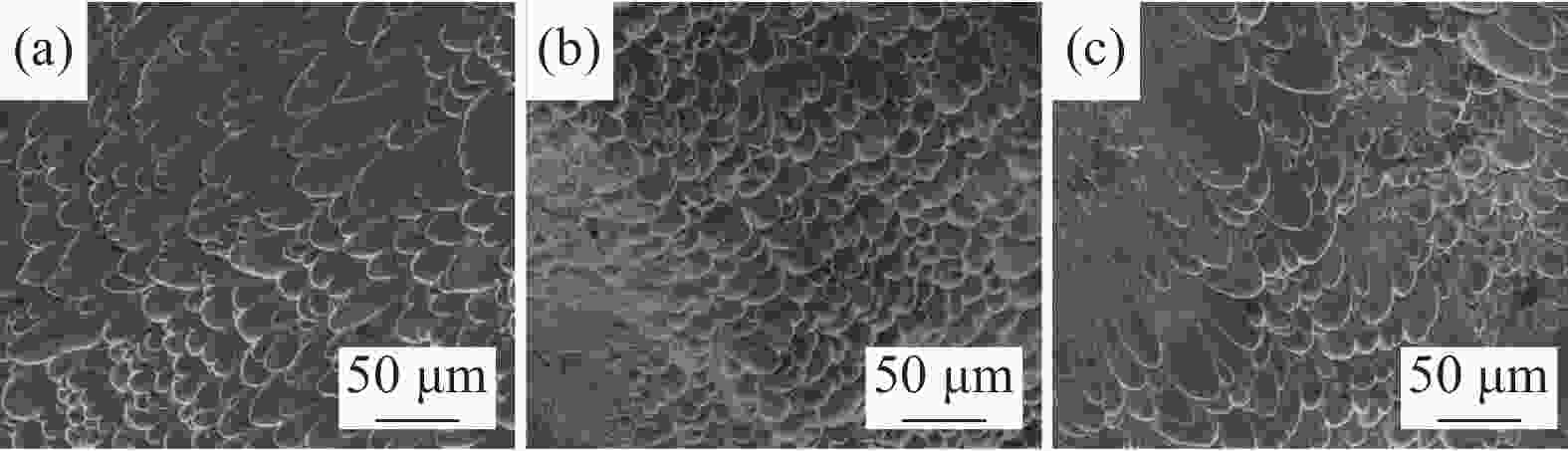

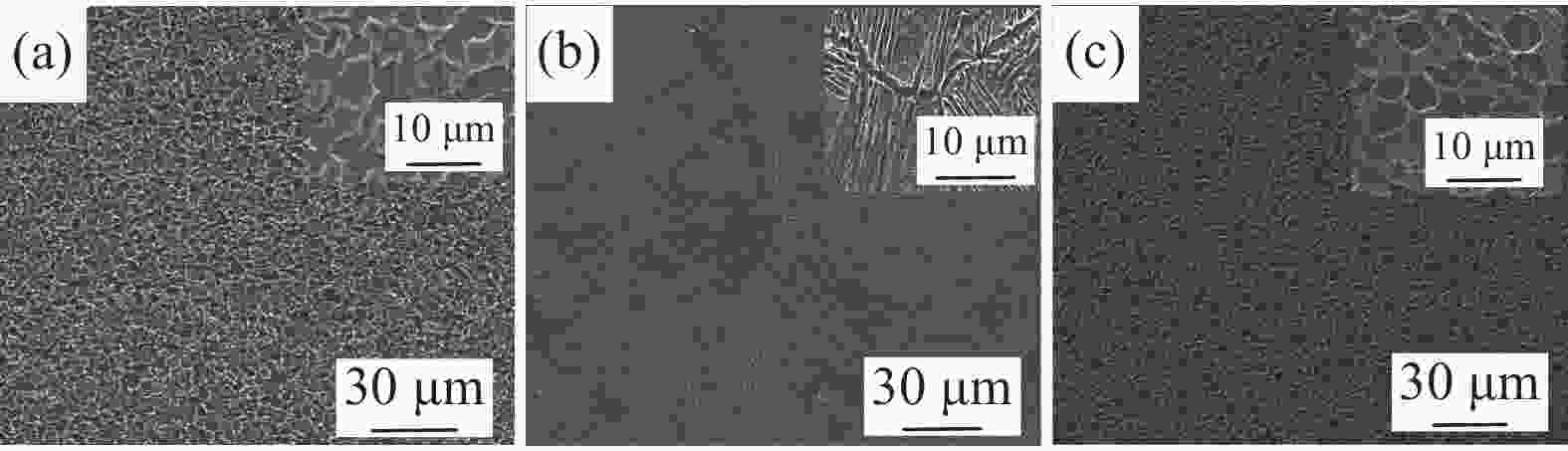

摘要: 利用Hopkinson 压杆试验系统对圆柱形试样进行室温动态压缩冲击试验,研究不同热处理制度下Ti-1023钛合金的微观组织、绝热剪切带的形成特征。结果表明,相变点以上固溶处理使Ti-1023合金组织晶粒尺寸增大,β晶界处析出细针状α相;相变点以下的固溶时效使晶粒内部析出大量球状α相,相变点以下的固溶双重时效处理的组织晶粒更为细小均匀。在较高应变率加载条件下,不同组织均表现出明显的应变率增强和增塑效应,具有明显的热塑性失稳特征。相变点以上固溶时效组织动态强度高,但塑性差,绝热剪切敏感性最大;相变点以下固溶单重时效组织最不易发生绝热剪切,但强度低;固溶双重时效组织比固溶单重时效组织的动态强度高,塑性较好,具有最好的抗冲击承载能力。

-

关键词:

- Ti-1023钛合金 /

- 固溶时效 /

- 力学性能 /

- 微观组织 /

- 绝热剪切

Abstract: Using the Hopkinson pressure bar test system to conduct room temperature dynamic compression experiments for cylindrical samples, the formation characteristics of adiabatic shear bands and the microstructure of Ti-1023 titanium alloy under different heat treatment regimes were studied. The results show that the grain size of Ti-1023 alloy is increased by the solid solution treatment above the phase transition point. The fine acicular α phase precipitates at the β grain boundary. The solid solution aging below the phase transition point causes a large number of spherical α phases in the grains, and the grain size of the tissue grains with dual aging treatment is even smaller. Under the loading conditions of different strain rates, all different tissues show obvious strain rate enhancement and plasticizing effect, reflecting apparent characteristics of thermoplastic instability. The dynamic strength of the solid solution aging group above the phase transition point was the highest, but the plastic difference was the worst and being presented with the greatest adiabatic shear sensitivity. It is the most difficult to produce adiabatic shear in the solid solution single aging structures below the phase transition point, but the material strength is low. The solid solution dual aging tissue has higher dynamic strength and better plasticity than the solid solution single heavy aging tissue,which has the best resistance to impact bearing capacity.-

Key words:

- Ti-1023 titanium alloy /

- solution and aging /

- mechanical properties /

- microstructure /

- adiabatic shear

-

表 1 Ti-1023钛合金化学成分

Table 1. Chemical composition of Ti-1023 alloy

% H O N Fe Al V Ti 0.01 0.03 0.03 1.93 2.93 10.13 余量 -

[1] Zhu Zhishou. Recent research and development of titanium alloys for aviation application in China[J]. Journal of Aeron Materials, 2014,34(4):44−50. (朱知寿. 我国航空用钛合金技术研究现状及发展[J]. 航空材料学报, 2014,34(4):44−50.Zhu Zhishou. Recent research and development of titanium alloys for aviation application in China[J]. Journal of Aeron Materials, 2014(4): 44-50 [2] Ye Yong, Wang Jinyan. An overview on application status and processing technology development of titanium alloy[J]. Materials Review, 2012,26(S2):360−363. (叶勇, 王金彦. 钛合金的应用现状及加工技术发展概况[J]. 材料导报, 2012,26(S2):360−363.Ye Yong, Wang Jinyan. An overview on application status and processing technology development of titanium Alloy[J]. Materials Review, 2012, 26 (S1): 360-363 [3] Yang Dongyu, Fu Yanyan, Hui Songxiao, et al. Research and application of high strength and high toughness titanium alloys[J]. Chinese Journal of Rare Materials, 2011,35(4):575−580. (杨冬雨, 付艳艳, 惠松骁, 等. 高强高韧钛合金研究与应用进展[J]. 稀有金属, 2011,35(4):575−580. doi: 10.3969/j.issn.0258-7076.2011.04.017Yang Dongyu, Fu Yanyan, Hui Songxiao, et al. Research and application of high strength and high toughness titanium alloys[J]. Chinese Journal of Rare Materials, 2011, 35(4): 575-580 doi: 10.3969/j.issn.0258-7076.2011.04.017 [4] Raghuna S L, Stapleton A M, Dashwood R J, et al. Micromechanics of Ti–10V–2Fe–3Al: In situ synchrotron characterisation and modelling[J]. Acta Materialia, 2007,55:6861−6872. doi: 10.1016/j.actamat.2007.08.049 [5] Jim Williams. Thermo-mechanical processing of high-performance Ti alloys: recent progress and future needs[J]. Journal of Materials Processing Technology, 2001,117(3):370−373. doi: 10.1016/S0924-0136(01)00803-2 [6] Welk Brian A. Microstructural and property relationships in β-titanium alloy Ti-5553[D]. US: Ohio State University, 2010. [7] Qiu Wei, Lu Shiqiang, Ouyang Delai. Investigation on the hot temperature deformation behavior and microstructure evolution of forged titanium alloy TB6[J]. Journal of Plasticity Engineering, 2010,17(3):38−43. (邱伟, 鲁世强, 欧阳德来, 等. 锻态TB6钛合金热变形行为及组织演变[J]. 塑性工程学报, 2010,17(3):38−43. doi: 10.3969/j.issn.1007-2012.2010.03.008Qu Wei, Lu shiqiang, Ouyang Delai. Investigation on the hot temperature deformation behavior and microstructure evolution of forged titanium alloyTB6[J]. Journal of Plasticity Engineering, 2010, 17(3): 38-43 doi: 10.3969/j.issn.1007-2012.2010.03.008 [8] Ouyang Delai, Lu Shiqiang, Cui Xia, et al. Transformation of deformation-induced martensite in TB6 titanium alloy[J]. Chinese Journal of Nonferrous Metals, 2010,20(12):2307−2312. (欧阳德来, 鲁世强, 崔霞, 等. TB6钛合金热变形诱导马氏体转变[J]. 中国有色金属学报, 2010,20(12):2307−2312.Ouyang Delai, Lu Shiqiang, Cui Xia, et al. Transformation of deformation-induced martensite in TB6 titanium alloy[J]. Chinese Journal of Nonferrous Metals, 2010, 20(12): 2307-2312 [9] Bao Ruqiang, Huang Xu, Huang Lijun. Investigation on hot processes of Ti-10V-2Fe-3Al alloy[J]. Chinese Journal of Rare Materials, 2005,29(2):214−218. (鲍如强, 黄旭, 黄利军. Ti-10V-2Fe-3Al合金热工艺的研究[J]. 稀有金属, 2005,29(2):214−218.Bao Ruqiang, Huang Xu, Huang Lijun. Investigation on hot processes of Ti-10 V-2 Fe-3 Al alloy[J]. Chinese Journal of Rare Materials, 2005, 29(2): 214-218 [10] Zhang Wei, Wang Kaixuan, Wang Tao, et al. Study on microstructure and property of Ti-1023 titanium alloy bar[J]. Chinese Hot Working Technology, 2013,42(17):117−119. (张维, 王凯旋, 王涛, 等. Ti-1023钛合金棒材组织和性能的研究[J]. 热加工工艺, 2013,42(17):117−119.Zhang Wei, Wang Kaixuan, Wang Tao, et al. Study on microstructure and property of Ti-1023 titanium alloy bar[J]. Chinese Hot Working Technology, 2013, 42(17): 117-119 [11] Wang Xiaoyan, Liu Jianrong, Lei Jiafeng, et al. Effects of primary and secondary α phase on tensile property and fracture toughness of Ti-1023 alloy[J]. Acta Metallurgica Sinica, 2007,43(11):1129−1137. (王晓燕, 刘建荣, 雷家峰, 等. 初生及次生α相对Ti-1023合金拉伸性能和断裂韧性的影响[J]. 金属学报, 2007,43(11):1129−1137.Wang Xiaoyan, Liu Jianrong, Lei Jiafeng, et al. Effects of primary and secondary α phase on tensile property and fracture toughness of Ti-1023 alloy[J]. Acta Metallurgica Sinica, 2007, 43(11): 1129-1137 [12] Wang Ding, Wang Lin, Dai Huaxiang, et al. Dynamic properties and adiabatic shear sensitivity of TB2 titanium alloy[J]. Ordnance Material Science and Engineering, 2016,39(5):100−103. (王丁, 王琳, 代华湘, 等. TB2钛合金动态力学性能及绝热剪切敏感性研究[J]. 兵器材料科学与工程, 2016,39(5):100−103.Wang Ding, Wang Lin, Dai Huaxiang, et al. Dynamic properties and adiabatic shear sensitivity of TB2 titanium alloy[J]. Ordnance Material Science and Engineering, 2016, 39(5): 100-103 [13] He J, Li D, Chen H, et al. Microstructures and mechanical properties of TB2 forgings[J]. Rare Metal Materials and Engineering, 2006,35(8):152−155. [14] You Zhenping, Ye Wenjun, Hui Songxiao, et al. Study on dynamic mechanical properties and adiabatic shearing of TB10 titanium alloy[J]. Chinese Journal of Rare Materials, 2008,32(6):799−802. (尤振平, 叶文君, 惠松骁, 等. TB10钛合金的动态力学性能及绝热剪切分析[J]. 稀有金属, 2008,32(6):799−802. doi: 10.3969/j.issn.0258-7076.2008.06.024You Zhenpin, Ye Wenjun, Hui Songxiao, et al. Study on dynamic mechanical properties and adiabatic shearing of TB10 titanium alloy[J]. Chinese Journal of Rare Materials, 2008, 32(6): 799-802 doi: 10.3969/j.issn.0258-7076.2008.06.024 [15] 常辉. Ti-B19合金的固态相变动力学及其组织演变规律[D]. 西安: 西北工业大学, 2006.Chang Hui. Solid phase transformation kinetics and microstructure evolutions of Ti-B19 alloy[D]. Xi’an: Northwestern Polytechnical University, 2006. [16] Ma Quan, Guo Aihong, Zhou Lian. Microstructure evolution and tensile properties of Ti1023 titanium alloy during aging[J]. The Chinese Journal of Nonferrous Metals, 2019,29(6):1219−1225. (马权, 郭爱红, 周廉. Ti1023钛合金在时效过程中的组织演化和拉伸性能[J]. 中国有色金属学报, 2019,29(6):1219−1225. doi: 10.19476/j.ysxb.1004.0609.2019.06.10Ma Quan, Guo Aihong, Zhou Lian. Microstructure evolution and tensile properties of Ti1023 titanium alloy during aging[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(6): 1219-1225 doi: 10.19476/j.ysxb.1004.0609.2019.06.10 [17] Ivasishin O M, Markovsky R, Semiatin S L, et al. Aging response of coarse- and fine-grained β titanium alloys[J]. Materials Science & Engineering A, 2005,405(1/2):296−305. [18] Shang Guoqiang, Kou Hongchao, Fei Yue, et al. Influence of aging processing on microstructure and mechanical properties of Ti-10V-2Fe-3Al alloy[J]. Rare Metal Materials & Engineering, 2010,39(6):1061−1065. (商国强, 寇宏超, 费跃, 等. 时效工艺对Ti-10V-2Fe-3Al合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2010,39(6):1061−1065.Shang Guoqiang, Kou Hongchao, Fei Yue, et al. Influence of aging processing on microstructure and mechanical properties of Ti-10 V-2 Fe-3 Al alloy[J]. Rare Metal Materials & Engineering, 2010, 39(6): 1061-1065 -

下载:

下载: