Study on iron removal from industrial titanium gypsum

-

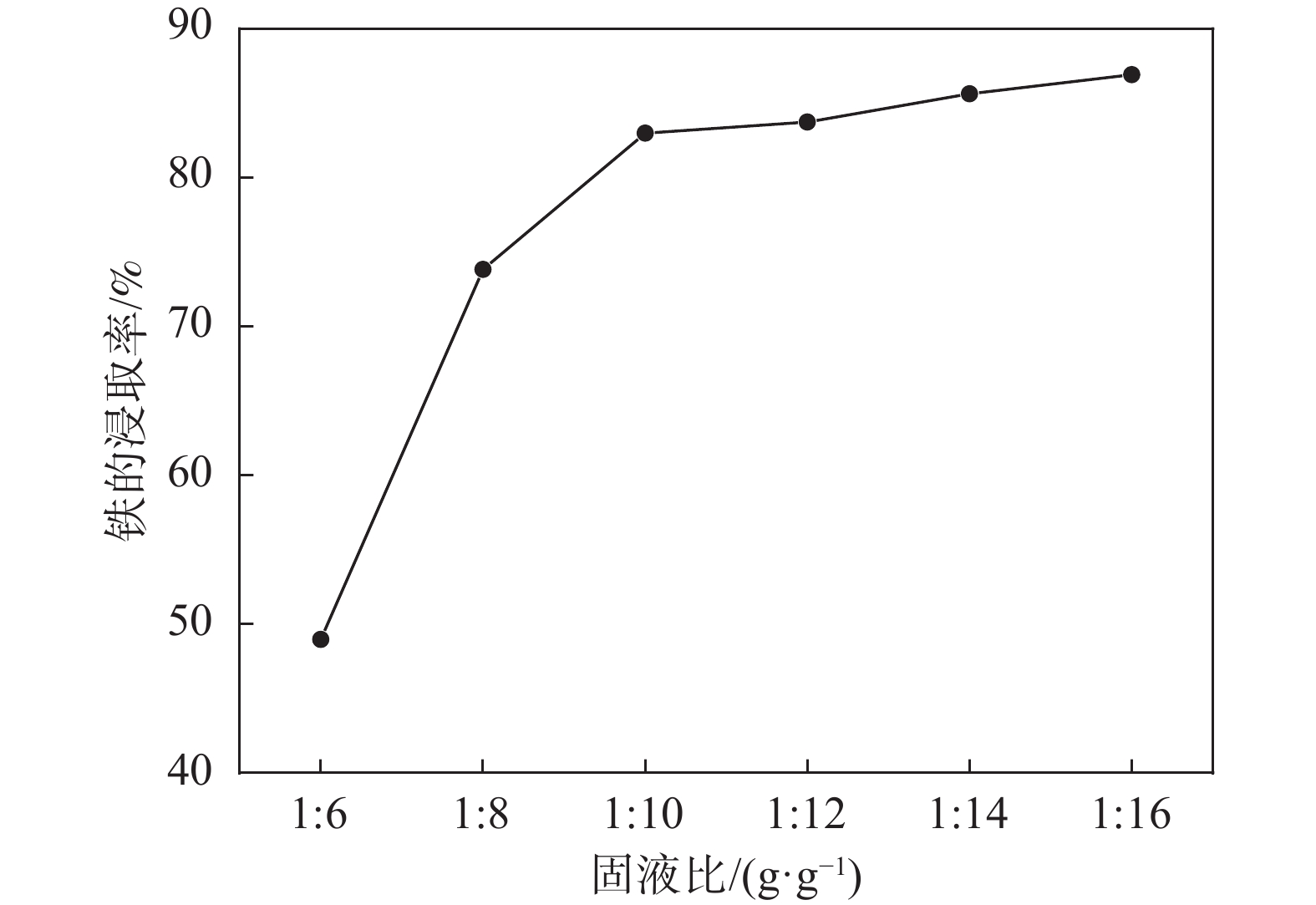

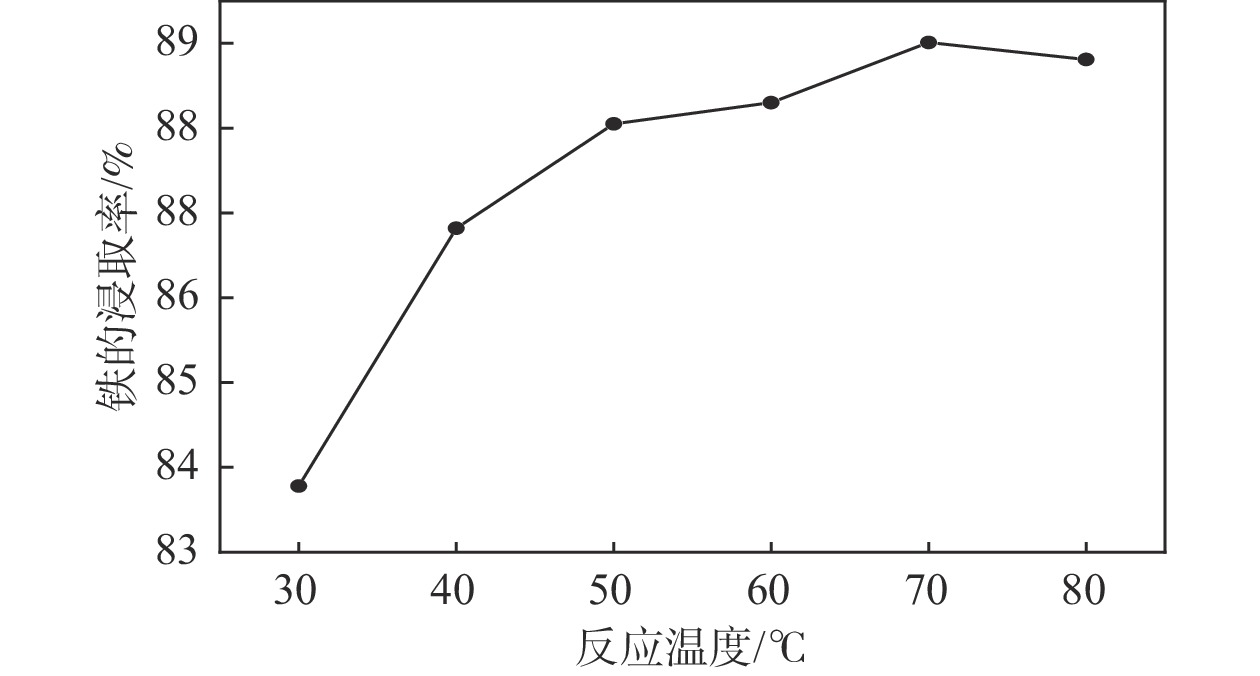

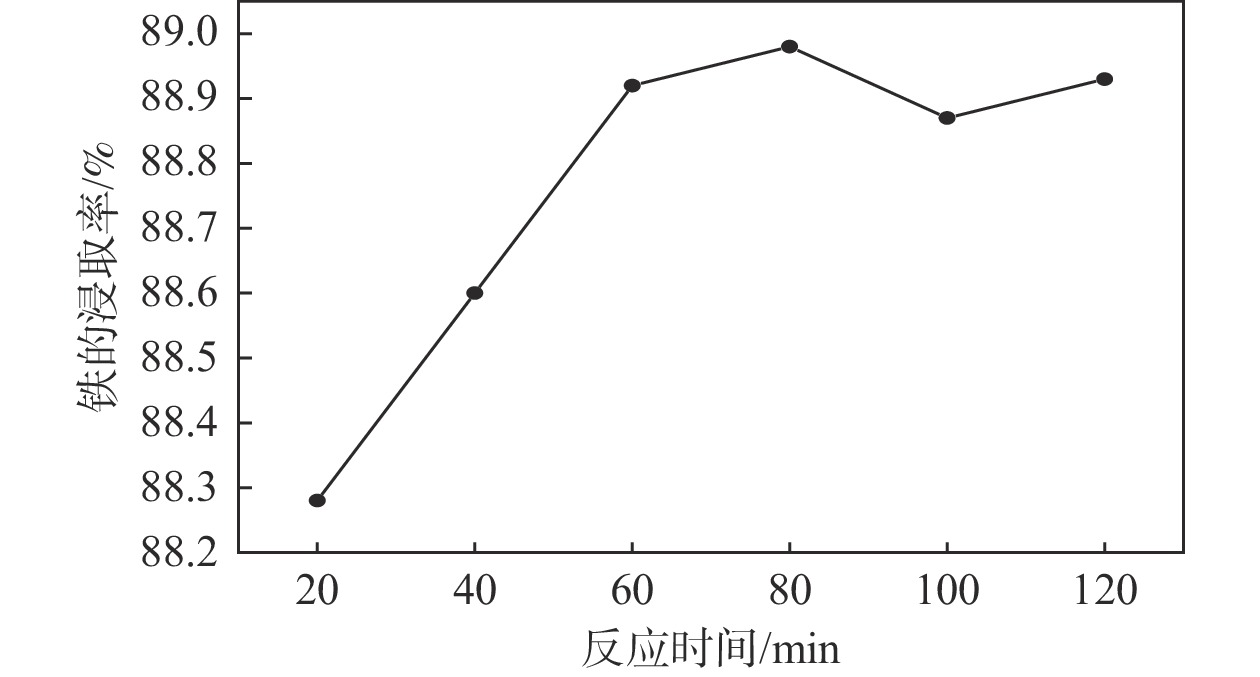

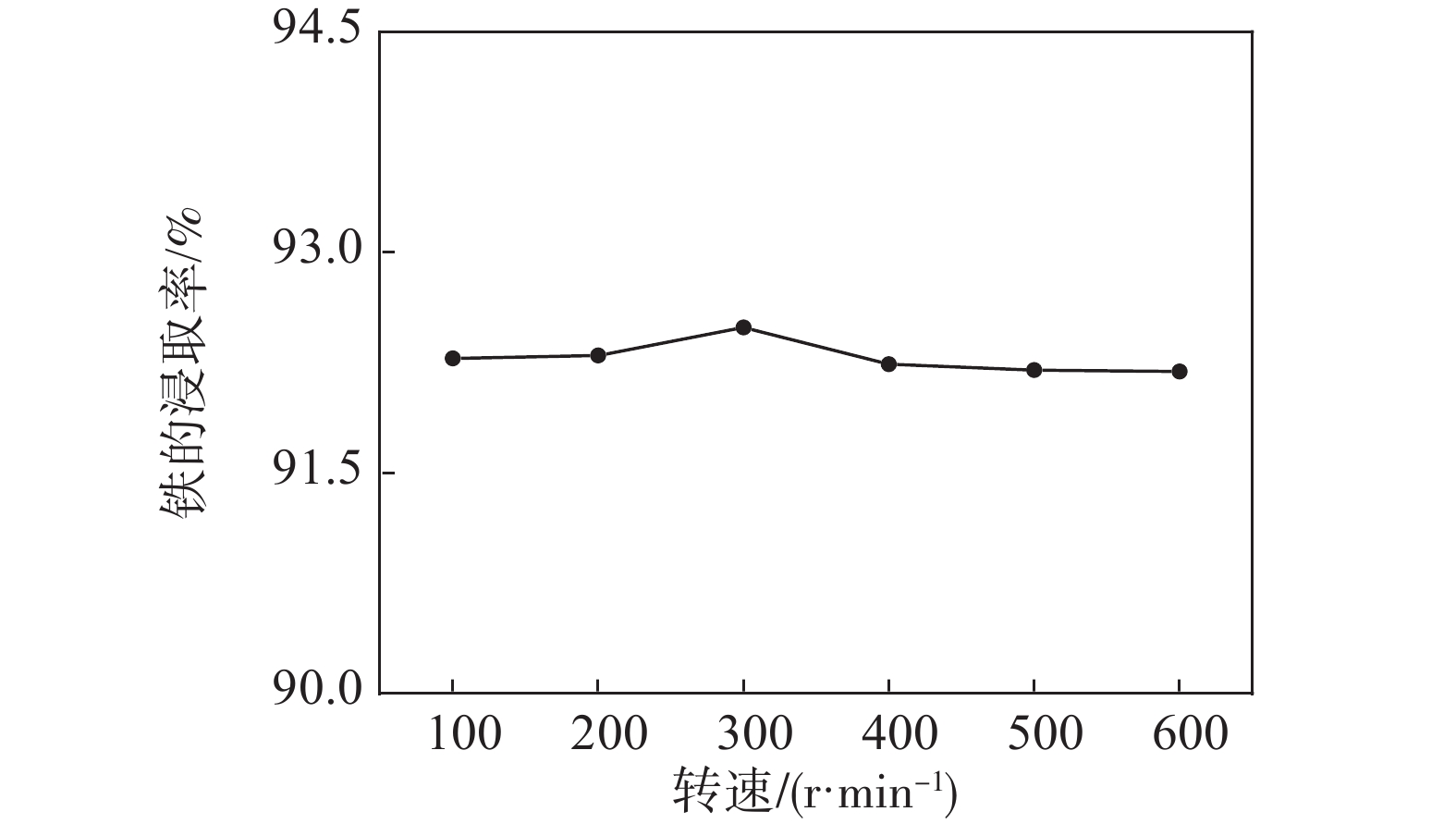

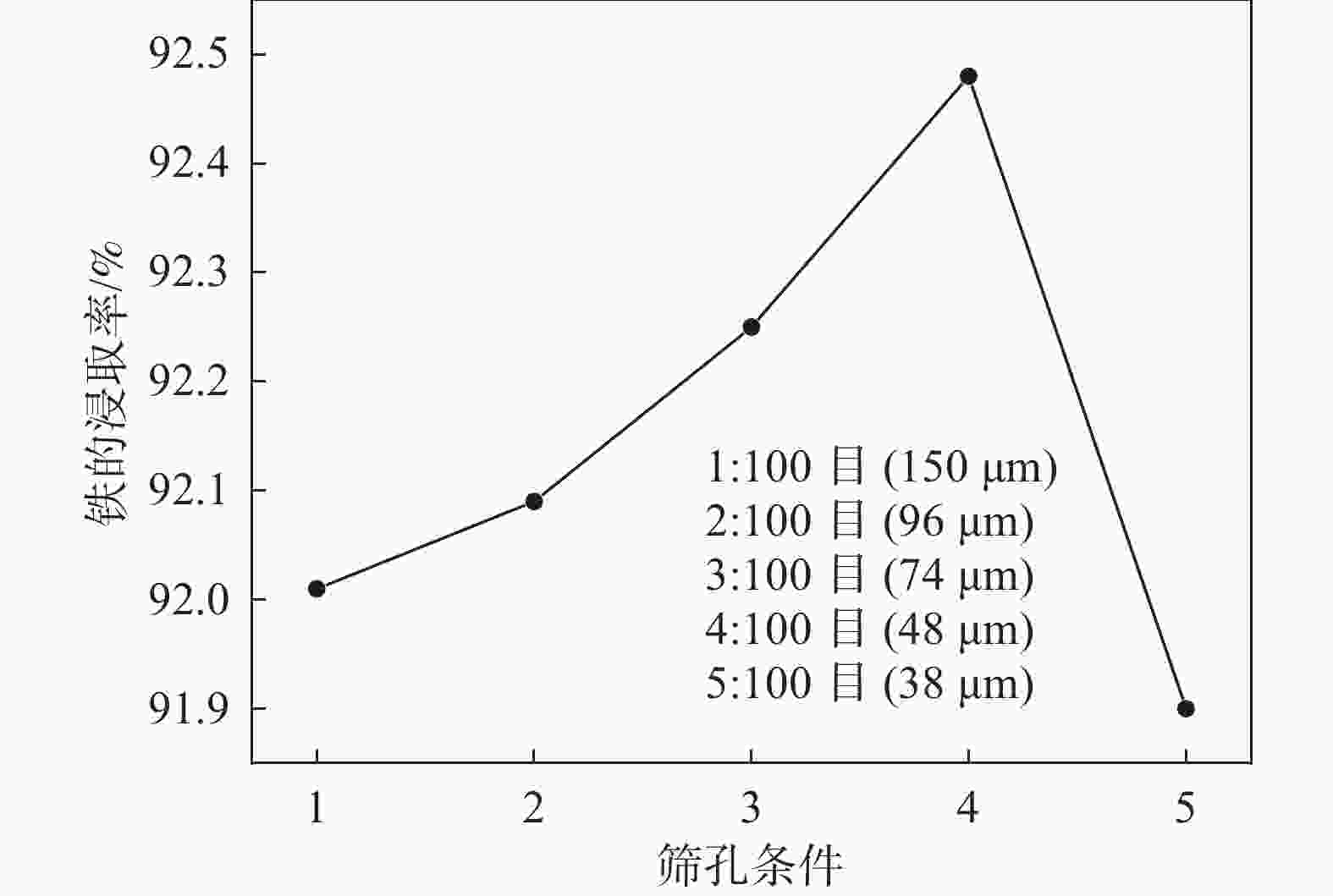

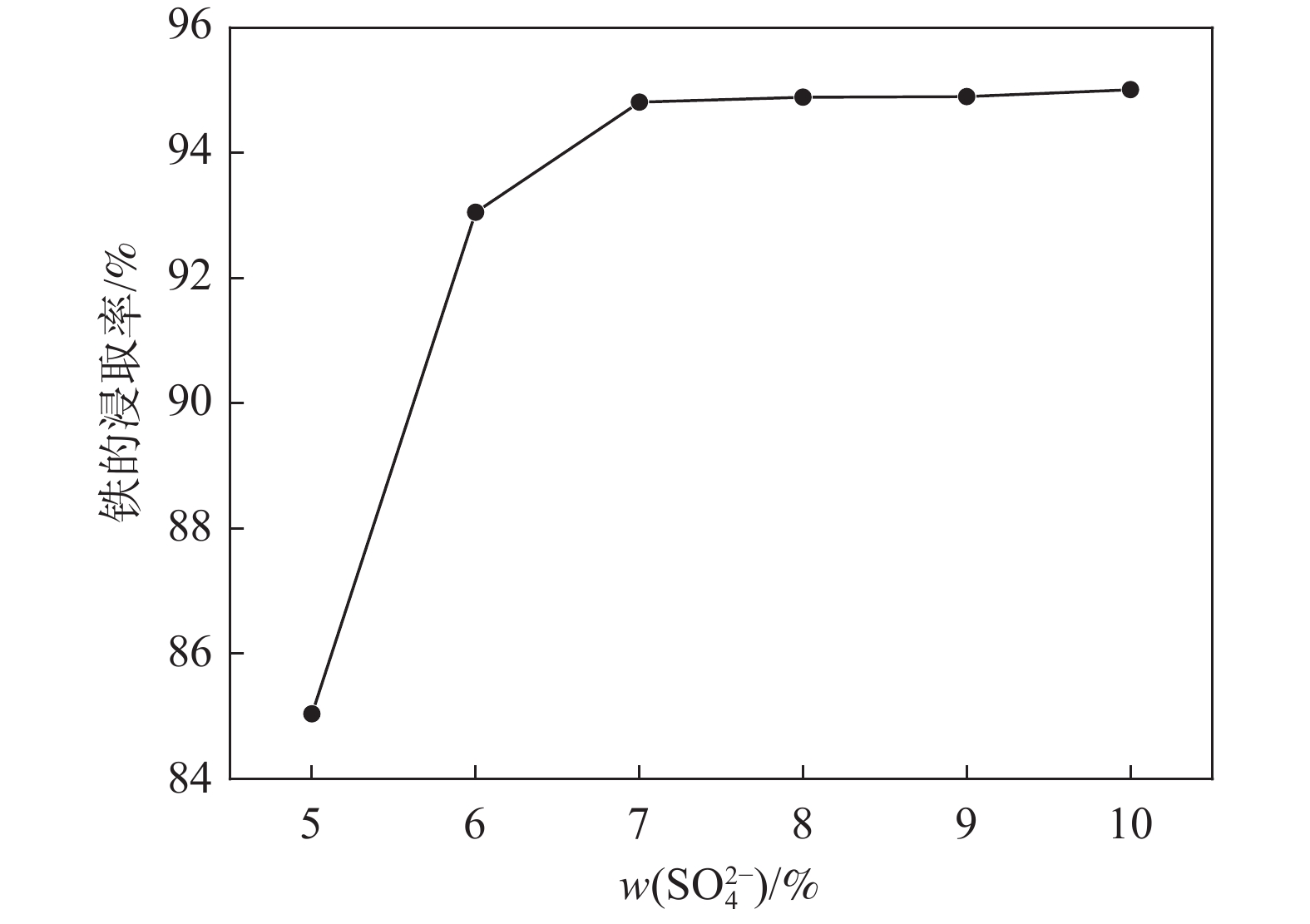

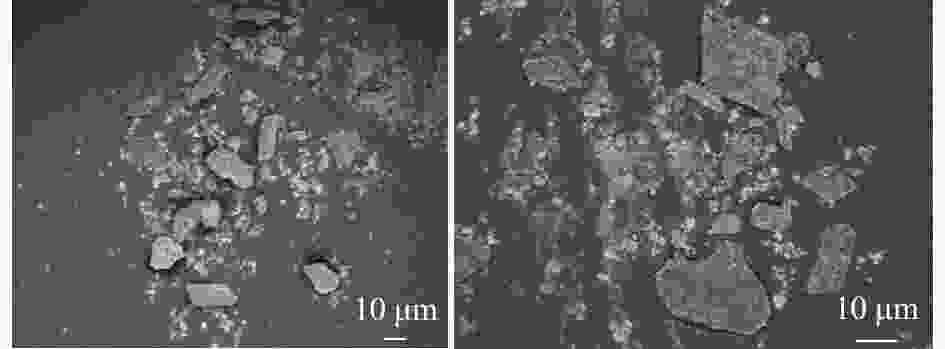

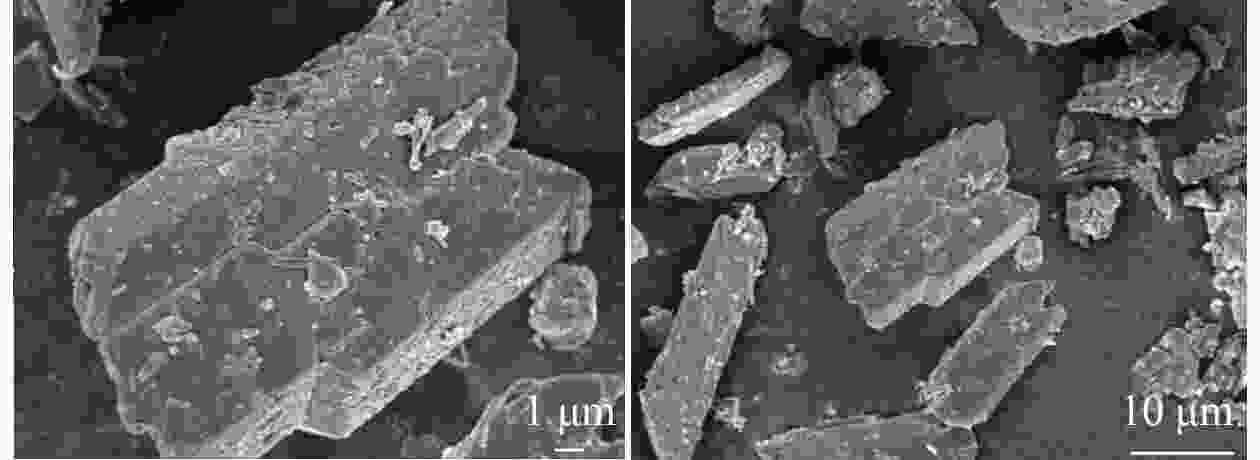

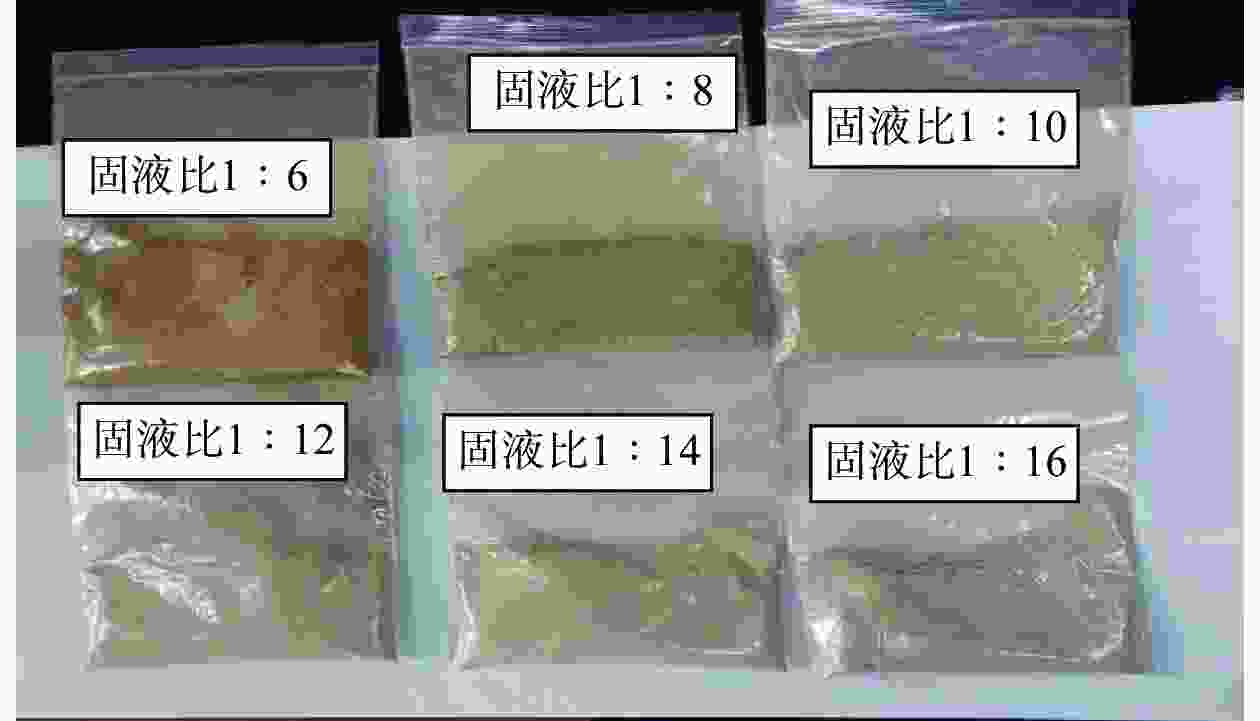

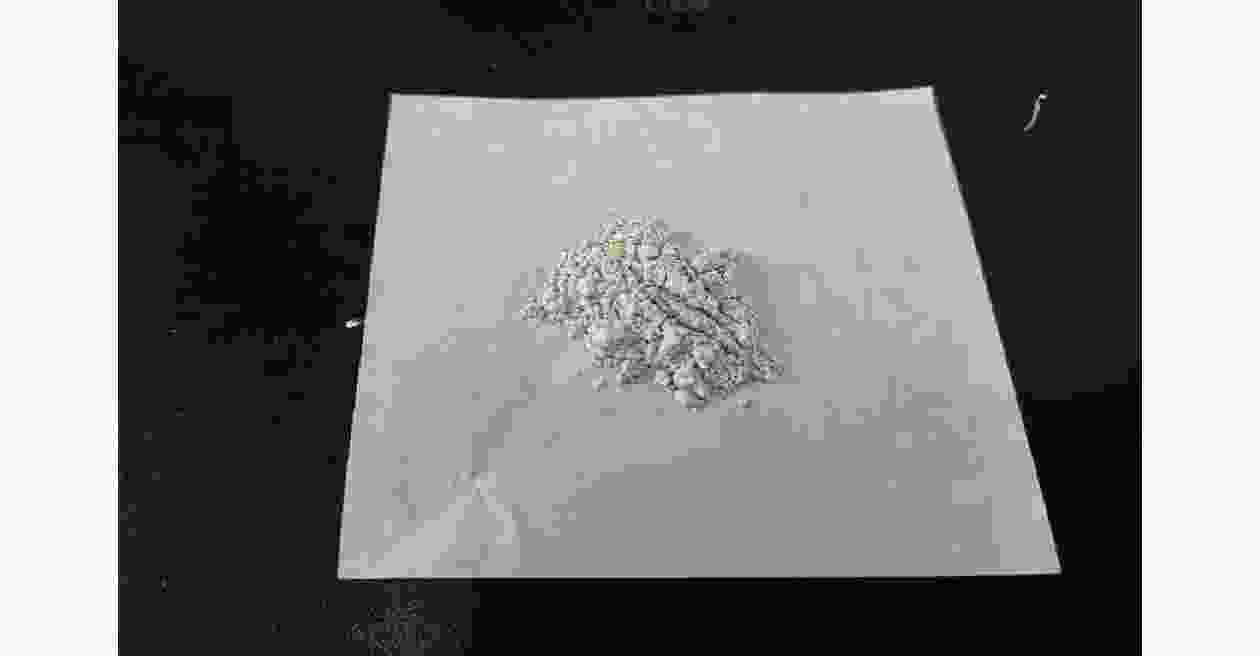

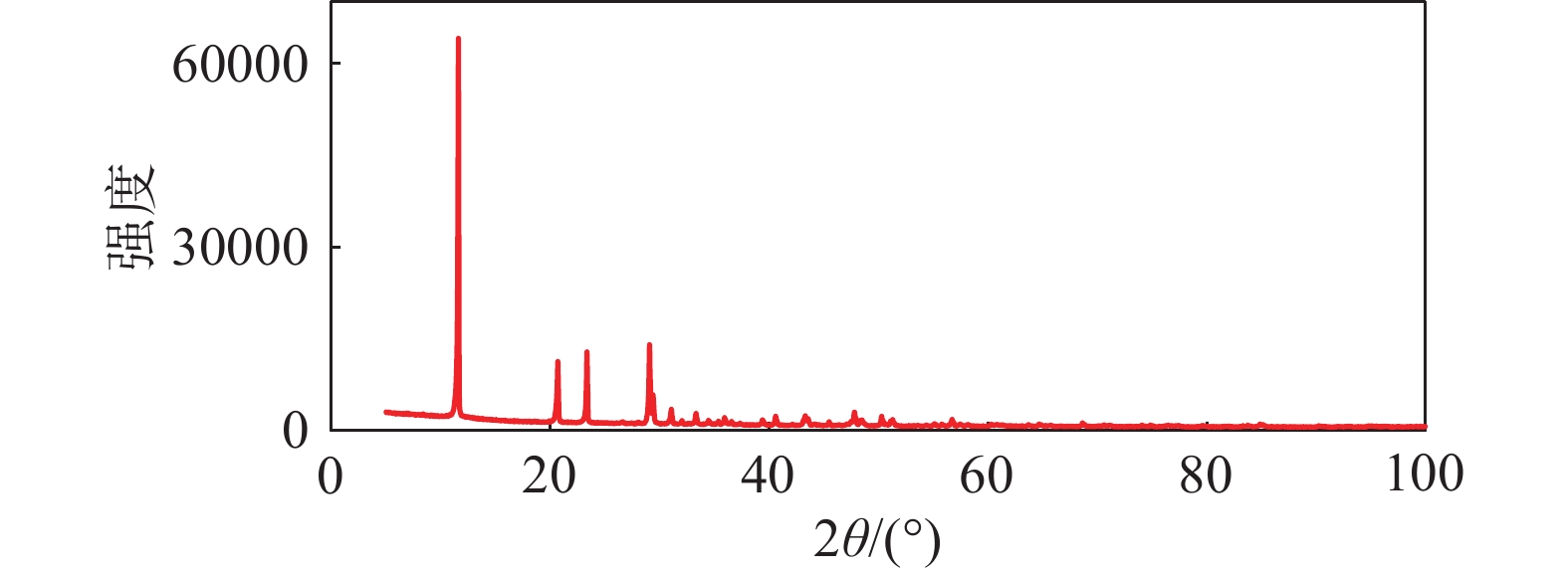

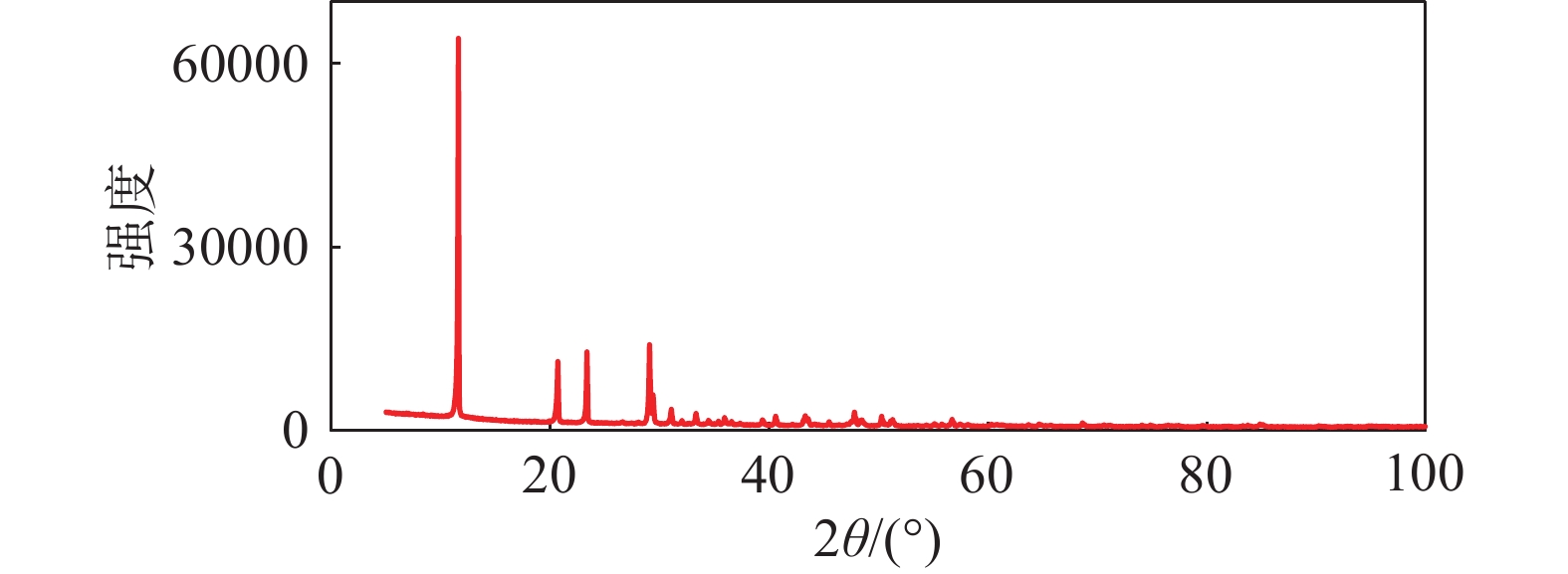

摘要: 针对硫酸酸浸钛石膏进行除铁工艺研究,去除钛石膏中的铁离子杂质,实现钛石膏纯度和白度的有效改善,为钛石膏下游产品的开发利用提供充足的原料。试验研究了固液比、反应温度、反应时间、转速、粒度和硫酸浓度等不同酸浸条件下的除铁效果,获得适宜的工艺条件,结合其物相、微观相貌、粒度分布等属性的变化情况,同时探讨了钛石膏除杂机理。结果表明,在钛石膏硫酸酸浸除杂过程中,适宜的工艺条件为:固液比为 1:10 g/g、反应温度为70 ℃、反应时间为60 min、SO42−质量分数为7%、转速为 400 r/min、粒度为150 μm,此时钛石膏除铁率可达到94%,白度有了明显的改善。Abstract: In this study, the removal of iron impurity contained in the industrial sulfuric acid leaching titanium gypsum was investigated, which leads to effective improvement of purity and whiteness of titanium gypsum, providing sufficient raw materials for the development and utilization of titanium gypsum downstream products. The effect of iron removal under different acid leaching conditions such as solid-liquid ratio, reaction temperature, reaction time, rotation speed, particle size and sulfuric acid concentration was studied and the optimum process conditions was discovered. Furthermore, the impurity removal mechanism of titanium gypsum was found out based on the changes of phase, microstructure and particle size distribution. During the process of removing iron from titanium gypsum by sulfuric acid leaching, the optimal process parameters are obtained as follows: solid-liquid ratio of 1:10 g/g, reaction temperature of 70 ℃, reaction time of 60 min, SO42− mass fraction of 7%, rotating speed of 400 r/min and particle size of 150 μm, under which the iron removal leaching rate of titanium gypsum can reach 94%. Under the optimal conditions, the acid leaching product changes from light yellow to gray white, and the whiteness is evidently improved.

-

Key words:

- titanium gypsum /

- iron removal /

- Fe2+ /

- sulfuric acid /

- solid-liquid ratio /

- reaction temperature /

- leaching rate

-

表 1 钛石膏主要元素组成

Table 1. Main element composition of titanium gypsum

% O Fe Ca S C Al Mn Mg Zn Si 52.79 20.98 11.75 10.88 2.04 0.43 0.42 0.34 0.23 0.08 表 2 钛石膏原样及优化后试样的粒径点分布

Table 2. Particle size distribution of titanium gypsum samples

粒径/μm 含量/% 原样 优化后 ≤1 9.37 5.42 1~2 7.18 3.85 2~5 12.31 9.28 5~10 10.60 10.60 10~20 12.54 15.85 20~45 17.70 25.79 45~75 13.76 15.32 75~100 6.75 6.38 100~200 9.00 6.80 200~300 0.79 0.71 -

[1] He Yan. Production status and market analysis of titanium dioxide at home and abroad[J]. Chemical Industry Times, 1998,(1):38−40. (何燕. 国内外钛白粉生产状况与市场分析[J]. 化工时刊, 1998,(1):38−40.He Yan. Production status and market analysis of titanium dioxide at home and abroad[J]. Chemical Industry Times, 1998(1): 38-40 [2] Zhang Kai, Ren Tingyan, Zhu Xinfeng, et al. Status quo of emission and comprehensive utilization of industrial by-product gypsum in China[J]. Wall Material Innovation and Building Energy Saving, 2009,(12):26−28. (张凯, 任婷艳, 朱新锋, 等. 国内工业副产石膏的排放及综合利用现状[J]. 墙材革新与建筑节能, 2009,(12):26−28.Zhang Kai, Ren Tingyan, Zhu Xinfeng, et al. Status quo of emission and comprehensive utilization of industrial by-product gypsum in China[J]. Wall Material Innovation and Building Energy Saving, 2009(12): 26-28 [3] 刘洪, 郝朝阳, 朱静平. 钛白石膏的物相组成及其脱水性能的研究[J]. 西昌学院学报(自然科学版), 2010, 24(3): 29-30.Liu Hong, Hao Chaoyang, Zhu Jingping, Study on phase composition and dewatering property of titanium white gypsum[J]. Journal of Xichang College (Natural Science Edition), 2010, 24(3): 29-30. [4] Xu Ping, Lin Hai, Xing Xifeng, et al. Experimental study on acid wastewater treatment in titanium dioxide plant[J]. Industrial Water Treatment, 2007,(7):53−56. (许平, 林海, 邢喜峰, 等. 钛白粉厂酸性废水处理的试验研究[J]. 工业水处理, 2007,(7):53−56.Xu Ping, Lin Hai, Xing Xifeng, et al. Experimental study on acid wastewater treatment in titanium dioxide plant[J]. Industrial Water Treatment, 2007(7): 53-56 [5] Wang Jianwei, Ren Xiulian, Wei Qifeng, et al. Research status and prospect of comprehensive utilization of waste acid of titanium dioxide[J]. Hydrometallurgy of China, 2009,41(9):4−7. (王建伟, 任秀莲, 魏琦峰, 等. 钛白废酸的综合利用研究现状及展望[J]. 无机盐工业, 2009,41(9):4−7.Wang Jianwei, Ren Xiulian, Wei Qingfeng, et al. Research status and prospect of comprehensive utilization of waste acid of titanium dioxide[J]. Hydrometallurgy of China, 2009, 41(9): 4-7 [6] Peng Zhihui, Liu Qiaoling, Peng Jiahui, et al. Study on titanium gypsum as cement retarder[J]. Journal of Chongqing University of Architecture, 2004,(1):93−96. (彭志辉, 刘巧玲, 彭家惠, 等. 钛石膏作水泥缓凝剂研究[J]. 重庆建筑大学学报, 2004,(1):93−96.Peng Zhihui, Liu Qiaoling, Peng Jiahui, et al. Study on titanium gypsum as cement retarder[J]. Journal of Chongqing University of Architecture, 2004(1): 93-96 [7] Liu Changchun, Li Rongjun, Liu Lei. Experimental study on titanium gypsum as cement retarder[J]. Cement, 2006,(11):4−6. (刘长春, 李荣军, 刘磊. 钛石膏作水泥缓凝剂的试验研究[J]. 水泥, 2006,(11):4−6.Liu Changchun, Li Rongjun, Liu Lei. Experimental study on titanium gypsum as cement retarder[J]. Cement, 2006(11): 4-6 [8] Gazquez M J, Bolivar J P, Vaca F, et al. Evaluation of the use of TiO2 industry red gypsum waste in cement production[J]. Cement & Concrete Composites, 2013,37(1):76−81. [9] Zhao Yujing, Shi Huisheng. Study on flyash-titanium white gypsum roadbed materials[J]. Journal of Building Materials, 2000,(4):328−334. (赵玉静, 施惠生. 粉煤灰-钛白石膏路基材料的研究[J]. 建筑材料学报, 2000,(4):328−334.Zhao Yujing, Shi Huisheng. Study on flyash-titanium white gypsum roadbed materials[J]. Journal of Building Materials, 2000(4): 328-334 [10] Shi Huisheng, Yuan Ling, Zhao Yujing. Study on modification of chemical waste gypsum fly ash composite cementitious material[J]. Journal of Building Materials, 2002,(2):126−131. (施惠生, 袁玲, 赵玉静. 化工废石膏粉煤灰复合胶凝材料的改性研究[J]. 建筑材料学报, 2002,(2):126−131.Shi Huisheng, Yuan Ling, Zhao Yujing. Study on modification of chemical waste gypsum fly ash composite cementitious material[J]. Journal of Building Materials, 2002(2): 126-131 [11] Ma Yuan, Fan Chuangang, Wu You, et al. Preparation and characterization of persulfur titanium gypsum slag cement[J]. Non-metallic Mines, 2016,39(6):41−44. (马远, 樊传刚, 吴悠, 等. 过硫钛石膏矿渣水泥的制备与性能表征[J]. 非金属矿, 2016,39(6):41−44. doi: 10.3969/j.issn.1000-8098.2016.06.013Ma Yuan, Fan Chuangang, Wu You, et al. Preparation and characterization of persulfur titanium gypsum slag cement[J]. Non-metallic Mines, 2016, 39(6): 41-44 doi: 10.3969/j.issn.1000-8098.2016.06.013 [12] Fauziah I, Zauyah S, Jamal T. Characterization and land application of red gypsum: a waste product from the titanium dioxide industry[J]. Science of the Total Environment, 1996,188(2-3):243−251. doi: 10.1016/0048-9697(96)05179-0 [13] Wang Xiao, Liu Qiang, Yang Liushuan, et al. Characteristics and thermogravimetric analysis of titanium gypsum particles[J]. Bull Chin Ceram Soc, 2014,33(1):212−215. (汪潇, 刘强, 杨留栓, 等. 钛石膏颗粒物特性及其热重分析[J]. 硅酸盐通报, 2014,33(1):212−215.Wang Xiao, Liu Qiang, Yang Liushuan, et al. Characteristics and thermogravimetric analysis of titanium gypsum particles[J]. Bull Chin Ceram Soc, 2014, 33(1): 212-215 [14] Meng Hua, Li Qipeng, Shi Junjie, et al. Technical and economic analysis of leaching titanium gypsum iron impurities by waste acid of titanium white[J]. Industrial Minerals and Processing, 2021,50(5):32−37. (孟华, 李琪鹏, 石俊杰, 等. 利用钛白废酸浸出钛石膏铁杂质及技术经济分析[J]. 化工矿物与加工, 2021,50(5):32−37.Meng Hua, Li Qipeng, Shi Junjie, et al. Technical and economic analysis of leaching titanium gypsum iron impurities by waste acid of titanium white[J]. Industrial Minerals and Processing, 2021, 50(5): 32-37 [15] Liu Minrong, Tian Ying, Zhao Shuai. Effect of alkaline activator on properties of titanium-gypsum-fly ash composite cementing material[J]. HVFA, 2008,20(6):15−17. (刘民荣, 田颖, 赵帅. 碱性激发剂对钛石膏-粉煤灰复合胶结材料性能的影响[J]. 粉煤灰, 2008,20(6):15−17.Liu Minrong, Tian Ying, Zhao Shuai. Effect of alkaline activator on properties of titanium-gypsum-fly ash composite cementing material[J]. HVFA, 2008, 20(6): 15-17 [16] Amin Azdarpour, Mohammad Asadullah, Radzuan Junin, et al. Extraction of calcium from red gypsum for calcium carbonate production[J]. Fuel Processing Technology, 2015,130:12−19. doi: 10.1016/j.fuproc.2014.09.034 [17] Chen Shurui, Yang Shaoli, Ma Lan, et al. Experimental study on hydrochloric acid leaching of titanium gypsum[J]. Hydrometallurgy of China, 2020,52(2):65−68. (陈书锐, 杨绍利, 马兰, 等. 盐酸浸出钛石膏试验研究[J]. 无机盐工业, 2020,52(2):65−68. doi: 10.11962/1006-4990.2019-0111Chen Shurui, Yang Shaoli, Ma Lan, et al. Experimental study on hydrochloric acid leaching of titanium gypsum[J]. Hydrometallurgy of China, 2020, 52(2): 65-68 doi: 10.11962/1006-4990.2019-0111 [18] 刘巽伯, 魏金照, 孙丽玲. 胶凝材料-水泥、石灰、石膏的生产和性能[M]. 上海: 同济大学出版社, 1990: 14.Liu Xunbo, Wei Jinzhao, Sun Liling. Production and properties of cementing materials - cement, lime, gypsum[M]. Shanghai: Tongji University Press, 1990: 14. [19] Liu Fengling, Peng Qianyun, Liu Hong. Preparation of CaSO4 whisker by titanium gypsum[J]. Chemical Engineering Design Communications, 2018,44(1):70−72. (刘凤铃, 彭佥赟, 刘洪. 钛石膏制备CaSO4晶须[J]. 化工设计通讯, 2018,44(1):70−72.Liu Fengling, Peng Qianyun, Liu Hong. Preparation of CaSO4 whisker by titanium gypsum[J]. Chemical Engineering Design Communications, 2018, 44(1): 70-72 [20] Wang Qian, Peng Tongjiang, Sun Hongjuan, et al. Phase transition of gypsum and anhydrite in titanium-gypsum -H2SO4-H2O system[J]. Bull Chin Ceram Soc, 2022,41(2):725−732. (王倩, 彭同江, 孙红娟, 等. 钛石膏-H2SO4-H2O体系中石膏-硬石膏的相变规律[J]. 硅酸盐通报, 2022,41(2):725−732.Wang Qian, Peng Tongjiang, Sun Hongjuan, et al. Phase transition of gypsum and anhydrite in titanium-gypsum -H2SO4-H2O system[J]. Bull Chin Ceram Soc, 2022, 41(2): 725-732 -

下载:

下载: