Thermodynamic analysis of recovering valuable elements from steel slag by thermite reduction in converter

-

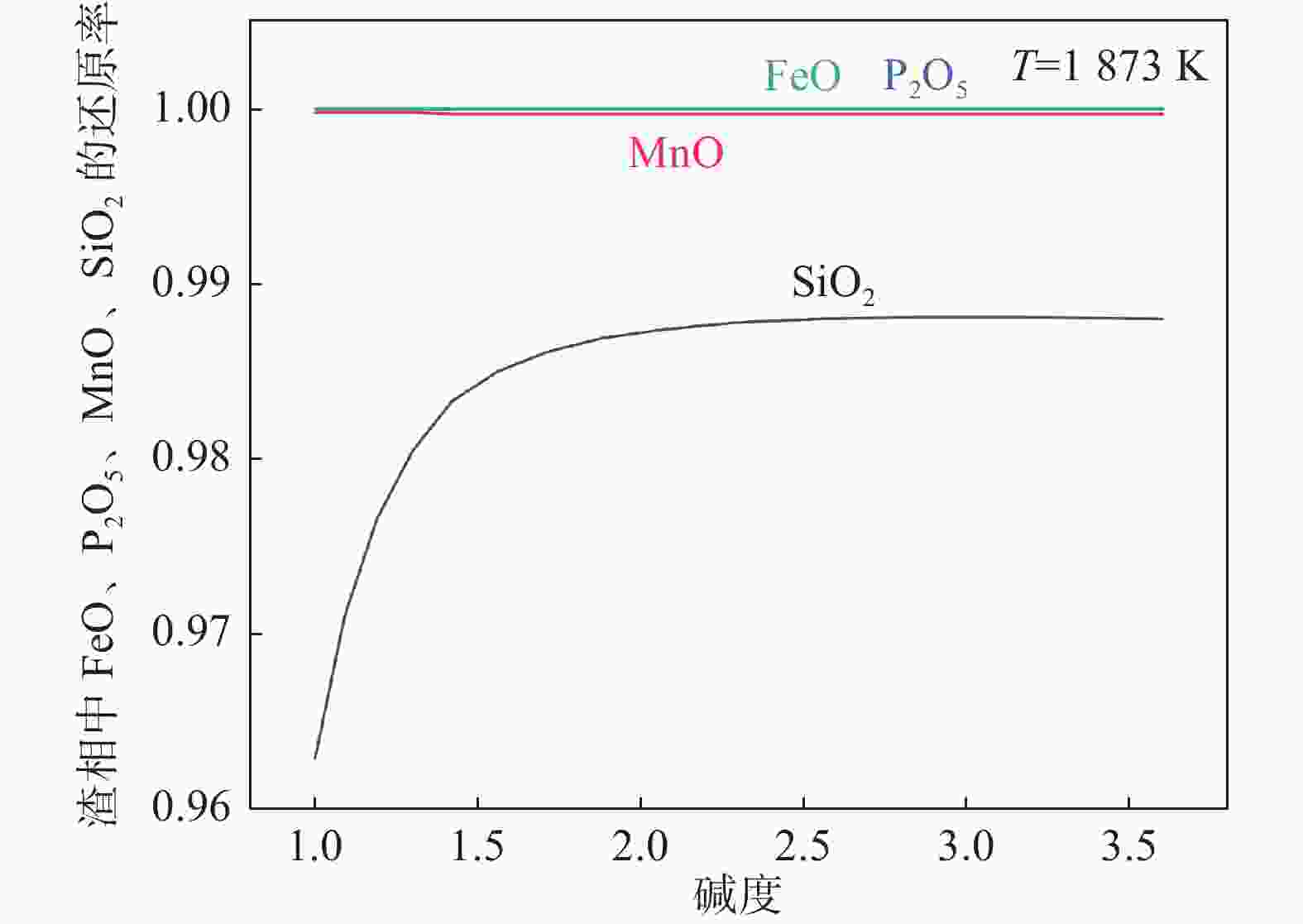

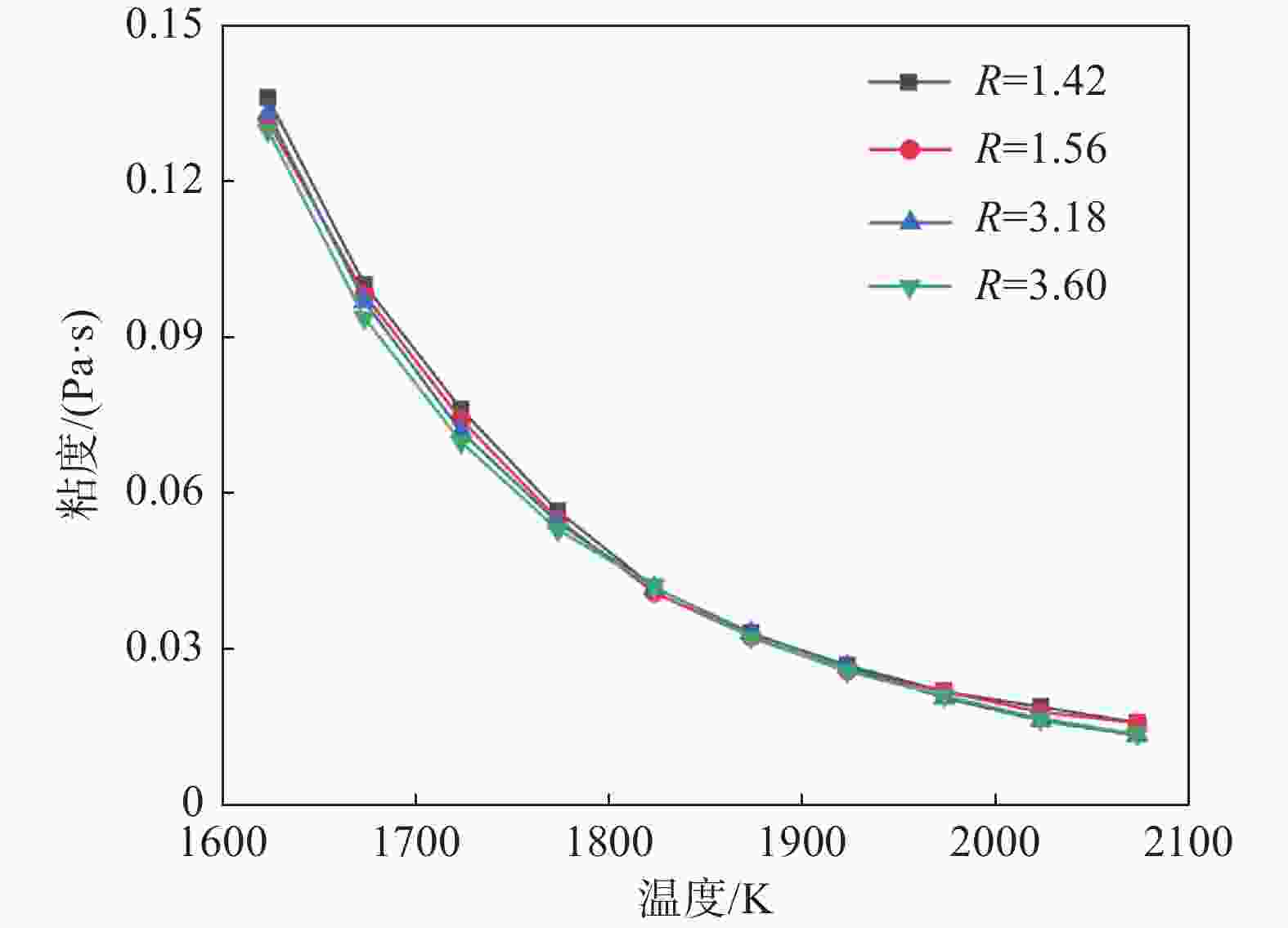

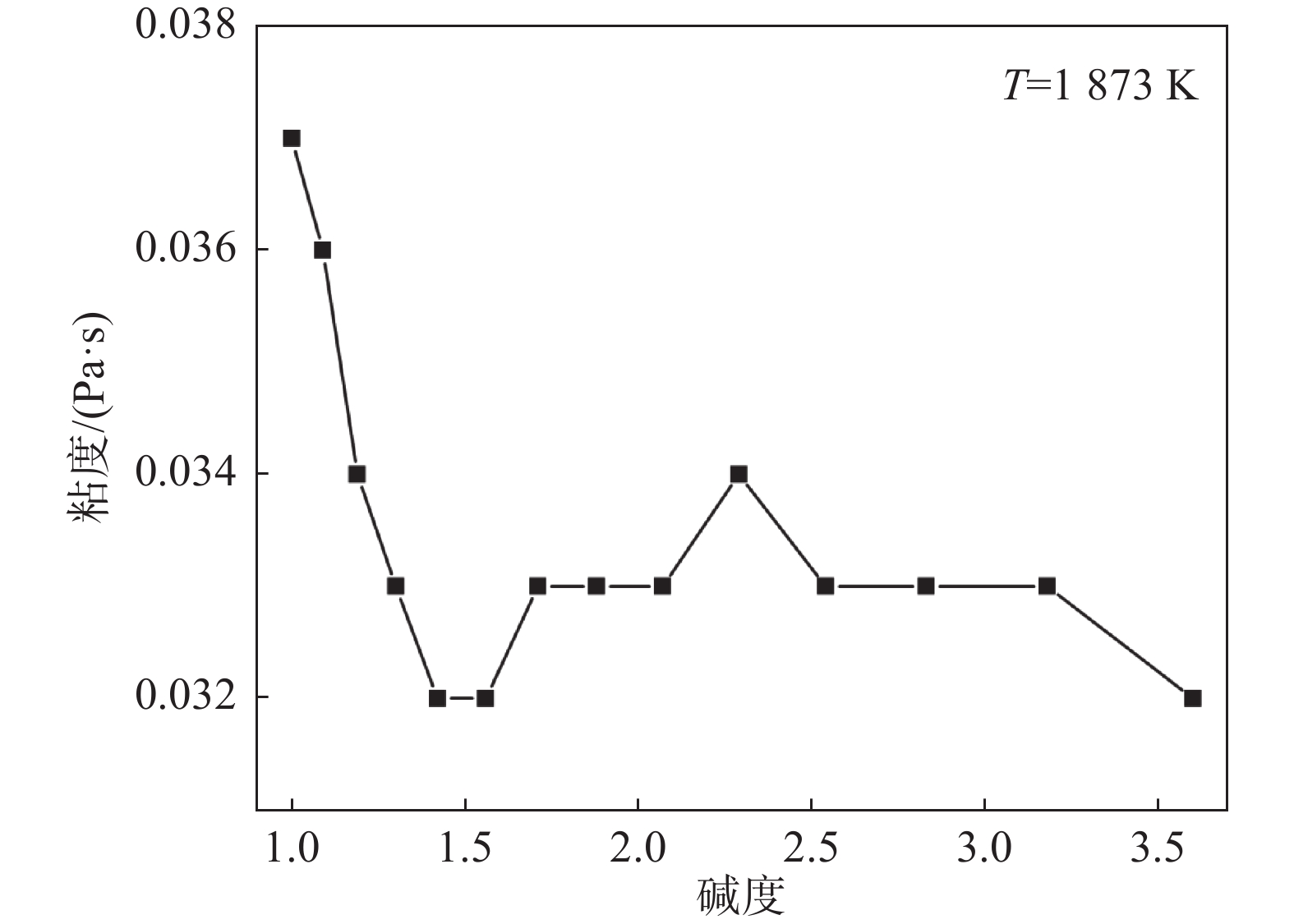

摘要: 针对转炉钢渣中铁、磷、锰及硅等有价元素的回收及钢渣资源化利用的问题,通过Factsage8.2软件热力学计算系统分析了转炉钢渣铝热还原回收有价元素的热力学条件和影响规律。结果表明,转炉钢渣的碱度对铝热还原回收FeO、P2O5、MnO的影响不大,提高转炉钢渣碱度有利于SiO2的还原回收;温度变化对FeO、P2O5、MnO回收的影响也不大,但是温度升高不利于转炉钢渣中SiO2的还原。当转炉钢渣碱度为3.18,温度为

1873 K、w(Al/Slag)=20%时,铝热还原转炉钢渣回收有价元素的效果相对最佳,转炉钢渣中的FeO、P2O5、MnO、SiO2的还原率高达100%、100%、99.97%、98.12%。这为转炉钢渣铝热还原回收有价元素及钢渣资源化利用提供重要的研究基础。Abstract: Aiming at recovery of valuable elements such as Fe, P, Mn and Si from Bessemer steel slag and utilization of steel slag, the thermodynamic conditions and influencing rules of thermite reduction and recovery of valuable elements from Bessemer steel slag were analyzed by a Factsage8.2 software thermodynamic calculation system. The results show that basicity of the slag has little effect on the recovery of FeO, P2O5 and MnO in thermite reduction, and the improvement of slag basicity is beneficial to SiO2 recovery. The change of temperature has little effect on the recovery of FeO, P2O5 and MnO, but increasing temperature is not conducive to the reduction of SiO2 in the steel slag. When the slag basicity is 3.18 and the temperature is1873 K, w(Al/Slag)=20%, the recovery of valuable elements can be achieved the relatively best effect, and the reduction rates of FeO, P2O5, MnO and SiO2 in the slag are as high as 100%, 100%, 99.97% and 98.12%, respectively. These studied results can be used for the efficient recovery of valuable elements and resource utilization of steel slag by thermite reduction.-

Key words:

- converter steel slag /

- thermite reduction /

- valuable elements /

- recovery /

- reduction rates /

- thermodynamic conditions

-

表 1 转炉钢渣的主要成分

Table 1. Main components of converter steel slag

% CaO SiO2 MgO P2O5 MnO FeO Al2O3 35 11 11 2 4 30 7 -

[1] Yüksel I. A review of steel slag usage in construction industry for sustainable development[J]. Environ. Dev. Sustain., 2017,(2):1−19. [2] Feng J J, Sun J W. A comparison of the 10-year properties of converter steel slag activated by high temperature and an alkaline activator[J]. Constr. Build. Mater., 2020,234:116948. doi: 10.1016/j.conbuildmat.2019.116948 [3] 鲁慧慧. 转炉钢渣回收铁试验研究[D]. 西安: 西安建筑科技大学, 2010.Lu Huihui. Experimental reserrch on recovery of iron from BOF slag[D]. Xi, an: Xi , an University of Architecture and Technology, 2010. [4] 崔玉元. 钢渣中有价组元回收及资源化利用的基础研究[D]. 沈阳: 东北大学, 2013.Cui Yuyuan. Fundamental research on recovery of valuable components and resource[D]. Shenyang: Northeastern University, 2013. [5] Wang Deyong, Li Yong, Liu Jian, et al. A new design of Fe and P simultaneous recovery from steel slag[J]. China Metallurgy, 2011,21(8):50−54. (王德永, 李勇, 刘建, 等. 钢渣中同时回收铁和磷的资源化利用新思路[J]. 中国冶金, 2011,21(8):50−54.Wang Deyong, Li Yong, Liu Jian, et al. A new design of Fe and P simultaneous recovery from steel slag[J]. China Metallurgy, 2011, 21 (8): 50-54 [6] Tian Zhen, Yu Qingxian, Chen Min. Thermodynamic study on production of Fe-Si-Mn alloy from adjusted converter slag[J]. Advanced Materials Research, 2011,295-297:2290−2293. doi: 10.4028/www.scientific.net/AMR.295-297.2290 [7] 黄伟军, 陈敏, 纪安. 利用熔融改质钢渣冶炼Fe-Si-Mn合金的热力学研究[C]//第十六届冶金反应工程学会议论文集. 唐山: 中国金属学会, 2012.Huang Weijun, Chen Min, Ji An. Thermodynamic study on production of Fe-Si-Mn alloy from adjusted converter slag[C]//Proceedings of the 16th Conference on Metallurgical Reaction Engineering. Tangshan: China Metal Society, 2012. [8] Ai Liqun, Zhang Yanlong, Zhu Yiheng. Research on carbothermic reduction for dephosphorization from converter slag by microwave heating[J]. Iron Steel Vanadium Titanium, 2015,36(6):63−67. (艾立群, 张彦龙, 朱祎姮. 微波碳热还原转炉钢渣脱磷研究[J]. 钢铁钒钛, 2015,36(6):63−67.Ai Liqun, Zhang Yanlong, Zhu Yiheng. Research on carbothermic reduction for dephosphorization from converter slag by microwave heating[J]. Iron Steel Vanadium Titanium, 2015, 36 (6): 63-67 [9] Zhang Yanlong, Ai Liqun, Zhang Xiaomei, et al. Recovering iron from converter steel slag by microwave processing[J]. Mining and Metallurgy Engineering, 2015,35(4):80−83. (张彦龙, 艾立群, 张小妹, 等. 微波处理转炉钢渣回收铁的试验研究[J]. 矿冶工程, 2015,35(4):80−83.Zhang Yanlong, Ai Liqun, Zhang Xiaomei, et al. Recovering iron from converter steel slag by microwave processing[J]. Mining and Metallurgy Engineering, 2015, 35 (4): 80-83 [10] Lv Yan, Zhang Meng, Ai Liqun, et al. Research on carbothermic reduction for dephosphorization from converter slag by microwave heating[J]. Steelmaking, 2010,26(4):70−74. (吕岩, 张猛, 艾立群, 等. 微波处理碳热还原转炉钢渣的脱磷试验研究[J]. 炼钢, 2010,26(4):70−74.Lv Yan, Zhang Meng, Ai Liqun, et al. Research on carbothermic reduction for dephosphorization from converter slag by microwave heating[J]. Steelmaking, 2010, 26 (4): 70-74 [11] He Sai, Lin Lu, Liu Yaqin, et al. Recovery of valuable elements from molten modified phosphorous steel slag by carbothermic reduction[J]. Iron & Steel, 2022,57(6):167−174. (何赛, 林路, 刘亚琴, 等. 熔融改质含磷钢渣碳热还原回收有价元素试验[J]. 钢铁, 2022,57(6):167−174.He Sai, Lin Lu, Liu Yaqin, et al. Recovery of valuable elements from molten modified phosphorous steel slag by carbothermic reduction[J]. Iron & Steel, 2022, 57 (6): 167-174 [12] Shen Xiang, Chen Min, Zheng Xiaorui. Migration behavior of components in converter slag during smelting reduction process using aluminum dross[J]. ISIJ International, 2021,61(1):49−54. doi: 10.2355/isijinternational.ISIJINT-2020-436 [13] Jung Ho Heo, Yongsug Chung, Joo Hyun Park. Recovery of iron and removal of hazardous elements from waste copper slag via a novel aluminothermic smelting reduction (ASR)process[J]. Journal of Cleaner Production, 2016,137:777−787. doi: 10.1016/j.jclepro.2016.07.154 [14] Jung Ho Heo, Joo Hyun Park. Thermochemical analysis for the reduction behavior of FeO in EAF slag via aluminothermic smelting reduction (ASR) process: Part Ι. Effect of aluminum on Fe & Mn recovery[J]. Calphad, 2017,58:219−228. doi: 10.1016/j.calphad.2017.02.005 [15] Liu Chao, Zhang Yuzhu, Kang Yue. Factsage calculation of the influence of MgO on the viscosity of BF slag[J]. Journal of Hebei Union University (Natural Science Edition), 2014,36(4):25−29. (刘超, 张玉柱, 康月. Factsage计算MgO含量对高炉渣粘度的影响[J]. 河北联合大学学报(自然科学版), 2014,36(4):25−29.Liu Chao, Zhang Yuzhu, Kang Yue. Factsage calculation of the influence of MgO on the viscosity of BF slag[J]. Journal of Hebei Union University (Natural Science Edition), 2014, 36 (4): 25-29 -

下载:

下载: