Effect of aging temperature on microstructure and properties of Monel K500 alloy

-

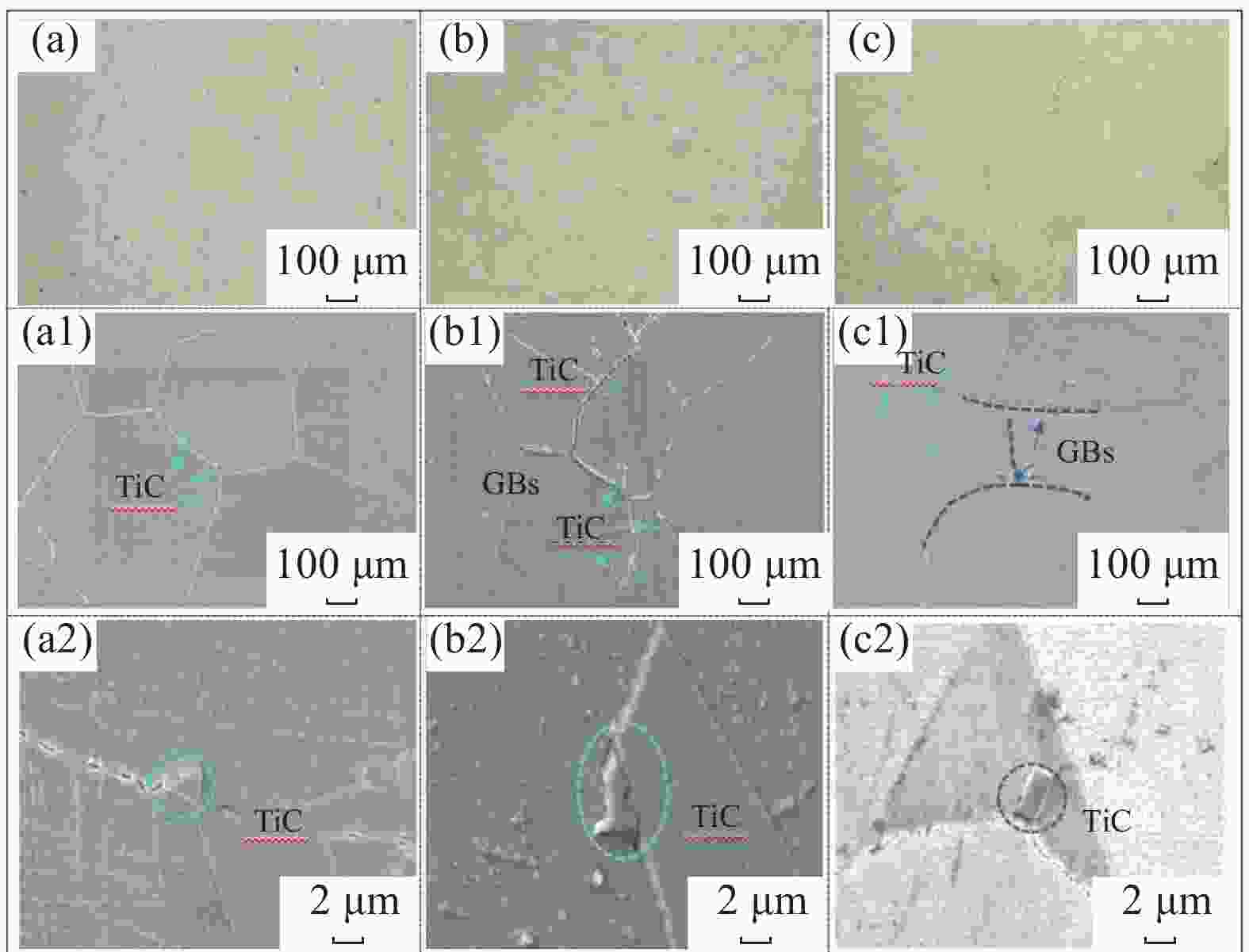

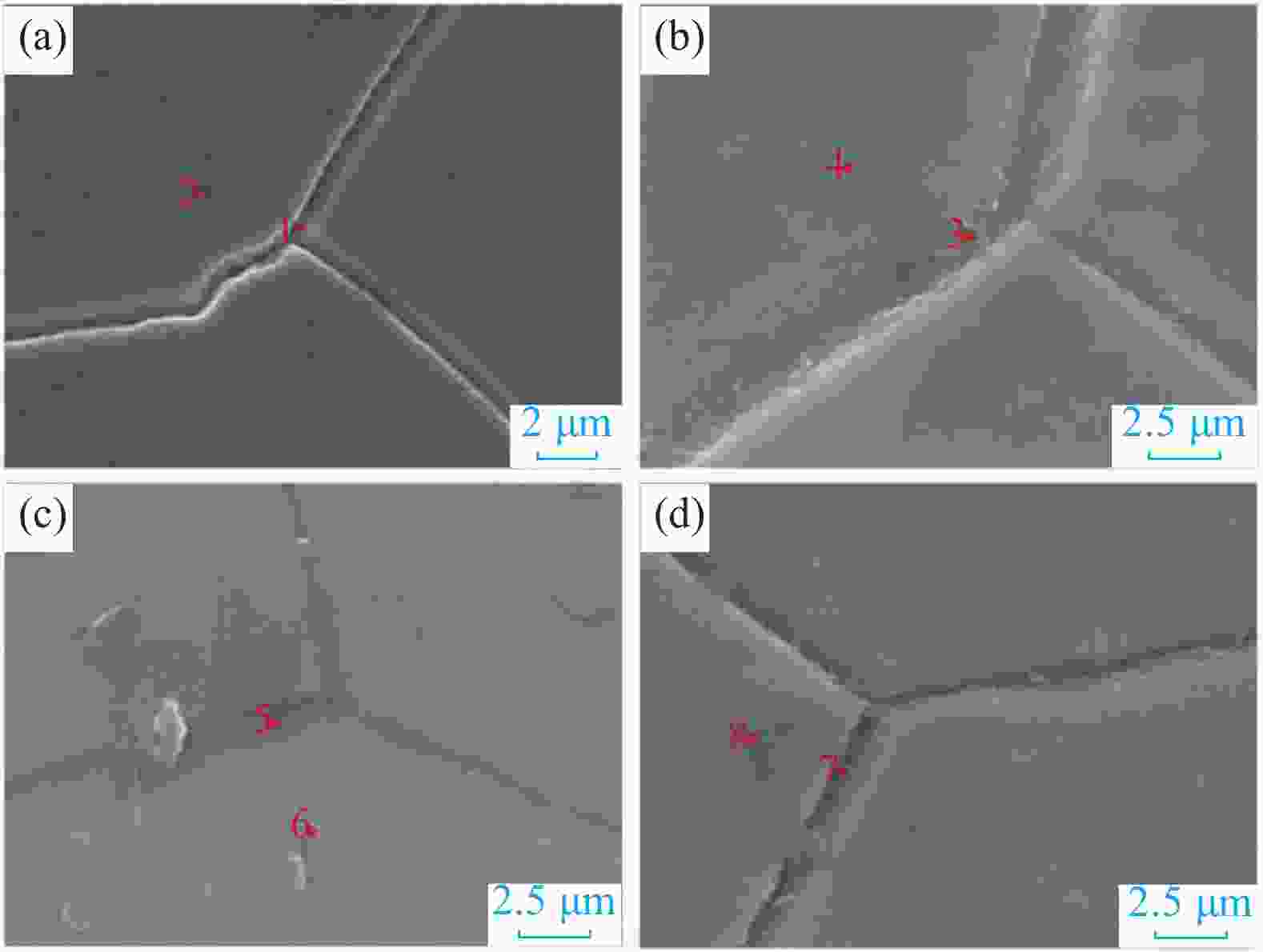

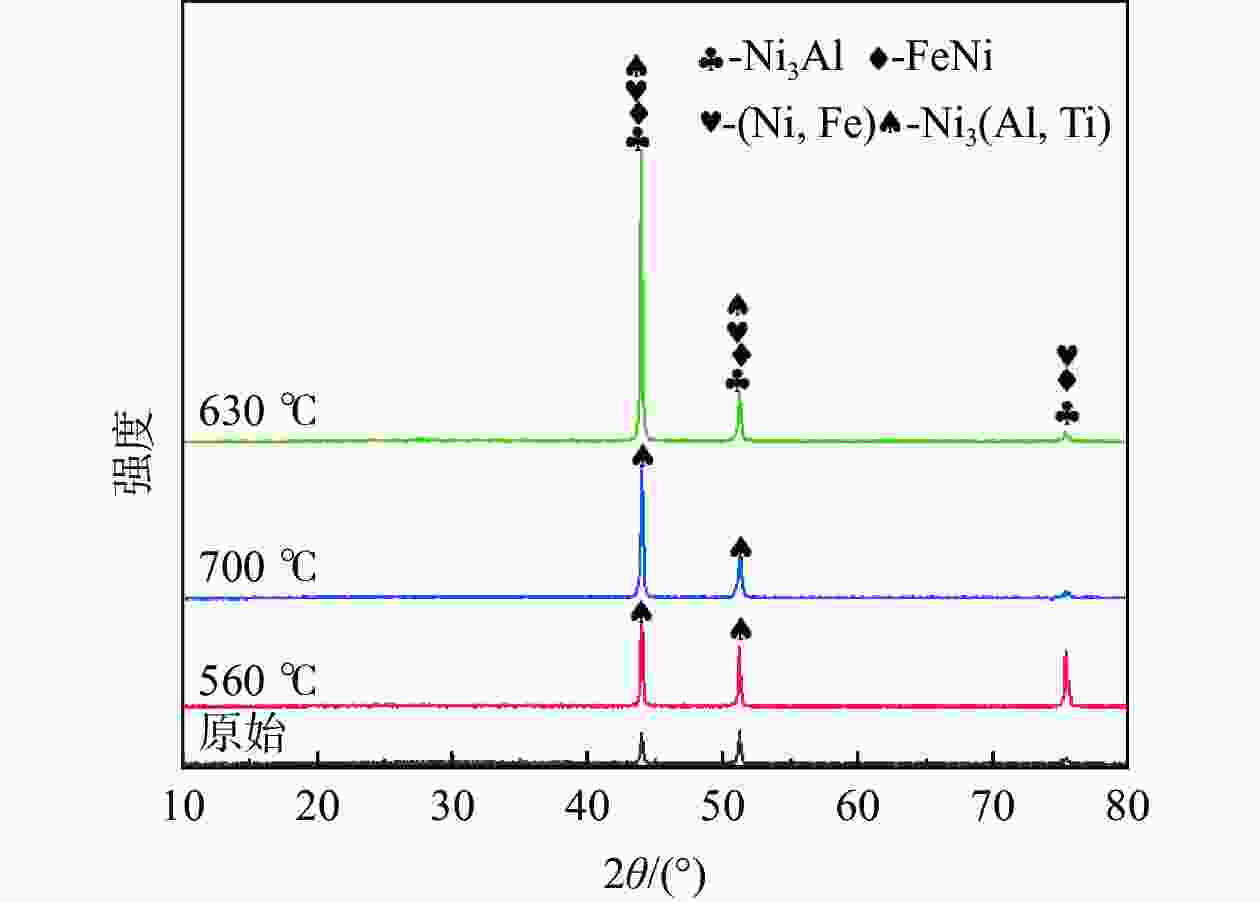

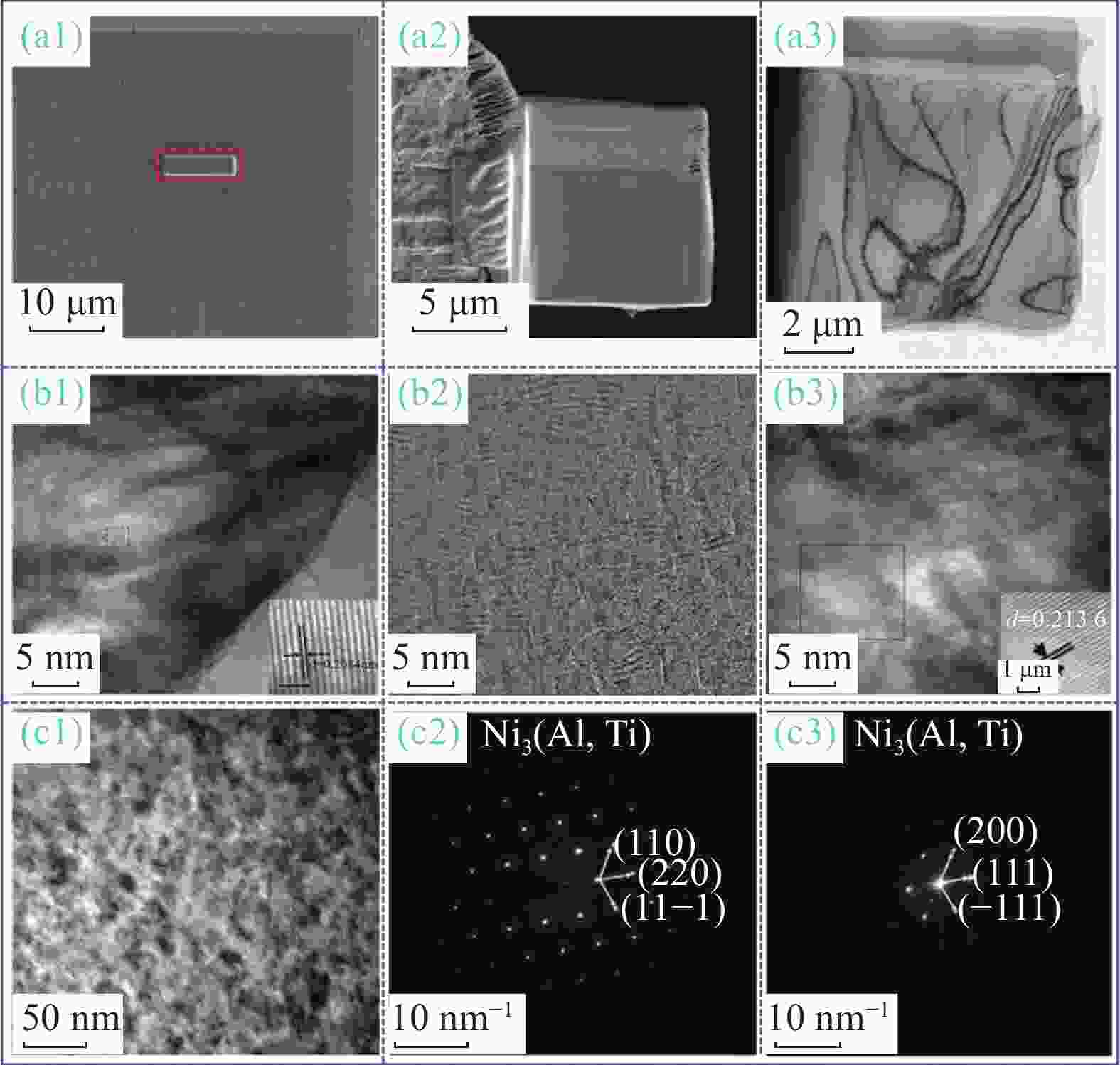

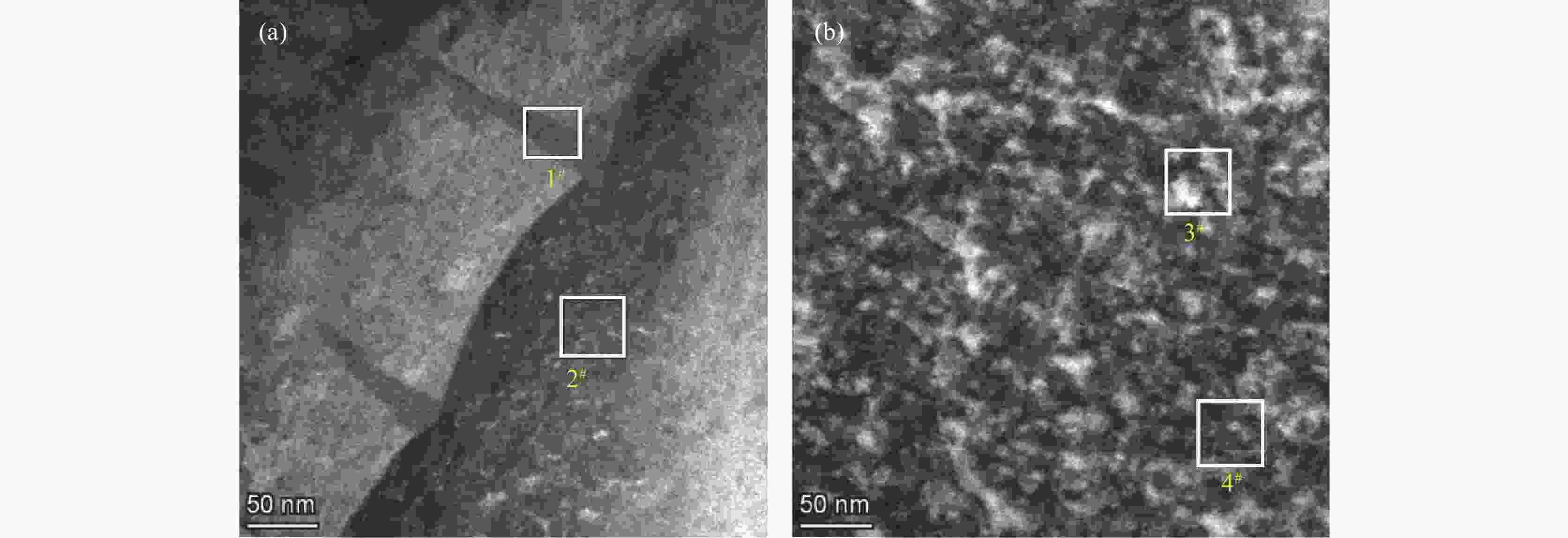

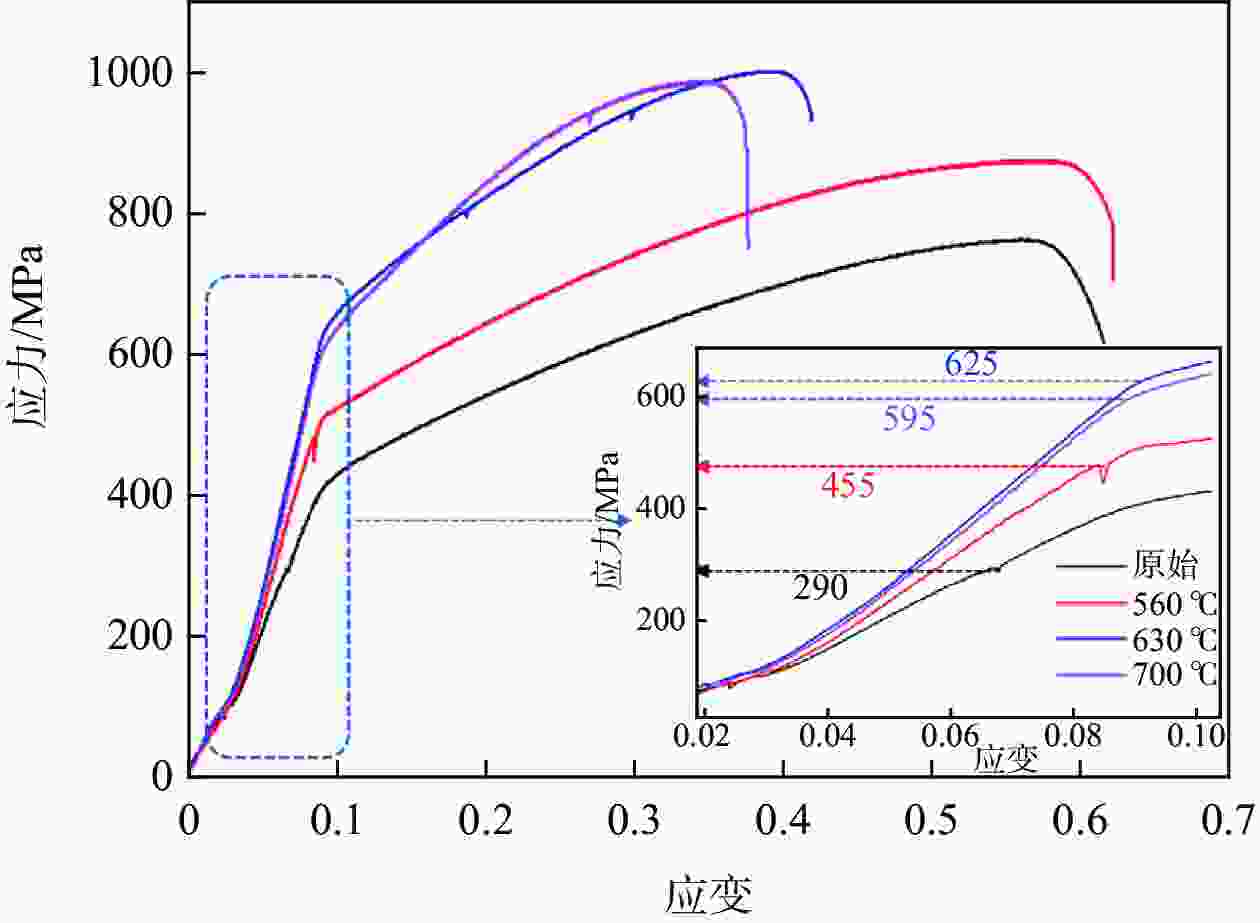

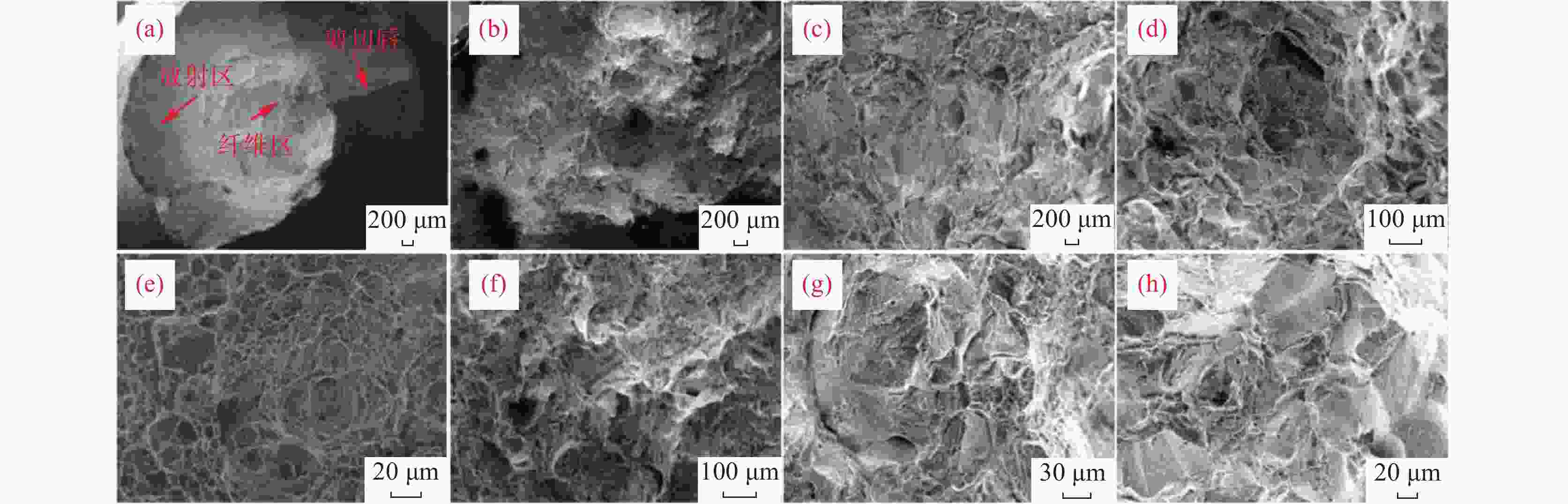

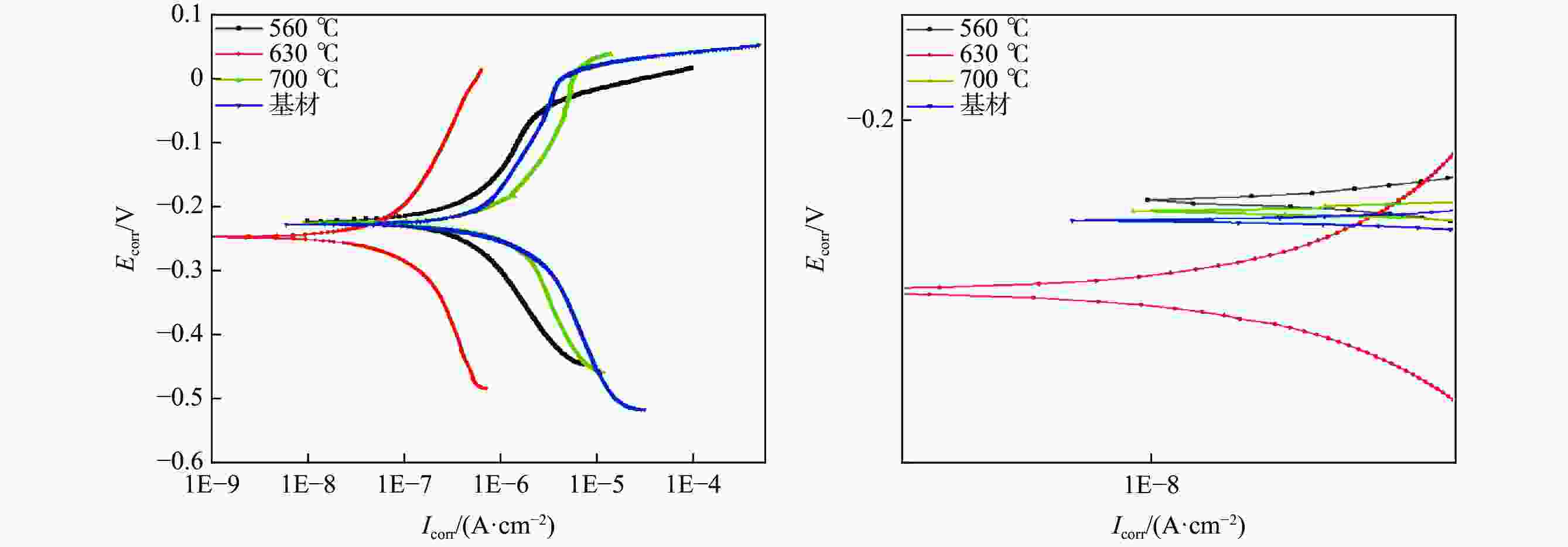

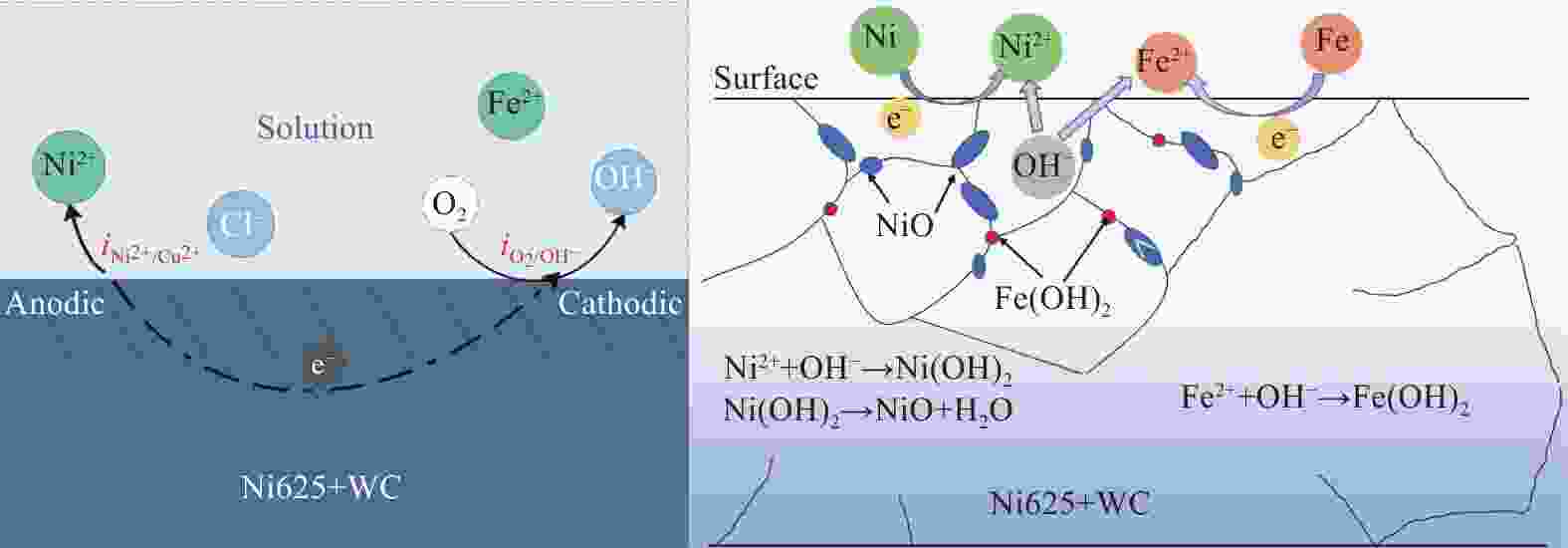

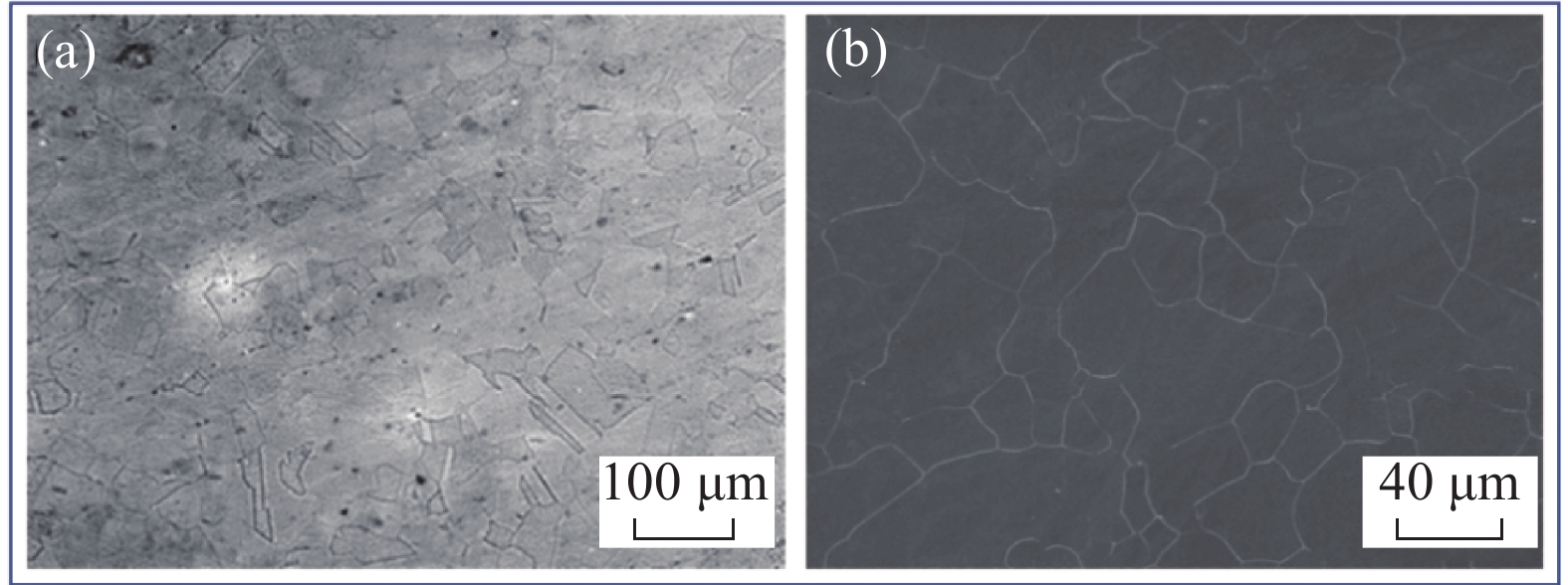

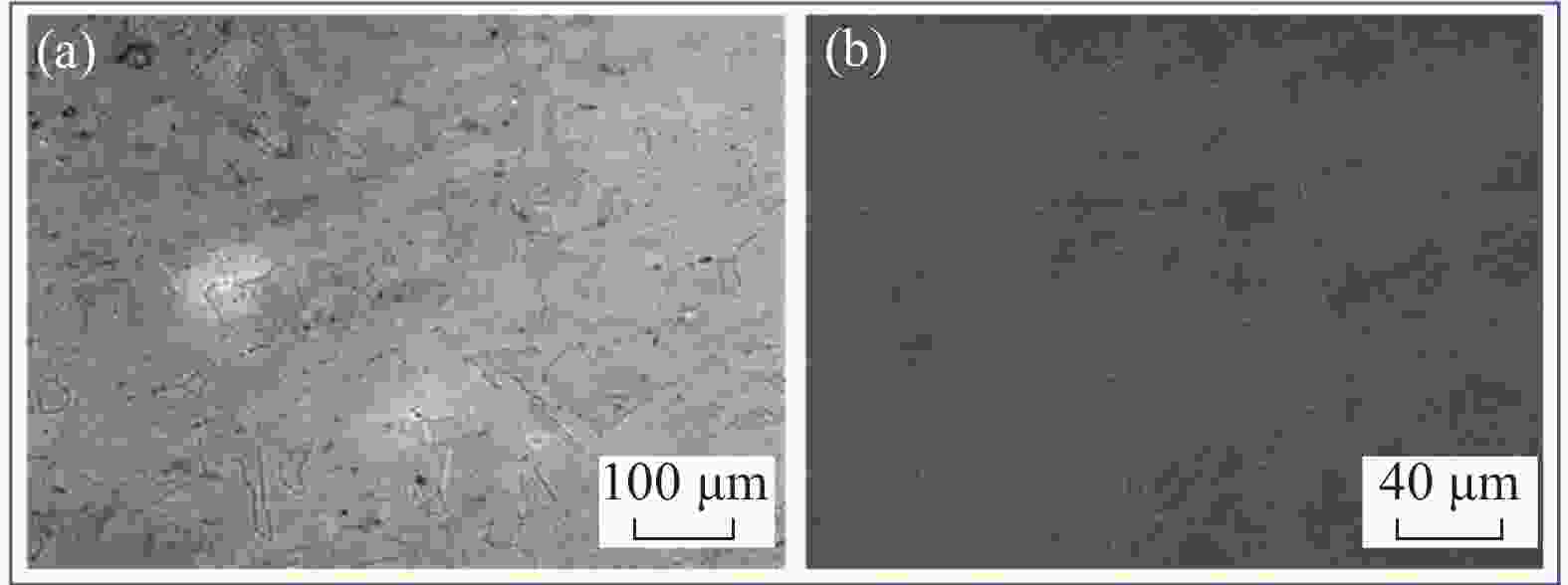

摘要: 采用固溶+时效工艺对Monel K500合金进行了时效处理,通过显微硬度和拉伸性能测试,以及OM、SEM、TEM、XRD等分析表征,研究了时效温度对Monel K500合金组织结构以及性能的影响。结果表明,时效处理后形成的多边形TiC颗粒强化相主要分布在晶界处,同时晶界处Al元素含量增多,过饱和固溶体发生脱溶分解,Al、Ti元素以Ni3(Al, Ti)第二相形式析出,合金硬度与强度提高。经电化学腐蚀后,该合金生成腐蚀产物NiO和CuO。随着时效温度的升高,第二相含量逐渐增加,但过高的温度导致第二相长大,故时效温度为560~700 ℃时,强化效果随着温度升高呈先升高后降低趋势。时效温度为630 ℃时,合金的硬度(HV)为329.26,强度994.56 MPa,均达到最大值,但耐腐蚀性能在该温度下反而有所降低。Abstract: The heat treatment of solution + aging process was conducted on Monel K500 alloy. For investigating the effect of aging temperature on the microstructure and properties of Monel K500 alloy, the micro-hardness and tensile properties were measured and the microstructure of the samples was analyzed by OM, SEM, TEM and XRD. The results showed that hardening phase of polygonal TiC particles mainly distributed at grain boundaries. Meanwhile, Al content at the grain boundary increases after aging treatment, and precipitation decomposition in the supersaturated solid solution occurred, which caused Al and Ti elements to precipitate in the form of Ni3 (Al, Ti) second phase. The corrosion products NiO and CuO formed after electrochemical etching. With the increasing aging temperature, the volume fraction of precipitates increases, but the high temperature causes the coarsening of precipitates. So, the strengthening effect firstly increases and then decreases with the increase of aging temperature in the range of 560~700 ℃. After aging treatment at 630 ℃, the hardness (HV) and strength of the Monel K500 alloy can reach the maximum value of 329.26 and 994.56 MPa, respectively. However, the corrosion resistance decreases when alloy subject to aging treatment at this temperature.

-

Key words:

- Monel K500 alloy /

- aging treatment /

- temperature /

- microstructure /

- mechanical properties /

- precipitated phase

-

表 1 不同温度时效处理Monel K500合金元素分布

Table 1. Element distribution of Monel K500 alloy aged at different temperatures

T/ ℃ 位置 y/% Al Ti Ni Cu Fe Mn Si 25 1 3.05 0.68 66.91 27.32 1.09 0.79 0.16 25 2 6.63 0.22 64.29 26.43 1.04 0.77 0.22 560 3 7.27 0.56 66.28 24.09 1.23 0.56 0.00 560 4 6.37 1.19 65.90 24.70 1.17 0.65 0.00 630 5 7.42 0.75 63.62 26.69 0.899 0.64 0.00 630 6 7.36 1.27 62.99 26.56 1.13 0.62 0.07 700 7 7.41 0.91 63.32 26.49 1.19 0.69 0.00 700 8 6.43 1.21 63.46 26.86 0.96 0.94 0.14 表 2 630 ℃时效处理Monel K500合金元素分布

Table 2. Element distribution in Monel K500 alloy aged at 630 ℃

区域 y/% Al Si Ti Mn Fe Cu Ni 1# 3.02 1.91 1.32 2.37 3.33 30.66 bal. 2# 3.40 1.90 1.26 2.45 1.34 22.72 bal. 3# 6.43 1.32 3.27 2.15 2.43 23.43 bal. 4# 4.15 1.70 1.06 2.24 0.20 35.93 bal. 表 3 不同温度时效处理后Monel K500合金及显微硬度

Table 3. Microhardness of Monel K500 alloy aged at different temperatures

时效温度/ ℃ 显微硬度(HV) 测点1 测点2 测点3 测点4 测点5 平均值 基材 243.2 229.1 221.0 249.3 248.5 238.22 560 242.0 243.0 275.7 263.4 240.8 252.98 630 317.0 333.7 326.5 340.6 328.5 329.26 700 273.0 292.8 268.5 280.7 296.8 282.36 表 4 不同温度时效处理后K500合金拉伸力学性能

Table 4. Tensile properties of K500 alloy aged at different temperatures

温度/ ℃ 拉伸速率/

(mm·s−1)抗拉强度/

MPa屈服强度/

MPa延伸率/

%基材 1.5 777.20 290 53.80 560 1.5 863.92 455 44.02 630 1.5 994.56 625 33.82 700 1.5 976.04 595 27.73 表 5 电化学腐蚀测试结果

Table 5. Electrochemical corrosion test results

温度/ ℃ Ecorr/mV Icorr/(A·cm−2) 腐蚀速率/(mm·a−1) 基材 −227.3 2.190×10−6 2.050 560 −221.9 1.185×10−6 1.959 630 −246.2 4.161×10−6 2.868 700 −224.9 2.089×10−6 2.003 -

[1] Jia Chengtao. Characteristics and application of nickel base corrosion resistant alloy[J]. China New Technology and New Products, 2017,(1):2. (贾成涛. 镍基耐蚀合金特性及其应用研究分析[J]. 中国新技术新产品, 2017,(1):2.Jia Chengtao. Characteristics and application of nickel base corrosion resistant alloy [J]. China New Technology and New Products, 2017(1): 2. [2] Shi Xiaoyu, Wen Daosheng, Wang Shouren, et al. Investigation on friction and wear performance of laser cladding Ni-based alloy coating on brake disc[J]. Optik-International Journal for Light and Electron Optics, 2021,242:167227. doi: 10.1016/j.ijleo.2021.167227 [3] Huang Xu, Zhang Jiacheng, Cheng Yuan, et al. Effect of h-BN addition on the microstructure characteristics, residual stress and tribological behavior of WC-reinforced Ni-based composite coatings[J]. Surface and Coatings Technology, 2021,405:126534. doi: 10.1016/j.surfcoat.2020.126534 [4] Zhu Zongyuan, Li Bangjun. Study on performance of Monel K500 alloy electric submersible pump shaft[J]. Shanghai Metals, 1997,19(6):28−32. (朱宗元, 李邦俊. 蒙乃尔K500合金潜油电泵轴性能的研宄[J]. 上海金属, 1997,19(6):28−32.Zhu Zongyuan, Li Bangjun. Study on performance of Monel K500 alloy electric submersible pump shaft [J]. Shanghai Metals, 1997, 19(6): 28-32. [5] Xu Wei, Xu Ting, Wang Lulu, et al. Research status and prospect of hard particle reinforced nickel base alloy composite coating[J]. Machinery Manufacturing & Automation, 2016,45(2):40−42. (许伟, 徐婷, 汪路路, 等. 硬质颗粒增强镍基合金复合镀层研究现状与展望[J]. 机械制造与自动化, 2016,45(2):40−42. doi: 10.3969/j.issn.1671-5276.2016.02.011Xu Wei, Xu Ting, Wang Lulu, et al. Research status and prospect of hard particle reinforced nickel base alloy composite coating [J]. Machinery Manufacturing & Automation, 2016, 45(2): 40-42. doi: 10.3969/j.issn.1671-5276.2016.02.011 [6] 李赛. GH600热变形行为及显微组织分析[D]. 鞍山: 辽宁科技大学, 2012.Li Sai. Thermal deformation behavior and microstructure analysis of GH600 [D]. Anshan: University of Science and Technology Liaoning, 2012. [7] Wang Rui. Research and aplication of nickel-based high temperature alloy[J]. Modern Chemical Research, 2017,(7):50−51. (王睿. 镍基高温合金的研究和应用[J]. 当代化工研究, 2017,(7):50−51.Wang Rui. Research and aplication of nickel-based high temperature alloy[J]. Modern Chemical Research, 2017(7): 50-51. [8] Yang Qian, Huang Wanzhen, Kong Fanzhi. Microstructure and corrosion resistance of laser cladding TiC-H13 coating[J]. Hot Working Technology, 2016,45(2):117−119,122. (杨倩, 黄宛真, 孔凡志. 激光熔覆TiC-H13涂层的微结构及耐腐蚀性能的研究[J]. 热加工工艺, 2016,45(2):117−119,122.Yang Qian, Huang Wanzhen, Kong Fanzhi. Microstructure and corrosion resistance of laser cladding TiC-H13 coating [J]. Hot Working Technology, 2016, 45(2): 117-119, 122. [9] Shahmoradi A R, Talebibahmanbigloo N, Javidparvar A A, et al. Studying the adsorption/inhibition impact of the cellulose and lignin compounds extracted from agricultural waste on the mild steel corrosion in HCl solution[J]. J Mol Liq, 2020,304:112751. doi: 10.1016/j.molliq.2020.112751 [10] Zou Juntao, Lei Chunjuan, Hong Bo, et al. Effects of melt holding time on microstructure and hardness of silicon Monel alloy[J]. Hot Working Technology, 2013,42(15):22−25. (邹军涛, 雷春娟, 洪波, 等. 熔体保温时间对含硅蒙乃尔合金组织与硬度的影响[J]. 热加工工艺, 2013,42(15):22−25.Zou Juntao, Lei Chunjuan, Hong Bo, et al. Effects of melt holding time on microstructure and hardness of silicon Monel alloy [J]. Hot Working Technology, 2013, 42(15): 22-25. [11] Han Chang, Zou Juntao, Fan Zhikan. Effect of heat treatment on microstructure and hardness of monel alloy containing silicon[J]. Transactions of Materials and Heat Treatment, 2009,30(2):105−109. (韩昶, 邹军涛, 范志康. 热处理对含Si蒙乃尔合金组织及硬度的影响[J]. 材料热处理学报, 2009,30(2):105−109.Han Chang, Zou Juntao, Fan Zhikan. Effect of heat treatment on microstructure and hardness of monel alloy containing silicon[J]. Transactions of Materials and Heat Treatment, 2009, 30(2): 105-109. [12] Prabhu Ashwin G, Sathishkumar N, Pravinkumar K, et al. Heat treatment and analysis of nickel super alloy for gas turbine applications[J]. Materials Today: Proceedings, 2021,(39):1417−1421. [13] Zhang Zuogui, Liu Xiangfa, Bian Xiufang. Thermodynamics and kinetic of forming TiC in Al-Ti-C system[J]. ACTA Metallurgica Sinaca, 2000,36(10):1025−1029. (张作贵, 刘相法, 边秀房. Al-Ti-C系中TiC形成的热力学与动力学研究[J]. 金属学报, 2000,36(10):1025−1029.Zhang Zuogui, Liu Xiangfa, Bian Xiufang. Thermodynamics and kinetic of forming TiC in Al-Ti-C system[J]. ACTA Metallurgica Sinaca, 2000, 36(10): 1025-1029 [14] Dey G K, Tewari R, Rao P, et al. Precipitation hardening in nickel-copper base alloy monel K500[J]. Metallurgical and Materials Transactions A, 1993,24A:2709−2719. [15] 杨东光. Al、Si、Ti对时效Monel合金强化及抗氟性能的影响[D]. 昆明: 昆明理工大学, 2012.Yang Dongguang. Effect of Al、Si、Ti on strengthening and fluorine resistance of aging Monel alloy[D]. Kunming: Kunming University of Science and Technology, 2012. [16] Javidparvar A, Naderi R, Ramezanzadeh B. L-cysteine reduced/functionalized graphene oxide application as a smart/control release nanocarrier of sustainable cerium ions for epoxy coating anti-corrosion properties improvement[J]. J Hazard Mater, 2020,389:122−135. -

下载:

下载: