Phase simulation and experiment of anorthite-diopside glass-ceramics based on stainless steel slag containing chromium

-

摘要: 含铬不锈钢渣的大量堆存会导致铬元素的浸出而对环境造成严重的危害,微晶玻璃因其良好的固铬性能和物理性能而具有研究价值。为探究该体系中铬元素的赋存规律,用热力学软件FactSage 7.2对含铬不锈钢渣制备的钙长石-透辉石系微晶玻璃进行了生成相含量的模拟,以此为指导使用含铬不锈钢渣制备了钙长石-透辉石系微晶玻璃,并研究了助熔剂和铬含量对该体系微晶玻璃的结晶和物理性能的影响。结果表明,在模拟计算中,铬元素首先富集在尖晶石相中,最大富集度在10%~20%,多余的铬元素以Cr2O3的形式出现在体系中。在对应的试验探究中,当铬含量达到5%时,体系中的含铬相仍然只有尖晶石相,这使得材料有较好的固铬性能。助熔剂使微晶玻璃具有更高的硬度,铬浸出试验中钙长石-透辉石体系均未检出铬元素。该试验为含铬固体废弃物制备微晶玻璃提供了理论依据。Abstract: Chromium-containing stainless steel slag will lead to the leaching of chromium and environment problems. Glass-ceramics possess excellent chromium fixation and physical properties. In order to explore the occurrence law of chromium in anorthite-diopside system, the phase equilibrium of anorthite-diopside glass ceramics was calculated by using thermodynamic software FactSage 7.2, and the sample were prepared by using chromium-containing stainless steel slag. The effects of flux and chromium content on the crystallization and physical properties of the system glass ceramics were studied. The samples were prepared by one-step method with simultaneous nucleation and crystallization. The results show that in the simulation calculation, chromium is first enriched in the spinel phase, and the excess chromium appears in the system in the form of Cr2O3. In the corresponding experimental exploration, when the chromium content reaches 5%, the chromium-containing phase in the system is still only spinel phase, which makes the material have better chromium fixation properties. The flux endows glass-ceramics with higher hardness. Chromium is detected in anorthite-diopside system in toxic leaching experiment. The experiment provides a theoretical basis for the preparation of glass-ceramics from chromium-containing solid waste.

-

0. 引言

根据不锈钢的生产方式,不锈钢渣通常分为两大类:EAF(电弧炉)渣和AOD(氩氧脱碳炉)渣。在不锈钢生产中,不锈钢渣的产量约为不锈钢的三分之一。 EAF 炉渣和 AOD 炉渣分别含有约 1.71% 和 3.22% 的 Cr2O3。这些Cr2O3在堆垛过程中可能被氧化成有毒的Cr6+,对环境产生影响,因此对不锈钢应进行有效处理[1-4]。

玻璃陶瓷是一种具有良好物理和化学性能的硅酸盐材料[5-6]。制备微晶玻璃的原料成分与不锈钢渣非常相似,其中Cr2O3和Fe2O3均可作为微晶玻璃的成核剂[7-14]。因此,用含铬不锈钢渣生产微晶玻璃时,无需添加额外的成核剂。已有研究指出透辉石基微晶玻璃具有良好的固铬性能。含铬材料制备的透辉石相微晶玻璃可以使铬元素生成MgCr2O4,这种不溶相阻止了不锈钢渣中铬的浸出[3]。 Al2O3 是不锈钢渣中的常见成分,钙长石也可作为可能的目标晶相[15]。钙长石相的存在可能会增加材料的固铬性能,钙长石与透辉石共存的体系研究鲜有报道。

为了为含铬不锈钢渣制备微晶玻璃提供更多的理论依据,探究体系中铬元素的赋存规律,利用热力学软件FactSage 7.2对该体系的烧结过程进行了生成相模拟计算,探究了体系中铬的赋存规律。笔者以AOD渣为原材料,添加分析纯氧化物配置得到体系要求的组分。使用形核与结晶同时完成的一步法制备了样品,探究了助溶剂与Cr2O3含量对材料结晶与硬度及耐腐蚀性的影响。

1. 试验方法

1.1 生成相模拟

试验使用理论上生成透辉石与钙长石的化学成分为1∶1的组分,即Mol(CaO∶SiO2∶MgO∶Al2O3)=2∶4∶1∶1。相平衡计算均由热力学软件FactSage 7.2计算得出。为使计算结果简洁明了,计算结果中只保留了稳定的固体相,未将液体相画出。

1.2 样品制备

以电炉不锈钢渣(EAF)为主要原材料,添加分析纯Al2O3、MgO、SiO2以得到体系要求的组分。样品成分如表1所示,其中AOD渣的成分由XRF(岛津XRF1800)检测得出。

表 1 主要原材料的化学组成Table 1. Chemical composition of main raw materials成分 EAF/% 混合钢渣/% CaO 51.9213 22.1288 SiO2 28.4218 47.4188 MgO 5.8954 7.9302 Al2O3 3.0794 20.153 Cr2O3 1.4192 0.6048 Fe2O3 3.227 1.3753 MnO 0.976 0.416 称量原料,充分混合后置于刚玉坩埚中,在管式炉(空气气氛)中以5 ℃/min的速率升温至1400 ℃保温4 h,使样品充分熔融。随后降温至1200 ℃保温2 h,使样品完成结晶。待冷却至室温即得到样品。

1.3 样品表征

将部分样品研磨成−74 μm颗粒,用于XRD分析,设备为德国布鲁克D8 Advance。部分样品进行抛光处理以进行SEM观察,设备为热场发射扫描电子显微镜SUPAR 40。

1.4 性能测试

硬度计(DHV-1000Z)的试验压力为9.8 N,保压时间为15 s。耐酸碱性测试中,将试样制成质量略大于0.1 g的小块,放入干燥箱中干燥至恒重,然后放入稀盐酸溶液中浸泡48 h,测定质量的损失[16],见公式(1)。

$$ {C}_{失}=\frac{{M}_{a}-{M}_{b}}{{M}_{a}}\times 100\% $$ (1) 式中

$ {C}_{失} $ —失重率,%;$ {M}_{a} $ —浸泡前质量,g;$ {M}_{b} $ —浸出后质量,g。铬浸出试验通过ICP-OES(Thermo ICAP PRO)测定浸出液中Cr的含量来分析。浸出液的制备参照了GB/T 33999—2017中的相关规定,将样品研磨至粒度为74 μm,取10 g在室温下浸泡于去离子水中。在磁力搅拌器上搅拌8 h后继续静置64 h得到浸出液。

2. 试验结果

2.1 生成相计算

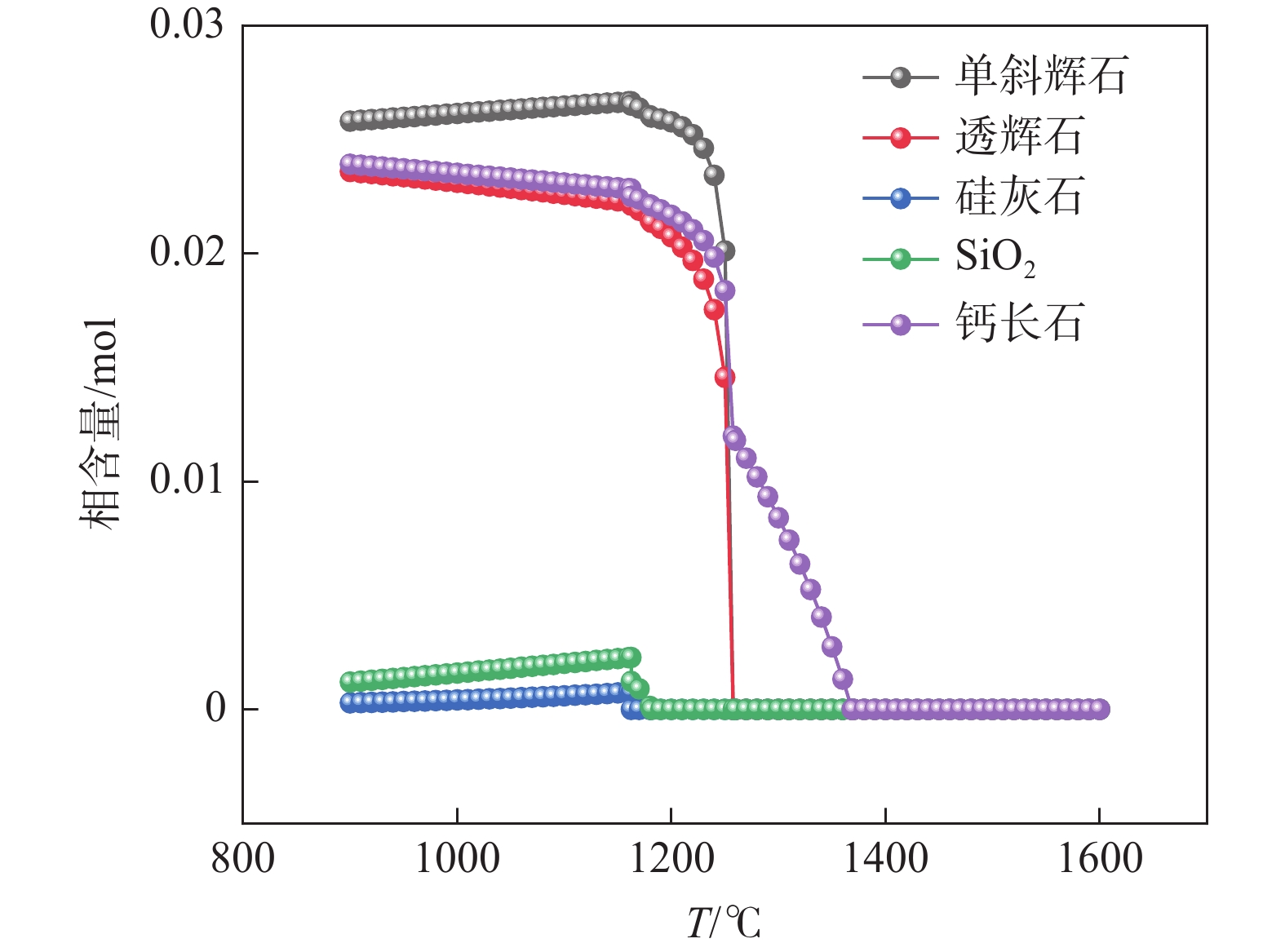

如图1所示,使用热力学软件FactSage 7.2对组分为mol(CaO∶SiO2∶MgO∶Al2O3)=2∶4∶1∶1的体系进行了生成相模拟。计算结果表明体系生成了透辉石与钙长石相,且在1400 ℃时全熔融为液相。因为类质同象现象,体系还生成了其他单斜辉石相及硅灰石相和未能完全参与反应的SiO2。

在上述体系的基础上增加了Cr2O3,增加量与计算结果如图2所示,生成的晶相与不添加Cr2O3的体系基本相同。随着铬含量的增加,体系均能生成钙长石和透辉石相,且倾向于生成钙长石。体系中尖晶石的含量也随Cr2O3的增加显著增加,而且计算结果中,尖晶石相与Cr2O3呈现明显的负相关性,这可以说明大量的铬元素富集在了尖晶石相中。不能富集在尖晶石相中的铬元素以Cr2O3和钙铝榴石存在于体系中。

图3为1400 ℃时不同Cr2O3含量下铬元素的赋存相。结果表明,该体系中铬元素大都富集在尖晶石相中,这使得该体系具有较好的固铬性能。当Cr2O3含量达到20%时,体系中的尖晶石相含量不再增加,推测体系尖晶石相含量达到最大值。

2.2 复合助熔剂及铬含量的影响

以试验生成相计算为指导,不锈钢渣为主要材料制备了微晶玻璃,图4所示为原钢渣直接烧制、配置后的钢渣以及添加了1%Na2O+K2O+CaF2复合助熔剂的样品的XRD检测结果。配置后的钢渣相比原钢渣体系中生成的相有较大差别。钢渣体系中晶相以钙铝黄长石、Ca2SiO4和钙铝榴石为主,而配置后的钢渣与计算结果相似,以钙长石和透辉石为主,除此以外还生成了少量的MgSiO3。图4中的饼状图为XRD中各项的半定量分析结果,由图4可知,体系更倾向于生成钙长石。与计算结果不同的是,检测结果中未见钙铝榴石。

对该组样品使用了扫描电子显微镜进行分析,结果如图5、6所示。完全由钢渣制备的样品的微观形貌为大小均匀的颗粒状,这导致了实际样品的机械性能很差,脆度和硬度都很低。配置后的样品微观相貌呈现层状,其上分布不规则的孔洞。孔洞中可见大小均匀的颗粒相。

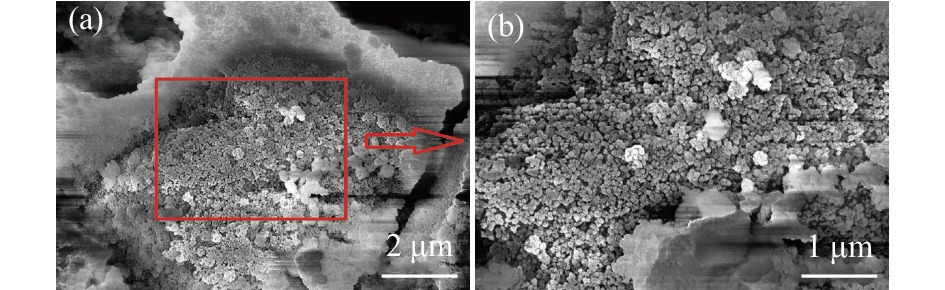

复合助熔剂对样品微观形貌的影响如图6所示。复合助熔剂有效地降低了体系的熔点[16],微观形貌呈现大小均匀的颗粒状,颗粒团簇分布,整体较为紧密。

在上述成分的基础上,分别制备了Cr2O3质量分数为2%、3%、4%和5%的样品。XRD检测结果如图7所示。检测结果与前述计算结果基本吻合。铬元素全部富集在尖晶石相中,未在其他相中检测出铬元素。随着铬含量的增加,体系出现了更多的尖晶石相,半定量分析结果表明体系更倾向于生成钙长石。体系的峰强呈现下降趋势,这可能是因为随着铬元素的增加体系生成了更多的新相,含有铬元素的尖晶石作为晶核剂诱导了更多的类质同象现象出现。

对该组样品使用了扫描电子显微镜进行分析,结果如图8所示。铬含量的增加改变了晶粒的形状,使原本的颗粒状晶粒变成了形状不规则的条状,相比铬含量较少的样品孔隙略有增加,致密度呈现下降的趋势。

2.3 硬度、耐腐蚀性能及铬浸出测试

表2为助熔剂对钙长石-透辉石系微晶玻璃硬度及耐腐蚀性的影响。助熔剂的添加显著增加了样品的硬度,对于样品的耐腐蚀性也有较好的改善。结合样品的微观形貌,这可能是因为助熔剂使样品晶粒变得更为致密,孔隙减少,因而改善了样品的硬度和耐酸碱腐蚀性能。

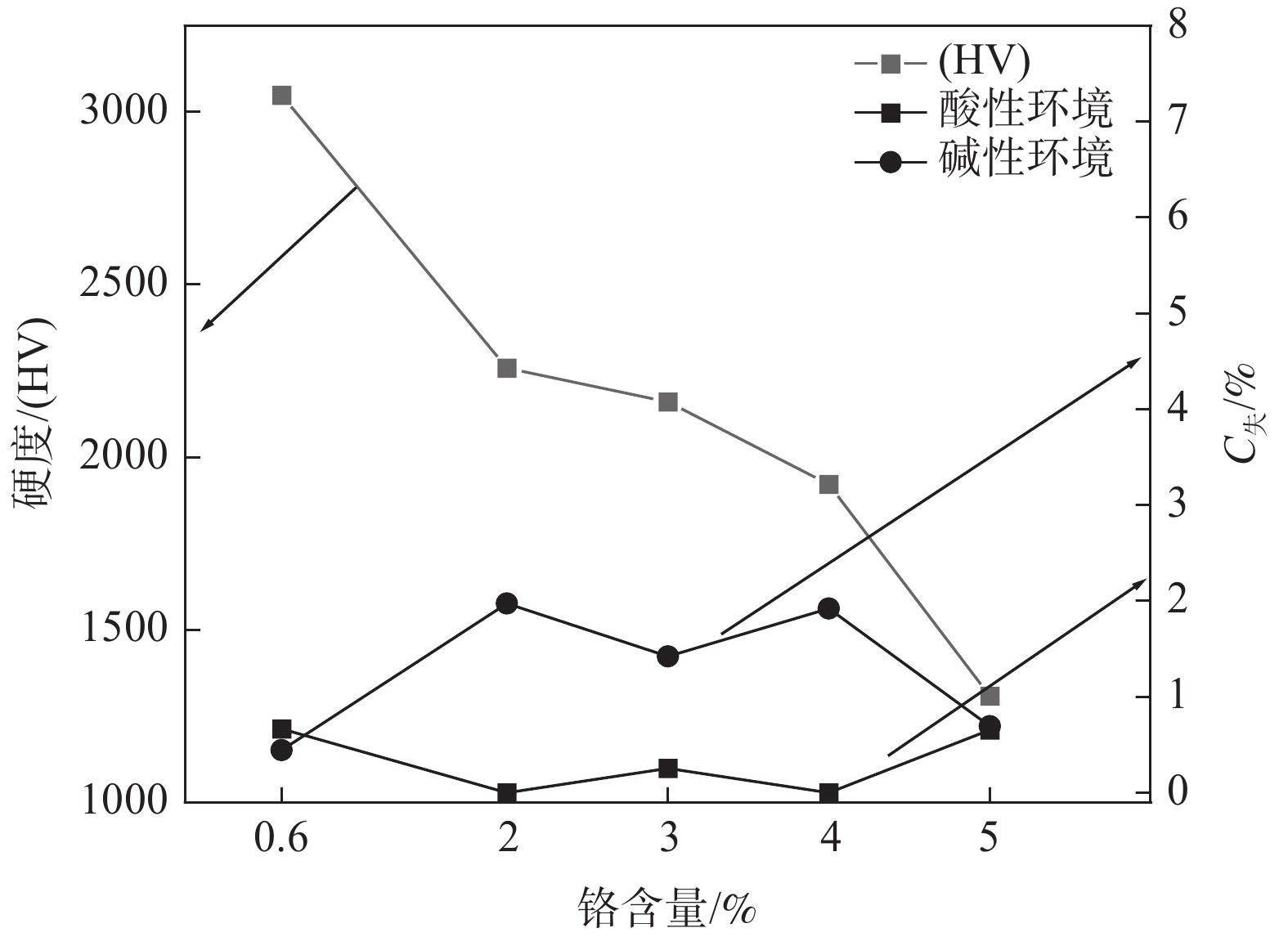

表 2 助熔剂对样品硬度及耐腐蚀性的影响Table 2. Effect of flux on hardness and corrosion resistance of samples原料 硬度(HV) 失重率/% 酸性环境 碱性环境 混合钢渣 594.3 2.97 1 助熔剂-混合钢渣 3049 0.667 0.446 图9所示为铬含量对样品硬度及耐腐蚀性能的影响。硬度测试中,铬含量的增加降低了样品的显微硬度,添加助熔剂的样品硬度达到了3000左右。耐酸碱测试中,结果表明样品的耐酸性整体优于耐碱性,随着铬含量的增加,耐酸性和耐碱性在实验条件下没有表现出较明显的趋势。结合微观形貌,铬含量的增加使得样品致密度下降,孔隙增加,这可能导致了材料的硬度和耐腐蚀性能下降。

如表3所示,铬浸出试验中,完全由钢渣制备的样品检出了0.311 mg/L的铬,其他样品均未检出铬元素。这与XRD检测结果中含铬相仅有MgCr2O4的结果相对应,MgCr2O4作为一种不溶相使该体系的微晶玻璃具有较好的固铬性能。

表 3 铬浸出试验ICP-OES测试结果Table 3. ICP-OES results of chromium leaching样品 Cr/ (mg·L−1) EAF钢渣 0.311 混合钢渣 未检出 助熔剂-混合钢渣 未检出 Cr-2% 未检出 Cr-3% 未检出 Cr-4% 未检出 Cr-5% 未检出 3. 结论

1)热力学软件FactSage 7.2的模拟相平衡计算显示,在含铬不锈钢渣制备的钙长石-透辉石体系中,铬元素首先富集在尖晶石相中。1400 ℃条件下体系对Cr的最大富集度在10%~20%。其余的铬元素以Cr2O3的形式存在。

2)与完全由不锈钢渣制备的微晶玻璃相比,配置后的钢渣制备的微晶玻璃因为生成了尖晶石相而具有更好的固铬性能,生成相与计算结果基本吻合,Cr2O3质量分数为5%的样品中含铬相也只有尖晶石。半定量分析显示体系更倾向于生成钙长石相。铬含量的增加改变了样品的微观形貌,整体由颗粒状变为了形状不规则的条状,增加了孔隙使得致密度下降。

3)添加助熔剂增加了样品的硬度,其硬度(HV)值最高达到3000 左右,铬含量的增加降低了样品的硬度。样品的耐酸性优于耐碱性,铬含量对耐腐蚀性影响不大。所有配置后的钢渣制备的样品在铬浸出试验中均未检出铬元素。

-

表 1 主要原材料的化学组成

Table 1. Chemical composition of main raw materials

成分 EAF/% 混合钢渣/% CaO 51.9213 22.1288 SiO2 28.4218 47.4188 MgO 5.8954 7.9302 Al2O3 3.0794 20.153 Cr2O3 1.4192 0.6048 Fe2O3 3.227 1.3753 MnO 0.976 0.416 表 2 助熔剂对样品硬度及耐腐蚀性的影响

Table 2. Effect of flux on hardness and corrosion resistance of samples

原料 硬度(HV) 失重率/% 酸性环境 碱性环境 混合钢渣 594.3 2.97 1 助熔剂-混合钢渣 3049 0.667 0.446 表 3 铬浸出试验ICP-OES测试结果

Table 3. ICP-OES results of chromium leaching

样品 Cr/ (mg·L−1) EAF钢渣 0.311 混合钢渣 未检出 助熔剂-混合钢渣 未检出 Cr-2% 未检出 Cr-3% 未检出 Cr-4% 未检出 Cr-5% 未检出 -

[1] Shen Huiting, Forssberg E ,Nordström Ulf . Physicochemical and mineralogical properties of stainless steel slags oriented to metal recovery[J]. Resour Conserv Recy, 2004,40(3):245−271. [2] Philip K Gbor, Valentina Mokri, Charles Q Jia. Characterization of smelter slags[J]. J Environ Sci Heal A, 2000,35(2):147−167. [3] Zhang S, Zhang Y, Wu T. Effect of Cr2O3 on the crystallization behavior of synthetic diopside and characterization of Cr-doped diopside glass ceramics[J]. Ceram Int, 2018,44:10119−10129. [4] 郭育良, 金会心, 王伟杰. 不锈钢生产中含铬固体废弃物的回收利用[J]. 中国冶金, 2021, 31(1): 81-85, 92.Guo Yuliang, Jin Huixin, Wang Weijie. Recycling of solid waste containing chromium in stainless steel production [J]. China Met, 2021, 31(1): 81-85,92. [5] Abdel-Hameed S A M , El-kheshen A A. Thermal and chemical properties of diopside-wollastonite glass-ceramics in the SiO2–CaO–MgO system from raw materials[J]. Ceram Int, 2003, 29: 265–269. [6] Rawlings R D, Wu J P, Boccaccini A R. Glass-ceramics: their production fromwastes—a review[J]. J Mater Sci, 2006,41: 733–761. [7] Eoh Y J, Kim E S. Effect of heat-treatment on the dielectric properties of CaMgSi2O6 glass-ceramics with Cr2O3–Fe2O3–TiO2[J]. Jpn J Appl Phys, 2014,53(8S3):08NB01. [8] Barbieri L, Leonelli C, Manfrenini T. Solubility, reactivity and nucleation effect of Cr2O3 in the CaO-MgO-Al2O3-SiO2 glassy system[J]. J Mater Sci, 1994,29(23):6273−6280. [9] Rezvani M, Eftekhari-Yekta B, Solati-Hashjin M, et al. Effect of Cr2O3, Fe2O3 and TiO2 nucleates on the crystallization behaviour of SiO2–Al2O3–CaO–MgO(R2O) glass-ceramics[J]. Ceram Int, 2004,31(1):75−80. [10] Baldi G, Generali E, Leonelli C, et al. Effects of nucleating agents on diopside crystallization in new glass-ceramics for tile-glaze application[J]. J Mater Sci, 1995, 30: 3251–3255. [11] Khater G A . Influence of Cr2O3, LiF, CaF2 and TiO2 nucleates on the crystallization behavior and microstructure of glass-ceramics based on blast-furnace slag[J]. Ceram Int, 2011, 37: 2193–2199. [12] He D, Gao C, Pan J, et al. Preparation of glass-ceramics with diopside as the main crystalline phase from low and medium titanium-bearing blast furnace slag[J]. Ceram Int, 2018, 44(2): 1384–1393. [13] Liu Z, Zong Y, Hou J. Preparation of slag glass ceramic from electric arc furnace slag, quartz sand and talc under various MgO/Al2O3 ratios[J]. Adv Appl Ceram, 2016, 115: 144–151. [14] Kim J, Hwang S, Sung W, et al. Thermal and dielectric properties of glass-ceramics sintered based on diopside and anorthite composition[J]. J Electroceram, 2009,23:209−213. [15] Li J L, Xu A J, He D F, et al. Effect of FeO on the formation of spinel phases and chromium distribution in the CaO-SiO2-MgO-Al2O3-Cr2O3 system[J]. Int J Min Met Mater, 2013,20(3):253−258. [16] Xu Changwei, Chen Yong, Meng Qihan, et al. Effects of fluxes on sintering and properties of CaO-MgO-Al2O3-SiO2 glass-ceramics[J]. Mater Rep, 2015,29(S2):443−445,488. (徐长伟, 陈勇, 孟琦涵, 等. 助熔剂对CaO—MgO—Al2O3—SiO2系微晶玻璃烧结和性能的影响[J]. 材料导报:纳米与新材料专辑, 2015,29(S2):443−445,488.Xv Changwei, Chen Yong, Meng Qihan, et al. Effects of Fluxes on Sintering and Properties of CaO-MgO-Al_2 O_3-SiO_2 Glass-ceramics[J]. Mater Rep, 2015, 29(S2): 443-445+488. 期刊类型引用(0)

其他类型引用(2)

-

下载:

下载:

下载:

下载: