Research on heat treatment properties of TC4 titanium alloy based on electron beam additive manufacturing

-

摘要: 将电子束选区熔化制备的试件增加热处理工艺,利用扫描电子显微镜和金相显微镜研究了热处理后TC4钛合金试件的组织特征;并通过试件力学性能的变化,揭示了不同热处理工艺选择对电子束选区熔化成形产品的影响。结果表明:不论是空冷处理还是炉冷处理,试件在相变点温度以下加热其抗拉强度提升,在相变点温度以上加热其抗拉强度会下降。通过观察微观组织与分析拉伸断口可知,TC4钛合金试件在经过950 ℃和1 000 ℃热处理的组织由于β相转变为魏氏组织而抗拉强度下降;而加热至850 ℃时由于未达到相变点温度,其内部为网篮组织而性能稳定。恰当的热处理工艺能使增材制造成形的TC4钛合金的抗拉强度等力学性能更优。Abstract: In this paper, heat treatment was carried out for TC4 titanium alloy specimens prepared by electron beam selective melting. The microstructure characteristics of the TC4 titanium alloy specimens after heat treatment were studied by using scanning electron microscope and metallographic microscope. The mechanical properties of the TC4 titanium alloy specimens were investigated. The influence of heat treatment process on the specimen was revealed. The results show that the tensile strength of the specimens increased via heat treatment below phase transition temperature with the air cooling or furnace cooling, while the tensile strength of the specimens decreased by heat treatment at temperatures higher than the phase transition point. By observing the microstructure and analyzing the tensile fracture, it is found that the tensile strength of TC4 titanium alloy specimens decreased via heat treatment at 950 ℃ and 1 000 ℃, due to the transformation of β phase into Widmanstatten structure. However, at 850 ℃ of heat treatment temperature, the properties of the TC4 titanium alloy specimens were stable, because the microstructure inside was still equiaxed before reaching the phase transition point. Those results suggest the TC4 titanium alloy manufactured by EBSM have good mechanical properties by an appropriate heat treatment process.

-

Key words:

- Ti-6Al-4V /

- EBSM /

- heat-treatment /

- mechanical property

-

0. 引言

增材制造技术是近年来迅速发展的新型制造技术,与传统的减材制造技术所不同的是,增材制造技术是一种根据所需要的产品构建三维模型,运用粉末状金属、高分子材料等可粘合材料,通过将材料逐层打印,制备高性能、高致密金属的制造技术。目前的3D打印技术主要分为选区激光熔融技术(SLM)、激光融化成型技术(LMD)、电子束选区熔化技术(EBSM)等[1]。电子束选区熔化技术相对于与传统减材制造其优势在于成形流程短、制造过程无需模具、材料利用率接近100%;此外,电子束加工的真空环境能避免杂质气体影响合金性能;高温电子束易于制备难熔金属,尤其适合钛合金的制造[2]。

采用3D打印技术成形钛合金零件时,由于粉末/丝材特殊的加工性能,成形工件的抗拉强度比不上传统铸造的零件。针对上述的性能缺陷,国内外学者运用不同的原理,采用不同的工艺优化方法对合金性能缺陷进行了探究。其中研究较多的方法主要有:对粉末进行预热、优化工艺参数或者对制件进行后续热处理等,都可以相应地改善合金的缺陷,提高合金的组织性能[3]。

目前关于增材制造TC4钛合金热处理工艺的研究尚少,国内外仅有的研究证实了恰当的热处理工艺可以提升3D打印成形的钛合金性能。通过不同的加热和冷却方式使TC4钛合金发生不同相变,从而得到不同的金相组织。热处理是提升增材制造钛合金的力学性能的重要工艺之一,笔者对3D打印成形的TC4钛合金试件,采用不同的热处理工艺,比较常态以及不同热处理工艺下试件的显微组织、力学性能的不同,从而探究不同热处理工艺对电子束增材制造的TC4钛合金的影响机制。

1. 试验设备、材料及方法

1.1 试验设备

试验采用瑞典Arcam公司的Arcam A2X型电子束选区熔化成形设备,该设备分为两个机柜,左侧为控制柜,包含计算机(用作图形用户界面)、PLC及其他电子设备(包括高压电源)、控制柜顶部的警报塔(用于指示系统的当前状态);右侧为成形柜,包含真空室、真空系统和电子束单元[4]。

EBSM设备内部结构如图1所示。主要包含顶部的灯丝,接通电源电流时把灯丝加热;当灯丝温度足够时,电子即被丝极释放出来,然后通过阳极加速运动经过像散线圈、聚焦线圈。聚焦线圈将电子聚集形成电子束,而偏转线圈的作用则是通过磁场控制高能量高密度电子束的发射与偏转方向。

成形缸内的成形平台随着一层粉末的打印完成将下降一个二维截面,铺粉机构随之进行下一层的铺粉[5]。电子束继续扫描下一成形层的金属粉末以完成打印工艺,而未被扫描熔化的粉末则会起到一定的支撑作用,与此同时新的成形层会与上成形层聚合为一体。由电子束、铺粉机构、成形平台的依次往复运动,每一个二维截面的加工成形以及融合成一体直至形成三维零件实体。

1.2 试验材料

钛及其合金凭借着低密度、高强度、低质量比和出色的高温耐腐蚀性、优异的焊接性能、生物兼容性能,使其成功应用于高可靠性能的行业,如医药以及航空航天、汽车、化工等产业[6]。由于电子束选区熔化技术当前选材的局限性,在制备TC4钛合金时主要采用最小粒径为45~100 μm[7]的Ti-6Al-4V ELI钛合金粉末作为制备试验试件的原材料,其形貌如图2所示,化学成分如表1所示。

1.3 热处理工艺

TC4钛合金为(α+β)型钛合金,该合金的α、β组织由于加热温度不同会有很大差异。故以加热温度和冷却介质为参量进行试验。TC4钛合金的β相变点在950 ℃±50 ℃左右[8],即950 ℃以上加热β相会发生剧烈的转变,β相转变为针状、片状α组织,从而形成魏氏组织。

因此,为了验证热处理工艺能否改善3D打印成形的TC4钛合金的各项性能,设计了850、950、1000 ℃三个温度及空冷、炉冷两种冷却方式进行试验,具体参数设置如表2所示。

1.4 试验步骤

电子束加速电压为60 kV, 聚焦电流为25 mA(加工功率为1 500 W),灯丝电流为10 A,铺粉厚度为0.05 mm,用16 mA的束流对成材板进行预热。预热时间为25 min,成材板的温度达到640 ℃。对粉末进行预热,对已经预热好的粉末层进行熔化扫描,扫描速度为450 mm/s。整个制备过程中,成形仓维持在6×10−2 Pa的真空度,然后再充入5~8 Pa的氦气作为保护气体,成形过程结束后形成1×105 Pa大气环境,有助于零件的成形仓和成形件的快速冷却。整个增材制造过程共15.5 h,其中包括冷却5.5 h。

表 1 Ti-6Al-4V ELI粉末化学成分Table 1. Chemical constituents of Ti-6Al-4V ELI powder% Al V C Fe O N H Ti 6 4 0.03 0.1 0.1 0.01 0.003 Balance 表 2 钛合金试件热处理工艺参数Table 2. Heat treatment process parameters of titanium alloy specimen序号 加热温度/℃ 保温时间/h 冷却方式 1 850 1 空冷 2 950 1 空冷 3 1000 1 空冷 4 850 1 炉冷 5 950 1 炉冷 6 1000 1 炉冷 7 常态 常态 常态 制备完成后,对试件进行上述热处理工艺后进行性能检测和拉伸试验:拉伸速率为3×10−3 m/s,试件的拉伸面为圆形,面积为19.635 mm2,标距为55 mm。将经过不同热处理的拉断试件进行切块处理,将试件拉伸断裂口部分各切下3 mm左右的块状,以作扫描电镜制样。金相组织观察试验为试件中截取4 mm的块状,经过500#、1000#、1500#、2 000#规格的砂纸打磨后抛光,利用Kroll试剂腐蚀后进行观察。

热处理工艺采用了KSL-1700X型高温马弗炉;拉伸设备为WDW-100电子万能试验机;拉伸断口分析试验采用了S-4800型扫描电镜;金相组织观察设备为NK-800型智能金相显微镜。

2. 试验结果与分析

2.1 拉伸试验分析结果

将基于ESBM纵向打印成形的常态及不同热处理工艺后的TC4钛合金试件进行拉伸试验,拉伸性能如表3所示(FC:炉冷工艺;AC:空冷工艺)。从试验数据可以得知:由EBSM制备的TC4钛合金常态下抗拉强度达到740 MPa,加热至850 ℃后,空冷及炉冷处理的试件抗拉强度较常态都有所提升;加热至950 ℃后,两种冷却方式的试件的抗拉强度都开始下降,且屈服强度呈断崖式下降。加热至1000 ℃后冷却的两试件抗拉强度和屈服强度都明显弱于其他试件。

2.2 拉伸断裂口分析

2.2.1 宏观断口分析

通过观察图3的30倍扫描电镜下断口形貌分析得到,常态拉伸断口属于延性断裂,存在严重颈缩变形现象,断口轮廓为椭圆形并呈杯锥状,纤维区与放射区表面呈金属光泽,较粗糙,无明显剪切唇,但断面比较平滑。

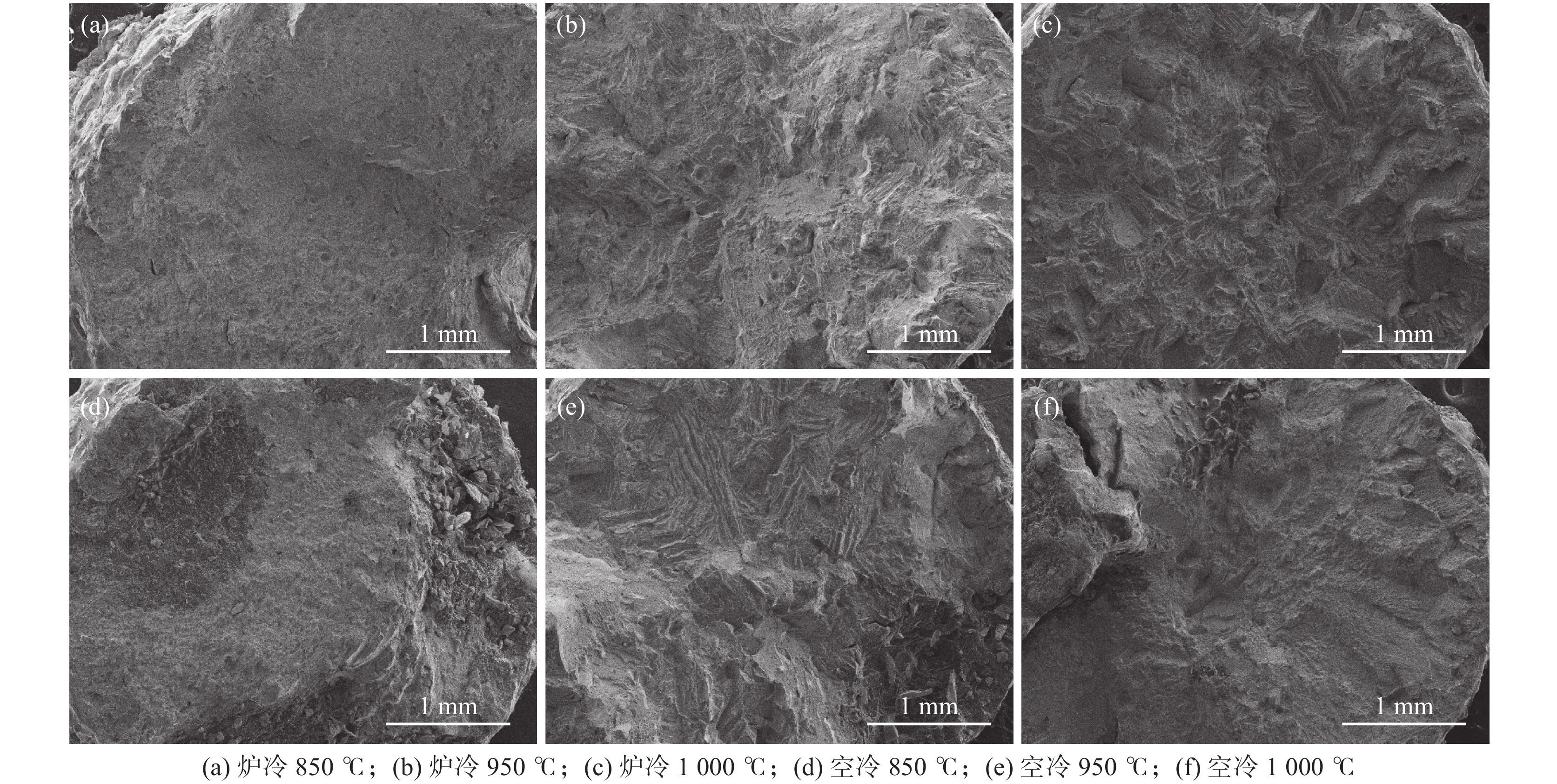

表 3 拉伸试件室温拉伸力学性能Table 3. Tensile mechanical properties of titanium alloy specimens试件编号 抗拉强度/MPa 屈服强度/MPa 断面收缩率/% 常态 740.52 739.60 32.3 FC850 762.82 762.21 24.3 FC950 686.94 309.14 19.5 FC1000 544.23 244.87 9.1 AC850 747.14 734.91 20.1 AC950 727.28 352.23 17.2 AC1000 555.44 249.56 11.2 图4(a)为850 ℃炉冷试件呈现延性断裂纯剪切断口,出现轻微颈缩现象,在正拉应力作用下,断口处发生了滑移剪切,切断断口与拉伸轴线呈45°。断口表面比较粗糙,呈灰暗色,形成了许多小且浅的微孔。图4(b)为950 ℃炉冷试件呈现延性纯剪切断口,颈缩现象不明显,在正拉应力作用下,断口处发生了滑移剪切,切断断口与拉伸轴线呈45°。存在锯齿状纤维区以及放射状放射区,无明显剪切唇,表面微孔多而浅。图4(c)为1000 ℃炉冷试件在试验时没有出现明显的塑性变形,试件亦无显著拉长,几乎没有颈缩现象,断口相对平齐且光亮,属于典型的脆性断裂。

图4(d)的850 ℃空冷试件断口属于延性断裂,存在轻微颈缩现象,断口轮廓呈现杯锥状,断裂表面凹凸不平,纤维区呈锯齿状,颜色灰暗。图4(e)为950 ℃空冷试件断口属于延性断裂,存在一定的颈缩现象,断口呈现凿峰状。纤维区比较粗糙,存在大量纤维状小峰;放射区呈放射花样,有金属光泽。表面微孔极少,且只分布在最后断裂区域。图4(f)的1000 ℃空冷试件在拉伸时没有出现拉长且没有发生明显颈缩现象,表面相对平整且光亮,属于脆性断裂。断口存在一部分不规则拉断,但是观察得到该部分的拉伸断口亦较为平整,推测为试件在纵向打印成形时存在本身材料性能不均匀情况。

2.2.2 微观断口分析

图5为常态试件拉伸断裂口1000倍及5000倍扫描电镜形貌,观察得到该断口由等轴韧窝组成,其大多数韧窝较大、较深且不均匀,属于韧性断裂,具有更好的塑性。

图6(a)、(b)为850 ℃炉冷试件的断口扫描电镜形貌,将倍数放大到1000倍及5000倍后发现,该试件断口处仍由等轴韧窝组成,随着加热到850 ℃做炉冷处理后,断口处的等轴韧窝尺寸比常态试件拉伸断口的韧窝尺寸要增大且更深。说明了850 ℃热处理能使试件韧性提升,试件抗拉强度的提升也印证了这一现象。

图6(c)为950 ℃炉冷试件的1000倍显微图仍存在着大量韧窝,但形貌发生了改变:等轴韧窝已不复存在,取而代之的是被拉长的剪切韧窝(呈抛物线状)与大量的滑移平直区、撕裂棱混合组成。且观察到试件的韧窝尺寸较小、较浅,图6(d)圆圈位置观察到在韧窝底部存在滑移断裂过程中析出的第二相粒子。韧窝的尺寸较小以及抗拉强度的下降,说明950 ℃的热处理会该试件的力学性能下降,推测是950 ℃左右为钛合金相变点,内部组织的改变导致性能减弱。

图6(e)、(f)为1000 ℃炉冷试件的断口微观形貌,断口的韧窝数量已经很少,取而代之的是河流状花样。存在小且多的晶粒,晶界已经呈现解理平面并伴随着解理台阶。该断口属于穿晶断裂、脆性断裂。拉伸试验结果亦表明1000 ℃炉冷处理的试件是脆性断裂且抗拉强度和屈服强度大幅降低。

图6(g)为850 ℃空冷试件的扫描电镜断口形貌,将断口放大至1000倍可以观察到该区显微形貌由大且深的等轴韧窝组成。比较常态试件的断口得到:850 ℃空冷工艺的拉伸断口韧窝尺寸明显更大更深且分布较密集均匀,其力学性能较常态试件会有所改善。对比同是850 ℃但做炉冷工艺的试件断口得到:该试件的断口韧窝大小和深度都不具备明显优势,由图6(h)观察到在韧窝底部存在析出的第二相粒子。

图6(i)为950 ℃空冷试件的在1000倍断口形貌,可以观察到韧窝的尺寸变得极小,表面存在有少数河流花样、解理台阶、滑移平直区和撕裂棱,但总体仍为韧性断裂。通过图6(j)可观察到韧窝变得极小,且浅,圆圈位置亦存在大量析出的第二相粒子。相对于850 ℃空冷试件而言,该试件断口不再是纯粹的等轴韧窝组成,开始出现准解理形貌,且析出的β相粒子单位面积增多。由此可得出,在950 ℃该加热温度(β相变点)附近,钛合金试件的β相组织开始发生转变。

图6(k)、(l)为1000 ℃空冷试件的断口形貌,断口处出现了河流花样、撕裂棱及解理台阶,可以观察到断口表面韧窝形状不明显,更多的是台阶状的解理面,属于脆性断裂。相对于950 ℃空冷试件的网格状密集韧窝,该试件断口韧窝已无处可寻,取而代之的是相互平行的、位于不同高度的晶面形成的解理台阶。对比1000 ℃炉冷工艺的试件断口得到:两者存在韧窝数目极少,前者大多数为河流花样且伴随着小而多的晶粒,后者则大部分为解理台阶。虽然形貌存在差异,却都代表了脆性断裂。

2.3 金相组织观察分析

EBSM制备Ti-6Al-4V成形的相转变过程如下:对于一层材料,由于电子束的熔化深度大于1个粉末层厚度,液相多次转化β相;之后,由于冷却速度很快,β相先转化成α'马氏体;在后续的成形中,材料多次被加热至固态相变温度,使得α'马氏体分解为α+β相组成的网篮组织[9]。

图7(a)为炉冷850 ℃试件的微观组织,观察到试件的内部β相经过高温后在变形和冷却过程α相被部分打断,最终组织呈现宽针状的、互相交织的长条状α,属于典型的网篮组织。网篮组织具有良好的拉伸塑性和拉伸强度,在拉伸试验中发现该试件的拉伸强度及屈服强度最好,与试验结果相符。

图7(b)为炉冷950 ℃试件的微观组织,通过观察得到试件组织主要为等轴α相及次生的由β相加热冷却成核长大的针状α。内部组织的β相开始转化呈细长针状α,而这种组织形态会导致合金的力学性能减弱,塑性会大幅降低。拉伸数据表明试件抗拉强度下降少许,但屈服强度呈断崖式下降。对比850 ℃炉冷试件,该试件的微观组织最显著的差异是由长条状α变成针状α,而在两试件的拉伸数据中,只有屈服强度存在较大变化,得出针状α组织会使材料塑性下降的结论。

图7(c)为炉冷1000 ℃试件的微观组织,观察到合金内部已不存在等轴组织,取而代之的是在较高温度区间加热且以中等速度冷却形成的片状α组织(与针状α组织相比,长宽较小呈片层状)以及晶间β组织,属于魏氏组织。拉伸结果表明1000 ℃炉冷处理的试件抗拉强度仅为544 MPa、屈服强度仅有244 MPa。强度远远低于常态合金试件,相对于850 ℃及950 ℃炉冷试件亦较低,与试验结果相符合。

图7(d)为空冷850 ℃试件的金相组织,图中可观察到该试件亦是纵横交错,交织均匀的长条状α组织,形成明显的网篮组织。两试件的500倍微观组织都是典型的网篮组织,单位面积内的组织大小、形态及分布都大同小异,两者的性能并不会有太大差异。拉伸试验数据印证了这一点:两者的抗拉强度和屈服强度相差不大,且相对常态试件都有了改善。

图7(e)为空冷950 ℃拉伸试件的微观组织,图中可观察到合金的微观组织为细长针状α组织和晶间β组织。与950 ℃炉冷处理的试件相比,该试件的针状α组织较长、分布较密集。由拉伸数据得到,该试件抗拉强度稍降但屈服强度断崖式下降,与950 ℃炉冷试件情况一致。印证上述了针状α组织会使材料塑性下降的结论。

图7(f)为空冷1000 ℃试件的微观组织,清晰观察到该合金显微组织由粗大片状α组织和原始β晶界组成,存在着魏氏组织。相对于850 ℃空冷试件的网篮组织及950 ℃空冷试件的针状α组织,显然该试件的魏氏组织所决定的性能较弱,与拉伸试验结果符合。相对于1000 ℃炉冷试件,由于冷却速度的不同,次生片层α相的厚度也有所差异。但两者皆为片状α组织,所决定的材料性能差异不会过大,拉伸实验数据与该结论亦符合。

3. 结论

研究了不同热处理工艺对EBSM制备的TC4钛合金试件拉伸力学性能、拉伸断裂口和金相组织上的影响,以期利用热处理改善3D打印钛合金的性能缺陷。

1)常温下传统铸造成形的TC4钛合金试件的抗拉强度为986 MPa、屈服强度为918 MPa左右,而本研究由EBSM制备的钛合金常态常温抗拉强度仅有740 MPa、屈服强度仅739 MPa。

2)炉冷850 ℃、空冷850 ℃两试件得到典型的网篮组织,该组织的力学性能优异,抗拉性能表现良好。炉冷950 ℃、空冷950 ℃两试件则是针状α组织;炉冷1000 ℃、空冷1000 ℃则表现为魏氏组织,这两种组织在力学性能上表现为拉伸强度较弱、拉伸塑性极差。

3)炉冷850 ℃、炉冷950 ℃、空冷850 ℃、空冷950 ℃四根试件完全呈现了韧性断裂形貌,而炉冷1000 ℃、空冷1000 ℃两根试件表现出典型的脆性断裂。

4)试件加热至850 ℃,炉冷后抗拉强度从740 MPa提升至762.82 MPa;空冷后提升到747.14 MPa。与传统铸造的986 MPa相比仍略显不足,但证实了热处理确能提升由增材制造成形的钛合金性能。

-

表 1 Ti-6Al-4V ELI粉末化学成分

Table 1. Chemical constituents of Ti-6Al-4V ELI powder

% Al V C Fe O N H Ti 6 4 0.03 0.1 0.1 0.01 0.003 Balance 表 2 钛合金试件热处理工艺参数

Table 2. Heat treatment process parameters of titanium alloy specimen

序号 加热温度/℃ 保温时间/h 冷却方式 1 850 1 空冷 2 950 1 空冷 3 1000 1 空冷 4 850 1 炉冷 5 950 1 炉冷 6 1000 1 炉冷 7 常态 常态 常态 表 3 拉伸试件室温拉伸力学性能

Table 3. Tensile mechanical properties of titanium alloy specimens

试件编号 抗拉强度/MPa 屈服强度/MPa 断面收缩率/% 常态 740.52 739.60 32.3 FC850 762.82 762.21 24.3 FC950 686.94 309.14 19.5 FC1000 544.23 244.87 9.1 AC850 747.14 734.91 20.1 AC950 727.28 352.23 17.2 AC1000 555.44 249.56 11.2 -

[1] Sun Changjin, Zhao Yuhui, Wang Zhiguo, et al. Research on the development status and trend of nondestructive testing technology for new concept structures with additives[J]. Vacuum, 2019,56(4):65−70. (孙长进, 赵宇辉, 王志国, 等. 增材新概念结构无损检测技术发展现状及趋势研究[J]. 真空, 2019,56(4):65−70. [2] Lai Qi, Li Junhan, Wu Enhui, et al. Research progress of electron beam vapor deposition[J]. Iron Steel Vanadium Titanium, 2020,41(4):76−81. (赖奇, 李俊翰, 吴恩辉, 等. 电子束气相沉积的研究进展[J]. 钢铁钒钛, 2020,41(4):76−81. [3] Tang Chaolan, Wen Jingqing, Zhang Weixiang, et al. 3D printing forming technology and defects of titanium alloy[J]. Journal of Aeronautical Materials, 2019,39(1):38−47. (唐超兰, 温竟青, 张伟祥, 等. 钛合金3D打印成形技术及缺陷[J]. 航空材料学报, 2019,39(1):38−47. [4] Sun Baofu, Chen Jiaqi, Zhang Rui, et al. Influence of electron beam selective melting direction on properties of TC4 alloy[J]. Iron Steel Vanadium Titanium, 2021,42(2):43−47,90. (孙宝福, 陈家琪, 张瑞, 等. 电子束选区熔化成形方向选择对TC4合金性能的影响[J]. 钢铁钒钛, 2021,42(2):43−47,90. [5] Guo Chao, Zhang Pingping, Lin Feng. Research progress of electron beam selective melting additive manufacturing technology[J]. Industrial Technology Innovation, 2017,4(4):6−14. (郭超, 张平平, 林峰. 电子束选区熔化增材制造技术研究进展[J]. 工业技术创新, 2017,4(4):6−14. [6] 蔡云. TC4钛合金高温拉伸力学性能研究和组织演变[D]. 南京: 南京航空航天大学, 2009.Cai Yun. Study on tensile mechanical properties and microstructure evolution of TC4 titanium alloy at high temperature [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2009. [7] 姜毅. 选区激光熔化成形过程的应力场模拟及实验研究[D]. 武汉: 华中科技大学, 2012.Jiang Yi. Stress field simulation and experimental study of selective laser melting forming process [D]. Wuhan: Huazhong University of Science and Technology, 2012. [8] 黄薇. 电子束增材制造钛合金的组织特征与拉伸性能研究[D]. 南昌: 南昌航空大学, 2017.Huang Wei. Study on microstructure and tensile properties of titanium alloy manufactured by electron beam additive [D]. Nanchang: Nanchang Hangkong University, 2017. [9] Ge W J, Guo C, Lin F. Microstructure of pre-alloyed Ti6Al4V and Ti45Al7Nb blend powder formed by electron beam[J]. Rare Metal Materials and Engineering, 2015,44(11):2623−2627. doi: 10.1016/S1875-5372(16)60006-1 期刊类型引用(3)

1. 黄星光,孙宝福. 不同工艺参数对电子束熔丝沉积304不锈钢力学性能及显微组织研究. 钢铁钒钛. 2024(03): 162-168 .  本站查看

本站查看2. 陈冬雪,徐博翰,张建飞,黄星光,孙宝福. 热等静压对SEBM成形TC4钛合金性能的影响分析. 电焊机. 2023(06): 36-41 .  百度学术

百度学术3. 刘婧颖,李浩楠,徐昊,杨知硕,林忠亮,王洪飞,白清顺. 根部圆角滚压强化的高精度钛合金螺栓疲劳失效研究. 机械制造与自动化. 2023(06): 15-17+44 .  百度学术

百度学术其他类型引用(5)

-

下载:

下载:

下载:

下载:

百度学术

百度学术