Microstructure and properties of electron beam welded TA1 medium plate and analysis of joint strengthening

-

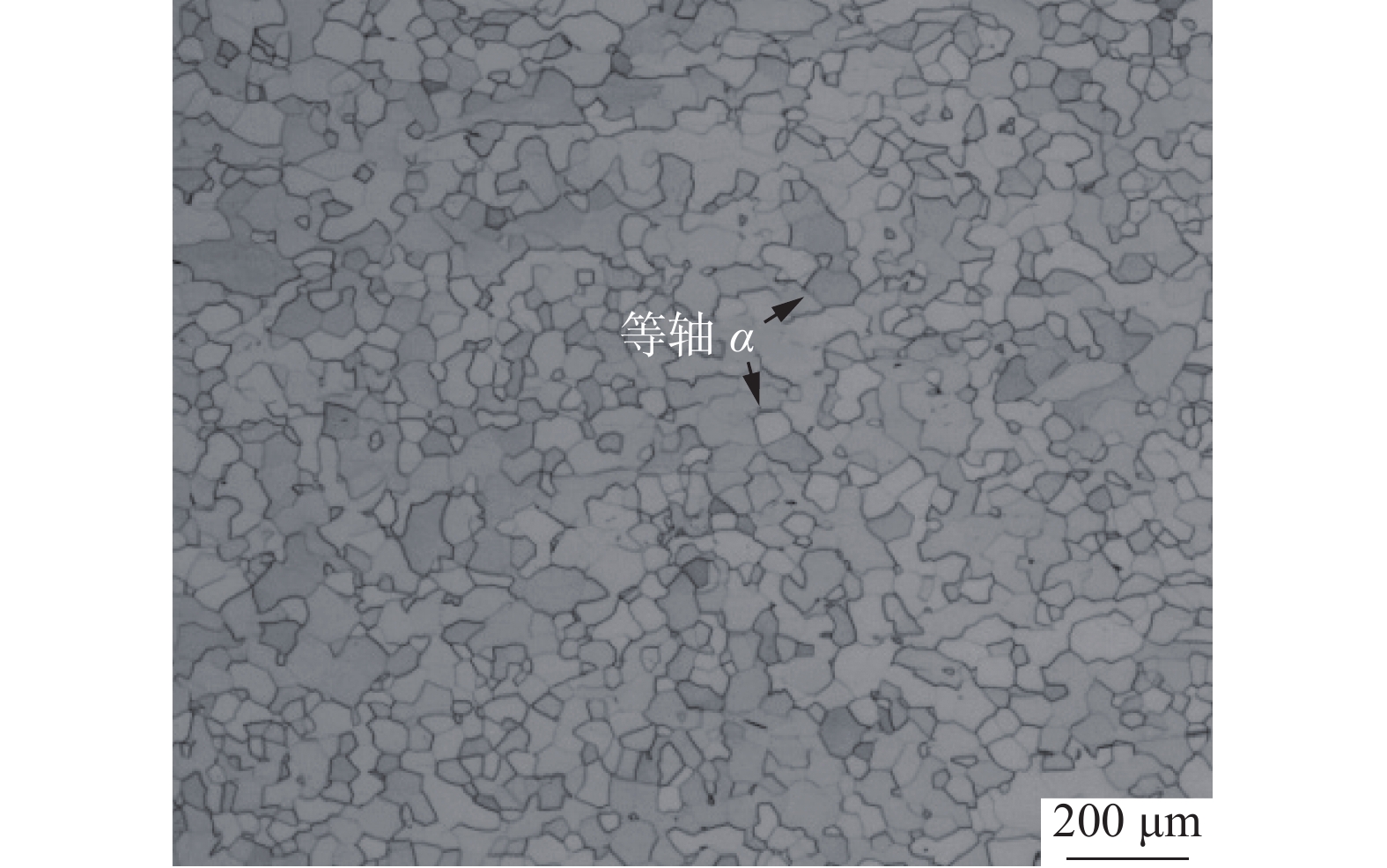

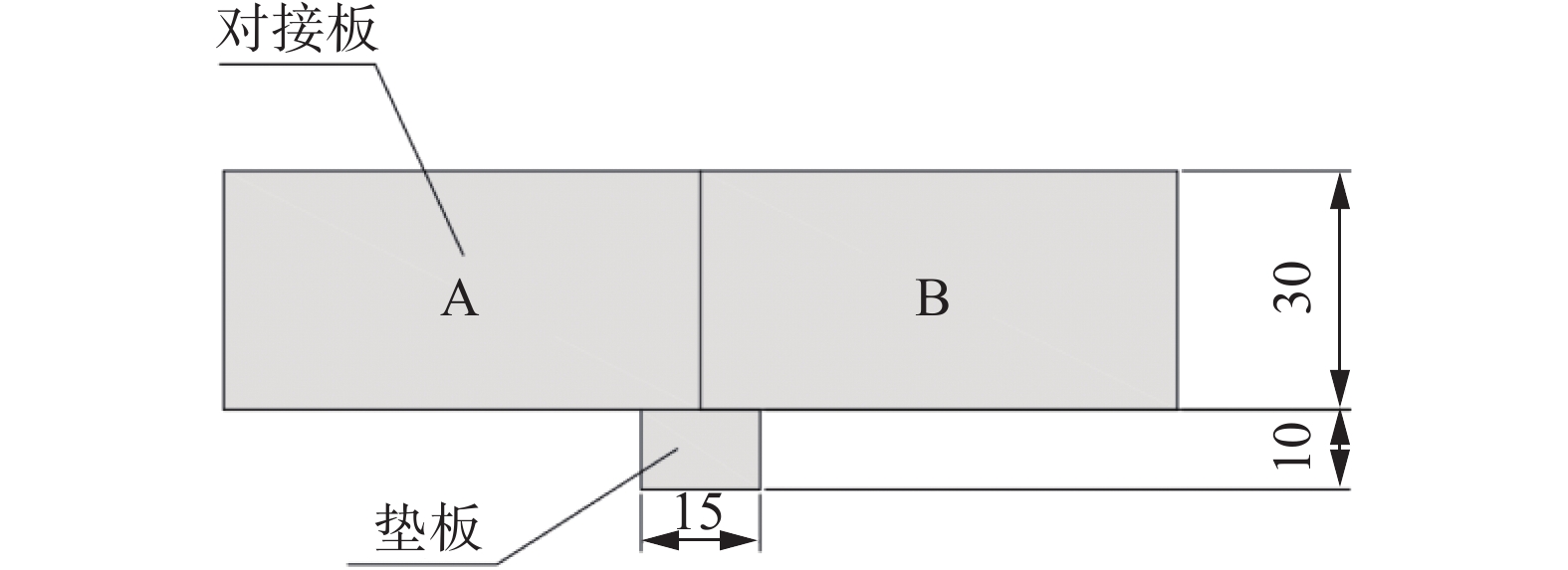

摘要: 采用真空电子束焊对30 mm厚TA1工业纯钛试板开展焊接试验,结合光学金相显微镜(OM)、维氏硬度、拉伸试验及电子背散射衍射(EBSD)对接头进行宏微观组织性能检验,分析电子束焊接过程对TA1材料微观组织与力学性能的影响及接头强化原因。结果表明:电子束焊接热循环过程使TA1母材至焊缝组织由等轴α向锯齿α转变;焊缝及热影响区的强度、硬度均高于母材;接头性能得到强化与锯齿α及针状α马氏体对硬度的提升作用、焊缝及热影响区内细小的锯齿状α晶粒以及微细孪晶对焊接组织的细化作用有关。Abstract: Electron beam welding was used to weld 30 mm thick TA1 pure titanium plates. Combined with optical microscope (OM) and electron backscatter diffraction (EBSD), the microstructure, Vickers hardness and tensile test of the joint were carried out. The influence of welding process on microstructure and mechanical properties of TA1 material and the strengthening reason of the joint were analyzed. The results show that the microstructure from TA1 base metal to weld metal changes from equiaxed α to serrated α. The strength and hardness of welding seam and the heat affected zone are higher than the base metal. The strengthening of the joint properties is related to the increasing effect of serrated α and acicular α martensite on the hardness, the existence of a large number of serrated α lower than the grain size of the base metal in the weld seam and heat-affected zone, and the refining effect of micro-twinning on the welding microstructure.

-

Key words:

- TA1 /

- electron beam welding /

- microstructures /

- mechanical properties

-

0. 引言

攀钢高炉渣既是一种工业废弃物,更是富含钛元素的二次资源。近几十年来,高钛型高炉渣固体废弃物资源化利用,主要加工成矿渣碎石、渣砂等产品用于建筑行业作为砂、石骨料,及少量的含铁物料用于铁产品提炼深加工。攀钢含钛高炉渣不仅是一笔可观的战略资源,也是一笔巨大的财富,仅仅将其作为建筑材料而不对其中的钛加以利用,资源浪费是惊人的[1]。因此,非提钛方法、高附加值利用高钛型高炉渣中钛资源,就成为一种合理而重要的综合利用方式。

TiO2由于光化学性质稳定、无毒、光催化效果好而受到广泛的关注。以纯TiO2作为光催化材料已经在很多领域得到应用,光催化建材、空气净化剂、污水处理设备等都已经问世,但因纯TiO2大批量使用成本过高使应用受到限制[2]。高炉渣中TiO2质量分数为20%~23%,各种元素都是稳定元素,炉渣中的钒和铁使其光催化活性增强,而其他的如钙、镁、铝等的存在基本不影响TiO2的光催化性能,因此利用它作为光催化降解剂是完全可能的[3-5]。东北大学杨合等人[6-7]用处理的含钛炉渣制备催化剂降解某种惰性颜料、糠醛废水等,发现其具有光催化性。但直接利用高钛型高炉渣制备光催化材料,其光催化响应较弱,光催化降解率较低,不能满足各应用领域的要求。有研究表明,在TiO2中有选择性地掺杂适量金属离子对TiO2的光催化性能起到很好的改善作用[8-10]。因此,笔者采用液相法,以含钛高炉渣为原料,Co(NO3)2·6H2O为掺杂离子给体,制备Co掺杂含钛高炉渣的光催化剂,用所制备的催化剂进行光催化分解有机物的研究,考察质量掺杂比、煅烧温度、煅烧时间等对光催化性能的影响。

1. 试验部分

1.1 仪器与试剂

试验仪器主要有光化学反应仪(BOT-GHX-Ⅱ型,北京中仪博腾科技有限公司),X射线衍射仪(DK7735型,荷兰帕纳科公司),箱式电阻炉(SX2-5-12A型,绍兴市上虞道墟科析仪器厂),紫外分光光度计(T-6型,南京菲勒仪器有限公司),离心机(TD4C型,常州金坛良友仪器有限公司),密封式制样粉碎机(MZ-100型,南昌市力源矿冶设备有限公司)磁力搅拌器(RHbasic2S25型,苏州江东精密仪器有限公司),电热恒温鼓风干燥箱(101型,北京永光明医疗仪器厂)等。

试验用高钛型高炉渣取自攀钢高炉。主要试剂有硝酸钴(分析纯)、冰乙酸(分析纯),硝酸(分析纯),亚甲基蓝(分析纯),溶液均用去离子水配置。

1.2 光催化剂的制备

将高钛型高炉渣(化学成分见表1)粉碎研磨至几十微米级,取10 g高钛型高炉渣与水混合均匀,搅拌下加入 4 mol/L乙酸5 mL,得溶液A;将适量Co(NO3)2·6H2O与水混合均匀,得溶液B;将溶液B滴入溶液A中,滴加完毕,用1 mol/L的HNO3调节体系pH至4~5,搅拌均匀;再在60 ℃水浴下剧烈搅拌2 h,得悬浊液;将悬浊液置于干燥箱中,90 ℃干燥12 h,烘干固体研磨;置于马弗炉中,于600~800 ℃下煅烧1~5 h,冷却至室温,研磨至30~60 μm,得钴掺杂高钛型高炉渣光催化材料。

表 1 高钛型高炉渣的主要成分Table 1. Main compositions of high titanium blast furnace slag% TiO2 Fe2O3 SiO2 MgO Al2O3 CaO V2O5 F 23.16 2.64 24.01 7.47 13.49 27.19 0.82 0.12 1.3 光催化材料降解测试方法

试验采用光催化材料水溶液体系降解测试方法(GB/T 23762—2009)[11]来评价光催化剂的活性。具体方法如下:样品测试前,置于紫外灯下照射8 h,确保其表面吸附的有机物被彻底分解。在光催化反应容器中,加入刚配置好的10 mg/L亚甲基蓝溶液650 mL,再加入1.2节制备的光催化剂0.26 g,在磁力搅拌下使其充分混合并保持流动,暗反应15 min,使混合液达到吸附-解吸平衡,然后在500 W紫外灯照射下(波长365.0 nm),反应120 min,取10 mL溶液,经3 000 r/min离心分离5 min,在紫外分光光度计上,于664 nm处,使用1 cm比色皿,以水调零测量上清液的吸光值,计算亚甲基蓝降解率。计算公式为:

$${{\eta = }}\frac{{{{{A}}_{\rm{0}}} - {{{A}}_{{t}}}}}{{{{{A}}_{\rm{0}}}}} \times 100\% $$ (1) 其中,η为降解率;A0为降解前原亚甲基蓝溶液的吸光度;At为光降解t时间后亚甲基蓝溶液的吸光度。

2. 结果与讨论

2.1 光催化剂XRD表征分析

在Co-Ti质量掺杂比为0.03,煅烧时间为2 h的条件下,选取煅烧温度400、600 、800 ℃下制备的高炉渣光催化剂及未掺杂高炉渣进行XRD表征。由图1可知,高炉渣及高炉渣光催化剂中二氧化钛主要以钙钛矿的形式存在,由于Co的掺杂含量较低,没有出现钴氧化物的衍射峰。当煅烧温度为800 ℃时,钙钛矿的峰强明显减弱,说明此时该物相减少,原因可能是温度升高,二氧化钛由锐钛型转为金红石型。因此,高炉渣光催化剂制备煅烧温度应低于800 ℃。

2.2 煅烧温度对高炉渣光催化效果的影响

在Co-Ti质量掺杂比为0.03,煅烧时间为2 h的条件下,考察在不同煅烧温度下制备的钴掺杂高炉渣光催化剂紫外光光催化降解亚甲基蓝的效果(见图2)。由图2可知,随着煅烧温度的升高,降解率呈M型趋势变化,当煅烧温度为600 ℃时,光催化降解率最高,达到89.0%,而600~750 ℃都呈下降趋势,在800 ℃时有回升,800~1 000 ℃时,又呈下降趋势。当温度为650 ℃时,与600 ℃相比催化降解率降低约15%;当温度升至750 ℃时,催化降解率降低至约50%,催化性能大大降低。

李琪等[12]研究发现,氮元素可以提高光催化剂的分散性,使得TiO2的比表面积增大,从而促进光催化剂的光催化活性。因煅烧温度越高,高炉渣中的N元素含量越低,从而使高炉渣催化剂的光催化活性降低。当温度达到一定水平时,光催化效果受N元素影响将明显减少。这主要是由于以下三个方面的原因:① TiO2晶型的改变与温度有关。锐钛型TiO2转化为金红石型TiO2的温度是610 ~915 ℃,锐钛型TiO2完全转变为金红石型TiO2,煅烧温度须高于1 000 ℃[13];且锐钛矿型TiO2比金红石型TiO2具有更高的光催化活性[14]。温度的升高使得锐钛型 TiO2组分减少,金红石型TiO2组分增多,导致催化剂光催化活性降低。②因为晶粒尺寸的增大,当温度增大到750 ℃,发生晶粒之间的烧结,导致晶粒尺寸增大,光催化剂的有效表面积减少。③因为高炉渣中其他元素的影响,高温下的载体表面的其他金属离子跑到TiO2晶型当中,而这些离子会对光生电子空穴的分离产生消极作用[15]。因此,在试验过程中煅烧温度不应太高,600 ℃为最优。

2.3 Co掺杂量对高炉渣光催化效果的影响

在煅烧时间为2 h,煅烧温度为600 ℃的条件下,考察在不同Co-Ti质量掺杂比(w(Co)∶w(Ti))下制备的Co-高炉渣光催化剂紫外光催化降解亚甲基蓝的效果(见图3)。

由试验可知,未掺杂的高钛型高炉渣的光催化活性为56.6%。由图3可知,当Co-Ti质量掺杂比为0.01时,亚甲基蓝降解效率达到80%左右,比质量掺杂比为0.02时高出了约5%;这是因为导带的形成能随着Co掺杂量的增加而增加,并且当Co掺杂量增加时,大量的光电子被束缚并且不能穿过禁带跑向价带以下,因此对紫外线的响应变弱[16]。质量掺杂比为0.03时,降解效率达最高为89.0%,但当其大于0.03时,光催化降解率呈下降趋势。这是因为,随着Co的添加而生成的空位能量升高,一方面这些空位形成低能态价态很容易造成光生电子复合,另一方面,这些空位形成能低,在这种情况下,电子-空穴重组变得容易。掺杂的Co降低光生电子的分离能并实现了大量的紫外光吸收,但是由于电子-空穴对在空位上的复合却导致量子产率低下。因此,光催化剂的催化活性与Co掺杂量不存在正比相关性,Co最佳的掺杂量Co-Ti质量掺杂比为0.03。

2.4 煅烧时间对高炉渣光催化效果的影响

在煅烧温度为600 ℃,Co-Ti质量掺杂比为0.03的条件下,考察在不同煅烧时间下制备的Co-高炉渣光催化剂紫外光催化降解亚甲基蓝的效果。

由图4可知,随着煅烧时间的增加,催化剂的光催化降解效率是先升高后降低的过程,煅烧时间为2 h时,降解效率达到最高。适宜的煅烧时间,Co有足够时间掺杂到TiO2晶体结构中,晶格被拉伸变形,空位拉伸增多,使光电载流子和空位复合率有所下降,大量的载流子因不能与空位复合而得到充分利用。同时,长时间保温煅烧,促使晶粒继续长大,晶粒过于粗大使得光催化剂的有效表面积大大降低。因此煅烧适当时间,将晶粒尺寸控制在一定范围,才使得光催化效率尽可能提高。综上考虑,最佳煅烧时间为2 h。

2.5 正交试验分析

为了进一步确定光催化剂制备条件对降解效率的影响及最优的制备方案,选取煅烧温度、煅烧时间和Co掺杂量(w(Co)∶w(Ti))为因素,每个因素选取三个水平,选用L9表,进行了正交试验,试验结果及分析见表2。由表2可知,三个因素对降解效率的影响依次是:煅烧温度>Co掺杂量>煅烧时间;试验的最优方案是B1A2C2,即煅烧温度600 ℃,w(Co)∶w(Ti)为0.03,煅烧时间2 h。空列的极差小,考虑为试验误差。

表 2 正交试验结果与分析Table 2. Results and analysis of orthogonal tests试验号 Aw(Co)∶

w(Ti)B煅烧温

度/℃空列 C煅烧时

间/h降解效

率/%1 1(0.02) 1(600) 1 1(1) 75.26 2 1(0.02) 2(700) 2 2(2) 70.53 3 1(0.02) 3(800) 3 3(3) 65.21 4 2(0.03) 1(600) 2 3(3) 79.22 5 2(0.03) 2(700) 3 1(1) 70.22 6 2(0.03) 3(800) 1 2(2) 79.20 7 3(0.04) 1(600) 3 2(2) 75.18 8 3(0.04) 2(700) 1 3(3) 60.28 9 3(0.04) 3(800) 2 1(1) 70.25 k1 70.33 76.55 71.58 71.91 k2 76.21 67.01 73.33 74.97 k3 68.57 71.55 70.20 68.24 极差R 7.64 9.54 3.13 6.73 因素主→次 BAC 最优方案 B1A2C2 3. 结论

1)采用液相法掺杂Co制备高钛型高炉渣光催化剂,可大大增强其光催化活性,光催化降解效率最高可达89.0%,比未掺杂之前提高了32.4%。

2)制备Co掺杂高钛型高炉渣光催化剂的最佳工艺条件是:煅烧温度600 ℃,w(Co)∶w(Ti)=0.03,煅烧时间2 h;其中煅烧温度影响最大,其次是Co掺杂量,煅烧时间影响最小。

-

表 1 TA1 化学成分

Table 1. Chemical composition of TA1 plate

% Fe C N H O Ti 0.035 0.011 0.002 0.001 0.038 余量 表 2 电子束焊接工艺参数

Table 2. Process parameters of EBW

工艺

参数加速电压

/kV聚焦电流

/mA束流

/mA焊接速度/(mm·s−1) 扫描频率

/Hz扫描幅值

/mm聚焦

方式定位焊 150 2250 30 15 8 000 0.5 下聚焦 深熔焊 150 2250 90 15 8 000 0.5 下聚焦 表 3 TA1母材及接头室温(25 ℃)拉伸性能

Table 3. Tensile properties of BM and welded joints at room temperature

样品分类 取样

位置Rp0.2

/MPaRm

/MPaA

/%Z

/%断口距焊缝

/mm焊缝直径

/mm断口直径/mm

母材上层 200.3 334.0 43.7 74.3 中层 188.0 326.5 50.3 75.5 下层 191.7 331.3 48.0 74.3

接头上层 225.7 335.3 47.7 76.0 12.4 4.6 4.2 中层 220.7 332.7 46.7 76.7 11.1 4.6 4.2 下层 216.0 335.3 45.7 76.0 9.7 4.6 4.3 注:Rp0.2-屈服强度;Rm-抗拉强度;A-断后伸长率;Z-断面收缩率。 -

[1] Zhao Yongqing. Current situation and development trend of titanium alloys[J]. Materials China, 2010,29(5):1−8. (赵永庆. 国内外钛合金研究的发展现状及趋势[J]. 中国材料进展, 2010,29(5):1−8. [2] Wang Yating, Lin Naiming, Tang Bin. Development of thermal oxidation of titanium and titanium alloys[J]. Corrosion & Protection, 2014,35(10):965−970. (王娅婷, 林乃明, 唐宾. 钛及钛合金热氧化工艺的研究现状[J]. 腐蚀与防护, 2014,35(10):965−970. [3] Li Xingyu, Li Fang, Hua Xueming, et al. Laser welding technology of industrial pure titanium TA2[J]. Electric Welding Machine, 2018,48(7):19−24,35. (李兴宇, 李芳, 华学明, 等. 工业纯钛TA2板激光焊接工艺[J]. 电焊机, 2018,48(7):19−24,35. [4] Huang Jiuling, Kong Liang, Wang Min, et al. Pure titanium TA2 thin plate double tungsten electrode argon arc welding process[J]. Transactions of the China Welding Institution, 2019,40(9):14−18,161. (黄九龄, 孔 谅, 王 敏, 等. 纯钛TA2薄板双钨极氩弧焊焊接工艺[J]. 焊接学报, 2019,40(9):14−18,161. [5] Zhou Ranhui, Gao Fuyang, Liu Xiangqian, et al. Review on friction stir welding of titanium and titanium alloys[J]. Development and Application of Materials, 2018,33(4):127−136. (周冉辉, 高福洋, 刘向前, 等. 钛及钛合金搅拌摩擦焊接技术综述[J]. 材料开发与应用, 2018,33(4):127−136. [6] Hao Zongbin, Li Xiaoquan, Fan Jinkai. Experimental research on one-side welding both sides formation of plasma arc welding for TA2 plates with thickness of 8 mm[J]. Hot Working Technology, 2017,46(11):214−217. (郝宗斌, 李晓泉, 范晋楷. 8 mm TA2纯钛厚板等离子弧单面焊双面成形试验研究[J]. 热加工工艺, 2017,46(11):214−217. [7] Zhang Binggang, Wu Lin, Feng Jicai. Development status of EBW technology both at home and abroad[J]. Welding & Joining, 2004,(2):5−8. (张秉刚, 吴林, 冯吉才. 国内外电子束焊接技术研究现状[J]. 焊接, 2004,(2):5−8. doi: 10.3969/j.issn.1001-1382.2004.02.001 [8] Li Yajiang, Liu Kun. Application and advanced bonding technology of titanium alloy in aviation industry[J]. Aeronautical Manufacturing Technology, 2015,(16):34−37. (李亚江, 刘坤. 钛合金在航空领域的应用及其先进连接技术[J]. 航空制造技术, 2015,(16):34−37. [9] Huang Yong, Fan Ding, Zhang Han. Effect of surface activating flux on weld penetration of A-TIG welding for titanium alloy[J]. Rare Metal Materials and Engineering, 2006,(10):1586−1588. (黄勇, 樊丁, 张涵. 表面活性剂对钛合金A-TIG焊熔深的影响[J]. 稀有金属材料与工程, 2006,(10):1586−1588. doi: 10.3321/j.issn:1002-185X.2006.10.018 [10] 王文翰. 焊接技术手册[M]. 郑州: 河南科学技术出版社, 2001: 293.Wang Wenhan. Welding technical manual [M]. Zhengzhou: Henan Science and Technology Press, 2001: 293. [11] Li Zhen, Shi Yan, Liu Jia, et al. Effect of laser welding parameters on microstructure and mechanical properties of commercial pure titanium[J]. Applied Laser, 2016,36(1):53−57. (李镇, 石岩, 刘佳, 等. 工艺参数对工业纯钛激光焊接接头组织性能的影响[J]. 应用激光, 2016,36(1):53−57. [12] Chen Zhenghua, Yang Chunhua, Huang Changqing, et al. Investigation of the twinning in plastic deformation of magnesium alloy[J]. Materials Reports, 2006,20(8):107−113. (陈振华, 杨春花, 黄长清, 等. 镁合金塑性变形中孪生的研究[J]. 材料导报, 2006,20(8):107−113. doi: 10.3321/j.issn:1005-023X.2006.08.031 [13] Wang Y N, Huang J C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy[J]. Acta Materialia, 2007,55(3):897−905. doi: 10.1016/j.actamat.2006.09.010 [14] Nemat N S, Guo W G, Cheng J Y. Mechanical properties and deformation mechanisms of a commercially pure titanium[J]. Acta Materialia, 1999,47(13):3705−3720. doi: 10.1016/S1359-6454(99)00203-7 [15] Duan Xiaoge, Jiang Haitao, Liu Jixiong, et al. Recrystallization process of commercial pure titanium cold rolled sheet[J]. Chinese Journal of Rare Metals, 2012,36(3):353−356. (段晓鸽, 江海涛, 刘继雄, 等. 工业纯钛TA2冷轧板再结晶过程的研究[J]. 稀有金属, 2012,36(3):353−356. doi: 10.3969/j.issn.0258-7076.2012.03.003 [16] Liu H, Nakata K, Yamamoto N, et al. Mechanical properties and strengthening mechanisms in laser beam welds of pure titanium[J]. Science and Technology of Welding and Joining, 2011,16(7):581−585. doi: 10.1179/1362171811Y.0000000054 [17] Liao Zhiqian, Wang Zhongping. Plasma welding of titanium alloy thick-plate[J]. Development and Application of Materials, 2005,20(4):27−28,37. (廖志谦, 王忠平. 钛合金厚板的等离子焊接[J]. 材料开发与应用, 2005,20(4):27−28,37. doi: 10.3969/j.issn.1003-1545.2005.04.008 [18] Ni Cong, Shi Yan, Chen Junke, et al. Technology research of laser welded commercial pure titanium[J]. Applied Laser, 2015,35(2):212−215. (倪聪, 石岩, 陈俊科, 等. 工业纯钛板激光焊接工艺研究[J]. 应用激光, 2015,35(2):212−215. doi: 10.3788/AL20153502.0212 -

下载:

下载:

下载:

下载: