Effect of La on non-metallic inclusions in FeCrAl alloy

-

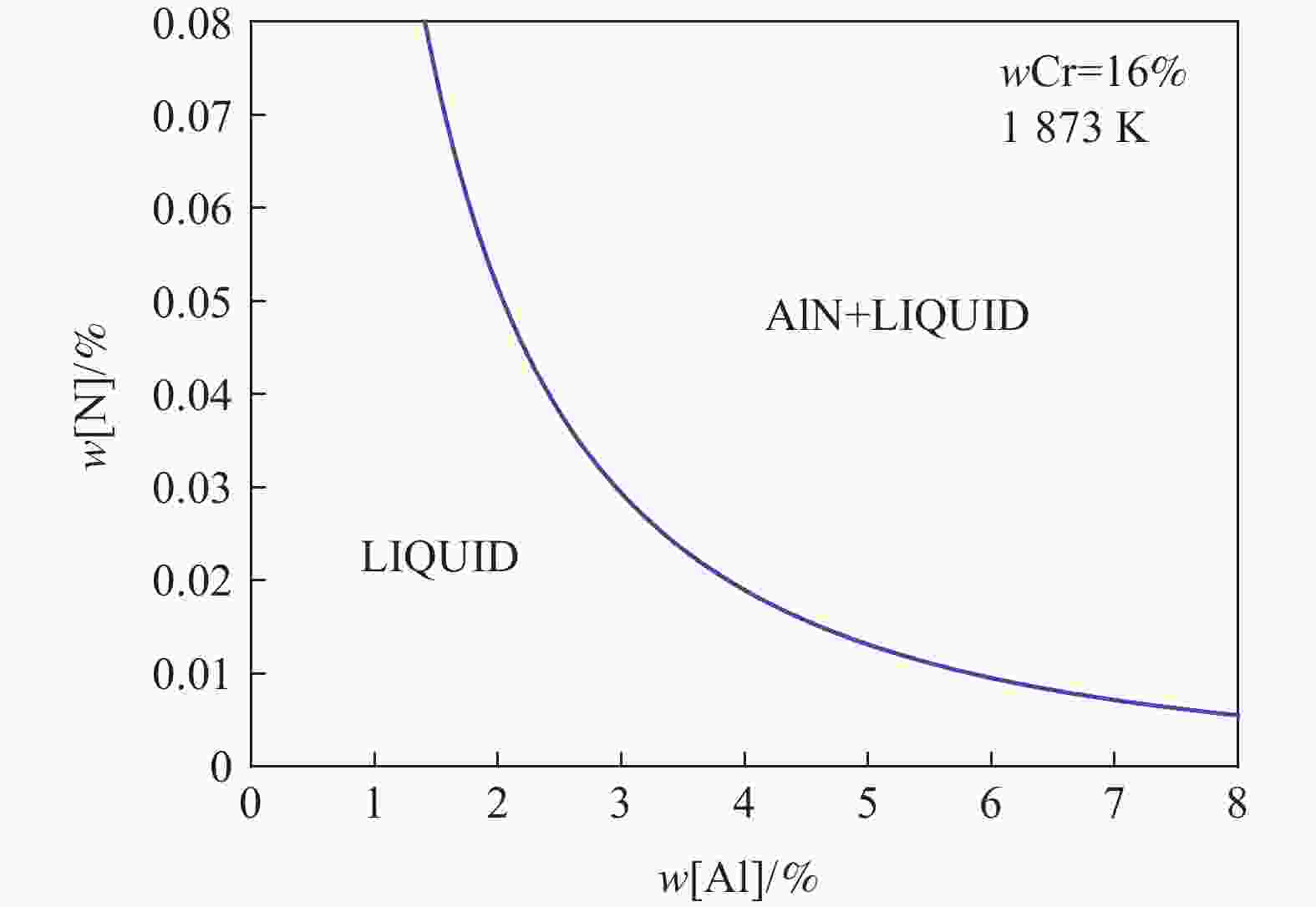

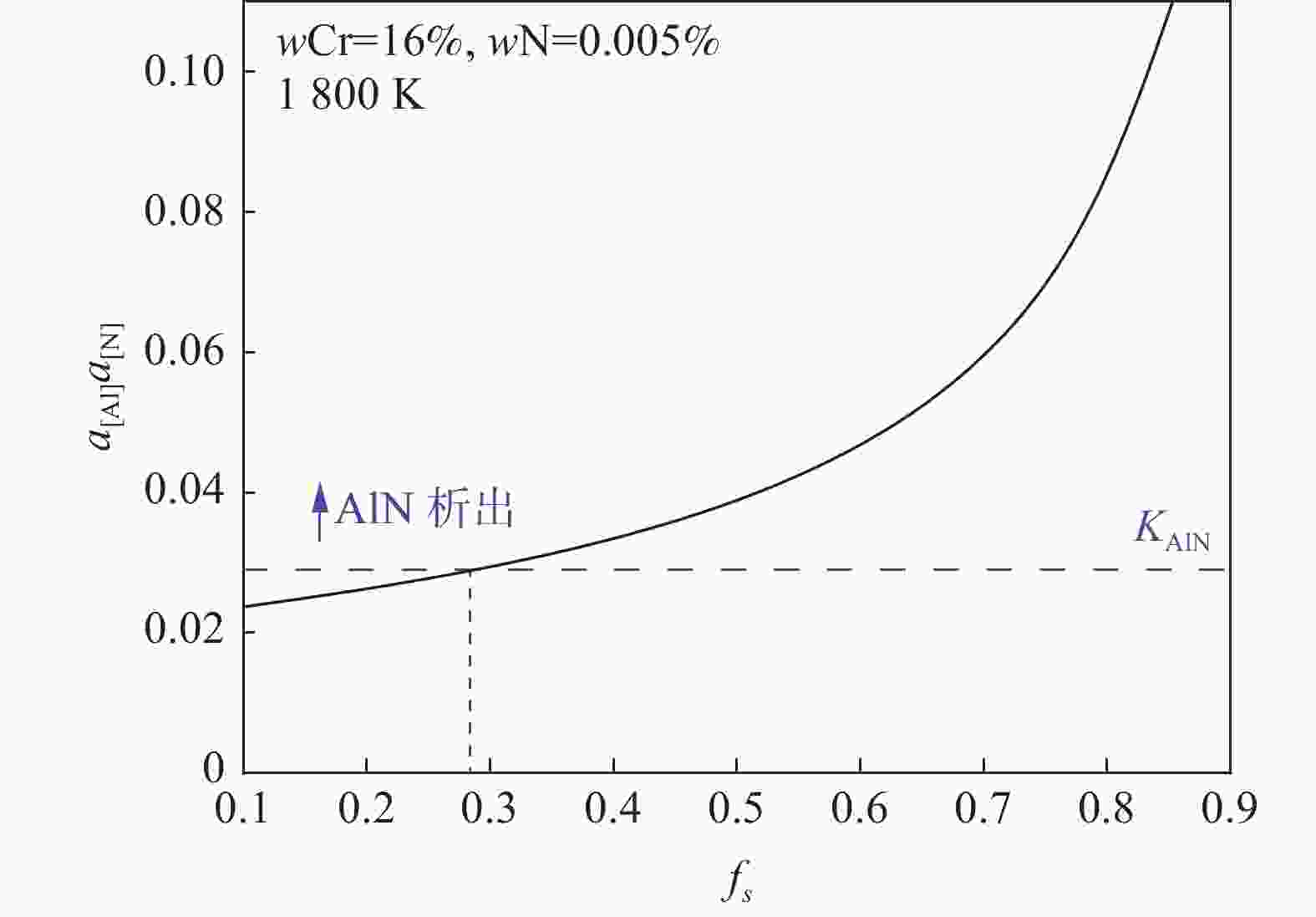

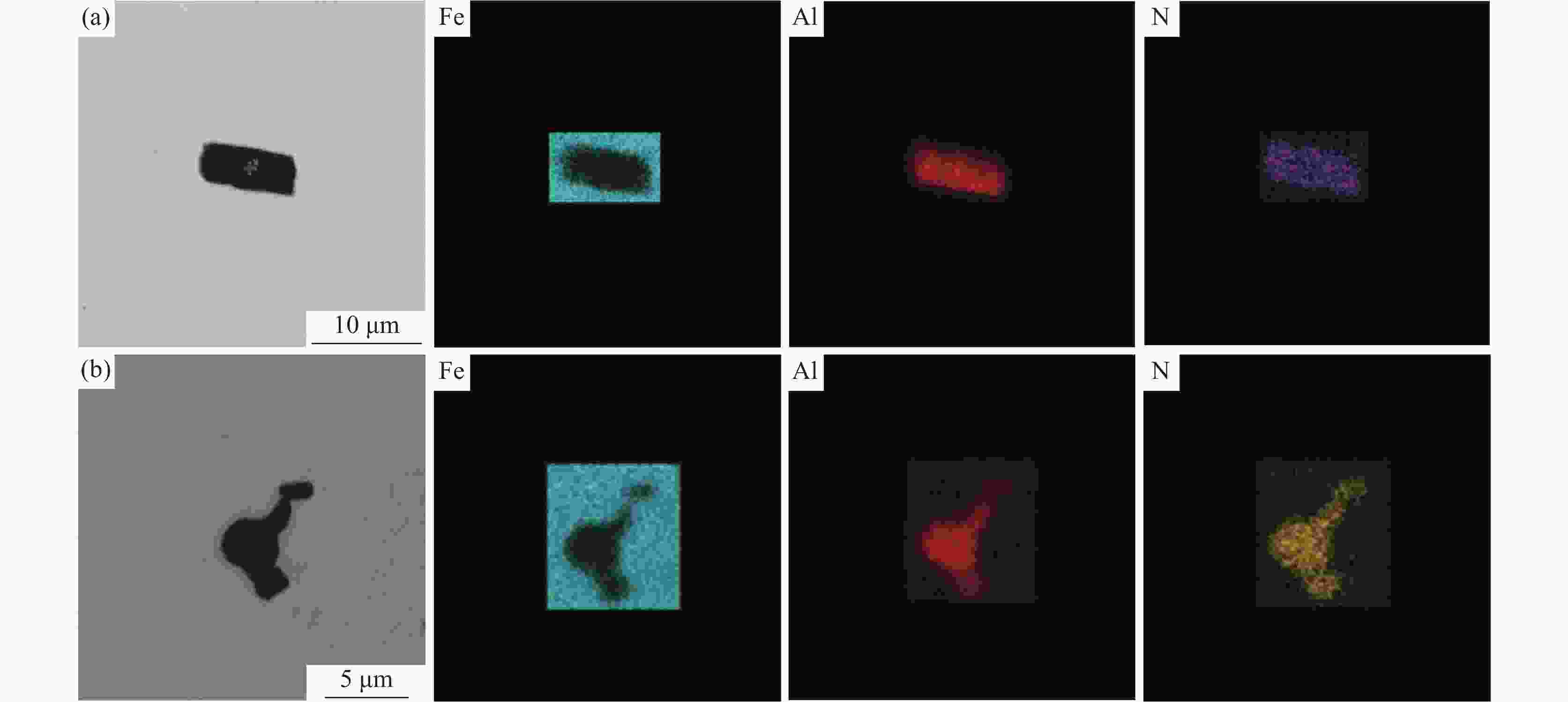

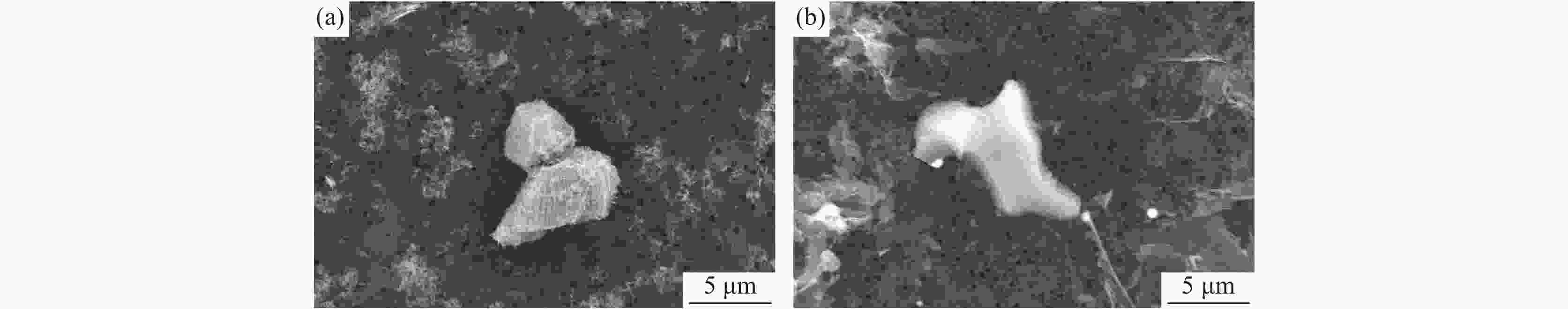

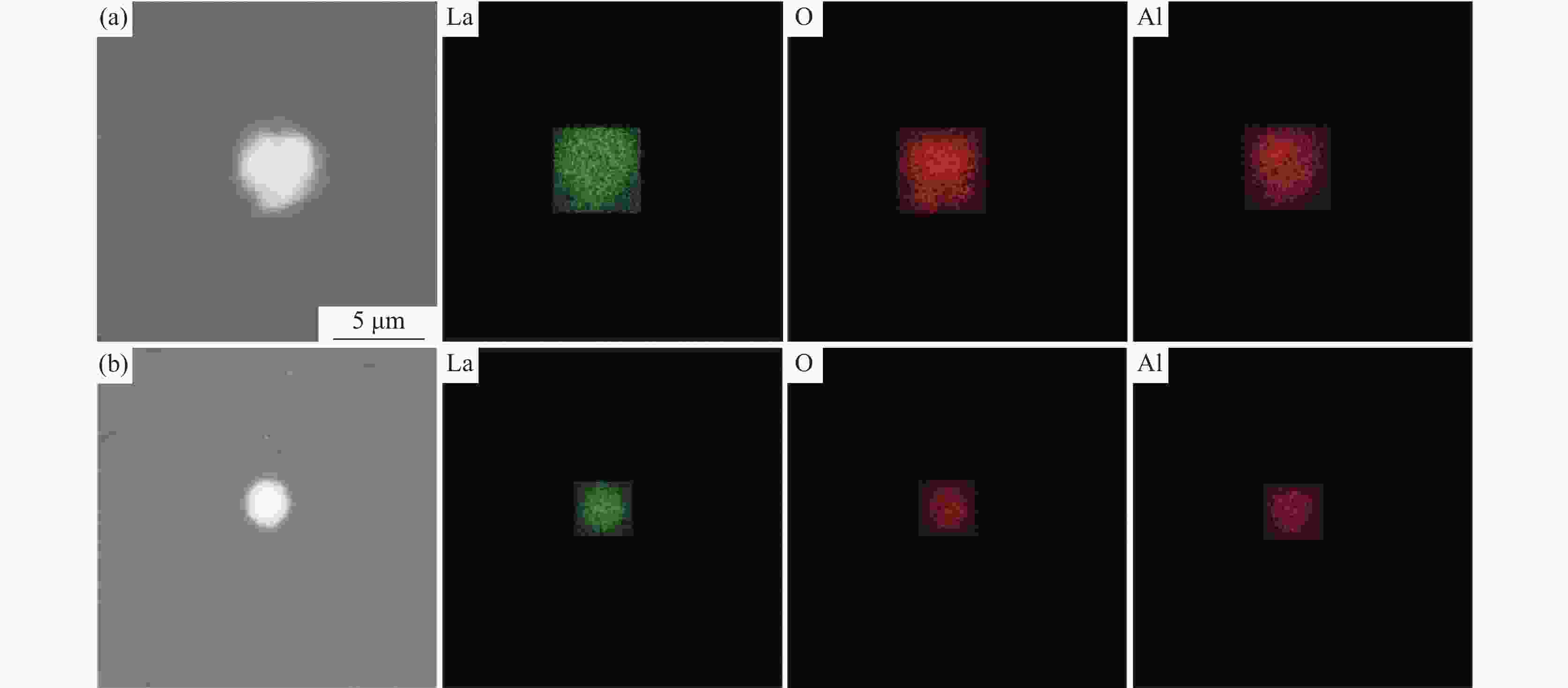

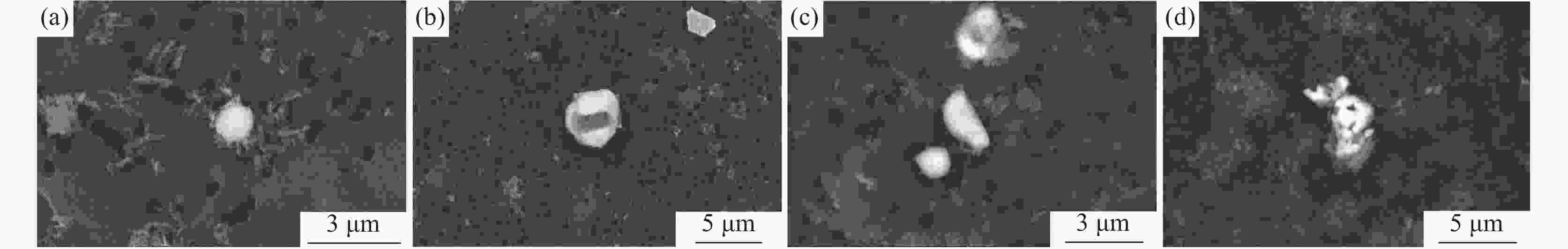

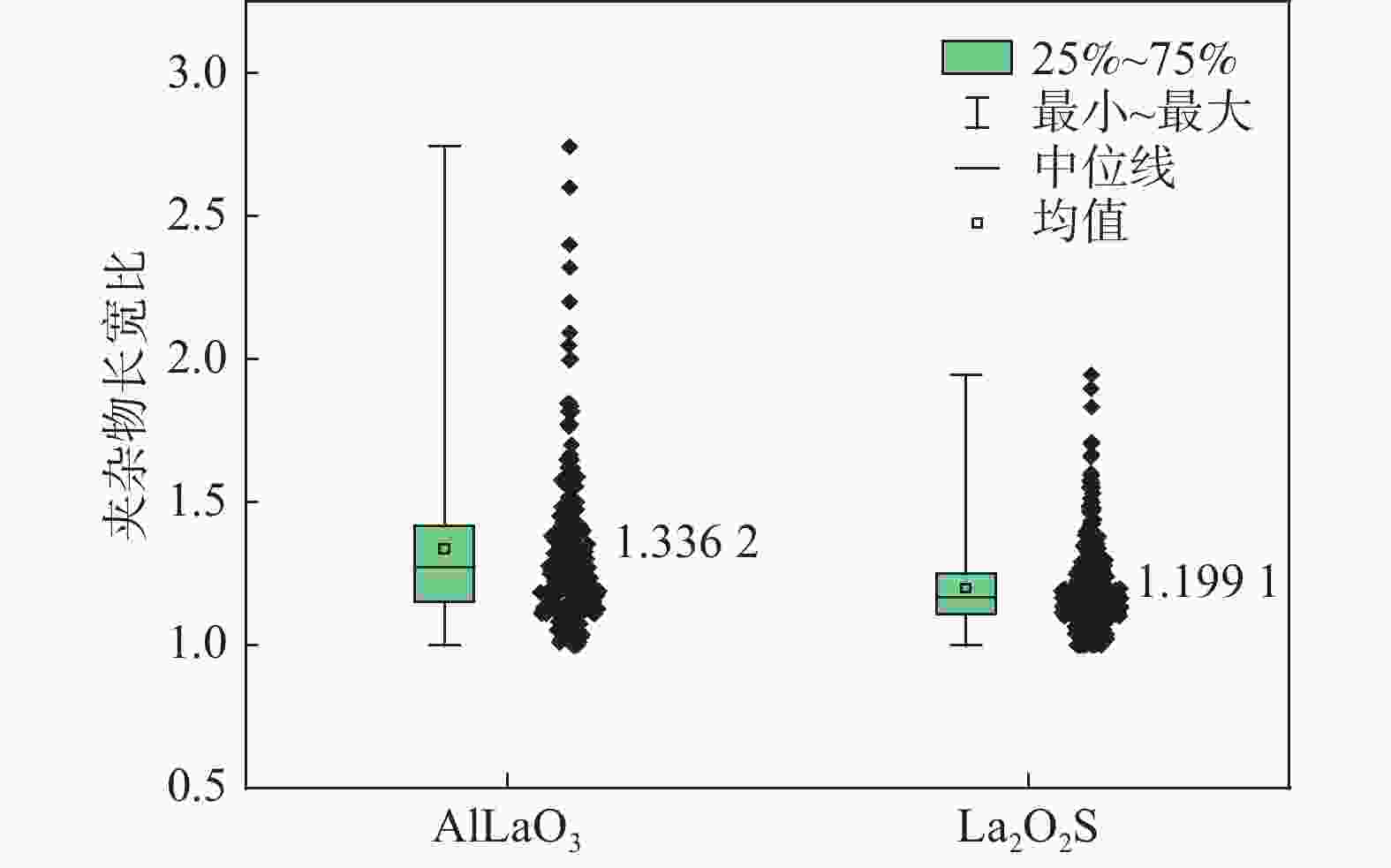

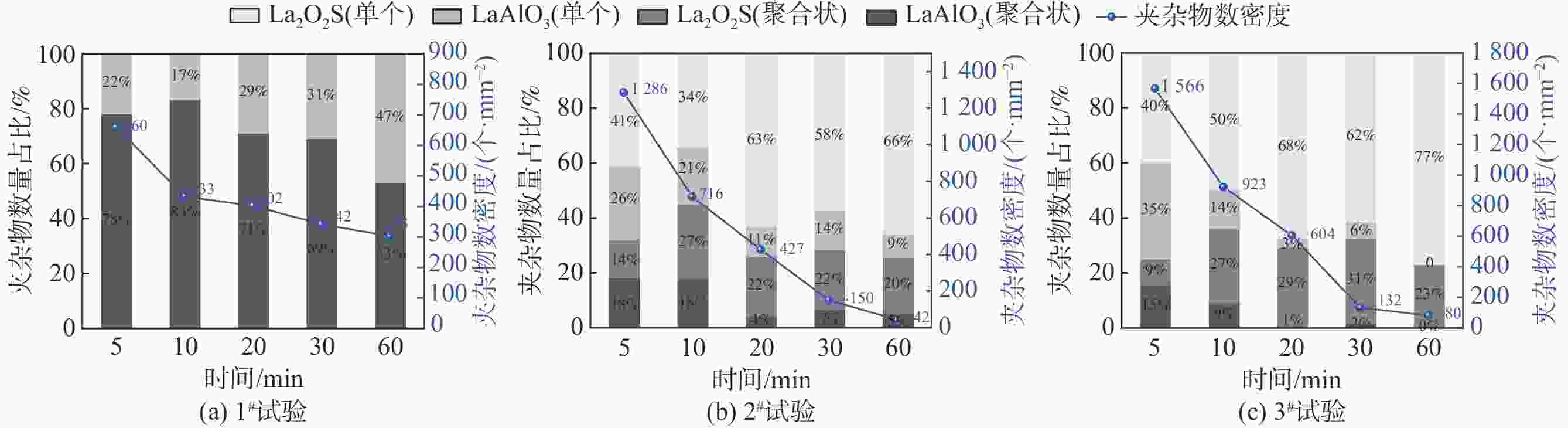

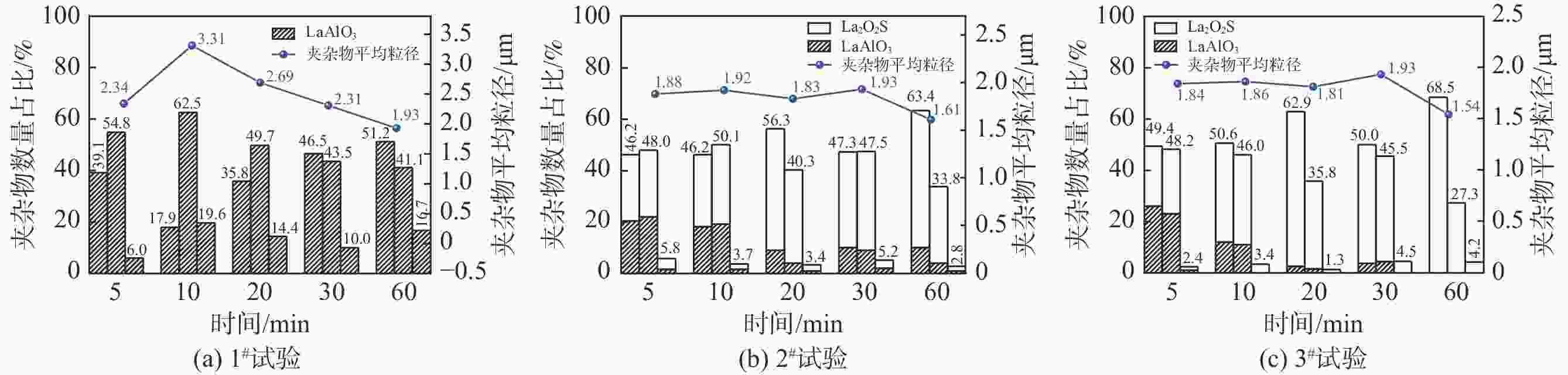

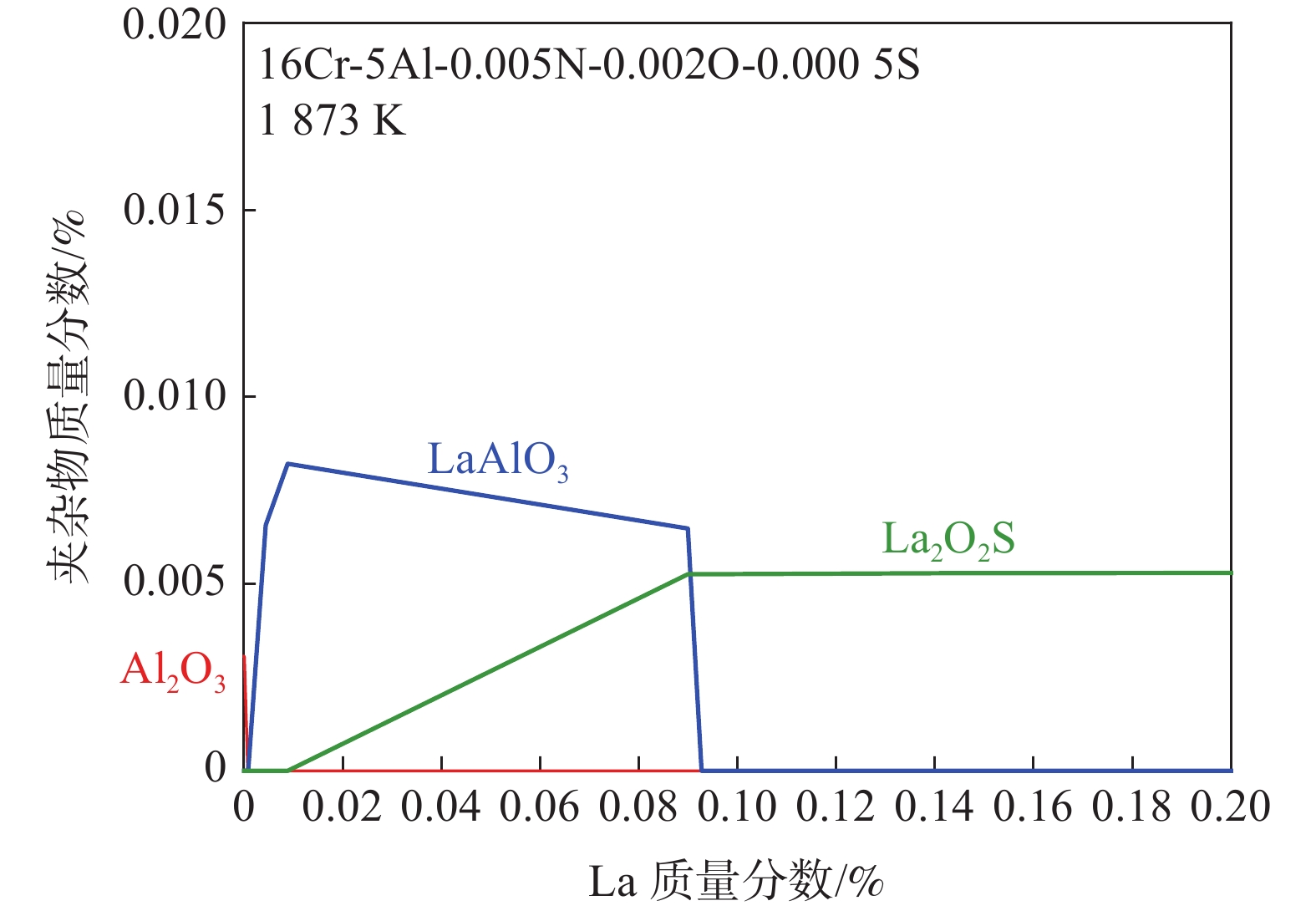

摘要: 为研究稀土La对FeCrAl合金中夹杂物类型及分布的影响,在热力学分析的基础上,借助SEM-EDS观察分析了夹杂物三维形貌及其成分,统计分析了夹杂物尺寸及数量。结果表明,1600 ℃时FeCrAl合金中只存在单一Al2O3夹杂。凝固过程中,随着体系中固相率的增大,AlN在凝固前沿析出。加入质量分数为0.0093%的La后,Al2O3被变质为LaAlO3。La添加量为0.0378%时,主要夹杂物类型为LaAlO3+La2O2S,夹杂物数量明显增多,且随着保温时长的增加, La2O2S比例逐渐增加。La添加量为0.0964%时,La2O2S比例进一步增加,保温60 min后,钢中只有单一La2O2S夹杂稳定存在。夹杂物聚合特性对夹杂物粒径影响显著。1600 ℃下保温60 min,仅含单一LaAlO3的试样中,LaAlO3在保温前期呈现较强的聚合趋势,夹杂物平均粒径先由2.34 μm增大至3.31 μm,随后减小至1.93 μm。La2O2S聚合趋势较弱,含有La2O2S的试样中,夹杂物平均粒径较小且变化稳定,在保温前期,夹杂物平均粒径稳定在1.8~2.0 μm。Abstract: In order to study the influence of rare earth La addition on the type and distribution of inclusions in FeCrAl alloys, based on thermodynamic analysis, the three-dimensional morphology and composition of inclusions were observed and analyzed by SEM-EDS, and the size and quantity of inclusions were statistically analyzed. The results show that single Al2O3 only inclusion exists in FeCrAl alloy at 1600 ℃. During the solidification process, with the increase of the solid fraction in the system, AlN precipitates at the solidification front. After adding 0.0093% La, Al2O3 transforms into LaAlO3. When the addition amount of La is 0.0378%, the type of inclusions is LaAlO3+La2O2S, and the number of inclusions increases significantly. As holding time prolongs, the proportion of La2O2S gradually increases. When the addition amount of La is 0.0964%, the proportion of La2O2S is further increased. After 60 min of heat preservation, single La2O2S only inclusion exists stably in the steel. The particle size of the inclusions is significantly affected by the aggregation properties of the inclusions. In the samples containing single LaAlO3 only at 1600 ℃ for 60 min, LaAlO3 shows a strong tendency to aggregate in the early stage of the incubation, and average particle size of the inclusions firstly increases from 2.34 μm to 3.31 μm, and then decreases to 1.93 μm. The tendency of La2O2S to aggregate is weak. In the samples containing La2O2S, average particle size of inclusions is small and uniform, in the early stage of heat preservation, average particle size of inclusions remains in the range of 1.8−2.0 μm.

-

Key words:

- FeCrAl alloy /

- La /

- inclusions /

- AlN precipitates /

- agglomeration

-

表 1 试验钢化学成分

Table 1. Chemical compositions of experimental steels

% 编号 Cr Al La C N S O [O]1 [O]2 1# 15.96 5.07 0.0093 0.156 0.0052 0.0005 0.0019 0.0030 <0.0001 2# 16.03 4.96 0.0378 0.132 0.0068 0.0007 0.0023 0.0055 <0.0001 3# 15.92 5.05 0.0964 0.128 0.0046 <0.0005 0.0013 0.0056 <0.0001 表 2 溶质元素的平衡分配系数及扩散系数

Table 2. Equilibrium partition coefficient and diffusion coefficient of solute elements

溶质元素 $ {k}^{\delta /L} $ $ {D}_{\mathrm{s}} $/(m2·s−1) Al 0.96 5.9×10−4×exp(−241417/RT) Cr 0.95 2.4×10−4×exp(−239785/RT) N 0.25 8×10−7×exp(−79078/RT) 表 3 钢中元素相互作用系数

Table 3. Coefficient of interaction of elements in steel

$ {e}_{{\rm{Al}}}^{{\rm{Al}}} $ $ {r}_{{\rm{Al}}}^{{\rm{Al}}} $ $ {e}_{{\rm{Al}}}^{{\rm{Cr}}} $ $ {r}_{{\rm{Al}}}^{{\rm{Cr}}} $ $ {e}_{{\rm{Al}}}^{{\rm{N}}} $ $ {r}_{{\rm{Al}}}^{{\rm{N}}} $ $ {e}_{{\rm{N}}}^{{\rm{Al}}} $ $ {r}_{{\rm{N}}}^{{\rm{Al}}} $ $ {e}_{{\rm{N}}}^{{\rm{Cr}}} $ $ {r}_{{\rm{N}}}^{{\rm{Cr}}} $ $ {e}_{{\rm{N}}}^{{\rm{N}}} $ $ {r}_{{\rm{N}}}^{{\rm{N}}} $ 0.043 −0.001 0.0122 0 0.033 0 0.017 0 −0.06 0.0007 0 0 表 4 试样中不同夹杂物类型

Table 4. Different inclusion types in steel samples

编号 夹杂物类型 不同稀土处理时间夹杂物类型变化 5 min 10 min 20 min 30 min 60 min 1# AlN √ √ √ √ √ Al2O3 √ √ √ LaAlO3 √ √ √ √ √ La2O2S 2# AlN √ √ √ √ √ Al2O3 √ √ LaAlO3 √ √ √ √ √ La2O2S √ √ √ √ √ 3# AlN √ √ √ √ √ Al2O3 √ √ LaAlO3 √ √ √ √ La2O2S √ √ √ √ √ -

[1] Pint B A. Experimental observations in support of the dynamic-segregation theory to explain the reactive-element effect[J]. Oxidation of Metals, 1996,45(1):1−37. [2] Smialek J L. Invited review paper in commemoration of over 50 years of oxidation of metals: alumina scale adhesion mechanisms: A retrospective assessment[J]. Oxidation of Metals, 2022,97(2):1−50. [3] Pan D, Zhang R, Wang H, et al. Formation and stability of oxide layer in FeCrAl fuel cladding material under high-temperature steam[J]. Journal of Alloys and Compounds, 2016,684:549−555. doi: 10.1016/j.jallcom.2016.05.145 [4] Park D J, Kim H G, Park J Y, et al. A study of the oxidation of FeCrAl alloy in pressurized water and high-temperature steam environment[J]. Corrosion Science, 2015,94:459−465. doi: 10.1016/j.corsci.2015.02.027 [5] Pauletto G, Vaccari A, Groppi G, et al. FeCrAl as a catalyst support[J]. Chemical Reviews, 2020,120(15):7516−7550. doi: 10.1021/acs.chemrev.0c00149 [6] Kim D H, Yu B Y, Cha P R, et al. A study on FeCrAl foam as effective catalyst support under thermal and mechanical stresses[J]. Surface and Coatings Technology, 2012,209:169−176. doi: 10.1016/j.surfcoat.2012.08.017 [7] Jiang G, Xu D, Feng P, et al. Corrosion of FeCrAl alloys used as fuel cladding in nuclear reactors[J]. Journal of Alloys and Compounds, 2021,869:1−12. [8] Yamamoto Y, Pint B A, Terrani K A, et al. Development and property evaluation of nuclear grade wrought FeCrAl fuel cladding for light water reactors[J]. Journal of Nuclear Materials, 2015,467:703−716. doi: 10.1016/j.jnucmat.2015.10.019 [9] Wang W, Zhu H, Han Y, et al. Effect of Al content on non-metallic inclusions in Fe–23Mn–xAl–0.7C lightweight steels[J]. Ironmaking & Steelmaking, 2021,48(9):1038−1047. [10] Yin H. Inclusion characterization and thermodynamics for high-Al advanced high-strength steels[J]. Iron & Steel Technology, 2006,3(6):64−73. [11] He Y, Liu J, Qiu S, et al. Thermodynamic analysis of inclusion characteristics in as-cast FeCrAl-(La) alloys[J]. Ironmaking & Steelmaking, 2018,47(1):1−9. [12] Jo J O, Jung M S, Park J H, et al. Thermodynamic interaction between chromium and aluminum in liquid Fe–Cr alloys containing 26% Cr[J]. ISIJ International, 2011,51(2):208−213. doi: 10.2355/isijinternational.51.208 [13] Yuan F, Wang X, Zhang J, et al. Numerical simulation of Al2O3 deposition at a nozzle during continuous casting[J]. Journal of University of Science and Technology Beijing, Mineral, Metallurgy, Material, 2008,15(3):227−235. doi: 10.1016/S1005-8850(08)60043-2 [14] Zhang L, Thomas B G. State of the art in the control of inclusions during steel ingot casting[J]. Metallurgical and Materials Transactions B, 2006,37(5):733−761. doi: 10.1007/s11663-006-0057-0 [15] Wang H, Bao Y, Zhi J, et al. Effect of rare earth Ce on the morphology and distribution of Al2O3 inclusions in high strength IF steel containing phosphorus during continuous casting and rolling process[J]. ISIJ International, 2021,61(3):657−666. doi: 10.2355/isijinternational.ISIJINT-2020-053 [16] Wang L, Lin Q, Ji J, et al. New study concerning development of application of rare earth metals in steels[J]. Journal of Alloys and Compounds, 2006,408:384−386. [17] Yang Z, Pan J, Wang Z, et al. New insights into the mechanism of yttrium changing high-temperature oxide growth of Fe-13Cr–6Al–2Mo–0.5Nb alloy for fuel cladding[J]. Corrosion Science, 2020,172:1−9. [18] Yang Jichun, Wang Jun, Ren Lei, et al. Effect of cerium on microstructure and impact property of S32550 duplex stainless steel[J]. Iron & Steel, 2020,55(1):86−92,100. (杨吉春, 王军, 任磊, 等. 铈对S32550双相不锈钢微观组织及冲击性能的影响[J]. 钢铁, 2020,55(1):86−92,100. doi: 10.13228/j.boyuan.issn0449-749x.20190165Yang Jichun, Wang Jun, Ren Lei, et al. Effect of cerium on microstructure and impact property of S32550 duplex stainless steel[J]. Iron & Steel, 2020, 55(1): 86-92, 100. doi: 10.13228/j.boyuan.issn0449-749x.20190165 [19] Wang Y, Liu C. Evolution and deformability of inclusions in steel containing rare‐earth element under different deoxidation conditions[J]. Steel Research International, 2022,93(8):1−11. [20] Ma Shuai, Li Yang, Jiang Zhouhua, et al. Effect of Ce on evolution of inclusions in 440C stainless bearing steel[J]. China Metallurgy, 2022,32(6):71−78. (马帅, 李阳, 姜周华, 等. Ce对440C不锈轴承钢夹杂物演变的影响[J]. 中国冶金, 2022,32(6):71−78.Ma Shuai, Li Yang, Jiang Zhouhua, et al. Effect of Ce on evolution of inclusions in 440 C stainless bearing steel[J]. China Metallurgy, 2022, 32(6): 71-78. [21] Ishii K, Kohno M, Ishikawa S, et al. Effect of rare-earth elements on high-temperature oxidation resistance of Fe–20Cr–5Al alloy foils[J]. Materials Transactions, JIM, 1997,38(9):787−792. doi: 10.2320/matertrans1989.38.787 [22] Ishi K, Tangiguchi S. Effect of La and Hf additions on the high-temperature oxidation resistance of high-purity Fe–20Cr–5Al alloy foils[J]. Oxidation of Metals, 2000,54:491−508. doi: 10.1023/A:1004694719134 [23] Ukai S, Kato S, Furukawa T, et al. High-temperature creep deformation in FeCrAl-oxide dispersion strengthened alloy cladding[J]. Materials Science and Engineering:A, 2020,794:1−13. [24] Wang Y, Liu C. Agglomeration characteristics of various inclusions in Al-killed molten steel containing rare earth element[J]. Metallurgical and Materials Transactions B, 2020,51(6):2585−2595. doi: 10.1007/s11663-020-01938-1 [25] Zhang Q, Min Y, Xu H, et al. Formation and evolution of silicate inclusions in molten steel by magnesium treatment[J]. ISIJ International, 2019,59(3):391−397. doi: 10.2355/isijinternational.ISIJINT-2018-543 [26] Yang Zhiji, Liu Woyuan. Study on solid solubility and precipitated phase of mixed rare earth in steel[J]. Iron & Steel, 1986,(4):36−41. (杨植玑, 刘沃垣. 混合稀土在钢铁中的固溶量及析出相的研究[J]. 钢铁, 1986,(4):36−41. doi: 10.13228/j.boyuan.issn0449-749x.1986.04.009Yang Zhiji, Liu Woyuan. Study on solid solubility and precipitated phase of mixed rare earth in steel[J]. Iron & Steel, 1986(4): 36-41. doi: 10.13228/j.boyuan.issn0449-749x.1986.04.009 [27] Brody H D. Solute redistribution in dendritic solidification [D]. Cambridge, MA Aug: Massachusetts Institute of Technology, 1965. [28] Clyne T W, Kurz W. Solute redistribution during solidification with rapid solid state diffusion[J]. Metallurgical Transactions A, 1981,12(6):965−971. doi: 10.1007/BF02643477 [29] Won Y M, Thomas B G. Simple model of microsegregation during solidification of steels[J]. Metallurgical and Materials Transactions A, 2001,32(7):1755−1767. doi: 10.1007/s11661-001-0152-4 [30] Ghosh A. Mathematical model for prediction of composition of inclusions formed during solidification of liquid steel[J]. ISIJ International, 2009,49(12):1819−1827. doi: 10.2355/isijinternational.49.1819 [31] 陈家祥. 炼钢常用图表数据手册[M]. 北京: 冶金工业出版社, 1984.Chen Jiaxiang. Steelmaking common chart data manual[M] . Beijing: Metallurgical Industry Press, 1984. [32] Thermodynamic data for steelmaking [M]. Sendai-shi: Tohoku University Press, 2010. [33] Wagner C. Thermodynamics of alloys [M]. Cambridge: Addison-Wesle Press, 1952. [34] Wang H, Bai B, Jiang S, et al. An in situ study of the formation of rare earth inclusions in arsenic high carbon steels[J]. ISIJ International, 2019,59(7):1259−1265. doi: 10.2355/isijinternational.ISIJINT-2018-853 -

下载:

下载: