Study on deterioration of physicochemical properties of tundish slag for high carbon steel during continuous casting process

-

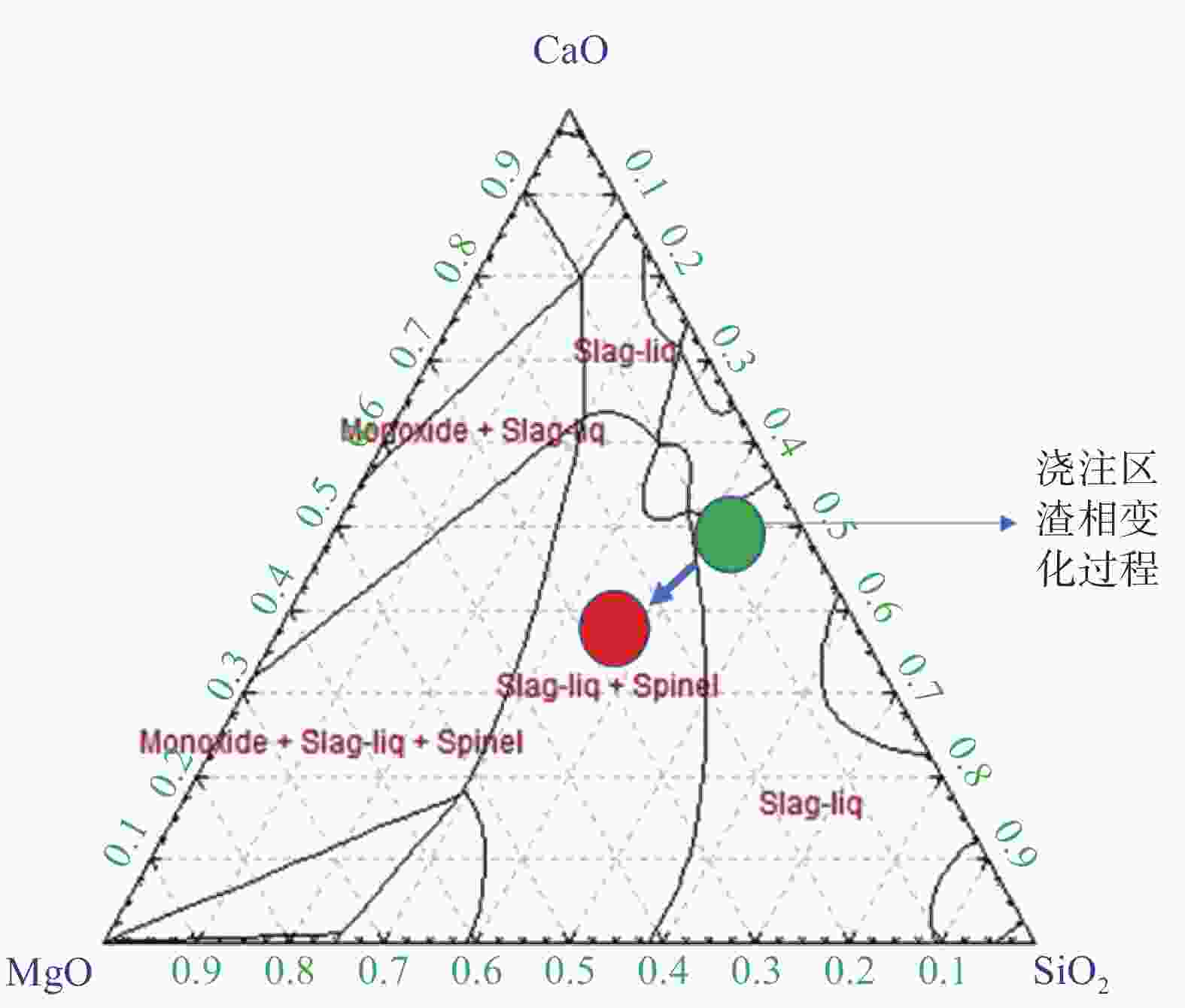

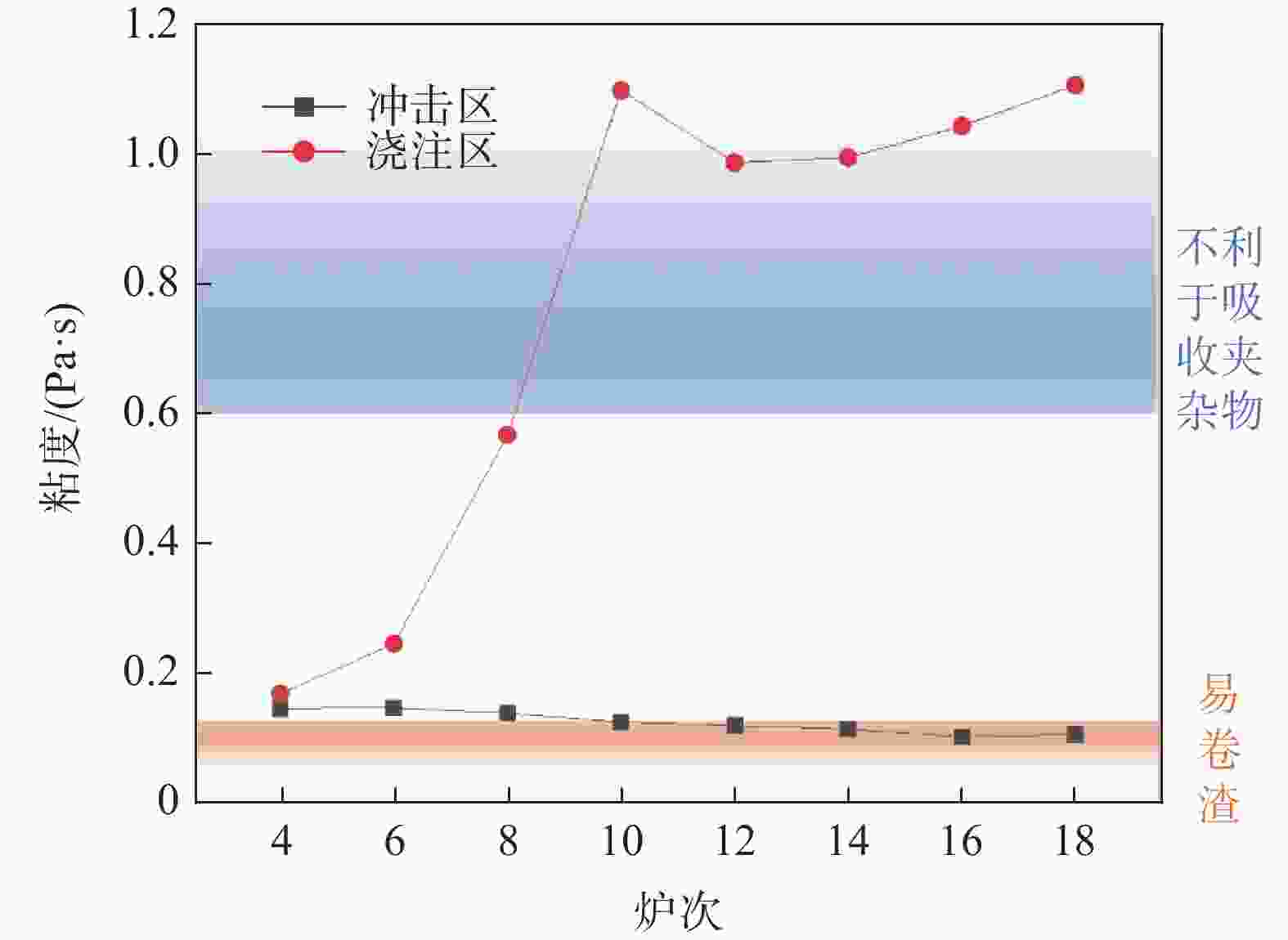

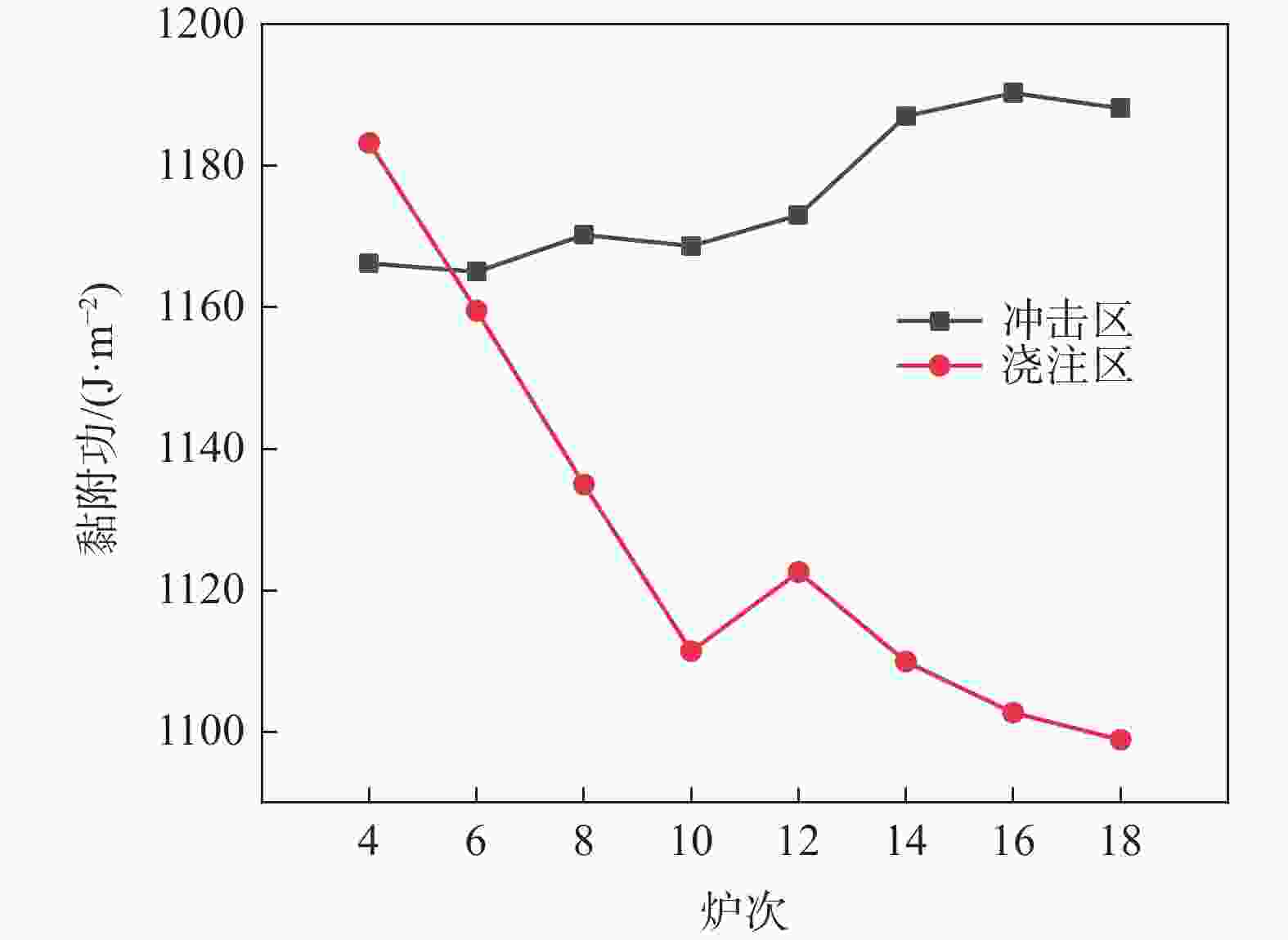

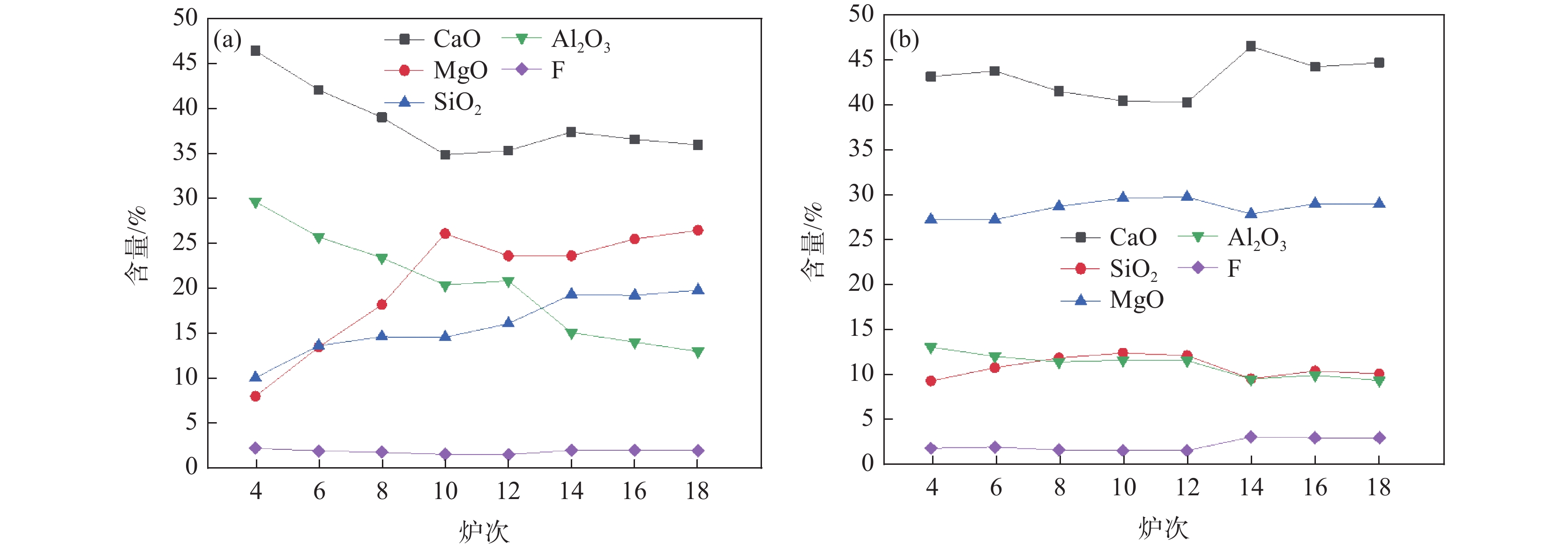

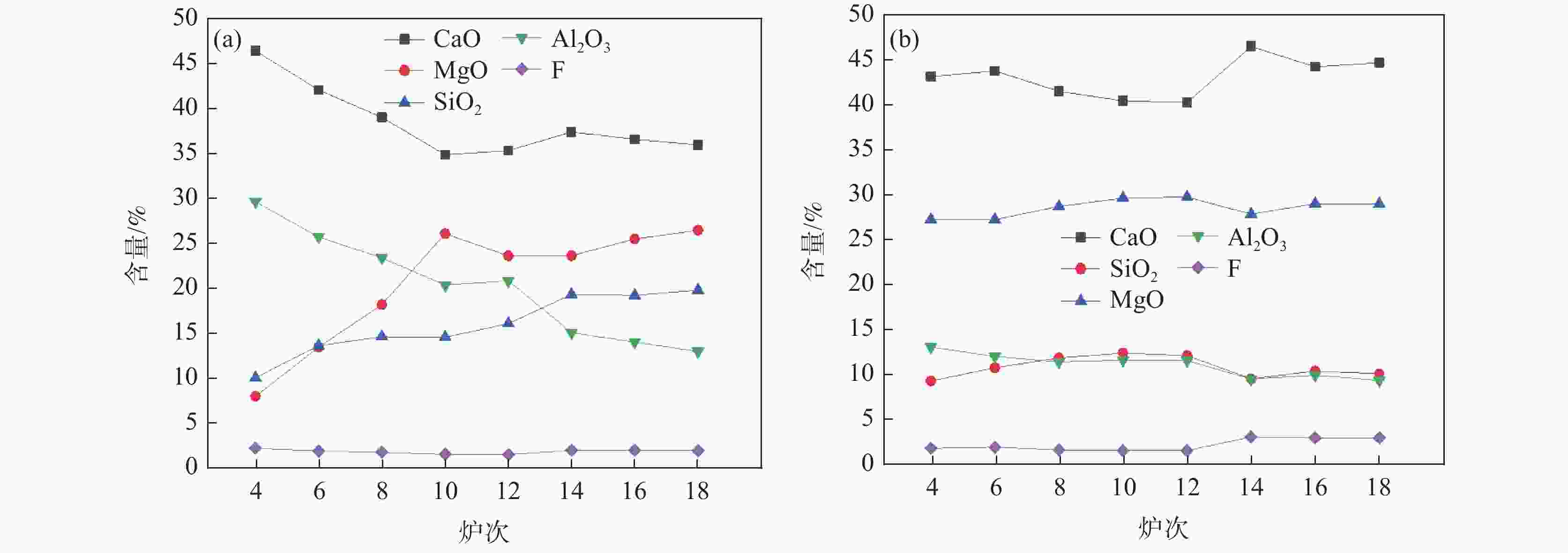

摘要: 中包渣在浇铸过程中保持良好的理化性能对稳定钢液纯净度具有重要意义。针对高碳钢中间包在连铸过程中各炉次的中包渣的理化性能进行测试研究,并利用Factsage对熔渣的高温物相进行热力学计算,分析其成分、熔点、粘度、表面张力演变规律。结果表明,中间包冲击区与浇注区渣的理化性能呈现不同的变化规律。随浇注炉次的增加,浇注区中包渣的SiO2与MgO含量明显升高,由于高熔点组分增多,完全融化温度由1325 ℃升高到1500 ℃以上,粘度上涨接近10倍、表面张力由0.4 N/m上涨到0.8 N/m,中包渣对夹杂物的吸附能力变差。而冲击区中包渣变化规律与浇注区相反,在冲击区容易发生卷渣。Abstract: Well keeping physicochemical properties of tundish slag during continuous casting is of great significance to stabilize the cleanness of molten steel. In this study, the physicochemical properties of tundish slag for high carbon steel bloom in the process of continuous casting were tested and studied, and the high-temperature phase of molten slag was calculated by a Factsage software, and the evolution laws of its composition, melting point, viscosity and surface tension were analyzed. The results show that the physicochemical properties of slag in tundish pouring zone and impact zone show different changing evolution. With the increase of casting heats, the SiO2 and MgO contents of tundish slag in casting zone increase significantly. Due to the increase of high melting point components, the complete melting temperature rises from 1325 ℃ to more than 1500 ℃, the viscosity rises nearly 10 times, the surface tension rises from 0.4 N/m to 0.8 N/m, and the adsorption capacity of tundish slag to inclusions becomes poor. The change law of impact zone is opposite to that of pouring zone, and slag entrapment is easy to occur in the impact zone.

-

Key words:

- continuous casting /

- tundish slag /

- physicochemical properties /

- inclusions

-

表 1 原始中包渣成分

Table 1. Composition of original tundish slag

% CaO MgO SiO2 Al2O3 F 其他物质

(可挥发成分)40~50 0~10 5~10 30~40 1~5 0~10 表 2

${\varphi }_{{\rm{ms}}(i)}$ 的参考值Table 2.

${\varphi }_{{\rm{ms}}(i)}$ datai组元 ${\mathit{\varphi } }_{{{\rm{m}}}{{\rm{s}}}(\mathit{i})}$/ kJ SiO2 0.597 Al2O3 0.468 MgO 0.687 CaO 0.607 CaF2 0.326 -

[1] Sun Yongchao, Huang Jun, Wu Yonglai, et al. Study on impurity-absorptivity of basic tundish covering flux[J]. Iron Steel Vanadium Titanium, 2006,27(1):17−20. (孙永超, 黄俊, 吴永来, 等. 碱性中间包覆盖剂吸附夹杂能力的研究[J]. 钢铁钒钛, 2006,27(1):17−20.Sun Yongchao, Huang Jun, Wu Yonglai, et al. Study on impurity-absorptivity of basic tundish covering flux[J]. Iron Steel Vanadium Titanium, 2006, 27(1): 17-20. [2] Wang Jianchang. Influence of high basicity tundish shielding agent on improvement of cleanliness of stainless steel 0Cr18Ni9[J]. Special Steel, 2015,36(4):38−40. (王建昌. 高碱度中间包覆盖剂对改善0Cr18Ni9不锈钢洁净度的影响[J]. 特殊钢, 2015,36(4):38−40.Wang Jianchang. Influence of high basicity tundish shielding agent on improvement of cleanliness of stainless steel 0 Cr18 Ni9[J]. Special Steel, 2015, 36(4): 38-40. [3] Zhang L, Wang W L, Shao H Q. Review of non-reactive CaO-Al2O3 based mold fluxes for casting high-aluminum steel[J]. Journal of Iron and Steel Research, International, 2019,36(4):336−344. [4] Li Dejun, Xu Mengchun, Lü Chunfeng, et al. Analysis on developments of covering fluxes for tundish[J]. Angang Technology, 2020,(1):15−18, 22. (李德军, 许孟春, 吕春风, 等. 中间包覆盖剂开发状况分析[J]. 鞍钢技术, 2020,(1):15−18, 22.Li Dejun, Xu Mengchun, Lv Chunfeng. et al. Analysis on developments of covering fluxes for tundish[J]. Angang Technology, 2020 (1): 15-18, 22. [5] Cheng Limei, Zhang Lifeng. Effect of basicity of tundish power on its melting property and wetting property[J]. China Metallurgy, 2018,28(S1):13−16. (程礼梅, 张立峰. 中间包覆盖剂碱度对熔化和润湿性能的影响[J]. 中国冶金, 2018,28(S1):13−16.Cheng Limei, Zhang Lifeng. Effect of basicity of tundish power on its melting property and wetting property[J]. China Metallurgy, 2018, 28(S1): 13-16. [6] Li Maokang, Zhang Jiongming, Luo Yanzhao, et al. Utilizing reduction calcium slag to make high basicity carbon-free tundish covering flux with low silicon[J]. Journal of Iron and Steel Research, 2014,26(1):16−21. (李茂康, 张炯明, 罗衍昭, 等. 利用还原钙渣配制高碱度低硅无碳中间包覆盖剂[J]. 钢铁研究学报, 2014,26(1):16−21.Li Maokang, Zhang Jiongming, Luo Yanshao, et al. Utilizing reduction calcium slag to make high basicity carbon-free tundish covering flux with low silicon[J]. Journal of Iron and Steel Research, 2014, 26(1): 16-21. [7] Tapia V H, Morales R D, Camacho J, et al. Influence of the tundish powder on steel cleanliness and nozzle clogging[J]. Steelmaking Conference Proceedings, 1996,79:539. [8] Xu Jinzhong, Han Yihua, Bi Yanxue, et al. Study on the dissolution behavior of Al2O3 for CaO-Al2O3 based slag[J]. Iron Steel Vanadium Titanium, 2018,39(2):127−131. (许进忠, 韩毅华, 毕延雪, 等. CaO-Al2O3基连铸保护渣对Al2O3溶解行为的研究[J]. 钢铁钒钛, 2018,39(2):127−131.Xu Jinzhong, Han Yihua, Bi Yanxue, et al. Study on the dissolution behavior of Al2O3 for CaO-Al2O3based slag[J]. Iron Steel Vanadium Titanium, 2018, 39(2): 127-131. [9] Yang Shufeng, Li Jingshe, Liu Wei. Motion of solid particles at molten metal–liquid slag interface[J]. JOM, 2015,67(12):2993−3001. doi: 10.1007/s11837-015-1642-y [10] 李晓亮. 中间包覆盖剂理化性能的研究[D]. 沈阳: 东北大学, 2010.Li Xiaoliang. Study on physiochemical properties of tundish covering flux[D]. Shengyang: Northeastern University, 2010. [11] Long Xiao, He Shengping, Wang Qian. Study on structure characteristics of solid slag films of mold fluxes for peritectic steel continuous casting[J]. Journal of Iron and Steel Research, 2018,30(1):21−25. (龙潇, 何生平, 王谦. 超高碱度连铸保护渣固渣膜凝固和结晶行为特性[J]. 钢铁研究学报, 2018,30(1):21−25.Long Xiao, He Shengping, Wang Qian. Study on structure characteristics of solid slag films of mold fluxes for peritectic steel continuous casting[J]. Journal of Iron and Steel Research, 2018, 30(1): 21-25. [12] Wang Xianyang, Hu Hao, Xie Xin, et al. Flow behavior of molten steel during fewer strands casting of six-strand bloom[J]. Continuous Casting, 2022,(2):25−34. (王先扬, 胡淏, 谢鑫, 等. 大方坯六流中间包少流浇注时钢液的流动行为[J]. 连铸, 2022,(2):25−34.Wang Xianyang, Hu Hao, Xie Xin, et al. Flow behavior of molten steel during fewer strands casting of six-strand bloom[J]. Continuous Casting, 2022 (2): 25-34. [13] 盖少群, 丁胜利, 张文涛, 等. 连铸中间包渣结壳机理研究[C]//2019全国高效连铸应用技术及铸坯质量控制研讨会. 扬州: 河北省金属学会, 2019.Gai Shaoqun, Ding Shengli, Zhang Wentao, et al. Research on the mechanism of tundish slag to form the solidified crusts for continuous carting[C]//2019 National High Efficiency Continuous Casting Application Technology and Slab Quality Control Seminar. Yangzhou: Hebei Province Society for Metals, 2019. [14] Xie Jian. Mechanism analysis for basic tundish fluxes to form the solidified crusts[J]. Journal of Materials and Metallurgy, 2010,9(1):15−17. (谢健. 碱性中间包覆盖剂结壳机理分析[J]. 材料与冶金学报, 2010,9(1):15−17.Xie Jian. Mechanism analysis for basic tundish fluxes to form the solidified crusts[J]. Journal of Materials and Metallurgy, 2010, 9(1): 15-17. [15] Zhang Yifei, Han Xiuli, Liu Lina, et al. Influence of basicity on crystallization temperature and crystalline phase of mould powder[J]. Iron Steel Vanadium Titanium, 2015,36(5):103−107. (张翼飞, 韩秀丽, 刘丽娜, 等. 碱度对保护渣结晶温度及结晶矿相的影响[J]. 钢铁钒钛, 2015,36(5):103−107.Zhang Yifei, Han Xiuli, Liu Lina, et al. Influence of basicity on crystallization temperature and crystalline phase of mould powder[J]. Iron Steel Vanadium Titanium, 2015, 36(5): 103-107. [16] Zheng D L, Shi C B, Li Z J, et al. Effect of SiO2 substitution with Al2O3 during high-Al TRIP steel casting on crystallization and structure of low-basicity CaO-SiO2-based mold flux[J]. Journal of Iron and Steel Research, International, 2020,27(1):33−41. doi: 10.1007/s42243-018-0218-9 [17] Xia Junfei, Xu Jifang, Liu Gongyuan, et al. Influence of CaO and SiO2 content on melting properties of CaO-SiO2-Al2O3-MgO slag system[J]. The Chinese Journal of Process Engineering, 2010,10(S1):78−82. (夏俊飞, 许继芳, 刘恭源, 等. CaO和SiO2含量对CaO-SiO2-Al2O3-MgO熔渣熔化性能的影响[J]. 过程工程学报, 2010,10(S1):78−82.Xia Junfei, Xu Jifang, Liu Gongyuan, et al. Influence of CaO and SiO2 content on melting properties of CaO-SiO2-Al2O3-MgO slag system[J]. The Chinese Journal of Process Engineering, 2010, 10(S1): 78-82. [18] 高杰. 高铝钢用中间包覆盖剂的研究[D]. 重庆: 重庆大学, 2008.Gao Jie. Study on covering fluxes in tundish for high aluminium steel[D]. Chongqing: Chongqing University, 2008. [19] Chen Xingrun, Hu Huanzhang. Effect of tundish fluxes on cleanliness of 430 stainless steel[J]. China Metallurgy, 2017,27(8):36−40. (陈兴润, 胡桓彰. 中间包覆盖剂对430不锈钢钢水洁净度的影响[J]. 中国冶金, 2017,27(8):36−40.Cheng Xinrun, Hu Huanzhang. Effect of tundish fluxes on cleanliness of 430 stainless steel[J]. China Metallurgy, 2017, 27(8): 36-40. [20] Du Yizhe, Yuan Yonggui, Li Li, et al. Insights into structure and properties of P2O5-based binary systems through molecular dynamics simulations[J]. Journal of Molecular Liquids, 2021,339:10. [21] Ren Yun, Sun Luyan, Zhao Fucai, et al. Effect of CaF2 content and basicity on viscosity of tundish covering fluxes[J]. Journal of Iron and Steel Research, 2015,27(1):35−39. (任耘, 孙璐艳, 赵福才, 等. CaF2及碱度变化对中间包覆盖剂黏度的影响[J]. 钢铁研究学报, 2015,27(1):35−39.Ren Yun, Sun Luyan, Zhao Fucai, et al. Effect of CaF2 content and basicity on viscosity of tundish covering fluxes [J]. Journal of Iron and Steel Research, 2015, 27(1): 35-39. [22] Mo Rongzhen, Zhang Lifeng, Ren Ying, et al. Review on effect of composition on viscosity of low-reactive mold flux for high-Al steel[J]. Journal of Iron and Steel Research, 2021,33(8):695−708. (莫嵘臻, 张立峰, 任英, 等. 高铝钢用低反应型保护渣成分对其黏度的影响[J]. 钢铁研究学报, 2021,33(8):695−708. doi: 10.13228/j.boyuan.issn1001-0963.20210087Mo Rongzhen, Zhang Lifeng, Ren Ying, et al. Review on effect of composition on viscosity of low-reactive mold flux for high-Al steel[J]. Journal of Iron and Steel Research, 2021, 33(8): 695-708. doi: 10.13228/j.boyuan.issn1001-0963.20210087 [23] 周业连, 邓志银, 朱苗勇. 非球形固态夹杂物穿过钢-渣界面行为研究 [J]. 过程工程学报, 2022, 22(2): 222-231.Zhou Yelian, Deng Zhiyin, Zhu Miaoyong. Consideration on removal of non-spherical solid inclusions at steel-slag interface[J]. The Chinese Journal of Process Engineering, 2022, 22(2): 222-231. [24] Abdeyazdan H, Monaghan B J. Interfacial tension in the CaO-Al2O3-SiO2-(MgO) liquid slag–solid oxide systems[J]. Metallurgical & Materials Transactions B, 2017,48(4):1−11. [25] Good R J, Oss C J V. The modern theory of contact angles and the hydrogen bond components of surface energies [M]. Boston: Springer, 1992. -

下载:

下载: