Research and application of rail universal pass design method

-

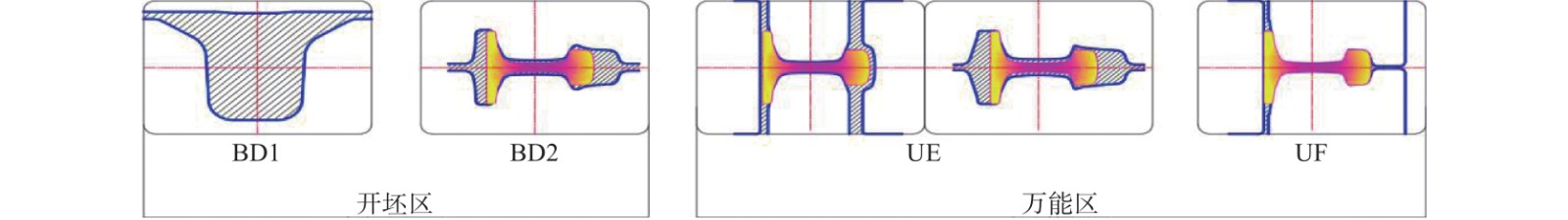

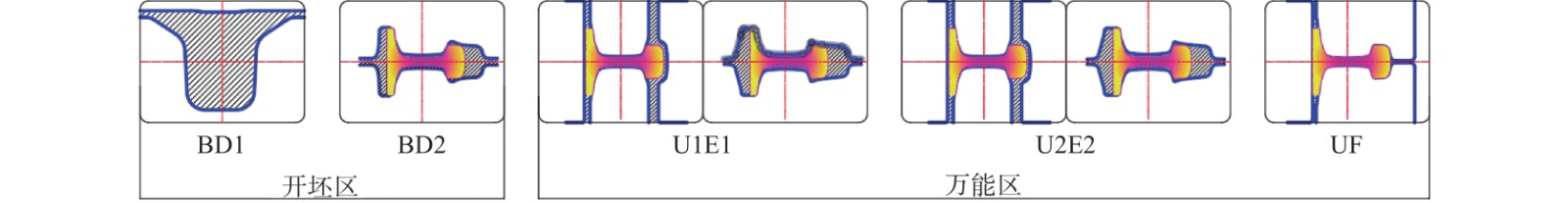

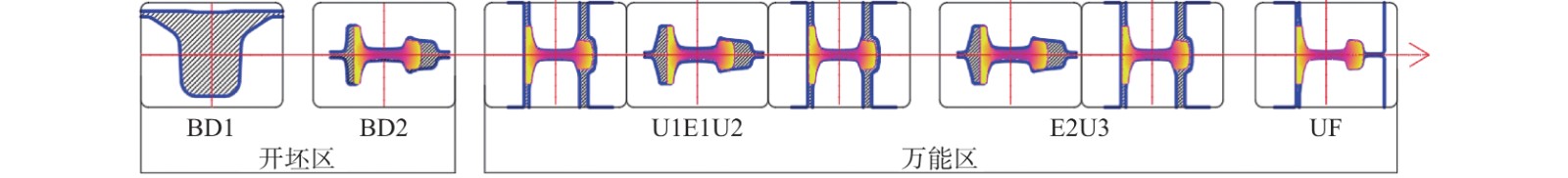

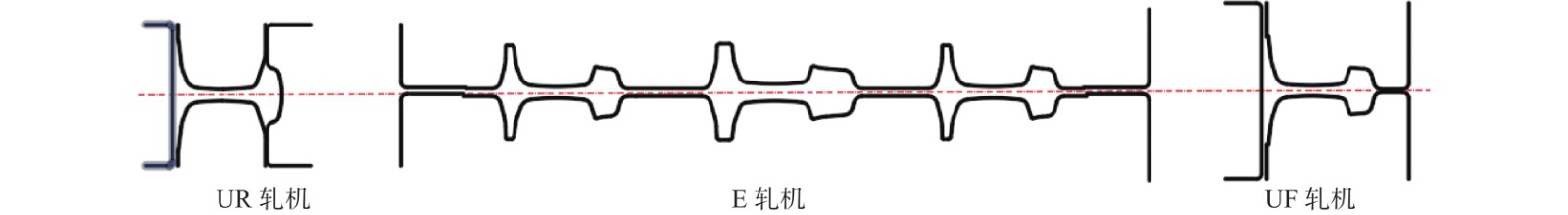

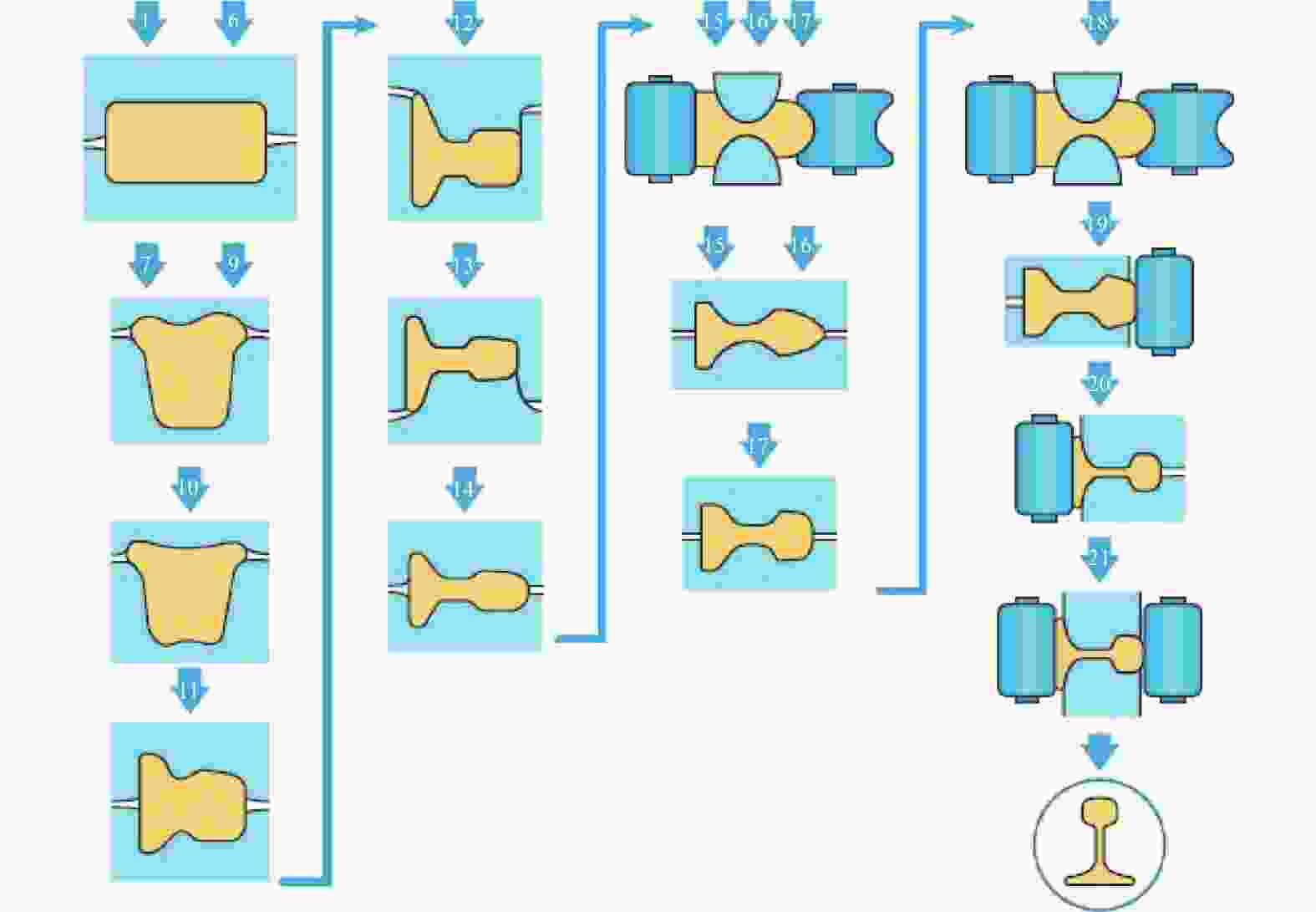

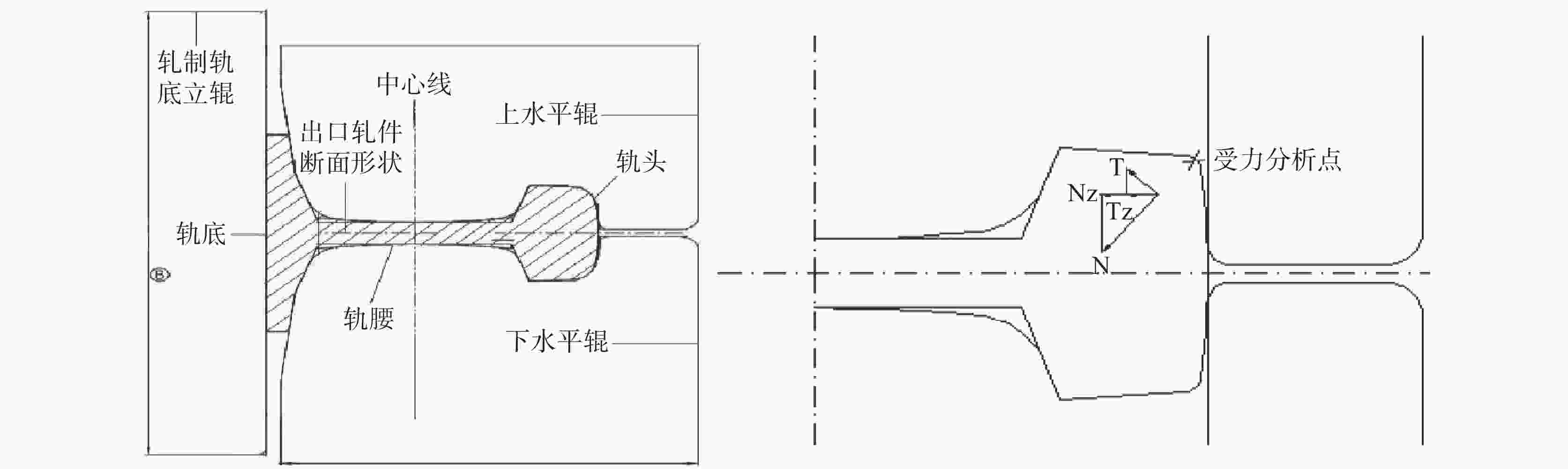

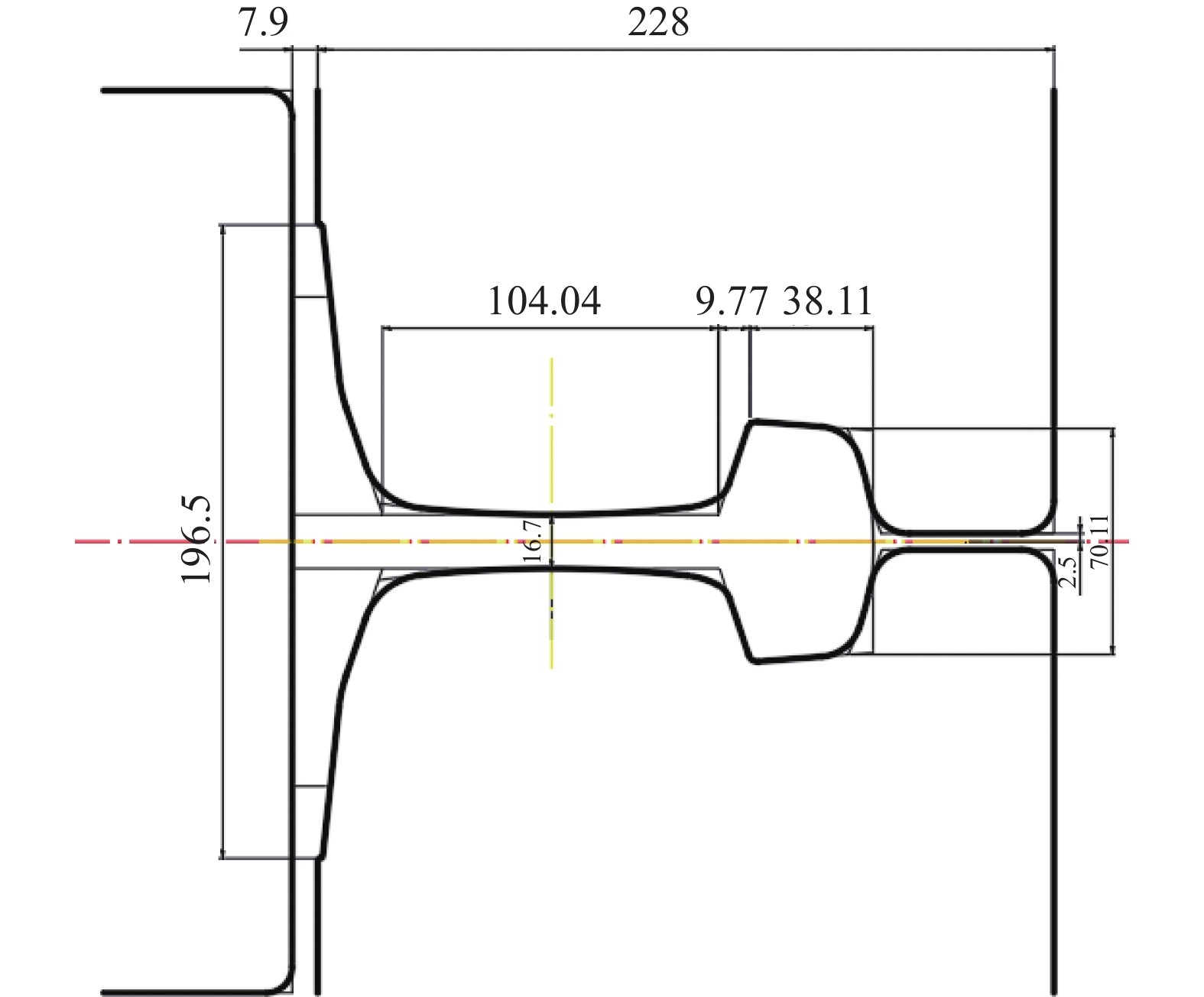

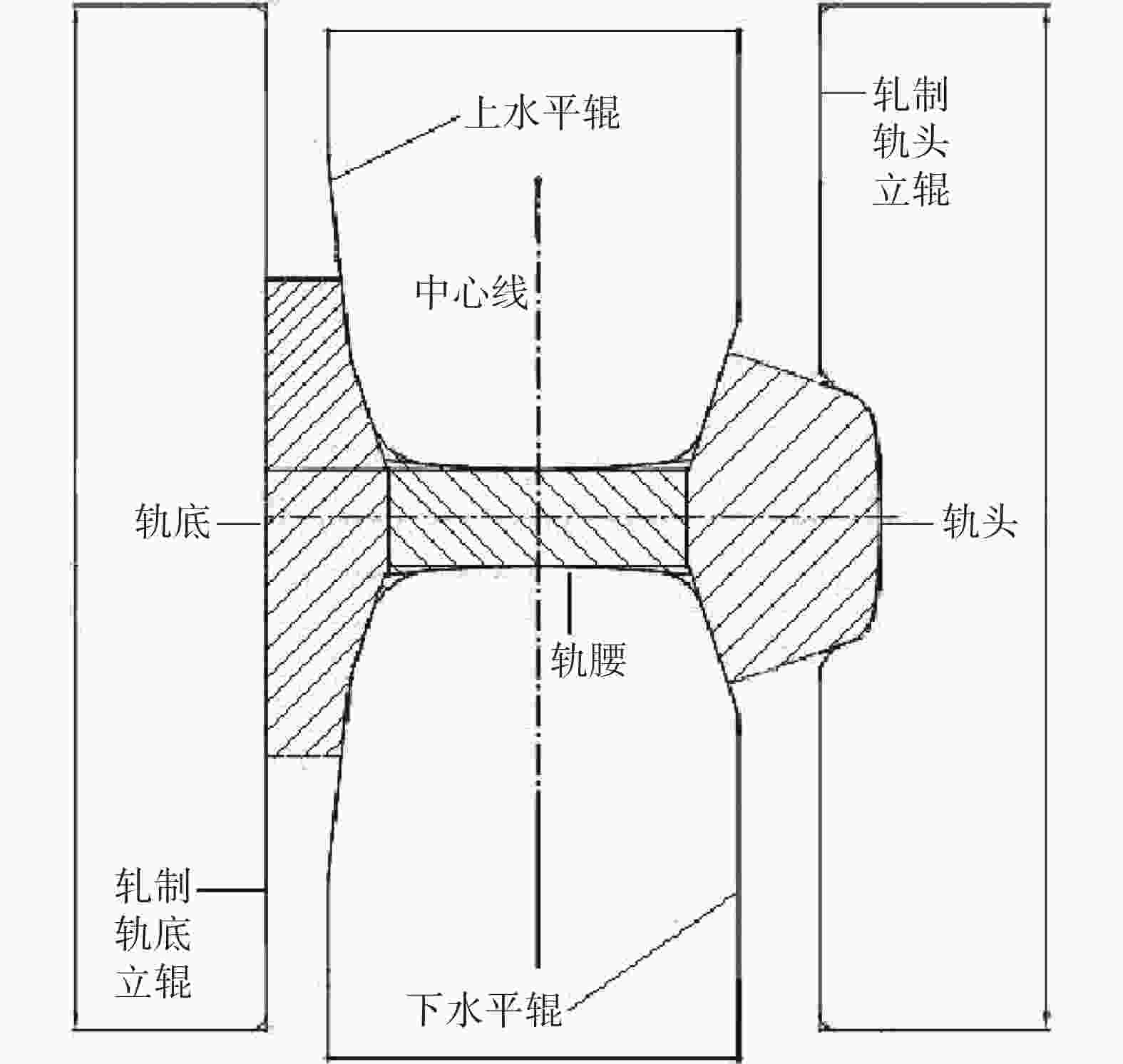

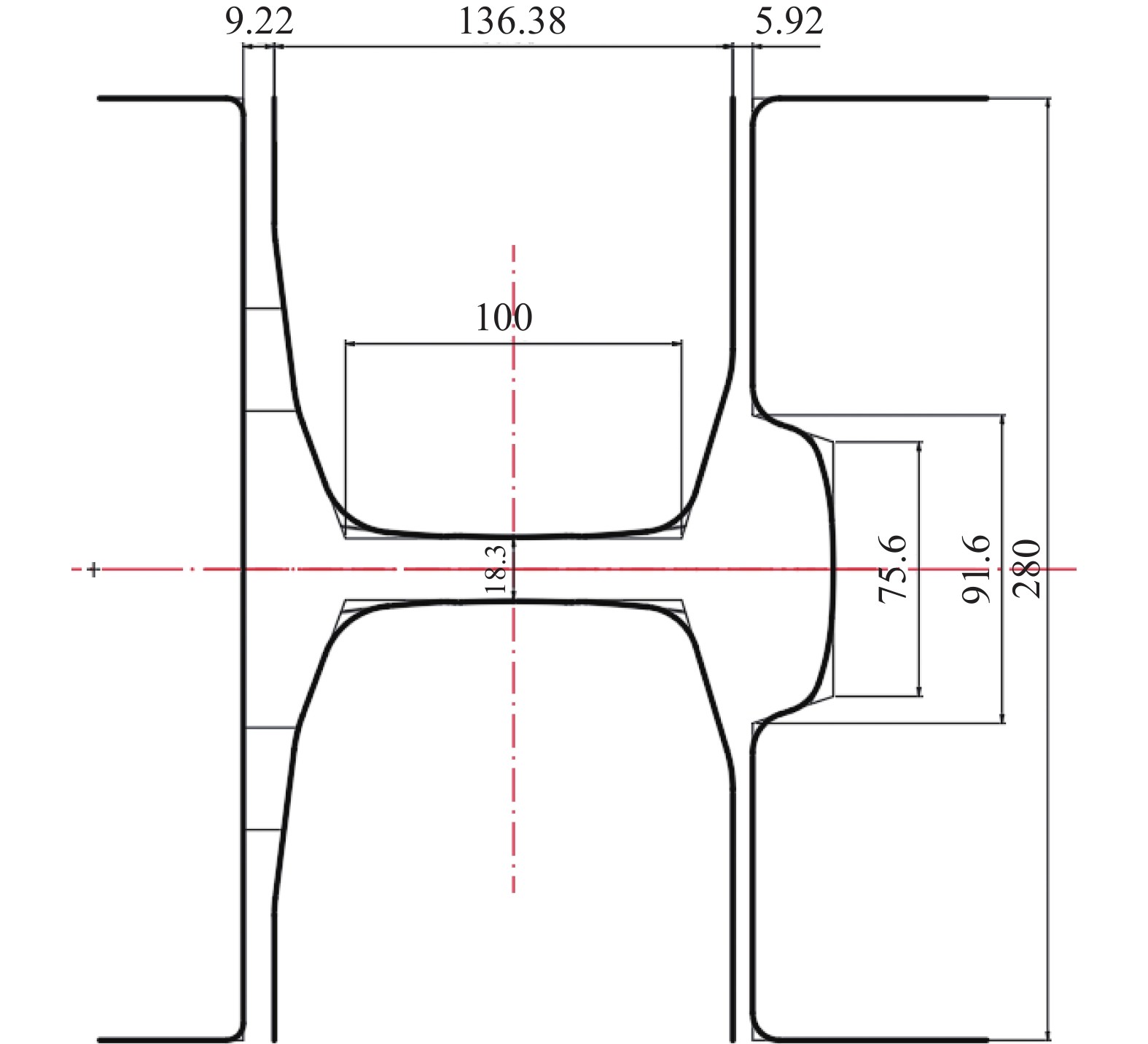

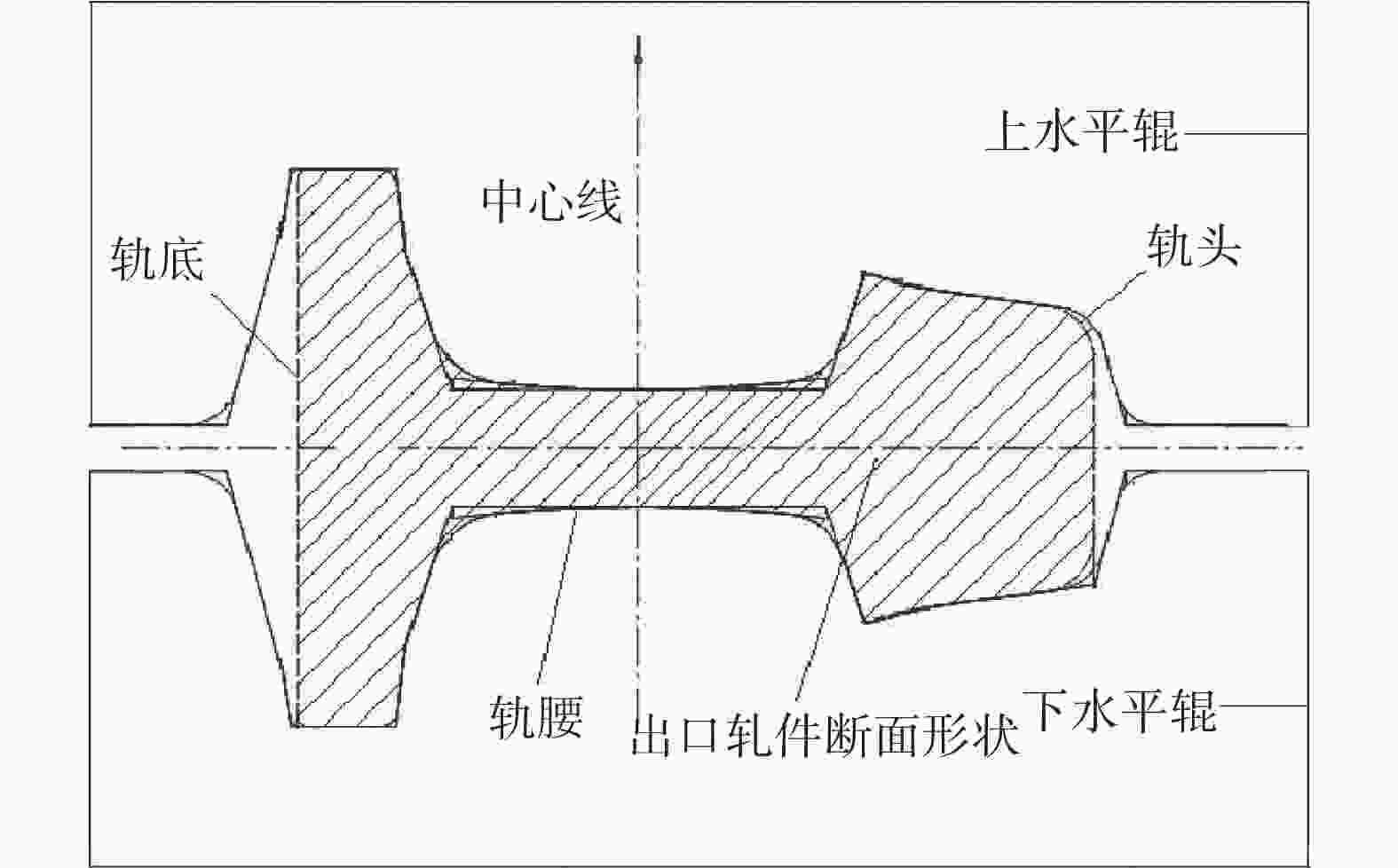

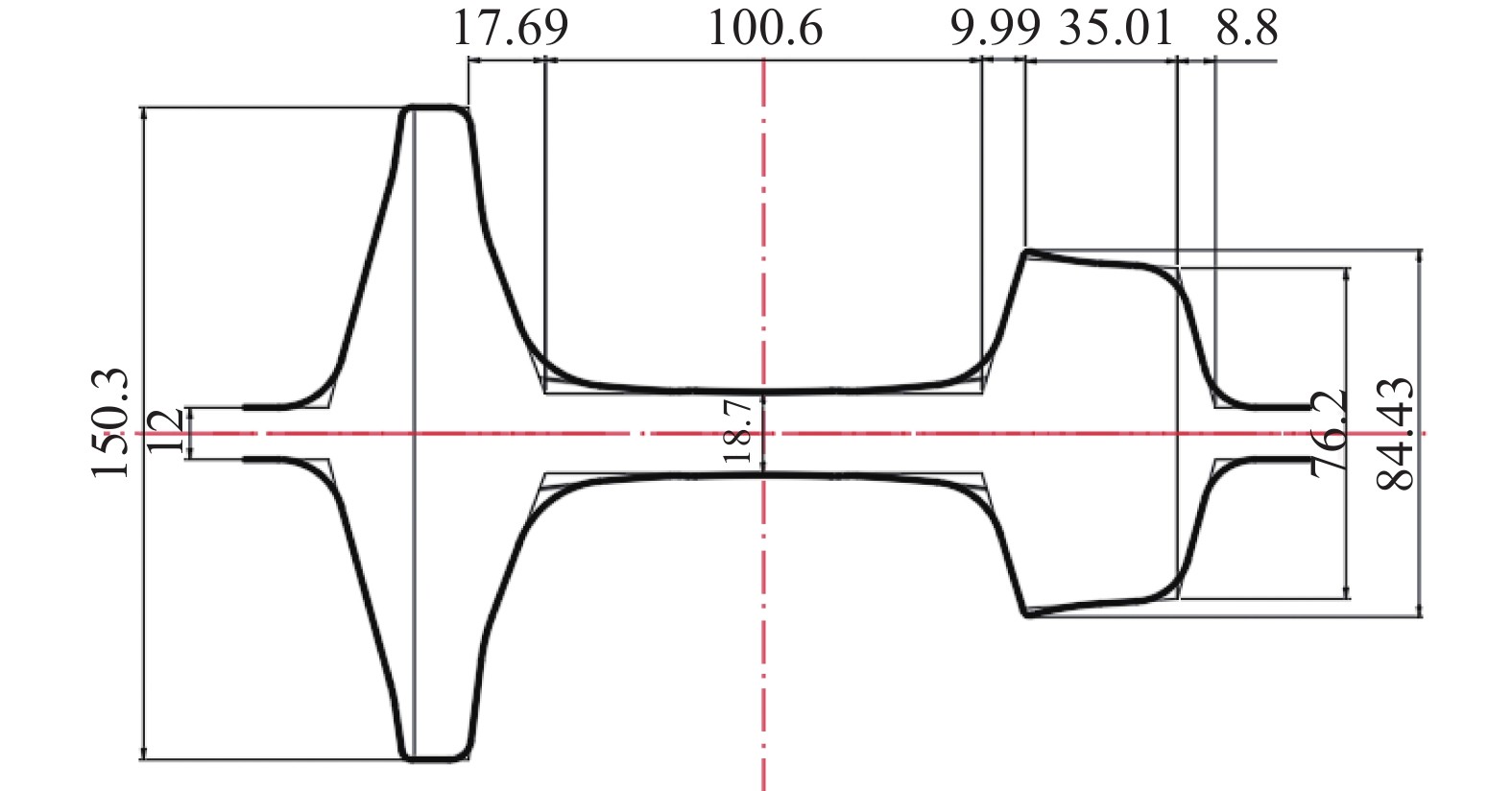

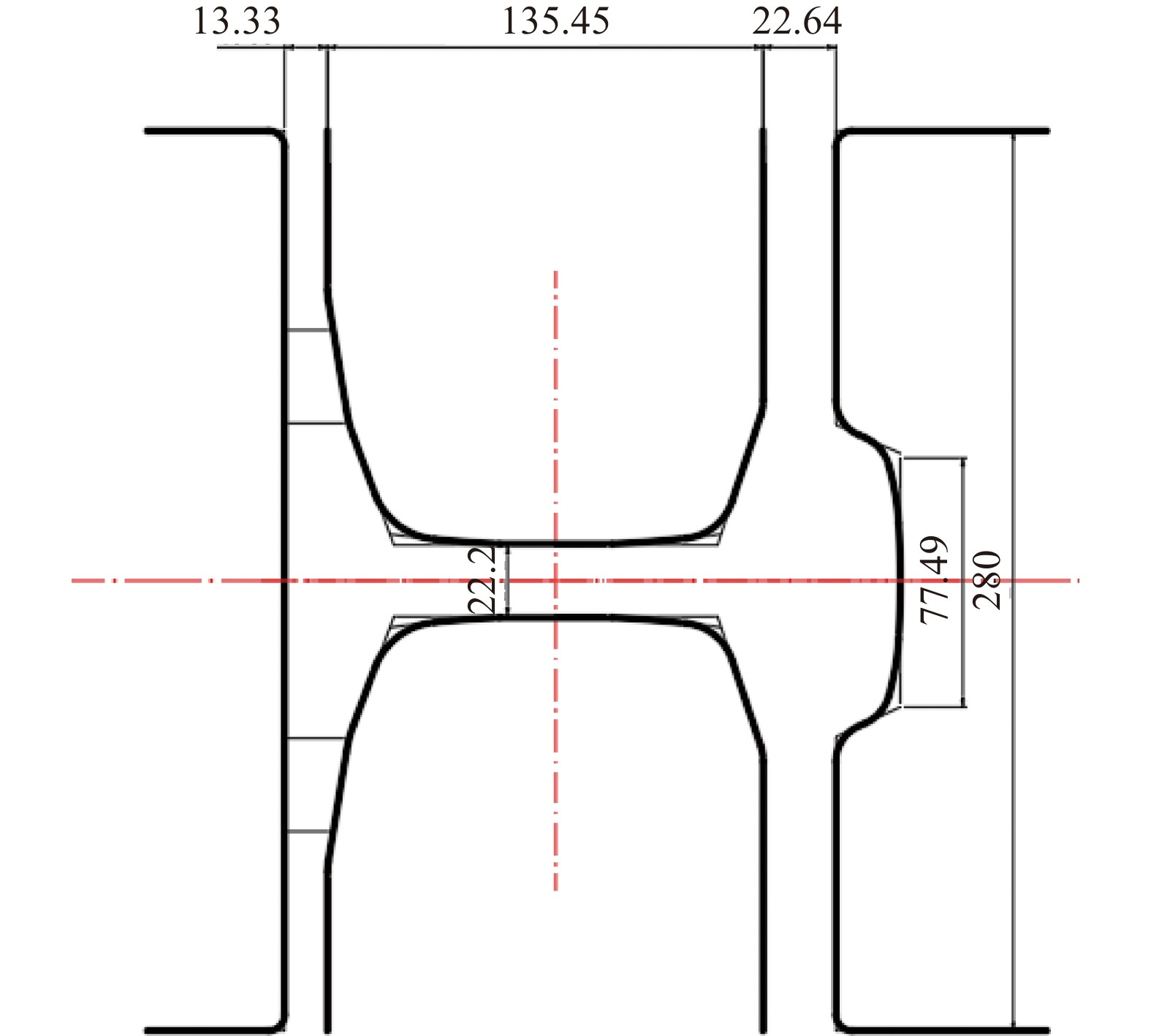

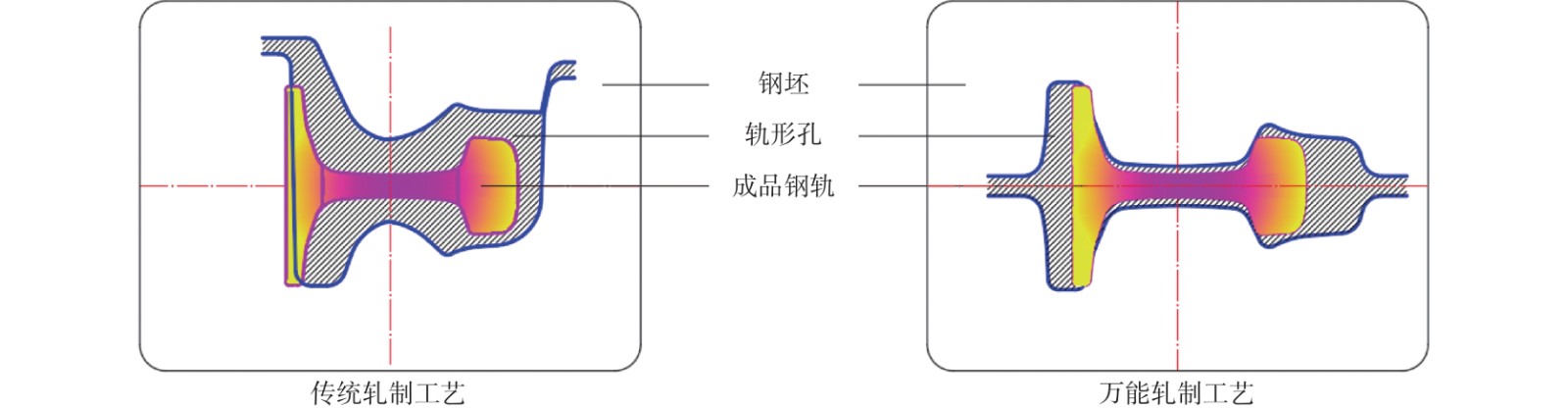

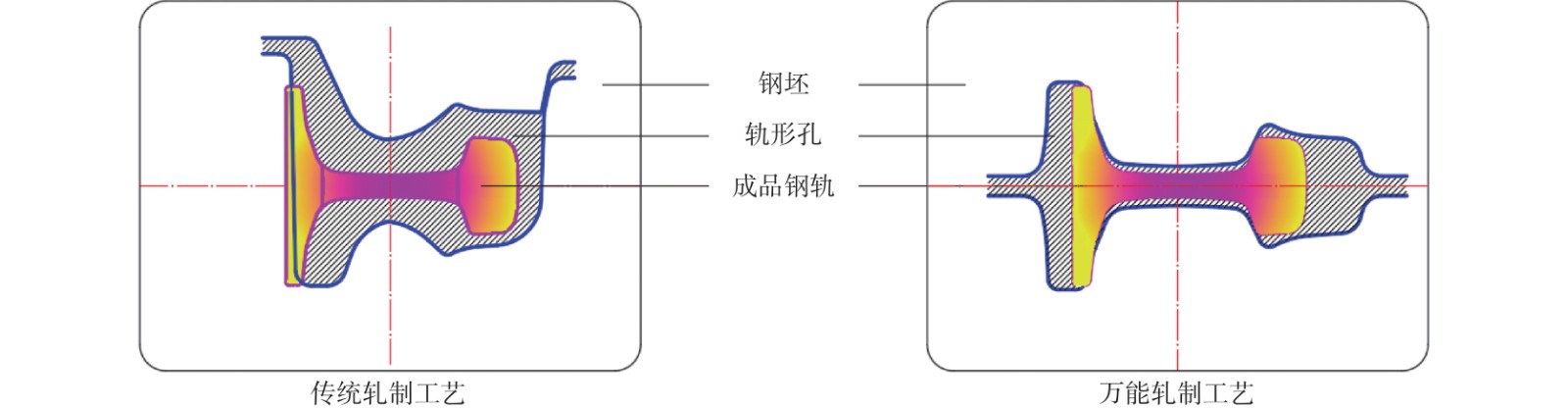

摘要: 结合实际生产经验,以七机架万能生产线钢轨产品为例进行了万能区孔型设计方法的研究与推演。根据成品尺寸及各道次的延伸系数、各孔型局部尺寸变形关系,反向推算出各道次轧件的断面面积、延伸系数,并在此基础上结合孔型设计经验确定出各道次孔型的结构形状、孔型尺寸。经现场应用表明,该研究成果可完全满足高精度钢轨的高效开发,具有减少孔型设计试错次数,设计效率高、产品成材率高、尺寸精度高及生产事故率低等特点。Abstract: Combined with practical production experience, taking the rail products of seven racks universal production line as an example, this paper studies and deduces the pass design method of the universal zone. According to the finished product size, each pass's elongation coefficient, the local size deformation relationship of each pass, the cross-sectional area, and the elongation coefficient of each pass are inversely calculated. On this basis, combined with the pass design experience, the structural shape and pass the size of each pass are determined. The field application for more than ten years shows that the research results can fully meet the efficient development of high-precision rail and have the characteristics of reducing the number of trial and error of pass design, high design efficiency, high product yield, and high dimensional accuracy and low production accident rate.

-

Key words:

- rail /

- universal pass /

- design method

-

-

[1] Tao Gongming, Ma Chaohui, Zhu Hualin, et al. Discussion on the layout of rolling mill for high quality rail[J]. Steel Rolling, 2017,34(3):48−51. (陶功明, 马朝辉, 朱华林, 等. 高质量钢轨的轧机布置形式探讨[J]. 轧钢, 2017,34(3):48−51. [2] Kang Yonglin, Zhu Guoming, Tao Gongming, et al. Digital technology and application of high precision section steel rolling[J]. Iron & Steel, 2017,52(3):49−57. (康永林, 朱国明, 陶功明, 等. 高精度型钢轧制数字化技术及应用[J]. 钢铁, 2017,52(3):49−57. -

下载:

下载: