Study of explosive composition to mechanical properties and interfacial structure of large-sized titanium-steel clad plates

-

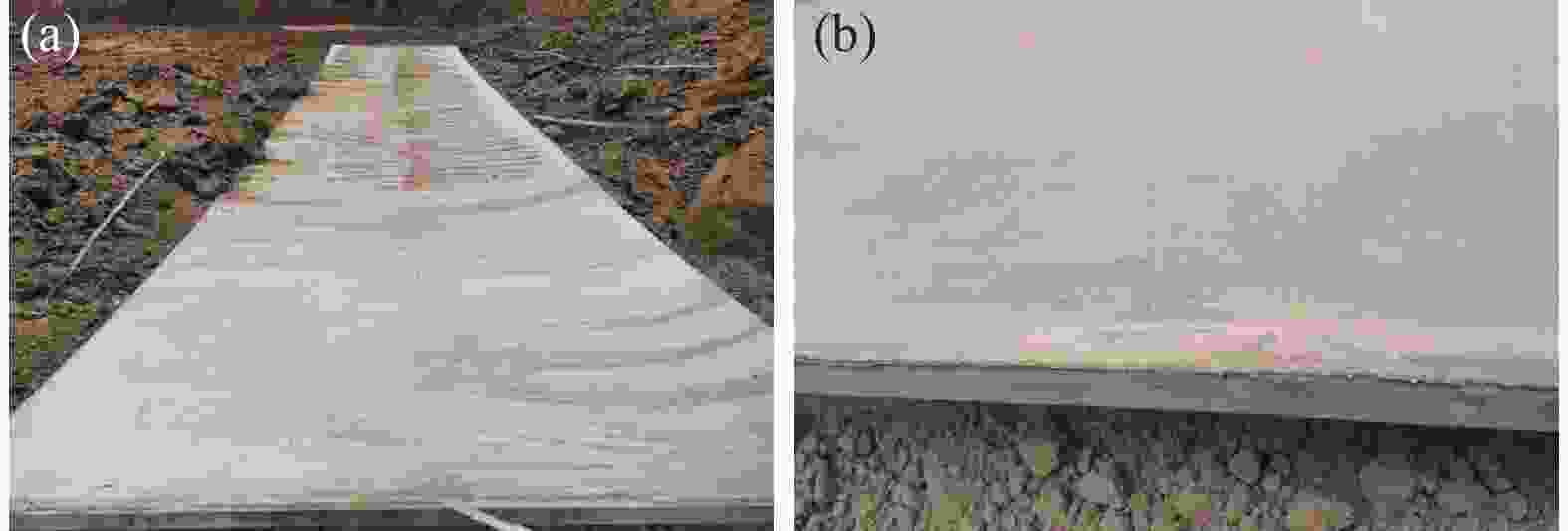

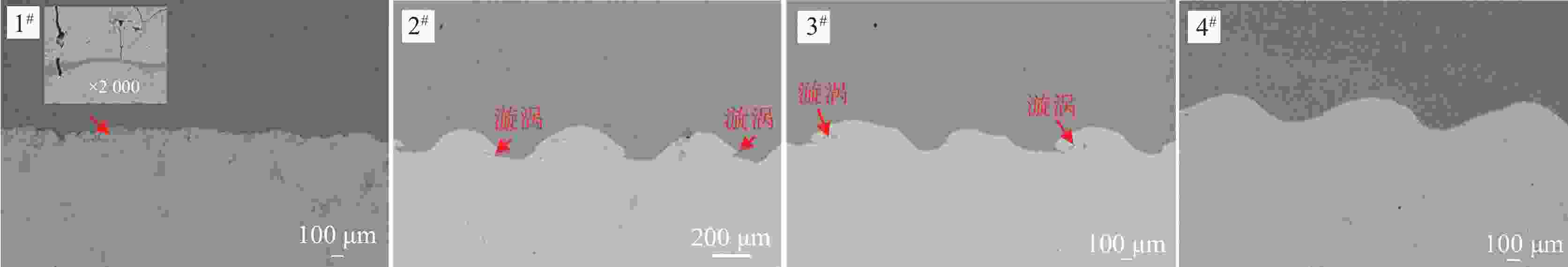

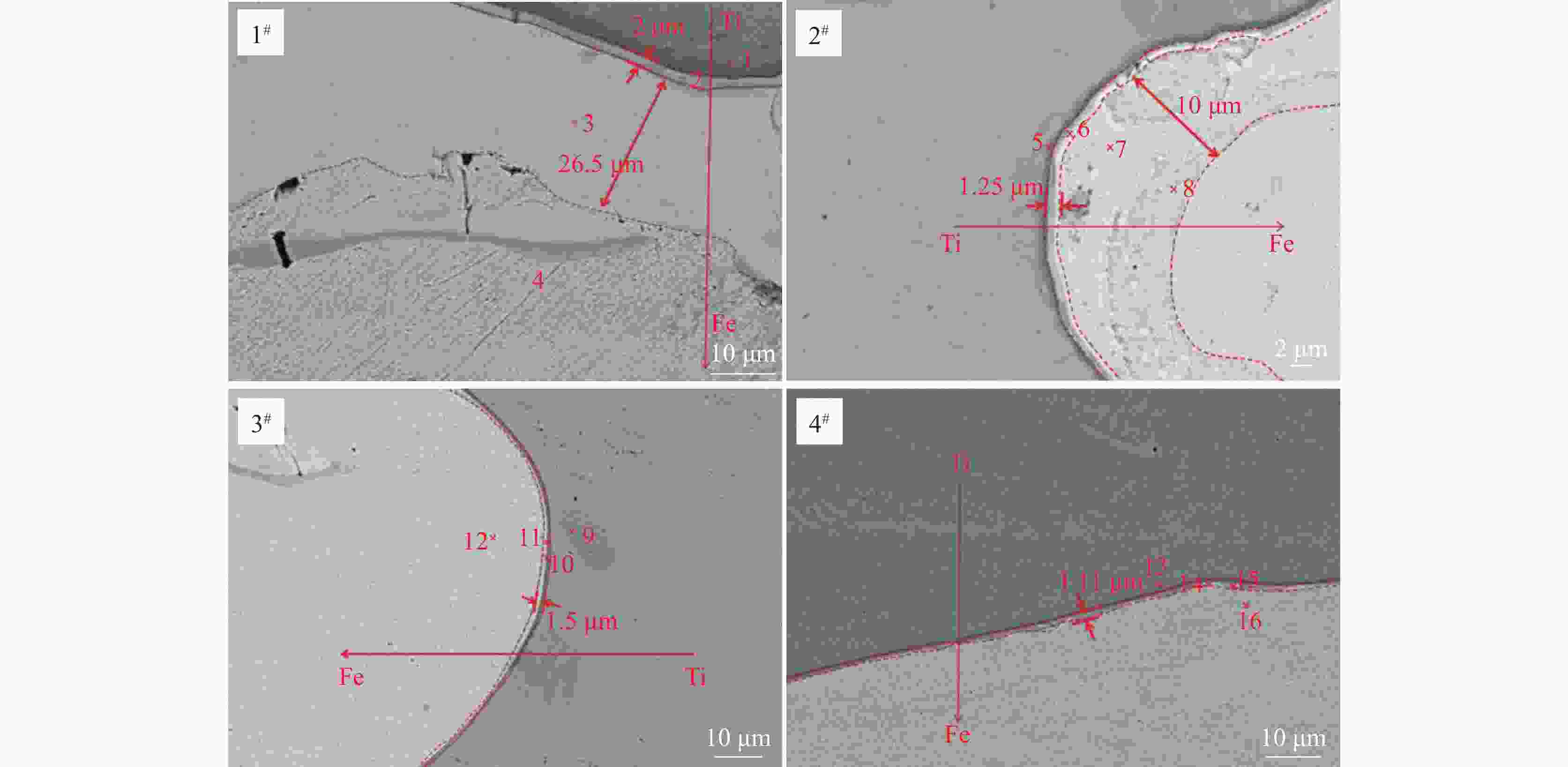

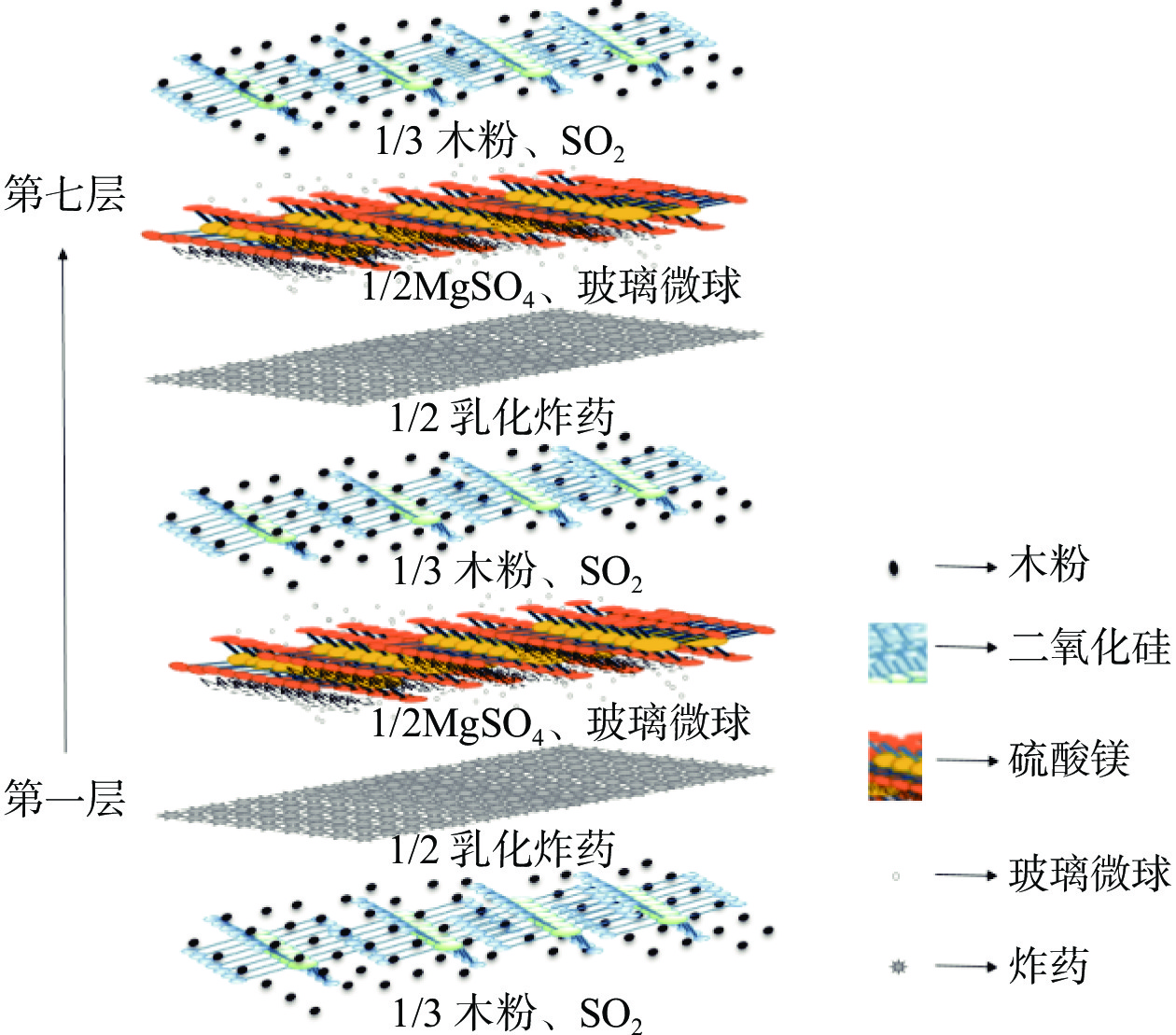

摘要: 分别以3 mm×3 m×7 m的TA2板和9 mm×3.2 m×7.2 m的Q235钢板作为覆板和基板,使用四种不同成分的炸药制备了大规格TA2/Q235钛/钢爆炸复合板,并对复合板的剪切强度以及界面组织进行了研究。结果表明,炸药的爆速、猛度和做功能力随乳化炸药含量的增多而增大。经UT检测,使用4#炸药爆炸制备的钛/钢复合板结合率接近100%;平均剪切强度最高为278 MPa。爆炸钛/钢复合板都存在一定厚度的界面层,炸药做功能力越强,界面层厚度越薄。该试验所制备的钛/钢复合板界面层厚度最薄仅为1.1 μm。爆炸钛/钢复合板界面层的形成是Ti和Fe元素互扩散的结果。扩散过程中,在高温的作用下,界面层中容易形成β-Ti、TiFe和TiFe2金属间化合物。Abstract: In this paper TA2 plate of 3 mm × 3 m × 7 m and Q235 steel plate of 9 mm × 3.2 m × 7.2 m are used as the clad plate and the base plate, respectively, large-sized TA1-Q235 titanium-steel clad plates were prepared with four different components of explosives and the shear strength and interface bonding microstructure were studied. The results show that the detonation velocity, brisance and power of explosive increases with the growing content of emulsion explosive. The ultrasonic testing (UT) results show the interface bonding rate of titanium-steel clad prepared with No.4 explosive can reach 100%, exhibiting a maximum average shear strength of 278 MPa. For explosive-welded titanium-steel clad plates, the interfacial bonding with derivative thickness related to the power of explosive. High power of explosive leads to thinner interface bonding and the thinnest interface bonding is 1.1 μm. The formation of titanium-steel clad plates is due to mutual diffusion of titanium element and steel element. With the function of high temperature, intermetallic compounds such as β-Ti, TiFe and TiFe2 are easily formed.

-

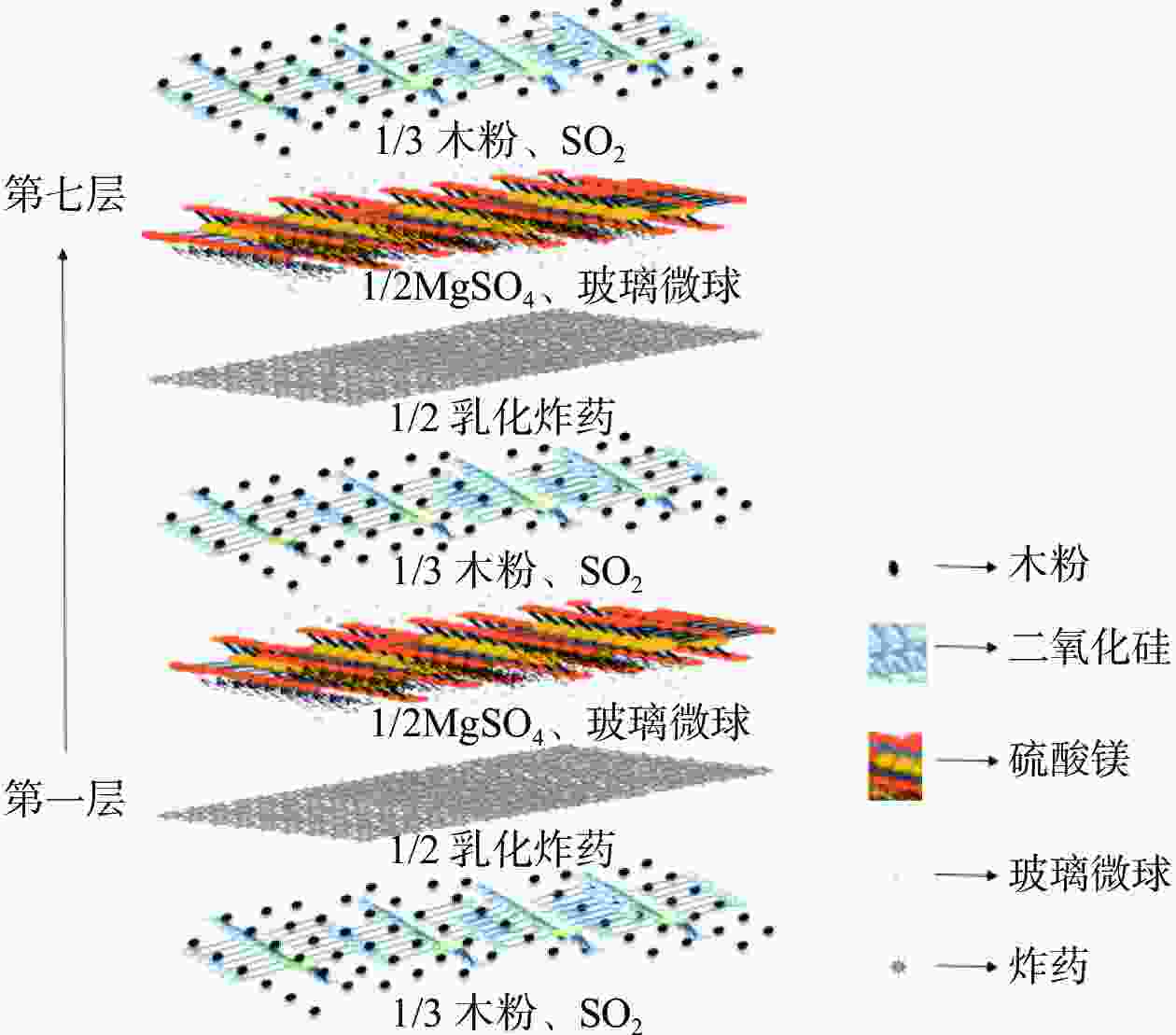

表 1 四种炸药成分

Table 1. Four different explosive compositions

炸药

编号乳化

炸药/%玻璃

微球/%硫酸

镁/%木粉/% 二氧化

硅/%1# 60 13 13 7 7 2# 65 11 11 6.5 6.5 3# 70 10 10 5 5 4# 75 8 8 4.5 4.5 表 2 炸药性能

Table 2. The properties of four different explosives

炸药编号 爆速/(m·s−1) 密度/(g·cm−3) 猛度/mm 做功能力/mL 水分/% 颗粒度/mm 流散性 1# 2050 0.75 9 180 0.30 0.25~0.60 优 2# 2160 0.72 9.5 185 0.25 0.25~0.60 优 3# 2250 0.69 9.8 190 0.35 0.25~0.60 优 4# 2400 0.60 10 199 0.34 0.25~0.60 优 表 3 四种不同配方炸药制备的钛/钢复合板剪切强度

Table 3. The shear strength of explosive-welded Ti/steel clad plates

炸药配方 剪切强度/ MPa 1 2 3 4 平均值 1# 240 265 260 250 254 2# 260 270 260 250 260 3# 290 270 260 235 264 4# 280 285 270 275 278 表 4 钛/钢复合板点扫描结果(原子分数)

Table 4. The point scanning data of Ti/steel clad plates (atom fraction)

% 元

素点1 点2 点3 点4 点5 点6 点7 点8 点9 点10 点11 点12 点13 点14 点15 点16 Ti 96.65 90.54 30.65 97.52 74.21 16.44 1.55 97.68 86.05 50.58 95.29 52.95 35.30 0.18 Fe 0.84 7.51 61.55 97.49 0.98 19.74 77.33 89.49 0.62 10.32 45.27 98.91 0.58 45.75 52.20 94.89 -

[1] Bai Yuliang, Liu Xuefeng, Wang Wenjing, et al. Current status and research trends in processing and application of titanium/stell composite plate[J]. Chinese Journal of Engineering, 2021,43(1):85−96. (白于良, 刘雪峰, 王文静, 等. 钛/钢复合板及其制备应用研究现状与发展趋势[J]. 工程科学学报, 2021,43(1):85−96. Bai Yuliang, Liu Xuefeng, Wang Wenjing, et al . Current status and research trends in processing and application of titanium/stell composite plate[J]. Chinese Journal of Engineering,2021 ,43 (1 ):85 −96 .[2] Marcin Szmul, Katarzyna Stan Glowinska, Mrta Janusz Skuza, et al. The interface zone of explosively welded titanium/steel after short term heat treatment[J]. Metallurgical and Materials Transactions A, 2021,52A:1588−1595. [3] Yang Xiaoyu, Guo Kai, Gao Yunzhe, et al. Effect of carbon content on interfacial microstructure and mechanical properties of a vacuum hot-compressed bonding titanium steel composite[J]. Materials Science and Engineering A, 2021,824:141802−1-11. doi: 10.1016/j.msea.2021.141802 [4] Han Xiaomin. Investigation on the explosive welding technology and its micrstructure and property of titanium-steel composite plate[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016. (韩小敏. 钛-钢复合板爆炸焊接工艺及组织与性能研究[D]. 南京航天航空大学, 2016.Han Xiaomin. Investigation on the explosive welding technology and its micrstructure and property of titanium-steel composite plate[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016. [5] Li Boxin. Interfacial structure and regulation of microstructure and properties in Ti/steel clas plate[D]. Chongqing: Chongqing University, 2019. (李博新. 钛/钢复合板界面结构及其组织性能调控[D]. 重庆大学, 2019.Li Boxin. Interfacial structure and regulation of microstructure and properties in Ti/steel clas plate[D]. Chongqing: Chongqing University, 2019. [6] Chai Xiyang, Shi Zhongran, Chai Feng, et al. Effect of heating temperature on microstructure and mechanical properties of titanium clad steel by hot roll bonding[J]. Rare Metal Materials and Engineering, 2019,48(8):2701−2710. (柴希阳, 师仲然, 柴锋, 等. 加热温度对轧制钛/钢复合板组织与性能的影响[J]. 稀有金属材料与工程, 2019,48(8):2701−2710. Chai Xiyang, Shi Zhongran, Chai Feng, et al . Effect of heating temperature on microstructure and mechanical properties of titanium clad steel by hot roll bonding[J]. Rare Metal Materials and Engineering,2019 ,48 (8 ):2701 −2710 .[7] Luo Zong’an, Yang Dehan, Xie Guangming, et al. Production process and performance of titanium-steel vacuum roll-cladding plates[J]. Journal of Iron and Steel Research, 2019,31(2):213−220. (骆宗安, 杨德翰, 谢广明, 等. 真空制坯热轧钛/钢复合板工艺及性能[J]. 钢铁研究学报, 2019,31(2):213−220. Luo Zong’an, Yang Dehan, Xie Guangming, et al . Production process and performance of titanium-steel vacuum roll-cladding plates[J]. Journal of Iron and Steel Research,2019 ,31 (2 ):213 −220 .[8] Kumar R R, Gupta R K, Sarkar A, et al. Vacuum diffusion bonding of alpha-titanium alloy to stainless steel for aerospace applications: Interfacial microstructure and mechanical characteristics[J]. Materials Characterization, 2022,183:111607−111607. doi: 10.1016/j.matchar.2021.111607 [9] Kundu S, Sam S, Mishra B, et al. Diffusion bonding of microduplex stainless steel and Ti alloy with and without interlayer: interface microstructure and strength properties[J]. Metall Mater Trans A, 2014,45(1):317. doi: 10.1007/s11661-013-1972-8 [10] Xu Zhefeng. Research progress of titanium steel composite plate prepared by hot pressing diffusion method[J]. Hot Working Technology, 2017,46(10):14−17. (许哲峰. 热压扩散法制备钛钢复合板的研究进展[J]. 热加工工艺, 2017,46(10):14−17. Xu Zhefeng . Research progress of titanium steel composite plate prepared by hot pressing diffusion method[J]. Hot Working Technology,2017 ,46 (10 ):14 −17 .[11] Wu Jiangtao, Wang Hunian, Wang Yunlong, et al. Research on relationship between shearing strength and interface wave amplitude ration of titanium clad plate[J]. Hot Working Technology, 2013,42(1):12−13. (吴江涛, 王虎年, 王云龙, 等. 钛/钢爆炸复合板界面波幅比与剪切强度关系研究[J]. 热加工工艺, 2013,42(1):12−13. Wu Jiangtao, Wang Hunian, Wang Yunlong, et al . Research on relationship between shearing strength and interface wave amplitude ration of titanium clad plate[J]. Hot Working Technology,2013 ,42 (1 ):12 −13 . -

下载:

下载: