Study on the hot deformation characteristics of M35 high speed steel by electron beam smelting

-

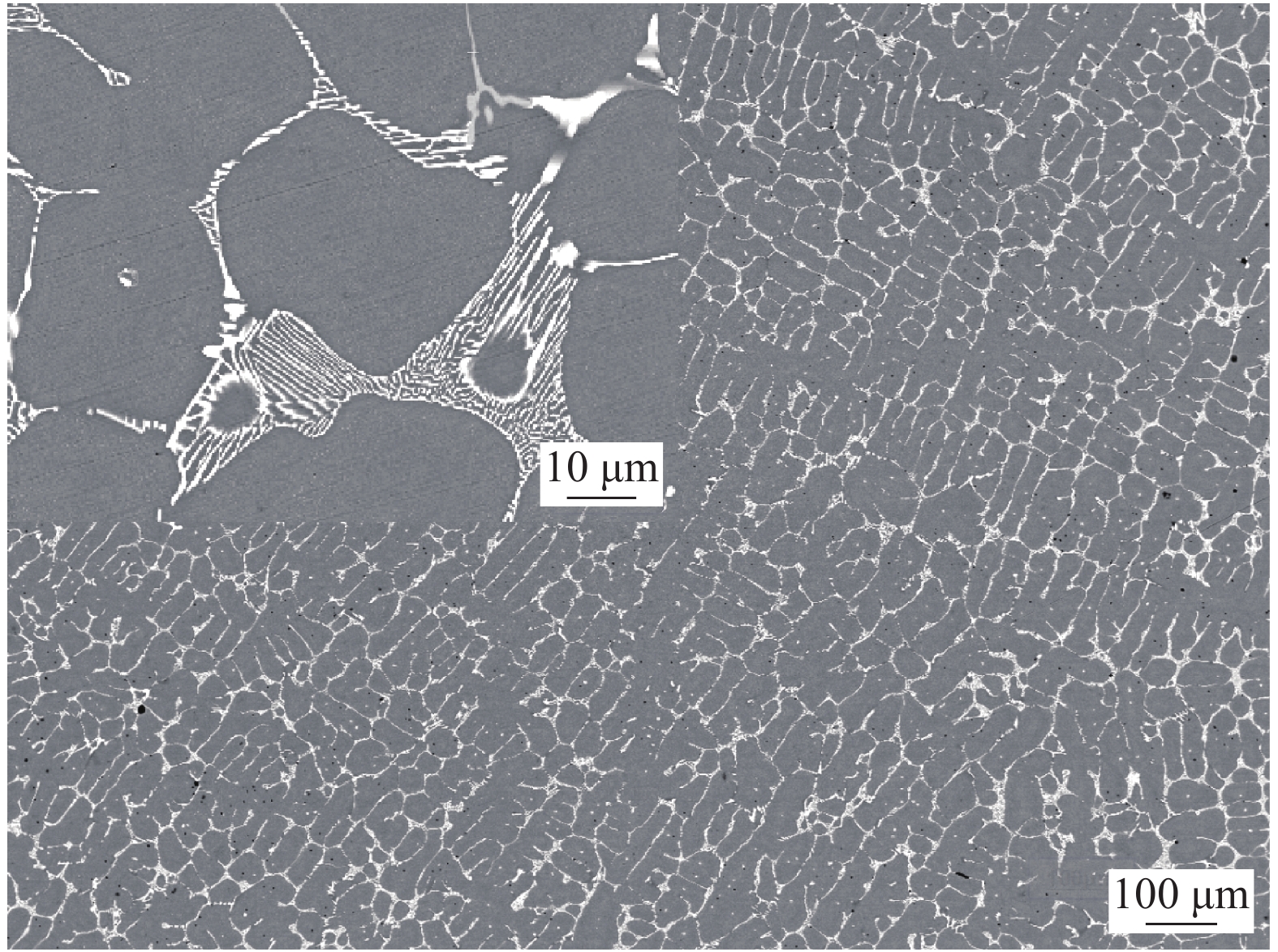

摘要: 利用Gleeble-3500热模拟试验机对电子束熔炼M35高速钢进行了热压缩试验,研究了其在变形温度为1273~1423 K,应变速率为0.01~10 s−1条件下的热变形行为,研究了其碳化物组织的演变规律,建立了电子束熔炼M35高速钢的热变形本构方程,并通过动态材料模型(DMM)建立了电子束熔炼M35高速钢的热加工图。同时将其与普通熔炼M35高速钢的热变形行为进行比较分析。结果表明,电子束熔炼M35高速钢的真应力-应变曲线符合动态再结晶曲线特征,在高应变速率下曲线出现锯齿特征,流变应力随应变速率的提高和温度的减小而增大。热变形过程中的变形行为可用双曲正弦函数来表征,其平均激活能为504.642 kJ/mol。通过热加工图能展现M35高速钢的热变形失稳区域,得到其热加工的最佳变形条件的区域为:变形温度为1400~1423 K, 应变速率为0.01~1 s−1。Abstract: A Gleeble-3500 thermal simulation testing machine was used to conduct thermal compression experiments on electron beam melting M35 high speed steel. The hot deformation behavior under the conditions of deformation temperature of 1 273~1 423 K and strain rate of 0.01~10 s−1 was established. The evolution law of its carbide structure was studied, the thermal deformation constitutive equation of electron beam melting M35 high-speed steel, and the use of dynamic material model (DMM) to establish the electron beam melting M35 high speed steel hot processing map. At the same time, it is compared and analyzed with the hot deformation behavior of normal melting M35 high speed steel, The results show that the true stress-strain curve of electron beam melting M35 high speed steel conforms to the characteristics of dynamic recrystallization curve, the curve appears jagged at high strain rates, and the stress increases with the increase of strain rate and decrease of temperature. The deformation behavior in the hot deformation process can be characterized by a hyperbolic sine function, and its average activation energy is 504.642 kJ/mol. Through the hot processing map, the hot deformation instability area of M35 high-speed steel is intuitively displayed, and the best deformation conditions for hot working are obtained as follows: the deformation temperature is 1 400~1 423 K, and the strain rate is 0.01~1 s−1 .

-

表 1 电子束熔炼M35高速钢的化学成分

Table 1. Chemical compositions of the EBS M35 steel

% W Mo Cr V Co C Si Mn P S Fe 原料 6.42 5.06 4.17 1.85 4.62 0.93 0.44 0.21 0.029 0.004 Bal. 熔炼后 6.42 4.90 4.18 1.84 4.51 0.93 0.35 0.09 0.027 0.004 Bal. -

[1] (邓玉昆, 陈景榕, 王世章. 高速钢[M]. 北京: 冶金工艺出版社, 2002.)Deng Yukun, Chen Jingrong, Wang Shizhang. High speed steel[M]. Beijing: Metallurgical Industry Press, 2002. [2] (梁伟. 高速钢的碳化物控制研究[J]. 钢铁钒钛, 2020, 41(4): 130−138.)Liang Wei. Study on the carbide control of high speed steel[J]. Iron Steel Vanadium Titanium,2020, 41(4): 130−138. [3] Wu Hongqing. Research status and development of high speed steel at home and abroad[J]. Mold Making, 2017,17(12):93−100. (吴红庆. 国内外高速钢的研究现状和进展[J]. 模具制造, 2017,17(12):93−100. doi: 10.3969/j.issn.1671-3508.2017.12.023 [4] Tany, Youxg, Youqf, et al. Microstructure and deformation behavior of nickel based superalloy Inconel 740 prepared by electron beam smelting[J]. Materials Characterization, 2016,114:267−276. doi: 10.1016/j.matchar.2016.03.009 [5] Youxg, Tany, Youqf, et al. Preparation of Inconel 740 superalloy by electron beam smelting[J]. Journal of Alloys & Compounds, 2016,676:202−208. [6] Fischmeister H F, Riedl R, Karagöz S. Solidification of high-speed tool steels[J]. Metallurgical Transactions A, 1989,20(10):2133−2148. doi: 10.1007/BF02650299 [7] (陈雷雷. 高速钢合金碳化物控制研究[D]. 南京: 东南大学, 2016.)Chen Leilei. Study on alloy carbides control in high speed steel[D].Nanjing:Southeast University, 2016. [8] (王栋. 稀土对M35高速钢组织和性能的影响[D]. 南京: 东南大学, 2005.)Wang Dong. The effecits of Re on performance and microstructure of M35 high speed steel[D].Nanjing:Southeast University, 2005. [9] (周清. 塑性变形微观组织及控制[M]. 北京: 科学出版社, 2016.)Zhou Qing. Plastic deformation microstructure and control[M]. Beijing: Science Press, 2016. [10] Niu Sizhe,Kou Hongchao. The characteristics of serration in Al0.5CoCrFeNi high entropy alloy[J]. Materials Science & Engineering A, 2017,702:96−103. [11] Wang Jian. Hot deformation behaviors of M35 high speed steell[J]. Journal of Plasticity Engineering, 2016,23(6):144−150. (王坚. M35高速钢的热变形行为研究[J]. 塑性工程学报, 2016,23(6):144−150. [12] John J Jonas, Xavier Quelence, Lan Jiang. The avrami kinetics of dynamic recrystallization[J]. Acta Mater, 2009,33(2):1−9. [13] Medina S F, Hernandez C A. Modeling of the dynamic recrystallization of austenite in low alloy and micro-alloyed steels[J]. Acta Mater, 1996,44(1):165−171. doi: 10.1016/1359-6454(95)00154-6 [14] Zener C, Hollomon H. Effect of strain-rate upon the plastic flow of steel[J]. J. Appl. Phys, 1944,15:22−27. doi: 10.1063/1.1707363 [15] Liu Jiantao, Chang Hongbing, Wu Ruiheng, et al. Investigation on hot deformation behavior of AISI T1 high speed steel[J]. Mater Charact, 2000,(45):175−186. [16] Suresh K, Rao K P, Prasad Y, et al. Effect of calcium addition on the hot working behavior of as-cast AZ31 magnesium alloy[J]. Materials Science and Engineering A, 2013,588:272−279. doi: 10.1016/j.msea.2013.09.031 [17] Dharmendra C, Rao K P, Zhao F, et al. Effect of silicon content on hot working, processing maps, and microstructural evolution of cast TX32-0.4 Al magnesium alloy[J]. Materials Science and Engineering A, 2014,606:11−23. doi: 10.1016/j.msea.2014.03.087 [18] Kang F W, Zhang G Q, Sun J F, et al. Hot deformation behavior of a spray formed superalloy[J]. Journal of Materials Processing Technology, 2008,204(1):147−151. [19] Prasad Y, Gegel H L, Doraivelu S M, et al. Modeling of dynamic material behavior in hot deformation: forging of Ti-6242[J]. Metallurgical Transactions A, 1984,15(10):1883−1892. doi: 10.1007/BF02664902 [20] Pradad Y. Recent advances in the science of mechanical processing[J]. Indian Journal of Technology, 1990,28(6−8):435−451. -

下载:

下载: