Research on hot deformation behavior of MnS inclusions in gear steel

-

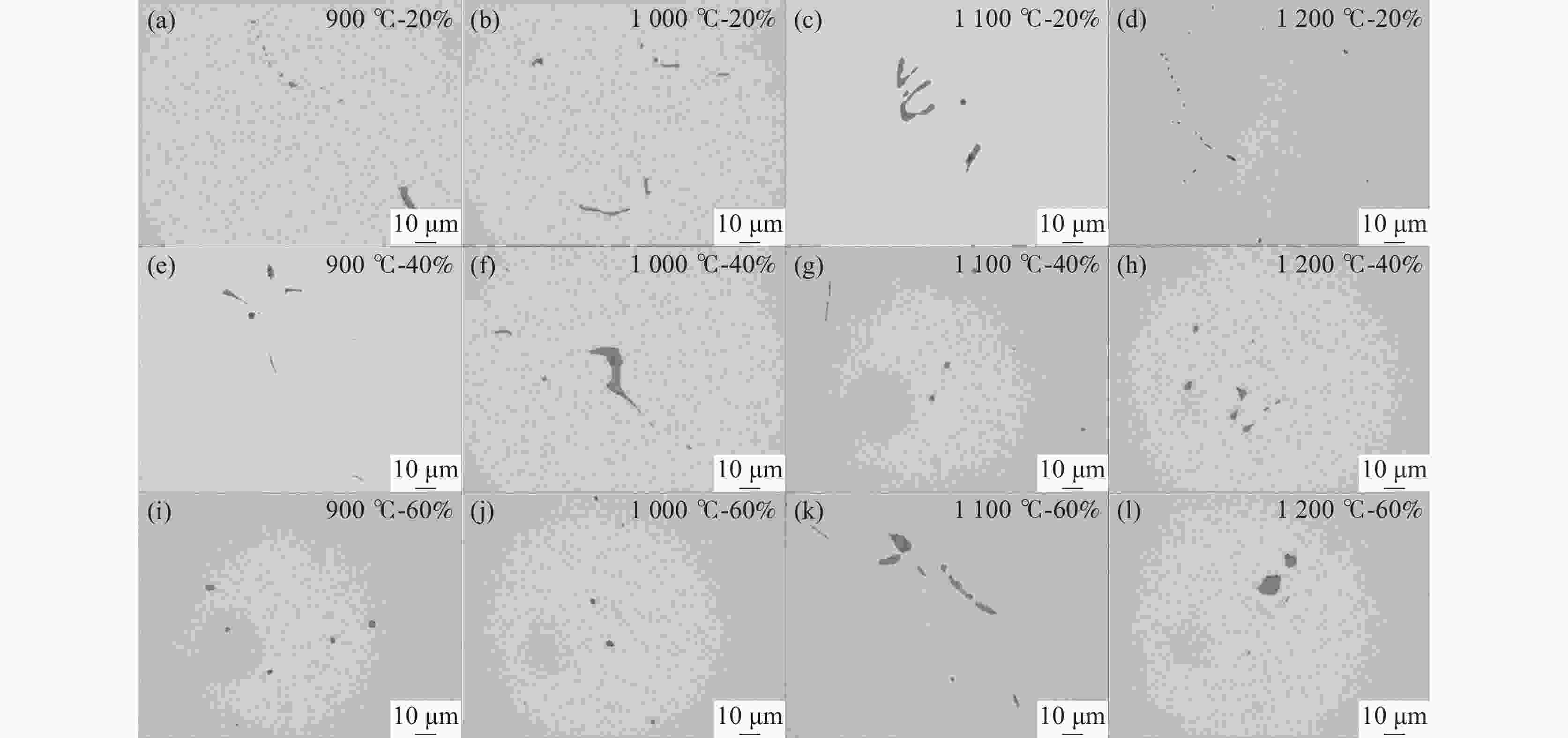

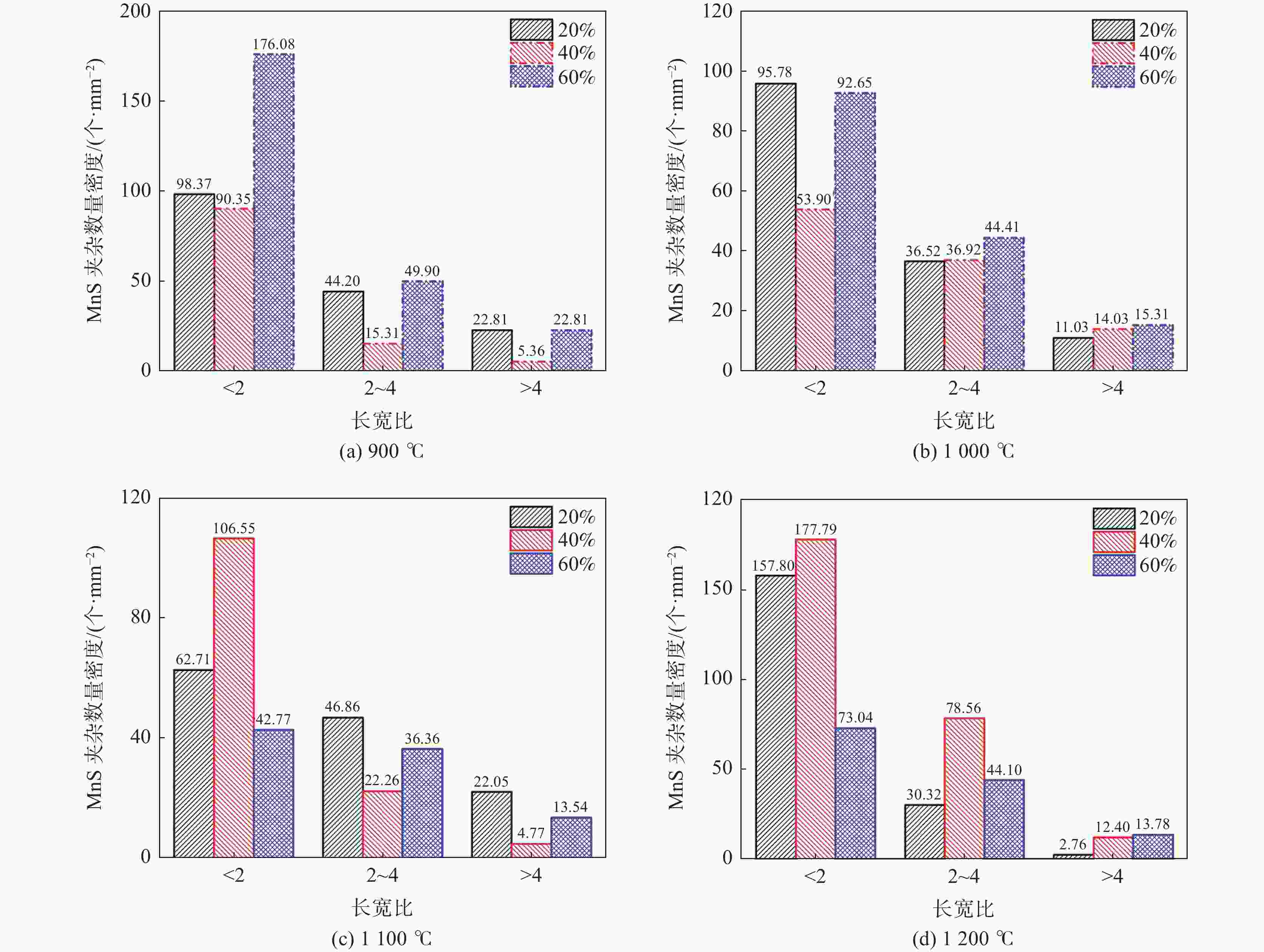

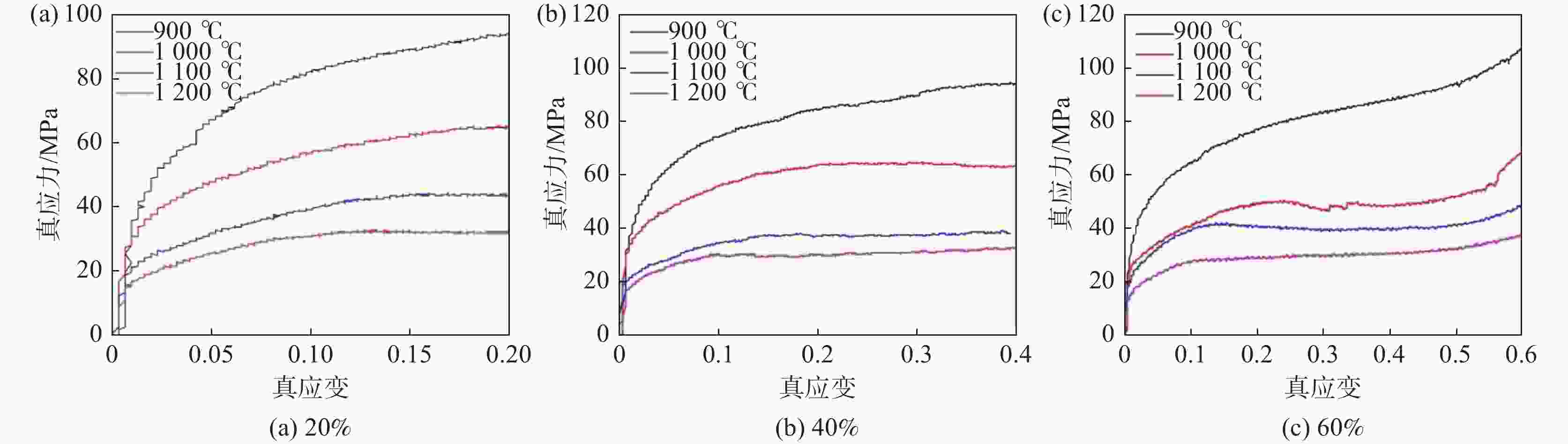

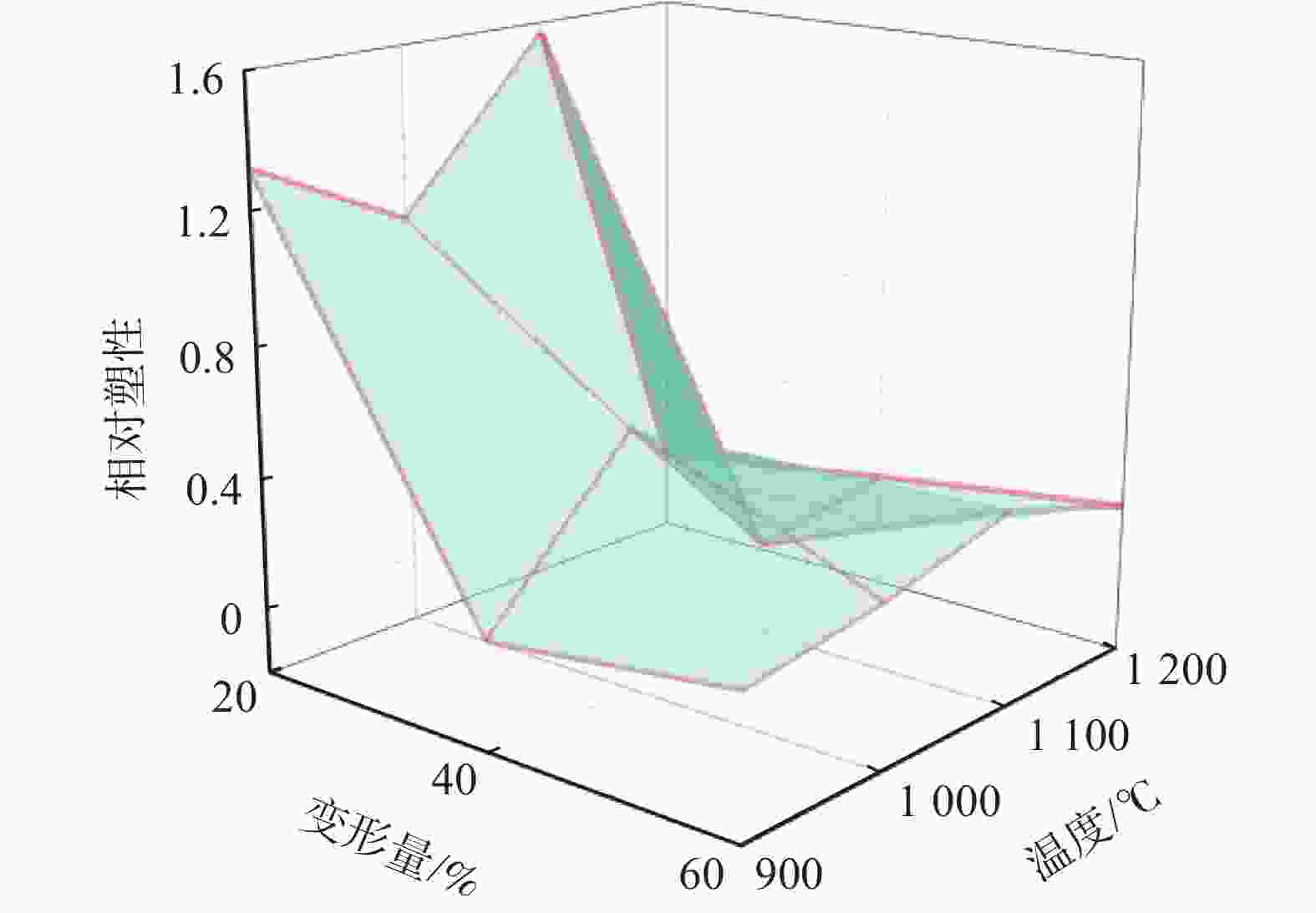

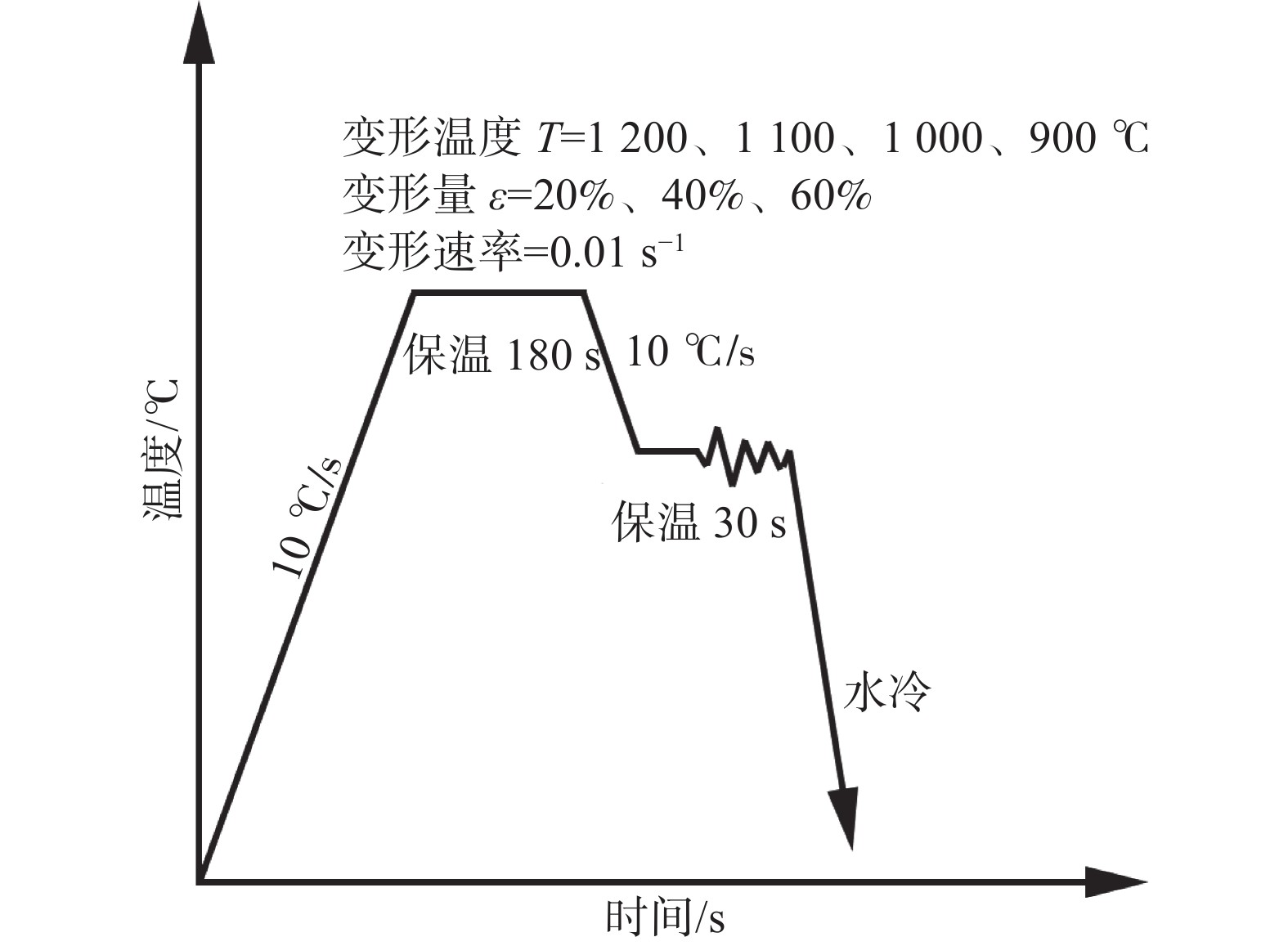

摘要: 利用Gleeble-1500热-力学模拟试验机对齿轮钢试样进行压缩试验,研究了不同变形温度、变形量对钢中硫化锰夹杂物形貌、尺寸及相对塑性的影响。研究发现,在变形过程中,硫化物的碎化与长大现象交替进行,变形温度与变形量对硫化锰夹杂物的尺寸影响较大。随着变形量的增加,低温时长宽比小于2的硫化物数量呈先降低后增多的趋势,同时相对塑性呈现降低的趋势,高温时长宽比小于2的硫化物数量呈先增大后降低的趋势,相对塑性呈现增加的趋势。在实际轧制过程中选择低温大变形量或高温小变形量轧制制度,能够获得数量较多,长宽比较小的硫化锰夹杂物。Abstract: A compression test was conducted via a Gleeble-1500 thermo-mechanical simulator. The effects of different deformation temperatures and deformation on the size and relative plasticity of MnS inclusions in steel were studied. It is found that fragmentation and growth of MnS occurred alternately during the deformation process, and the temperature and the deformation greatly influence the size of MnS. With the increase of deformation, the quantity of MnS with an aspect ratio of less than two decreases first and then increases. The relative plasticity shows a trend to decrease at low temperatures. Nevertheless, the quantity and relative plasticity of MnS changed oppositely when gear steel was deformed at high temperatures. Choosing large deformation at low temperature or small deformation at the high-temperature rolling system in actual production can obtain many MnS inclusions with a small aspect ratio.

-

Key words:

- gear steel /

- MnS inclusions /

- deformation /

- deformation temperature /

- relative plasticity

-

表 1 试验钢化学成分

Table 1. Chemical composition of test steel

% C Si Mn P S Nb+Ti+Cr+Mo Fe ≤0.25 ≤0.6 ≤2.0 ≤0.018 ≤0.01 ≤0.2 余量 -

[1] Yang Wen, Yang Xiaogang, Zhang Lifeng, et al. Review of control of MnS inclusions in steel[J]. Steelmaking, 2013,29(6):71−78. (杨文, 杨小刚, 张立峰, 等. 钢中MnS夹杂物控制综述[J]. 炼钢, 2013,29(6):71−78. doi: 10.3969/j.issn.1002-1043.2013.06.017 [2] Domizzi G, Anteri G, Ovejero-Garcı́a J. Influence of sulphur content and inclusion distribution on the hydrogen induced blister cracking in pressure vessel and pipeline steels[J]. Corrosion Science, 2001,43(2):325−339. doi: 10.1016/S0010-938X(00)00084-6 [3] Li Jilin, Feng Junning, Li Yongquan, et al. Morphologies and formation mechanism of MnS inclusion defects in cast steel[J]. Hot Working Technology, 2021,50(1):74−77. (李吉林, 冯俊宁, 李涌泉, 等. 铸钢中MnS夹杂缺陷的形貌及形成机制[J]. 热加工工艺, 2021,50(1):74−77. [4] Shao Xiaojing, Lv Lige, Du Qian, et al. Thermal deformation behavior of MnS inclusions in non-quenched and tempered steel[J]. Heat Treatment of Metals, 2018,43(5):144−147. (邵肖静, 吕利鸽, 杜倩, 等. 非调质钢中MnS夹杂物的热变形行为[J]. 金属热处理, 2018,43(5):144−147. [5] Lou Dechun, Cui Kun, Wu Xiaochun, et al. Behavior of MnS during hot deformation[J]. Journal of Iron and Steel Research, 1996,(6):11−14. (娄德春, 崔昆, 吴晓春, 等. 硫化锰夹杂物的热变形行为[J]. 钢铁研究学报, 1996,(6):11−14. [6] Lou Dechun, Cui Kun, Wu Xiaochun, et al. Numerical simulation of the deformation behavior of inclusions in S-RE system free-cutting steel[J]. Materials for Mechanical Engineering, 1997,(1):12−15. (娄德春, 崔昆, 吴晓春, 等. 硫复合系易切削钢中夹杂物热变形行为的数值模拟[J]. 机械工程材料, 1997,(1):12−15. [7] Lou Dechun, Cui Kun, Wu Xiaochun. Effect of technology rolling parameters on relative plasticity of slags MnS[J]. Research on Iron & Steel, 1996,(5):27−29. (娄德春, 崔昆, 吴晓春. 轧制工艺参数对硫化锰夹杂物相对塑性的影响[J]. 钢铁研究, 1996,(5):27−29. [8] 鲁金龙. 大规格曲轴用非调质钢中MnS形成机理及控制工艺研究[D]. 北京: 北京科技大学, 2020: 91.Lu Jinlong. Research on formation mechanism and control process of MnS in Non-quenched and tempered steel for heavy crankshaft[J]. Beijing: University of Science and Technology Beijing, 2020: 91. [9] Lv Naibing, Ma Yue, Liu Ke, et al. Nucleation, growth and maturation analysis of MnS during solidification in axle steel ingots[J]. Iron and Steel, 2020,(7):58−64. (吕迺冰, 马跃, 刘珂, 等. 车轴钢铸锭中MnS的生成、长大、熟化规律分析[J]. 钢铁, 2020,(7):58−64. [10] Yong Qilong, Liu Qingyou, Liu Su, et al. Theoretical analysis on controlled element of Ostwald ripening process of manganese sulfide in steels[J]. Special Steel, 2004,25(6):7−7. (雍岐龙, 刘清友, 刘苏, 等. 硫化锰在钢中的Ostwald熟化过程的控制性元素的理论分析[J]. 特殊钢, 2004,25(6):7−7. doi: 10.3969/j.issn.1003-8620.2004.06.002 -

下载:

下载: