Study on microstructure and properties of TiC-based high manganese steel bonded cemented carbide prepared by spark plasma sintering

-

摘要: 采用放电等离子烧结技术(SPS)制备含有不同TiC质量分数的硬质合金,揭示材料的显微结构对其硬度和磨损行为的影响机理,探索高TiC质量分数硬质合金作为耐磨材料的可能性。结果表明:SPS烧结可以得到组织致密的样品,TiC质量分数为55%的硬质合金孔隙率为0.07%,随着TiC质量分数的增加,硬质合金的孔隙率也随之上升,当TiC质量分数为70%时,孔隙率为0.21%。在烧结过程中,Mo在TiC颗粒周围参与形成复杂的核壳结构,Ni分布于金属粘结相中。大尺寸TiC颗粒保持原始形貌,小尺寸TiC颗粒逐渐球化,并出现颗粒富集区。硬质合金的硬度随TiC质量分数的增加而增加,TiC质量分数70%的硬质合金的显微硬度(HV)相较于TiC质量分数55%的增加559。通过摩擦磨损试验发现,TiC颗粒受到应力出现破碎与剥落,TiC质量分数55%硬质合金的磨损率最高,耐磨性最差。TiC质量分数70%硬质合金的磨损率最低,耐磨性最好。Abstract: Cemented carbides with different TiC mass fractions were prepared by spark plasma sintering (SPS) to reveal the influence mechanism of microstructure on hardness and wear behavior, and to explore the possibility of cemented carbides with high TiC mass fraction as wear-resistant materials. The results show that the sample with compact microstructure can be obtained by SPS sintering. The porosity of cemented carbide with 55% TiC mass fraction is 0.07%, and the porosity of cemented carbide increases with the increase of TiC mass fraction. In the sintering process, Mo participates in the formation of complex core-shell structure around TiC particles, and Ni distributes in the metal bonded phase. The large size TiC particles keeps their original morphology, while the small size TiC particles spheroidizes gradually and the particle enrichment area appears. The hardness of cemented carbide increases with the increase of TiC mass fraction. The microhardness (HV) of cemented carbide with 70% TiC mass fraction is 559 higher than that with 55% TiC mass fraction. The friction and wear tests show that the TiC particles are broken and spalling under stress, and the cemented carbide with 55% TiC mass fraction has the highest wear rate and the worst wear resistance. The cemented carbide with 70% TiC mass fraction has the lowest wear rate and the best wear resistance.

-

Key words:

- cermet /

- TiC /

- high manganese steel /

- spark plasma sintering /

- microhardness /

- friction and wear

-

0. 引言

硬质合金是一种由硬质相和金属(或者合金)粘结相组成的结构材料[1]。硬质合金将基体合金的金属特性(高延展性和韧性)与增强材料的陶瓷特性(高强度、高模量和耐磨性)相结合,从而提高了合金的剪切和压缩强度,并且具有更高的工作温度[2]。TiC具有低密度、高熔点、极高的硬度、高抗氧化性、耐磨性等特点并且可以与Fe基合金稳定结合,是一种优秀的复合材料增强体,近年来备受关注。TiC基高锰钢结硬质合金是一种广泛使用的钢结硬质合金,因其独特的性能而广泛应用于石油和水泥生产、矿山勘探和煤炭开采领域[3]。传统真空烧结由于成分及工艺等方面原因生产的TiC基高锰钢结硬质合金的性能尚不理想,特别是其关键指标孔隙率过高,严重制约了该复合材料在航天、航海等行业特殊工况下的应用[4]。

放电等离子烧结技术(Spark Plasma Sintering,简称SPS)是一种新工艺,通过该工艺,陶瓷粉末可以在较低的温度和较短的保温时间下快速烧结至近乎全密度。SPS的最大优点是,由于粒子表面的氧化层可以通过粒子之间的火花等离子体去除,生胚的致密烧结可以在短时间内完成,而不会出现显著的晶粒生长,SPS制备TiC硬质合金越来越受到人们的关注。Zhang[5]等人通过研究不同烧结方式对50TiC-10TiN-30Ni-6Mo-4C复合材料性能的影响,发现 SPS可以在较短的时间内和较低的烧结温度下获得良好的综合力学性能。Zheng[6]等人通过SPS烧结制备了33TiC-10TiN-32Ni-16Mo-6.9WC-1.5C-0.6Cr3C的硬质合金,添加纳米添加剂可以显著提高硬质合金的硬度并降低生产成本。此外Han[7]通过SPS技术获得了一种新型晶内/晶间型TiC基硬质合金,该复合材料有望成为一种性能优良的刀具制造材料。

以上研究的硬质合金中TiC的质量分数多在50%以下,关于高TiC质量分数硬质合金的研究较少,且随着TiC质量分数的增加,传统真空烧结难以制备致密的硬质合金。SPS在烧结过程中对液相施加轴向的压力,能有效降低样品的孔隙率,使用SPS制备高TiC质量分数硬质合金的研究也鲜有报道。笔者采用SPS烧结工艺,探索制备高TiC质量分数硬质合金。此外,利用SEM及对应能谱对其成分与显微结构进行分析,揭示不同TiC质量分数下材料的显微组织对硬度和磨损性能的影响规律。

1. 试验原料及方法

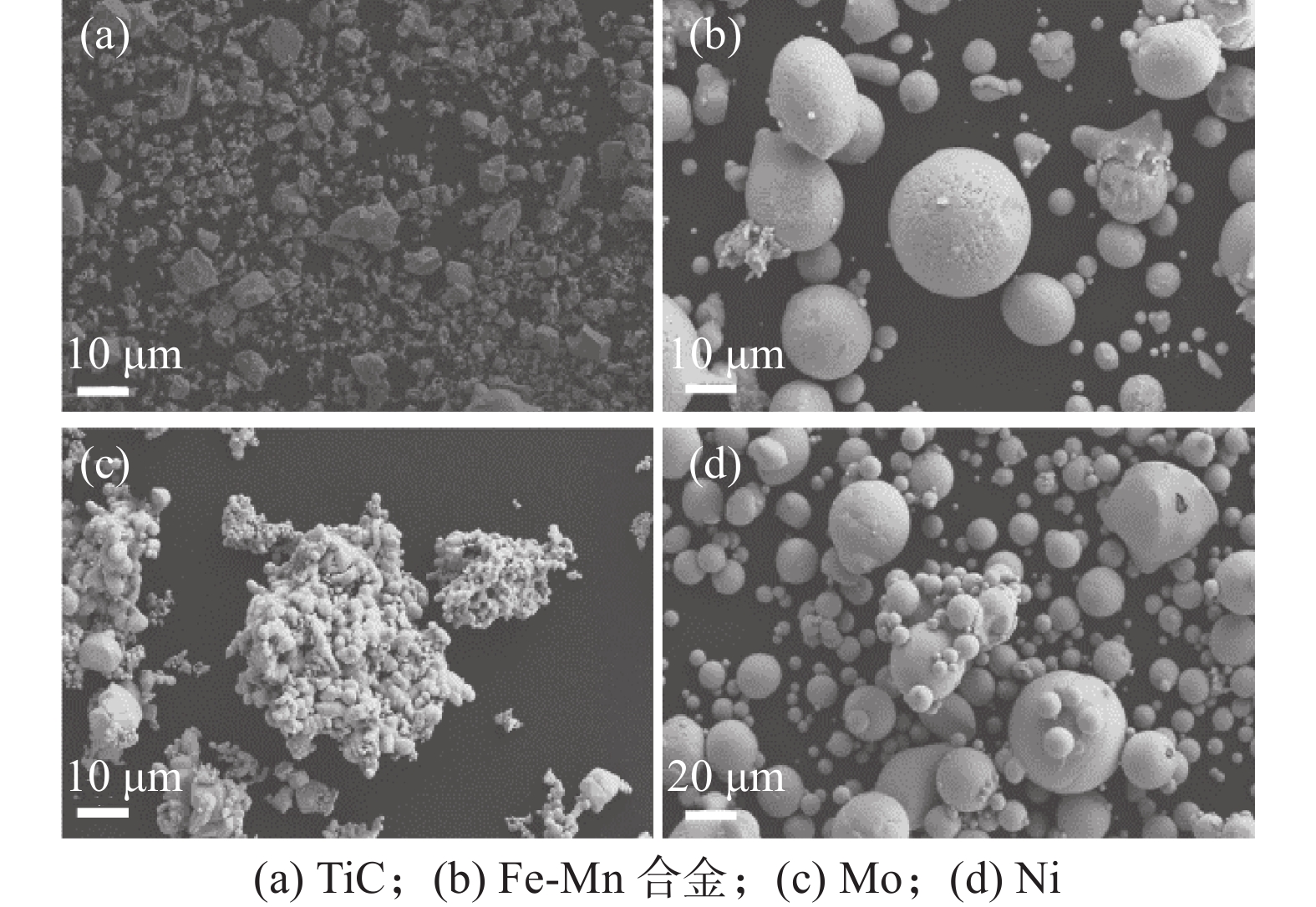

考虑到TiC质量分数过高时,硬质相与粘结相难以形成均匀的硬质合金,因此设计了55% 、60%、65% 和70%四种TiC质量分数的硬质合金,采用SPS烧结工艺,探索制备高TiC质量分数硬质合金。制备方法如下:将原料粉末称重并混合,不同TiC质量分数的混合粉末成分及配比见表1。图1为原始粉末的形貌。TiC粉末纯度为99.0%,粒径为2~10 μm。混合粉末在行星球磨机(QM-3SP4)中湿磨10 h,湿磨介质为乙醇,磨球材质为不锈钢。行星球磨机的转速为150 r/min,磨球与粉末的重量比为4∶1,研磨后的粉末在干燥箱中于70 ℃干燥4 h。对于传统真空烧结,有文献指出[5]硬质合金粉末1300 ℃下烧结样品孔隙率高达25.41%,而SPS法可以获得组织致密的样品[7]。对于SPS工艺,将混合粉末放入石墨模具(直径20 mm)中,使用SPS系统(山东广和SPS-30)在真空中烧结。施加的单轴压力为40 MPa,升温速率为100 ℃/min,真空度为1×10−3 Pa,并在1400 ℃的烧结温度下保温保压10 min。

表 1 金属基TiC陶瓷的成分配比Table 1. Composition ratio of metal-based TiC ceramics% 编号 TiC Ni Mo Fe-Mn A 55 2 2 余量 B 60 2 2 余量 C 65 2 2 余量 D 70 2 2 余量 所有金相试样均采用标准抛光技术制备,处理后样品的显微组织采用光学显微镜(徕卡DMI3000)和配有能谱的扫描电子显微镜(Carl Zeiss Gemini300)进行表征。摩擦磨损所用试验仪器为往复式摩擦磨损仪。加载力为50 N,频率5 Hz,时间1800 s,磨痕单次行程6 mm,磨球材质为氮化硅,磨球直径4 mm。使用显微硬度仪(EM-1500L)检测复合材料的显微硬度,加载力为4.9 N,加载时间10 s,取点间隔为10 µm,共取20个点,所得结果取平均值。通过对材料组织与性能的分析,揭示显微组织中不同TiC质量分数对复合材料磨损性能的影响。

2. 结果与讨论

2.1 硬质合金的显微组织

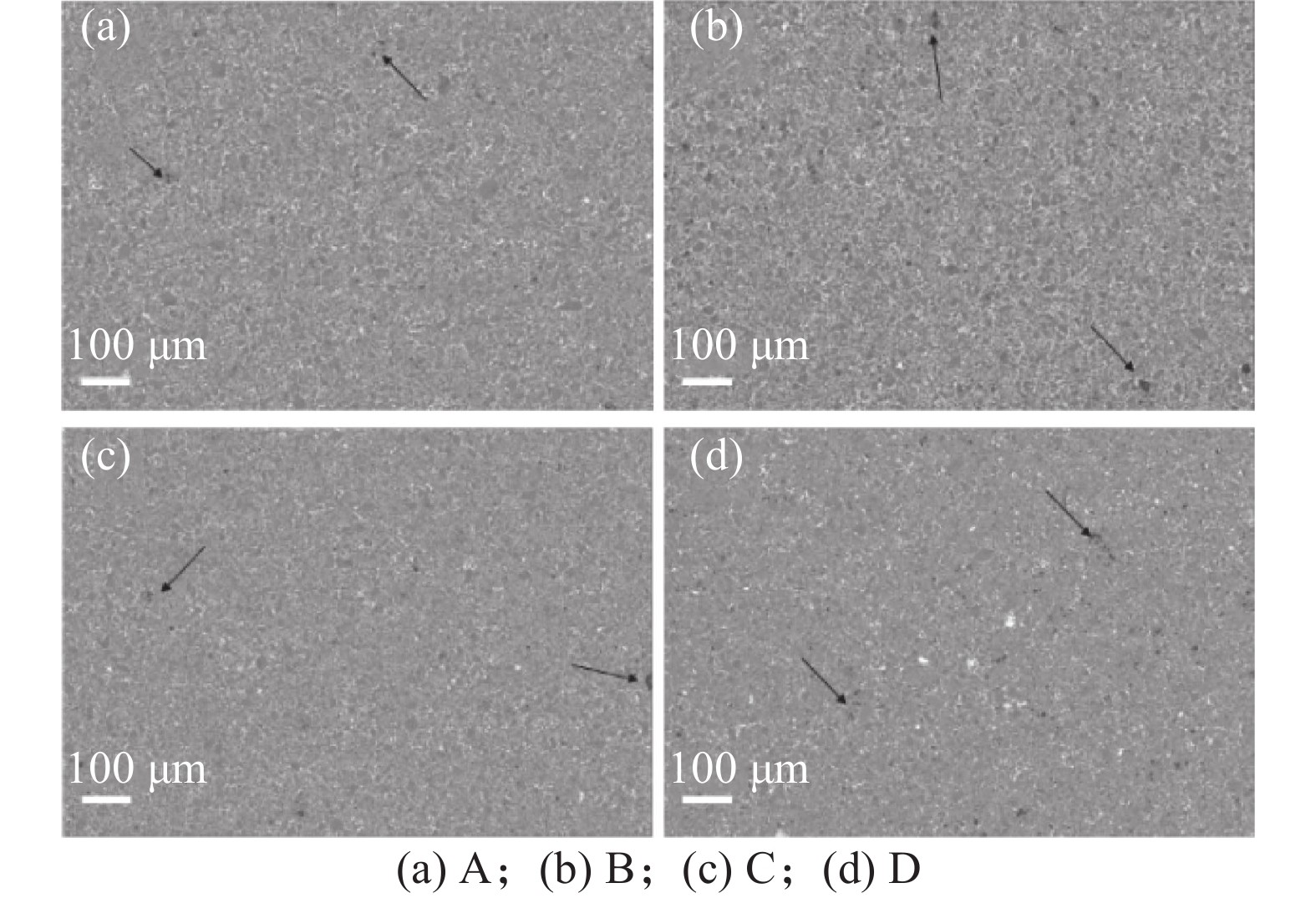

图2为不同TiC质量分数硬质合金的组织形貌。硬质合金的显微组织主要由灰色TiC颗粒和白色高锰钢两相构成。图2中箭头所指区域为孔隙,随着TiC质量分数的增加,复合材料的孔隙率略有增加。TiC质量分数55%的硬质合金孔隙率仅为0.07%,当TiC质量分数为70%时,孔隙率为0.21%。在烧结过程中,液相会受到轴向的压力向下流动,从而填补烧结时产生的气孔,同时较长的保温时间有助于液相完全扩散和浸润,减少了孔隙的产生。当TiC质量分数增加时,液相高锰钢难以完全填补孔隙,孔隙率增加。

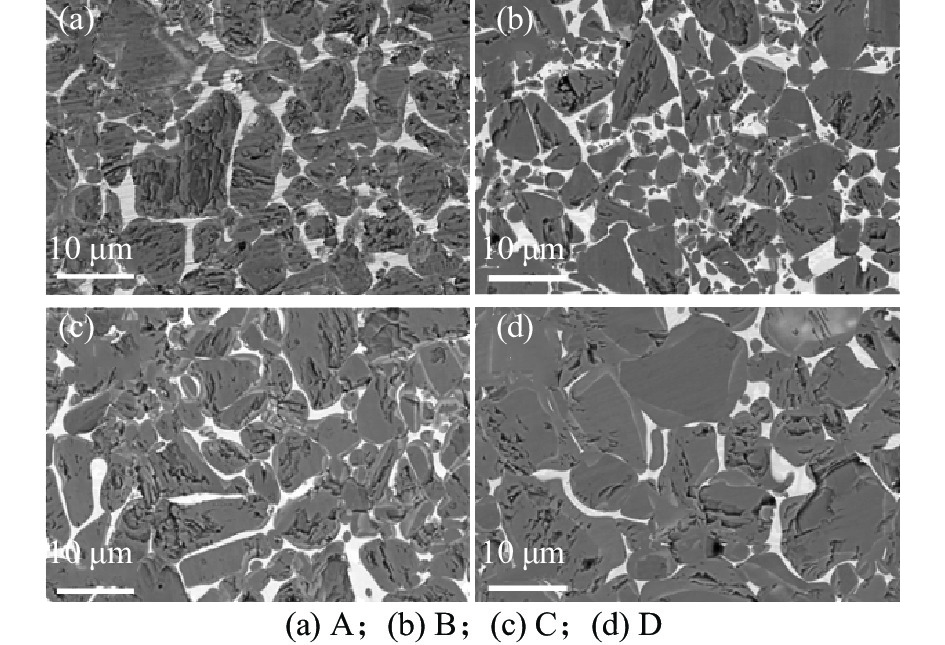

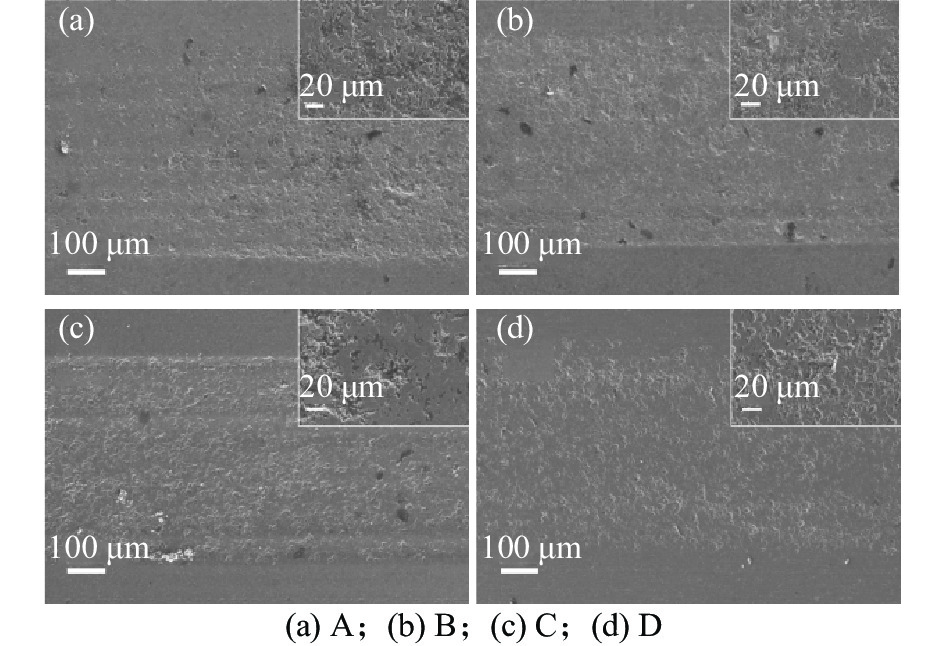

除孔隙率之外,复合材料中增强相的粒度及空间分布也是造成性能差异的主要因素之一。图3为不同TiC质量分数下硬质合金高倍数SEM组织形貌。质量分数为55%和60%TiC的硬质合金中TiC颗粒分布均匀,如图3(a)和(b)所示。当TiC质量分数增加,图(c)TiC出现小颗粒的富集区。当TiC质量分数达到70%时,大小颗粒发生明显团聚,颗粒分布不均匀。

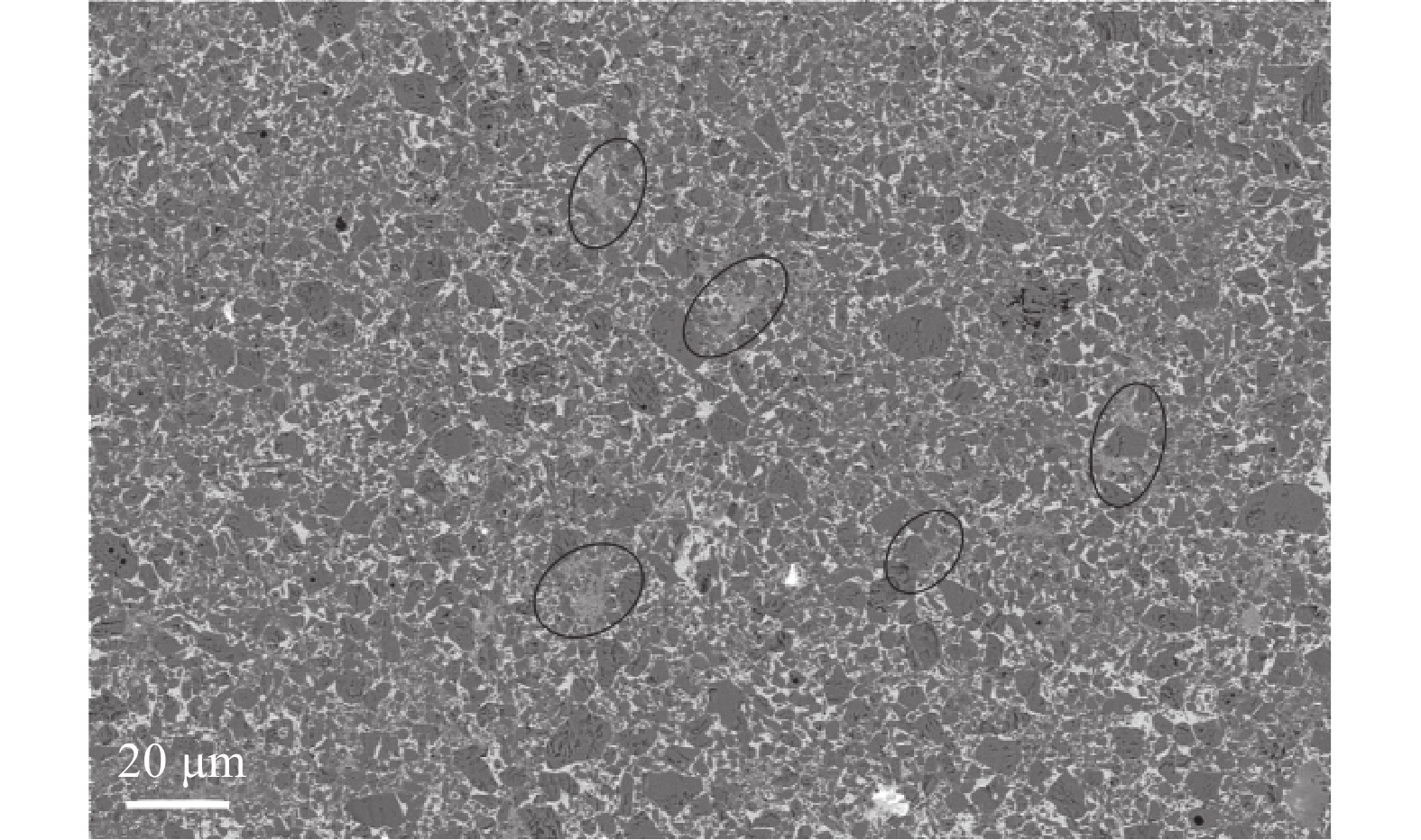

图4为硬质合金B的TiC颗粒富集区。图4中用黑色圆圈标记的区域为TiC颗粒的富集区。随着TiC质量分数的增加,复合材料中小尺寸的TiC富集区增加。颗粒富集区被视为一个大颗粒,能承受外部施加的载荷。当裂纹扩展到TiC颗粒富集区时,大颗粒TiC迫使裂纹改变扩展方向,并能持续穿过高锰钢材料。在裂纹穿透阶段,合金的基体对韧性的提高起着主导作用。在断裂阶段,合金的硬质相特征、颗粒形状和尺寸起主导作用。TiC颗粒尺寸较大,颗粒形状呈棱角状,应力导致TiC颗粒断裂,合金的断裂强度大大提高,TiC的刚度远高于高锰钢,在断裂过程中可消耗更多的能量。

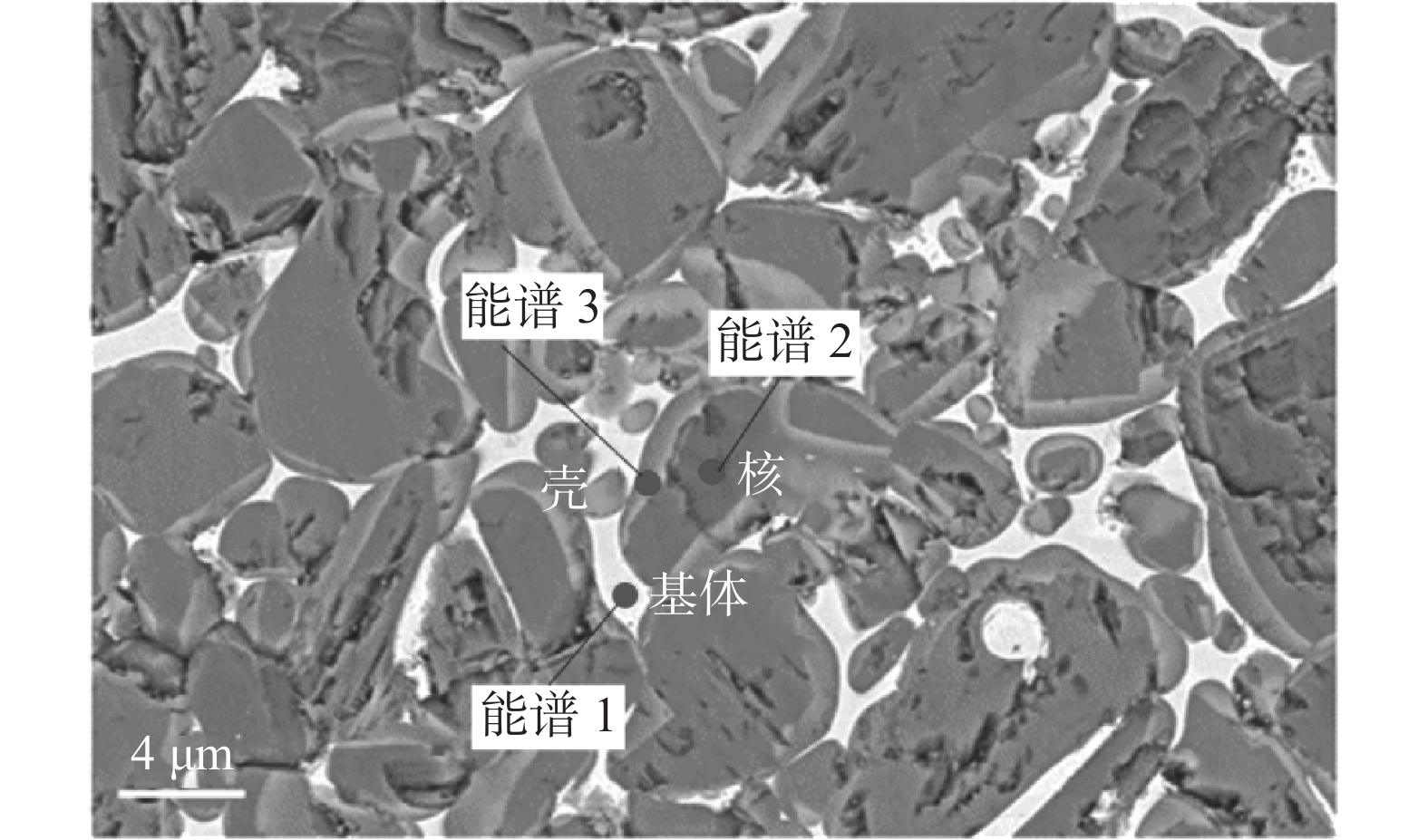

图5为硬质合金B的核壳结构。核壳结构的形成十分复杂,主要为烧结过程中固相的扩散机制以及液相的沉淀溶解机制。图5中尺寸较小的TiC颗粒逐渐球化,而较大尺寸的颗粒大多仍保持原始的形貌。在烧结过程中,TiC颗粒的形状会受到基体成分、加热温度及保温时间的影响。从热力学和动力学的角度看,在一定温度下加热时,形状不规则、曲率半径小的TiC粒子边缘比曲率半径大的TiC粒子边缘具有更大的表面能,更容易溶解到液体基体中。随着溶解速度的加快,TiC颗粒由不规则形状向近似球形转变。同时会有小尺寸的TiC颗粒缺失并被液态基体所取代。随着温度的降低,基体中TiC的溶解减少,发生了析出反应。析出的TiC先在未完全溶解的TiC粒子边缘或易成核的地方成核,影响TiC颗粒的分布和粒径。

对图5中核壳结构区域进行 EDS 分析,结果如表2所示,通过EDS能谱发现Mo沉积在TiC颗粒周围。在烧结过程中Mo会与基体中的C反应生成Mo2C,并在温度达到1200 ℃时溶于基体。在冷却时溶解在基体中的Mo2C会逐渐沉积到陶瓷颗粒表面并和原始的陶瓷颗粒形成复杂的核壳结构。核壳结构表明Mo可以在TiC颗粒边缘均匀分布,通过包覆TiC颗粒降低液体基质与TiC颗粒之间的接触角,改善TiC颗粒与基体金属的润湿性[8-13]。Mo可以降低TiC在基质中的溶解度,细化晶粒。Ni溶于高锰钢的基体,不与Mo结合生成核壳结构,Ni可以防止碳化物团聚,溶于基体时可以细化晶粒并提高合金的力学性能。有文献指出[14],添加Ni粉可以显著改善材料的耐磨性及韧性。

表 2 硬质合金B核壳结构EDS原子比能谱Table 2. EDS atomic specific energy spectrum of cermet B core-shell structure% C Ti Cr Mn Fe Ni Mo 总量 谱图3 52.10 40.19 0.85 4.62 2.23 100.00 谱图2 45.70 7.78 0.38 5.50 37.55 3.09 100.00 谱图1 54.51 45.26 0.22 100.00 2.2 硬质合金材料的显微硬度

硬质合金A的显微硬度(HV,下同)为2146,硬质合金B的显微硬度为2369,硬质合金C的显微硬度为2430,硬质合金D的显微硬度为2723,与A相比,硬质合金D的显微硬度增加559 。硬质合金的显微硬度随着TiC质量分数的增加而增加。显微硬度为单位面积所受载荷大小,当TiC质量分数增加,单位面积下TiC所占面积增加,由于高锰钢基体显微硬度小于TiC,硬质合金显微硬度增加。

2.3 硬质合金材料的摩擦磨损

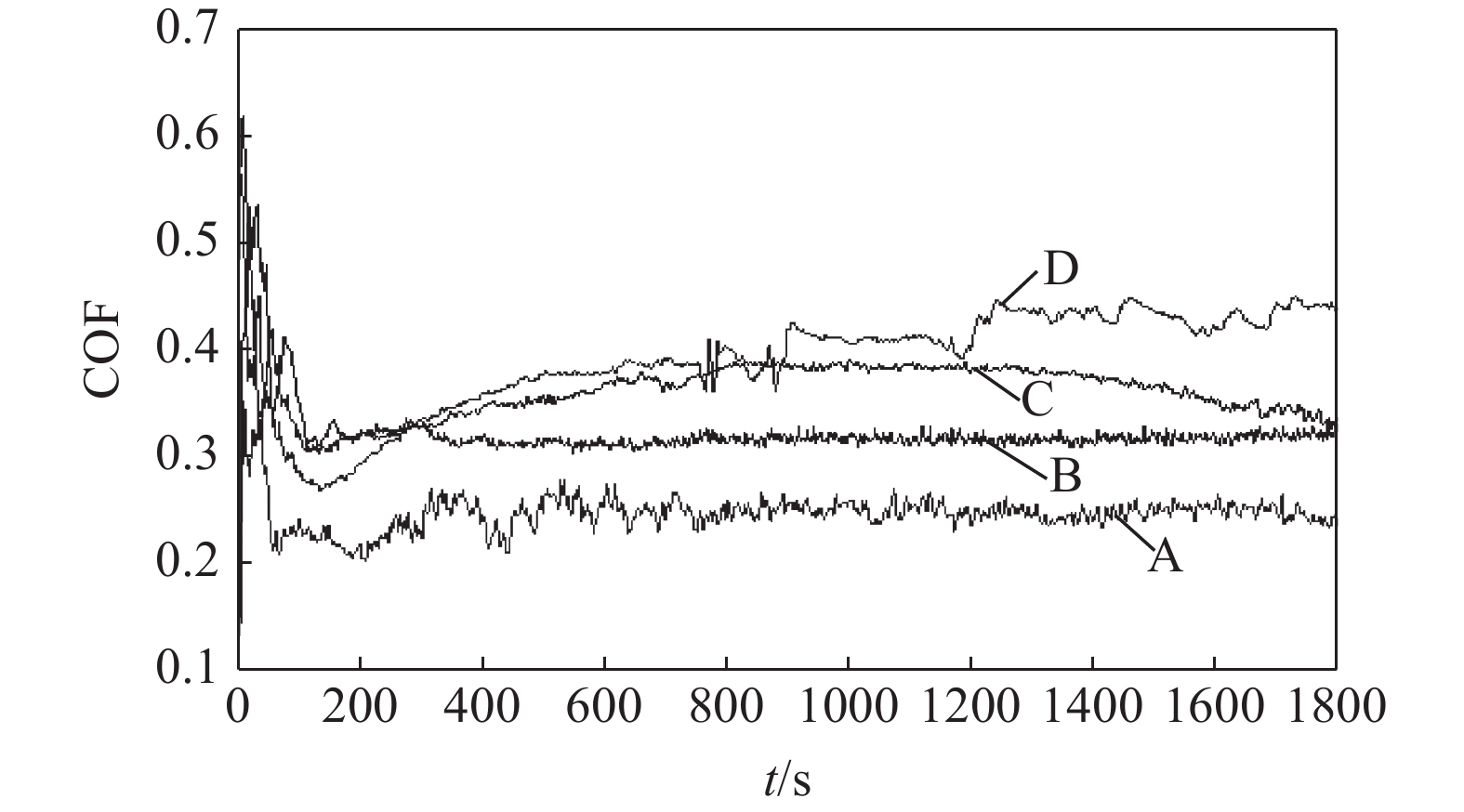

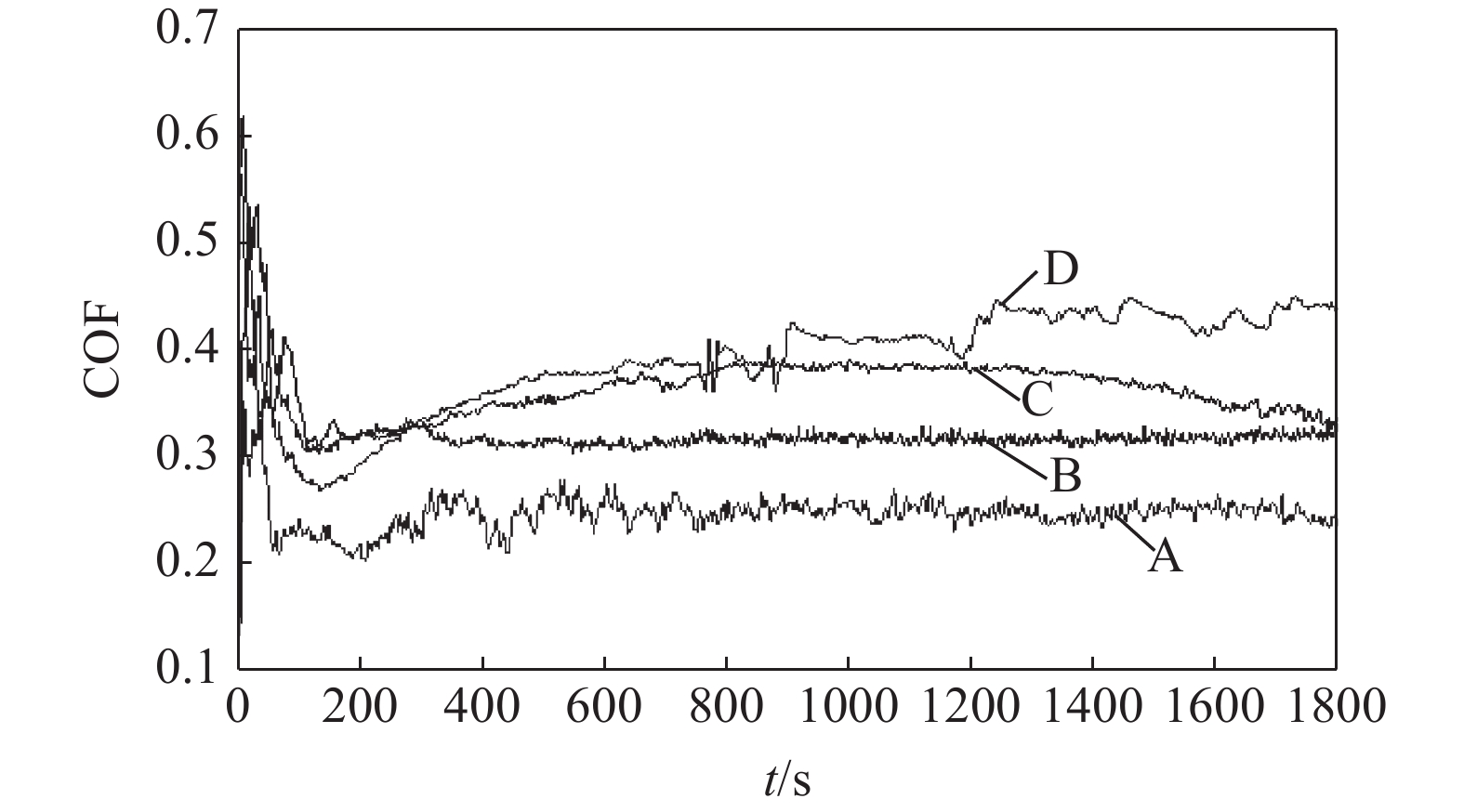

图6为不同TiC质量分数下硬质合金的摩擦系数。TiC质量分数为55%的摩擦系数最低。不同TiC质量分数复合材料的摩擦系数均呈现先突变增加后急剧减小。摩擦系数反映材料表面形貌、接触形式及载荷和滑动速度间的相互作用。摩擦系数不仅与基体组织还与表面粗糙度有很大关系。在摩擦试验开始阶段,样品表面粗糙,摩擦系数急剧增加。随着摩擦的进行,A,B摩擦系数逐渐趋向稳定。TiC质量分数为70%时,样品硬度最高,摩擦时导致高锰钢流失,TiC颗粒未发生破碎与崩裂,表面粗糙度增加,摩擦系数增加。

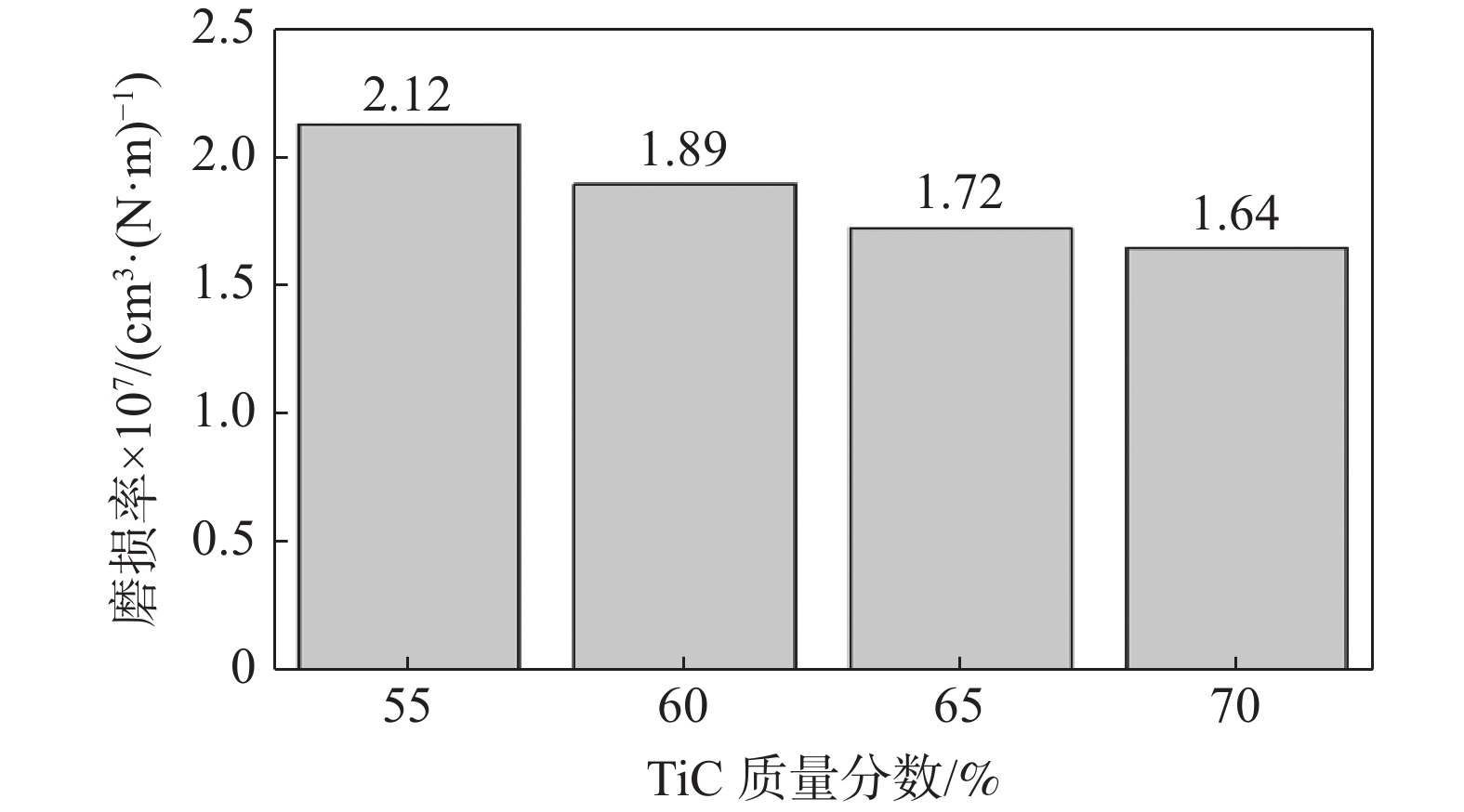

图7为不同TiC质量分数硬质合金的磨损率。磨损率计算公式为:

$$ K=V/PS $$ 其中, K 为磨损率,cm3/(N·m);V为磨损量,cm3;P 为法向载荷,N;S 为摩擦行程,m。

磨损率越低,硬质合金的耐磨性越好。磨损率随TiC质量分数的增加呈相反趋势,TiC质量分数为55%的硬质合金的磨损率最高。由于硬质TiC颗粒的增加,从而提高了硬度并减少了硬质合金与磨球的实际接触面积,磨损率随实际接触面积的减小而降低。

图8为不同TiC质量分数硬质合金磨损表面形貌。硬质合金在摩擦磨损过程中均出现TiC颗粒的破碎与剥落。图8(a)、(b)中黑色位置为摩擦后TiC颗粒破碎留下的坑洞。图8(a)、(b)、(c)可看到清晰的磨痕边界,图8(d)磨痕边界较为模糊。随着TiC质量分数的增加,陶瓷颗粒的破碎与剥落逐渐减小。硬质合金发生明显塑性变形,TiC颗粒崩碎后留下较大的坑洞,TiC颗粒的破碎带动周围的基体发生剥落。质量分数为70%的硬质合金摩擦性能最好,如图8(d)所示,由于TiC质量分数最高,颗粒富集的区域增多,同时硬度增加,磨球与试样的实际接触面积减小,硬质合金更耐磨。

试样在载荷作用下,高锰钢发生塑性变形,合金缺陷从孔隙处向前生长扩散,当缺陷移动到TiC相颗粒边缘时,在局部产生较高的应力集中。当应力高于TiC颗粒的断裂强度时,TiC颗粒断裂,高锰钢与TiC之间的结合强度不高,TiC与高锰钢之间的界面在外力作用下随TiC颗粒的断裂成片状剥落。

3. 结论

1)通过SPS制备高TiC质量分数的硬质合金。烧结后的硬质合金中TiC颗粒分布均匀,样品致密度良好,TiC质量分数55%的孔隙率为0.07%,TiC质量分数70%的孔隙率为0.21%。随TiC质量分数的增加,硬质合金孔隙率上升且出现TiC富集区,TiC质量分数为70%时TiC发生团聚。

2)Mo促使TiC颗粒表面形成复杂的核壳结构,Ni溶解于高锰钢基体。在烧结过程中,粒径较小的TiC颗粒逐渐球化,大尺寸颗粒保持原始形状。

3)随TiC质量分数增加,TiC质量分数70%的硬质合金显微硬度(HV)比TiC质量分数55%的增加559 。通过摩擦磨损试验发现,TiC颗粒受到应力出现破碎与剥落,TiC质量分数为55%的硬质合金磨损率最高,耐磨性最差,TiC质量分数70%的硬质合金耐磨性最好。实际应用中,TiC质量分数70%的硬质合金作为预制体制备耐磨部件,可显著提高耐磨性。

4)与低TiC含量的硬质合金相比,高TiC含量的硬质合金耐磨性更好。下一步可尝试制备TiC质量分数为75%与80%的硬质合金,并通过摩擦磨损与三体磨损测试其耐磨性能,探索更高TiC质量分数硬质合金作为耐磨部件的可能性。

-

表 1 金属基TiC陶瓷的成分配比

Table 1. Composition ratio of metal-based TiC ceramics

% 编号 TiC Ni Mo Fe-Mn A 55 2 2 余量 B 60 2 2 余量 C 65 2 2 余量 D 70 2 2 余量 表 2 硬质合金B核壳结构EDS原子比能谱

Table 2. EDS atomic specific energy spectrum of cermet B core-shell structure

% C Ti Cr Mn Fe Ni Mo 总量 谱图3 52.10 40.19 0.85 4.62 2.23 100.00 谱图2 45.70 7.78 0.38 5.50 37.55 3.09 100.00 谱图1 54.51 45.26 0.22 100.00 -

[1] Lu Qingzhong, Zhang Furun, Yu Lixin. The condition and trend of Ti(C, N) cermet[J]. Journal of Wuhan Institute of Science and Technology, 2002,(5):42−46. (陆庆忠, 张福润, 余立新. Ti(C, N)基硬质合金的研究现状及发展趋势[J]. 武汉科技学院学报, 2002,(5):42−46. [2] Prava Dalai R, Das S, Das K. Development of TiC reinforced austenitic manganese steel[J]. Canadian Metallurgical Quarterly, 2014,53(3):317−325. doi: 10.1179/1879139514Y.0000000140 [3] Ning Jiapei, Zheng Kaihong, Wang Juan, et al. Microstructure and abrasive wear properties of TiC-reinforced hadfield steel matrix composites[J]. Rare Metal Materials and Engineering, 2020,49(7):2407−2416. (宁嘉沛, 郑开宏, 王娟, 等. TiC增强高锰钢基复合材料的组织与磨料磨损性能[J]. 稀有金属材料与工程, 2020,49(7):2407−2416. [4] 熊拥军, 李溪滨, 刘如铁, 等. 新型TiC钢结硬质合金致密化技术[J]. 中南大学学报(自然科学版), 2009, 40(6): 1563-1567.Xiong Yongjun, Li Xibin, Liu Rutie, et al. Densification processing of a new steel bonded titanium carbide[J]. Journal of Central South University (Science and Technology), 2009, 40(6): 1563-1567. [5] Zhang M, Yang Q, Xiong W, et al. Effect of vacuum-sintering temperature on magnetic and mechanical properties of TiC-TiN-Ni-Mo-C cermets[J]. Metallurgical and Materials Transactions A, 2018,49(8):3550−3555. doi: 10.1007/s11661-018-4659-3 [6] Zheng Y, Wang S, You M, et al. Fabrication of nanocomposite Ti(C, N)-based cermet by spark plasma sintering[J]. Materials Chemistry and Physics, 2005,92(1):64−70. doi: 10.1016/j.matchemphys.2004.12.031 [7] Han C, Kong M. Fabrication and properties of TiC-based cermet with intra/intergranular microstructure[J]. Materials & Design, 2009,30(4):1205−1208. [8] Zhou S, Zhao W, Xiong W. Microstructure and properties of the cermets based on Ti(C, N)[J]. Int. J. Refract Met. Hard Mater., 2009,27:26−32. doi: 10.1016/j.ijrmhm.2008.01.011 [9] Xiong J, Guo Z X, Shen B L, et al. The effect of WC, Mo2C, TaC content on the microstructure and properties of ultra-fine TiC 0.7 N 0.3 cermet[J]. Mater. Design., 2007,28(5):1689−1694. doi: 10.1016/j.matdes.2006.03.005 [10] Stewart T L, Plucknett K P. The effects of Mo2C additions on the microstructure and sliding wear of TiC0.3N0.7-Ni3Al cermets[J]. Int. J. Refract. Met. Hard Mater., 2015,50:227−239. doi: 10.1016/j.ijrmhm.2015.01.013 [11] Liu C, Lin N, He Y H. Influence of Mo2C and TaC additions on the microstructure and mechanical properties of Ti(C, N)-based cermets[J]. Ceram. Int., 2016,42(2):3569−3574. doi: 10.1016/j.ceramint.2015.10.168 [12] Wan W C, Xiong J, Li Y H, et al. Erosion-corrosion behavior of Ti(C, N)-based cermets containing different secondary carbides[J]. Int. J. Refract. Met. Hard Mater., 2017,66:180−187. doi: 10.1016/j.ijrmhm.2017.03.018 [13] Shin S G, Lee J H. Effect of carbide additions on grain growth in TiC-Ni cermets[J]. Met. Mater. Int., 2006,12(1):57−62. doi: 10.1007/BF03027524 [14] Li Y, Hu J, Wang H, et al. Study of TiC/Ni3Al composites by laser ignited self-propagating high-temperature synthesis (LISHS)[J]. Chemical Engineering Journal, 2008,140(1-3):621−625. doi: 10.1016/j.cej.2007.11.034 期刊类型引用(0)

其他类型引用(1)

-

下载:

下载:

下载:

下载: