Study on viscous flow characteristics of CaO-SiO2- MgO-Al2O3-TiO2-CaCl2 slag system

-

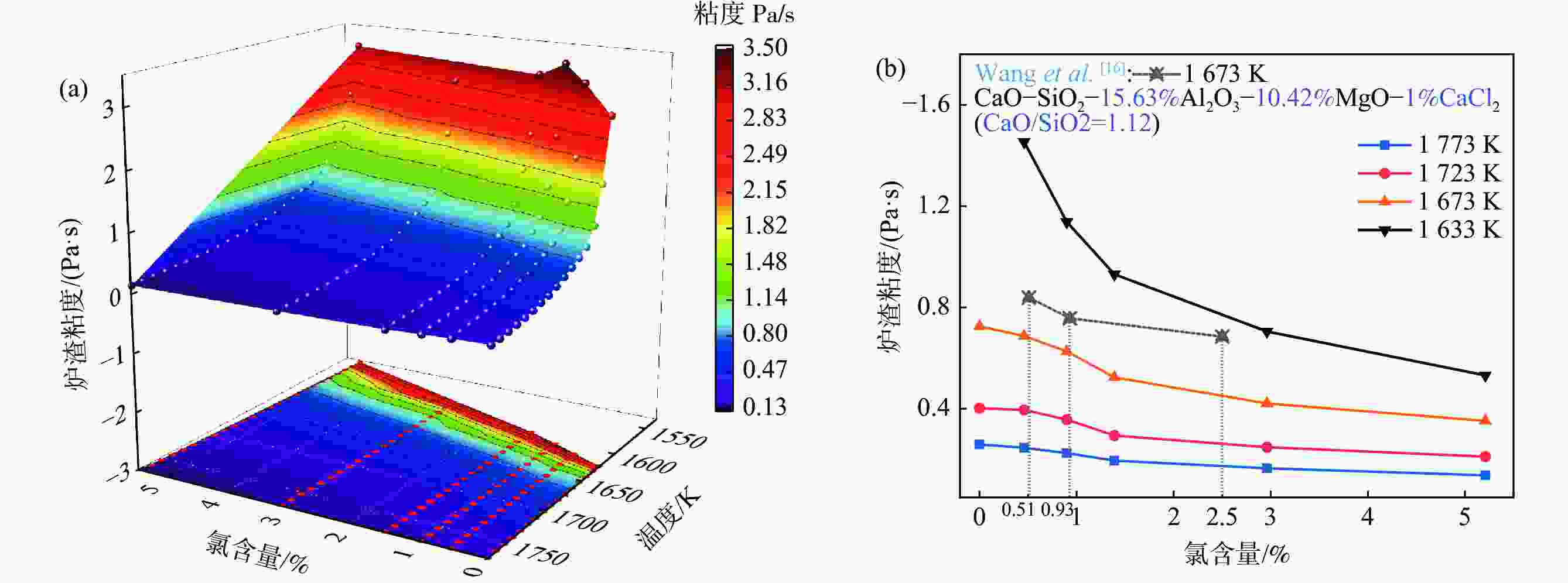

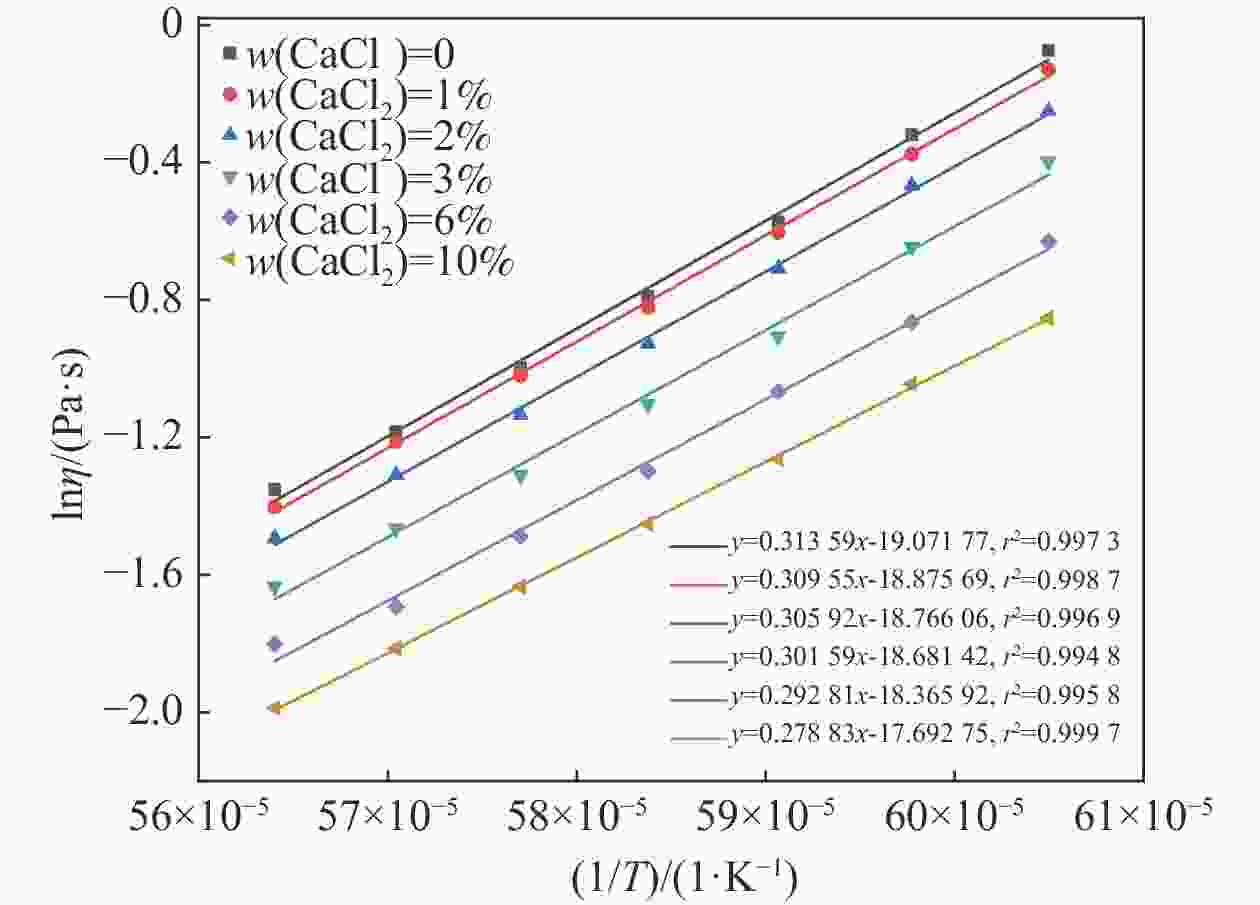

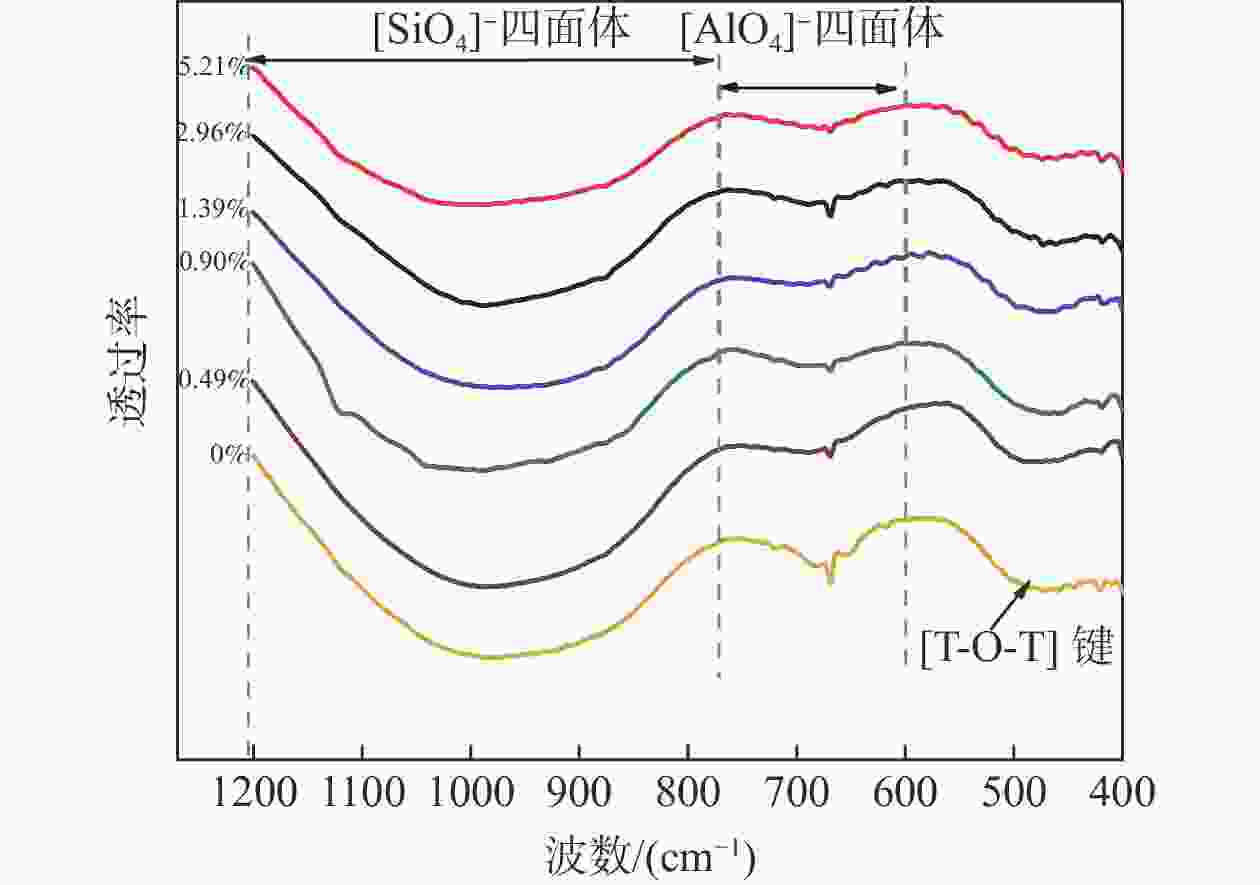

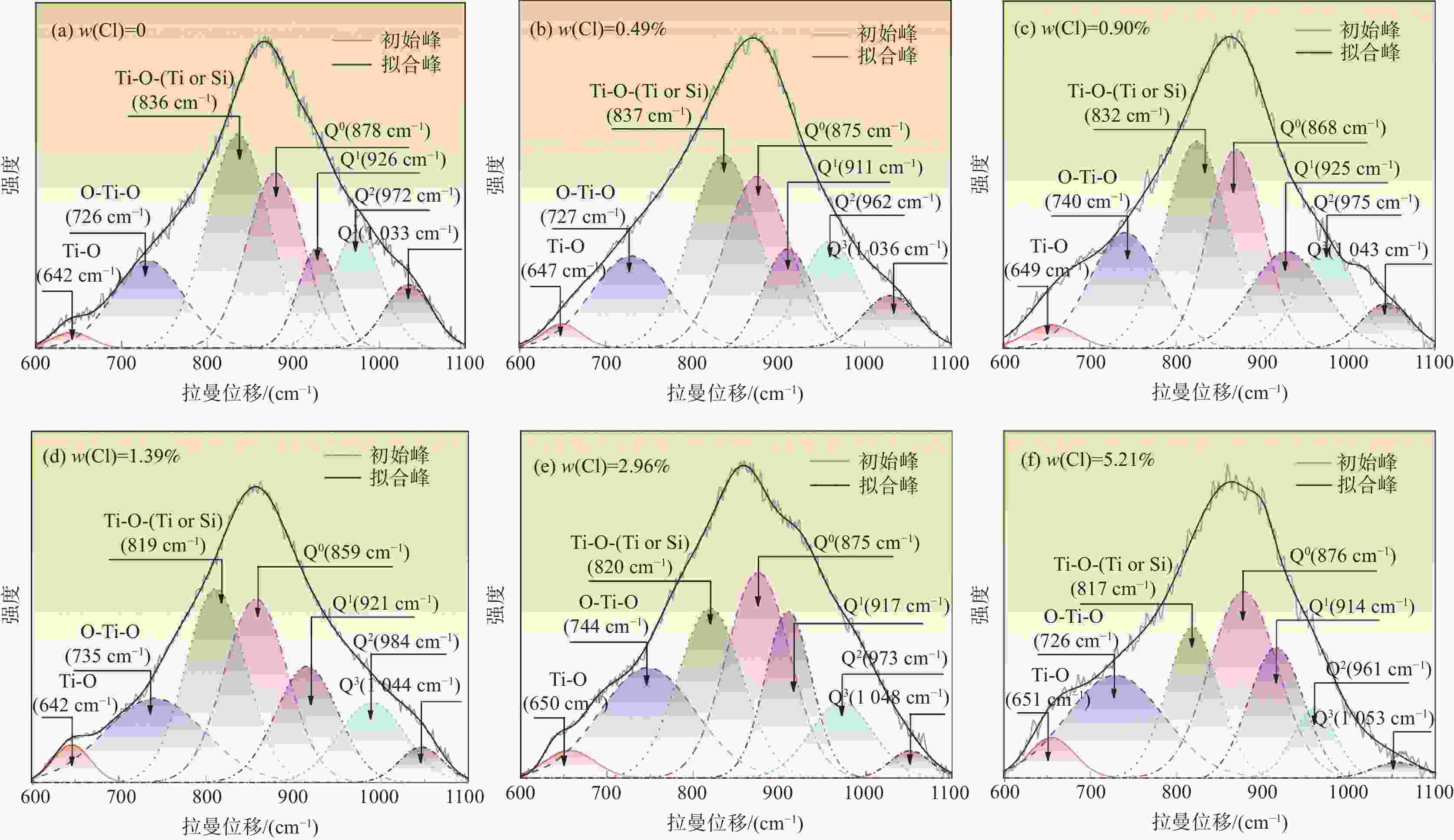

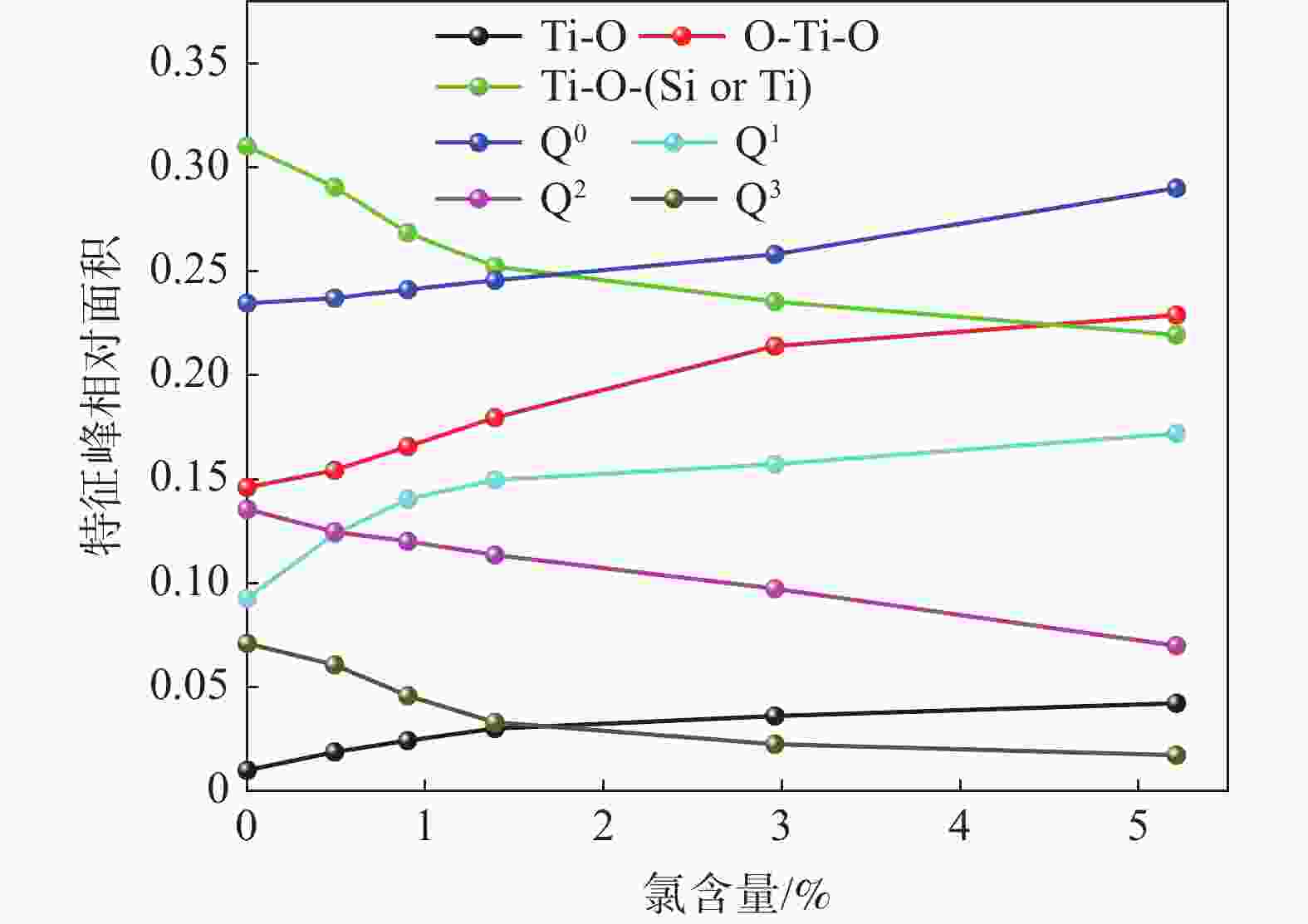

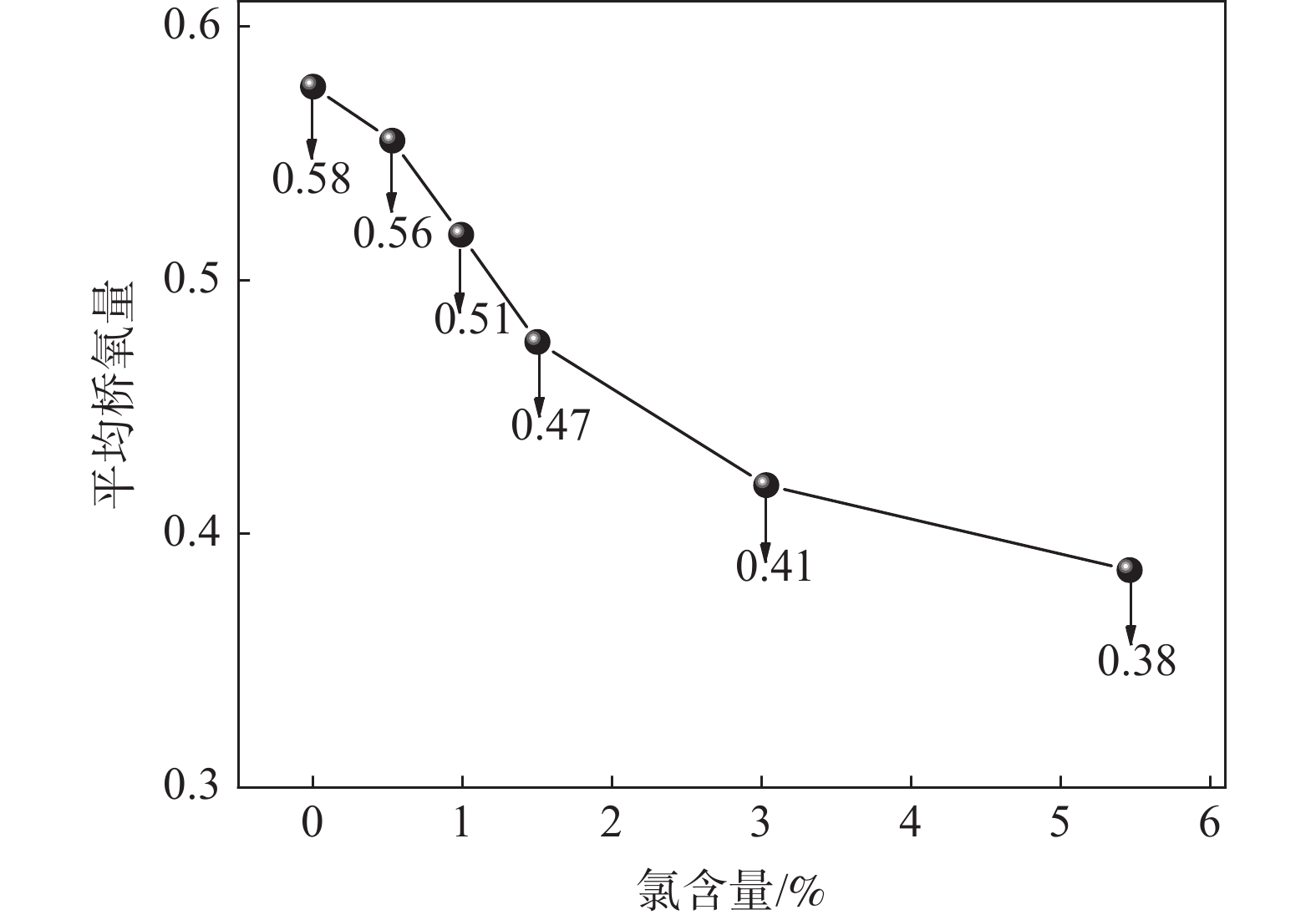

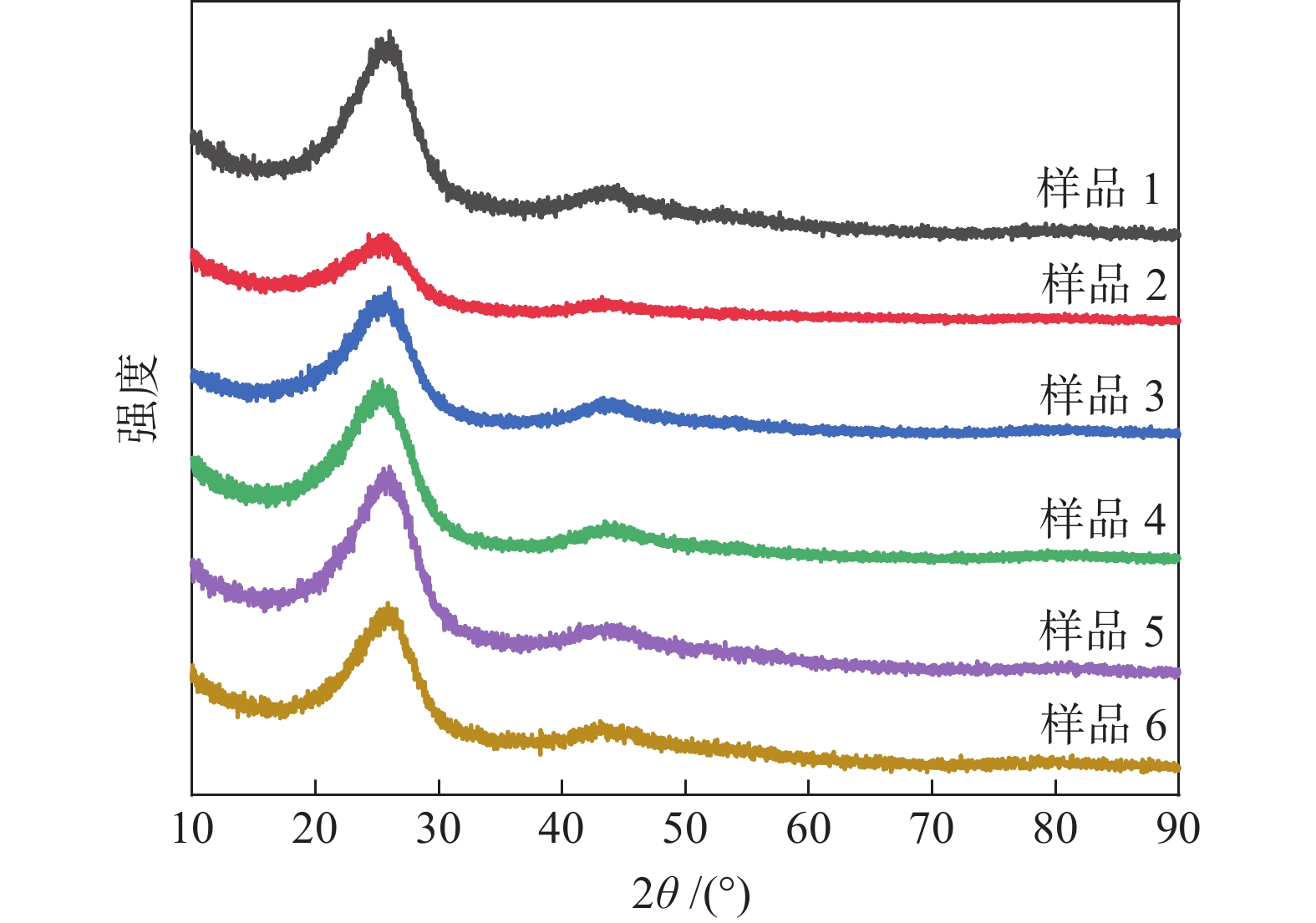

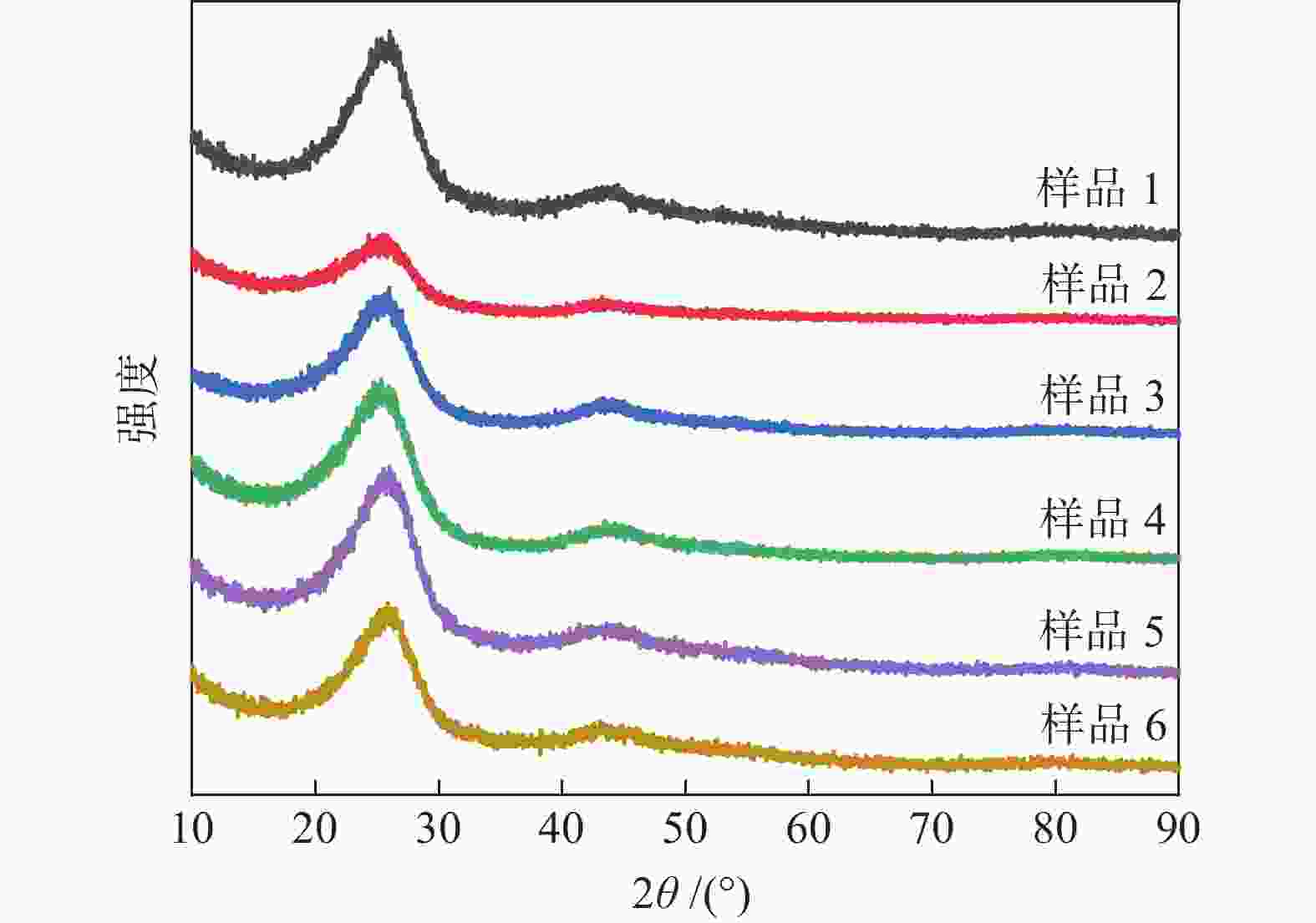

摘要: 炉渣的粘流特性与高炉的稳定顺行密切相关。研究了含氯高钛渣(CaO-SiO2-MgO-Al2O3-TiO2-CaCl2)的粘度和熔化性温度,并采用傅里叶变换红外光谱(FTIR)和拉曼光谱(Raman)分析其结构演变。结果表明,氯元素的加入可以降低炉渣粘度,简化炉渣结构。由于氯元素在高温下容易蒸发,因此在粘度测试过程中氯含量略有下降。粘性流动活化能的变化趋势与粘度的变化趋势相似。[SiO4]-四面体结构和Ti-O-(Ti或Si)键也会被破坏。Q2和Q3单元的相对面积分数减少,Q0和Q1单元的相对面积分数增加,导致炉渣聚合度降低。Abstract: The viscous flow characteristics of slag are closely related to the stability of the blast furnace. In this paper, the viscosity and melting temperature of chlorine-containing high-titanium slag (CaO-SiO2-MgO-Al2O3-TiO2-CaCl2) were studied, and their structural evolution was analyzed by Fourier transform infrared spectroscopy (FTIR) and Raman spectroscopy. The results show that the addition of chlorine element can reduce the viscosity of the slag and simplify the structure of the slag. Due to the easy evaporation of chlorine element at high temperature, the chlorine content decreased slightly during the viscosity test. The variation trend of viscous flow activation energy is similar to that of viscosity. The [SiO4]− tetrahedral structure and Ti-O-Ti/Si bonds are also broken. The relative area fractions of the Q2 and Q3 units decreased and the relative area fractions of the Q0 and Q1 units increased, resulting in a decrease in the degree of slag polymerization.

-

表 1 渣样主要化学成分

Table 1. Main chemical compositions of slag sample

% 编号 CaO SiO2 MgO Al2O3 TiO2 CaCl2 C/S 1 29.82 25.97 7.41 14.33 22.47 0.00 1.15 2 29.52 25.71 7.34 14.19 22.24 1.00 1.15 3 29.22 25.45 7.26 14.04 22.03 2.00 1.15 4 28.93 25.19 7.19 13.90 21.79 3.00 1.15 5 28.03 24.41 6.97 13.47 21.12 6.00 1.15 6 26.84 23.37 6.67 12.90 20.22 10.00 1.15 表 2 不同Cl含量对熔渣粘流活化能的影响

Table 2. The effect of different Cl content on activation energy of slag viscous flow

编号 氯含量/% 活化能Ea/( kJ·mol−1) 1 0 260.719 2 0.49 257.360 3 0.90 254.341 4 1.39 250.742 5 2.96 243.442 6 5.21 231.819 -

[1] Ou Yang, Sun Yongsheng, Yu Jianwen, et al. Research status and development prospect of utilization of vanadium- titanium magnetite[J]. Journal of Iron and Steel Research, 2021,33(4):267−278. (欧杨, 孙永升, 余建文, 等. 钒钛磁铁矿加工利用研究现状及发展趋势[J]. 钢铁研究学报, 2021,33(4):267−278. doi: 10.13228/j.boyuan.issn1001-0963.20200229Ou Yang, Sun Yongshen, Yu Jianwen, et al. Research status and development prospect of utilization of vanadium- titanium magnetite[J]. Journal of Iron and Steel Research, 2021, 33(4): 267-278. doi: 10.13228/j.boyuan.issn1001-0963.20200229 [2] Yan Zhiming, Lü Xuewei, He Wenchao, et al. Effect of TiO2 on the liquid zone and apparent viscosity of SiO2-CaO-8%MgO-14%Al2O3 system[J]. ISIJ Int, 2017,57(1):31−36. doi: 10.2355/isijinternational.ISIJINT-2016-420 [3] Pang Zhengde, Lü Xuewei, Jiang Yuyang, et al. Blast furnace ironmaking process with super-high TiO2 in the slag: Viscosity and melting properties of the slag[J]. Metall Mater Trans B, 2019,51(2):722−731. [4] Zhang Xu, Zhang Jianliang, Hu Zhengwen, et al. Effect of CaCl2 on RDI and RI of sinter[J]. J Iron Steel Res Int, 2010,17(11):7−12. doi: 10.1016/S1006-706X(10)60162-8 [5] Okeda M, Hasegawa M, Iwase M. Solubilities of chlorine in CaO-SiO2-Al2O3-MgO slags: Correlation between sulfide and chloride capacities[J]. Metall Mater Trans B, 2010,42(2):281−290. [6] Shankar Amitabh, Mårten Görnerup, Lahiri A K, et al. Experimental investigation of the viscosities in CaO-SiO2-MgO-Al2O3 and CaO-SiO2-MgO-Al2O3-TiO2 slags[J]. Metall Mater Trans B, 2007,38(6):911−915. doi: 10.1007/s11663-007-9087-5 [7] Liu Wenguo, Qin Jianghao, Xing Xiangdong, et al. Viscosity and structure evolution of CaO–SiO2–MgO–Al2O3–BaO slag with the CaO/SiO2 mass ratio of 0.9[J]. Ceram Int, 2021,47(23):33483−33489. doi: 10.1016/j.ceramint.2021.08.255 [8] Wang Zhanjun, Il Sohn. Effect of substituting CaO with BaO on the viscosity and structure of CaO‐BaO‐SiO2‐MgO‐Al2O3 slags[J]. J Am Ceram Soc, 2018,101(9):4285−4296. doi: 10.1111/jace.15559 [9] Jiao Kexin, Zhang Jianliang, Wang Zhiyu, et al. Effect of TiO2 and FeO on the viscosity and structure of blast furnace primary slags[J]. Steel Res Int, 2017,88(5):1600296. doi: 10.1002/srin.201600296 [10] Fan Xiaoyue, Zhang Jianliang, Jiao Kexin, et al. Influence of B2O3 on viscosity and structure of low MgO slag containing titanium[J]. Metall Res Technol, 2018,115(3):313. doi: 10.1051/metal/2017103 [11] Ren Shan, Zhang Jianliang, Wu Liushun, et al. Influence of B2O3 on viscosity of high Ti-bearing blast furnace slag[J]. ISIJ Int, 2012,52(6):984−991. doi: 10.2355/isijinternational.52.984 [12] Wang Wanlin, Dai Shifan, Zhou Lejun, et al. Viscosity and structure of MgO–SiO2-based slag melt with varying B2O3 content[J]. Ceram Int, 2020,46(3):3631−3636. doi: 10.1016/j.ceramint.2019.10.082 [13] Lin Yinhe, Zhang Liqiang, Huang Xiaoli. Influence of CaF2 on the apparent viscosity of CaO-SiO2-MgO-Al2O3-TiO2 slags[J]. Metall Res Technol, 2017,114(6):606. doi: 10.1051/metal/2017067 [14] Chang Zhiyu, Jiao Kexin, Zhang Jianliang, et al. Effect of TiO2 and MnO on viscosity of blast furnace slag and thermodynamic analysis[J]. ISIJ Int, 2018,58(12):2173−2179. doi: 10.2355/isijinternational.ISIJINT-2018-379 [15] Zheng Jianlu, Xing Xiangdong, Pang Zhuogang, et al. Effect of Na2CO3, HF, and CO2 treatment on the regeneration of exhausted activated carbon used in sintering flue gas[J]. ACS Omega, 2021,6(39):25762−25771. doi: 10.1021/acsomega.1c04182 [16] Wang Cui, Zhang Jianliang, Zhang Heshun, et al. Effect of chlorine on the viscosities and structures of blast furnace slags[J]. Ironmak. Steelmak., 2016,43(10):769−774. doi: 10.1080/03019233.2016.1234541 [17] Lee Sunghee, Dong Joon Min. Anionic effect of chloride, fluoride, and sulfide ions on the viscosity of slag melt[J]. J Am Ceram Soc, 2017,100(6):2543−2552. doi: 10.1111/jace.14787 [18] Zhang Guohua, Chou Kuochen, Zhang Jianliang. Influence of TiO2 on viscosity of aluminosilicate melts[J]. Ironmak. Steelmak., 2013,41(1):47−50. [19] Long Minghua, Zhang Dongsheng, Xiao Yangwu, et al. Effect of MgO/Al2O3 ratio on fluidity and structure of blast furnace slag[J]. Journal of Chongqing University of Technology (Natural Science), 2015,29(7):49−53. (龙明华, 张东升, 肖扬武, 等. MgO/Al2O3比值对高炉炉渣流动性和结构的影响[J]. 重庆理工大学学报(自然科学), 2015,29(7):49−53.Long Minghua, Zhang Dongshen, Xiao Yangwu, et al. Effect of MgO/Al2O3 ratio on fluidity and structure of blast furnace slag[J]. Journal of Chongqing University of Technology (Natural Science), 2015, 29(7): 49-53. [20] Ge Zefeng, Kong Lingxue, Bai Jin, et al. Effect of CaO/Fe2O3 ratio on slag viscosity behavior under entrained flow gasification conditions[J]. Fuel, 2019,258(2):231−236. [21] Xie Feng, Lu Diankun, Yang Hongying, et al. Solvent extraction of silver and gold from alkaline cyanide solution with LIX 7950[J]. Mineral Processing and Extractive Metallurgy Review, 2013,35(4):229−238. [22] Sutradhar Dipankar, Asit K Chandra, Cl halogen bonding. Nature and effect of substituent at electron donor Cl atom[J]. Chemistry Select, 2020,5(2):554−563. [23] Hu Kai, Lü Xuewei, Li Shengping, et al. Viscosity of TiO2-FeO-Ti2O3-SiO2-MgO-CaO-Al2O3 for high-titania slag smelting process[J]. Metall. Mater. Trans. B, 2018,49:1963−1973. doi: 10.1007/s11663-018-1284-x [24] Zheng Kai, Zhang Zuotai, Liu Lili, et al. Investigation of the viscosity and structural properties of CaO-SiO2-TiO2 slags[J]. Metall. Mater. Trans. B, 2014,45(4):1389−1397. doi: 10.1007/s11663-014-0053-8 [25] Pang Zhuogang, Xing Xiangdong, Zheng Jianlu, et al. The effect of TiO2 on the thermal stability and structure of high acidity slag for mineral wool production[J]. Journal of Non-Crystalline Solids, 2021,571:121071. doi: 10.1016/j.jnoncrysol.2021.121071 [26] Joo Hyun Park, Dong Joon Min, Hyo Seok Song. The effect of CaF2 on the viscosities and structures of CaO-SiO2(-MgO)-CaF2 slags[J]. Metall Mater Trans B, 2002,33(4):723−729. [27] Xing Xiangdong, Pang Zhuogang, Mo Chuan, et al. Effect of MgO and BaO on viscosity and structure of blast furnace slag[J]. J Non-Cryst Solids, 2020,530:119801. doi: 10.1016/j.jnoncrysol.2019.119801 [28] Bjoern O Mysen, Frederick J Ryerson, David Virgo. The influence of TiO2 on the structure and derivative properties of silicate melts[J]. Am Mineral, 1980,65(11-12):1150−1165. [29] Chen Ziwei, Wang Hao, Sun Yongqi, et al. Insight into the relationship between viscosity and structure of CaO-SiO2-MgO-Al2O3 molten slags[J]. Metallurgical and Materials Transactions B, 2019,50(6):2930−2941. doi: 10.1007/s11663-019-01660-7 -

下载:

下载: