Study on the high-temperteraure tensile property and damage behavior in GH4141 superalloy

-

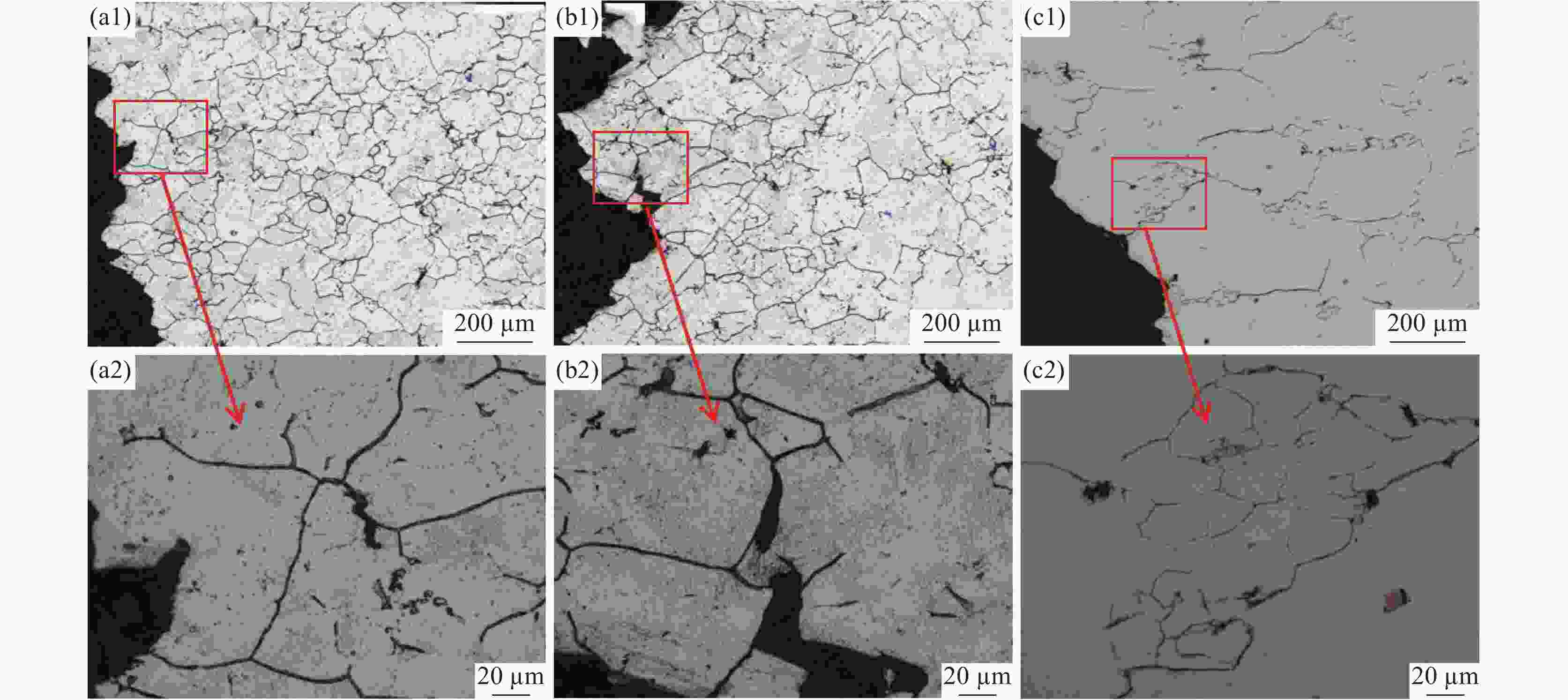

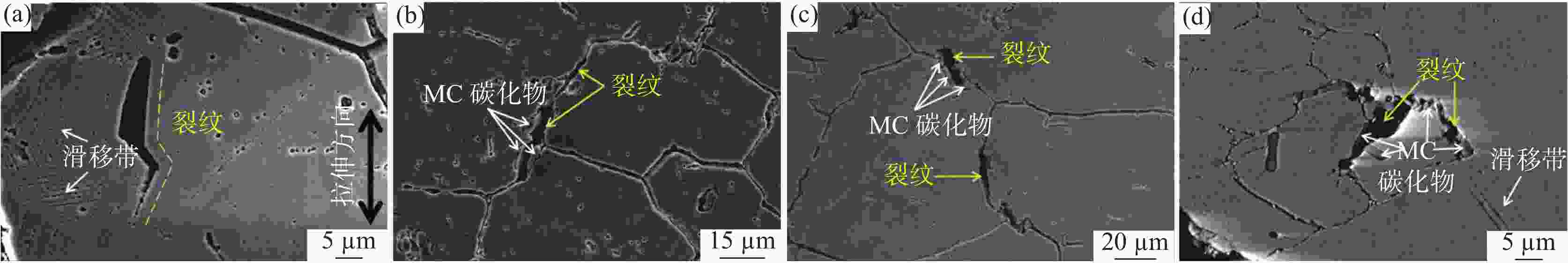

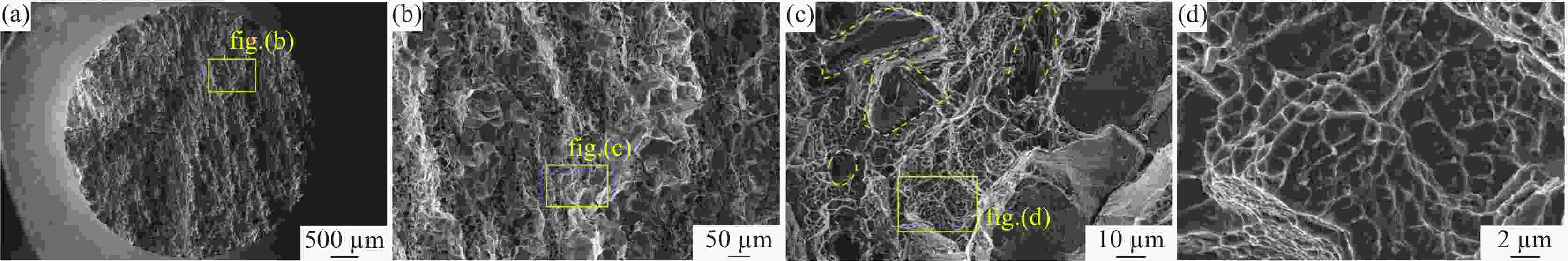

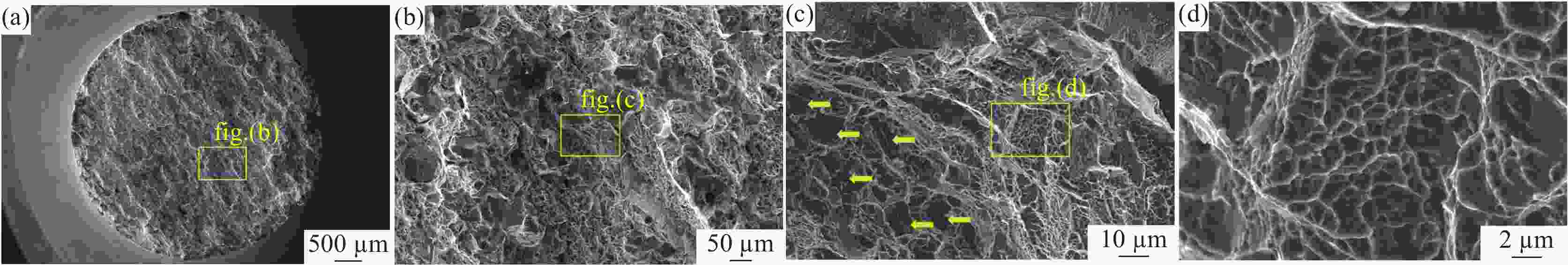

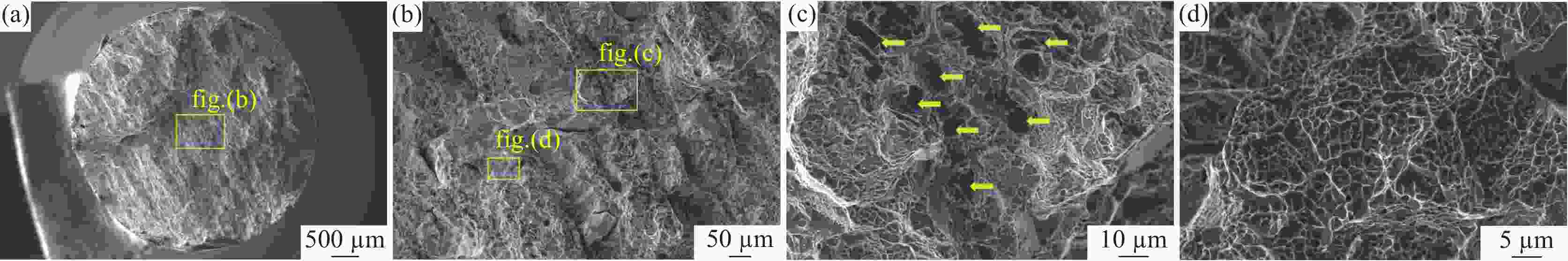

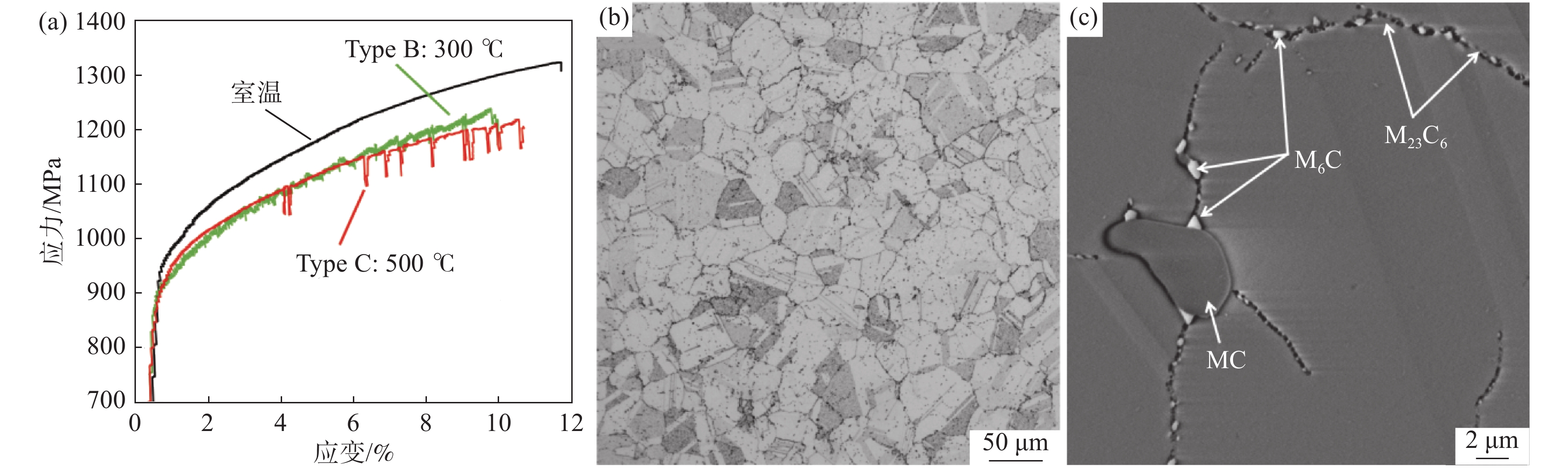

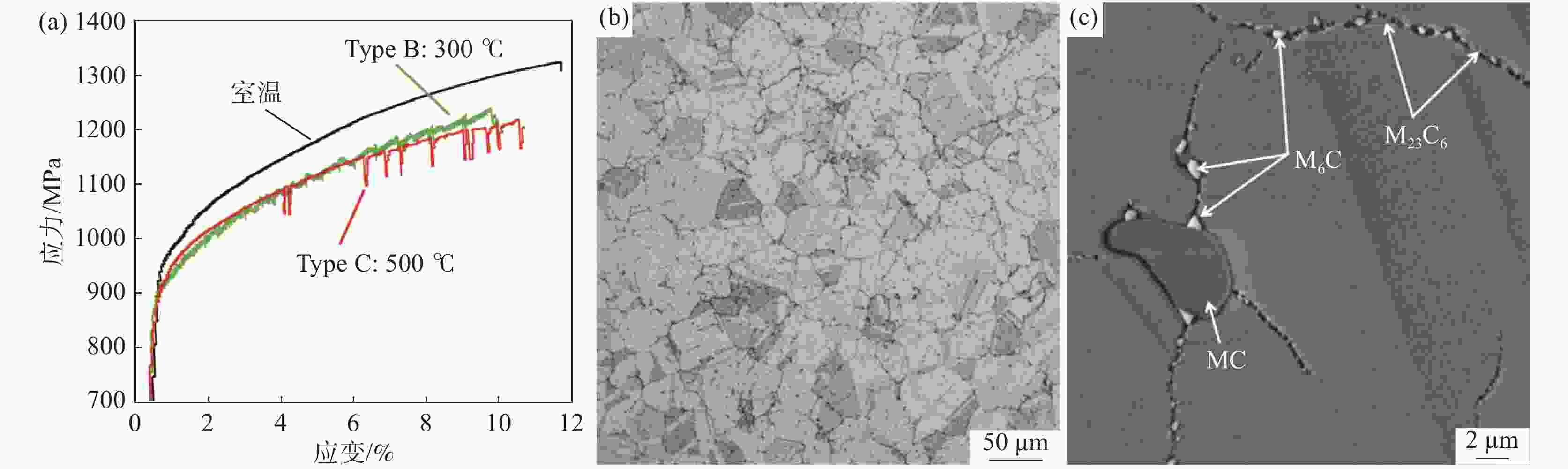

摘要: 研究了室温、300 ℃和500 ℃环境下GH4141合金的拉伸性能,结果表明,合金高温下的抗拉强度明显低于室温,300 ℃和500 ℃拉伸结果表现出锯齿状的应力-应变曲线,并且两种高温环境下的抗拉强度相当。不同温度下断口附近的微观组织表征结果显示裂纹主要在晶界位置产生,无论晶界是否含有粗大MC型碳化物。M6C和M23C6构成的链状碳化物使得晶界具有良好塑性,在断口表面形成大量的韧窝形貌。晶粒内部裂纹的产生与滑移带的形成密切相关,延缓滑移带的产生则归因于间隙元素、替代元素以及γ′强化析出相对位错的钉扎效应。注意到500 ℃环境下拉伸过程发生了再结晶现象,在粗大晶粒附近形成细小晶粒,并且伴随着少量碳化物,同时沿晶断裂现象明显减弱。然而,室温和300 ℃环境下的断口特征表现为穿晶和沿晶混合断裂模式,并未发生再结晶现象。Abstract: This study focuses on the tensile properties of GH4141 superalloy tested at room temperature, 300 ℃ and 500 ℃, respectively. The tensile strength obtained at high temperatures of 300 ℃ and 500 ℃ with serrated stress-strain curves are lower than that obtained at room temperature. In addition, the tensile strength tested at 500 ℃ is comparable to the value achieved at 300 ℃. The microstructure near the fracture surface of the superalloy is characterized. It is showed that cracks are formed at the grain boundary, irrespective of the observation of MC type carbides. The carbide composed of M6C and M23C6 with chain morphology endows grain boundary with a good plasticity which is reflected by numerous dimples in the fractographs. The initiation of cracks within the grains is associated with formation of slip bands. The activation of slip band can be delayed by dislocation pinning effect related to the interstitial elements, substituted elements and the γ′ strengthening precipitate phase. It should be noted that recrystallization occurred during tensile testing at 500 ℃ with a few carbides observed in the vicinity of fracture surface, while the intergranular fracture phenomenon was attenuated. However, the fractography of specimens tested at 300 ℃ exhibit both intergranular and transgranular fracture without recrystallization.

-

Key words:

- GH4141 superalloy /

- high temperature tensile property /

- dynamic strain aging /

- damage /

- carbides

-

表 1 GH4141合金化学成分

Table 1. Chemical composition of GH4141 superalloy

% C Cr Al Ti Co Mo B Mn Si S Fe Ni 0.06~0.12 18~20 1.4~1.8 3~3.5 10~12 9~10.5 0.003~0.01 <0.1 <0.5 <0.015 <5.0 Bal. -

[1] Shen Daogui. GH141 high strength superalloy[J]. Aerospace Material and Technology, 1985,(6):5−10. (沈道贵. GH141高强度高温合金[J]. 宇航材料工艺, 1985,(6):5−10.Shen Daogui. GH141 high strength superalloy[J]. Aerospace Material and Technology, 1985(6): 5-10. [2] Rao C V, Srinivas N C S, Sastry G V S, et al. Dynamic strain aging, deformation and fracture behaviour of the nickel base superalloy Inconel 617[J]. Materials Science and Engineering:A, 2019,742:44−60. doi: 10.1016/j.msea.2018.10.123 [3] Prasad K, Sarkar R, Ghosal P, et al. Tensile deformation behaviour of forged disc of IN 718 superalloy at 650 ℃[J]. Materials & Design, 2010,31(9):4502−4507. [4] Jena P S M, Sahu J K. Serrated flow in nickel base super alloy 720 Li at 350 and 450 ℃: Effect of chromium and cobalt segregation at dislocation core[J]. Materials Letters, 2022,321:132425. doi: 10.1016/j.matlet.2022.132425 [5] Xiao Dongping, Zhou Yang, Fu Jianhui, et al. Solidification segregation characteristic and homogenization treatment of GH141 superalloy[J]. Heat Treatment of Metals, 2022,47(5):141−147. (肖东平, 周扬, 付建辉, 等. GH141合金的凝固偏析特性及均匀化处理[J]. 金属热处理, 2022,47(5):141−147.Xiao Dongping, Zhou Yang, Fu Jianhui, et al. Solidification segregation characteristic and homogenization treatment of GH141 superalloy[J]. Heat Treatment of Metals, 2022, 47(5): 141-147. [6] Xiao Dongping, Fu Jianhui, Chen Qi, et al. Hot deformation behavior and microstructure evolution of GH4141 superalloy[J]. Journal of Plasticity Engineering, 2022,29(9):157−164. (肖东平, 付建辉, 陈琦, 等. GH4141高温合金热变形行为及组织演变[J]. 塑性工程学报, 2022,29(9):157−164.Xiao Dongping, Fu Jianhui, Chen Qi, et al. Hot deformation behavior and microstructure evolution of GH4141 superalloy[J]. Journal of Plasticity Engineering, 2022, 29(9): 157-164. [7] Xiao Dongping, Wang Fu, Zhou Yang, et al. Grain growth behavior of GH4141 superalloy during solution treatment process[J]. Heat Treatment of Metals, 2023,48(3):221−225. (肖东平, 王福, 周扬, 等. GH4141高温合金固溶处理过程中的晶粒长大行为[J]. 金属热处理, 2023,48(3):221−225.Xiao Dongping, Wang Fu, Zhou Yang, et al. Grain growth behavior of GH4141 superalloy during solution treatment process[J]. Heat Treatment of Metals, 2023, 48(3): 221-225. [8] 李宁, 李爱民, 王艾竹, 等. 固溶处理冷却速度对GH4141合金组织及性能的影响[C]// 第十三届中国高温合金年会论文集. 北京: 冶金工业出版社, 2015: 46-49Li Ning, Li Aimin, Wang Aizhu, et al.The effect of different cooling speeds after solution treatment on the microstructure an properties of GH4141 alloy[C]//Proceedings of the Thirteenth China Superalloy Annual Conference. Beijing: Metallurgical Industry Press, 2015: 46-49. [9] Yu Huichen, Xie Shishu, Lü Junying, et al. Microstructures control in Ni-base superalloy GH141[J]. Journal of Materials Engineering, 2003,(5):7−10. (于慧臣, 谢世殊, 吕俊英, 等. GH141合金的显微组织控制[J]. 材料工程, 2003,(5):7−10.Yu Huichen, Xie Shishu, Lv Junying, et al. Microstructures control in Ni-base superalloy GH141[J]. Journal of Materials Engineering, 2003 (5): 7-10. [10] Gopinath K, Gogia A K, Kamat S V, et al. Dynamic strain ageing in Ni-base superalloy 720Li[J]. Acta Materialia, 2009,57(4):1243−1253. doi: 10.1016/j.actamat.2008.11.005 [11] Rodriguez P, Venkadesan S. Serrated plastic flow revisited[J]. Solid State Phenomena, 1995,42:257−266. [12] Liu Yajing, Yang Hongcai, Yuan Ying. Carbides and γ′ precipitates in GH141[J]. Special Steel, 1996,17(6):12−16. (刘雅晶, 杨洪才, 袁英. GH141合金碳化物及γ′的沉淀[J]. 特殊钢, 1996,17(6):12−16.Liu Yajing, Yang Hongcai, Yuan Ying. Carbides and γ′ precipitates in GH141[J]. Special Steel, 1996, 17(6): 12-16. [13] Goodfellow A J. Strengthening mechanisms in polycrystalline nickel-based superalloys[J]. Materials Science and Technology, 2018,34(15):1793−1808. doi: 10.1080/02670836.2018.1461594 [14] Wu X, Yang M, Yuan F, et al. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility[J]. Proceedings of the National Academy of Sciences, 2015,112(47):14501−14505. doi: 10.1073/pnas.1517193112 [15] Max B, San Juan J, Nó M L, et al. Atomic species associated with the Portevin–Le Chatelier effect in superalloy 718 studied by mechanical spectroscopy[J]. Metallurgical and Materials Transactions A, 2018,49(6):2057−2068. doi: 10.1007/s11661-018-4579-2 -

下载:

下载: