High temperature compression properties of near α type Ti-1100 alloy prepared by titanium hydride based powder metallurgy

-

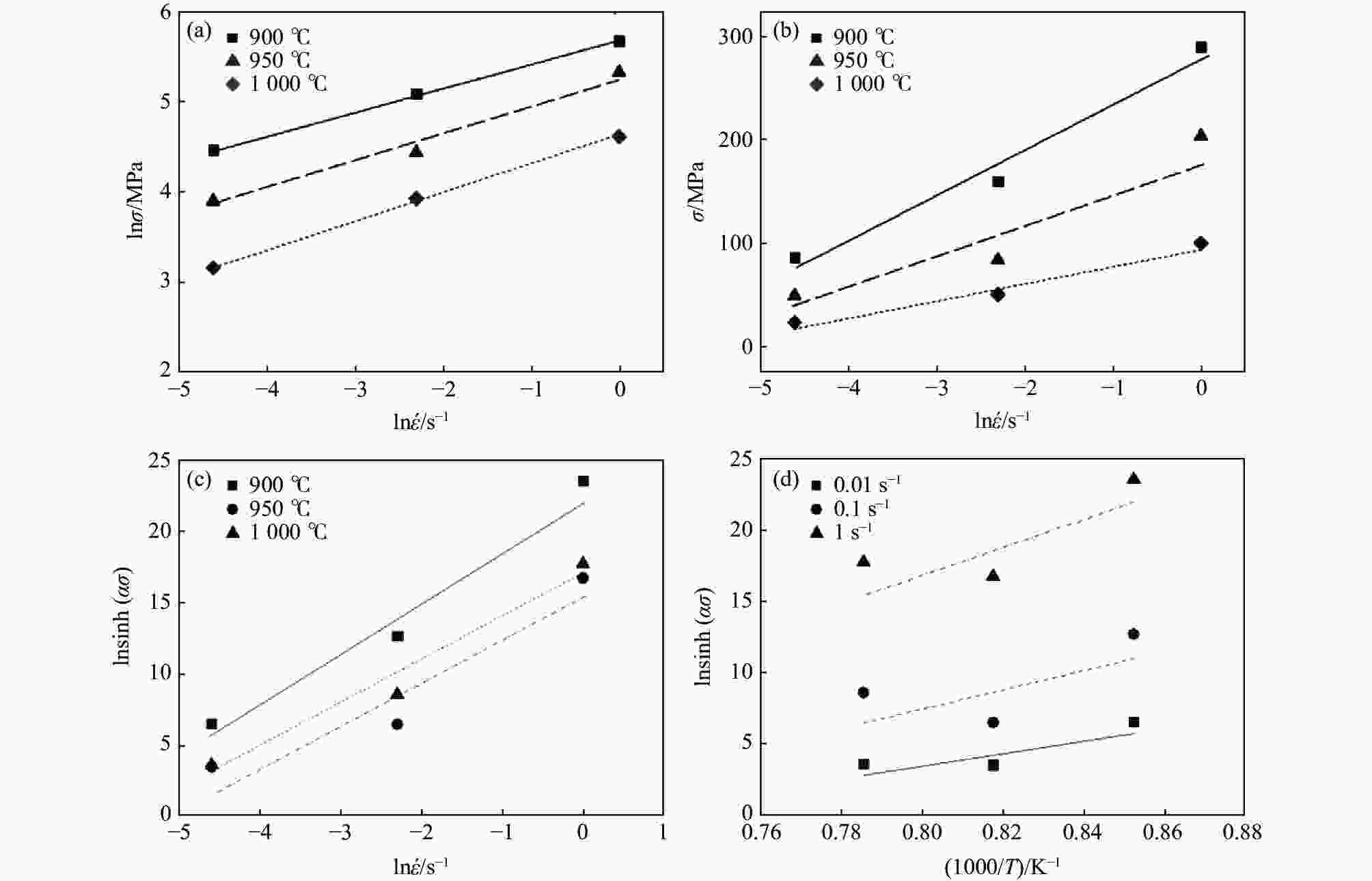

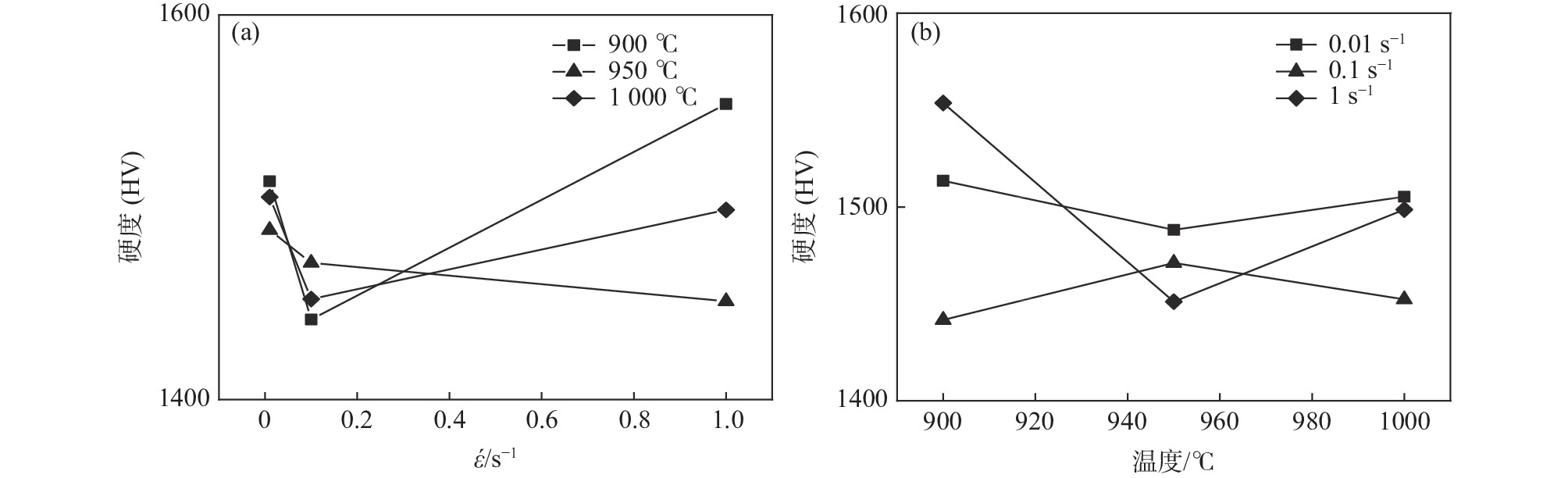

摘要: 以氢化钛粉为原料,采用粉末冶金法-热等静压法制备高温钛合金Ti-1100,并进行了等温压缩试验,通过压缩样品应力应变曲线进行压缩变形行为分析,再结合Arrhenius双曲正弦本构模型建立热压缩本构方程。通过应力应变曲线分析,发现应变速率在0.01 s−1时,所有样品在加工硬化后均表现出稳态流变行为;而应变速率为1 s−1、温度在900 ℃或1 000 ℃时,流变应力随着变形达到稳态流变状态后,呈增加趋势。应变速率为0.01、0.1、1 s−1时的热压缩变形激活能分别为96、165、232 kJ/mol。硬度测试结果表明显微硬度随温度和应变速率增加稍有降低趋势,当温度为950 ℃,应变速率为0.1 s−1时,合金的硬度普遍较小, 热加工性能最佳。Abstract: The isothermal compression experiments were carried out on high temperature titanium alloy Ti-1100 prepared by powder metallurgy using titanium hydride powder as raw material. The compression deformation behavior was analyzed through the obtained stress-strain curve of compressed samples, and then the thermal compression constitutive equation was established by using Arrhenius hyperbolic sinusoidal constitutive model. Through the analysis of the stress-strain curve, it is found out that when the strain rate is 0.01 s−1, all samples show steady-state rheological behavior. When the strain rate is 1 s−1 and the temperature is 900 ℃ or 1 000 ℃, the flow stress increases with deformation after steady-state rheological state. The activation energy of thermal compression deformation for strain rate at 0.01, 0.1 s−1 and 1 s−1 are 96, 165 kJ/mol and 232 kJ/mol, respectively. The hardness test results show that microhardness decreases slightly with increase of temperature and strain rate. When the temperature is 950 ℃ and the strain rate is 0.1 s−1, the hardness of the alloy is generally small and the best hot workability can be achieved.

-

表 1 本构方程参数值

Table 1. The parameters of the constitutive equation obtained

T/K β n1 α n A3 1173 0.02204 3.7964 0.08368 0.26341 0.01274 1223 0.02706 3.16718 0.08572 0.31574 0.10324 1273 0.05829 3.16184 0.1843 0.31627 0.75223 -

[1] Fu B G, Wang H W, Zou C M, et al. Microstructural characterization of in situ synthesized TiB in cast Ti-1100-0.10 B alloy[J]. Transactions of Nonferrous Metals Society of China, 2015,25:2206. doi: 10.1016/S1003-6326(15)63833-X [2] Cui W F, Zhou L, Luo G Z, et al. Effect of yttrium on mechanical properties, thermal stability and creep resistance of high temperature titanium alloy Ti-1100[J]. Journal of Rare Earths, 1999, 17(1): 38-41. [3] Shams SAA, Mirdamadi S, Abbasi S M, et al. Mechanism of martensitic to equiaxed microstructure evolution during hot deformation of a near-alpha Ti alloy[J]. Metallurgical and Materials Transactions A, 2017,48(6):2979−2992. [4] 付彬国. 合金元素对铸造Ti-1100合金组织及性能影响[D]. 哈尔滨: 哈尔滨工业大学, 2015.Fu Binguo. Effects of alloying elements on microstructures and properties of CAST Ti-1100 alloys[D]. Harbin: Harbin Institute of Technology, 2015. [5] Fang Z Z, Paramore J D, Sun P, et al. Powder metallurgy of titanium - past, present, and future[J]. International Materials Reviews, 2017,63(7):1−53. doi: 10.1080/09506608.2017.1366003 [6] Lütjering G, Williams J C. Titanium[M]. Springer Berlin Heidelberg, 2007. [7] Hagiwara M, Emura S. Property enhancement of orthorhombic Ti2AlNb-based intermetallic alloys[J]. Materials Science Forum, 2003,352(1):85. [8] Fang Z Z, Sun P, Wang H T. Hydrogen sintering of titanium to produce high density fine grain titanium alloys[J]. Advced Engineering Material, 2012,14:383−387. [9] Zhang H R, Niu H Z, Zang M, et al. Microstructures and mechanical behavior of a near α titanium alloy prepared by TiH2-based powder metallurgy[J]. Materials Science & Engineering A, 2020,770:138570. [10] Azevedo C R F, Rodrigues D, Neto F B. Ti–Al–V powder metallurgy (PM) via the hydrogenation–dehydrogenation (HDH) process[J]. Journal of Alloys and Compounds, 2003,353(1-2):217-227. doi: 10.1016/S0925-8388(02)01297-5 [11] Ivasishin O M, Eylon D, Bondarchuk V I, et al. Diffusion during powder metallurgy synthesis of titanium alloys[J]. Defect and DiffusionForum, 2008,277:177-185. doi: 10.4028/www.scientific.net/DDF.277.177 [12] 马兰, 杨绍利, 李俊翰, 等. 钒钛材料[M]. 北京: 冶金工业出版社, 2020.Ma Lan, Yang Shaoli, Li Junhan, et al. Vanadium titanium materials[M]. Beijing: Matellurgy Industry Press, 2020. [13] Zhu Yuling, Yang Shaoli, Ma Lan, et al. Effect of titanium hydride content on near-alpha multicomponent high temperature titanium alloy[J]. Iron Steel Vanadium Titanium, 2019,40(5):50−54. (朱钰玲, 杨绍利, 马兰, 等. 氢化钛含量对近α型多元高温钛合金的影响[J]. 钢铁钒钛, 2019,40(5):50−54. [14] Yang J, Wang G, Jiao X, et al. High-temperature deformation behavior of the extruded Ti-22Al-25Nb alloy fabricated by powder metallurgy[J]. Materials Characterization, 2018,137:170−179. doi: 10.1016/j.matchar.2018.01.019 [15] Yang J, Wang G, Jiao X, et al. Hot deformation behavior and microstructural evolution of Ti-22Al-25Nb-1.0B alloy prepared by elemental powder metallurgy[J]. Journal of Alloys and Compounds, 2017,695:1038−1044. doi: 10.1016/j.jallcom.2016.10.228 [16] Liang Houquan, Guo Hongzhen, Ning Yongquan, et al. Analysis on the constitutive relationship of TC18 titanium alloy based on the softening mechanism[J]. Acta Metallurgical Sinica, 2014,50(7):871-878. (梁后权, 郭鸿镇, 宁永权, 等. 基于软化机制的 TC18钛合金本构关系研究[J]. 金属学报, 2014,50(7):871-878. [17] Jia B H, Song W D, Tang H P, et al. Hot deformation behavior and constitutive model of TC18 titanium alloy during compression[J]. Rare Metals, 2014,33(4):383-389. doi: 10.1007/s12598-014-0328-x [18] Quan G Z, Wen H R, Jia P, et al. Construction of processing maps based on expanded data by BP-ANN and identification of optimal deforming parameters for Ti-6Al-4V alloy[J]. Int. J. Precis. Eng. Manuf., 2016,17(2):171−180. doi: 10.1007/s12541-016-0022-z -

下载:

下载: