Evenness of solidification structure and solute distribution in the continuous casting billet of gear steel

-

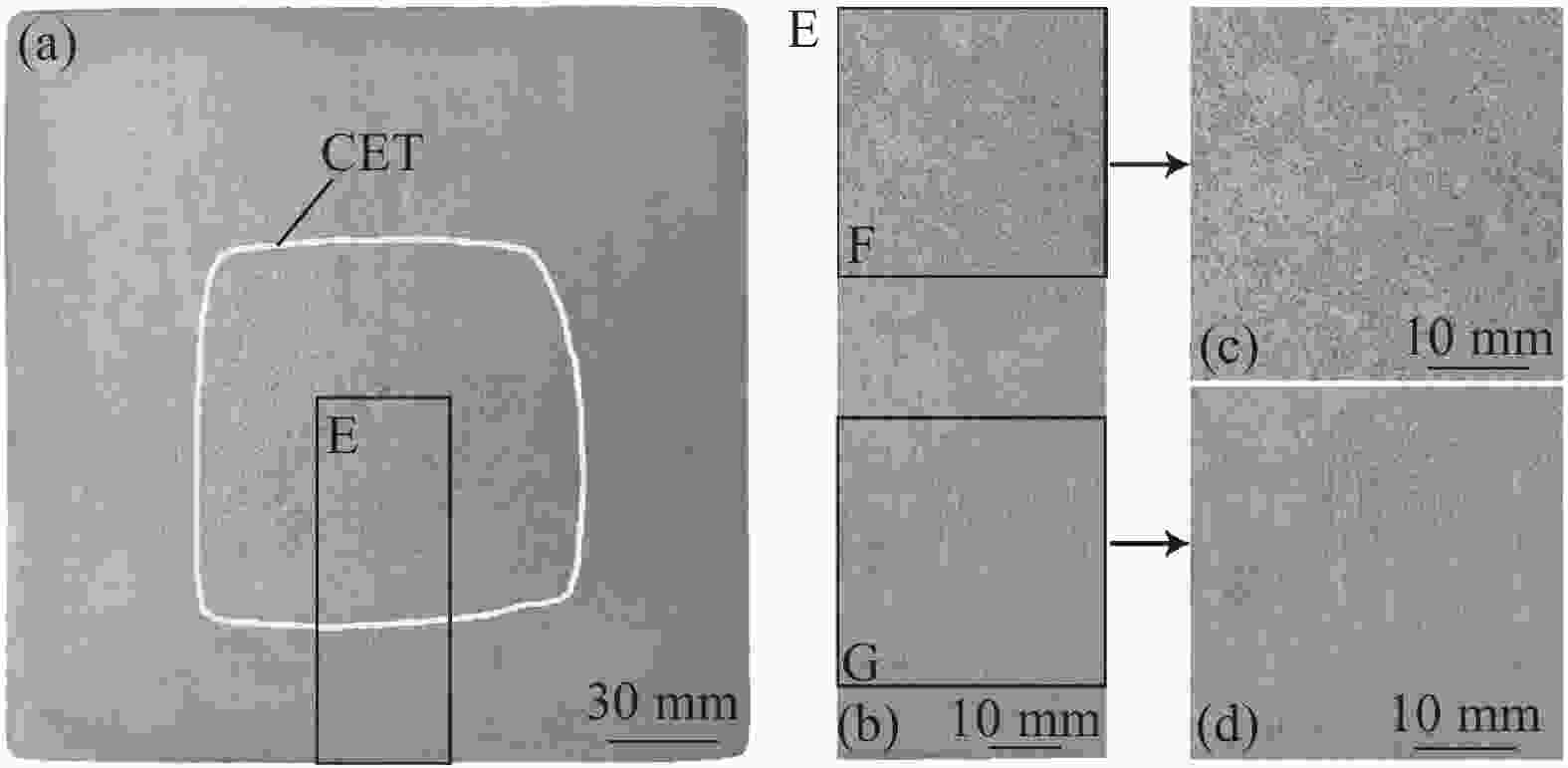

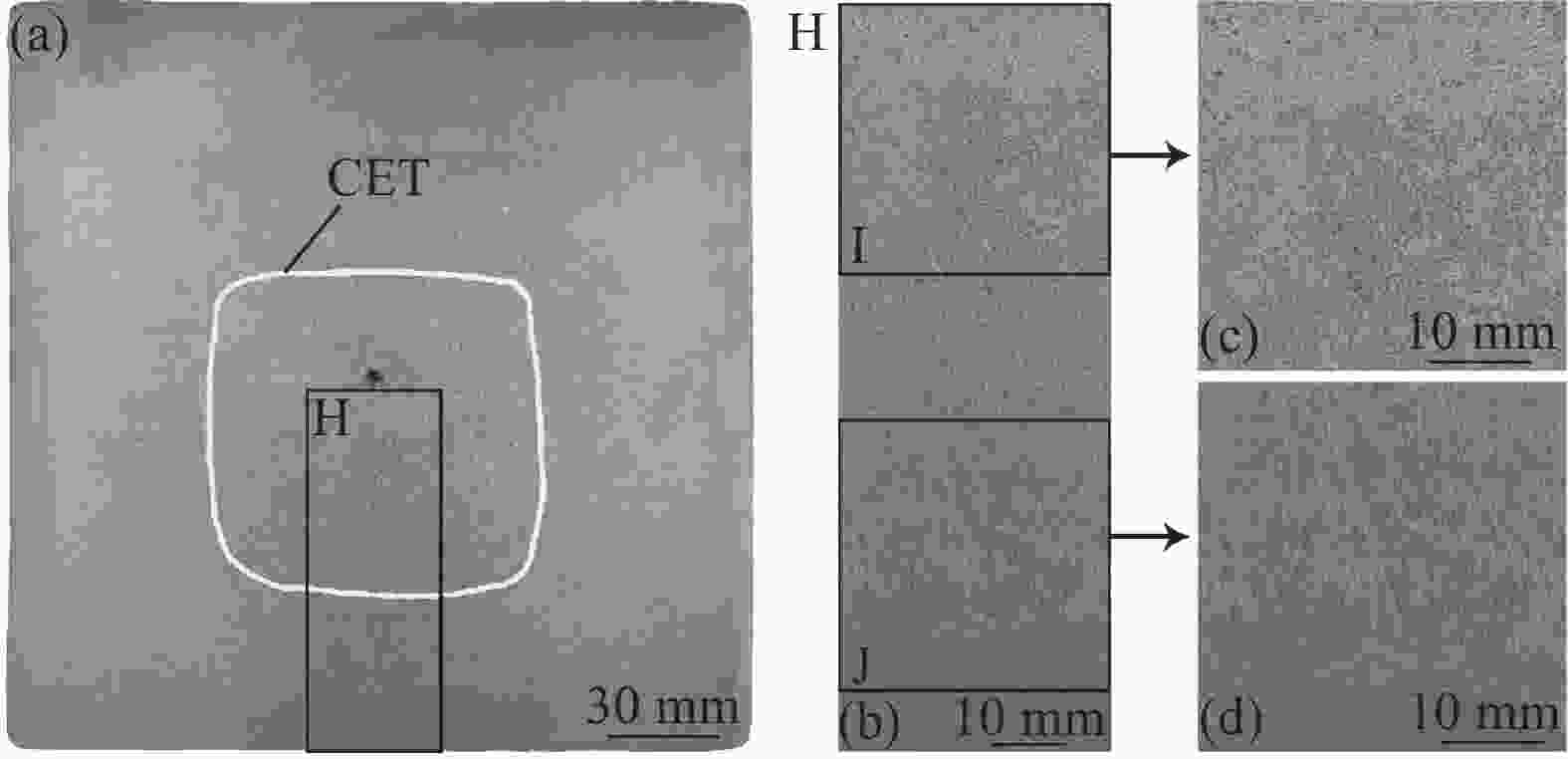

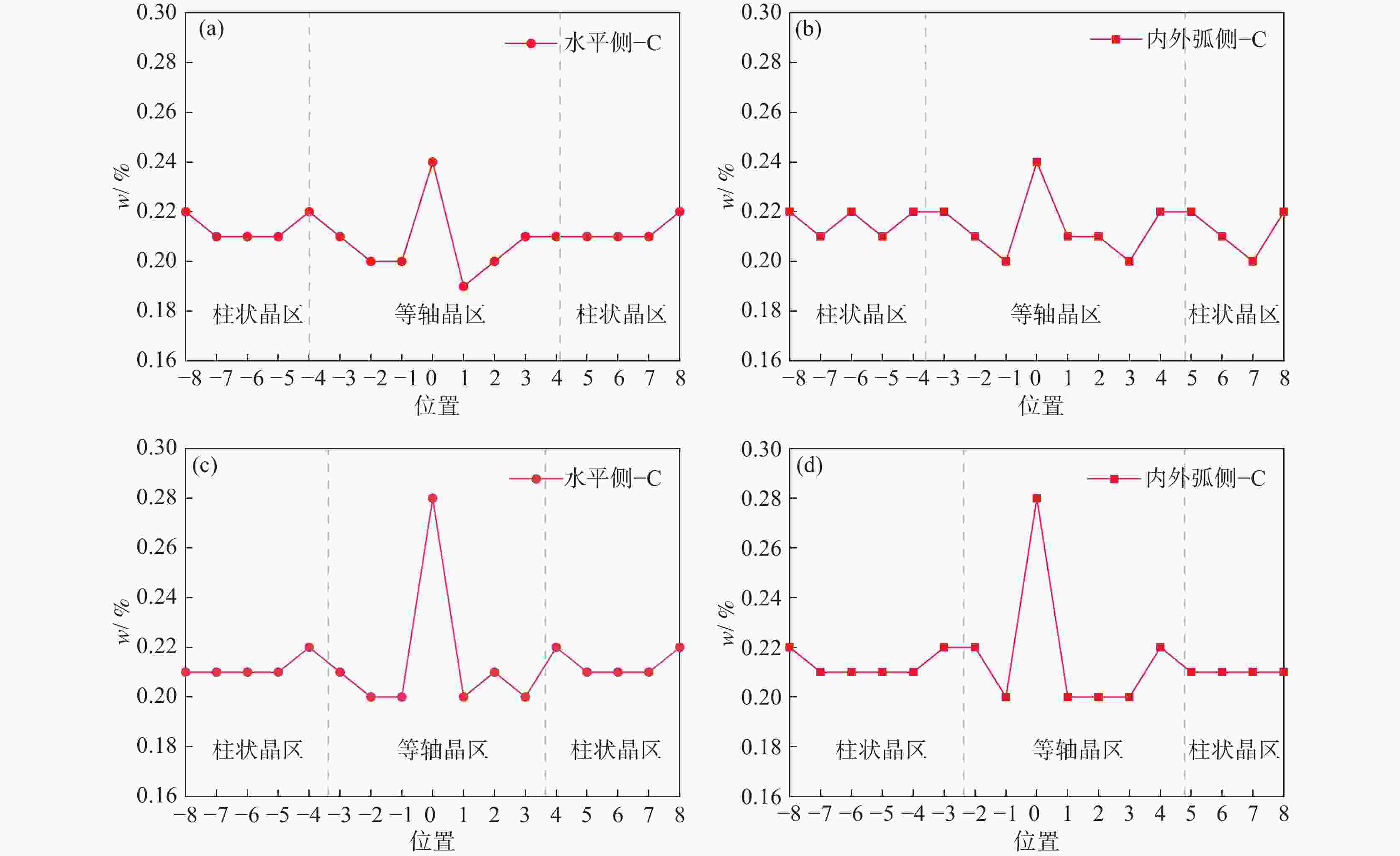

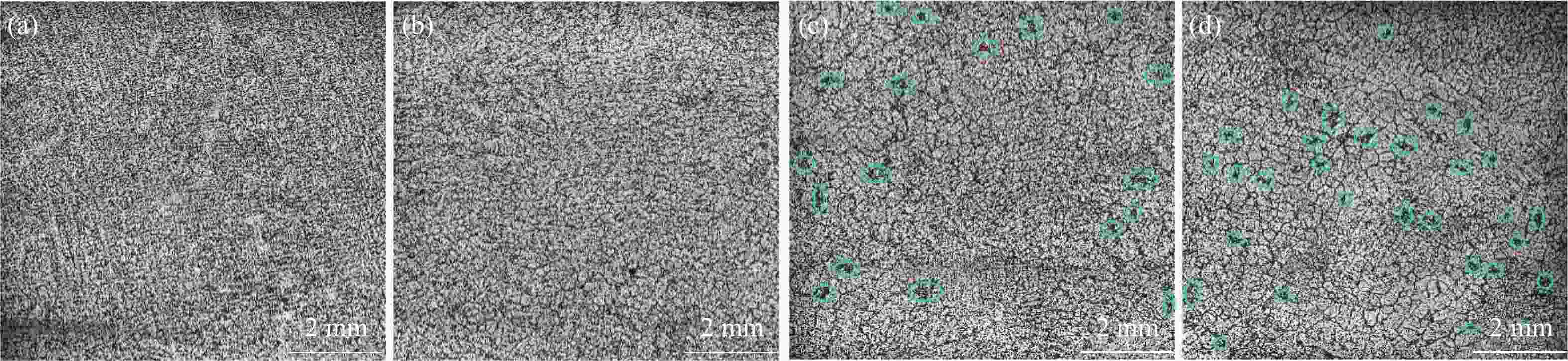

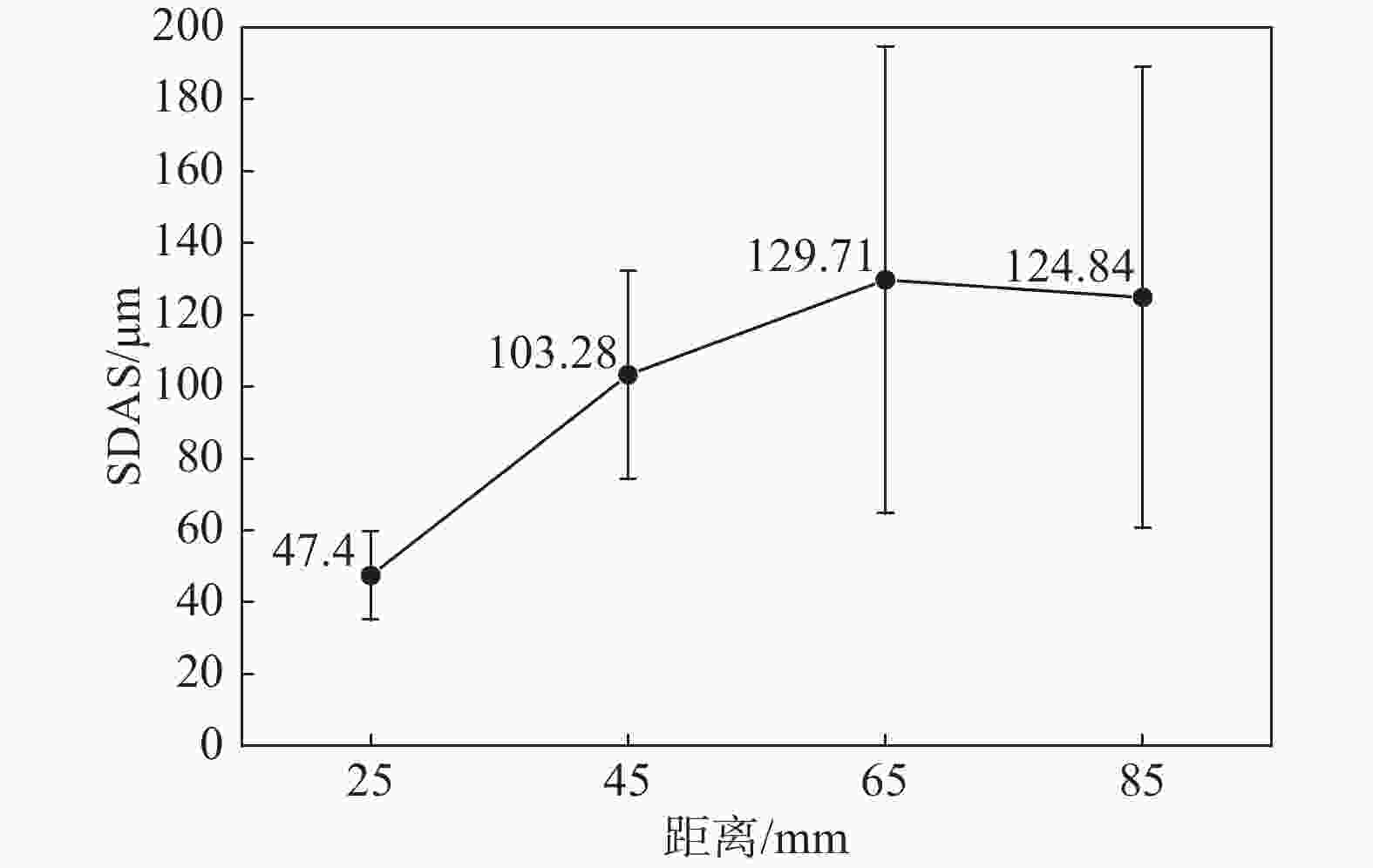

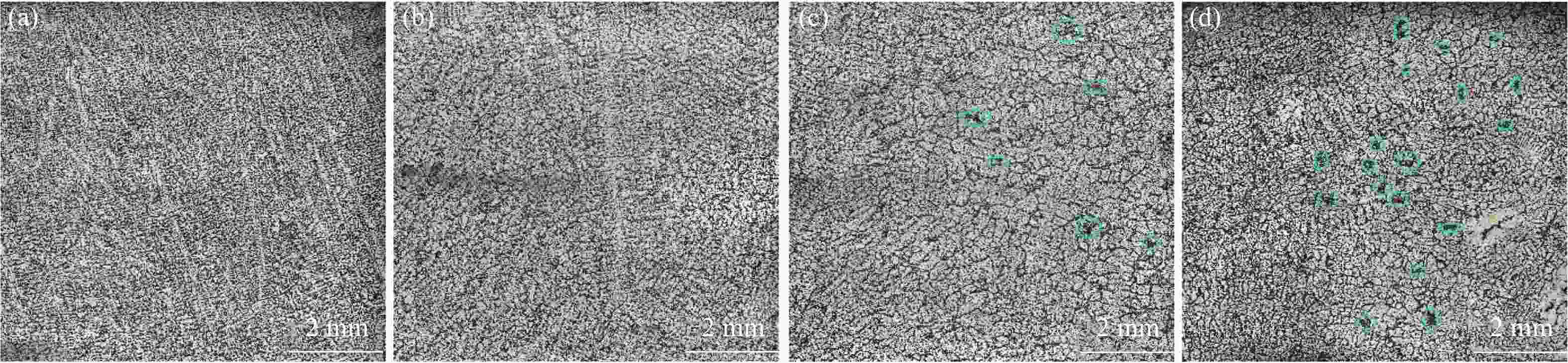

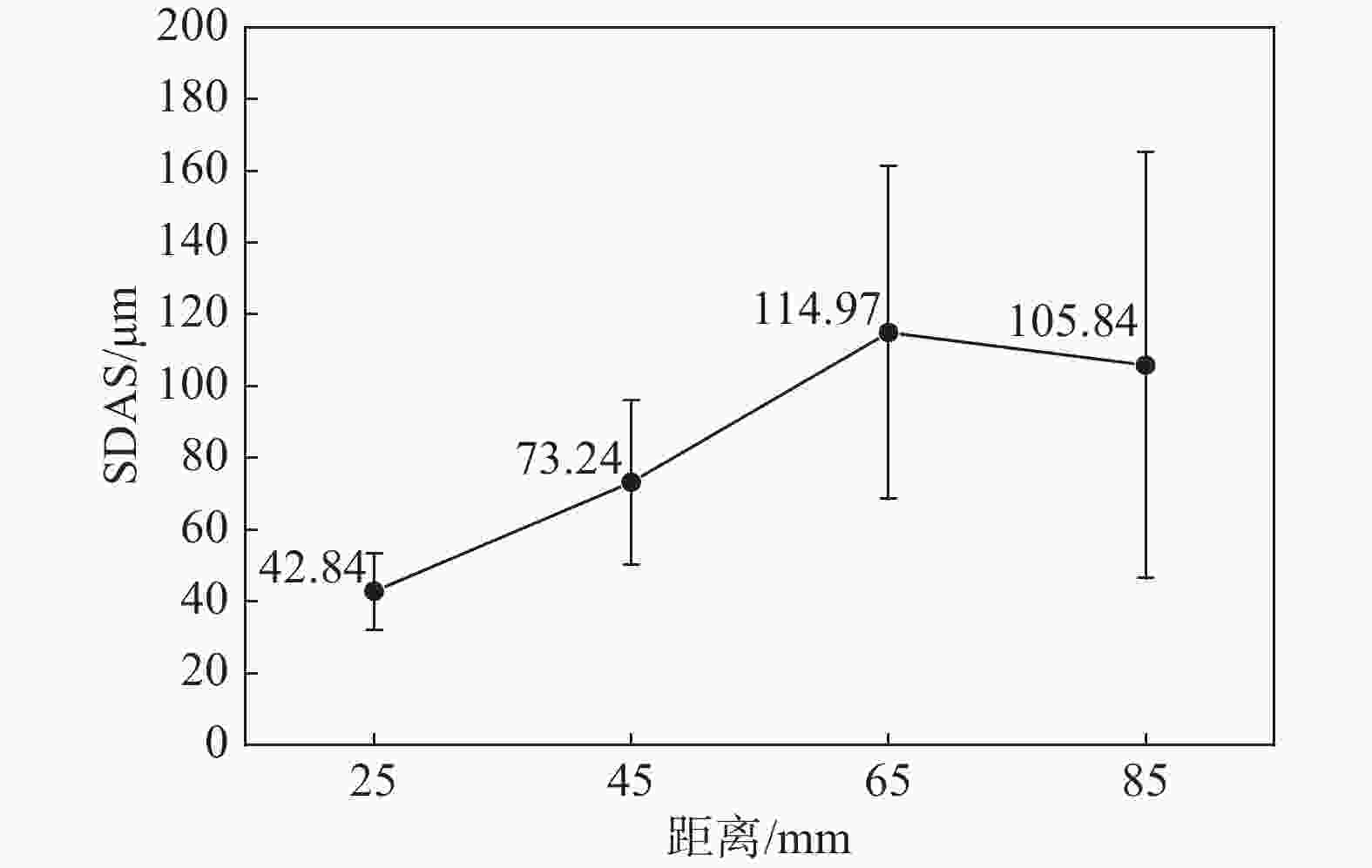

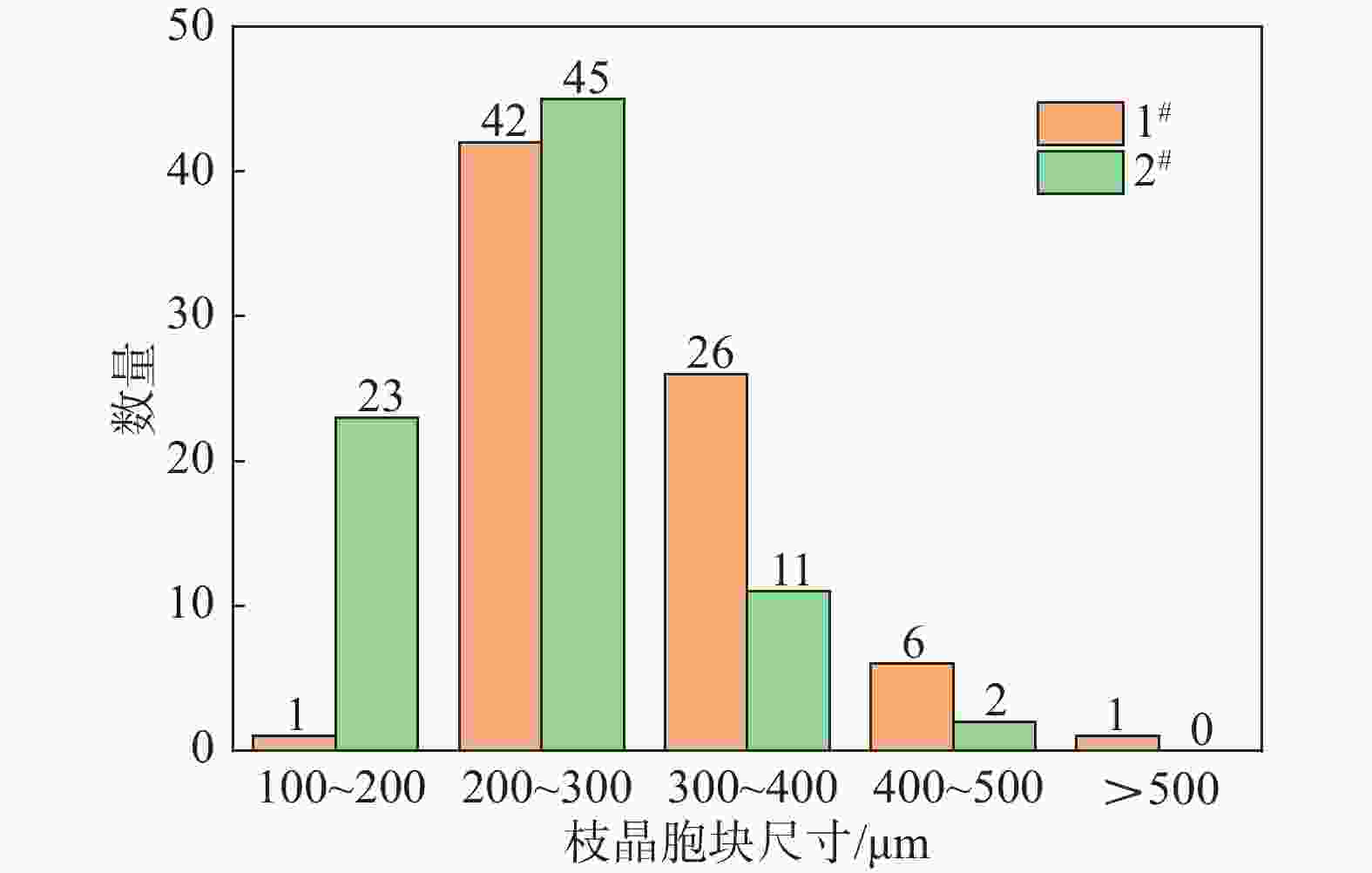

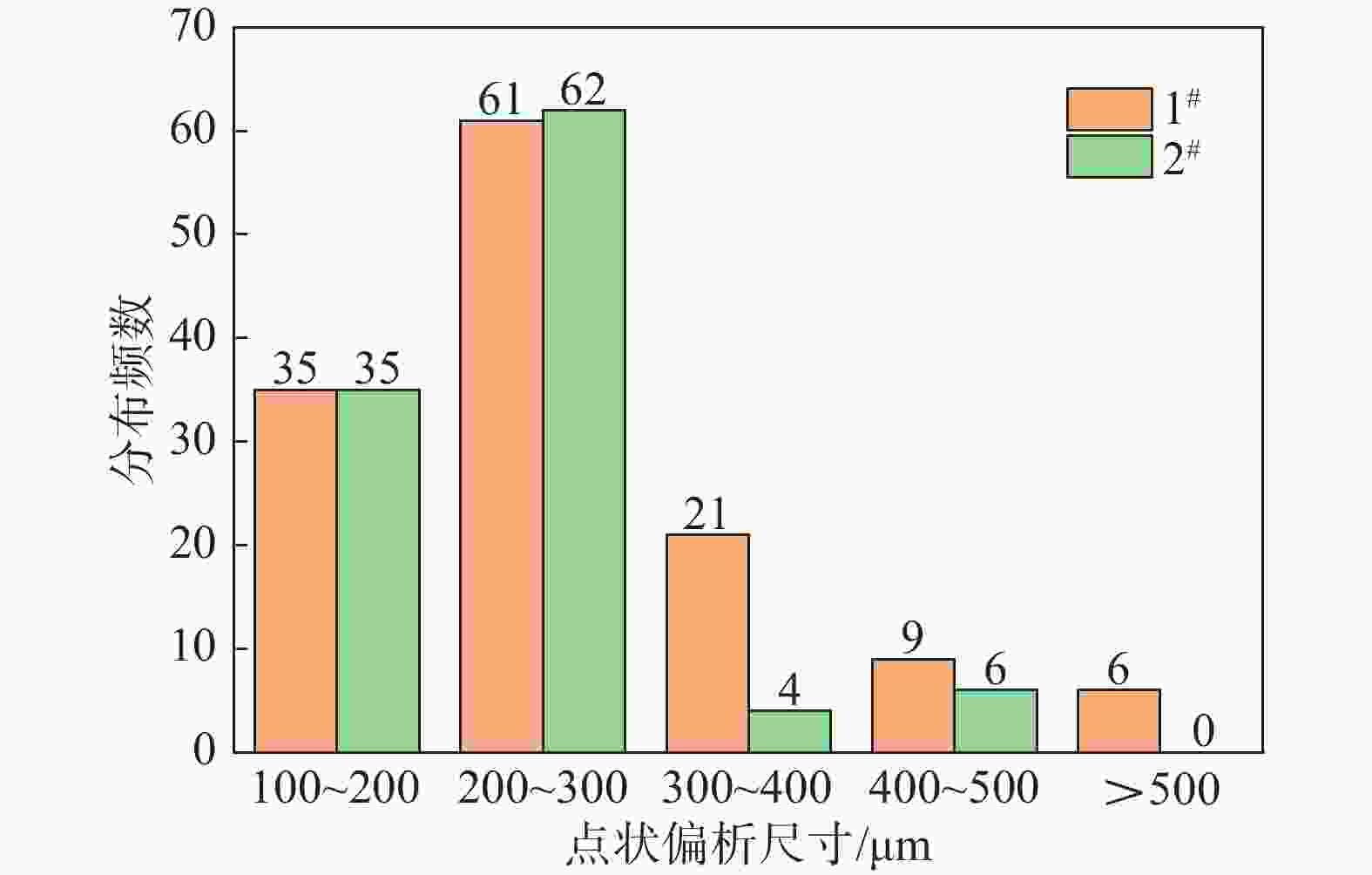

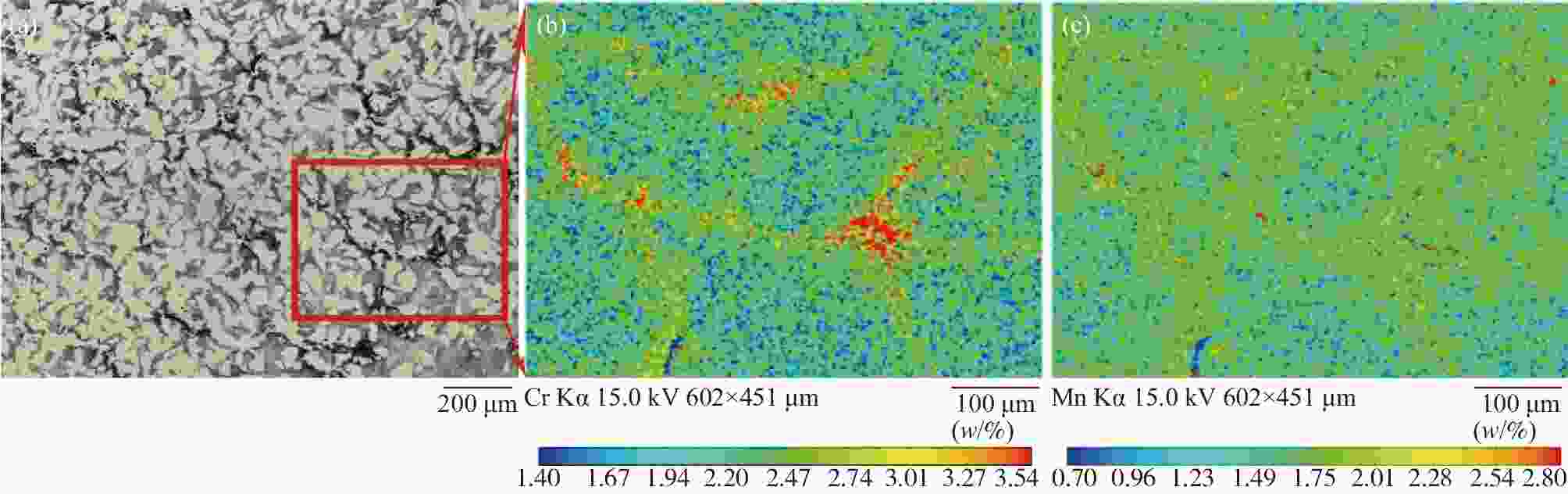

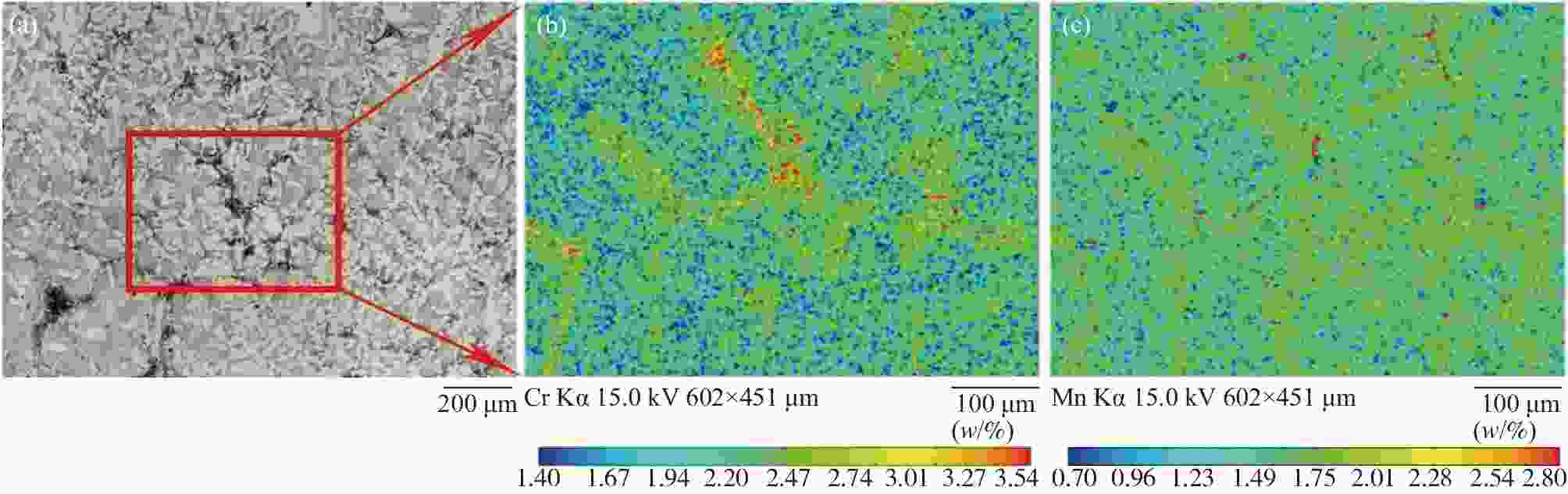

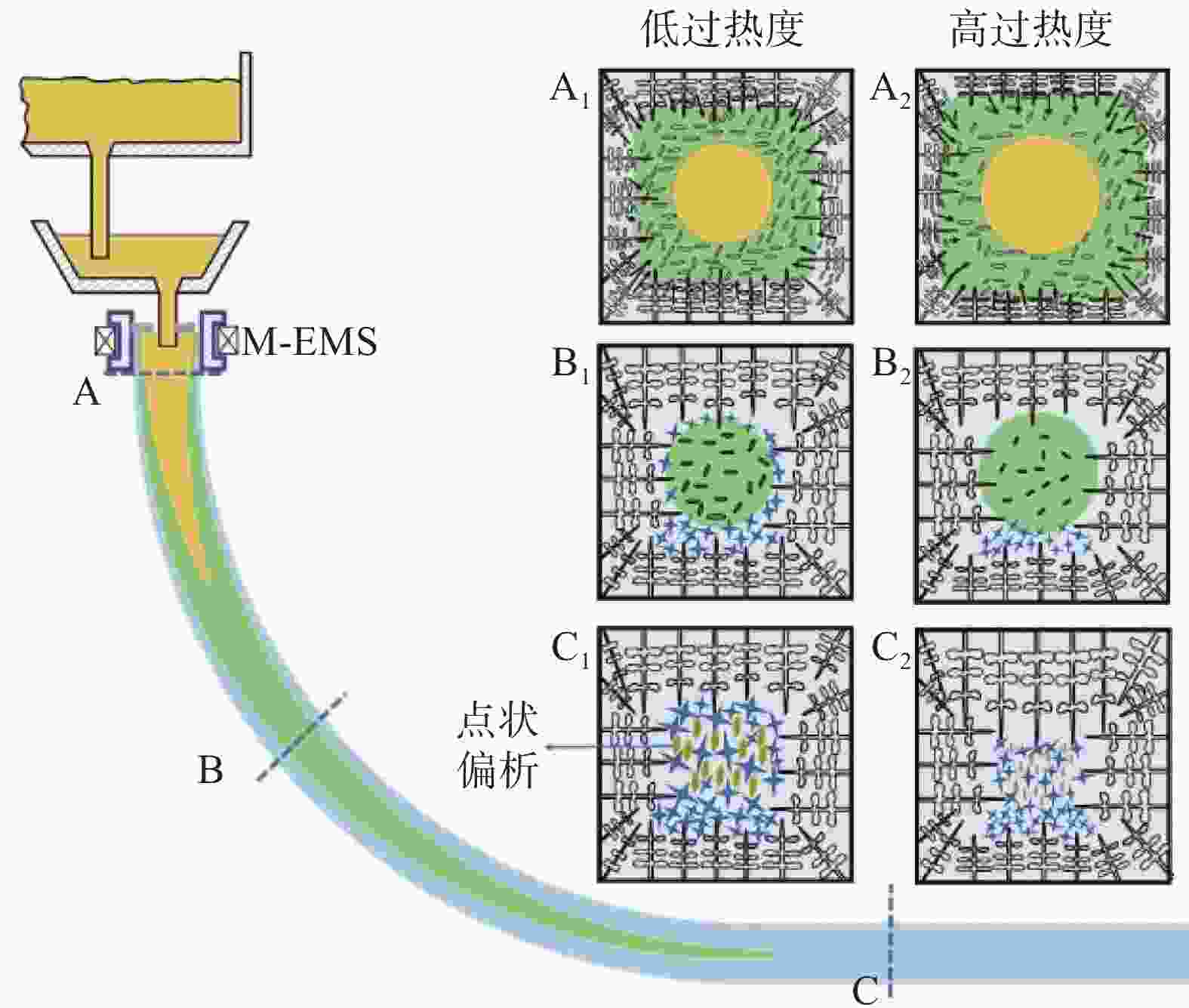

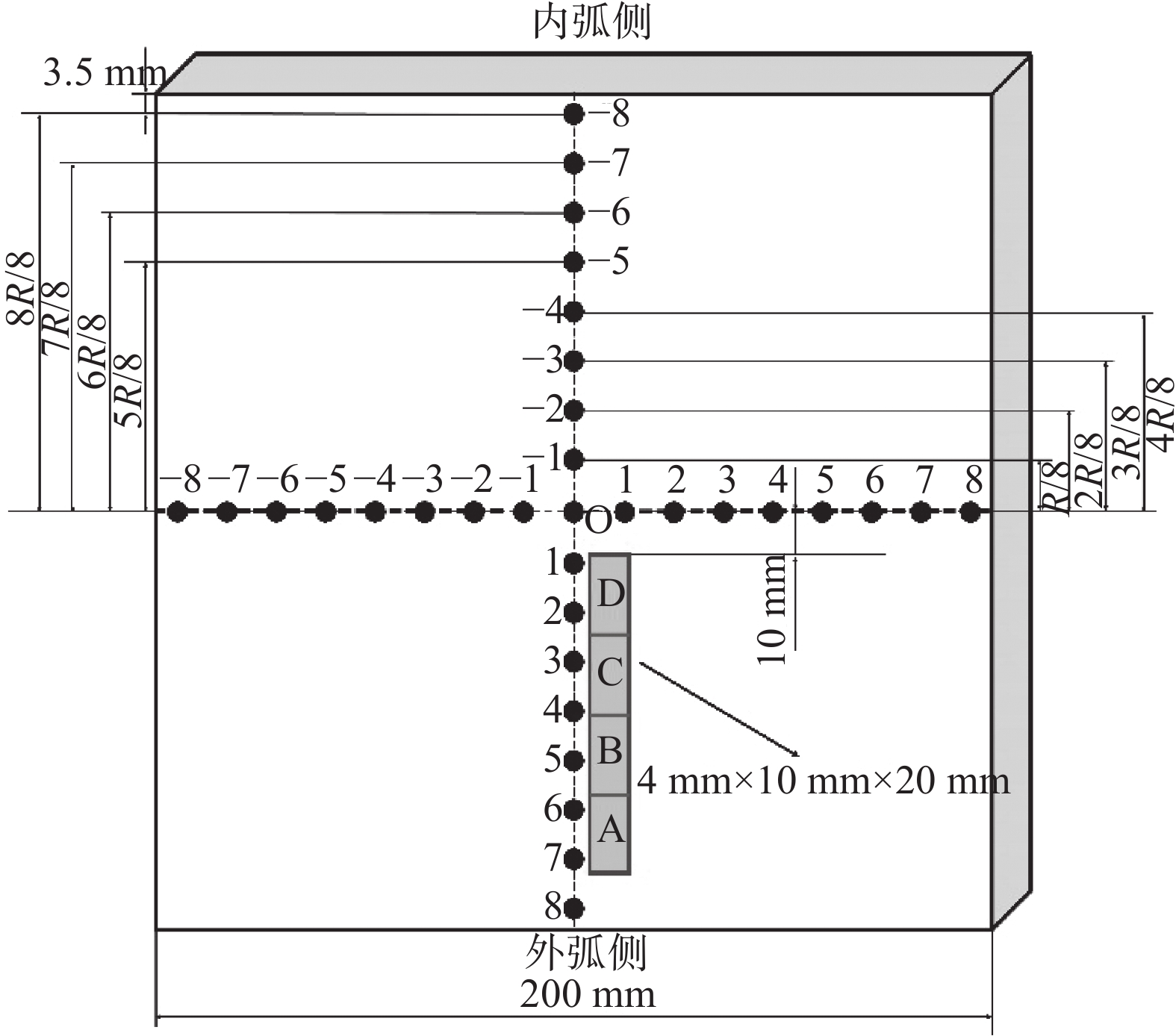

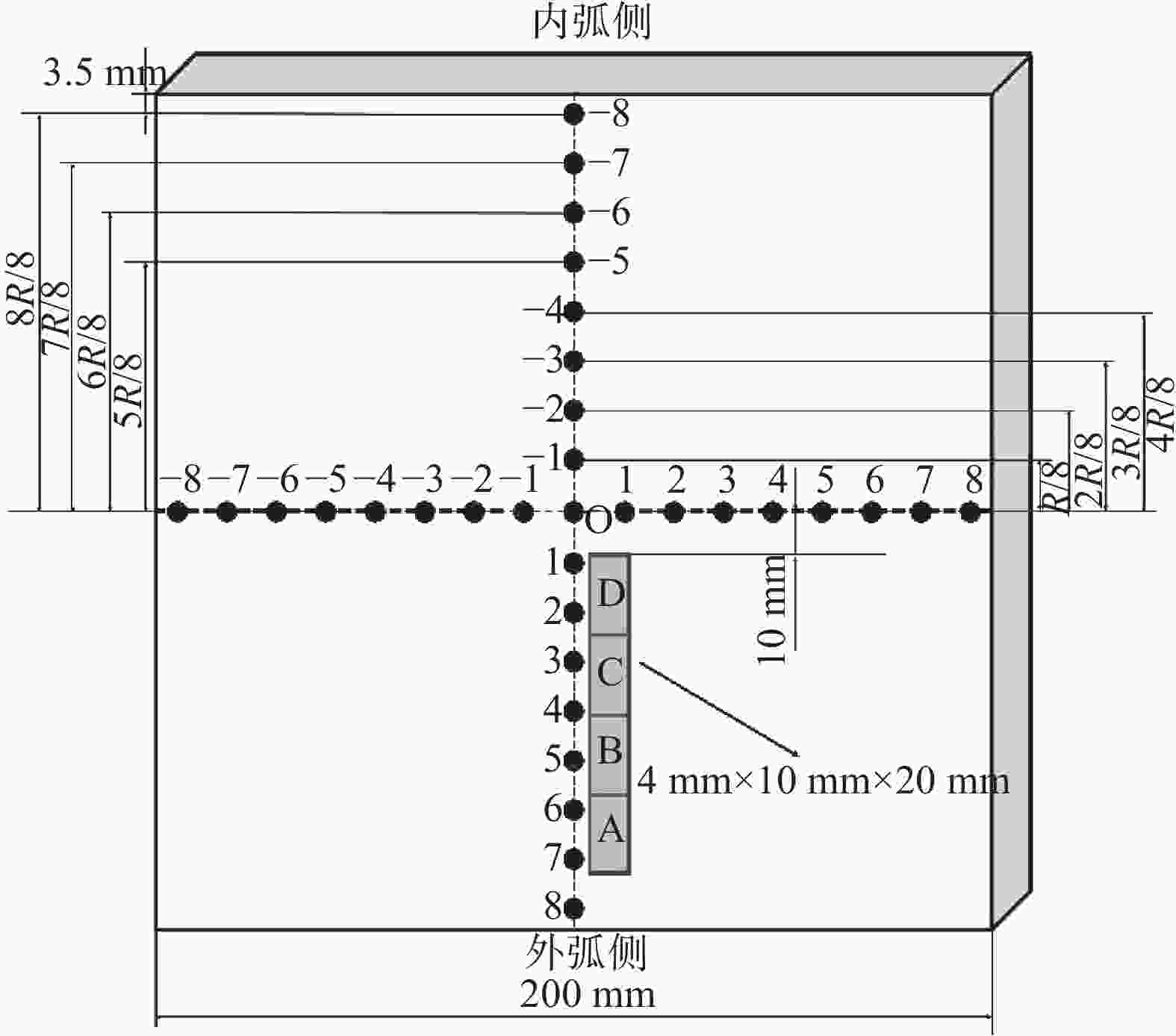

摘要: 分析了20CrMnTi齿轮钢200 mm×200 mm连铸坯凝固组织和溶质分布的均匀性,提出了不同过热度时粗大等轴晶和点状偏析的共生机理,制定了齿轮钢连铸均质性控制策略。结果表明,齿轮钢连铸坯凝固组织受到钢水过热度的直接影响,提高过热度会减小等轴晶面积,降低对中性,减小等轴晶尺寸;齿轮钢连铸坯凝固组织直接影响C元素中心偏析和断面分布均匀性,提高等轴晶率有利于降低中心偏析,但会增大等轴晶区溶质波动范围;齿轮钢连铸坯凝固组织直接影响半宏观尺度的点状偏析,提高等轴晶率会增加大尺寸点状偏析数量,Cr、Mn溶质偏聚程度也会增加。为了同时提高齿轮钢组织和成分均匀性,比较理想的连铸低倍结构特征是等轴晶率低、等轴晶尺寸小而均匀、对中性良好。Abstract: The evenness of solidification structure and solute distribution in the continuous casting billet of 20CrMnTi gear steel was experimentally investigated, and the symbiotic relationship and formation mechanism of coarse equiaxed dendrites and spot segregation were proposed. The control strategy on the homogeneity of continuous casting bloom for gear steel was developed. The results indicate that the solidification structure of the bloom is closely affected by superheat during casting. As the superheat increases, the ratio of equiaxed area decreases, the sizes of the equiaxed dendrites reduce, and the alignment of center equiaxed zone worsens. The central segregation and solute distribution evenness are related to solidification structure. The central segregation ratio decreases with the increase in equiaxed ratio, while the solute fluctuation range increases. In addition, the spot segregation is also relevant to the solidification structure. The number of large size spot segregation increases, and the concentration of Cr and Mn in the spot segregation increases, as the equiaxed ratio increases. In order to improve the evenness of microstructure and composition in gear steel, the target solidification structure of continuous casting bloom should possess low equiaxed ratio, small and uniform equiaxed dendrites, and good alignment of equiaxed zones.

-

Key words:

- gear steel /

- solidification structure /

- central segregation /

- carbon content range /

- spot segregation

-

表 1 20CrMnTi钢种主要化学成分

Table 1. Main chemical compositions of 20CrMnTi steel

% 编号 C Mn Si P S Cr Ti 标准范围 0.17~0.23 0.80~1.20 0.17~0.37 ≤0.030 ≤0.030 1.00~1.30 0.04~0.10 1# 0.21 0.92 1.07 0.013 0.030 1.16 0.061 2# 0.21 0.90 1.02 0.013 0.024 1.10 0.056 表 2 连铸机生产工艺参数

Table 2. Parameters of the continuous caster

试验号 拉速/

(m·min−1)过热

度/ ℃二冷比水量/

(L·kg−1)M-EMS F-EMS 1# 1.3 27 0.515 √ √ 2# 1.3 38 0.505 √ √ 注:M-EMS参数为100 A/3 Hz;F-EMS参数为50 A/5 Hz。 表 3 C元素偏析比、标准差和极差

Table 3. Segregation ratio, standard deviation and polar deviation of C contents

编号 碳偏析 正偏析 负偏析 标准差 极差 1# C 1.13 0.90 0.009 0.05 C(去除中心点) 1.04 0.90 0.008 0.03 2# C 1.32 0.94 0.014 0.08 C(去除中心点) 1.05 0.95 0.007 0.02 -

[1] Hunkel M, Kagathara J, Prahl U. The influence of segregations after forming on the heat treatment result of bevel gears[J]. Steel Research International, 2019,90(6):1800427. doi: 10.1002/srin.201800427 [2] Wang Y, Chen Y, Yu W. Effect of Cr/Mn segregation on pearlite—martensite banded structure of high carbon bearing steel[J]. International Journal of Minerals, Metallurgy and Materials, 2021,28(4):665−675. doi: 10.1007/s12613-020-2035-y [3] He Qingwen, Wang Bao, Wang Fuming, et al. Cause and preventive measure for central segregation of bearing steel bloom[J]. Iron & Steel, 2009,44(8):39−41. (何庆文, 王宝, 王福明, 等. 大方坯轴承钢中心偏析的成因及预防措施[J]. 钢铁, 2009,44(8):39−41. He Qingwen, Wang Bao, Wang Fuming, et al . Cause and preventive measure for central segregation of bearing steel bloom[J]. Iron & Steel,2009 ,44 (8 ):39 −41. [4] Qian Gang, Ruan Xiaojiang, Cai Xieao. Cause for central segregation of cc bloom from bearing steel and countermeasures[J]. Iron & Steel, 2002(5):16−18. (钱刚, 阮小江, 蔡燮鳌. 连铸轴承钢大方坯中心偏析的成因及对策[J]. 钢铁, 2002(5):16−18. doi: 10.3321/j.issn:0449-749X.2002.05.005 Qian Gang, Ruan Xiaojiang, Cai Xieao . Cause for central segregation of cc bloom from bearing steel and countermeasures[J]. Iron & Steel,2002 (5 ):16 −18 . doi: 10.3321/j.issn:0449-749X.2002.05.005[5] Lan Peng, Tie Zhanpeng, Zhang Wei, et al. Research progress on spot segregation defects in continuously cast semi-products[J]. Iron & Steel, 2020,55(2):11−22. (兰鹏, 铁占鹏, 张伟, 等. 连铸坯点状偏析缺陷研究进展[J]. 钢铁, 2020,55(2):11−22. Lan Peng, Tie Zhanpeng, Zhang Wei, et al . Research progress on spot segregation defects in continuously cast semi-products[J]. Iron & Steel,2020 ,55 (2 ):11 −22 .[6] Geng Hao, Zhang Zhonghua, Tang Haiyan, et al. Study on segregation and Nb-bearing precipitates of high-strength oil well casing steel[J]. Journal of Iron and Steel Research, 2019,31(4):387−393. (耿豪, 张忠铧, 唐海燕, 等. 高强度油井套管钢偏析与含Nb析出相研究[J]. 钢铁研究学报, 2019,31(4):387−393. Geng Hao, Zhang Zhonghua, Tang Haiyan, et al . Study on segregation and Nb-bearing precipitates of high-strength oil well casing steel[J]. Journal of Iron and Steel Research,2019 ,31 (4 ):387 −393 .[7] Zhang Zhuang, Li Haiyang, Zhou Lei, et al. As-cast spot segregation of gear steel and its evolution in the rolled products[J]. Acta Metallurgica Sinica, 2021,57(10):1281−1290. (张壮, 李海洋, 周蕾, 等. 齿轮钢铸态点状偏析及其在热轧棒材中的演变[J]. 金属学报, 2021,57(10):1281−1290. Zhang Zhuang, Li Haiyang, Zhou Lei, et al . As-cast spot segregation of gear steel and its evolution in the rolled products[J]. Acta Metallurgica Sinica,2021 ,57 (10 ):1281 −1290 .[8] Li Bo, Zhang Zhonghua, Liu Huasong, et al. Characteristics and evolution of the spot segregations and banded defects in high strength corrosion resistant tube steel[J]. Acta Metallurgica Sinica, 2019,55(6):762−772. (李博, 张忠铧, 刘华松, 等. 高强耐蚀管钢点状偏析及带状缺陷的特征与演变[J]. 金属学报, 2019,55(6):762−772. Li Bo, Zhang Zhonghua, Liu Huasong, et al . Characteristics and evolution of the spot segregations and banded defects in high strength corrosion resistant tube steel[J]. Acta Metallurgica Sinica,2019 ,55 (6 ):762 −772 .[9] Meng Qingyong, Wang Fuming, Li Changrong, et al. Influence of superheat on central macrosegregation of 12Cr2Mo1R steel heavy flat ingot during solidification[J]. Transactions of Materials and Heat Treatment, 2015,36(3):244−250. (孟庆勇, 王福明, 李长荣, 等. 过热度对12Cr2Mo1R大扁锭凝固过程中心宏观偏析的影响[J]. 材料热处理学报, 2015,36(3):244−250. Meng Qingyong, Wang Fuming, Li Changrong, et al . Influence of superheat on central macrosegregation of 12Cr2Mo1R steel heavy flat ingot during solidification[J]. Transactions of Materials and Heat Treatment,2015 ,36 (3 ):244 −250 .[10] Cheng Changgui, Che Fang, Shuai Jing, et al. Development of centerline segregation control technology for continuous casting strand[J]. Continuous Casting, 2009(6):39−43. (程常桂, 车芳, 帅静, 等. 连铸坯中心偏析控制技术的发展[J]. 连铸, 2009(6):39−43. Cheng Changgui, Che Fang, Shuai Jing, et al . Development of centerline segregation control technology for continuous casting strand[J]. Continuous Casting,2009 (6 ):39 −43 .[11] Wang Y, Zhang L, Zhang H, et al. Mechanism and control of sulfide inclusion accumulation in CET Zone of 37Mn5 round billet[J]. Metallurgical and Materials Transactions B, 2017,48(2):1004−1013. doi: 10.1007/s11663-016-0886-4 [12] Yim C H, Park J K, Oh K S, et al. The control of internal quality by the reduction of blooms with liquid core[C]//Steelmaking Conference Proceedings. Iron and Steel Society of Aime, 1998: 309-314. [13] Li Guijun, Zhang Guifang, Chen Yong, et al. Effect of liquid steel superheat on solidification of bloom in continuous casting[J]. Iron Steel Vanadium Titanium, 2005,26(1):1−4. (李桂军, 张桂芳, 陈永, 等. 连铸钢水过热度对大方坯凝固的影响[J]. 钢铁钒钛, 2005,26(1):1−4. Li Guijun, Zhang Guifang, Chen Yong, et al . Effect of liquid steel superheat on solidification of bloom in continuous casting[J]. Iron Steel Vanadium Titanium,2005 ,26 (1 ):1 −4 .[14] Xu Z G, Wang X H, Jiang M, et al. Investigation on formation of equiaxed zone in low carbon steel slabs[J]. Metallurgical Research & Technology, 2016,113(1):106. -

下载:

下载: