Current research status of advanced forming technology for high-performance titanium alloys

-

摘要: 主要介绍先进热成形技术、脉冲电流辅助成形技术和电磁辅助成形技术的特点,及其在钛合金薄壁板材成形中应用的研究进展。热成形是钛合金塑性加工应用最为普遍的成形工艺,利用高温下钛合金塑性变形软化的特征,能够实现复杂钛合金零件的成形。脉冲电流和电磁辅助成形技术目前尚未开展大规模的产业应用,其在高强度难成形材料的成形加工方面具有潜在应用前景。Abstract: In this paper, characteristics of advanced hot forming technology, pulse current assisted forming technology and electromagnetic assisted forming technology, and progress of these technologies application in titanium alloy thin-wall sheet forming had been reviewed. Hot forming is the most widely used forming process in the plastic processing of titanium alloy. The forming of complex titanium alloy parts can be realized by taking advantage of plastic deformation softening of titanium alloy at high temperature. Pulse current and electromagnetic assisted forming technology have not been widely used in industry, but they present potential application prospects in the forming of high strength and hard-deformation materials.

-

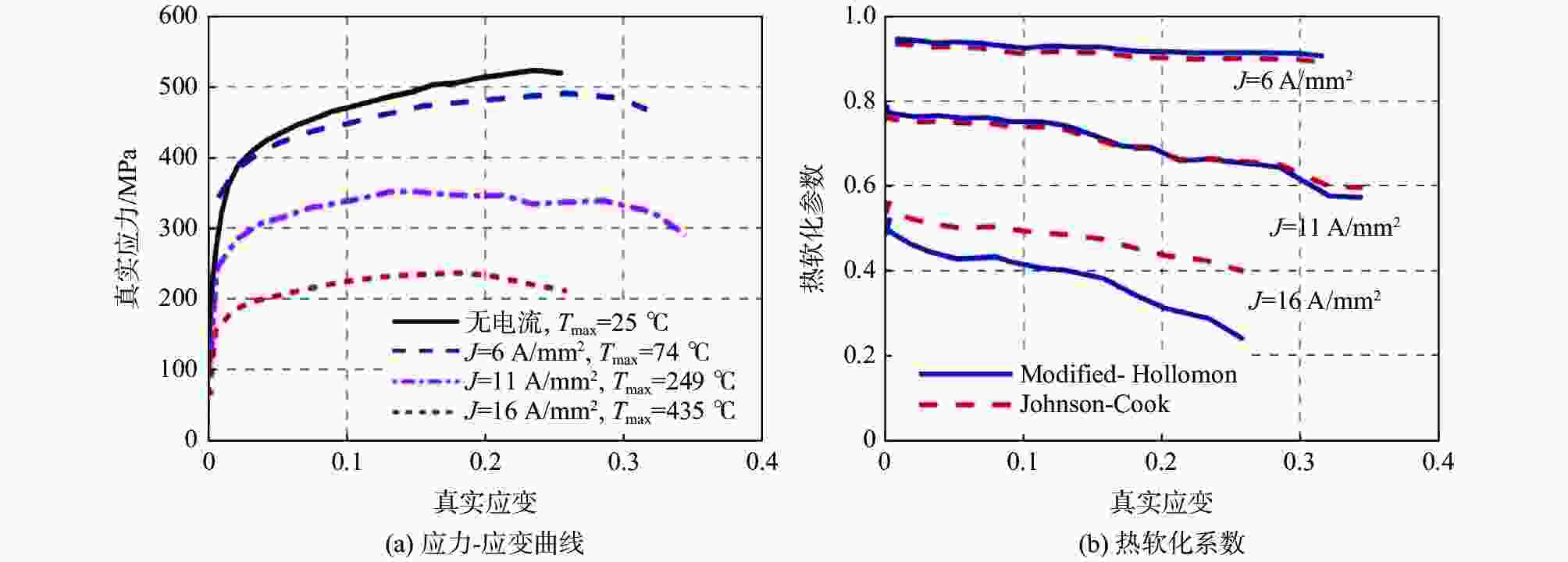

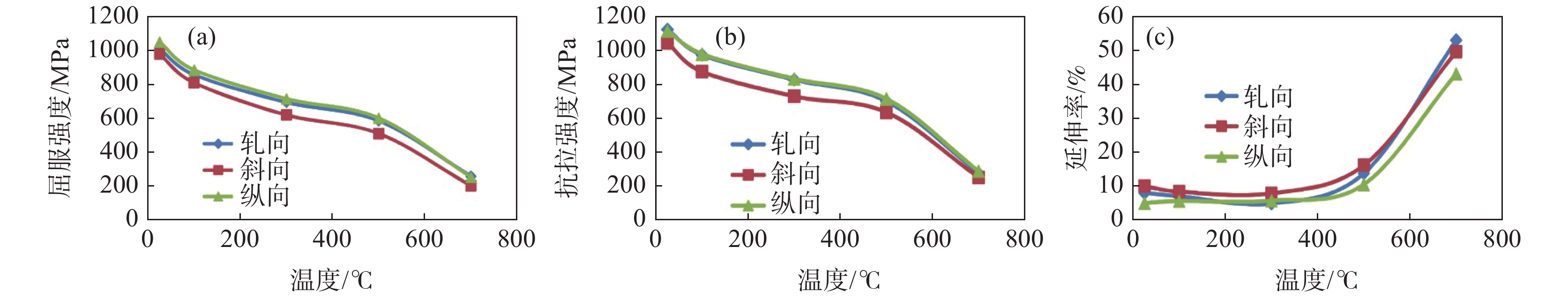

图 1 TC4钛合金屈服强度(a)、抗拉强度(b)和延伸率(c)随温度的变化曲线[11]

Figure 1. The yield strength (a), tensile strength (b) and elongation (c) of TC4 titanium alloy with forming temperature

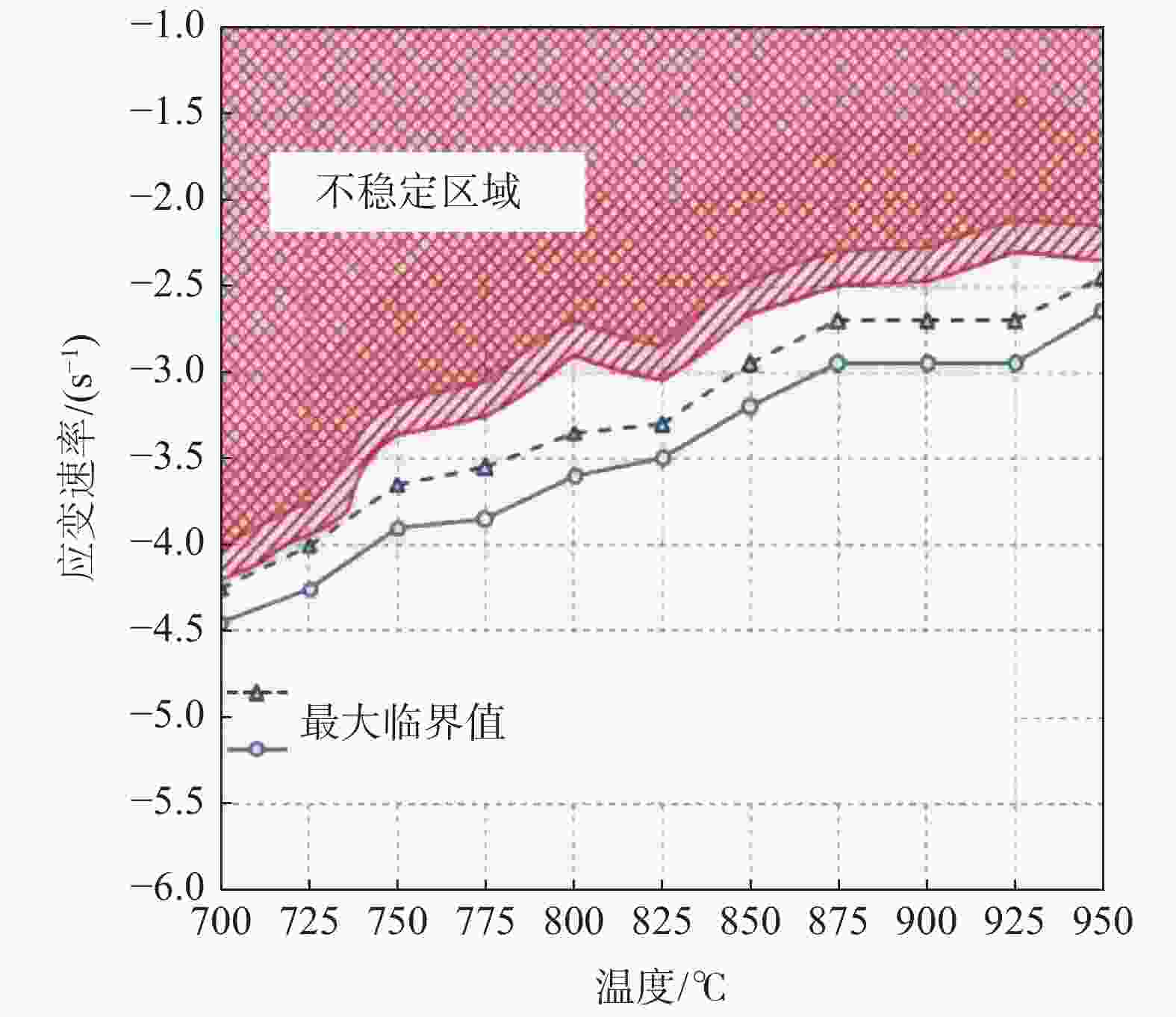

图 2 不同温度和应变率下钛合金加工极限图谱[13]

Figure 2. Processing map of titanium alloy at different temperatures and strain rates

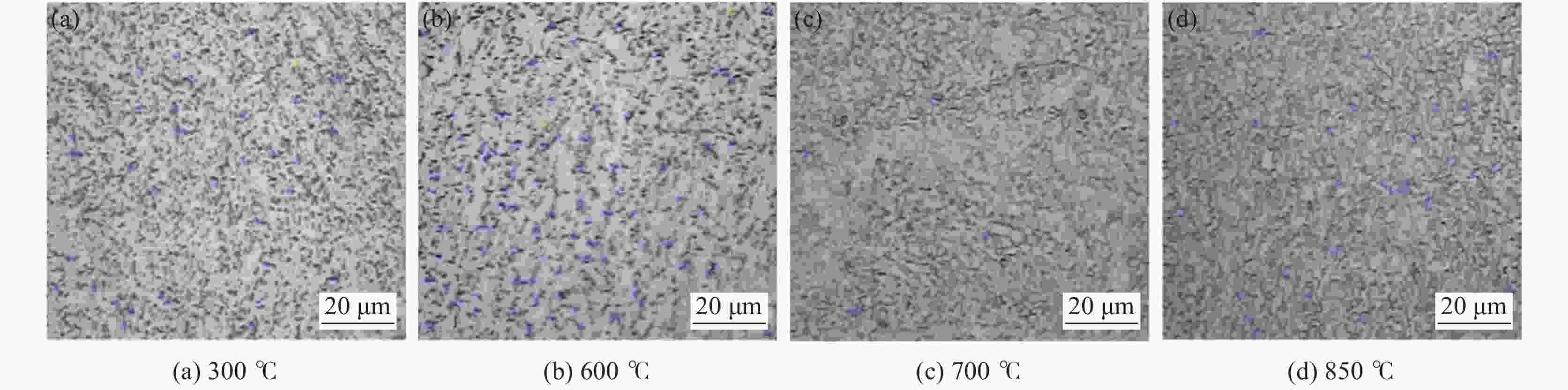

图 3 不同变形温度下TC4的显微组织结构[15]

Figure 3. The microstructure of TC4 alloy obtained under various forming temperatures

图 6 高能脉冲电流频率对TC4钛合金抗拉强度和延伸率的影响[40]

Figure 6. The effect of electropulsing frequency on tensile strength and elongation of TC4 alloy

图 8 常规冷拔和电流辅助冷拔TC4微观组织[44]

Figure 8. Microstructure of TC4 obtained from cold drawing and electric assisted drawing

图 10 高能脉冲频率下的拉拔组织形态和平均晶粒尺寸[40]

Figure 10. The microstructure and average grain size of TC4 alloy obtained from cold drawing process with electropulsing processing

图 11 电辅助电致塑性和非电致塑性效应定量研究[49]

Figure 11. Quantitative study of electroplastic and non-electroplastic effect

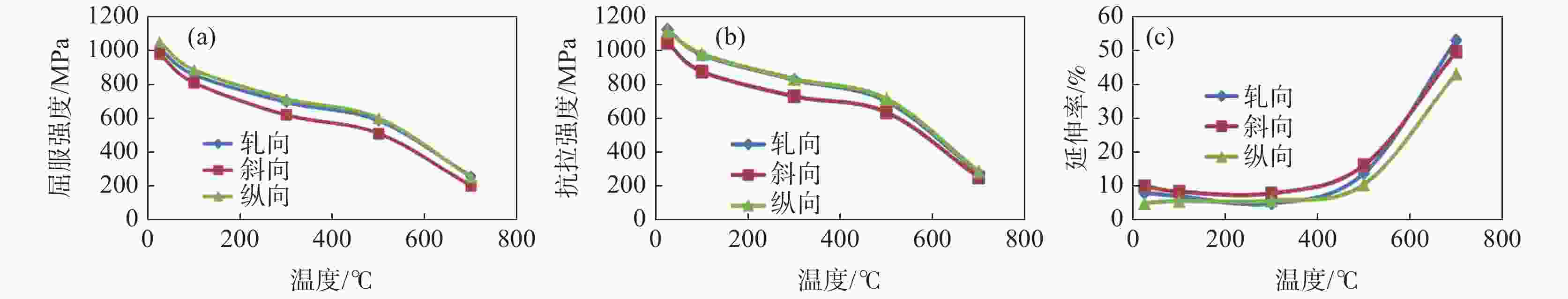

图 12 脉冲电流辅助条件下的应力应变曲线和热软化系数[50]

Figure 12. Stress-strain curve and thermal softening coefficient of TC4 alloying from electropulsing processing

-

[1] Zhao Yongqing. Current situation and development trend of titanium alloys[J]. Materials China, 2010,29(5):1−8. (赵永庆. 国内外钛合金研究的发展现状及趋势[J]. 中国材料进展, 2010,29(5):1−8. [2] Jin Hexi, Wei Kexiang, Li Jianming, et al. Research development of titanium alloy in aerospace industry[J]. The Chinese Journal of Nonferrous Metals, 2015,25(2):280−292. (金和喜, 魏克湘, 李建明, 等. 航空用钛合金研究进展[J]. 中国有色金属学报, 2015,25(2):280−292. [3] Li Liang, Sun Jianke, Meng Xiangjun. Application state and prospects for titanium alloys[J]. Titanium Industry Process, 2004,21(5):19−24. (李梁, 孙健科, 孟祥军. 钛合金的应用现状及发展前景[J]. 钛工业进展, 2004,21(5):19−24. doi: 10.3969/j.issn.1009-9964.2004.05.005 [4] Liu Xin, Yang Jingchao, Li Heng, et al. A critical review on tube joining by plastic deformation[J]. Acta Aeronautica et Astronautica Sinica, 2021,42:1−23. (刘欣, 杨景超, 李恒, 等. 管路构件塑性变形连接技术研究进展及挑战[J]. 航空学报, 2021,42:1−23. [5] 张翥, 王群骄, 莫畏. 钛的金属学和热处理[M]. 北京: 冶金工业出版社, 2009.Zhang Zhu, Wang Qunjiao, Mo Wei. Metalology and heat treatment of titanium[M]. Beijing: Metallurgical Industry Press, 2009. [6] Sprecher A F, Mannan S L, Conrad H. On the temperature rise associated with the electroplastic effect in titanium[J]. Scripta Metallurgica, 1983,17(6):769−772. doi: 10.1016/0036-9748(83)90491-X [7] 《稀有金属材料加工手册》编写组. 稀有金属材料加工手册[M]. 北京: 冶金工业出版社, 1984.Compilation Group. Manual for processing rare metal materials[M]. Beijing: Metallurgical Industry Press, 1984. [8] 张翥, 谢水生, 赵云豪. 钛材塑性加工技术[M]. 北京: 冶金工业出版社, 2010.Zhang Zhu, Xie Shuisheng, Zhao Yunhao. Plastic processing technology of titanium[M]. Beijing: Metallurgical Industry Press, 2010. [9] Mori K, Maki S, Tanaka Y. Warm and hot stamping of ultra high tensile strength steel sheets using resistance heating[J]. CIRP Annals, 2005,54(1):209−212. doi: 10.1016/S0007-8506(07)60085-7 [10] 李克俭. TC4钛合金板材热拉弯成形热力耦合数值模拟研究[D]. 秦皇岛: 燕山大学, 2015.Li Kejian. Coupled thermo-mechanicalfinite element analysis of hot stretch bending of TC4 titanium alloy sheet[D]. Qinhuangdao: Yanshan Univerty, 2015. [11] 肖宁斌. BTi-6431 S钛合金板材热成形性能评价研究[D]. 江苏: 南京航空航天大学, 2012.Xiao Ningbin. Research on hot formability of BTi-6431 S titanium alloy sheet[D]. Jiangsu: Nanjing University of Aeronautics and Astronautics, 2012. [12] Ozturk F, Remzi, Ece R E, et al. Mechanical and microstructural evaluations of hot formed titanium sheets by electrical resistance heating process[J]. Materials Science & Engineering:A, 2013,578:207−214. [13] Aksenov S A, Chumachenko E N, Logashina I V. Tensile testing of Ti-6Al-4V alloy superplasticity[J]. Materials Science Forum, 2013,762:392−397. doi: 10.4028/www.scientific.net/MSF.762.392 [14] Wang H, Zhao K X, Chu X R, et al. Constitutive modelling and microscopic analysis of TC4 alloy sheet at elevated temperature[J]. Results in Physics, 2019,13:1−11. [15] Wei S, Deng P R, Qiu J T, et al. Tensile deformation behavior of Ti-6Al-4V sheet at elevated temperature[J]. Materials Research Express, 2019,6(11):1−7. [16] Zhao J, Lv L X, Liu G, et al. Analysis of deformation inhomogeneity and slip mode of TA15 titanium alloy sheets during the hot tensile process based on crystal plasticity model[J]. Materials Science and Engineering: A, 2017. [17] Xiao J, Li D S, Li X Q, et al. Constitutive modeling and microstructure change of Ti-6Al-4V during the hot tensile deformation[J]. Journal of Alloys & Compounds, 2012,541:346−352. [18] Zhang Tao, Li Qi, He Lu, et al. Research on hot forming of abnormity part of titanium alloy TC2[J]. Aeronautical Manufacturing Technology, 2011,16:57−59. (张涛, 李琦, 何露, 等. TC2钛合金异型件热成形工艺研究[J]. 航空制造技术, 2011,16:57−59. doi: 10.3969/j.issn.1671-833X.2011.08.009 [19] 陈灿. TA32高温钛合金复杂飞机蒙皮零件热成形工艺研究[D]. 南京: 南京航空航天大学, 2018.Chen Can. Research on thermoforming process of complex aircraft skin parts for TA32 titanium alloy[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2018. [20] Tm A, Mt B, Kim B, et al. Hot stamping of titanium alloy sheets using partial contact heating[J]. Procedia Manufacturing, 2018,15:1149−1155. doi: 10.1016/j.promfg.2018.07.375 [21] Wang Anyang, Lu Zhen, Jiang Shaosong, et al. Control of wall thickness uniformity in variable temperature hot drawing of titanium alloy conical components[J]. Aerospace Manufacturing Technology, 2012,1:36−39. (王安阳, 卢振, 蒋少松, 等. 钛合金锥形构件变温热拉深成形壁厚均匀性控制[J]. 航天制造技术, 2012,1:36−39. [22] Fan G Q, Gao L. Numerical simulation and experimental investigation to improve the dimensional accuracy in electric hot incremental forming of Ti-6Al-4V titanium sheet[J]. The International Journal of Advanced Manufacturing Technology, 2014,72:1133−1141. doi: 10.1007/s00170-014-5769-8 [23] Vahdani M, Mirnia M J, Bakhshi-Jooybari M, et al. Electric hot incremental sheet forming of Ti-6Al-4V titanium, AA6061 aluminum, and DC01 steel sheets[J]. The International Journal of Advanced Manufacturing Technology, 2019,103:1−11. doi: 10.1007/s00170-019-03381-2 [24] Dong Wenbin, Zhang Yajing, Gou Ruibin, et al. Effect of external load on edge effect of laser bending[J]. Journal of Plasticity Engineering, 2020,27(11):47−51. (董文彬, 张雅晶, 缑瑞宾, 等. 外载荷对激光弯曲成形边界效应的影响[J]. 塑性工程学报, 2020,27(11):47−51. [25] Gisario A, Barletta M, Venettacci S. Improvements in springback control by external force laser-assisted sheet bending of titanium and aluminum alloys[J]. Optics & Laser Technology, 2016,86:46−53. [26] Gisario A, Mehrpouya M, Venettacci S, et al. Laser-assisted bending of titanium grade-2 sheets: Experimental analysis and numerical simulation[J]. Optics & Lasers in Engineering, 2017,92:110−119. [27] Hu Y, Luo M, Yao Z. Increasing the capability of laser peen forming to bend titanium alloy sheets with laser-assisted local heating[J]. Materials and Design, 2016,90:364−372. doi: 10.1016/j.matdes.2015.10.128 [28] Shidid D P, Gollo M H, Brandt M, et al. Study of effect of process parameters on titanium sheet metal bending using Nd: YAG laser[J]. Optics & Laser Technology, 2013,47:242−247. [29] Wang Yuting. Study on tensile bending forming process of titanium alloy by resistance heating[J]. Aerospace Materials & Technology, 1986,2:4−7. (王玉庭. 钛合金电阻加热拉弯成形工艺研究[J]. 宇航材料工艺, 1986,2:4−7. [30] Jiang Shuangshuang, Tang Zejun, Du Hao, et al. Research progress of the forming process of titanium alloy assisted by current[J]. Journal of Netshape Forming Engineering, 2017,2:7−13. (江双双, 汤泽军, 杜浩, 等. 钛合金电流辅助成形工艺研究进展[J]. 精密成形工程, 2017,2:7−13. doi: 10.3969/j.issn.1674-6457.2017.02.002 [31] Shen Yifu, Guo Xiaonan, Zhang Kun, et al. Effect of electric current pulse on metal materials[J]. Materials Science & Engineering, 1998,16(3):4−7. (沈以赴, 郭晓楠, 张坤, 等. 脉冲电流对金属材料的作用及其研究进展[J]. 材料科学与工程学报, 1998,16(3):4−7. [32] Okazaki K, Kagawa M, Conrad H. An evaluation of the contributions of skin, pinch and heating effects to the electroplastic effect in titatnium[J]. Materials Science & Engineering, 1980,45(2):109−116. [33] Rudolf C. Goswami R, Kang W, et al. Effects of electric current on the plastic deformation behavior of pure copper, iron, and titanium[J]. Acta Materialia, 2021,209:1−13. [34] Ding Junhao, Li Heng, Bian Tianjun, et al. Electroplasticity and electrically-assisted forming: A critical review[J]. Acta Aeronautica et Astronautica Sinica, 2018,39(1):15−32. (丁俊豪, 李恒, 边天军, 等. 电塑性及电流辅助成形研究动态及展望[J]. 航空学报, 2018,39(1):15−32. [35] Peng Shuhua, Yang Junjie, Li Yao. Analysis on mechanism of electro-plastic effect and its prospect[J]. Journal of Jianghan University (Nature Science Edition), 2013,2:63−67. (彭书华, 杨俊杰, 李尧. 电致塑性效应机制研究及其展望[J]. 江汉大学学报(自然科学版), 2013,2:63−67. [36] Fan G Q, Sun F T, Meng X G, et al. Electric hot incremental forming of Ti-6Al-4V titanium sheet[J]. The International Journal of Advanced Manufacturing Technology, 2010,49:941−947. doi: 10.1007/s00170-009-2472-2 [37] Ye X X, Tse ZTH, Tang G Y, et al. Effect of electroplastic rolling on deformability, mechanical property and microstructure evolution of Ti-6Al-4V alloy strip[J]. Materials Characterization, 2014,98:147−161. doi: 10.1016/j.matchar.2014.10.026 [38] Zhou Qiang, Li Xifeng, Chen Jun, et al. Experimental study on electroplastic V-bending properties of TC4 titanium alloys[J]. Journal of Plasticity Engineering, 2015,22(5):52−56. (周强, 李细锋, 陈军, 等. TC4钛合金电致塑性V型弯曲性能的实验研究[J]. 塑性工程学报, 2015,22(5):52−56. [39] 朱岩. 脉冲电流辅助钛及钛合金弯曲成形规律研究[D]. 太原: 太原理工大学, 2020.Zhu Yan. Research on pulse current-assisted bending forming law of titanium and titanium alloy[D]. Taiyuan: Taiyuan University of Technology, 2020. [40] Ye X X, Tse ZTZ, Tang G Y, et al. Influence of electropulsing globularization on the microstructure and mechanical properties of Ti-6Al-4V alloy strip with lamellar microstructure[J]. Materials Science & Engineering:A, 2015,622:1−6. [41] Li Ping, Xie Xiuming, Wang Huigan, et al. Electric-thermal-mechanical coupled simulation and springback prediction of Ti55 alloy electrical assisted V-bending[J]. The Chinese Journal of Nonferrous Metals, 2021,31(4):847−857. (李萍, 解修明, 汪会干, 等. Ti55合金电辅助V弯电热力耦合仿真及回弹预测[J]. 中国有色金属学报, 2021,31(4):847−857. doi: 10.11817/j.ysxb.1004.0609.2021-35962 [42] Shen Yifu, Guo Xiaonan, Yao Ge, et al. Exploration of a new approach to improve fatigue property of materials II—Crack growth resistance of Ti-6Al-4V alloys induced bu electric current pluse[J]. Chinese Journal of Materials Research, 1999,4:381−384. (沈以赴, 郭晓楠, 姚戈, 等. 材料疲劳恢复新途径的探索II—脉冲电流对Ti-6Al-4V合金裂纹扩展的阻滞[J]. 材料研究学报, 1999,4:381−384. [43] Song H, Wang Z J. Microcrack healing and local recrystallization in pre-deformed sheet by high density electropulsing[J]. Materials Science & Engineering:A, 2008,490:1−6. [44] Zhou Y, Chen G Q, Fu X S, et al. Effect of electropulsing on deformation behavior of Ti-6Al-4V alloy during cold drawing[J]. Transactions of Nonferrous Metals Society China, 2014,24:1012−1021. doi: 10.1016/S1003-6326(14)63156-3 [45] 宋辉. 脉冲电流处理对钛合金板材组织和性能影响的研究[D]. 哈尔滨: 哈尔滨工业大学, 2009.Song Hui. Study on the effects of electropulsing on microstructures and properties of titanium alloys sheet[D]. Harbin: Harbin Institute of Technology, 2009. ) [46] 江双双. 电脉冲辅助TC4钛合金板滚弯成形研究[D]. 南京: 南京航空航天大学, 2018.Jiang Shuangshuang. Investigation into the electrically-assisted roll bending process of a TC4 titanium alloy sheet[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2018. [47] Fan G Q, Gao L. Mechanical property of Ti-6Al-4V sheet in one-sided electric hot incremental forming[J]. The International Journal of Advanced Manufacturing Technology, 2014,72:989−994. doi: 10.1007/s00170-014-5733-7 [48] Ye X X, Tse ZTH, Tang G Y. Mechanical properties and tensile fracture of Ti-Al-V alloy strip under electropulsing-induced phase change[J]. Journal of Materials Research, 2015,30(2):206−223. doi: 10.1557/jmr.2014.367 [49] Ross C D, Kronenberger T J, Roth J T. Effect of DC current on the formability of 6Al4V titanium[C]//ASME 2006 International Manufacturing Science and Engineering Conference, 2006. [50] Magargee J, Morestin F, Cao J. Characterization of flow stress for commercially pure titanium subjected to electrically assisted deformation[C]//Asme International Manufacturing Science & Engineering Conference Collocated with the North American Manufacturing Research Conference, 2013. [51] Cao Fengchao, Zeng Yuansong, Liu Baosheng, et al. Study on electrically assisted stretch bending of L-section profile of titanium alloy[J]. Mechanical Science and Technology for Aerospace Engineering, 2019,38(9):1437−1442. (曹凤超, 曾元松, 刘宝胜, 等. 电流辅助钛合金L型材拉弯工艺研究[J]. 机械科学与技术, 2019,38(9):1437−1442. [52] Chen Pengyu, Cheng Lidong, Wang Chunju, et al. Electrically-assisted rolling process of curved thin foil micro-features[J]. Journal of Plasticity Engineering, 2019,26(2):79−84. (陈鹏宇, 程利冬, 王春举, 等. 薄板曲面微结构电流辅助滚压成形工艺研究[J]. 塑性工程学报, 2019,26(2):79−84. doi: 10.3969/j.issn.1007-2012.2019.02.010 [53] Psyk V, Risch D, Kinsey B L, et al. Electromagnetic forming—A review[J]. Journal of Materials Processing Technology, 2011,211(5):787−829. doi: 10.1016/j.jmatprotec.2010.12.012 [54] Nie Peng, Feng Zhichao, Wang Zhefeng. A study on electromagnetic sizing of large titanium alloy cylindrical parts with punching die[J]. Modern Manufacturing Engineering, 2019,467(8):46,88−92. (聂鹏, 冯志超, 王哲峰. 大型钛合金筒形件电磁冲模校圆研究[J]. 现代制造工程, 2019,467(8):46,88−92. [55] Cui Xiaohui, Zhou Xianglong, Du Zhihao, et al. New development of electromagnetic pulse forming technology and its application in aircraft skin parts manufacturing[J]. Aeronautical Manufacturing Technology, 2020,63(3):22−32. (崔晓辉, 周向龙, 杜志浩, 等. 电磁脉冲成形技术新进展及其在飞机蒙皮件制造中的应用[J]. 航空制造技术, 2020,63(3):22−32. [56] Li F Q, Zhao J, Mo J H, et al. Comparative study of the microstructure of Ti-6Al-4V titanium alloy sheets under quasi-static and high-velocity bulging[J]. Journal of Mechanical Science and Technology, 2017,31(3):1349−1356. doi: 10.1007/s12206-016-0843-9 [57] Lin Zundong, Lv Feng, Han Yujie, et al. Experimental study on formability and electromagnetic-assisted bending for TA32 titanium alloy sheets[J]. Forging & Stamping Technology, 2021,46(1):104−109. (林遵东, 吕枫, 韩玉杰, 等. TA32钛合金板成形性能与电磁辅助弯曲成形实验研究[J]. 锻压技术, 2021,46(1):104−109. [58] Li F Q, Mo J H, Li J J, et al. Formability of Ti-6Al-4V titanium alloy sheet in magnetic pulse bulging[J]. Materials and Design, 2013,52:337−344. doi: 10.1016/j.matdes.2013.05.064 [59] Li Fenqiang, Chen Xinyu, Jiang Jishuai. Application of electromagnetic forming technology in the forming of titanium alloy sheets[J]. Journal of Netshape Forming Engineering, 2021,13(5):43−50. (李奋强, 陈新宇, 蒋继帅. 电磁成形技术在钛合金板材成形中的应用[J]. 精密成形工程, 2021,13(5):43−50. doi: 10.3969/j.issn.1674-6457.2021.05.005 [60] Xiong Qi, Tang Hongtao, Wang Muxue, et al. Research progress of electromagnetic forming technique since 2011[J]. High Voltage Engineering, 2019,45(4):1171−1181. (熊奇, 唐红涛, 王沐雪, 等. 2011年以来电磁成形研究进展[J]. 高电压技术, 2019,45(4):1171−1181. -

下载:

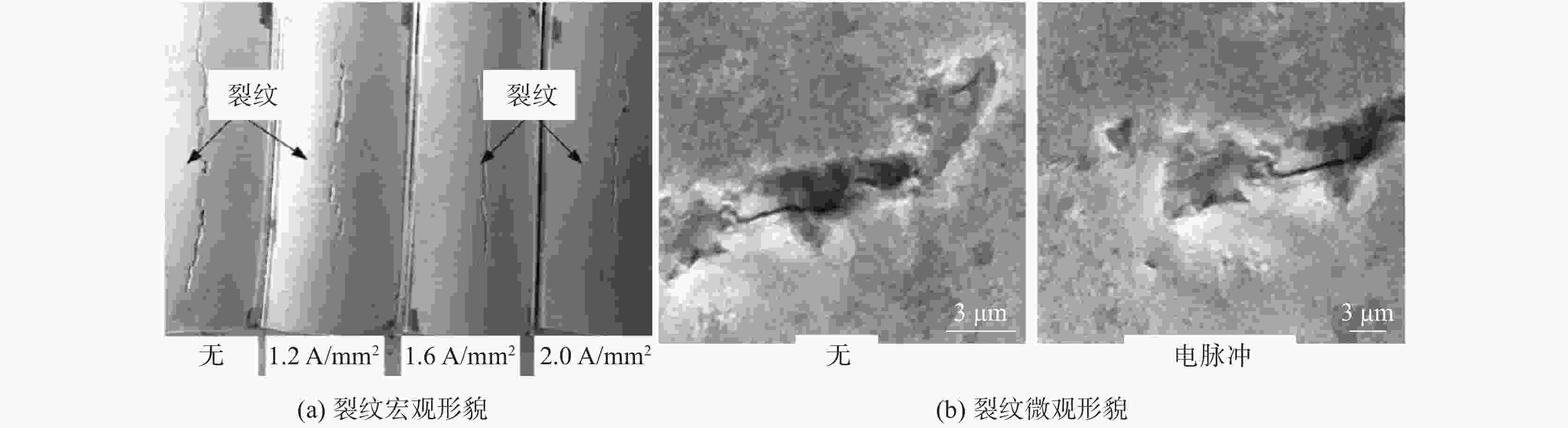

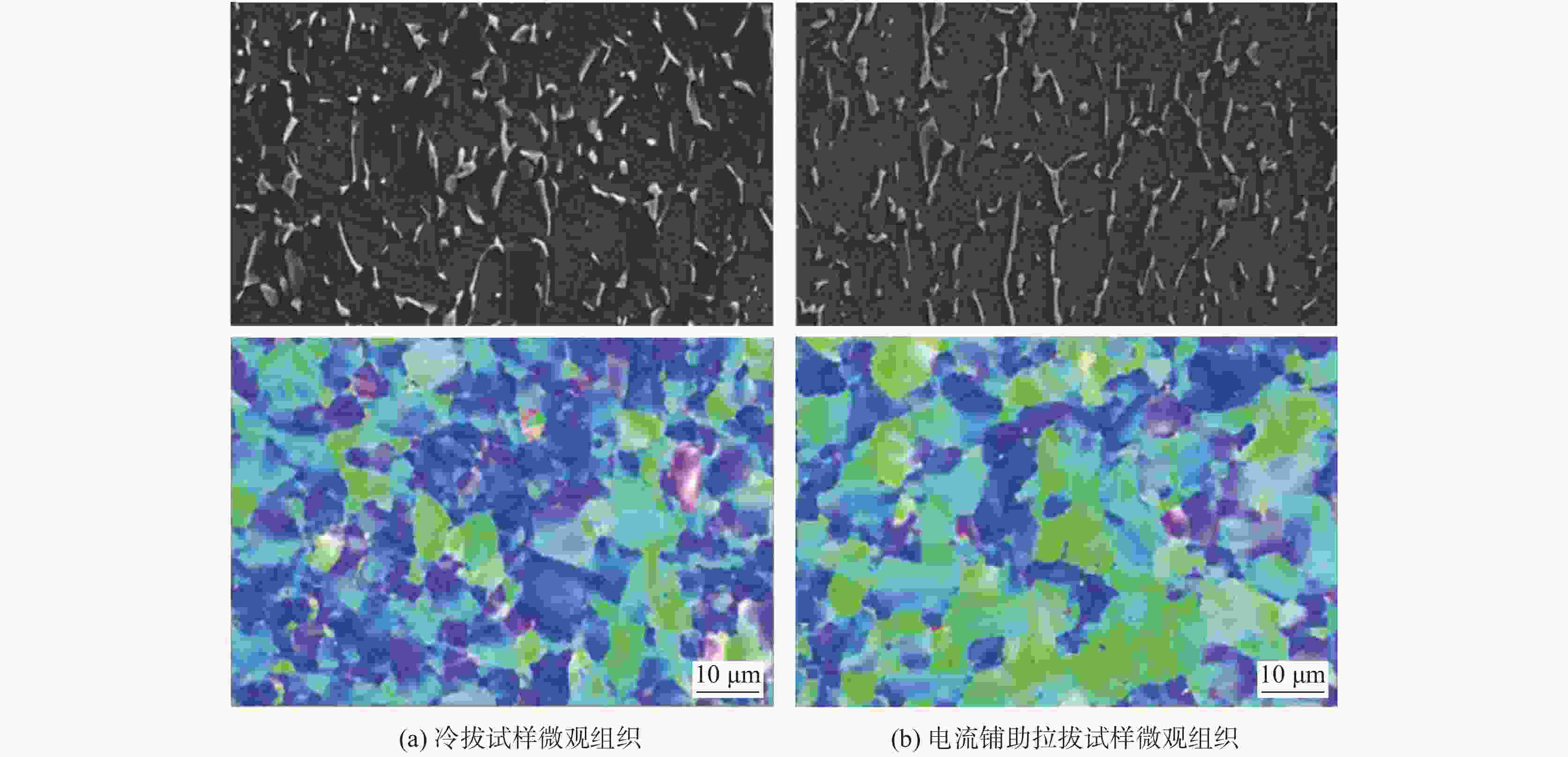

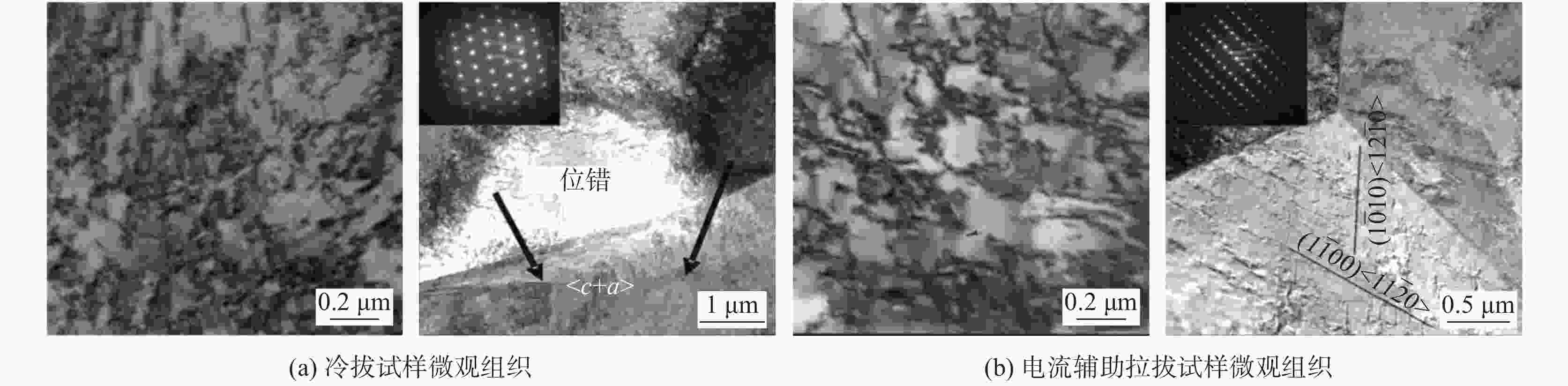

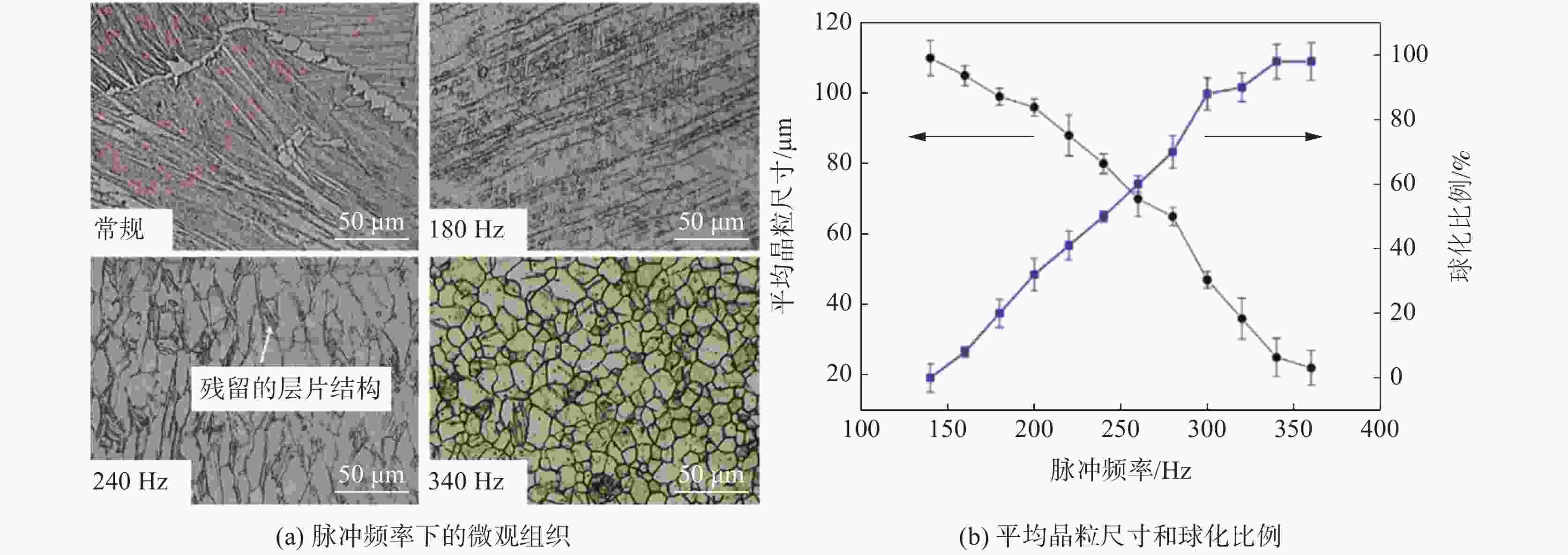

下载: