Experimental study on sintering of fine grained high-grade vanadium titanium magnetite concentrate from Pangang

-

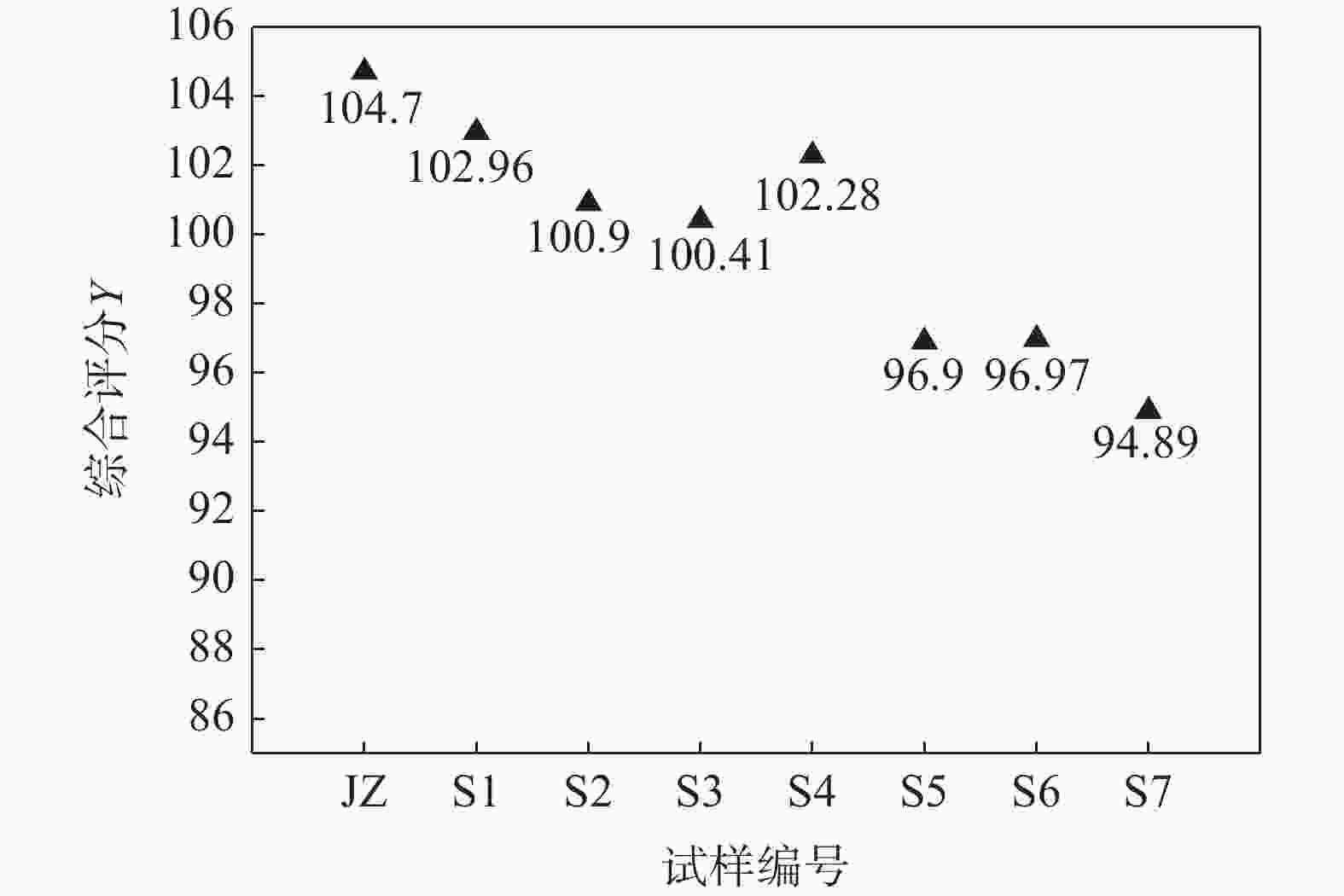

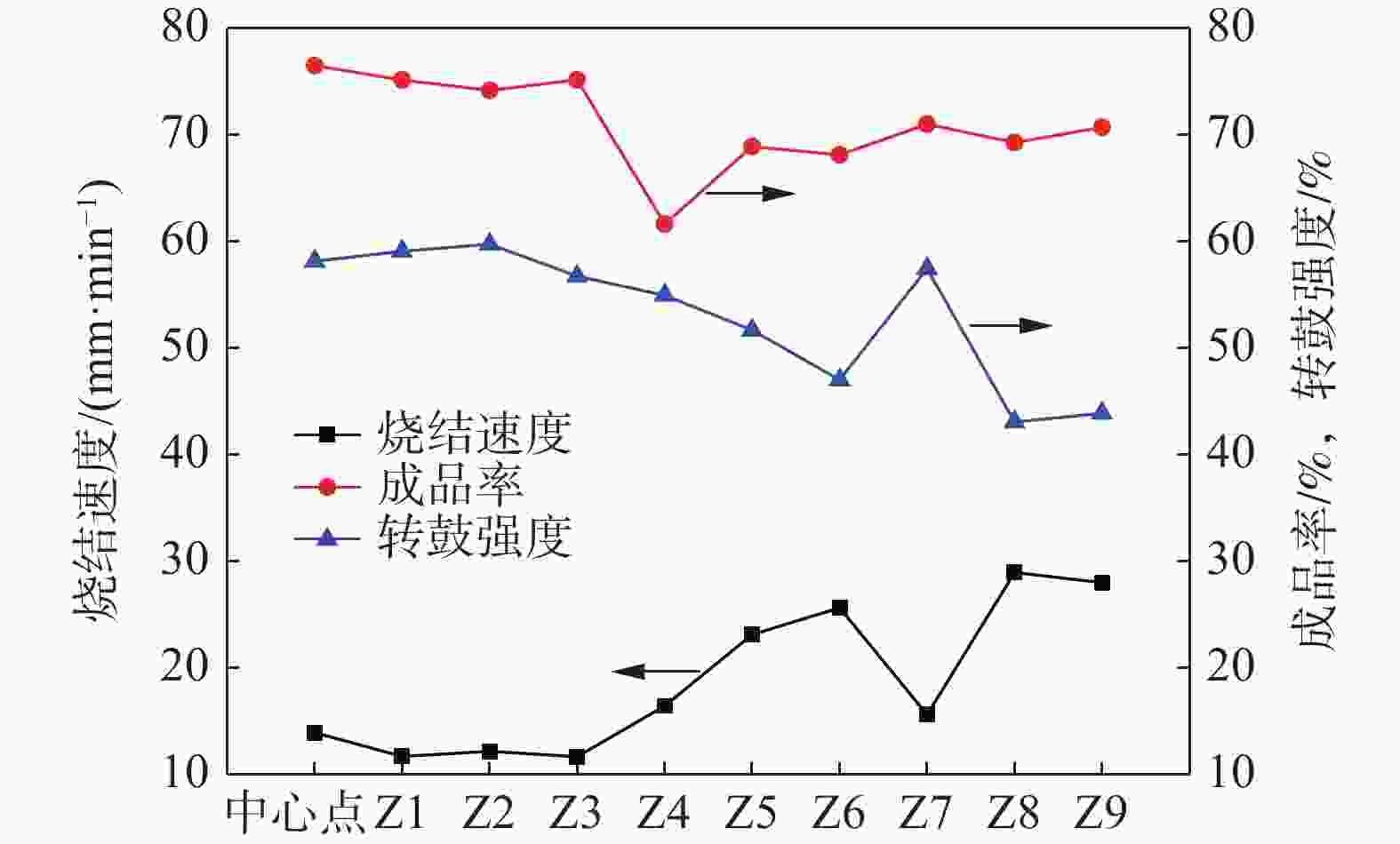

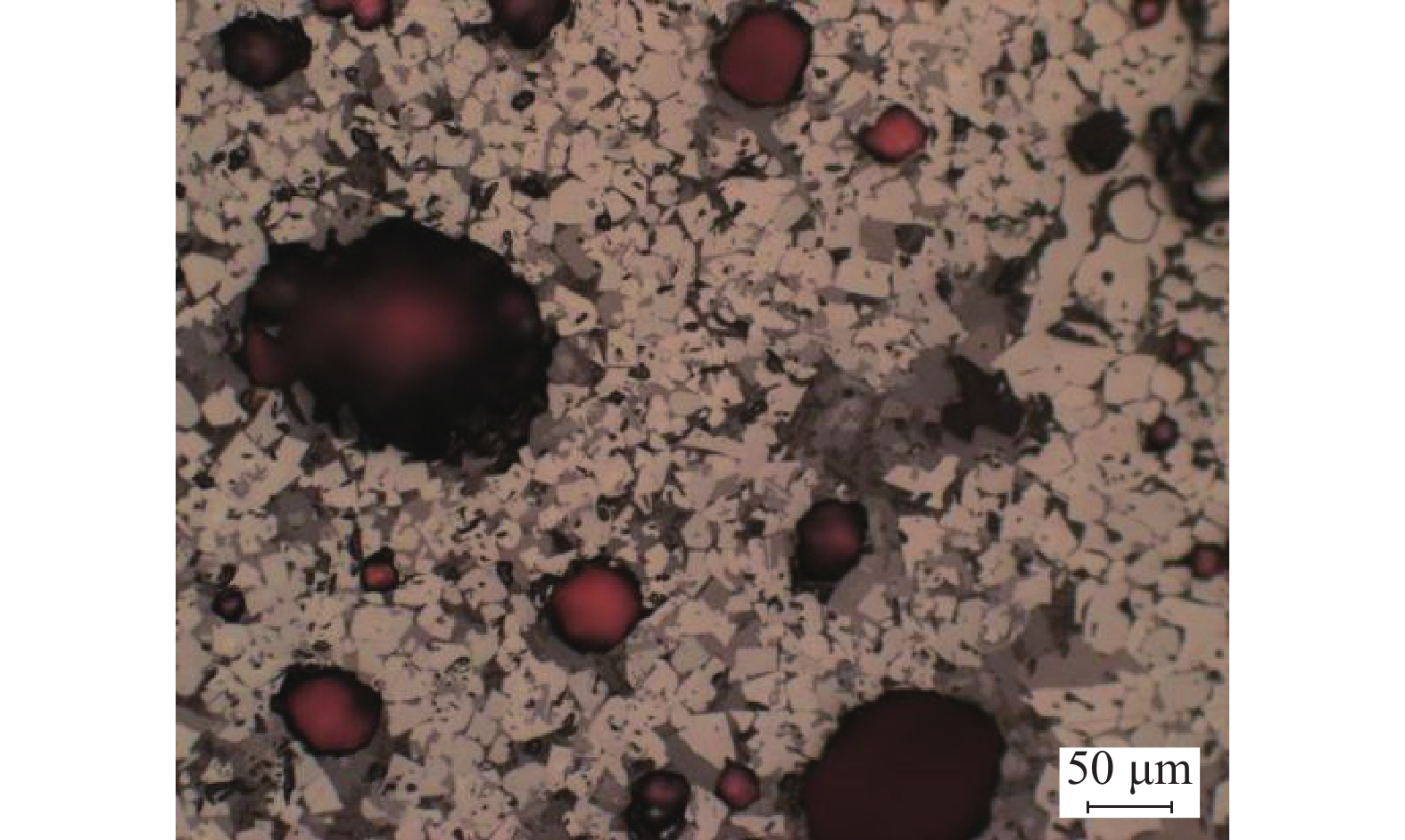

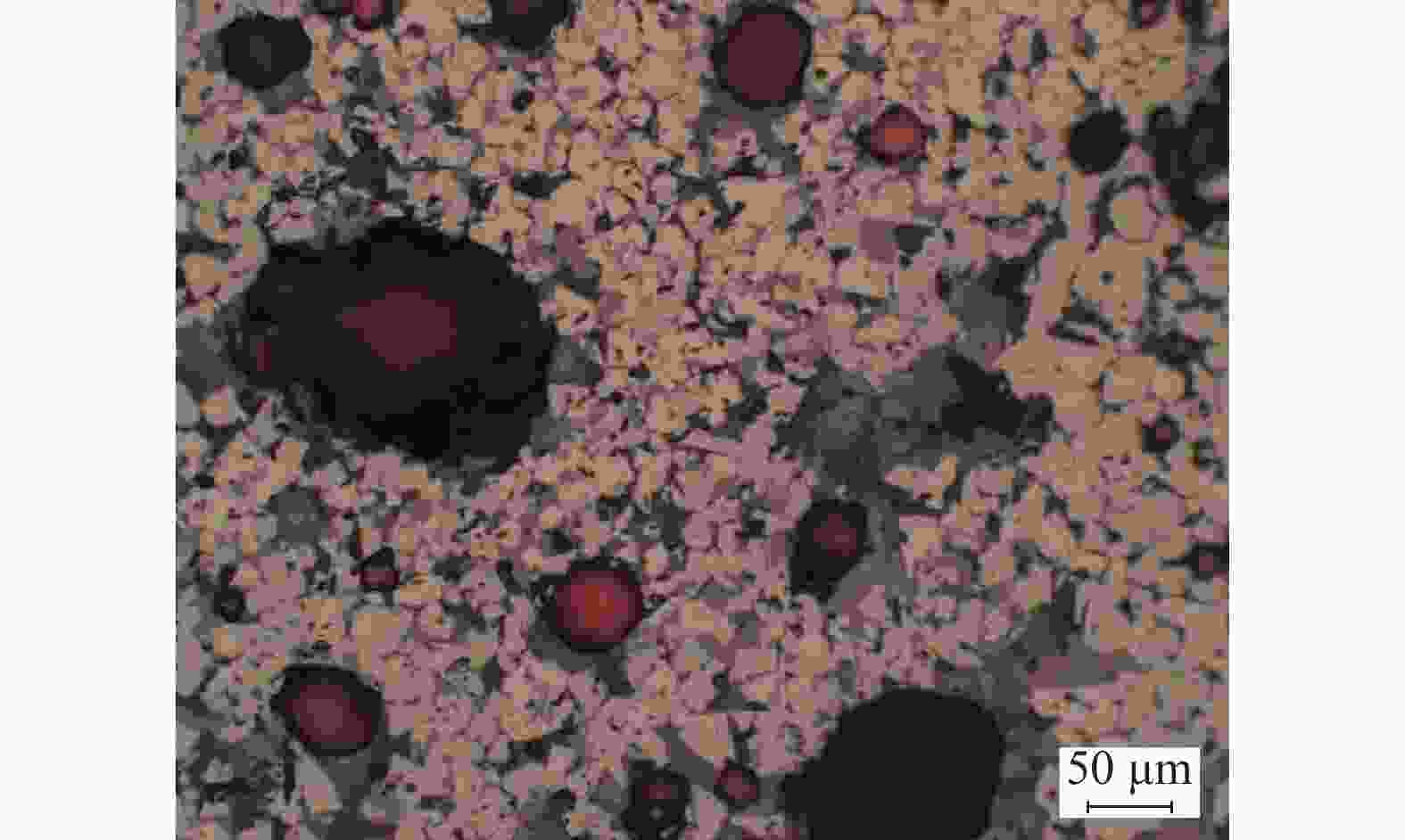

摘要: 针对高品位钒钛磁铁矿的理化性能,开展了单烧对比试验、高品位矿不同替代配比试验和最高替代配比条件下烧结燃料配比、混合料水份及料层厚度对烧结技术经济指标的参数寻优正交试验研究,试验研究表明,高品位矿具有高铁、低硅钛、粒度更细的特点,且对混合料水分控制非常敏感。随着烧结中高品位矿配比提高,烧结指标综合评分呈降低趋势,对该种烧结矿的技术经济指标的影响从大到小依次是水分、燃料配比、料层厚度,实验室得到的该种烧结矿最优烧结条件为混合料水6.5%,燃料比4.2%,料层厚度670 mm。工业试验结果表明,在烧结中配加20%的该种矿物,烧结矿TFe品位提高0.8个百分点, TiO2含量降低0.6个百分点,转鼓指数基本不变,烧结烟气中SiO2浓度降低22%。Abstract: In view of the physical and chemical properties of high-grade vanadium titanium magnetite, single firing contrast experiment, different substitute ratio experiment of high-grade ore and orthogonal experimental study on parameter optimization of sintering technical and economic indexes of sintering fuel ratio, mixture moisture and material layer thickness under the condition of highest substitute ratio were carried out. The experimental study shows that the high-grade ore has the characteristics of high iron, low silicon and titanium, finer particle size and is very sensitive to the moisture control of the mixture. With the increase of the ratio of high-grade ore in sintering, the comprehensive score of sintering index shows a decreasing trend. The influence on the technical and economic indexes of this sinter is water, fuel ratio and material layer thickness in descending order. The optimal sintering conditions of this sinter obtained in the laboratory are as follows: mixture water 6.5%, fuel ratio 4.2% and material layer thickness 670 mm. Industrial test results show that the sintered with addition of 20% of the mineral, the sinter high sinter TFe grade is increased by 0.8%, 0.6% lower content of TiO2, drum index is basically remain unchanged, the concentration of SiO2 sintering flue gas imports in low 22%.

-

Key words:

- sintering /

- fine grained level vanadium titanium magnetite /

- grade level /

- addition amount /

- drum index

-

表 1 试验用含铁原料主要化学成分

Table 1. Main chemical compositions of iron-containing raw materials

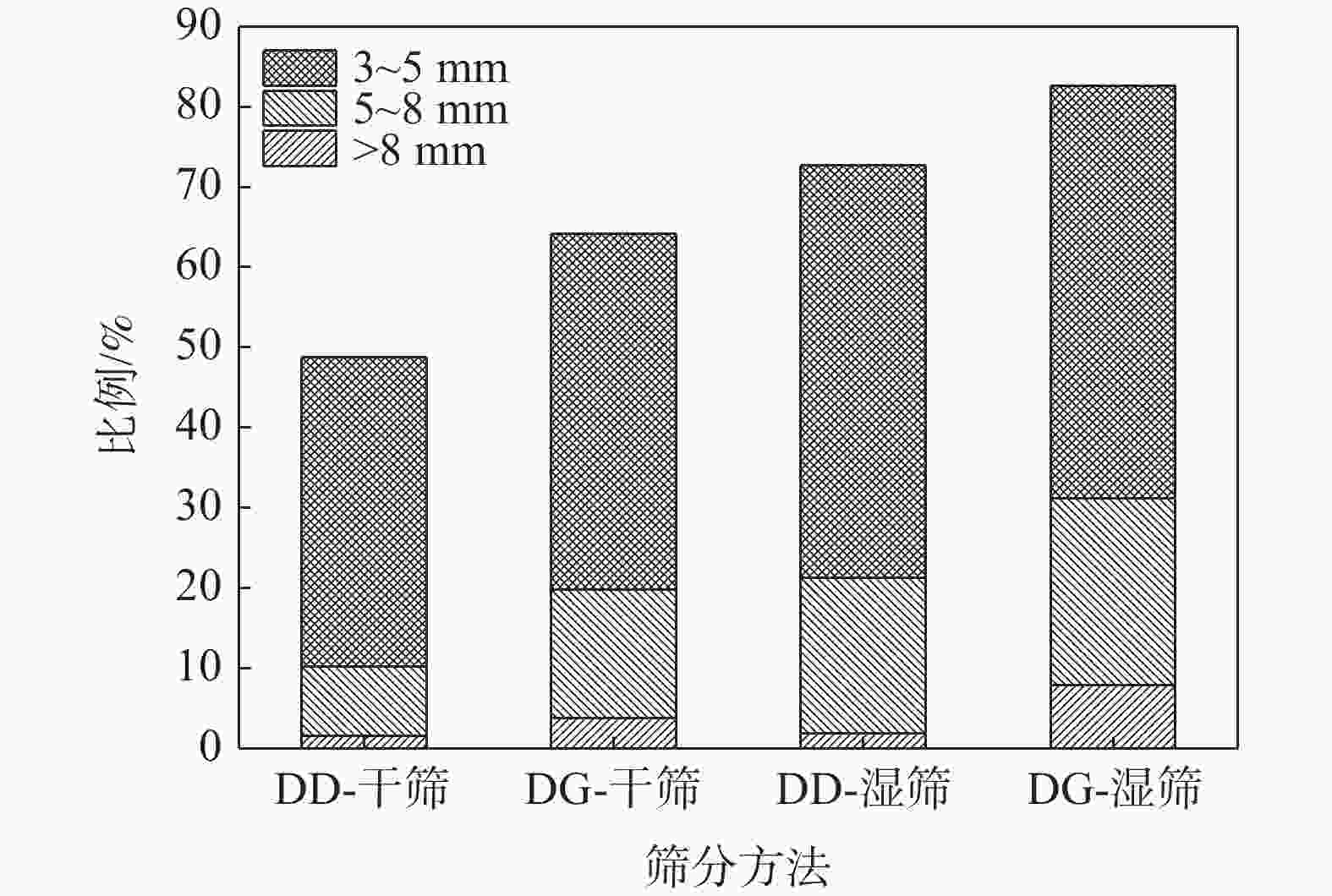

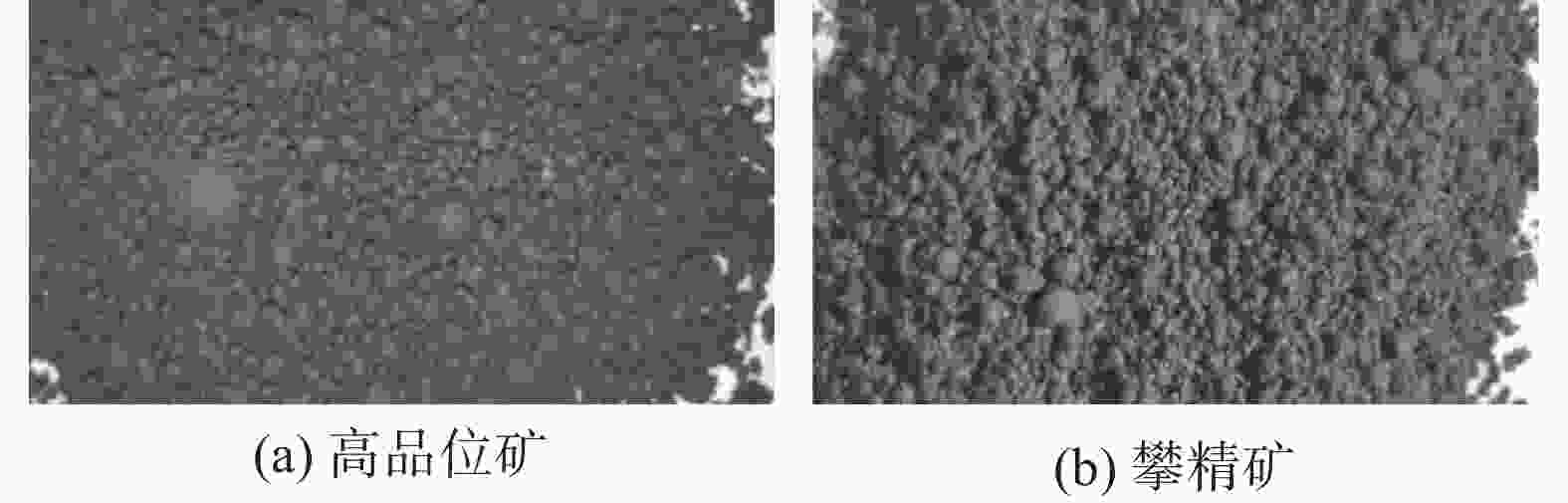

% 矿石 TFe SiO2 CaO V2O5 TiO2 S 攀精矿 53.70 3.60 0.40 0.56 12.25 0.713 高品位矿 61.7 2.80 0.7 0.70 6.08 0.669 南非粉 64.0 4.75 0.22 0.02 国高粉 58.35 7.05 3.69 0.09 1.32 0.74 中 粉 42.32 22.77 3.26 0.04 0.30 0.06 表 2 铁精矿的粒度组成对比

Table 2. Comparison of grain size

名 称 占比/% Dcp/

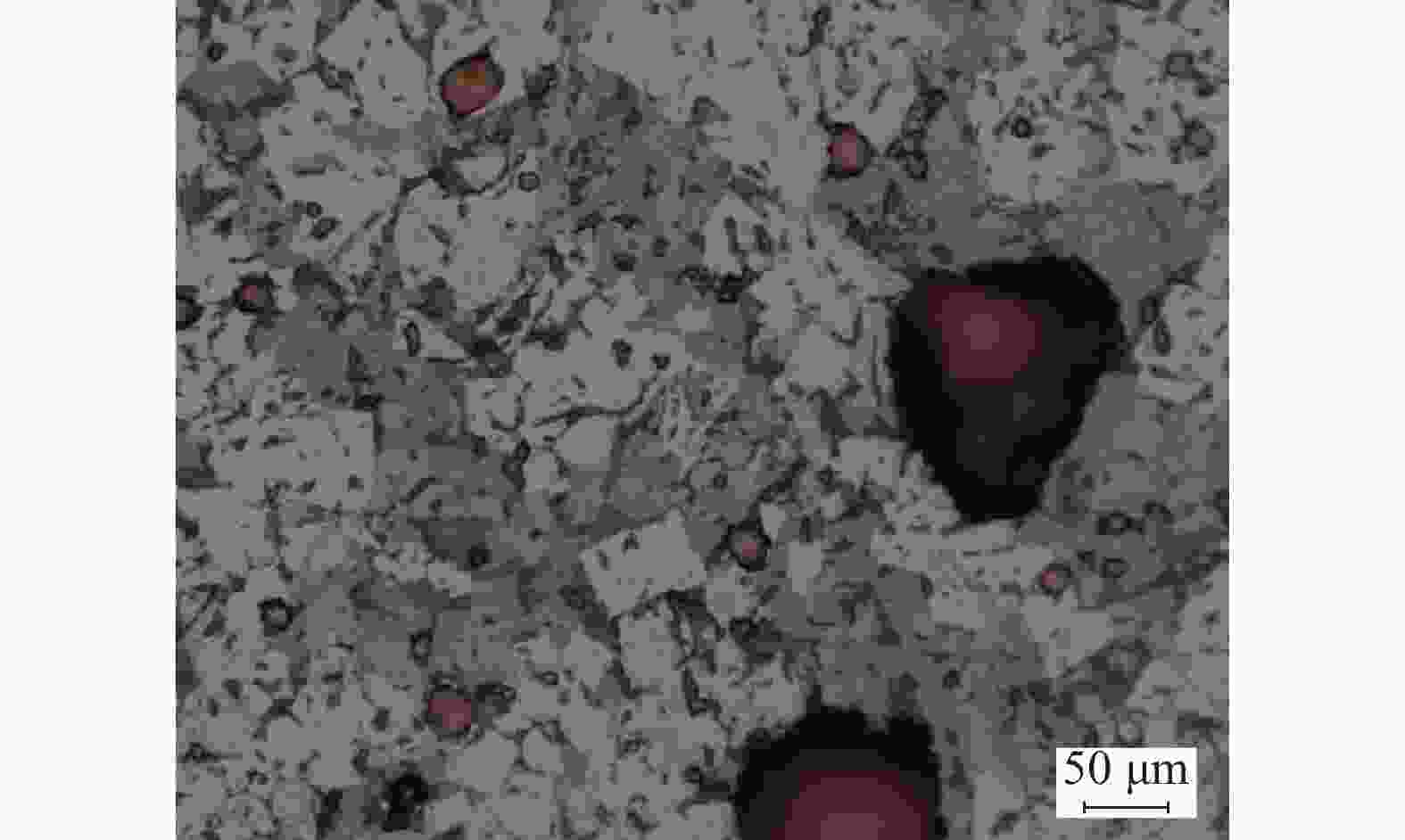

mm>0.074 mm 0.074~0.048 mm <0.048 mm 攀精矿 33.46 19.94 46.60 0.0359 高品位矿 1.08 12.85 86.07 0.0296 表 3 矿物的物相组成及质量分数占比

Table 3. Mineral phase compositions and ratios

% 矿名 钛磁铁矿 钛铁矿 钛辉石 钛赤铁矿 铁橄榄石 其他 攀精矿 73 4.6 2.8 6.9 6.9 5.8 高品位矿 80.4 5.1 3.2 2 9.3 表 4 两种单烧烧结矿化学分析及指标

Table 4. Chemical analysis and index of single sinter

编号 w/% R2 烧结速度/(mm·min−1) 成品率/% 转鼓强度/% TFe FeO SiO2 CaO TiO2 DD 49.85 8.34 4.67 8.57 9.60 1.79 8.93 69.60 58.13 DG 53.64 8.44 4.18 8.39 4.98 1.80 13.14 69.67 50.47 表 5 单烧试验烧结矿冶金性能检测

Table 5. Metallurgical properties of single sintering experiment

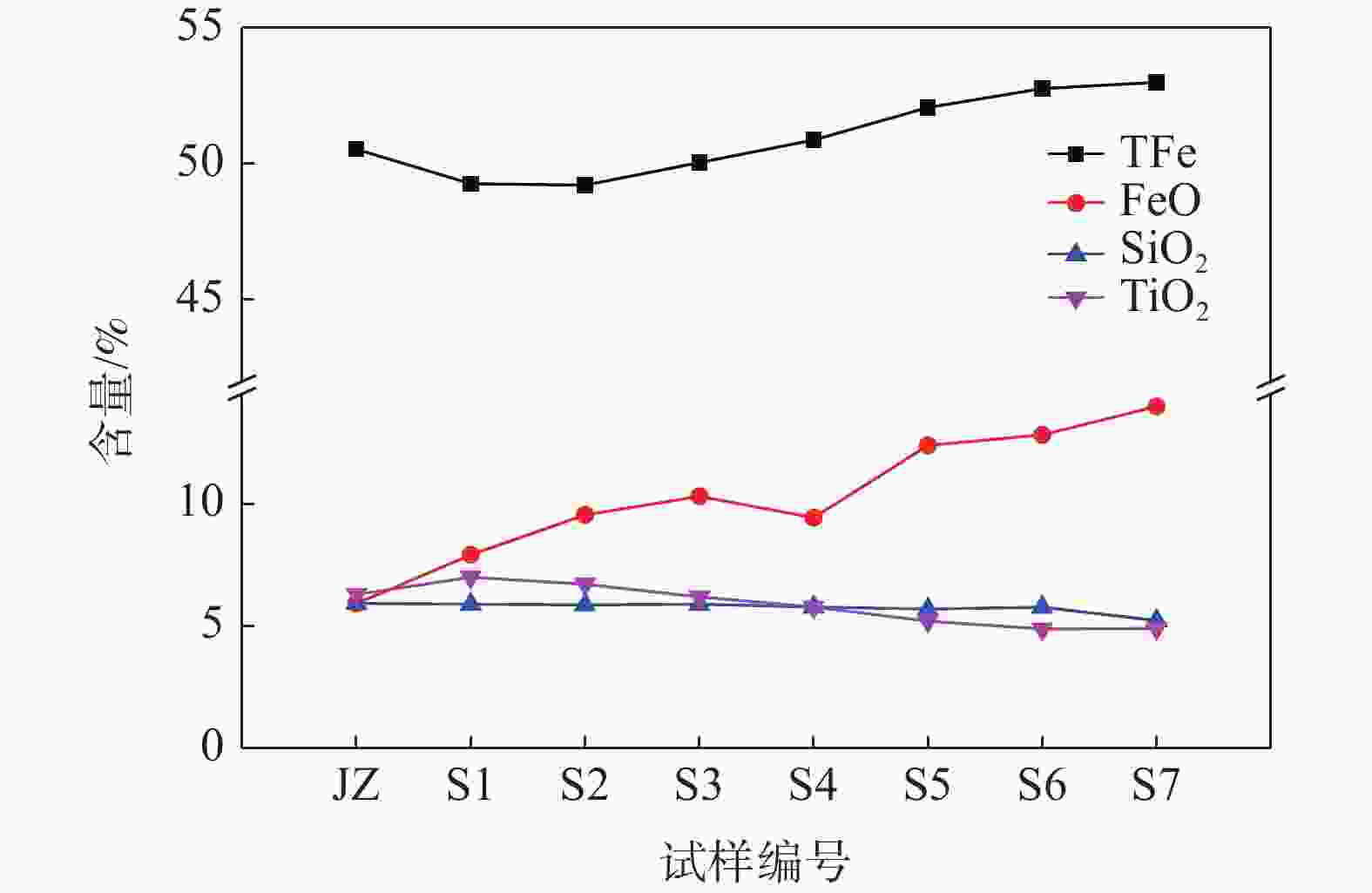

编号 软化开始温度/℃ 软化终了温度/℃ 软化区间/℃ 压差陡升温度/℃ 开始滴落温度/℃ 熔滴区间/℃ 中温还原率/% DD 1092 1167 72 1206 1482 276 78.49 DG 1081 1162 81 1201 1477 276 80.16 表 6 不同配比烧结试验配料方案

Table 6. Sintering experimental proportioning of different proportions

% 方案 高品位矿 攀精矿 进口矿 国高粉 中 粉 溶剂 燃料 S0 47.5 10 21 4.3 12.2 5 S1 10 50 16 6.5 12.5 5 S2 20 39.7 16 6.9 12.4 5 S3 30 29.3 16 7.4 12.3 5 S4 40 20.5 16 6.9 11.6 5 S5 50 11.6 16 6.4 11 5 S6 60 2.7 16 6 10.3 5 S7 76.2 8.5 10.3 5 表 7 不同配比烧结试验中各组烧结矿冶金性能检测

Table 7. Metallurgical properties of sinter in each group of sintering experiment

编号 软化开始温度/℃ 软化终了温度/℃ 软化区间温度/℃ 压差陡升温度/℃ 开始滴落温度/℃ 熔滴区间温度/℃ 中温还原率/% JZ 1081 1150 69 1183 1465 282 77.67 S4 1080 1155 75 1194 1467 273 81.77 S6 1093 1165 72 1201 1450 249 82.79 S7 1092 1158 66 1197 1461 264 82.39 表 8 L9正交试验方案

Table 8. L9 orthogonal experimental scheme

编号 水分/% 焦粉/% 料层厚度/mm 中心点 7.0 4.2 690 Z1 6.5 3.8 650 Z2 6.5 4.2 660 Z3 6.5 4.6 670 Z4 7.0 3.8 660 Z5 7.0 4.2 670 Z6 7.0 4.6 650 Z7 7.5 3.8 670 Z8 7.5 4.2 650 Z9 7.5 4.6 660 表 9 正交试验极差分析

Table 9. Orthogonal experimental analysis

水分/% 焦粉配比/% 料层厚度/mm 水平(1)均值K1 103.23 100.02 98.74 水平(2)均值K2 98.93 101.15 100.07 水平(3)均值K3 98.19 98.44 101.17 R极差 5.04 2.71 2.42 最优组 水平(1) 水平(2) 水平(3) 表 10 正交验证试验烧结矿技经指标

Table 10. Orthogonal verification index of experimental sinter

编号 烧结速度/(mm·min−1) 成品率/% 转鼓强度/% 中心点组 14.37 76.51 58.70 正交最优组 13.89 76.47 58.13 表 11 工业试验烧结检测结果

Table 11. Results of industrial sintering test

项类 w/% R2 点火温度/℃ 台时产量/(t·h−1) 烟气SO2浓度×106 转鼓指数/% TFe FeO SiO2 TiO2 基准期 50.04 7.93 5.63 6.61 1.86 1085.71 315.48 5087.03 66.99 阶段1 50.35 7.79 5.61 6.46 1.87 1076.67 311.68 5023.70 67.94 阶段2 50.64 8.13 5.62 6.34 1.83 1100.20 301.30 4605.36 67.12 阶段3 50.88 8.23 5.56 6.01 1.89 1123.20 306.71 3967.30 66.84 -

[1] Zhang Dianbo, Wan Haiming, Zheng Jiang. Analysis on globaliron ore resources and China’s iron ore supply and demand[J]. China Metallurgy, 2004,(6):26−29. (张典波, 万海明, 郑江. 世界铁矿石资源情况及中国铁矿石供需态势[J]. 中国冶金, 2004,(6):26−29.Zhang Dianbo, Wan Haiming, Zheng Jiang. Analysis on globaliron ore resources and China’s iron ore supply and demand[J]. China Metallurgy, 2004(6): 26-29. [2] Tang Xianjue. The progress history of sintering industry in our country[J]. Sintering and Pelletizing, 2008,(4):3−4. (唐先觉. 我国烧结行业的技术进步[J]. 烧结球团, 2008,(4):3−4.Tang Xianjue. The progress history of sintering industry in our country[J]. Sintering and Pelletizing, 2008(4): 3-4. [3] 周传典. 高炉炼铁生产技术手册[M]. 北京: 冶金工业出版社, 2002.Zhou Chuandian. Blast furnace ironmaking production of technical manuals[M]. Beijing: Metallurgical Industry Press, 2002. [4] 陈耀铭, 陈锐. 烧结球团矿微观结构[M]. 长沙: 中南大学出版社, 2011.Chen Yaoming, Chen Rui. Microstructure of sinter and pellet[M]. Changsha: Central South University Press, 2011. [5] Bai Dongdong, Han Xiuli, Li Changcun, et al. Research on the influence of the mineralization process of vanadium titanium sinter on quality[J]. Iron Steel Vanadium Titanium, 2018,39(5):111−114. (白冬冬, 韩秀丽, 李昌存, 等. 钒钛烧结矿矿相结构对其冶金性能的影响[J]. 钢铁钒钛, 2018,39(5):111−114.Bai Dongdong, Han Xiuli, Li Changcun, et al. Research on the influence of the mineralization process of vanadium titanium sinter on quality[J]. Iron Steel Vanadium Titanium, 2018, 39(5): 111-114. [6] Zhu Deqing, Zhang Kecheng, He Aoping, et al. Eeffect of enhances granulating on high Fe and low SiO2 sinter[J]. Sintering and Pelletizing, 2003,(1):9−13. (朱德庆, 张克诚, 何奥平, 等. 强化制粒对高铁低硅混合料烧结的影响[J]. 烧结球团, 2003,(1):9−13.Zhu Deqing, Zhang Kecheng, He Aoping, et al. Eeffect of enhances granulating on high Fe and low SiO2 sinter[J]. Sintering and Pelletizing, 2003(1): 9-13. [7] Rao Jiating, Zhang Yixian, Yang Xiaodong, et al. Experimental study on sintering by adding high grade vanadium-bearing titaniferous magnetite concentrate at Pangang[J]. Iron Steel Vanadium Titanium, 2012,33(2):44−49. (饶家庭, 张义贤, 羊小东, 等. 攀钢烧结配加高品位钒钛磁铁精矿试验研究[J]. 钢铁钒钛, 2012,33(2):44−49.Rao Jiating, Zhang Yixian, Yang Xiaodong, et al. Experimental study on sintering by adding high grade vanadium-bearing titaniferous magnetite concentrate at Pangang[J]. Iron Steel Vanadium Titanium, 2012, 33(2): 44-49. [8] Lin Wenkang, Hu Peng. Influence of TiO2 content and basicity level on the metallogenic regularity of V-Ti sinter[J]. Iron Steel Vanadium Titanium, 2020,41(4):94−99. (林文康, 胡鹏. TiO2含量和碱度水平对钒钛烧结矿成矿规律的影响研究[J]. 钢铁钒钛, 2020,41(4):94−99.Lin Wenkang, Hu Peng. Influence of TiO2 content and basicity level on the metallogenic regularity of V-Ti sinter[J]. Iron Steel Vanadium Titanium, 2020, 41(4): 94-99. [9] Wang Rongcheng, Fu Juying. Study on production of high Fe and low SiO2 sinter[J]. Iron and Steel, 2007,42(6):17−20. (王荣成, 傅菊英. 高铁低硅烧结技术研究[J]. 钢铁, 2007,42(6):17−20.Wang Rongcheng, Fu Juying. Study on production of high Fe and low SiO2 sinter[J]. Iron and Steel, 2007, 42(6): 17-20. [10] Wang Fubin, Liu Hefei, He Jianghong, et al. Analysis on operation process parameters of sintering and construction of sintering behavior model[J]. Sintering and Pelletizing, 2020,(4):29−34. (王福斌, 刘贺飞, 何江红, 等. 烧结运行工艺参数分析及烧结行为模型构建[J]. 烧结球团, 2020,(4):29−34.Wang Fubin, Liu Hefei, He Jianghong, et al. Analysis on operation process parameters of sintering and construction of sintering behavior model[J]. Sintering and Pelletizing, 2020(4): 29-34. -

下载:

下载: