The study of the role of Mg content in microstructure of Zn-1.6Al-xMg alloy coatings

-

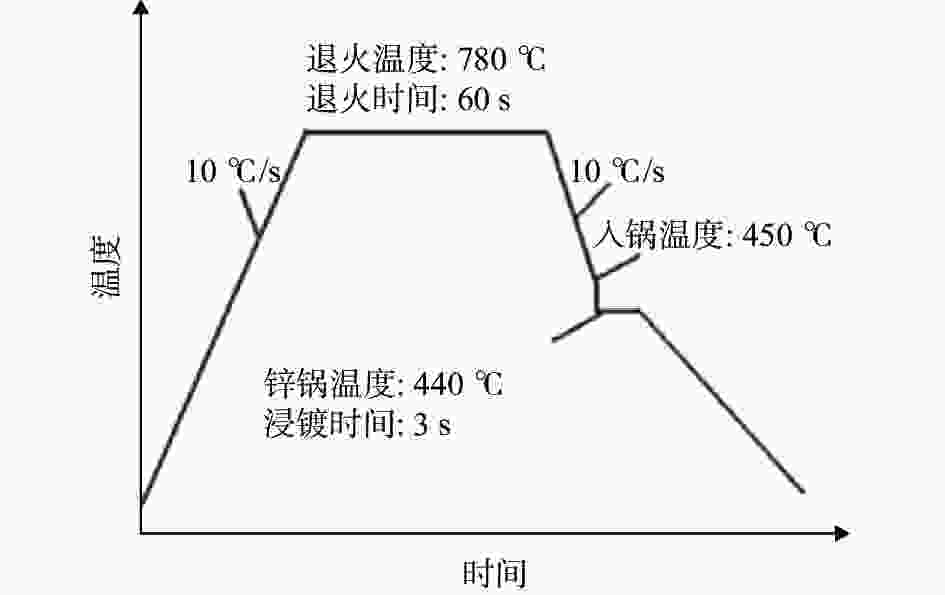

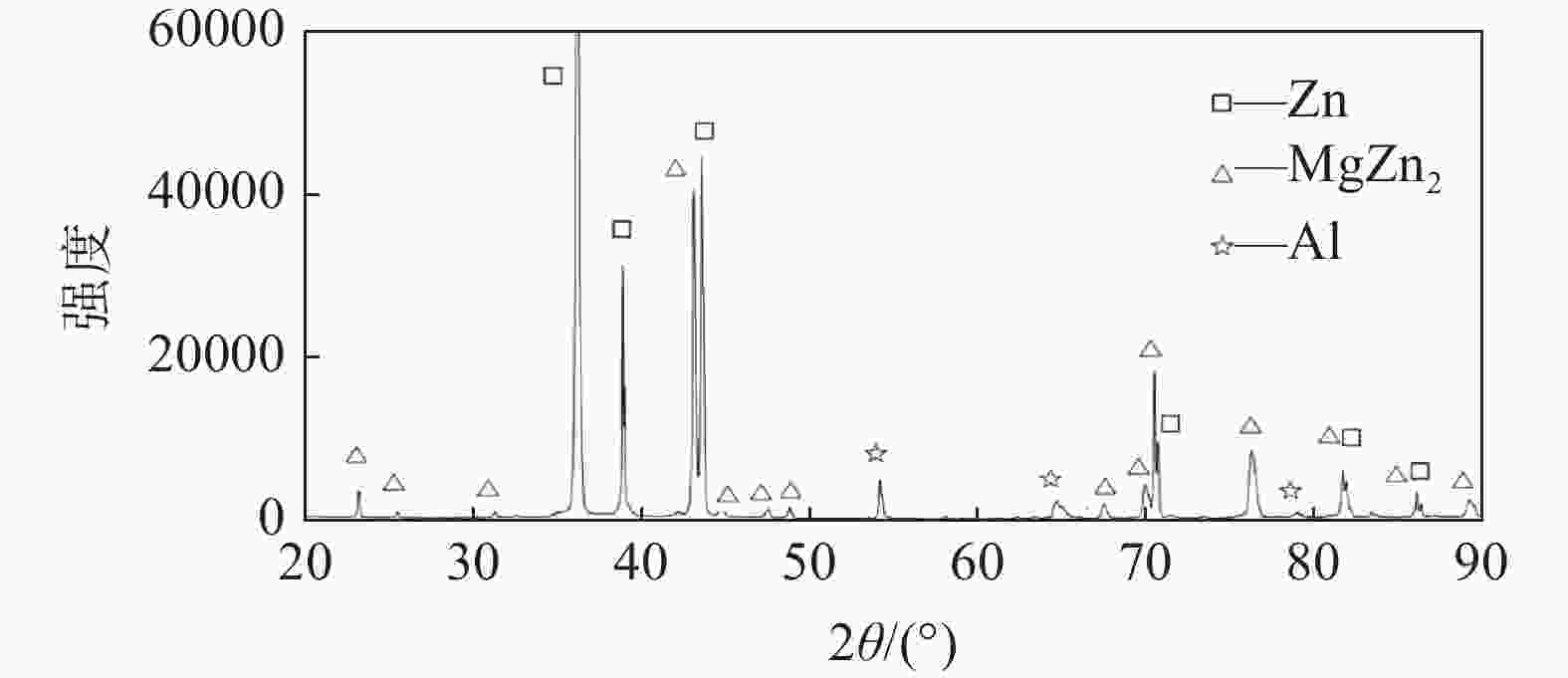

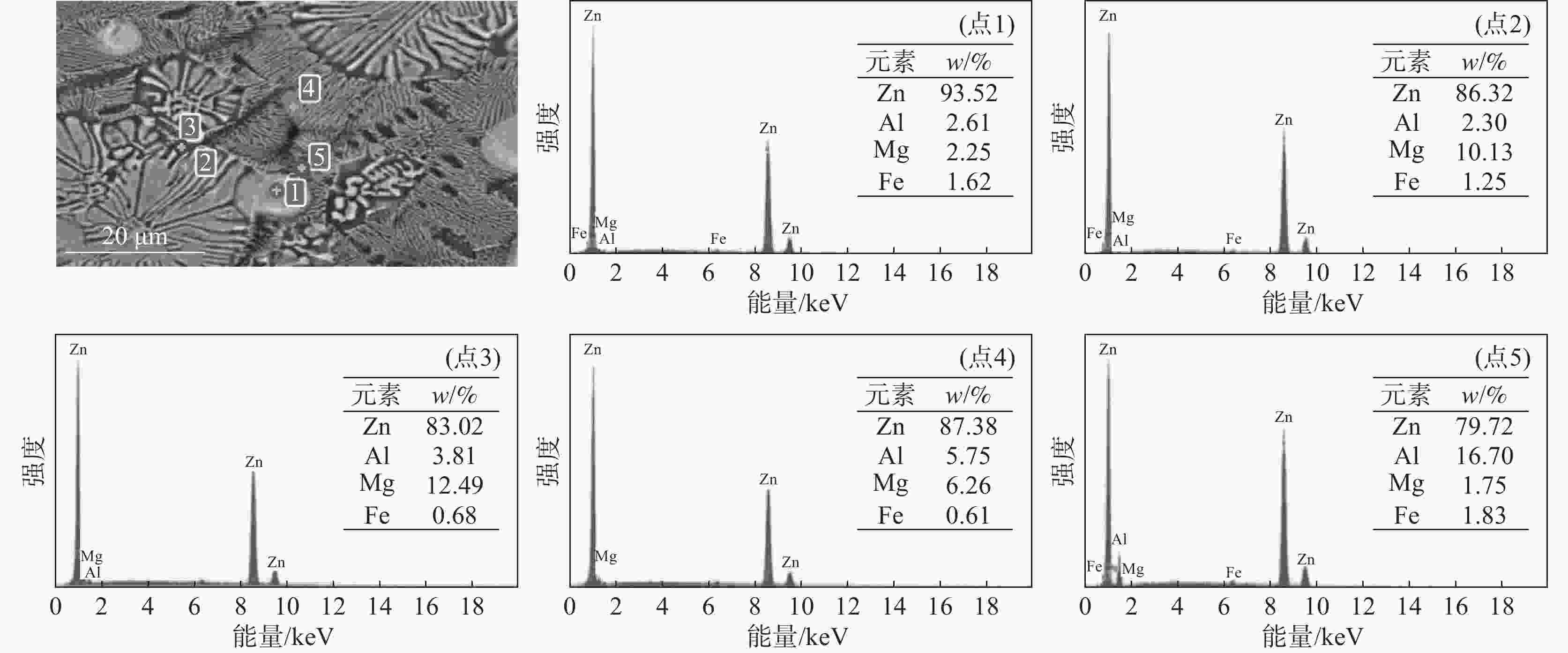

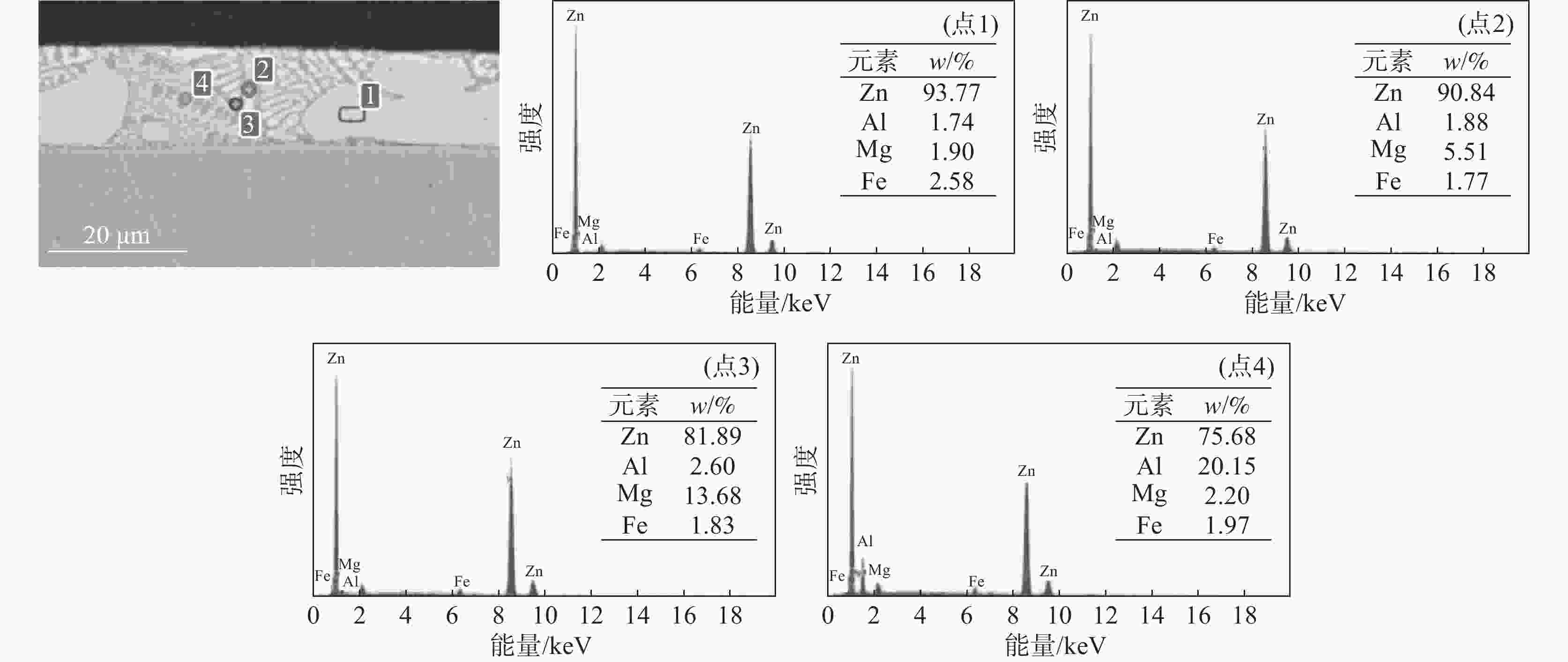

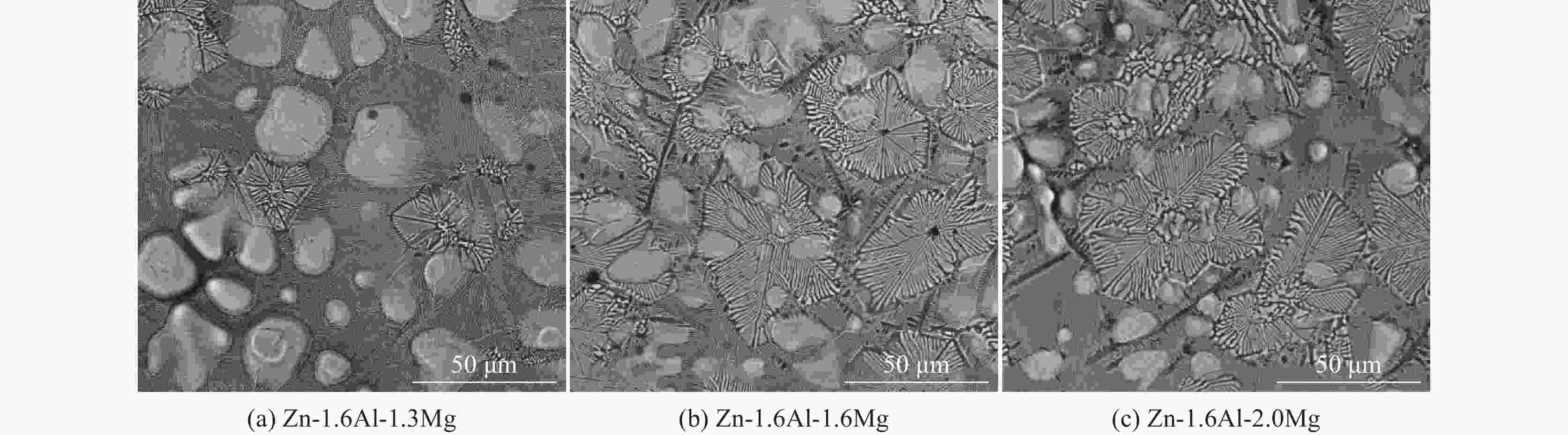

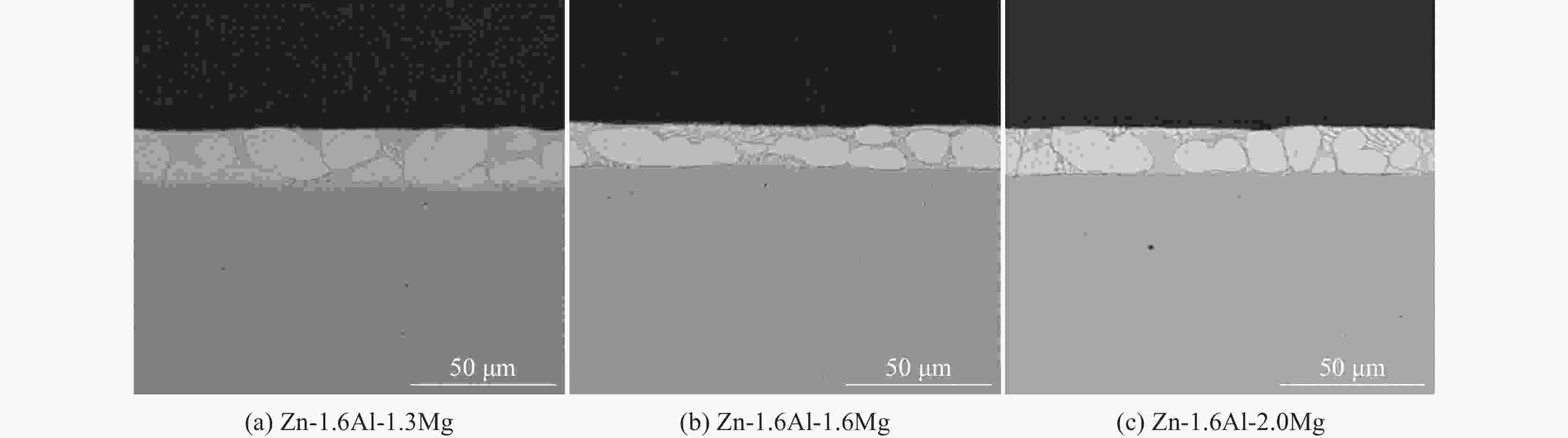

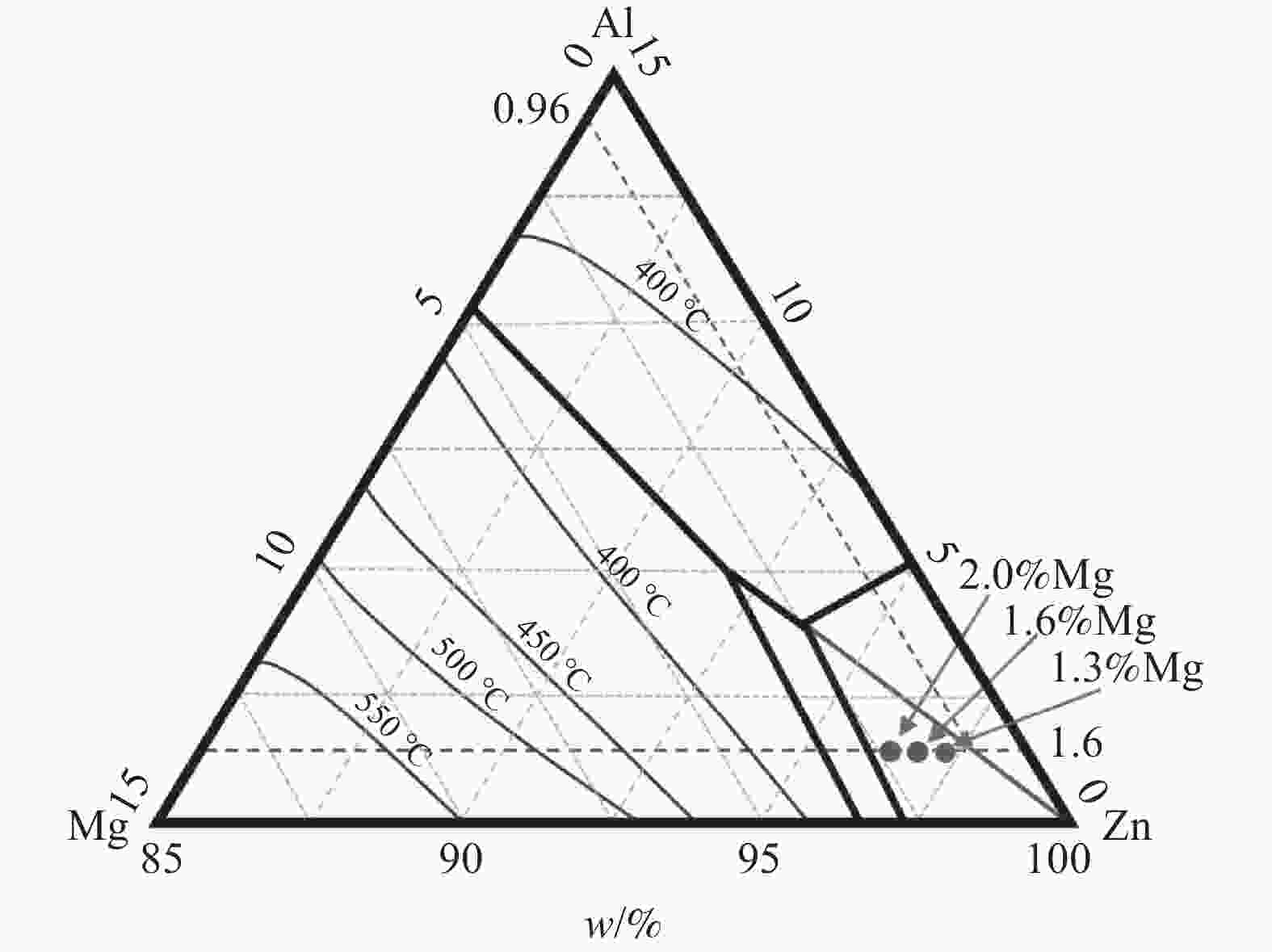

摘要: 利用热镀锌模拟机制备了Zn-1.6A1-1.3Mg、Zn-1.6A1-1.6Mg和Zn-1.6Al-2.0Mg热镀合金镀层钢板,并利用XRD、SEM和EDS对涂层的微观组织进行分析。结果表明,镀层由块状富Zn相、Zn/MgZn2二元共晶组织、细小的Zn/Al/MgZn2三元共晶组织和少量点状富Al相组成。随着Mg含量增加,镀层表面块状富Zn相的比例和尺寸减小,三元共晶组织减少,而二元共晶组织和条状富Al相的数量增多。在截面中,镀层的三元共晶组织随Mg含量升高而减少,二元共晶组织随Mg含量升高而增多。Abstract: The Zn-1.6Al-xMg alloy coating steel sheets with different Mg content were prepared by hot dip galvanizing simulator, and the microstructure of coatings was analyzed using XRD, SEM and EDS. The results indicate that all the microstructures of Zn-1.6Al-xMg coatings are composed of massive Zn-rich phases, Zn/MgZn2 binary eutectic structures, fine Zn/Al/MgZn2 ternary eutectic structures, and a few dotted Al-rich phases. However, the volume fraction of Zn-rich phases and ternary eutectic structures decreases with the increase in Mg content of coatings, while the volume fraction of binary eutectic structures increases. Furthermore, the dotted Al-rich phases gradually transform to banded structure. As for the cross section, the microstructure of coatings shows that the ternary eutectic structure decreases, while the binary eutectic structure increases with the increasing Mg content.

-

Key words:

- Zn-Al-Mg alloy coatings /

- Mg content /

- microstructure /

- eutectic structures /

- SEM

-

表 1 试验用锌铝镁镀液Al、Mg成分

Table 1. Composition of Al and Mg in Zn-Al-Mg coating solution for test

元素组成 目标/% 实测/% Al Mg Al Mg Zn-1.6Al-1.3Mg 1.6 1.3 1.6 1.32 Zn-1.6Al-1.6Mg 1.6 1.6 1.58 1.59 Zn-1.6Al-2.0Mg 1.6 2 1.63 2.01 -

[1] Song G M, Vystavel T, Van Derpers N, et al. Relation between microstructure and adhesion of hot dip galvanized zinc coatings on dual phase steel[J]. Acta Materialia, 2012,60(6/7):2973−2981. [2] Huang Yongzhi, Li Yungang. Overview of development of hot dip galvanizing and zinc alloy technology[J]. Plating and Finishing, 2012,34(2):21−25. (黄永智, 李运刚. 热镀锌及锌合金技术的发展概述[J]. 电镀与精饰, 2012,34(2):21−25. [3] Pistofidis N, Vourlias G, Konidaris S, et al. Microstructure of zinc hot-dip galvanized coatings used for corrosion protection[J]. Materials Letters, 2006,60(6):786−789. doi: 10.1016/j.matlet.2005.10.013 [4] Du Xin, Zhang Mancang, Duan Shengchao, et al. Research status of high corrosion resistant zinc aluminum magnesium coating[J]. Chinese Journal of Engineering, 2019,41(7):847−856. (杜昕, 张满仓, 段生朝, 等. 高耐蚀锌铝镁镀层研究现状[J]. 工程科学学报, 2019,41(7):847−856. [5] Tian Fei. Analysis of stamping forming based on zinc aluminum magnesium and zinc iron coatings[J]. Forging & Metalforming, 2019,16(16):38−40. (田飞. 基于锌铝镁和锌铁镀层的冲压成形分析[J]. 锻造与冲压, 2019,16(16):38−40. [6] Xie Yingxiu, Jin Xinyan, Wang Li. Progress in development and application of hot dip galvanized aluminum magnesium coating[J]. Journal of Iron and Steel Research, 2017,29(3):167−174. (谢英秀, 金鑫焱, 王利. 热浸镀锌铝镁镀层开发及应用进展[J]. 钢铁研究学报, 2017,29(3):167−174. [7] Huang Lvwen, Yu Yuhuan. Aluminized magnesium zinc materials and their application in photovoltaic building integration[J]. Guangdong Building Materials, 2016,32(8):36−37. (黄旅文, 余玉环. 镀铝镁锌材料及其在光伏建筑一体化上的运用[J]. 广东建材, 2016,32(8):36−37. doi: 10.3969/j.issn.1009-4806.2016.08.015 [8] 吕家舜. 热浸镀锌铝镁钢板镀层组织及腐蚀性能研究[J]. 材料工程, 2012, 56(10): 89-93.Lv Jiashun. Study on microstructure and corrosion performance of hot dip galvanized aluminum magnesium steel plate[J]. Journal of Materials Engineering, 2012, 56 (10): 89-93. [9] Tong Chen, Su Xuping, Wang Jianhua, et al. Effect of Mg on solidification structure and corrosion resistance of Zn-6%Al coating[J]. Hot Working Technology, 2012,41(12):99−103. (童晨, 苏旭平, 王建华, 等. Mg对Zn-6%Al镀层凝固组织的影响及耐腐蚀性的研究[J]. 热加工工艺, 2012,41(12):99−103. doi: 10.3969/j.issn.1001-3814.2012.12.032 [10] Yang Qiaoyan, Tang Maoyou, Liu Ya, et al. Effect of aluminum and magnesium on solidification structure and mechanical properties of zinc aluminum magnesium alloy[J]. Chinese Journal of Rare Metals, 2016,40(5):421−428. (杨巧燕, 汤茂友, 刘亚, 等. 铝和镁对锌铝镁合金凝固组织与力学性能的影响[J]. 稀有金属, 2016,40(5):421−428. [11] 李锋, 吕家舜, 杨洪刚, 等. 锌铝镁镀层钢板耐蚀性能研究[C]//2013年铁路和建筑用钢学术研讨会, 马鞍山: 安徽省金属学会, 2013: 338-346.Li Feng, Lv Jiashun, Yang Honggang, et al. Study on corrosion resistance of zinc aluminum magnesium coated steel plate [C]. 2013 Academic Sseminar on Railway and Building Steel, Maanshan: Anhui Institute of Metals, 2013: 338-346. [12] Sheng Hai, Hao Yulin, Liu Xingquan, et al. Effect of microstructure on corrosion resistance of zinc aluminum magnesium alloy hot dip coating[J]. Electroplating & Finishing, 2017,36(5):239−242. (生海, 郝玉林, 刘兴全, 等. 组织结构对锌–铝–镁合金热浸镀层耐蚀性的影响[J]. 电镀与涂饰, 2017,36(5):239−242. [13] Lv Jiashun, Li Feng, Yang Honggang. Microstructure test of hot dip galvanized aluminum magnesium coating[J]. Iron & Steel, 2013,48(6):75−79. (吕家舜, 李锋, 杨洪刚. 热浸镀锌铝镁镀层微观组织试验[J]. 钢铁, 2013,48(6):75−79. doi: 10.13228/j.boyuan.issn0449-749x.2013.06.012 [14] Schuerz S, Luckeneder G H, Fleischanderl M, et al. Chemistry of corrosion products on Zn-Al-Mg alloy coated steel sheet[J]. Corrosion Science, 2010,52(10):3271−3279. doi: 10.1016/j.corsci.2010.05.044 [15] Dutta M, Halder A, Singh S B. Morphology and properties of hot dip Zn-Mg and Zn-Mg-Al alloy coatings on steel sheet[J]. Surface & Coatings Technology, 2010,205(7):2578−2584. [16] Schuerz S, Fleischanderl M, Luckeneder G H, et al. Corrosion behavior of Zn-Al-Mg coated steel sheet in sodium chloride-containing environment[J]. Corrosion Science, 2009,51(10):2355−2363. doi: 10.1016/j.corsci.2009.06.019 [17] Su X P, Zhou J, Wang J H, et al. Thermodynamic analysis and experimental study on the oxidation of the Zn-Al-Mg coating baths[J]. Applied Surface Science, 2017,396:154−160. -

下载:

下载: