Experimental and simulation on the granulation process of blast furnace slag

-

摘要: 重点介绍了干式粒化工艺中的离心粒化工艺和气淬粒化工艺,由于高炉熔渣的粒化破碎是高温瞬态过程,只通过试验的手段难以监测,因此从试验和数值仿真两方面研究了干式粒化工艺的发展和应用现状。通过对两种工艺的总结和比较,认为气淬粒化工艺具有粒化效果好、处理渣量大等优点,从行业发展和工业化应用的角度来看,是未来匹配大型高炉生产过程最具发展前景的干式粒化工艺。Abstract: Emphasis was placed on the centrifugal granulation process and gas quenching granulation process during the dry granulation process. Due to the high-temperature transient process of granulation and crushing of blast furnace slag, it is difficult to monitor its specific change process solely through experimental means. Therefore, the development and application status of dry granulation process are studied from both experimental and numerical simulation perspectives. Through the summary and comparison of the two processes, the gas quenching granulation process has the advantages in good granulation effect and large slag handling capacity. From the perspective of industry development and industrial application, the gas quenching granulation process is the most promising dry granulation process in the future to match large blast furnace production processes.

-

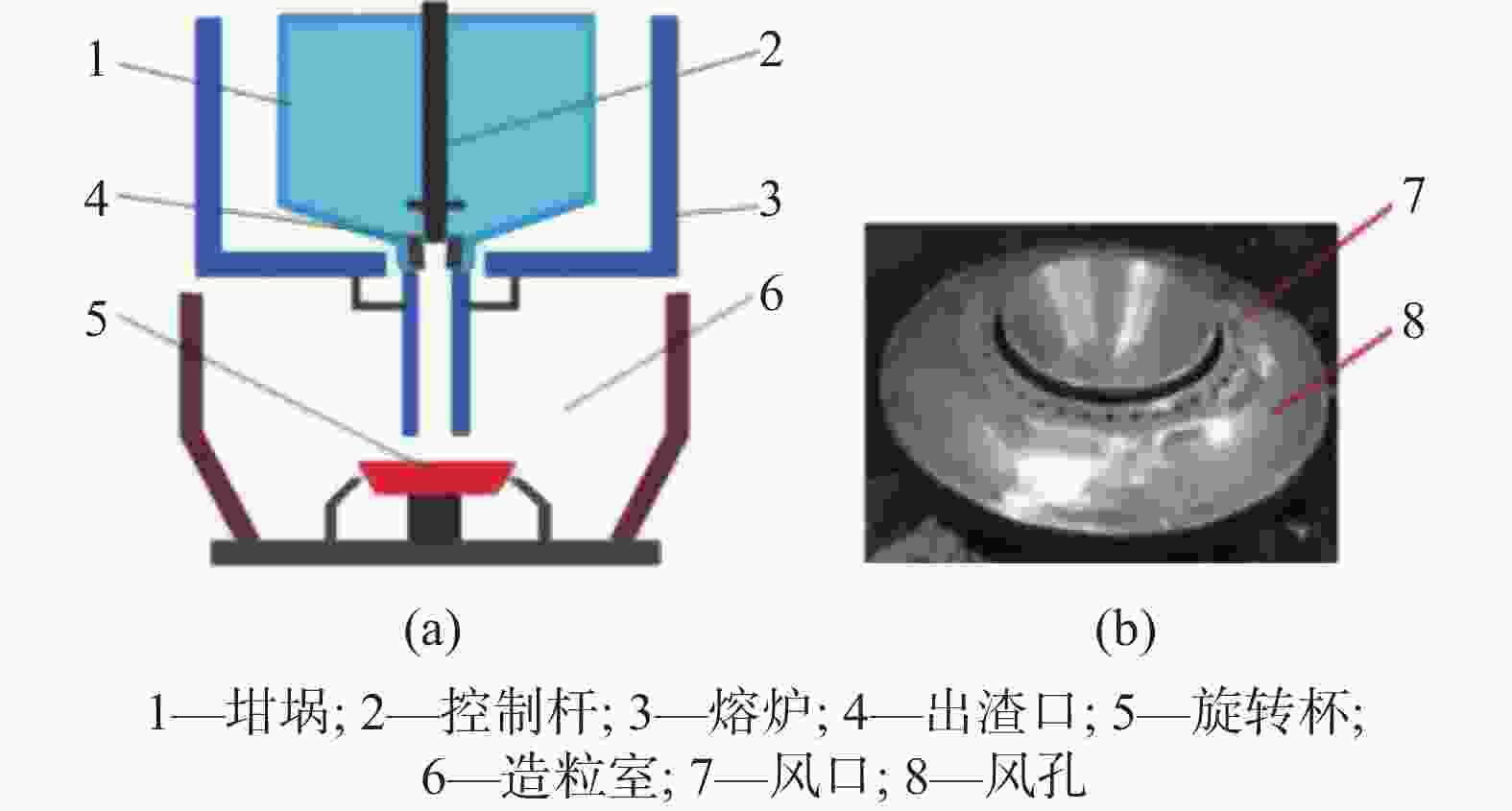

图 1 BSC转杯法粒化装置[13]

Figure 1. BSC rotary cup granulation device

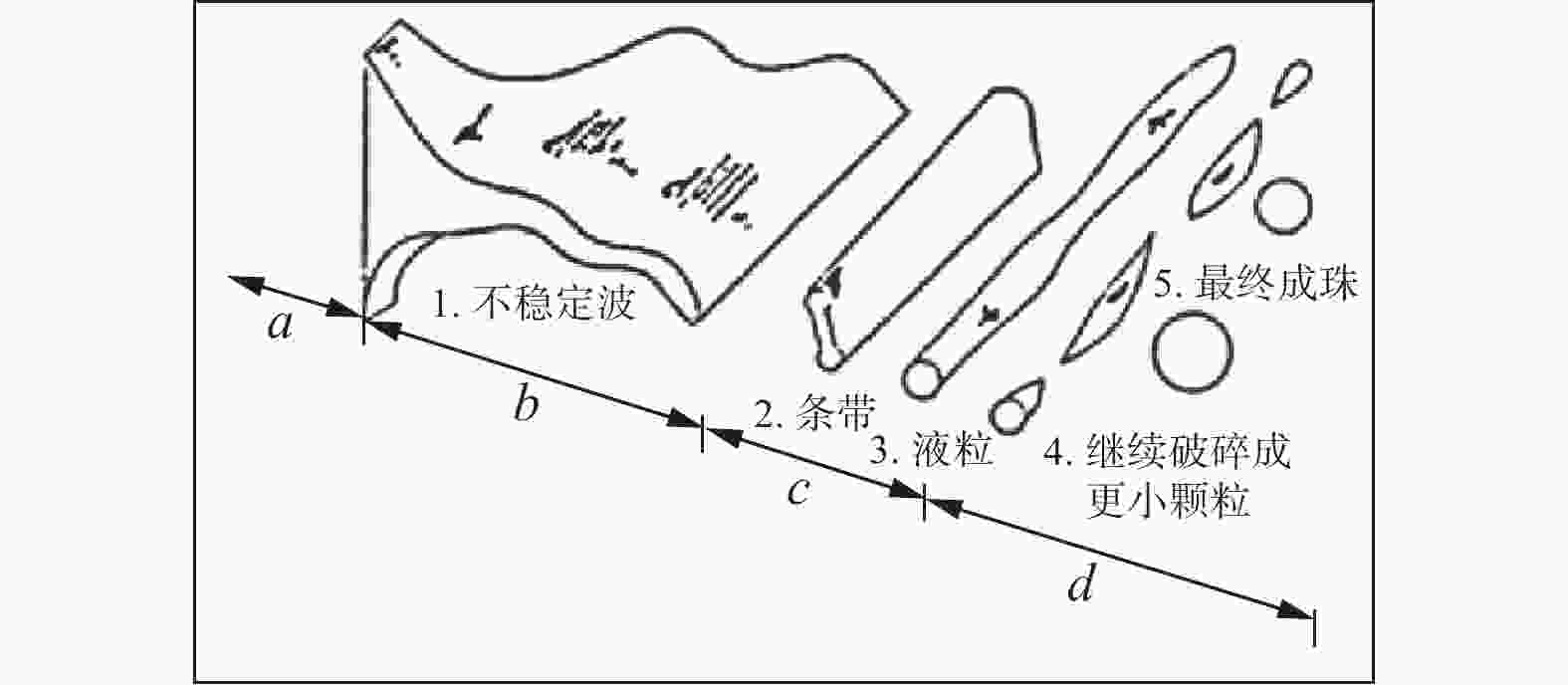

图 2 丝状模式下的粒化破碎[17]

Figure 2. Granulation and fragmentation in filamentous mode

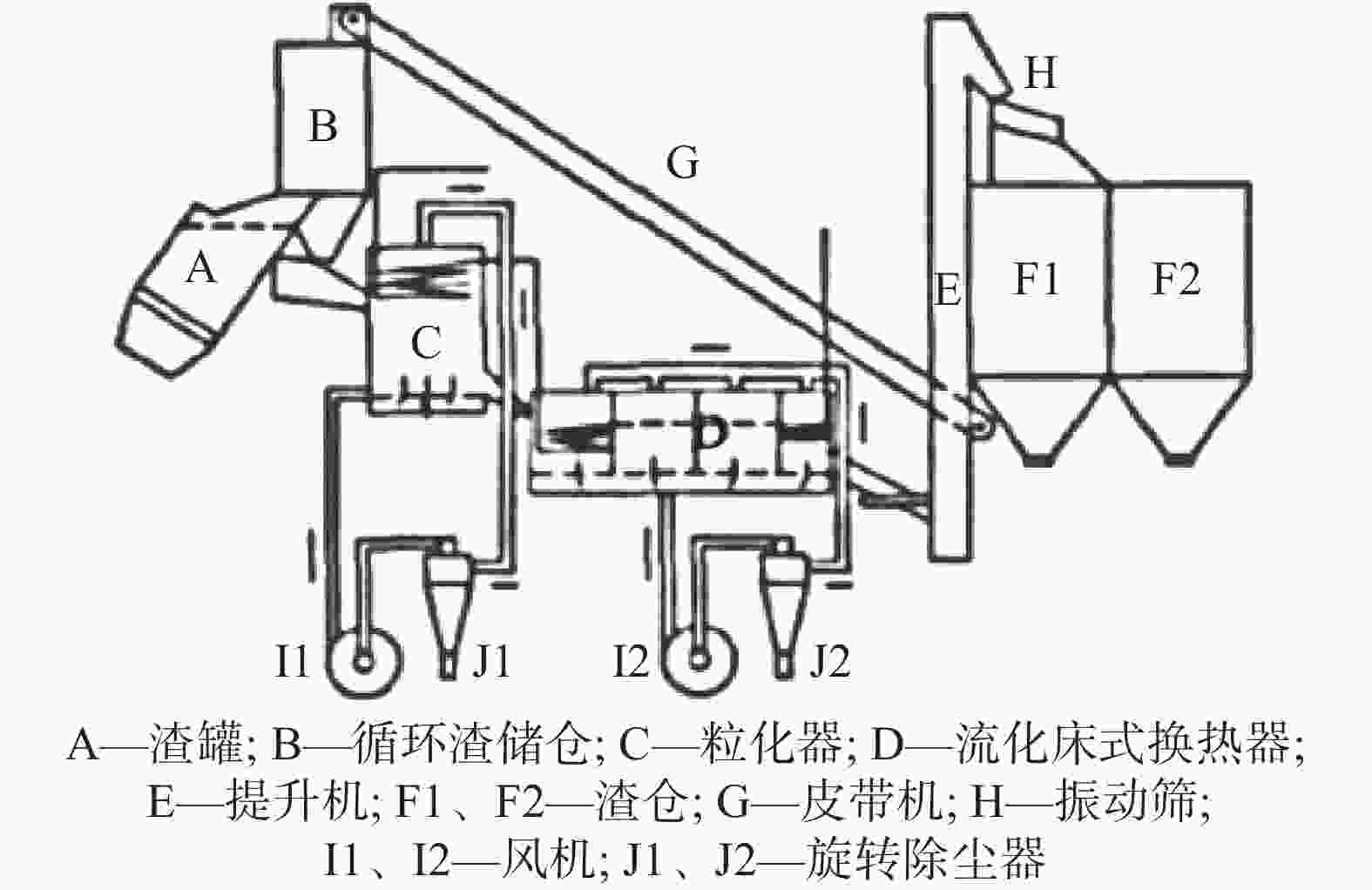

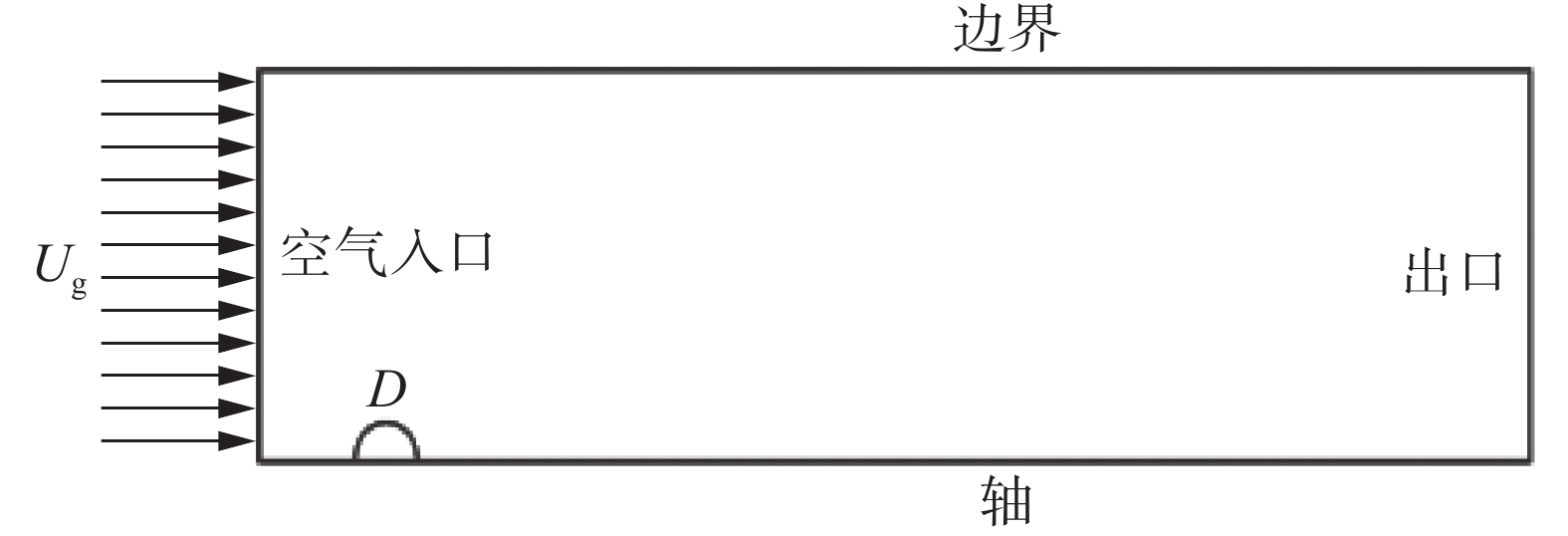

图 3 试验装置示意[21]

Figure 3. Schematic diagram of the experimental equipment

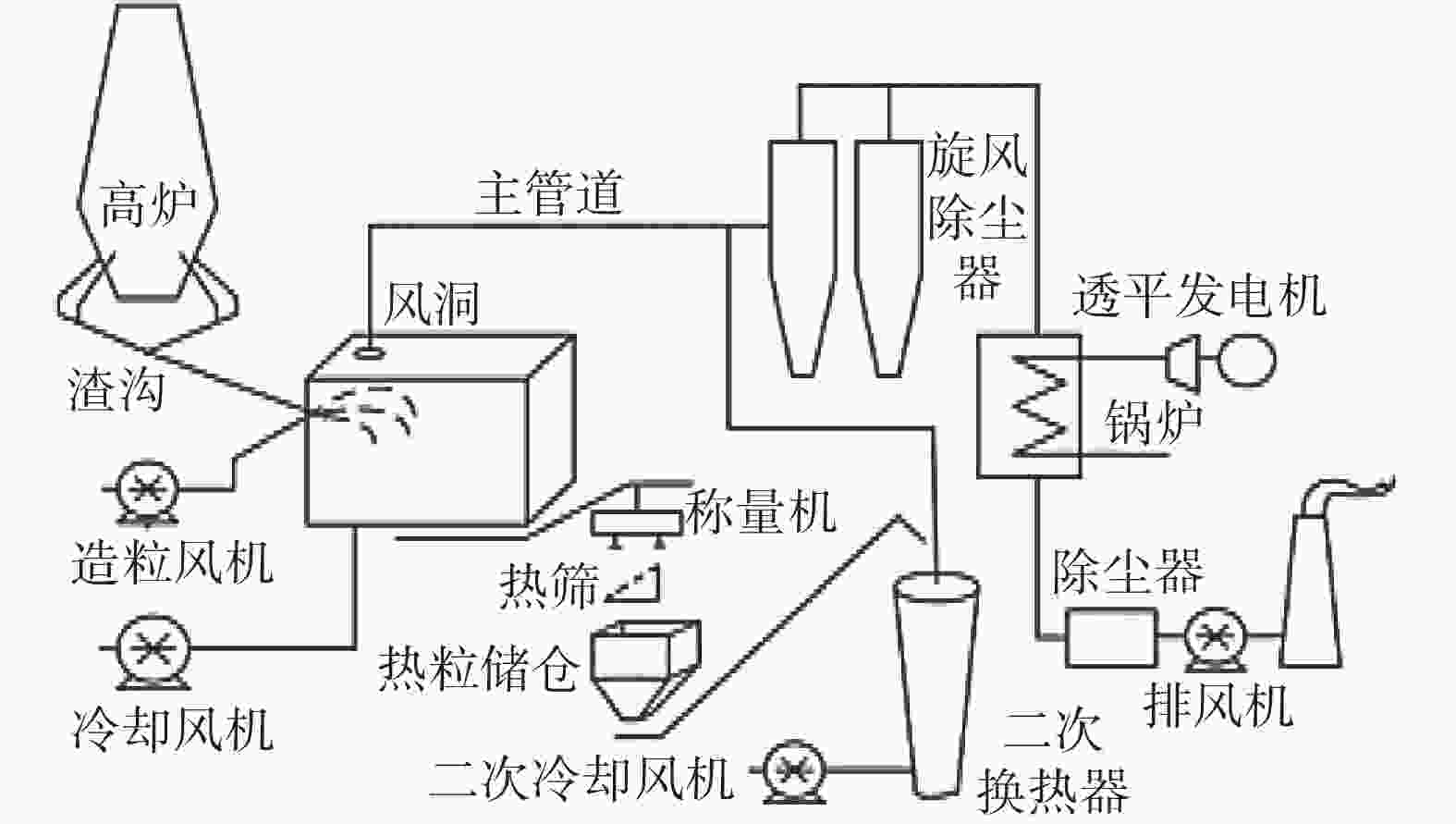

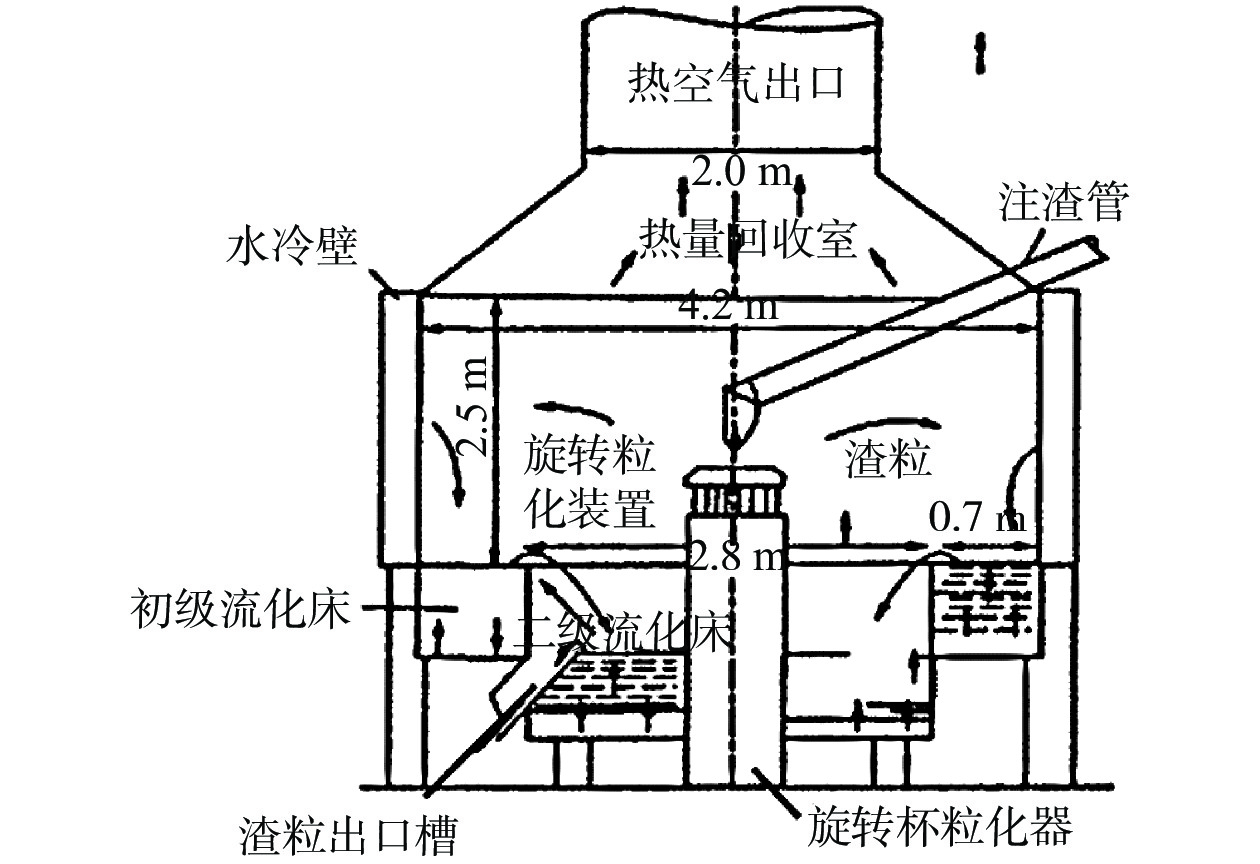

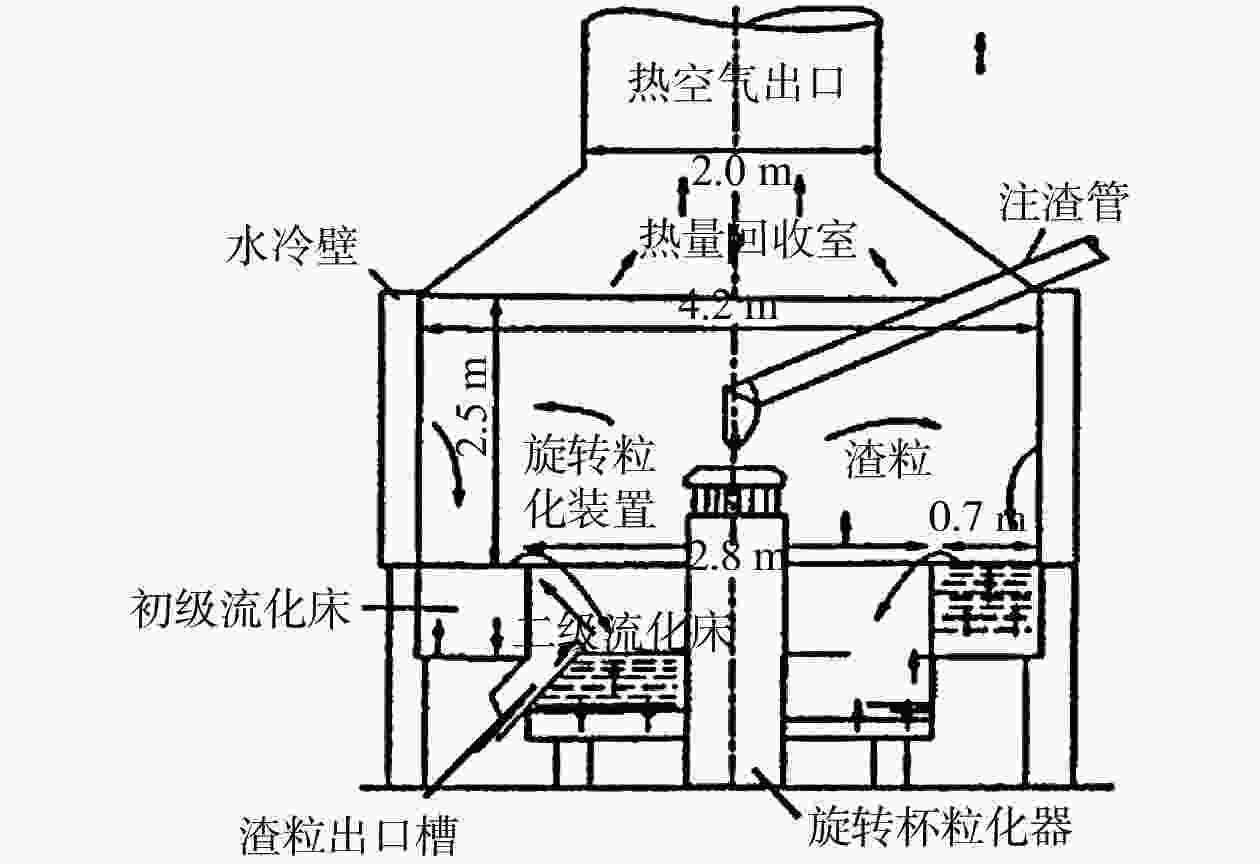

图 5 新日铁的高炉熔渣风淬处理工艺[41]

Figure 5. Blast furnace slag treated by air quenching process of Nippon Steel

图 6 高炉熔渣气淬成珠过程示意[43]

Figure 6. Process diagram of the molten blast furnace slag quenching into beads

图 7 高炉渣粒化仓物理模型[53]

Figure 7. Physical model of the blast furnace slag granulation silo

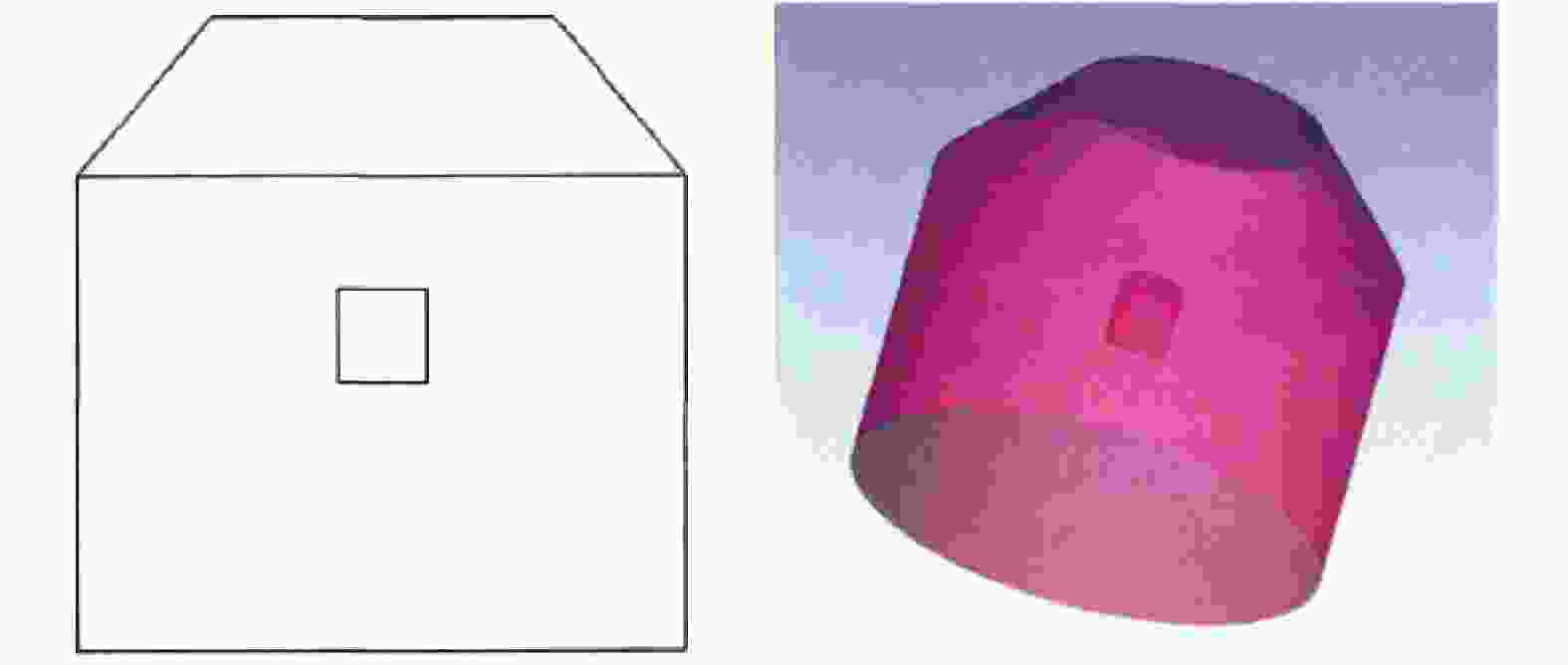

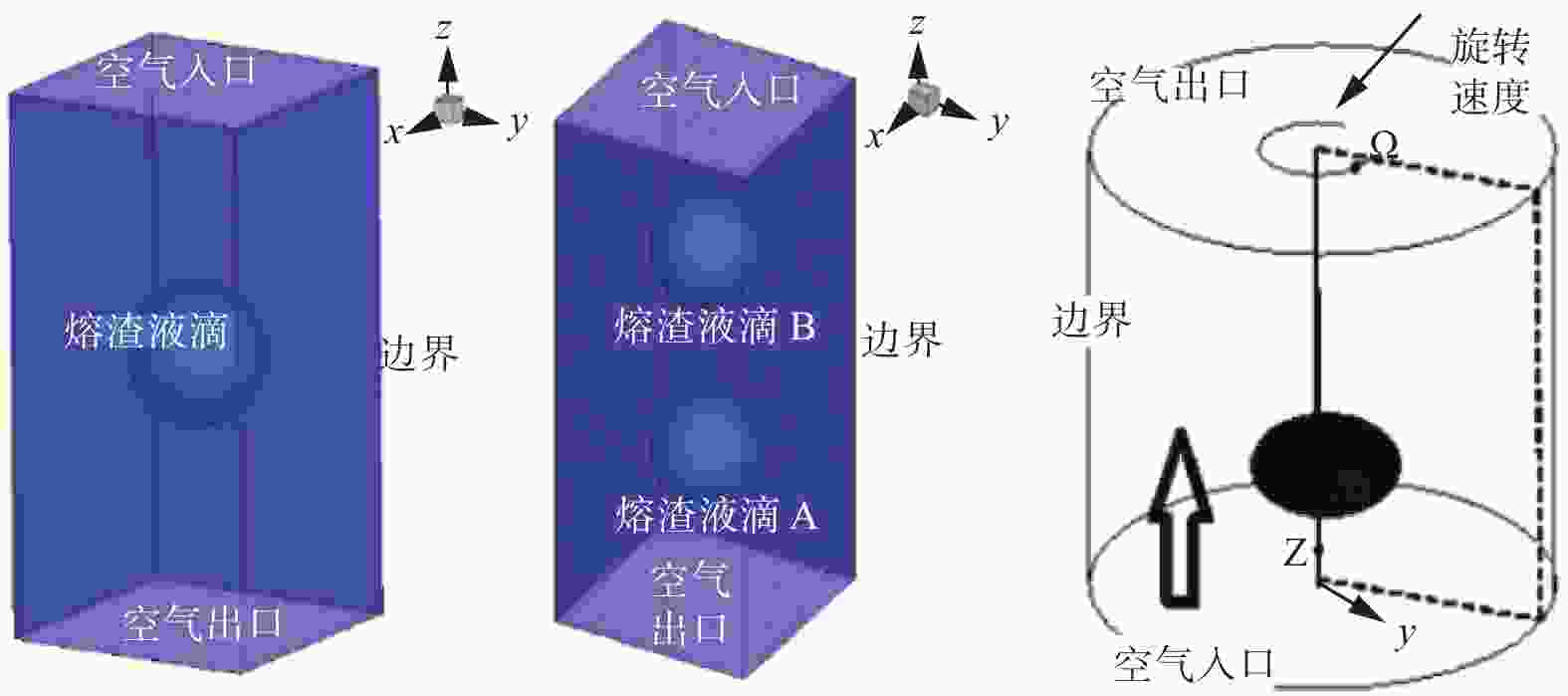

图 8 单颗粒、多颗粒以及旋转颗粒的物理模型[54]

Figure 8. Physical models of single particle, multi particle, and rotating particles

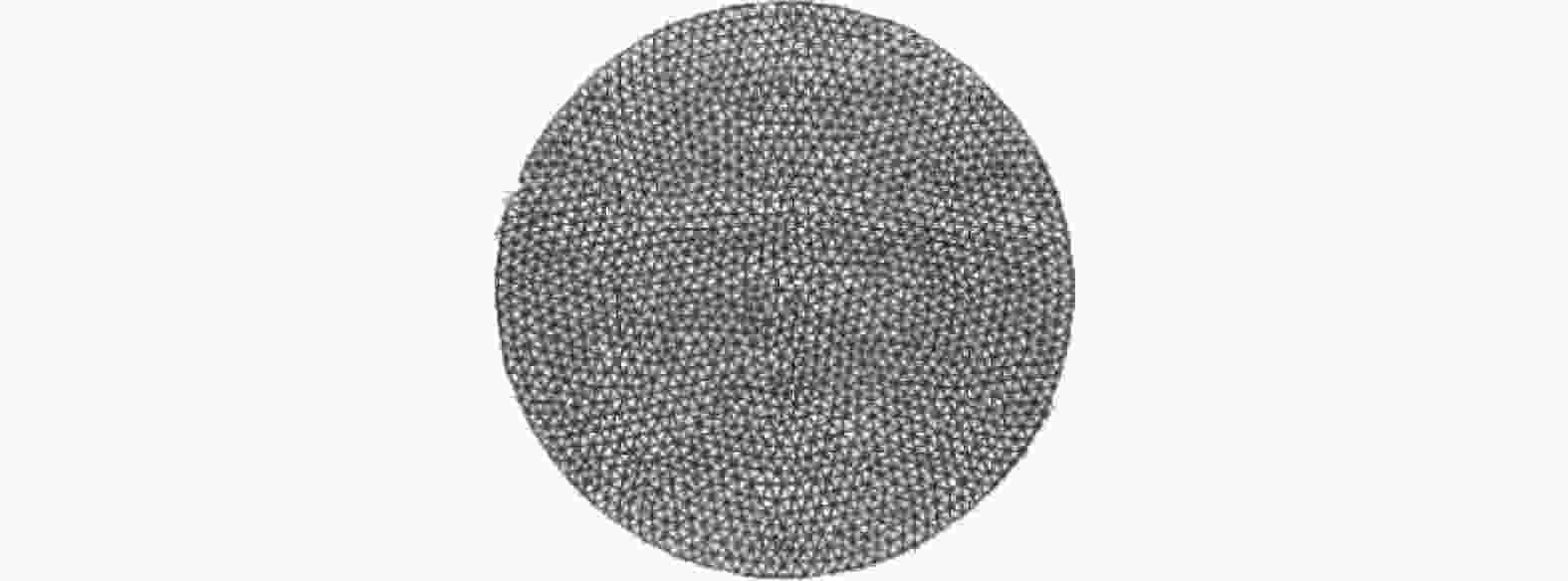

图 9 D=2 mm圆形熔渣的网格划分[60]

Figure 9. D=2 mm grid division of the circular slag

图 10 平板式转盘几何模型[62]

Figure 10. Geometric model of the flat plate turntable

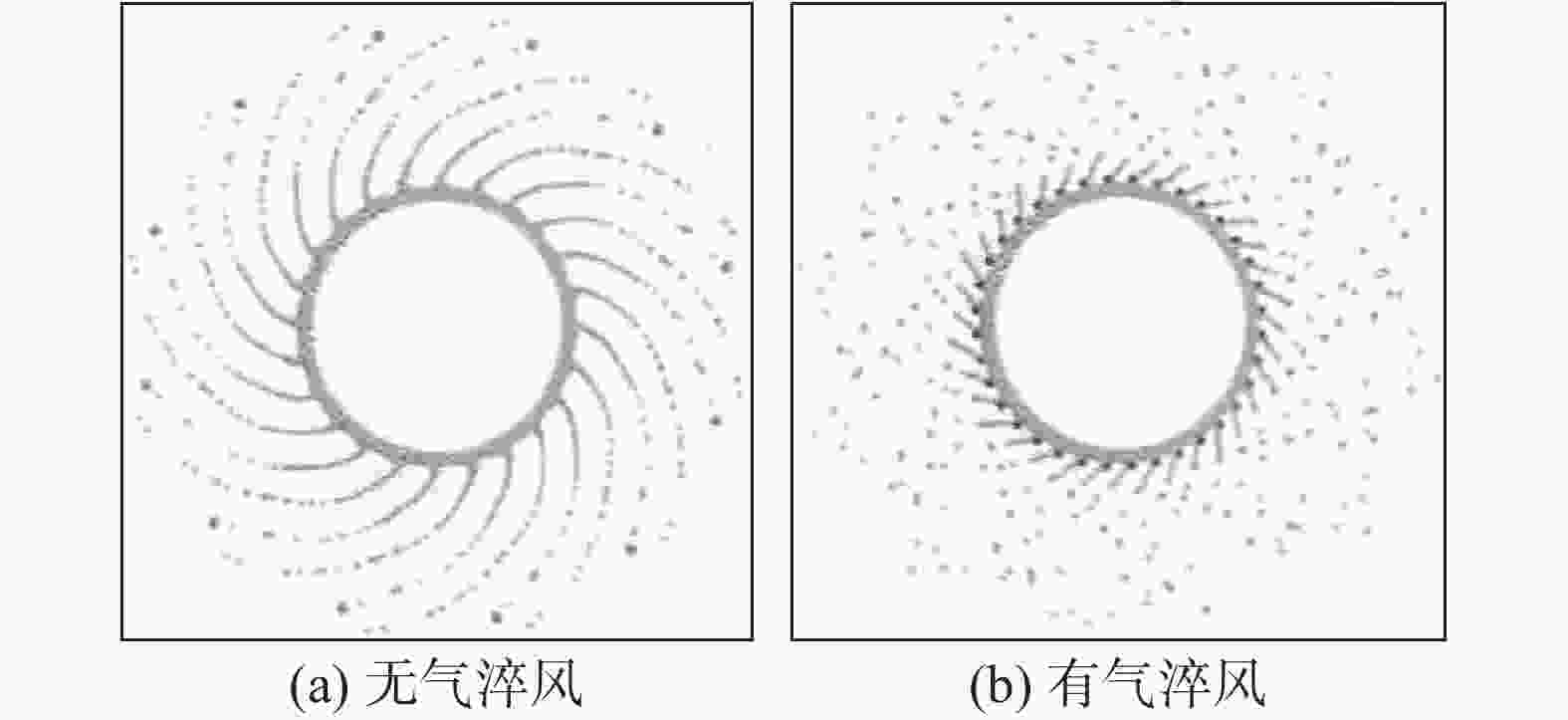

图 11 无气淬风和有气淬风的渣粒稳态粒化结果[63]

Figure 11. Results about centrifugal granulation of the liquid slag with and without wind blasting

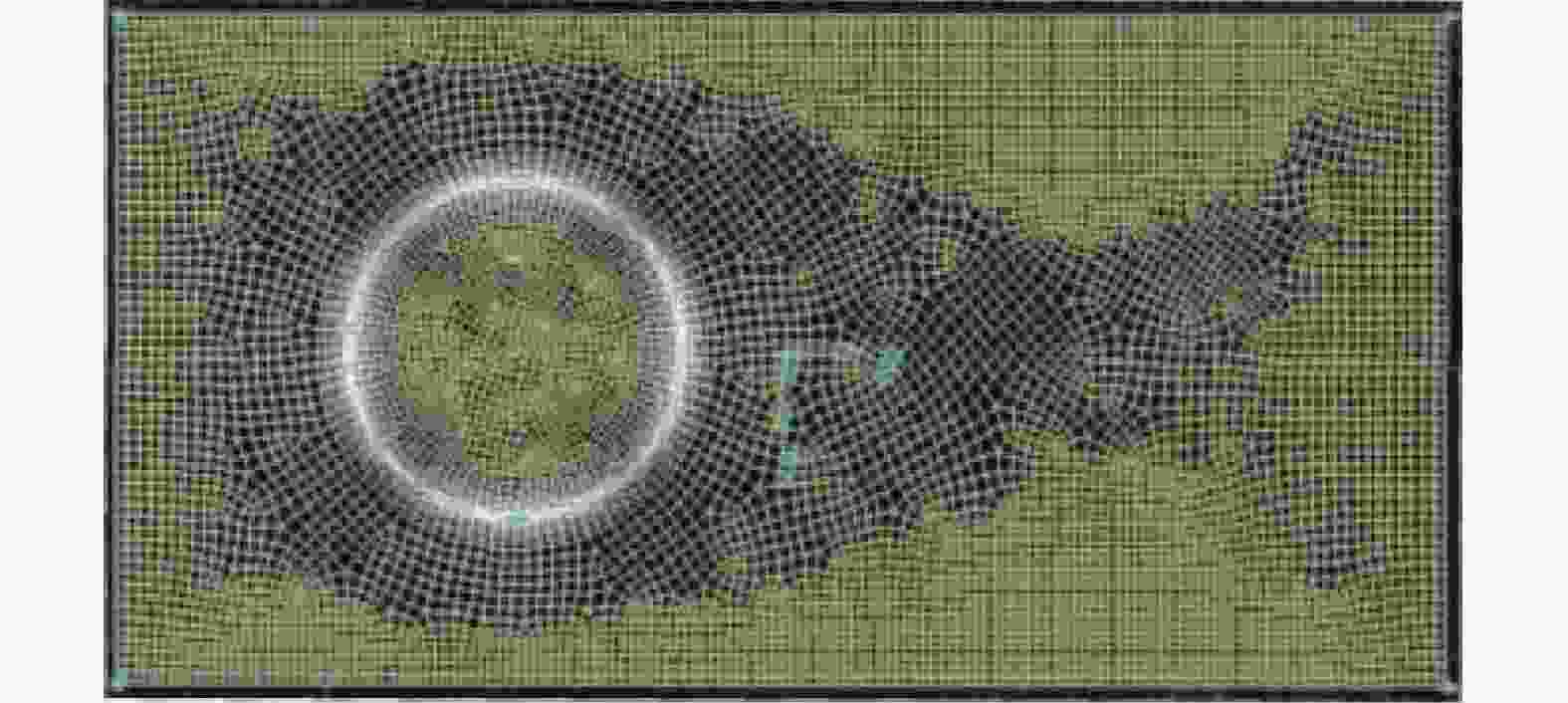

图 12 计算区域网格[42]

Figure 12. Mesh generation of the computational domain

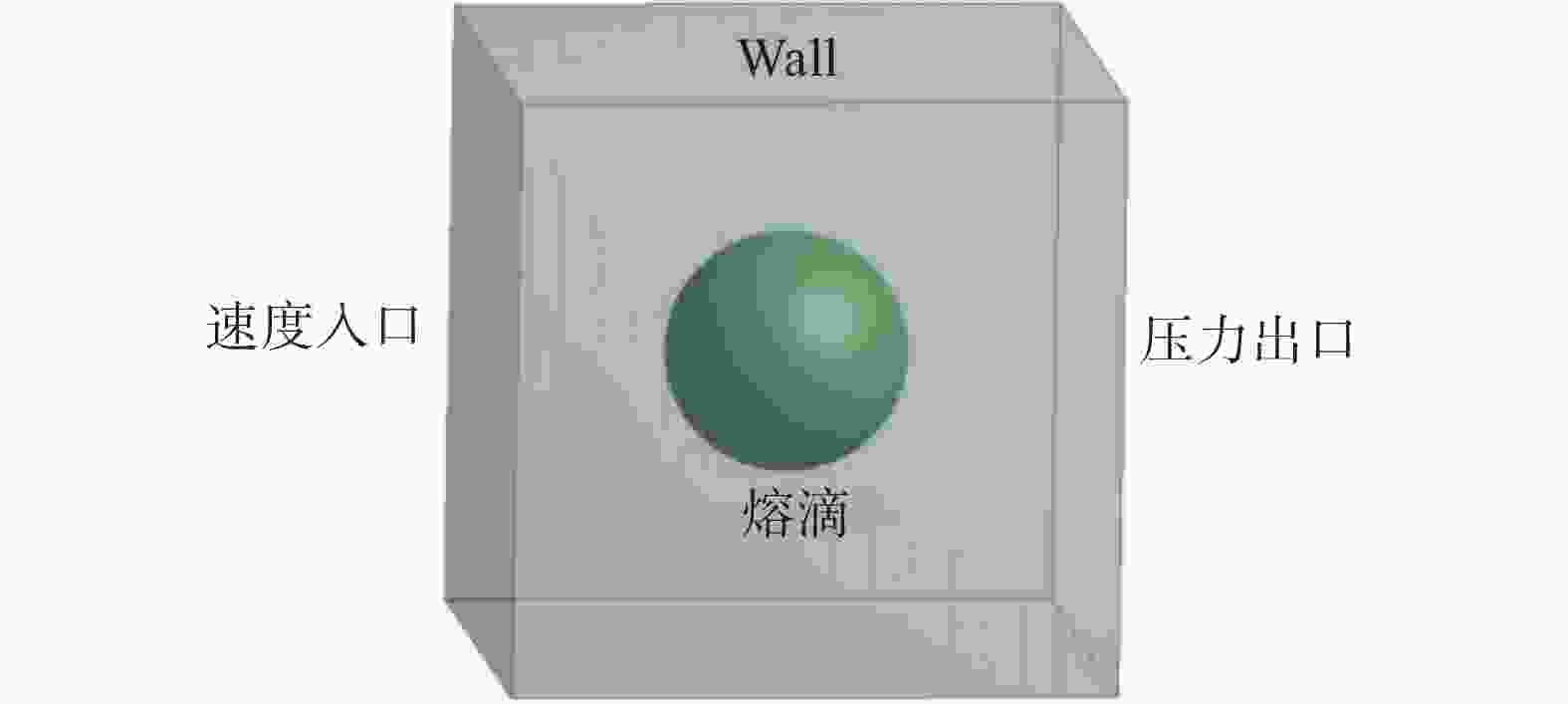

图 13 单颗粒熔渣换热三维模型[66]

Figure 13. A three-dimensional model of the single particle slag heat transfer

图 14 气淬粒化物理模型[67]

Figure 14. Physical model of gas quenching granulation

图 15 计算模型示意[69]

Figure 15. Schematic diagram of the computing model

-

[1] Wang Yihan,Wen Zongguo, Lü Xiaojun,et al. The spatial heterogeneity of synergy and trade-off linkages between carbon and air pollutant mitigations in China's steel industry[J]. Journal of Cleaner Production, 2023, 418(15):138166.1-138166.12. [2] Yu Jiyong, Xu Runsheng, Zhang Jianliang, et al. A review on reduction technology of air pollutant in current China's iron and steel industry[J]. Journal of Cleaner Production, 2023, 414(15):137659. [3] Li Hongke, Du Genjie, Du Jianlei, et al. The current situation and trend of the comprehensive utilization of solid waste in the steel industry[J]. China Steel Focus, 2021(1):116−117. (李红科, 杜根杰, 杜建磊, 等. 钢铁工业固废综合利用产业发展现状及趋势[J]. 冶金管理, 2021(1):116−117. Li Hongke, Du Genjie, Du Jianlei, et al . The current situation and trend of the comprehensive utilization of solid waste in the steel industry[J]. China Steel Focus,2021 (1 ):116 −117 .[4] Zhang Xinhua. Market review of domestic pig iron in 2022 and outlook for 2023 [EB/OL]. (2022-12-30)[2023-11-30] https://gc.mysteel.com/. (张新华. 国内生铁2022年市场回顾与2023年展望[EB/OL]. (2022-12-30)[2023-11-30] https://gc.mysteel.com/.Zhang Xinhua. Market review of domestic pig iron in 2022 and outlook for 2023 [EB/OL]. (2022-12-30)[2023-11-30] https://gc.mysteel.com/. [5] Liu Meng, Huang Zhongyuan, Zhang Jie. Present situation and trend of treatment technology for blast furnace slag[J]. Metallurgical Equipment, 2021(2):1−4. (刘猛, 黄忠源, 张杰. 高炉熔渣的处理技术现状及趋势[J]. 冶金设备, 2021(2):1−4. Liu Meng, Huang Zhongyuan, Zhang Jie . Present situation and trend of treatment technology for blast furnace slag[J]. Metallurgical Equipment,2021 (2 ):1 −4 .[6] Wang Kairong. Current situation of comprehensive utilization of solid waste resources[J]. China Nonferrous Metals, 2019(11):34−35. (王凯荣. 当前固废资源综合利用工作开展情况[J]. 中国有色金属, 2019(11):34−35. Wang Kairong . Current situation of comprehensive utilization of solid waste resources[J]. China Nonferrous Metals,2019 (11 ):34 −35 .[7] Liu Lingchuan. Development status and suggestions of comprehensive utilization of solid waste in China's iron and steel industry[J]. China Resources Comprehensive Utilization, 2021,39(1):113−116. (刘令传. 我国钢铁工业固废综合利用产业发展现状及建议[J]. 中国资源综合利用, 2021,39(1):113−116. Liu Lingchuan . Development status and suggestions of comprehensive utilization of solid waste in China's iron and steel industry[J]. China Resources Comprehensive Utilization,2021 ,39 (1 ):113 −116 .[8] Ni Jiandong. Application and research of solid waste in iron and steel in cement industry[J]. China Steel Focus, 2021(23):140−141. (倪建东. 论钢铁中的固废在水泥行业中的应用及研究[J]. 冶金管理, 2021(23):140−141. Ni Jiandong . Application and research of solid waste in iron and steel in cement industry[J]. China Steel Focus,2021 (23 ):140 −141 .[9] Ohta Akira, Den Hiroaki, Yoshinobu Yanagida, et al . Production of high glass content slag [J]. Tetsu to Hagane-Journal of the Iron and Steel Institute of Japan, 1983, 69 (12): S844. ( 大田昭, 佐藤博明, 佐藤芳行, et al. 高ガラス化率の成品スラグの製造 : 高炉スラグ熱回収方法の開発第 4 報[J], 鐵と鋼, 1983, 69(12): S844.Ohta Akira, Den Hiroaki, Yoshinobu Yanagida, et al. Production of high glass content slag [J]. Tetsu to Hagane-Journal of the Iron and Steel Institute of Japan, 1983, 69 (12): S844. [10] Fujii Koichi ,Tetsuyuki Nakamura, Tsuki Iwao Bashi Bridge, et al. Studies on the operating conditions with the experimental heat recovery equipment[J]. Tetsu to Hagane-journal of the Iron and Steel Institute of Japan, 1982, 68 (4): S93. ( 藤井孝一, 中村哲之, 岩橋槻雄, et al. 高炉スラグ熱回収試験設備による操業条件の検討: 高炉スラグの粒状化および熱回収法の研究第 V 報[J]. 鐵と鋼, 1982, 68(4): S93.Fujii Koichi ,Tetsuyuki Nakamura, Tsuki Iwao Bashi Bridge, et al. Studies on the operating conditions with the experimental heat recovery equipment[J]. Tetsu to Hagane-journal of the Iron and Steel Institute of Japan, 1982, 68 (4): S93. [11] Yan Zhaomin, Zhou Yangmin, Yang Zhiyuan, et al. Present situation and development trend of blast furnace slag comprehensive utilization[J]. Research on Iron & Steel, 2010,38(2):53−56. (闫兆民, 周扬民, 杨志远, 等. 高炉渣综合利用现状及发展趋势[J]. 钢铁研究, 2010,38(2):53−56. Yan Zhaomin, Zhou Yangmin, Yang Zhiyuan, et al . Present situation and development trend of blast furnace slag comprehensive utilization[J]. Research on Iron & Steel,2010 ,38 (2 ):53 −56 .[12] Kenny W F. Energy conservation in process industries[ M]. Orlando : Academic Press, 1984. [13] Pickering S J, Hay N, Roylanae T F, et al. New process for dry granulation and heat recovery from molten blast fumaee slag[J]. Ironmaking and Steelmaking, 1985,12(1):14−21. [14] Taihei Shimada, Tomohiro Akiyama, Eiki Kasai, et al. Atomization of molten slag by rotary-cup atomizer [J]. Bulletin of the Institute for Advanced Materials Processing, Tohoku University, 2001, 56 (1): 92-97. (嶋田太平, 秋山友宏, 葛西栄輝, et al. 回転カップアトマイザーを用いた溶融スラグの微粒化[J]. 東北大学素材工学研究所彙報, 2001, 56 (1): 92-97.Taihei Shimada, Tomohiro Akiyama, Eiki Kasai, et al. Atomization of molten slag by rotary-cup atomizer [J]. Bulletin of the Institute for Advanced Materials Processing, Tohoku University, 2001, 56 (1): 92-97. [15] Mizuochi T, Yagi J, Akiyama T. Granulation of molten slag for heat recovery [C] //37th Intersociety Energy Conversion Engineering Conference (IECEC), 2002: 641 - 646. [16] Maruoka N, Mizuochi T, Purwanto H. Feasibility study for recovering waste heat in the steel-making industry using a chemical recuperator [J].ISIJ International, 2004, 44 (2): 257 -262. [17] Liu Junxiang, Yu Qingbo, Li Peng, et al. Experimental study on dry-granulation of molten blast furnace slag[J]. Iron and Steel, 2010,45(2):95−98. (刘军祥, 于庆波, 李朋, 等. 高炉渣干法粒化试验研究[J]. 钢铁, 2010,45(2):95−98. Liu Junxiang, Yu Qingbo, Li Peng, et al . Experimental study on dry-granulation of molten blast furnace slag[J]. Iron and Steel,2010 ,45 (2 ):95 −98 .[18] Liu J, Yu Q, Guo Q. Experimental investigation of liquid disintegration by rotary cups[J]. Chemical Engineering Science, 2012,73:44−50. doi: 10.1016/j.ces.2012.01.010 [19] Yu Qingbo, Liu Junxiang, Hu Xianzhong, et al. Simulation experimental research of granulation process for iron slag[J]. Iron and Steel, 2009,44(4):82−85. (于庆波, 刘军祥, 胡贤忠, 等. 高炉渣破碎过程的模拟实验研究[J]. 钢铁, 2009,44(4):82−85. Yu Qingbo, Liu Junxiang, Hu Xianzhong, et al . Simulation experimental research of granulation process for iron slag[J]. Iron and Steel,2009 ,44 (4 ):82 −85 .[20] Yu Qingbo, Liu Junxiang, Dou Chenxi, et al. Dry granulation experiment of blast furnace slag by rotary cup atomizer[J]. Journal of Northeastern University (Natural Science), 2009, 30(8): 1163-1165, 1173. (于庆波, 刘军祥, 窦晨曦, 等. 转杯法高炉熔渣粒化实验研究[J]. 东北大学学报, 2009, 30(8): 1163-1165, 1173.Yu Qingbo, Liu Junxiang, Dou Chenxi, et al. Dry granulation experiment of blast furnace slag by rotary cup atomizer[J]. Journal of Northeastern University (Natural Science), 2009, 30(8): 1163-1165, 1173. [21] Zhu X, Zhang H, Tan Y, et al. Analogue experimental study on centrifugal-air blast granulation for molten slag[J]. Applied Thermal Engineering, 2015,88:157−164. doi: 10.1016/j.applthermaleng.2014.11.077 [22] Dai Xiaotian, Qi Yuanhong, Zhang Chunxia, et al. Analysis of blast furnace slag quenching dry granulation process[J]. Journal of lron and Steel Research, 2007(5):14−19. (戴晓天, 齐渊洪, 张春霞, 等. 高炉渣急冷干式粒化处理工艺分析[J]. 钢铁研究学报, 2007(5):14−19. Dai Xiaotian, Qi Yuanhong, Zhang Chunxia, et al . Analysis of blast furnace slag quenching dry granulation process[J]. Journal of lron and Steel Research,2007 (5 ):14 −19 .[23] Wu Junjun, Wang Hong, Zhu Xun, et al. Centrifugal granulation performance of liquid with various viscosities for heat recovery of blast furnace slag[J]. Applied Thermal Engineering, 2015, 89:1-11. [24] Wu Junjun. Centrifugal granulation mechanism of molten blast furnace slag[D]. Chongqing:Chongqing University, 2016. (吴君军. 高炉熔渣离心粒化机理及规律[D]. 重庆:重庆大学, 2016.Wu Junjun. Centrifugal granulation mechanism of molten blast furnace slag[D]. Chongqing:Chongqing University, 2016. [25] Wang Zhilong. Research progress in centrifugal granulation of high temperature liquid slag[J]. Modern Chemical Research, 2023(4):25−27. (王治龙. 高温液态熔渣离心粒化研究进展[J]. 当代化工研究, 2023(4):25−27. Wang Zhilong . Research progress in centrifugal granulation of high temperature liquid slag[J]. Modern Chemical Research,2023 (4 ):25 −27 .[26] Lü Yiwen, Zhu Xun, Wang Hong, et al. Centrifugal granulation and waste heat recovery technology for high temperature molten slag[J]. China Basic Science, 2020,22(2):28−35, 42. (吕义文, 朱恂, 王宏, 等. 高温液态熔渣离心粒化余热回收技术[J]. 中国基础科学, 2020,22(2):28−35, 42. Lü Yiwen, Zhu Xun, Wang Hong, et al . Centrifugal granulation and waste heat recovery technology for high temperature molten slag[J]. China Basic Science,2020 ,22 (2 ):28 −35, 42 .[27] Liu J X, Yu Q B, Dou C X, et al. Experimental study on heat transfer characteristics of apparatus for recovering the waste heat of blast furnace slag[J]. Advanced Materials Research, 2010,97-101:2343−2346. [28] Toshio Mizuochi, Tomohiro Akiyama, Taihei S, et al. Feasibility of rotary cup atomizer for slag granulation[J]. ISIJ International, 2001(12):1423−1428. [29] Szargut J T. Proceedings of the international conference[C]. Gliwice: University of Silesia, 1993: 731−738. [30] Dunskii V F, Nikitin N V, Shul’ ginova G A. Atomization by a rotating disk of liquids which poorly wet its surface[J]. Journal of Engineering Physics, 1985,48(1):42−45. [31] Xie J W, Zhao Y Y, Dunkley J J. Effects of processing conditions on powder particle size and morphology in centrifugal atomisation of tin[J]. Powder Metallurgy, 2004, 47(2). [32] Jahanshahi S, Deev A, Haque N, et al. Current status and future direction of low‐emission integrated steelmaking process[M]. EPD Symposium in Honor of Davi-d GC Robertson, 2014:303−316. [33] Jahanshahi S, Xie D, Pan Y, et al. Dry slag granulation with integrated heat recovery[C]// First Intl. Conference on Energy Efficiency and CO2 Reduction (EECR) in the Steel Industry, 2011. [34] POSCO, Carbon report 2013, South Korea, (2013). [35] Min Y Z, Chao L, Li L X, et al. The experimental study of molten blast slag dry granulation[J]. Advanced Materials Research, 2011,356-360:1882−1885. [36] Yan Zhaomin, Zhou Yangmin, Yang Zhiyuan, et al. Experimental study of plates dry granulation of BF slag[J]. Energy for Metallurgical Industry, 2010, 29(3):44-46. (闫兆民, 周扬民, 杨志远, 等. 高炉渣干式平盘粒化实验研究[J]. 冶金能源, 2010, 29(3).Yan Zhaomin, Zhou Yangmin, Yang Zhiyuan, et al. Experimental study of plates dry granulation of BF slag[J]. Energy for Metallurgical Industry, 2010, 29(3): 44-46. [37] Li Zonggang, Zhou Yangmin, Yi Chuijie, et al. Experimental study on the production of hot blast using hot blast furnace slag as heat carrier in rotary kiln heat transfer[J]. Energy for Metallurgical Industry, 2013,32(4):33−35. [38] Ji Huimin, Huang Youliang, Yi Chuijie, et al. Dry centrifugal granulation mechanism and experimental study of blast furnace slag[J]. China Powder Science and Technology, 2020,26(2):63−69. (纪慧敏, 黄友亮, 仪垂杰, 等. 高炉渣干式离心粒化机理及实验研究[J]. 中国粉体技术, 2020,26(2):63−69. Ji Huimin, Huang Youliang, Yi Chuijie, et al . Dry centrifugal granulation mechanism and experimental study of blast furnace slag[J]. China Powder Science and Technology,2020 ,26 (2 ):63 −69 .[39] Li Shun. Heat recovery from BF slag at home and abroad[J]. Industrial Heating, 2009(3):1−4. (李顺. 国内外熔融高炉渣显热回收方法[J]. 工业加热, 2009(3):1−4. Li Shun . Heat recovery from BF slag at home and abroad[J]. Industrial Heating,2009 (3 ):1 −4 .[40] Michiaki Sakakibara. Development of the technology on heat recovery from molten slag of blast furnace[J]. Iron and Steel, 1990,76(10):1587−1596. (榊原路晤. 高炉溶融スラグ顯熱総合回收技術の開発[J]. 鉄と鋼, 1990,76(10):1587−1596. Michiaki Sakakibara . Development of the technology on heat recovery from molten slag of blast furnace[J]. Iron and Steel,1990 ,76 (10 ):1587 −1596 .[41] Lü Xiaofang. Current status and progress in treating and recycling blast furnace slag[J]. Southern Metals, 2010(3):14−18. (吕晓芳. 高炉渣处理、回收利用技术的现状与进展[J]. 南方金属, 2010(3):14−18. Lü Xiaofang . Current status and progress in treating and recycling blast furnace slag[J]. Southern Metals,2010 (3 ):14 −18 .[42] Chang Hao. Simulation experimental study on granulating molten blast furnace slag by nozzle jetting and analysis of slag solidification[D]. Jinan:Shandong Jianzhu University, 2014. (常浩. 高炉熔渣喷射粒化模拟实验及凝固放热分析[D].济南: 山东建筑大学, 2014.Chang Hao. Simulation experimental study on granulating molten blast furnace slag by nozzle jetting and analysis of slag solidification[D]. Jinan: Shandong Jianzhu University, 2014. [43] Liu Zhenchao. The mechanism and experimental research on blast furnace slag gas quenching into glass beeds[D]. Tangshan: North China University of Science and Technology, 2018. (刘振超. 高炉渣气淬成珠机理及实验研究[D]. 唐山:华北理工大学, 2018.Liu Zhenchao. The mechanism and experimental research on blast furnace slag gas quenching into glass beeds[D]. Tangshan: North China University of Science and Technology, 2018. [44] Kang Yue, Liu Chao, Zhang Yuzhu, et al. Experimental study on granulation of blast furnace slag by gas quenching[J]. Journal of Northeastern University (Natural Science), 2020,41(2):212−216. (康月, 刘超, 张玉柱, 等. 气淬法粒化高炉渣实验研究[J]. 东北大学学报(自然科学版), 2020,41(2):212−216. Kang Yue, Liu Chao, Zhang Yuzhu, et al . Experimental study on granulation of blast furnace slag by gas quenching[J]. Journal of Northeastern University (Natural Science),2020 ,41 (2 ):212 −216 .[45] Kang Yue, Liu Chao, Zhang Yuzhu, et al. Granulation mechanism of gas quenching blast furnace slag with different basic ties[J]. Ironmaking & Steelmaking, 2020, 47(10). [46] Kang Yue, Liu Chao, Zhang Yuzhu. Feasibility analysis of blast furnace slag as gas quenching raw material[J]. China Metallurgy, 2021,31(5):127−131, 137. (康月, 刘超, 张玉柱. 高炉渣作为气淬喷吹原料的可行性分析[J]. 中国冶金, 2021,31(5):127−131,137. Kang Yue, Liu Chao, Zhang Yuzhu . Feasibility analysis of blast furnace slag as gas quenching raw material[J]. China Metallurgy,2021 ,31 (5 ):127 −131, 137 .[47] Wang Lili, Zhang Yuzhu, Ke Haibin, et al. Experimental investigation on granulation characteristics and waste heat recovery of molten slag in gas quenching dry granulation technique[J]. Applied Thermal Engineering, 2021, 184(1):1-7. [48] Li G, Guo M. Current development of slag valorisation in China[J]. Waste and Biomass Valorization, 2014,5(3):317−325. [49] Wang Zibing, Liu Yue, Zhang Yuzhu, et al. Experimental study on heat recovery of the process of gas blowing for blast furnace slag[J]. Iron Steel Vanadium Titanium, 2018,39(4):93−98. (王子兵, 刘跃, 张玉柱, 等. 高炉熔渣气淬粒化热量回收试验研究[J]. 钢铁钒钛, 2018,39(4):93−98. Wang Zibing, Liu Yue, Zhang Yuzhu, et al . Experimental study on heat recovery of the process of gas blowing for blast furnace slag[J]. Iron Steel Vanadium Titanium,2018 ,39 (4 ):93 −98 .[50] Li Shulei, Li Shuangfeng. Preliminary research on waste heat recovery from blast furnace slag by gas quenching[J]. Metallurgical Equipment, 2019(2):1−4, 18. [51] Wan Xinyu, Yan Dingliu, Gao Jianjun, et al. Experimental study on air-water mixed quenching process in dry type BF slag granulation and high efficient waste heat recovery[J]. Ironmaking, 2020,39(4):8−12. (万新宇, 严定鎏, 高建军,等. 高炉渣气-水混淬干法粒化及余热回收扩大试验研究[J]. 炼铁, 2020,39(4):8−12. Wan Xinyu, Yan Dingliu, Gao Jianjun, et al . Experimental study on air-water mixed quenching process in dry type BF slag granulation and high efficient waste heat recovery[J]. Ironmaking,2020 ,39 (4 ):8 −12 .[52] Guo Ying. Numerical simulation of granulation and waste heat recovery process for blast furnace slag[D]. Shenyang: Northeastern University, 2008. (郭英. 高炉渣破碎及余热回收过程的数值模拟[D]. 沈阳:东北大学, 2008.Guo Ying. Numerical simulation of granulation and waste heat recovery process for blast furnace slag[D]. Shenyang: Northeastern University, 2008. [53] Yang Shuguang. Numerical simulation of the flight heat transfer process of BF slag particle group in the granulation chamber[D]. Shenyang: Northeastern University, 2020. (杨曙光. 高炉渣颗粒群在粒化仓内飞行过程的传热数值模拟[D]. 沈阳:东北大学, 2020.Yang Shuguang. Numerical simulation of the flight heat transfer process of BF slag particle group in the granulation chamber[D]. Shenyang: Northeastern University, 2020. [54] Qiu Yongjun. Numerical research of solidification and heat transfer characteristics for an air-cooling molten blast furnace slag droplet[D]. Chongqing:Chongqing University, 2014. (邱勇军. 熔渣颗粒空气冷却相变换热特性的数值研究[D].重庆: 重庆大学, 2014.Qiu Yongjun. Numerical research of solidification and heat transfer characteristics for an air-cooling molten blast furnace slag droplet[D]. Chongqing:Chongqing University, 2014. [55] Liu Xiaoying. Numerical research of solidification and heat transfer characteristics for a molten blast furnace slag droplet [D].Chongqing: Chongqing University, 2016. (刘小英. 高温熔融高炉渣颗粒相变冷却换热特性的数值研究[D]. 重庆:重庆大学, 2016.Liu Xiaoying. Numerical research of solidification and heat transfer characteristics for a molten blast furnace slag droplet [D].Chongqing: Chongqing University, 2016. [56] Wu Junjun, Wang Hong, Zhu Xun, et al. Flow characteristics of molten blast furnace slag film on rotary ato-mizers with various configurations[J]. Journal of Iron and Steel Research, 2017,29(1):19−25. (吴君军, 王宏, 朱恂, 等. 不同结构粒化器表面高炉熔渣液膜的流动特性[J]. 钢铁研究学报, 2017,29(1):19−25. Wu Junjun, Wang Hong, Zhu Xun, et al . Flow characteristics of molten blast furnace slag film on rotary ato-mizers with various configurations[J]. Journal of Iron and Steel Research,2017 ,29 (1 ):19 −25 .[57] Xiang Yuhao, Zhu Xun, Wang Hong, et al. Numerical study on phase change cooling and crystallizati-on of a molten blast furnace slag droplet impacting the wall[J]. Journal of Engineering Thermophysics, 2022,43(5):1337−1344. (向宇豪, 朱恂, 王宏, 等. 熔融高炉渣液滴撞击壁面动态行为及相变换热特性的数值模拟[J]. 工程热物理学报, 2022,43(5):1337−1344. Xiang Yuhao, Zhu Xun, Wang Hong, et al . Numerical study on phase change cooling and crystallizati-on of a molten blast furnace slag droplet impacting the wall[J]. Journal of Engineering Thermophysics,2022 ,43 (5 ):1337 −1344 .[58] Pan Yuhua, Peter J Witt, Xie Dongsheng. CFD simulation of free surface flow and heat transfer of liquid slag on a spinning disc for a novel dry slag granulation process[J]. Progress in Computational Fluid Dynamics, An International Journal, 2010,10(5/6):292−299. [59] Hadley D T, Pan Y, Lim K, et al. Engineering design of direct contact counter current moving bed heat exchangers[J]. International Journal of Mineral Processing, 2015,14291-100. [60] Geng Miaohong. Numerical simulation of blast furnace slag solidification process[D].Shengyang: Northeastern University, 2007. (耿苗红. 高炉渣粒凝固过程的数值模拟[D]. 沈阳:东北大学, 2007.Geng Miaohong. Numerical simulation of blast furnace slag solidification process[D].Shengyang: Northeastern University, 2007. [61] Yang Yinkai. Numerical simulation of blast furnace slag's dry centrifugal granulation[D]. Wuhan:Wuhan University of Science and Technology, 2013. (杨银凯. 高炉熔渣干式离心粒化数值模拟研究[D]. 武汉:武汉科技大学, 2013.Yang Yinkai. Numerical simulation of blast furnace slag's dry centrifugal granulation[D]. Wuhan:Wuhan University of Science and Technology, 2013. [62] Chang Qingming, Cheng Yongkai, Li Xianwang, et al. Simulation study on the dry centrifugal granulation process of blast furnace slag[J]. Iron Steel Vanadium Titanium, 2014,35(1):69−73, 78. (常庆明, 程永楷, 李先旺, 等. 高炉渣干式离心粒化的建模仿真研究[J]. 钢铁钒钛, 2014,35(1):69−73, 78. doi: 10.7513/j.issn.1004-7638.2014.01.014 Chang Qingming, Cheng Yongkai, Li Xianwang, et al . Simulation study on the dry centrifugal granulation process of blast furnace slag[J]. Iron Steel Vanadium Titanium,2014 ,35 (1 ):69 −73, 78 . doi: 10.7513/j.issn.1004-7638.2014.01.014[63] Gao Jie, Feng Yanhui, Feng Daili, et al. Centrifugal granulation of liquid slag by wind quenching[J]. Journal of Engineering Thermophysics, 2021,42(5):1288−1292. (高洁, 冯妍卉, 冯黛丽, 等. 风淬作用下液态熔渣的离心粒化[J]. 工程热物理学报, 2021,42(5):1288−1292. Gao Jie, Feng Yanhui, Feng Daili, et al . Centrifugal granulation of liquid slag by wind quenching[J]. Journal of Engineering Thermophysics,2021 ,42 (5 ):1288 −1292 .[64] Yan Zhaomin, Zhou Yangmin, Yang Zhiyuan, et al. Experimental study of plates dry granulation of BF slag[J]. Energy for Metallurgical Industry, 2010,29(3):44−46. (闫兆民, 周扬民, 杨志远, 等. 高炉渣干式平盘粒化实验研究[J]. 冶金能源, 2010,29(3):44−46. Yan Zhaomin, Zhou Yangmin, Yang Zhiyuan, et al . Experimental study of plates dry granulation of BF slag[J]. Energy for Metallurgical Industry,2010 ,29 (3 ):44 −46 .[65] Kang Yue, Liu Chao, Zhang Yuzhu, et al. Phase transition simulation of air quenching blast furnace slag during cooling and solidification[J]. China Metallurgy, 2022,32(5):116−124. (康月, 刘超, 张玉柱, 等. 气淬高炉熔渣冷却凝固相变特性仿真[J]. 中国冶金, 2022,32(5):116−124. Kang Yue, Liu Chao, Zhang Yuzhu, et al . Phase transition simulation of air quenching blast furnace slag during cooling and solidification[J]. China Metallurgy,2022 ,32 (5 ):116 −124 .[66] Wang Lili. Research on the granulating mechanism and the heat transfer characteristics of blast furnace slag in gas quenching [D]. Tangshan: North China University of Science and Technology, 2021. (王丽丽. 气淬高炉熔渣粒化机理及传热特性研究[D]. 唐山:华北理工大学, 2021.Wang Lili. Research on the granulating mechanism and the heat transfer characteristics of blast furnace slag in gas quenching [D]. Tangshan: North China University of Science and Technology, 2021. [67] Wang Lili, Zhang Yuzhu, Ke Haibin, et al. Numerical simulation of molten slag film breakup during granulation process using air-quenching[J]. Journal of Materials and Metallurgy, 2020,19(2):87−93. (王丽丽, 张玉柱, 客海滨, 等. 气淬粒化工艺中熔渣液膜破碎数值模拟[J]. 材料与冶金学报, 2020,19(2):87−93. Wang Lili, Zhang Yuzhu, Ke Haibin, et al . Numerical simulation of molten slag film breakup during granulation process using air-quenching[J]. Journal of Materials and Metallurgy,2020 ,19 (2 ):87 −93 .[68] Liu Xiaohong, Wen Zhi, Du Yuhang, et al. Study on liquid film breaking process of gas quenched granulated slag[J]. Journal of Central South University (Science and Technology), 2022,53(8):2851−2860. (刘晓宏, 温治, 杜宇航, 等. 气淬粒化熔渣液膜破碎过程研究[J]. 中南大学学报(自然科学版), 2022,53(8):2851−2860. Liu Xiaohong, Wen Zhi, Du Yuhang, et al . Study on liquid film breaking process of gas quenched granulated slag[J]. Journal of Central South University (Science and Technology),2022 ,53 (8 ):2851 −2860 .[69] Du Yuhang, Liu Xiaohong, Wen Zhi, et al. Numerical simulation of the breakup of high temperature blast fur-nace slag droplet[J]. Journal of Materials and Metallurgy, 2023,22(1):23−29. (杜宇航, 刘晓宏, 温治, 等. 高炉渣液滴破碎过程数值模拟[J]. 材料与冶金学报, 2023,22(1):23−29. Du Yuhang, Liu Xiaohong, Wen Zhi, et al . Numerical simulation of the breakup of high temperature blast fur-nace slag droplet[J]. Journal of Materials and Metallurgy,2023 ,22 (1 ):23 −29 . -

下载:

下载: