Precipitation behavior of composite precipitates in Nb-Ti micro-alloy EH36 offshore steel

-

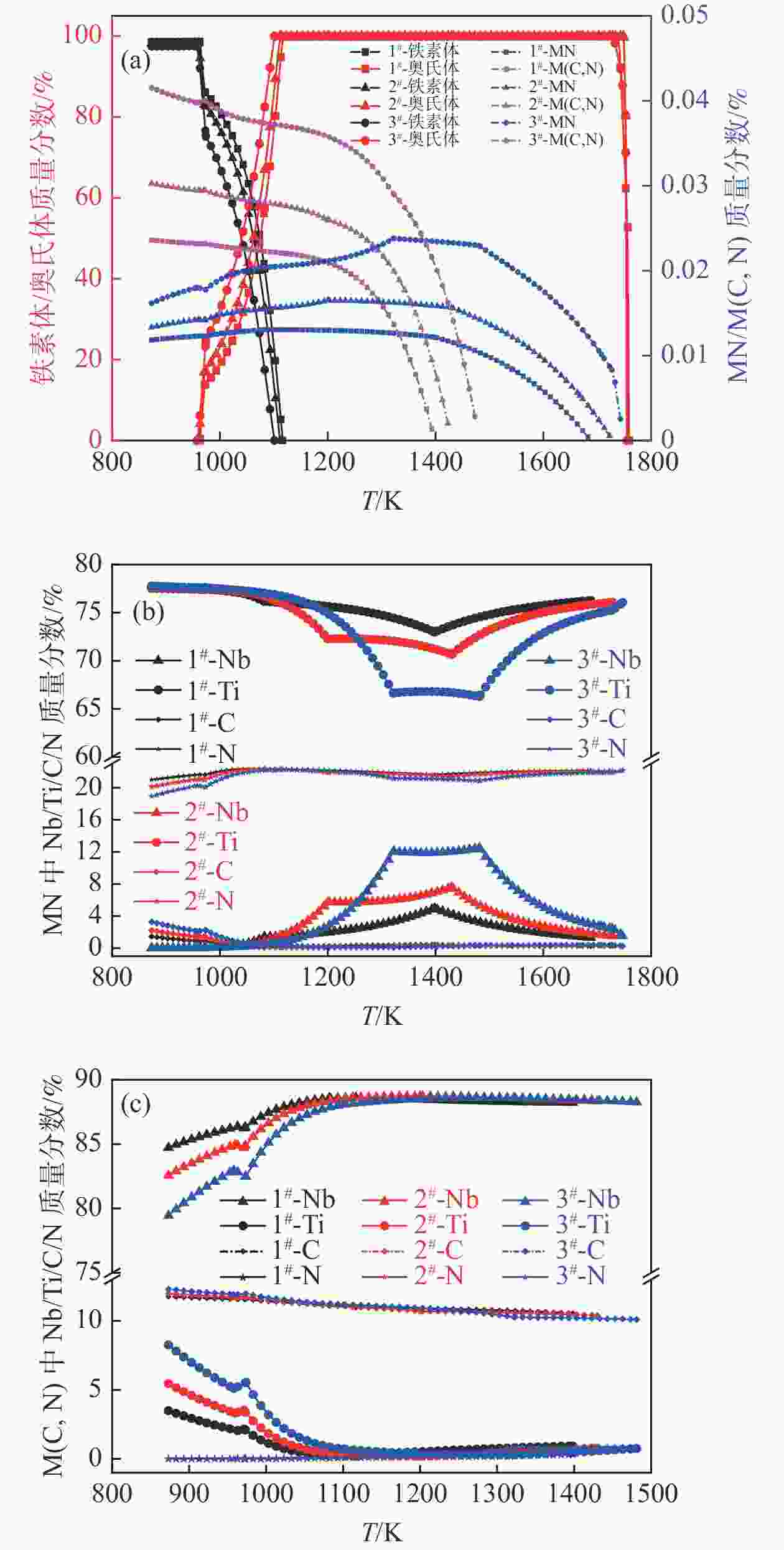

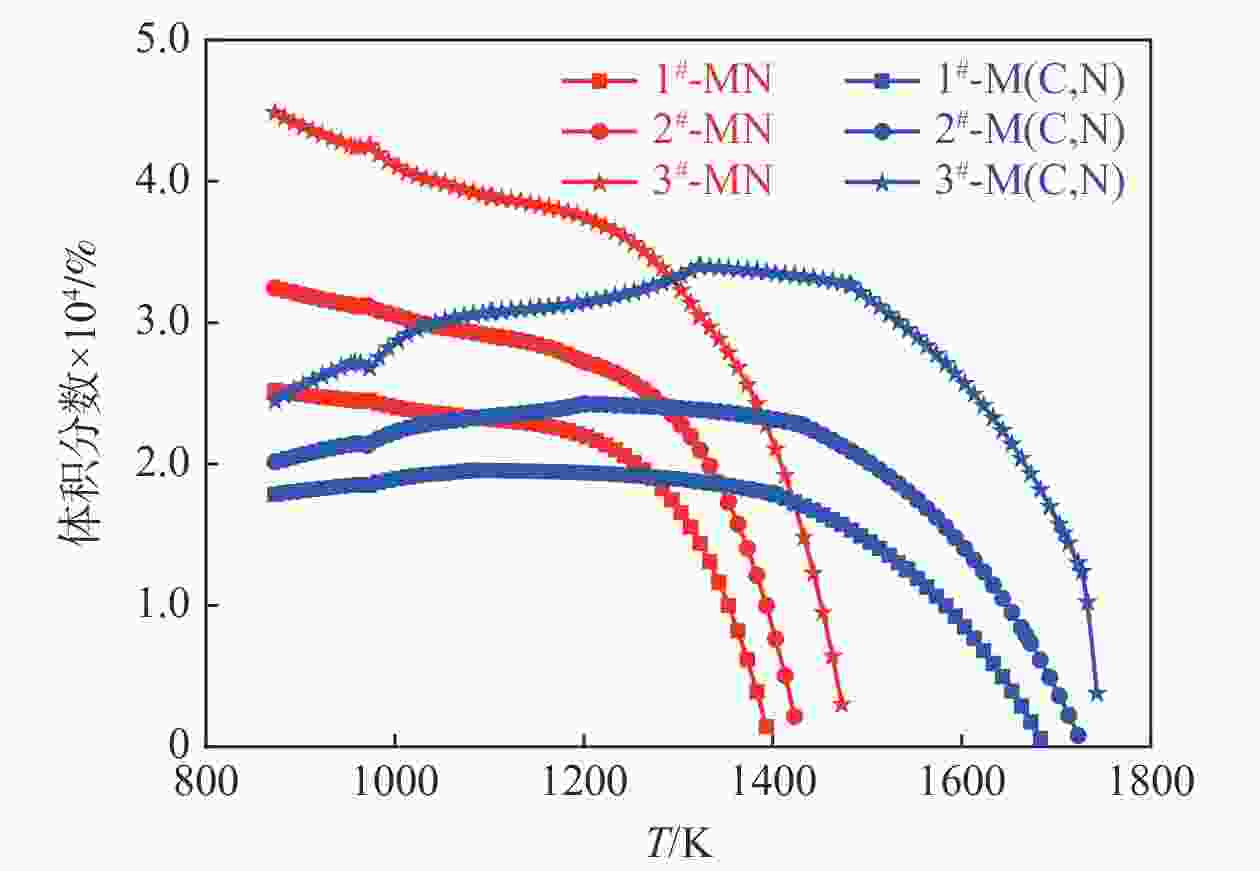

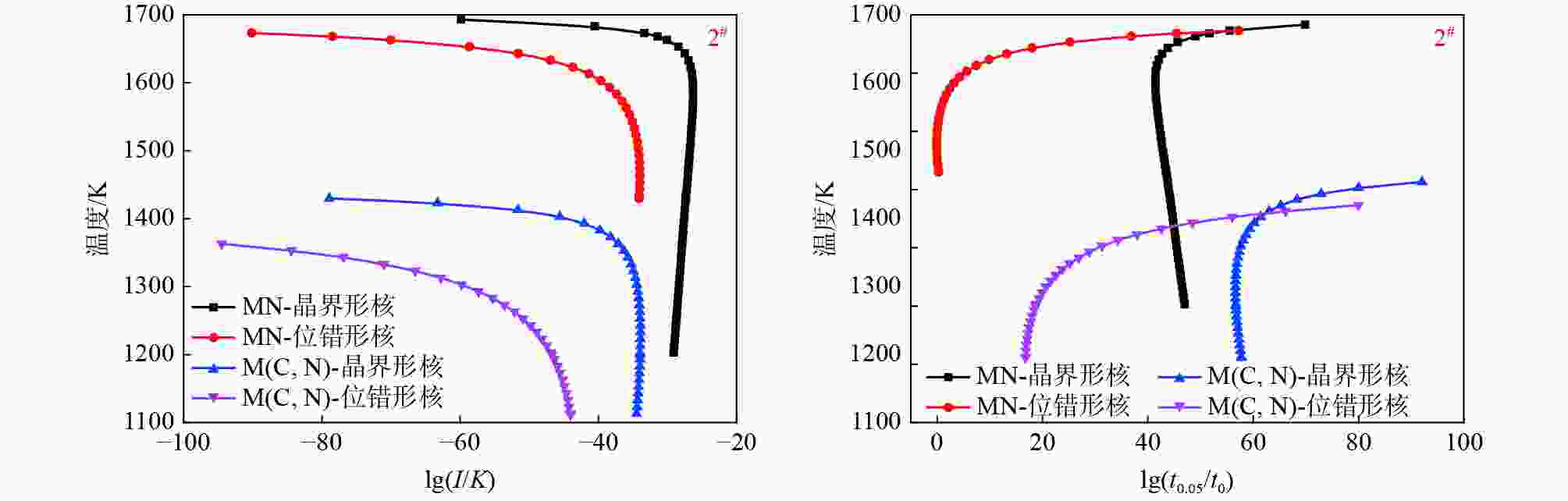

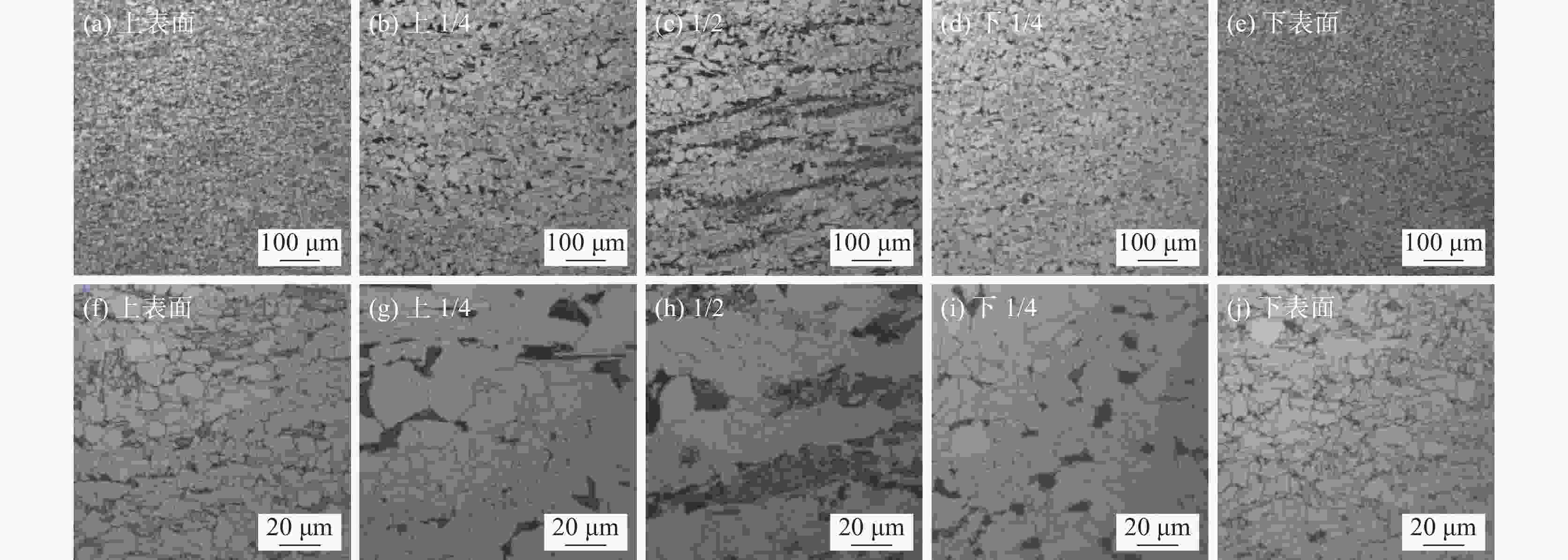

摘要: 基于EH36海工钢屈服强度影响因素的主成分回归分析,结合复合析出相固溶析出计算和经典析出动力学理论,系统研究了影响EH36海工钢屈服强度的主要因素和复合析出相的析出行为,并探讨了轧制过程奥氏体形变储能对复合析出相析出动力学的影响。结果表明,影响EH36海工钢屈服强度的主要因素为Ti、Nb和N。MN和M(C,N)分别在1728.5 K和1430.0 K开始析出,主要为(Ti,Nb)N和(Nb,Ti)C。在奥氏体相区,MN和M(C,N)的最大析出量分别为0.0165%和0.0277%,最大析出体积分数分别为0.000228%和0.000389%,发生晶界形核的最快沉淀析出温度分别为1580.3 K和1228.3 K。随着奥氏体形变储能的增加,MN和M(C,N)相对形核率呈增加趋势,析出孕育期明显缩短且沉淀强化作用增强。Abstract: Based on the principal component regression analysis of the factors affecting the yield strength of EH36 offshore steel, combined with the solid solution precipitation calculation of composite precipitation phase and the classical precipitation kinetics theory, the main factors affecting the yield strength of EH36 offshore steel and the precipitation behavior of composite precipitation phase in γ were systematically studied, and the influence of austenite deformation and energy storage during rolling on the precipitation kinetics of composite precipitation phase was discussed. The results show that the main factors affecting the yield strength of EH36 offshore steel are Ti, Nb and N. MN and M(C,N) began to precipitate at 1728.5 K and 1430.0 K, respectively, and were mainly (Ti,Nb)N and (Nb,Ti)C. In the austenite phase region, the maximum precipitation amounts of MN and M(C,N) are 0.0165% and 0.0277% respectively, and the maximum precipitation volume fractions are 0.000228% and 0.000389% respectively. The fastest precipitation temperatures for grain boundary nucleation are 1580.3 K and 1228.3 K respectively. With the increase of deformation energy storage, the relative nucleation rate of MN and M(C,N) increases, the incubation period of precipitation is obviously shortened and the precipitation strengthening effect is enhanced.

-

表 1 EH36海工钢主要化学成分

Table 1. Main chemical composition of EH36 steel

% C Si Mn S P Al Ti Nb N Ni, Mo, Cu, V 0.12~0.16 0.20~0.40 1.20~1.50 0.0010~0.0040 0.015~0.020 0.020~0.050 0.012~0.016 0.020~0.030 0.0030~0.0050 残余 表 2 相关参数统计及变量定义

Table 2. Statistics of related parameters and definition of variables

统计项 屈服强度/MPa 厚度/mm w/% C Si Mn P S Al Nb N Ti (因变量) (x1) (x2) (x3) (x4) (x5) (x6) (x7) (x8) (x9) (x10) 极小值 357 42 0.07 0.13 1.28 0.01 0.001 0.02 0.02 0.0018 0.007 极大值 472 80 0.17 0.41 1.58 0.028 0.008 0.05 0.033 0.0068 0.016 均值 421.17 50.69 0.12 0.24 1.35 0.018 0.0038 0.033 0.025 0.0041 0.012 标准差 24.56 7.79 0.0092 0.048 0.05 0.0034 0.0018 0.0049 0.0029 0.0006 0.0019 注:统计量为230个。 表 3 各成分的特征根和方差贡献率

Table 3. Characteristic root and variance contribution rate of each component

自变量成分 初始特征值 方差贡献率/% 累积贡献率/% Z1 3.347 33.474 33.474 Z2 2.015 20.155 53.628 Z3 1.8 17.995 71.623 Z4 1.018 10.175 81.798 Z5 0.584 5.836 87.634 Z6 0.399 3.994 91.628 Z7 0.322 3.223 94.851 Z8 0.241 2.413 97.264 Z9 0.196 1.96 99.224 Z10 0.078 0.776 100 表 4 主成分的成分矩阵

Table 4. Component Matrix of Principal Components

主成分向量 标准化后的自变量 x1* x2* x3* x4* x5* x6* x7* x8* x9* x10* l1 0.622 0.767 0.815 0.597 −0.158 −0.516 −0.093 0.118 −0.105 0.076 l2 0.383 −0.133 −0.306 0.483 0.157 0.337 −0.675 0.944 0.658 −0.092 l3 −0.221 0.266 0.08 −0.18 0.583 −0.181 −0.219 −0.109 0.397 0.707 l4 0.144 0.217 −0.079 0.1 0.572 0.445 0.417 0.181 −0.441 0.083 表 5 回归系数显著性检验结果

Table 5. Test results of significance of regression coefficient

自变量 标准化系数 差异性显著的检验值sig Z1 −0.070 −0.024 Z2 0.061 0.028 Z3 0.149 0.043 Z4 −0.152 0.055 表 6 各成分对屈服强度影响的多元线性回归方程

Table 6. Multiple linear regression equation of the influence of each component on yield strength

屈服强度/MPa 回归方程系数 厚度 C Si Mn P S Als Nb N Ti Y*=f(xi*) −0.101 −0.008 −0.023 −0.102 0.075 −0.013 0.029 −0.083 0.03 0.094 Y=f(xi) −0.013 −0.838 −0.477 −2.033 22.153 −7.453 5.928 −28.684 24.96 49.572 表 7 不同成分的EH36海工钢

Table 7. EH36 marine steel with different compositions

% 编号 C Si Mn P S Al Nb N Ti 1# 0.10 0.20 1.20 0.010 0.0010 0.020 0.020 0.0030 0.010 2# 0.12 0.24 1.35 0.018 0.0038 0.033 0.025 0.0041 0.012 3# 0.17 0.41 1.58 0.028 0.0050 0.050 0.033 0.0068 0.016 相 固溶度积公式 控制元素扩散系数D/(cm2·s−1) 界面能 σ/(J·m−2) 摩尔体积×105/(m3·mol−1) 晶格常数/nm NbC 3.70-9100/T 530 exp(-344000/RT) 1.3435-0.6054×10−3T 1.345 0.4470 TiC 2.75-7000/T 0.15 exp(-251000/RT) 1.2360-0.5570×10×3T 1.212 0.4318 NbN 2.80-8500/T 530 exp(-344000/RT) 1.2999-0.5858×10−3T 1.277 0.4394 TiN 0.32-8000/T 0.15 exp(-251000/RT) 1.1803-0.5318×10−3T 1.147 0.4282 表 9 晶界形核和位错形核条件下不同形变储能下复合析出相MN和M(C,N)形核参量的计算结果

Table 9. Nucleation parameters of MN and M(C,N) at different deformation energies and with grain boundary nucleation

T/K MN,lg(I/K) M(C,N),lg(I/K) 晶界形核 位错形核 晶界形核 位错形核 0 J/mol 2000 J/mol 4000 J/mol 0 J/mol 2000 J/mol 4000 J/mol 0 J/mol 2000 J/mol 4000 J/mol 0 J/mol 2000 J/mol 4000 J/mol 1353 −27.95 −27.56 −27.18 −33.16 −32.64 −32.13 −36.31 −35.93 −35.54 −84.44 −83.92 −83.41 1303 −28.32 −27.92 −27.52 −33.13 −32.59 −32.06 −34.44 −34.04 −33.63 −59.79 −59.26 −58.72 1253 −28.7 −28.29 −27.87 −33.28 −32.73 −32.17 −33.95 −33.54 −33.12 −50.9 −50.34 −49.78 1203 −29.1 −28.67 −28.23 −33.55 −32.97 −32.39 −33.95 −33.52 −33.08 −46.87 −46.29 −45.71 1153 −29.39 −28.94 −28.49 −33.57 −32.97 −32.36 −34.18 −33.73 −33.27 −44.89 −44.28 −43.68 1103 −29.65 −29.17 −28.7 −33.37 −32.73 −32.1 −34.48 −34 −33.53 −43.36 −42.73 −42.09 1053 −29.93 −29.43 −28.94 −33.59 −32.93 −32.27 −34.37 −33.88 −33.38 −41.2 −40.54 −39.88 -

[1] Zhao Mengjing, Wang Feng, Xi Xiaojun, et al. Effect of Y on inclusions characteristics and tensile properties in EH36 shipbuilding steel[J]. Iron & Steel, 2019,54(7):67−73. (赵梦静, 王峰, 习小军, 等. 钇对EH36船板钢夹杂物特性和拉伸性能的影响[J]. 钢铁, 2019,54(7):67−73.Zhao Mengjing, Wang Feng, Xi Xiaojun, et al. Effect of Y on inclusions characteristics and tensile properties in EH36 shipbuilding steel[J]. Iron & Steel, 2019, 54(7): 67-73. [2] Zhou Yutao, Yang Shufeng, Li Jingshe, et al. Inclusions evolution of high-grade ship plate steel in practical production processes[J]. Iron & Steel, 2019,54(1):33−42. (周宇涛, 杨树峰, 李京社, 等. 高级别船板钢生产过程中夹杂物的演变规律[J]. 钢铁, 2019,54(1):33−42.Zhou Yutao, Yang Shufeng, Li Jingshe, et al. Inclusions evolution of high-grade ship plate steel in practical production processes[J]. Iron & Steel, 2019, 54(1): 33-42. [3] Wang Hongtao, Tian Yong, Ye Qibin, et al. Development of heavy ship plate in extremely cold environment[J]. Steel Rolling, 2018,35(5):48−53. (王红涛, 田勇, 叶其斌, 等. 极寒环境下厚规格船舶用钢的发展[J]. 轧钢, 2018,35(5):48−53.Wang Hongtao, Tian Yong, Ye Qibin, et al. Development of heavy ship plate in extremely cold environment[J]. Steel Rolling, 2018, 35(5): 48-53. [4] Yang Kaisheng. Effect of heat treatment process and NbV-N microalloying on mechanical property and microstructure of grade ship plate steel[J]. China Metallurgy, 2017,10:34−39. (阳开生. 热处理及NbV-N微合金化对船板钢组织性能的影响[J]. 中国冶金, 2017,10:34−39.Yang Kaisheng. Effect of heat treatment process and NbV-N microalloying on mechanical property and microstructure of grade ship plate steel[J]. China Metallurgy, 2017, 10: 34-39. [5] Shu Wei, Wang Xuemin, Li Shurui, et al. Influence of second-phase particles containing Ti on microstructure and properties of weld-heat-affected-zone of a microalloyed steel[J]. Acta Metallurgica Sinica, 2010,8:997−1003. (舒玮, 王学敏, 李书瑞, 等. 含Ti复合第二相粒子对微合金钢焊接热影响区组织和性能的影响[J]. 金属学报, 2010,8:997−1003.Shu Wei, Wang Xuemin, Li Shurui, et al. Influence of second-phase particles containing Ti on microstructure and properties of weld-heat-affected-zone of a microalloyed steel[J]. Acta Metallurgica Sinica, 2010, 8: 997-1003. [6] Wu Shaowen, Zhang Caijun, Zheng Feifan, et al. Effect of second phase particles on austenite grain size in EH40 steel[J]. Heat Treatment of Metals, 2019,42(7):88−92. (武绍文, 张彩军, 郑非凡, 等. EH40钢中第二相粒子对奥氏体尺寸的影响[J]. 金属热处理, 2019,42(7):88−92.Wu Shaowen, Zhang Caijun, Zheng Feifan, et al. Effect of second phase particles on austenite grain size in EH40 steel[J]. Heat Treatment of Metals, 2019, 42(7): 88-92. [7] Liu Jiahe, Wang Zubin. Recent development on manufacturing technology of HSLA steel[J]. Iron & Steel, 1996,31(10):73−79. (刘嘉禾, 王祖滨. 低合金高强度钢生产工艺技术的发展[J]. 钢铁, 1996,31(10):73−79.Liu Jiahe, Wang Zubin. Recent development on manufacturing technology of HSLA steel[J]. Iron & Steel, 1996, 31(10): 73-79. [8] Shi Xiao, Wu Jianzhong, Guo Hanjie, et al. Precipitation behaviors of carbides and carbonitrides in DH36 high-strength ship plate steel[J]. Journal of Central South University (Science and Technology), 2018,283(3):14−24. (石骁, 吴建中, 郭汉杰, 等. DH36高强度船板钢中碳化物及碳氮化物析出行为[J]. 中南大学学报(自然科学版), 2018,283(3):14−24.Shi Xiao, Wu Jianzhong, Guo Hanjie, et al. Precipitation behaviors of carbides and carbonitrides in DH36 high-strength ship plate steel[J]. Journal of Central South University (Science and Technology), 2018, 283(3): 14-24. [9] Vanovsek W, Bernhard C, Fiedler M, et al. Effect of titanium on the solidification and postsolidification microstructure of high-strength steel welds[J]. Welding in the World, 2013,57(5):665−674. doi: 10.1007/s40194-013-0063-1 [10] Zou Xiaodong, Zhao Dapeng, Sun Jincheng, et al. An integrated study on the evolution of inclusions in EH36 shipbuilding steel with Mg addition: From casting to welding[J]. Metallurgical and Materials Transactions, B, 2018,49(2):481−489. doi: 10.1007/s11663-017-1163-x [11] Wang Bingxing, Wu Zhongzi, Lou Haonan, et al. Effect of oxide metallurgy on microstructure and properties of HAZ in EH36 steel[J]. Journal of Iron and Steel Research, 2019,31(2):154−161. (王丙兴, 武仲子, 娄号南, 等. 氧化物冶金工艺对EH36钢HAZ组织性能的影响[J]. 钢铁研究学报, 2019,31(2):154−161.Wang Bingxing, Wu Zhongzi, Lou Haonan, et al. Effect of oxide metallurgy on microstructure and properties of HAZ in EH36 steel[J]. Journal of Iron and Steel Research, 2019, 31(2): 154-161. [12] Shi Minghao, Duan Zhengtao, Zhang Pengyan, et al. Effect of inclusions on formation of acicular ferrite in Ti and Zr micro-alloying steel[J]. Journal of Northeastern University(Natural Science), 2012,10:1424−1427. (石明浩, 段争涛, 张朋彦, 等. 夹杂物对Ti, Zr微合金钢中针状铁素体形成的影响[J]. 东北大学学报(自然科学版), 2012,10:1424−1427.Shi Minghao, Duan Zhengtao, Zhang Pengyan, et al. Effect of inclusions on formation of acicular ferrite in Ti and Zr micro-alloying steel[J]. Journal of Northeastern University(Natural Science), 2012, 10: 1424-1427. [13] Wang Baoming, Zhao Zhiyi, Chen Lingfeng, et al. Principal component regression analysis on the size and quantity of inclusions affecting magnetic properties of non-oriented silicon steel[J]. Metallurgical Analysis, 2014,34(10):1−6. (王宝明, 赵志毅, 陈凌峰, 等. 夹杂物尺寸及数量对无取向硅钢磁性能影响的主成分回归分析[J]. 冶金分析, 2014,34(10):1−6.Wang Baoming, Zhao Zhiyi, Chen Lingfeng, et al. Principal component regression analysis on the size and quantity of inclusions affecting magnetic properties of non-oriented silicon steel [J]. Metallurgical Analysis, 2014, 34(10): 1-6. [14] Chen Lingfeng, Zhao Zhiyi, Wang Baoming, et al. Principal component regression analysis for effects of grain size on magnetic properties of non-oriented silicon steel[J]. Transactions of Materials and Heat Treatment, 2014,35(11):215−218. (陈凌峰, 赵志毅, 王宝明, 等. 晶粒尺寸对无取向硅钢磁性能影响的主成分回归分析[J]. 材料热处理学报, 2014,35(11):215−218.Chen Lingfeng, Zhao Zhiyi, Wang Baoming, et al. Principal component regression analysis for effects of grain size on magnetic properties of non-oriented silicon steel[J]. Transactions of Materials and Heat Treatment, 2014, 35(11): 215-218. [15] Chen Lingfeng, Zhao Zhiyi, Wang Baoming, et al. Principal component regression analysis on texture affecting magnetic properties of non-oriented silicon steel[J]. Hot Working Technology, 2015,44(16):62−64, 67. (陈凌峰, 赵志毅, 王宝明, 等. 织构对无取向硅钢磁性能影响的主成分回归分析[J]. 热加工工艺, 2015,44(16):62−64, 67.Chen Lingfeng, Zhao Zhiyi, Wang Baoming, et al. Principal component regression analysis on texture affecting magnetic properties of non-oriented silicon steel[J]. Hot Working Technology, 2015, 44(16): 62-64, 67. [16] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006.Yong Qilong. Secondary phases in steel [M]. Beijing: Metallurgical Industry Press, 2006. [17] Adrian H. Thermodynamic model for precipitation of carbonitrides in high strength low alloy steels containing up to three microalloying elements with or without additions of aluminium[J]. Materials Science and Technology, 1992,8(5):406−420. doi: 10.1179/mst.1992.8.5.406 [18] Zhang Ke, Sun Xinjun, Zhang Mingya, et al. Kinetics of (Ti, V, Mo)C precipitated in γ/α matrix of Ti-V-Mo complex microalloyed steel[J]. Acta Metallurgica Sinica, 2018,54(8):38−46. (张可, 孙新军, 张明亚, 等. Ti-V-Mo复合微合金钢中(Ti, V, Mo)C在γ/α中沉淀析出的动力学[J]. 金属学报, 2018,54(8):38−46.Zhang Ke, Sun Xinjun, Zhang Mingya, et al. Kinetics of (Ti, V, Mo)C precipitated in γ/α matrix of Ti-V-Mo complex microalloyed steel[J]. Acta Metallurgica Sinica, 2018, 54(8): 38-46. [19] Liu Min, Feng Xiaoming, Lai Chaobin, et al. Influence of hot rolling parameters on recrystallization of steel E690 for sea platform[J]. Heat Treatment of Metals, 2015,40(10):64−67. (刘敏, 冯小明, 赖朝彬, 等. 热轧工艺对海洋平台用钢E690再结晶的影响[J]. 金属热处理, 2015,40(10):64−67.Liu Min, Feng Xiaoming, Lai Chaobin, et al. Influence of hot rolling parameters on recrystallization of steel E690 for sea platform[J]. Heat Treatment of Metals, 2015, 40(10): 64-67. [20] Yao Na, Xing Chao. Precipitation kinetics of composite carbides of Nb-Ti-V-Mo microalloyed steel[J]. Iron Steel Vanadium Titanium, 2022,43(4):142−149. (姚娜, 兴超. Nb-Ti-V-Mo微合金钢中复合碳化物的析出动力学[J]. 钢铁钒钛, 2022,43(4):142−149.Yao Na, Xing Chao. Precipitation kinetics of composite carbides of Nb-Ti-V-Mo microalloyed steel[J]. Iron Steel Vanadium Titanium, 2022, 43(4): 142-149. [21] Wang Zhaodong, Qu Jinbo, Liu Xianghua, et al. Investigation of strain-induced precipitation behavior in microalloying steel by stress relaxation method[J]. Acta Metallurgica Sinica, 2000,36(6):618−621. (王昭东, 曲锦波, 刘相华, 等. 松弛法研究微合金钢碳氮化物的应变诱导析出行为[J]. 金属学报, 2000,36(6):618−621.Wang Zhaodong, Qu Jinbo, Liu Xianghua, et al. Investigation of strain-induced precipitation behavior in microalloying steel by stress relaxation method[J]. Acta Metallurgica Sinica, 2000, 36(6): 618-621. -

下载:

下载: