Ferrite grain size control of dual phase steel and its effect on mechanical properties and hydrogen diffusion properties

-

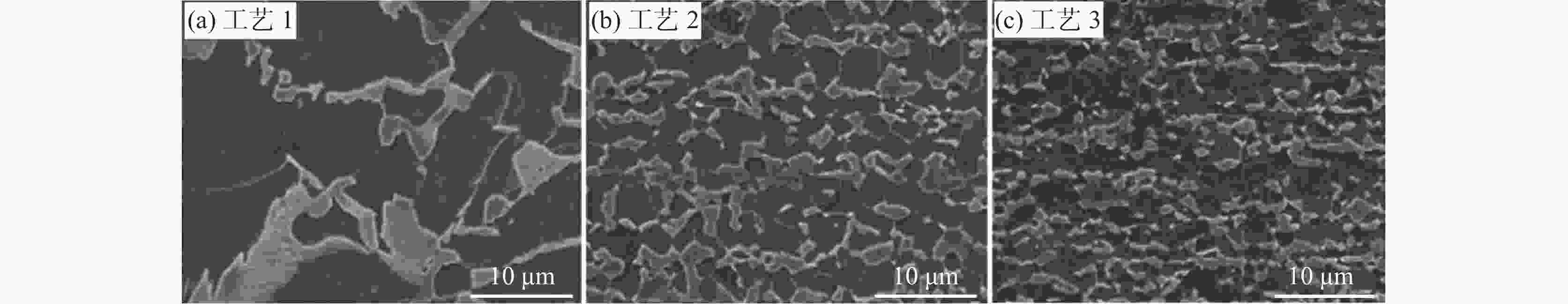

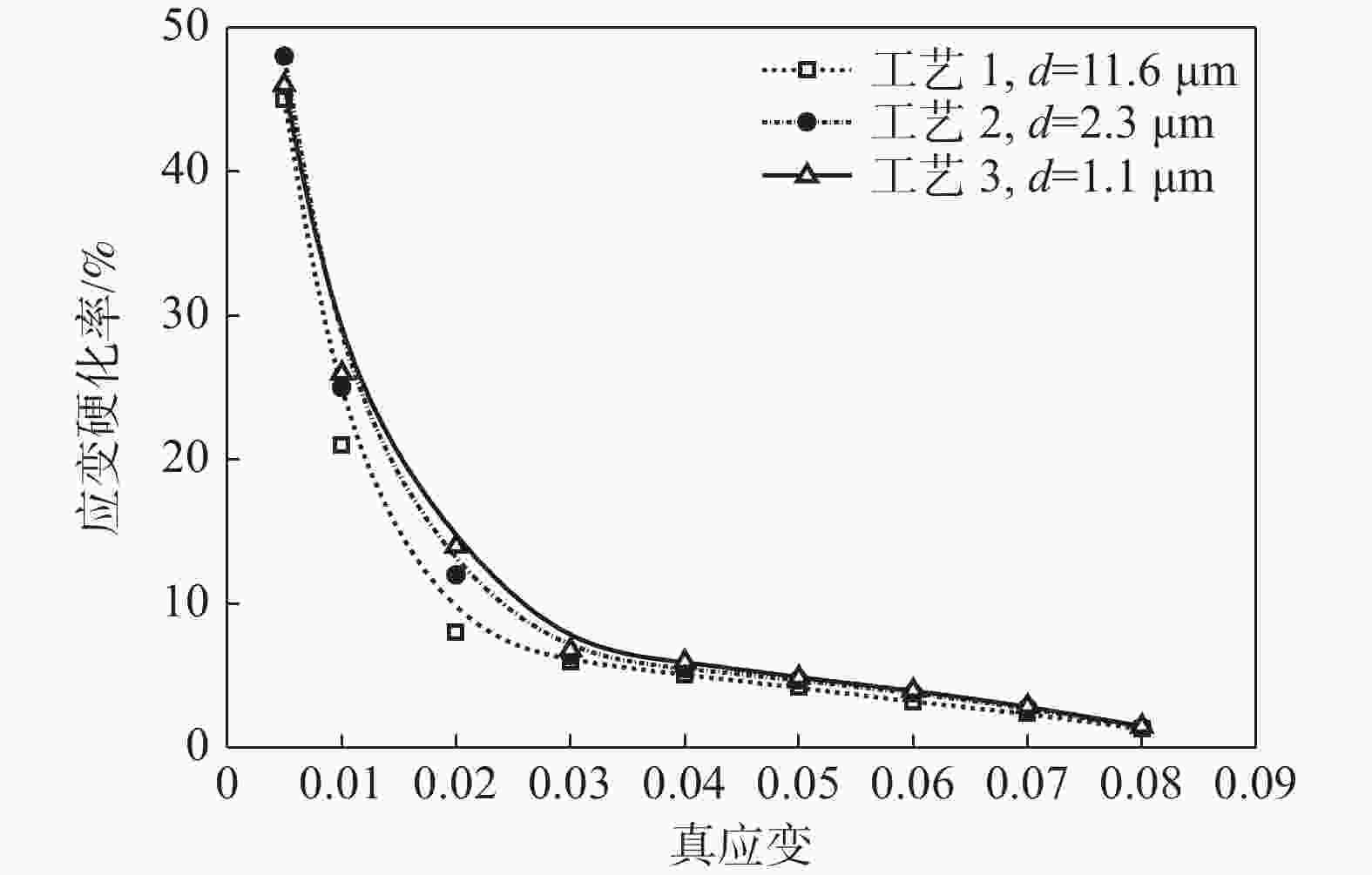

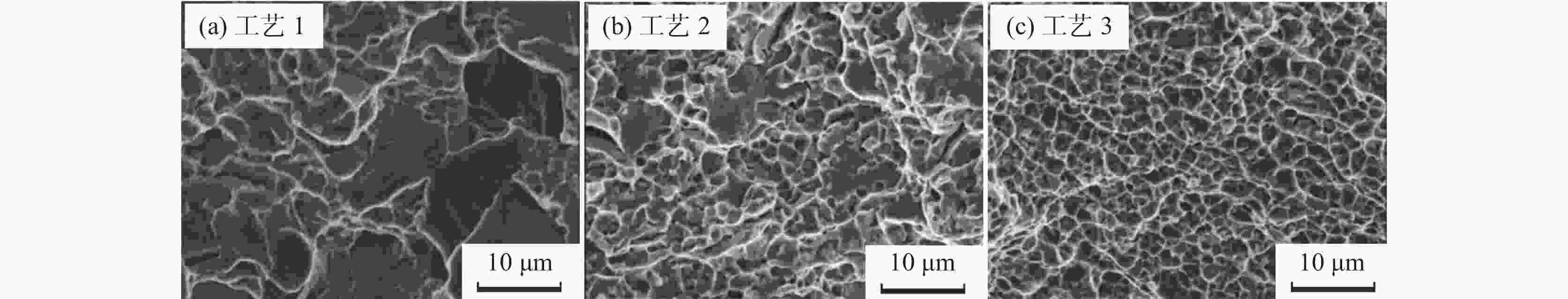

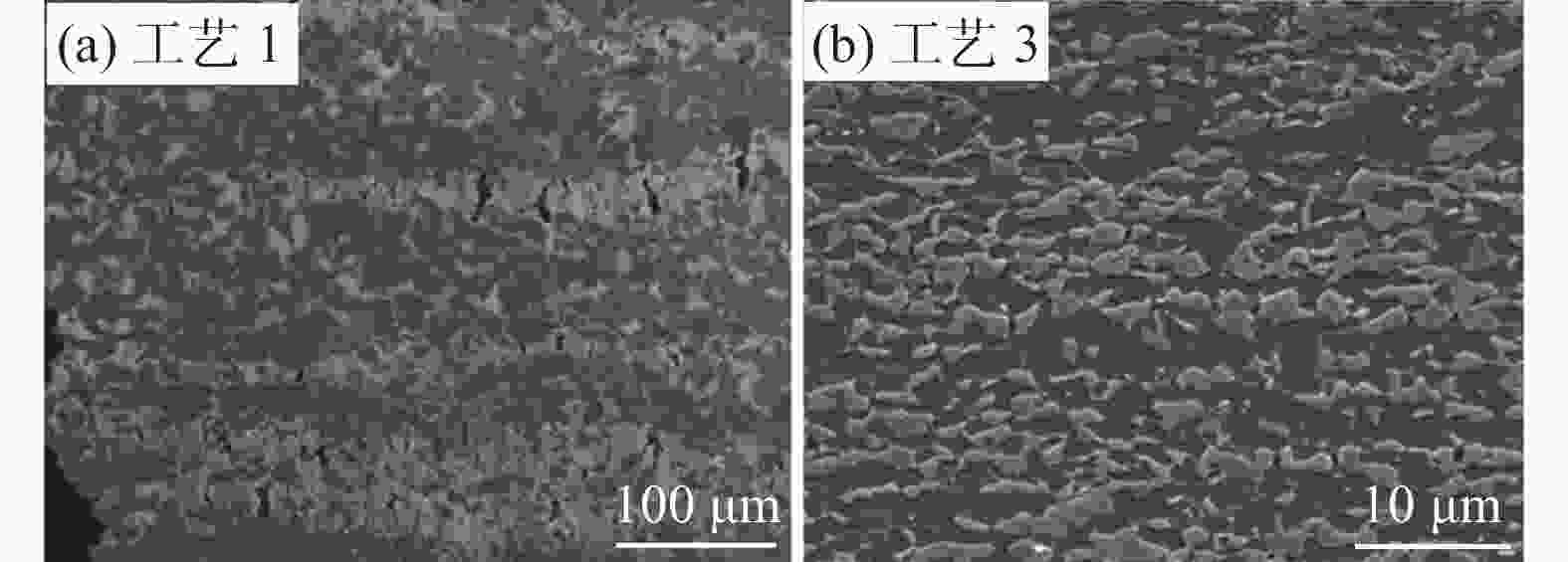

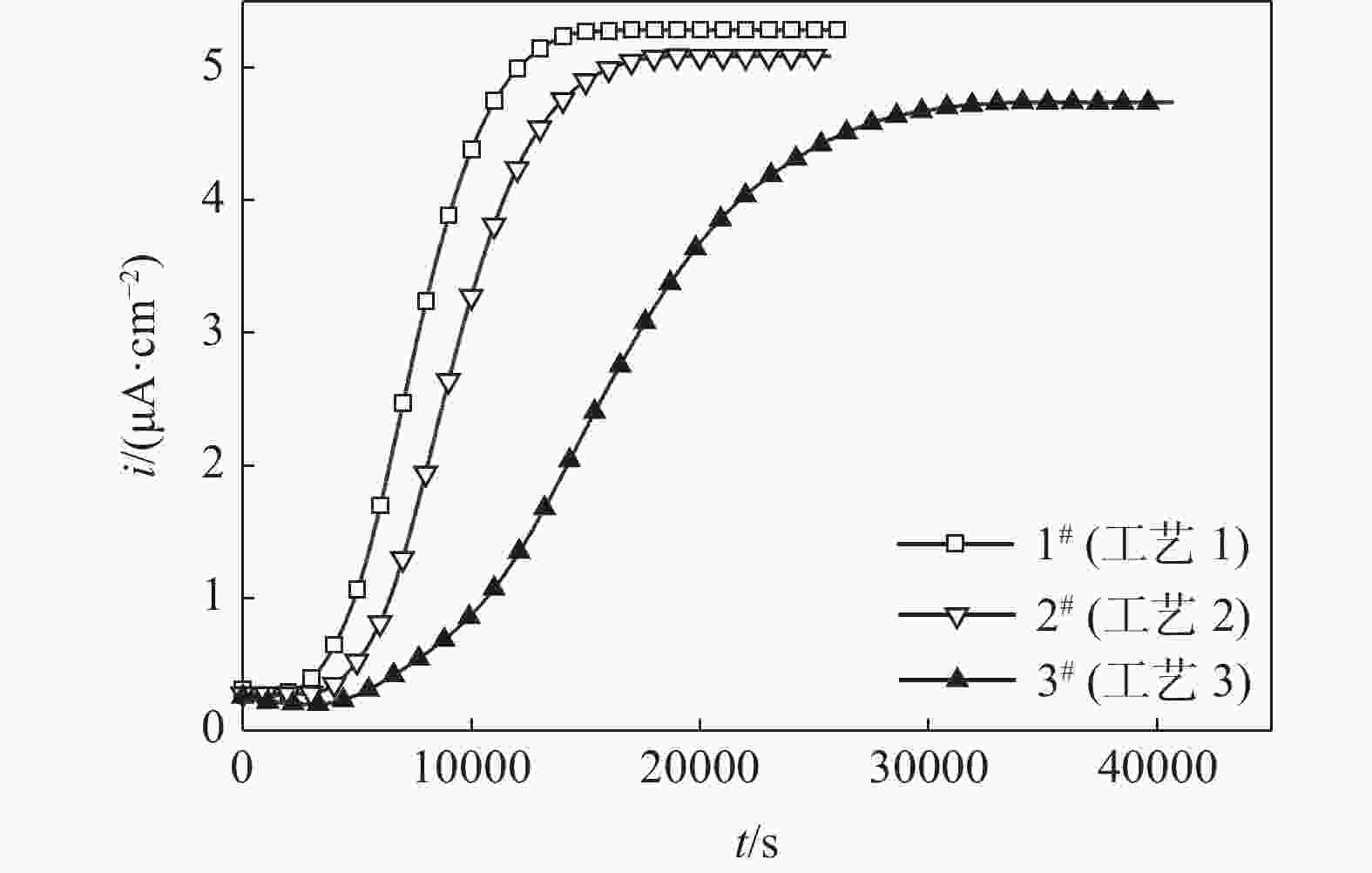

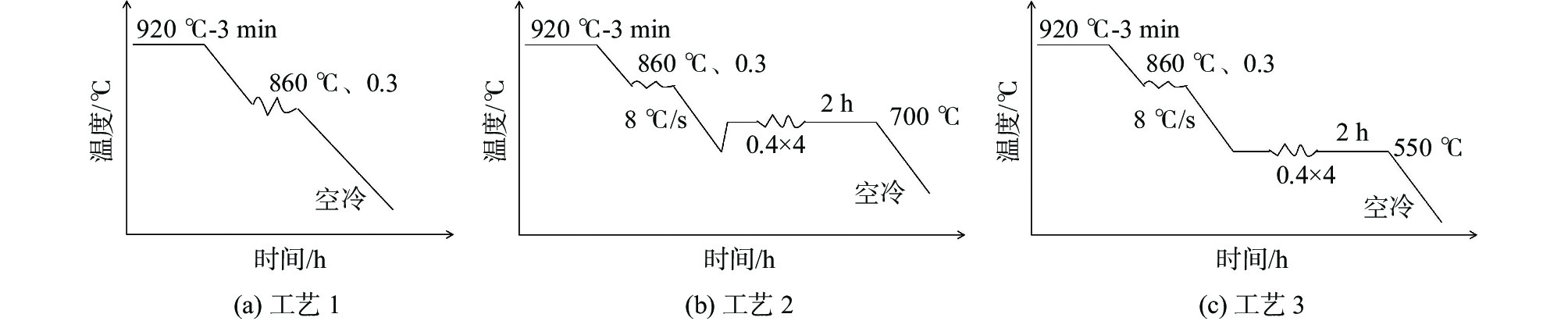

摘要: 通过920 ℃两相区奥氏体化3 min+形变热处理的热模拟工艺制备了三种不同马氏体晶粒尺寸的铁素体-马氏体双相钢,利用扫描电子显微镜、透射电子显微镜和拉伸试验对三种不同铁素体晶粒度的铁素体-马氏体双相钢的显微组织和力学性进行了表征,利用氢渗透试验对其氢扩散行为进行研究。结果表明:在同一马氏体含量水平(约30%)下,随着双相钢铁素体晶粒尺寸由11.6 μm下降至2.3 μm和1.1 μm,铁素体-马氏体材料的屈服强度和抗拉强度显著增大,其中抗拉强度由865 MPa增大至965 MPa和1 030 MPa,但三者材料的屈强比和延伸率变化不大。随着铁素体晶粒的细化,马氏体带被铁素体隔离,有效增强马氏体可塑性的同时,减缓了氢在试验钢中的扩散,氢扩散系数由3.91×10−12 m2/s下降为2.71×10−12 m2/s和9.80×10−13 m2/s。Abstract: Three different ferrite grain-sized ferrite-martensite dual-phase steels were prepared by large-strain warm deformation at different deformation temperatures in a thermal simulation process, followed by intercritical annealing at 920 ℃ for 3 min in this study. The dimensions were 11.6, 2.3 μm, and 1.1 μm, respectively, with the same content of martensite (about 30%.). The microstructure and mechanical properties of three ferrite-martensite dual-phase steels with different ferrite grain sizes were characterized by SEM, TEM and tensile test. The results show that the yield strength and tensile strength of ferrite-martensite materials increase significantly with the decrease of ferrite grain size from 11.6 to 2.3 and 1.1 μm at the same martensite content level (about 30%), the tensile strength increases from 865 MPa to 965 MPa and 1030 MPa, but the yield strength ratio and elongation of the three materials change little. With the refinement of ferrite grains, martensite bands are segregated by ferrite, which effectively enhances the plasticity of martensite and slows down the diffusion of hydrogen in test steel, The hydrogen diffusion coefficient decreased from 3.91×10−12 m2/s to 2.71×10−12 m2/s and 9.80×10−13 m2/s.

-

Key words:

- dual-phase steel /

- ferrite grain size /

- mechanical properties /

- hydrogen diffusion

-

表 1 试样的主要化学成分

Table 1. Main chemical components of sample

% C Mn Si Al N P S 0.16 1.45 0.20 0.03 0.003 0.001 0.003 表 2 三种热模拟工艺下的显微组织和力学性能参数

Table 2. Microstructure and mechanical properties of samples by three thermal simulation process

编号 马氏体含量/% 铁素体晶粒尺寸

/μm抗拉强度/MPa 屈服强度/MPa 延伸率/% 断面收缩率/% 屈强比 工艺1 31.2 11.6 865 435 7.5 13.2 0.502 工艺2 30.7 2.3 965 484 8.0 17.6 0.501 工艺3 29.9 1.1 1030 515 7.3 15.3 0.500 表 3 电化学氢渗透试验参数

Table 3. Parameters of electrochemical hydrogen permeation

试样编号 工艺 电流密度/

(mA·cm−2)厚度/

mm面积/

mm2J∞L×1012/

(mol·cm−1·s−1)氢扩散系数/

(m2·s−1)C0×106/

(mol·cm−3)1# 工艺1 10.0 1 5×5 9.32 3.91×10−12 15.77 2# 工艺2 10.0 1 5×5 8.76 2.17×10−12 18.83 3# 工艺3 10.0 1 5×5 7.46 9.80×10−13 23.48 -

[1] 董瀚, 孙新军, 刘清友, 等. 超细晶钢-钢的组织细化理论与控制技术[M]. 北京: 冶金工业出版社, 2003: 74.Dong Han, Sun Xinjun, Liu Qingyou, et al. Microstructure refinement theory and control technology of ultra fine grain steel[M]. Beijing: Metallurgical Industry Press, 2003: 74. [2] 翁宇庆. 超细晶钢[M]. 北京: 冶金工业出版社, 2003: 69-72.Weng Yuqing. Ultrafine grained steel[M]. Beijing: Metallurgical Industry Press, 2003: 69-72. [3] Ni Zhongyi, Zhu Xiaolei, Jia Jixiang, et al. Research progress on ultrafine grained steel materials at home and abroad[J]. Angang Technology, 2016,(2):9−11. (倪翀奕, 朱晓雷, 贾吉祥, 等. 国内外超细晶钢铁材料研究进展[J]. 鞍钢技术, 2016,(2):9−11. doi: 10.3969/j.issn.1006-4613.2016.02.002 [4] Zhang Sanhong. Ferrite nucleation at ceramic austenite interfaces[J]. ISIJ Int, 1996,36(10):1301−1309. doi: 10.2355/isijinternational.36.1301 [5] Liu Xianghua, Du Linxiu, Wang Guodong. Fine grain size steel by hot rolling and development of super steel[J]. Henan Metallurgy, 2004,12(3):3−6,17. (刘相华, 杜林秀, 王国栋. 热轧钢材的晶粒细化与超级钢开发[J]. 河南冶金, 2004,12(3):3−6,17. doi: 10.3969/j.issn.1006-3129.2004.03.001 [6] Yang Wangyue, Hu Anmin, Qi Junjie, et al. Microstructure refinement of deformation-enhanced transformation in low carbon steel[J]. Chinese Journal of Materials Research, 2001,(4):171−178. (杨王月, 胡安民, 齐俊杰, 等. 低碳钢形变强化相变的组织细化[J]. 材料研究学报, 2001,(4):171−178. [7] Sun Z Q, Yang W Y. Deformation enhanced transformation and dynamic recrystallization of ferrite in a low carbon steel during multipass hot deformation[J]. Mater. Sci. Eng., 2002,334:201−206. doi: 10.1016/S0921-5093(01)01806-8 [8] Matsumura Y, Yada H. Evolution of ultrafine-grained ferrite in hot successive deformation[J]. Trans. ISIJ, 1987,27:492−498. doi: 10.2355/isijinternational1966.27.492 [9] Beynon J H, Gloss R, Hodgson P D. The production of ultrafine ferrite in a low carbon microalloyed steel by thermomrchanical treatment[J]. Mater. Forum, 1992,16:37−42. [10] Choo W Y, Lee J S. Strain induced dynamic transformation of austenite to fine ferrite and it’s characteristics[J]. CAMP-ISIJ, 2000,13:1144. [11] Guo W, Zhao W M, Zhang T M, et al. Hydrogen permeation behavior of X80 steel under cathodic polarization and stress[J]. Journal of Chinese Society for Corrosion and Protection, 2015,35(4):353−358. [12] Calcagnotto M, Ponge D, Raabe D. On the effect of manganese on grain size stability and hardenability in ultrafine-grained ferrite/martensite dual-phase steels[J]. Metallurgical and Materials Transactions A, 2012,43(1):37−46. doi: 10.1007/s11661-011-0828-3 [13] Loidl M, Kolk O, Veith S, et al. Characterization of hydrogen embrittlement in automotive advanced high strength steels[J]. Materialwissenschaft und Werkstofftechnik, 2011,42(12):1105−1110. doi: 10.1002/mawe.201100917 -

下载:

下载: