Study on calcification reduction sodium removal of vanadium extraction tailings by coal-based rotary kiln method

-

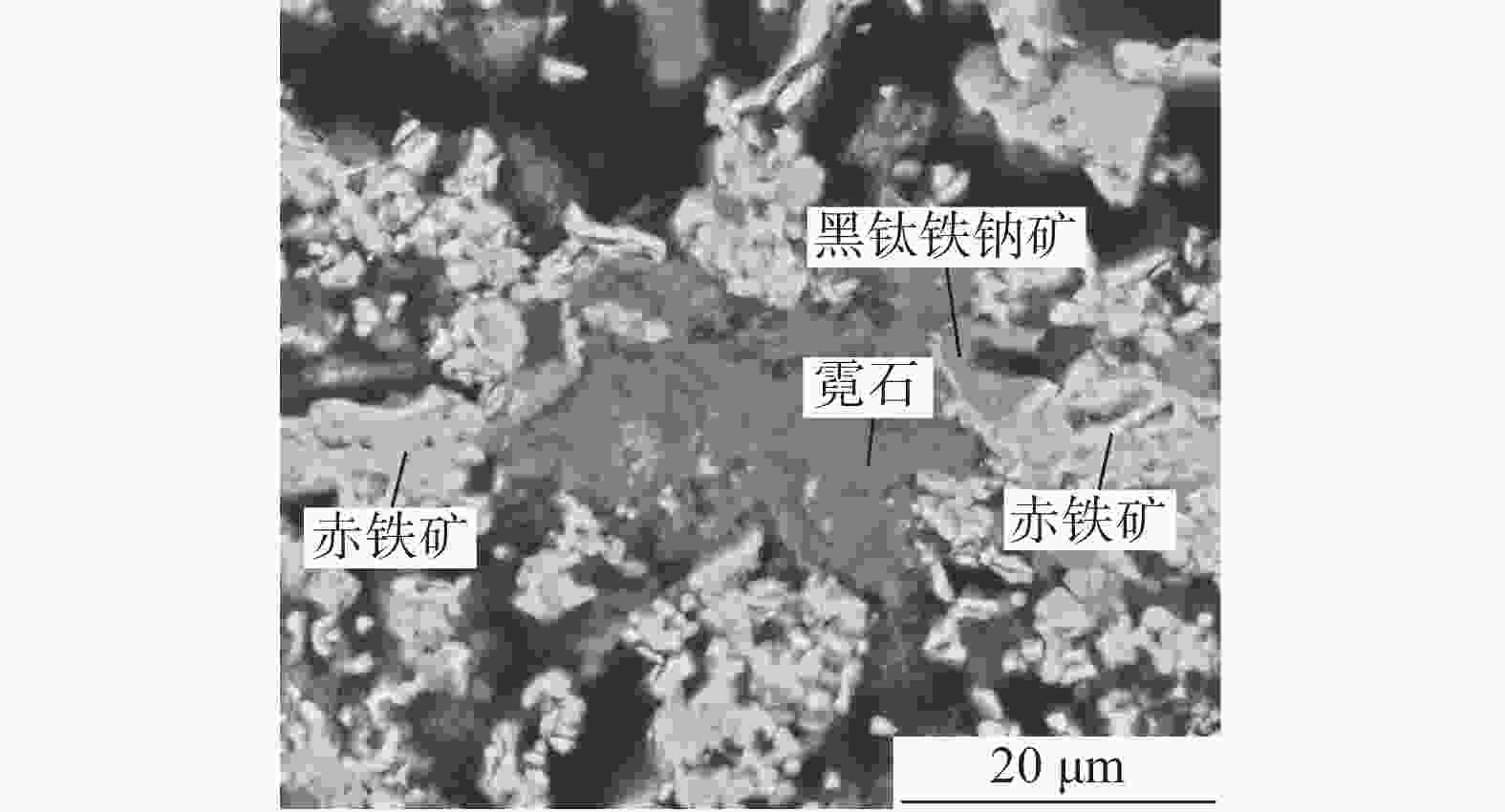

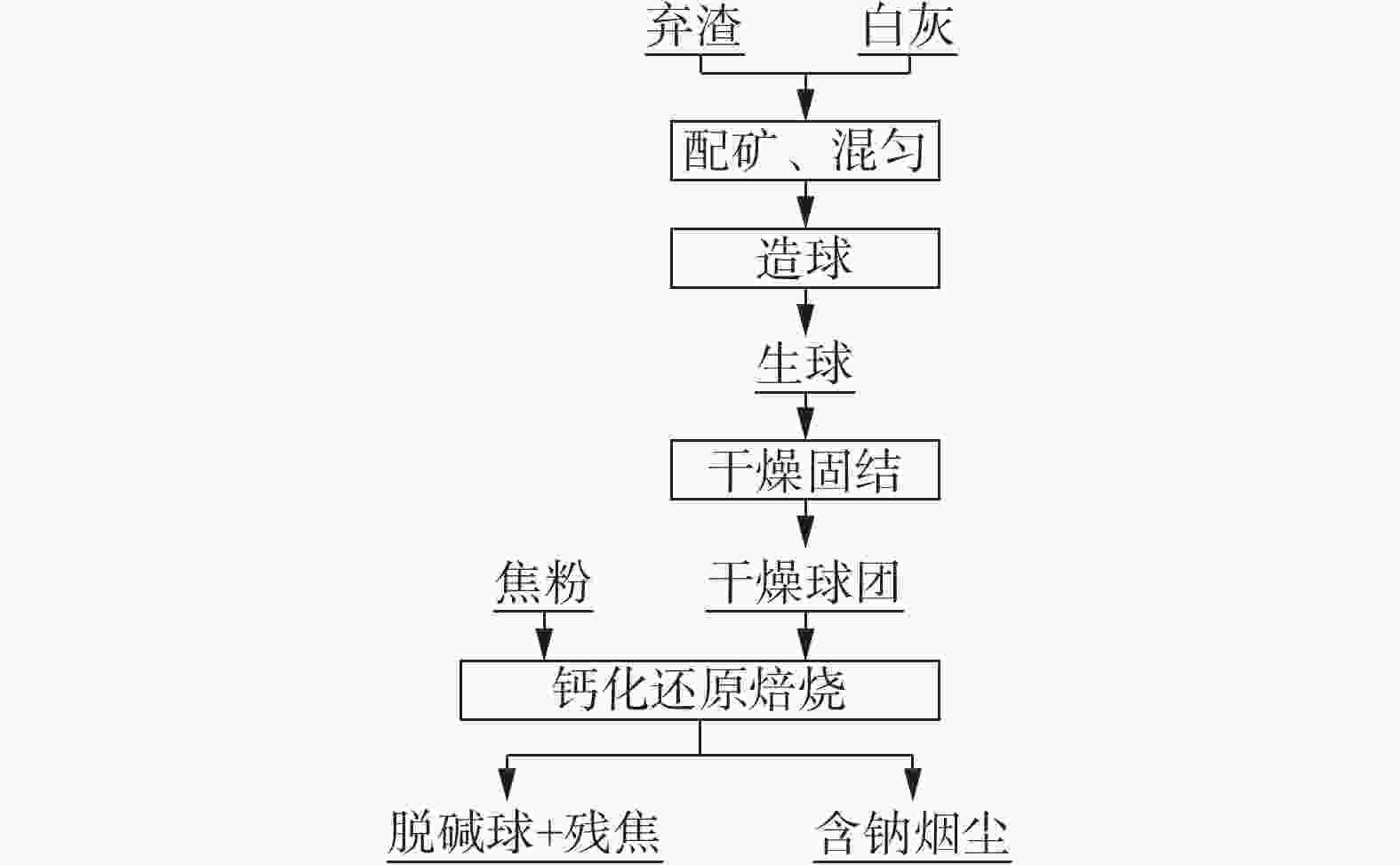

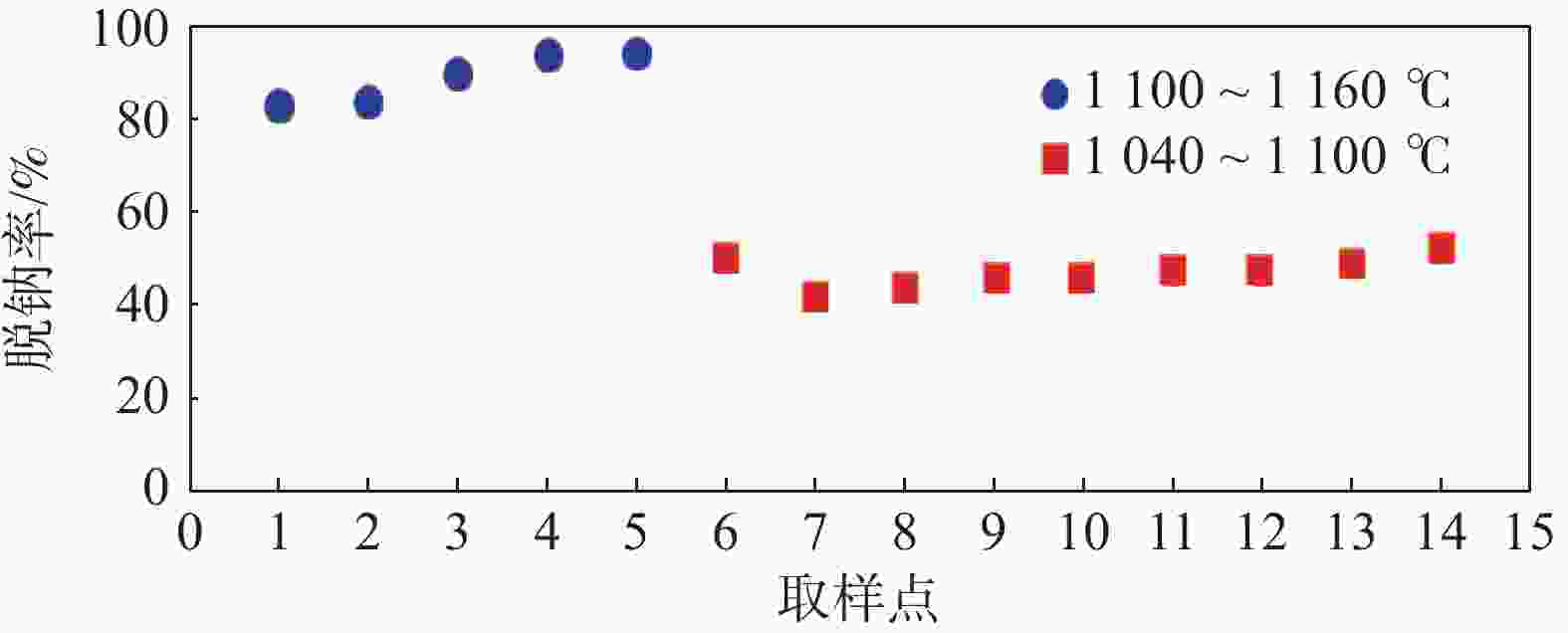

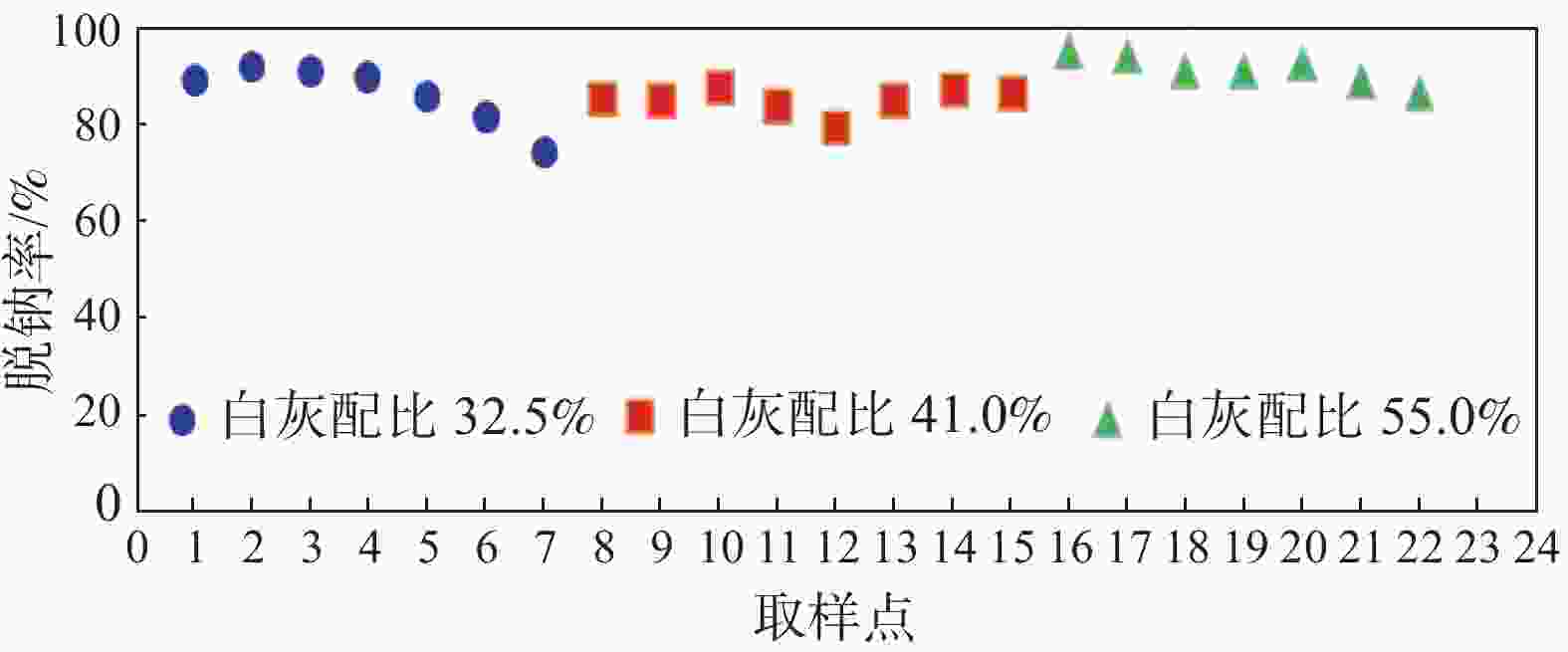

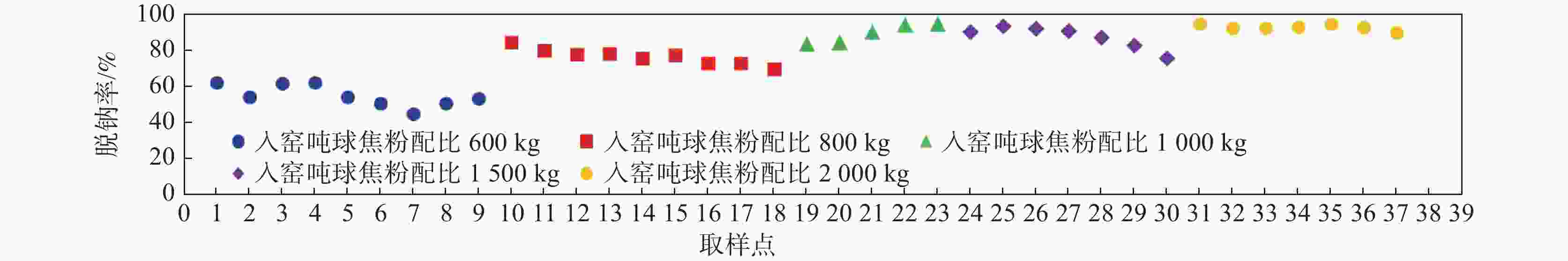

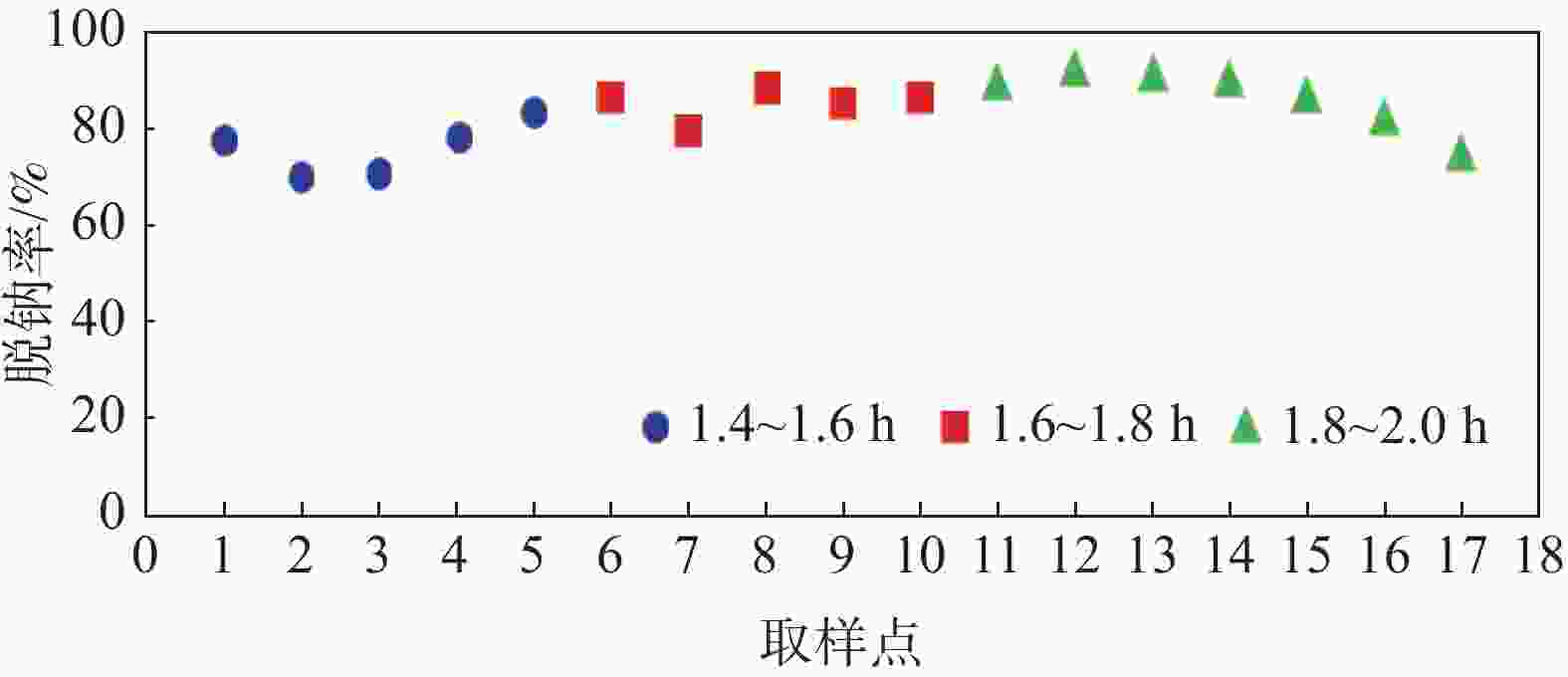

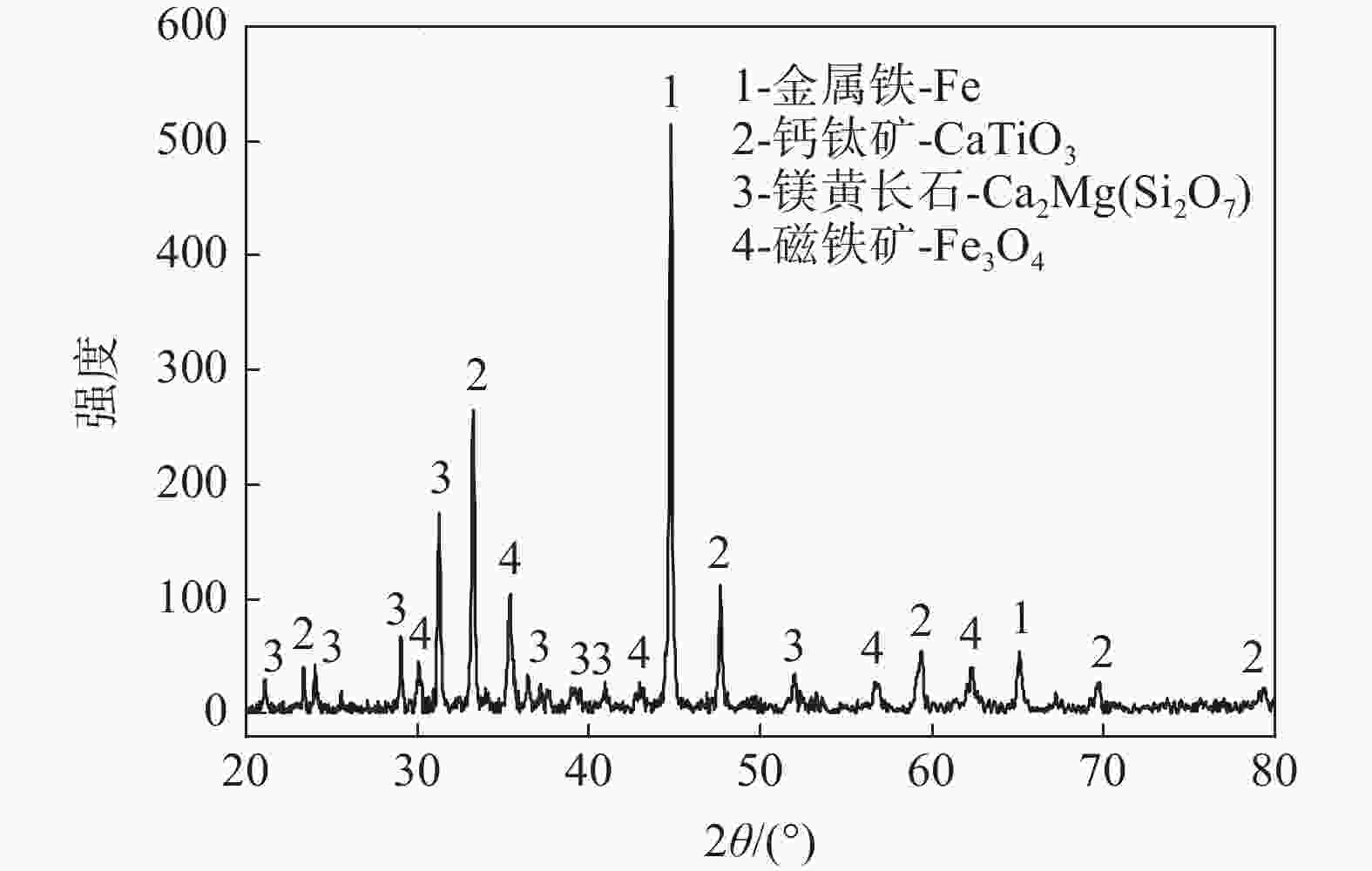

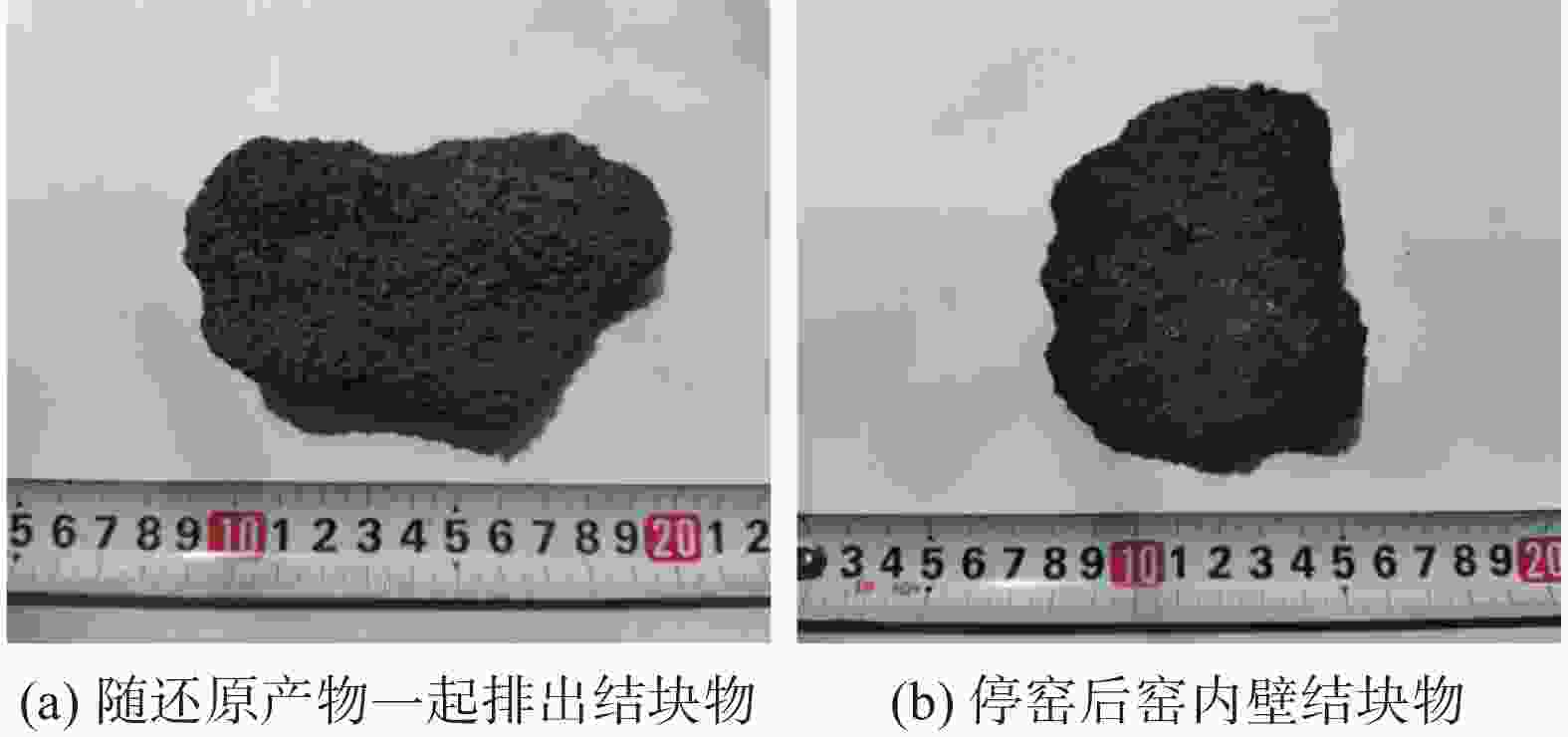

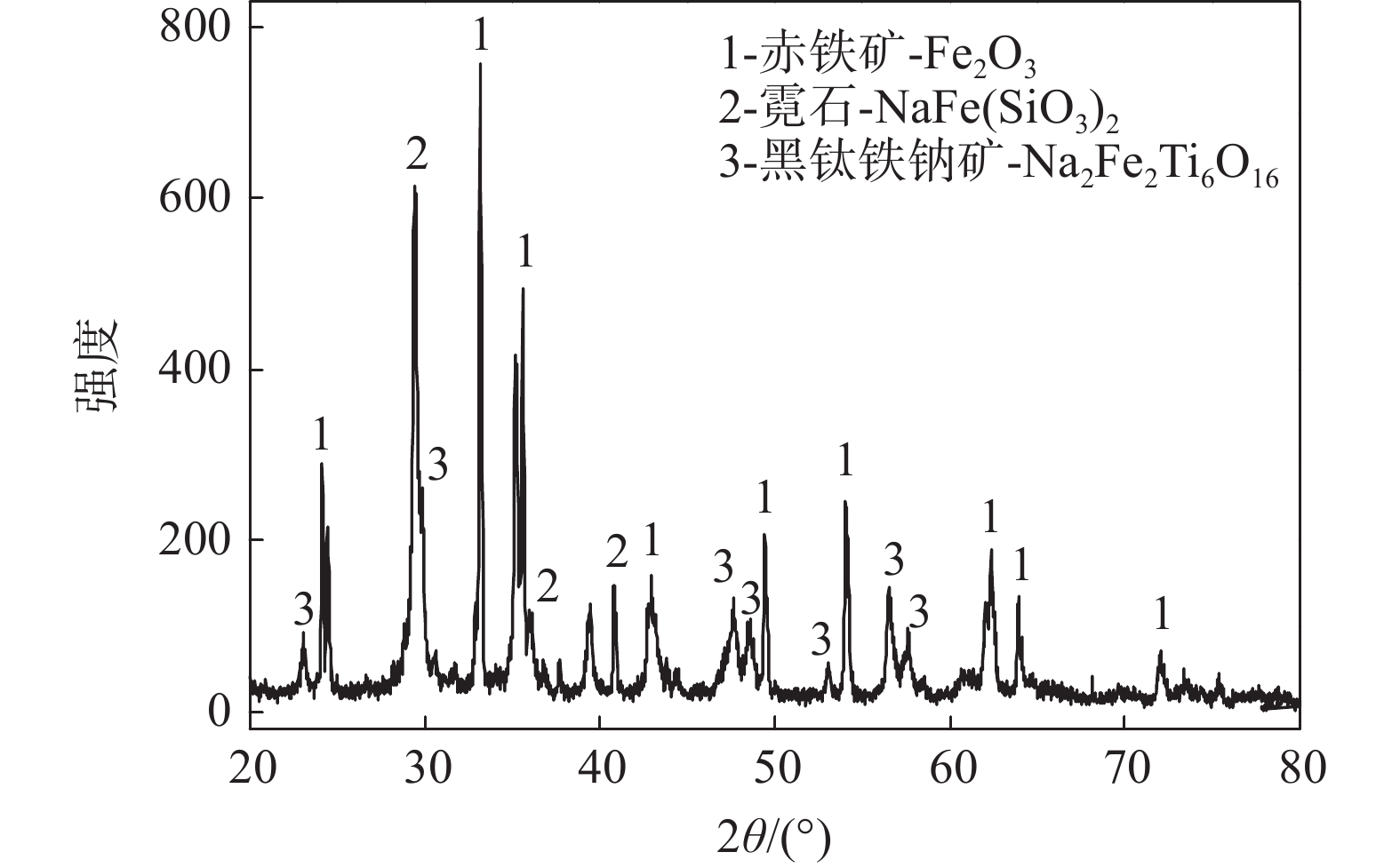

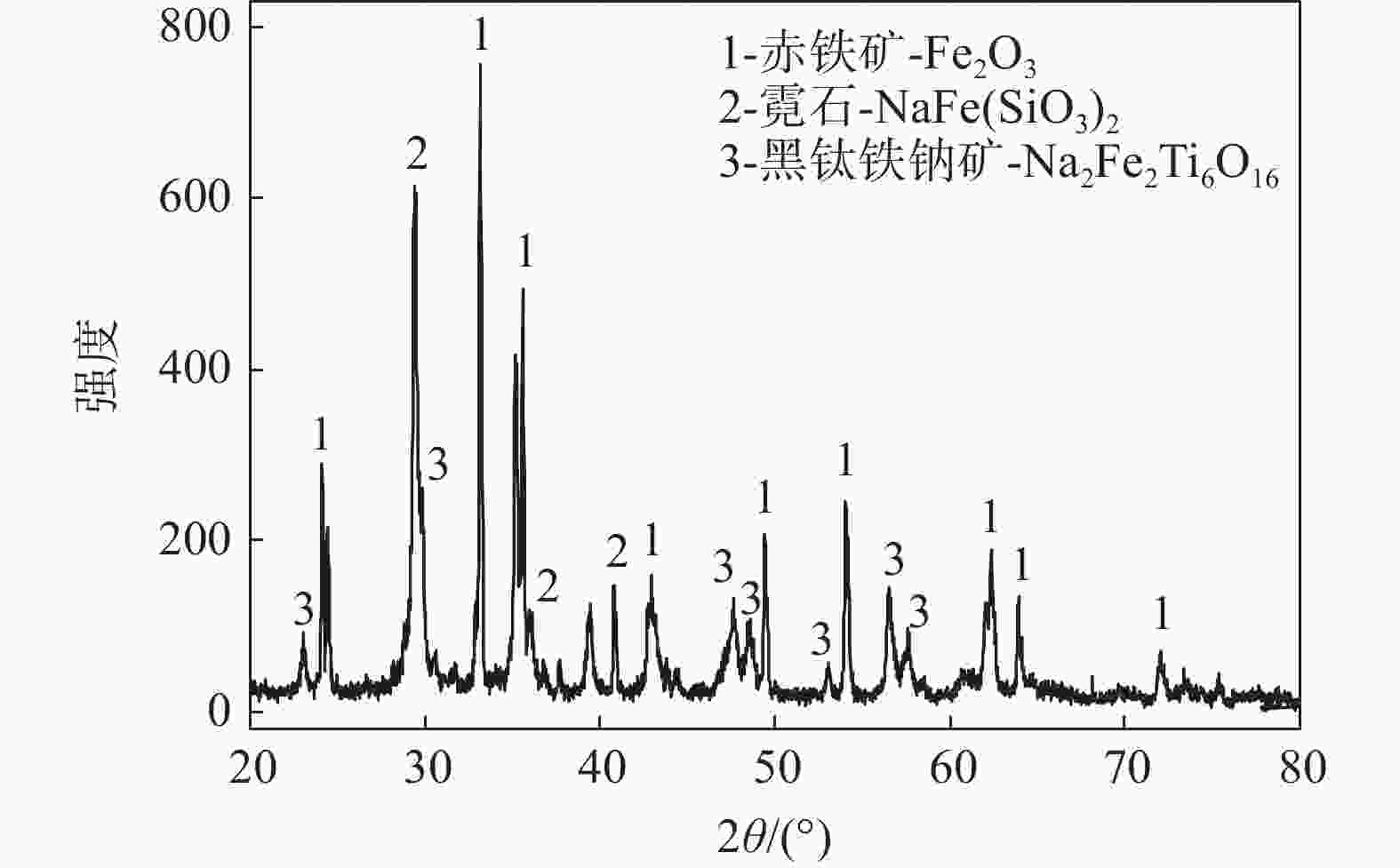

摘要: 针对提钒尾渣中钠含量高,导致难以返回烧结-高炉流程进行回收利用的问题,提出基于煤基回转窑还原的提钒尾渣钙化还原脱钠技术路线,并在Ø1 m×10 m回转窑中试线进行半工业试验,主要研究了高温段还原温度、白灰配比、入窑吨球焦粉配比、高温还原时间对提钒尾渣脱钠的影响规律,同时对脱钠后球团性能和回转窑结窑情况进行分析。结果表明,在高温段温度为1100~1160 ℃,高温段时间为1.8~2 h,入窑吨球焦粉配比为800~1000 kg,白灰配比为32.5%~41%的条件下,提钒尾渣脱钠率可达到80%以上,吨球焦粉实际消耗量为359 kg。窑内结块物主要由提钒尾渣球团粉末和焦粉灰分粉末组成,结块物呈疏松多孔状,由细颗粒相互粘结构成,窑转动过程会自动掉落,无明显结窑现象。Abstract: In view of the high sodium content in vanadium extraction tailings, which leads to the difficulty of returning to the sintering-blast furnace process for recycling, herein we proposed a calcification reduction sodium removal technology route for vanadium extraction tailings based on coal-based rotary kiln reduction, and conducted a semi-industrial test on a Ø1 m×10 m rotary kiln pilot line. The influence of reduction time in the high temperature section, white ash ratio, into the kiln ton-ball coke ratio and high temperature reduction time on vanadium extraction tailings sodium removal was mainly studied. At the same time, the performance of pellets after desalination and the situation of kiln formation in the rotary kiln were analyzed. Under the conditions of high temperature section temperature of 1100~1160 ℃, high temperature section time of 1.8~2 h, into the kiln ton-ball coke ratio of 800~1000 kg, white ash ratio of 32.5%~41%, the sodium removal rate of vanadium extraction tailings can reach more than 80%, and the coke consumption is 359 kg. The agglomeration in the kiln is mainly composed of vanadium extraction tailings pellet powder and coke ash powder. The agglomeration is loose and porous, consisting of fine particles which are sticky to each other. The agglomeration will fall off automatically during the kiln rotation process, without obvious kiln formation phenomenon.

-

表 1 提钒尾渣主要化学成分

Table 1. Main chemical composition of vanadium extraction tailing

% Na2O K2O TFe SiO2 TiO2 Al2O3 CaO MgO V2O5 4.85 0.016 32.32 13.64 11.92 2.78 1.88 1.69 1.34 表 2 脱钠球团主要成分

Table 2. Main composition of desalination pellets

% Na2O K2O MFe TFe SiO2 TiO2 Al2O3 CaO MgO V2O5 0.47 未检出 20.54 24.95 10.44 8.93 2.16 26.88 2.69 1.84 表 3 结窑物关键元素含量

Table 3. Key element content of agglomerate

% 样品 Fe Ca Mg Al Si Na 随窑排出 11.26 9.68 1.58 4.85 6.47 1.39 内壁附着 11.35 9.24 1.95 5.05 7.12 1.11 -

[1] Wang Guang, Diao Jiang, Liu Liang, et al. Production of high-carbon ferrochromium by carbothermal reduction of vanadium extraction tailings with high chromium content [C]//11th International Symposium on High-Temperature Metallurgical Processing, 2020: 823-833. [2] Wang Xin, Xiang Junyi, Ling Jiawei, et al. Comprehensive utilization of vanadium extraction tailings: A brief review [C]//Energy Technology 2020: Recycling, Carbon Dioxide Management and Other Technologies, 2020: 327-334. [3] Moskalyk R R , Alfantazi A M. Processing of vanadium: a review [J]. Minerals Engineering, 2003, 16 (9): 793-805. [4] Li Lanjie, Zhao Beibei, Wang Haixu, et al. The process of high efficiency dealkalization and ore blending in ironmaking of the extracted vanadium residue[J]. The Chinese Journal of Process Engineering, 2017,17(1):138−143. (李兰杰, 赵备备, 王海旭, 等. 提钒尾渣高效脱碱及配矿炼铁工艺[J]. 过程工程学报, 2017,17(1):138−143. Li Lanjie, Zhao Beibei, Wang Haixu, et al . The process of high efficiency dealkalization and ore blending in ironmaking of the extracted vanadium residue[J]. The Chinese Journal of Process Engineering,2017 ,17 (1 ):138 −143. [5] Monakhov I , Khromov S , Chernousov P. The flow of vanadium-bearing materials in industry[J]. Metallurgist, 2004, 48(7-8): 381-385. [6] Deng Rongrui, Xiao Hao, Xie Zhaoming, et al. A novel method for extracting vanadium by low temperature sodium roasting from converter vanadium slag[J]. Chinese J. Chem. Eng., 2020,28:2208−2213. doi: 10.1016/j.cjche.2020.03.038 [7] Xiang Junyi, Huang Qingyun, Lv Wei, et al. Recovery of tailings from the vanadium extraction process by carbothermic reduction method: Thermodynamic, experimental and hazardous potential assessment[J]. Journal of Hazardous Materials, 2018,357(5):128−137. [8] Liu Shiyuan, Zhen Yulan, He Xiaobo, et al. Recovery and separation of Fe and Mn from simulated chlorinated vanadium slag by molten salt electrolysis[J]. International Journal of Minerals Metallurgy and Materials, 2020,27(12):1678−1686. doi: 10.1007/s12613-020-2140-y [9] Hao Jianzhang, Liu Anqiang, Ma Minglong. Research on the properties of far infrared coatings from vanadium extraction tailings[J]. Paint Coatings Industry, 2009(9):13−15. (郝建璋, 刘安强, 马明龙. 提钒尾渣远红外涂料性能研究[J]. 涂料工业, 2009(9):13−15. Hao Jianzhang, Liu Anqiang, Ma Minglong . Research on the properties of far infrared coatings from vanadium extraction tailings[J]. Paint Coatings Industry,2009 (9 ):13 −15. [10] Xiu Dapeng, Wang Qichun, Yang Yuguo, et al. Techniques of making vanadium and titanium black porcelain and its appllcation in modern industry[J]. China Ceramics, 2008,44(4):41−43. (修大鹏, 王启春, 杨玉国, 等. 钒钛黑瓷的制造工艺及其在现代工业中的应用[J]. 中国陶瓷, 2008,44(4):41−43. Xiu Dapeng, Wang Qichun, Yang Yuguo, et al . Techniques of making vanadium and titanium black porcelain and its appllcation in modern industry[J]. China Ceramics,2008 ,44 (4 ):41 −43. [11] Yang Shaoli, Ma Lan, Liu Jinfeng, et al. Prospect of researching and developing vanadium functional materials using vanadium resources in Panxi area[J]. Iron Steel Vanadium Titanium, 2016,37(2):84−91. (杨绍利, 马兰, 刘金凤, 等. 利用攀西钒资源研究开发钒功能材料展望[J]. 钢铁钒钛, 2016,37(2):84−91. Yang Shaoli, Ma Lan, Liu Jinfeng, et al . Prospect of researching and developing vanadium functional materials using vanadium resources in Panxi area[J]. Iron Steel Vanadium Titanium,2016 ,37 (2 ):84 −91. [12] Wei Bo, Zhang Yimin, Bao Shenxu. Preparation of geopolymers from vanadium tailings by mechanical activation[J]. Construction and Building Materials, 2017,145:236−242. doi: 10.1016/j.conbuildmat.2017.03.234 [13] Li Lanjie, Chen Donghui, Bai Ruiguo. Leaching of vanadium from vanadium-containing residue by NaOH sub-molten salt[J]. The Chinese Journal of Process Engineering, 2011,11(5):747−754. (李兰杰, 陈东辉, 白瑞国. 含钒尾渣NaOH亚熔盐浸出提钒[J]. 过程工程学报, 2011,11(5):747−754. Li Lanjie, Chen Donghui, Bai Ruiguo . Leaching of vanadium from vanadium-containing residue by NaOH sub-molten salt[J]. The Chinese Journal of Process Engineering,2011 ,11 (5 ):747 −754. [14] Ge Huaiwen, Wei Chang, Fan Gang, et al. Pathbreaking experimentation study of a new leaching technology of extracted vanadium residue by acid leaching under oxygen pressure[J]. Shanxi Metallurgy, 2008(6):17−19. (葛怀文, 魏昶, 樊刚, 等. 提钒尾渣加压酸浸取钒新工艺探索实验[J]. 山西冶金, 2008(6):17−19. Ge Huaiwen, Wei Chang, Fan Gang, et al . Pathbreaking experimentation study of a new leaching technology of extracted vanadium residue by acid leaching under oxygen pressure[J]. Shanxi Metallurgy,2008 (6 ):17 −19. [15] Fan Gang, Wei Chang, Ge Huaiwen. Vanadium recovery from extracted vanadium residue by atmospheric pressure acid leaching[J]. Nonferrous Metals Engineering, 2010,62(4):65−68. (樊刚, 魏昶, 葛怀文. 提钒尾渣常压酸浸提钒[J]. 有色金属工程, 2010,62(4):65−68. doi: 10.3969/j.issn.2095-1744.2010.04.017 Fan Gang, Wei Chang, Ge Huaiwen . Vanadium recovery from extracted vanadium residue by atmospheric pressure acid leaching[J]. Nonferrous Metals Engineering,2010 ,62 (4 ):65 −68. doi: 10.3969/j.issn.2095-1744.2010.04.017[16] Zhang Ying, Zhang Ting’an, David Dreisinger, et al. Recovery of vanadium from calcification roasted-acid leaching tailing by enhanced acid leaching[J]. Journal of Hazardous Materials, 2019,369(5):632−641. [17] Li Lanjie. Fundamental applied research on resource utilization of vanadium tailings[D]. Shenyang: Northeastern University, 2013: 196. (李兰杰. 提钒尾渣资源化利用应用基础研究[D]. 沈阳: 东北大学, 2013: 196.Li Lanjie. Fundamental applied research on resource utilization of vanadium tailings[D]. Shenyang: Northeastern University, 2013: 196. -

下载:

下载: