The evolution of hot-rolled banded microstructure in low carbon microalloyed steels

-

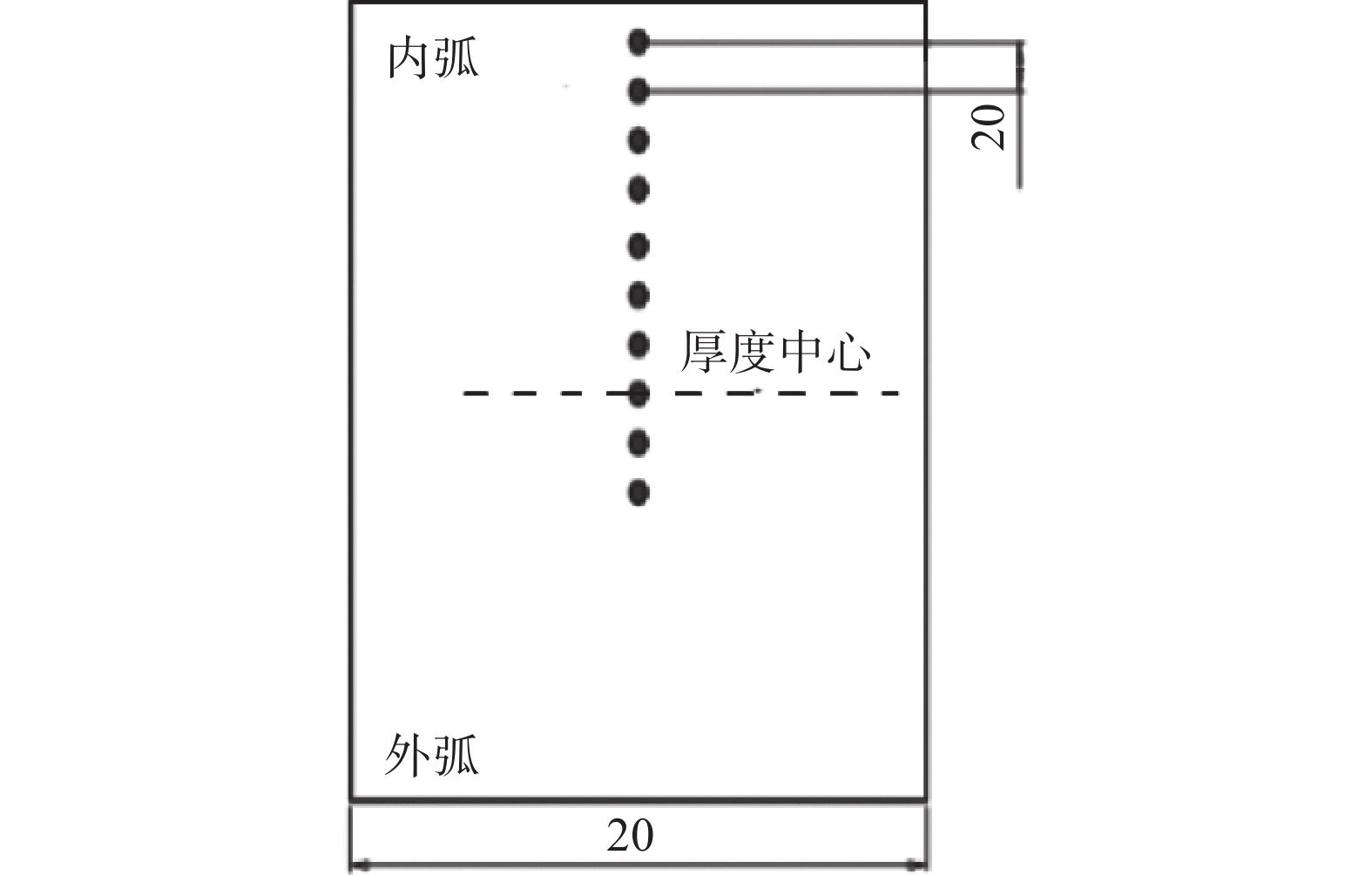

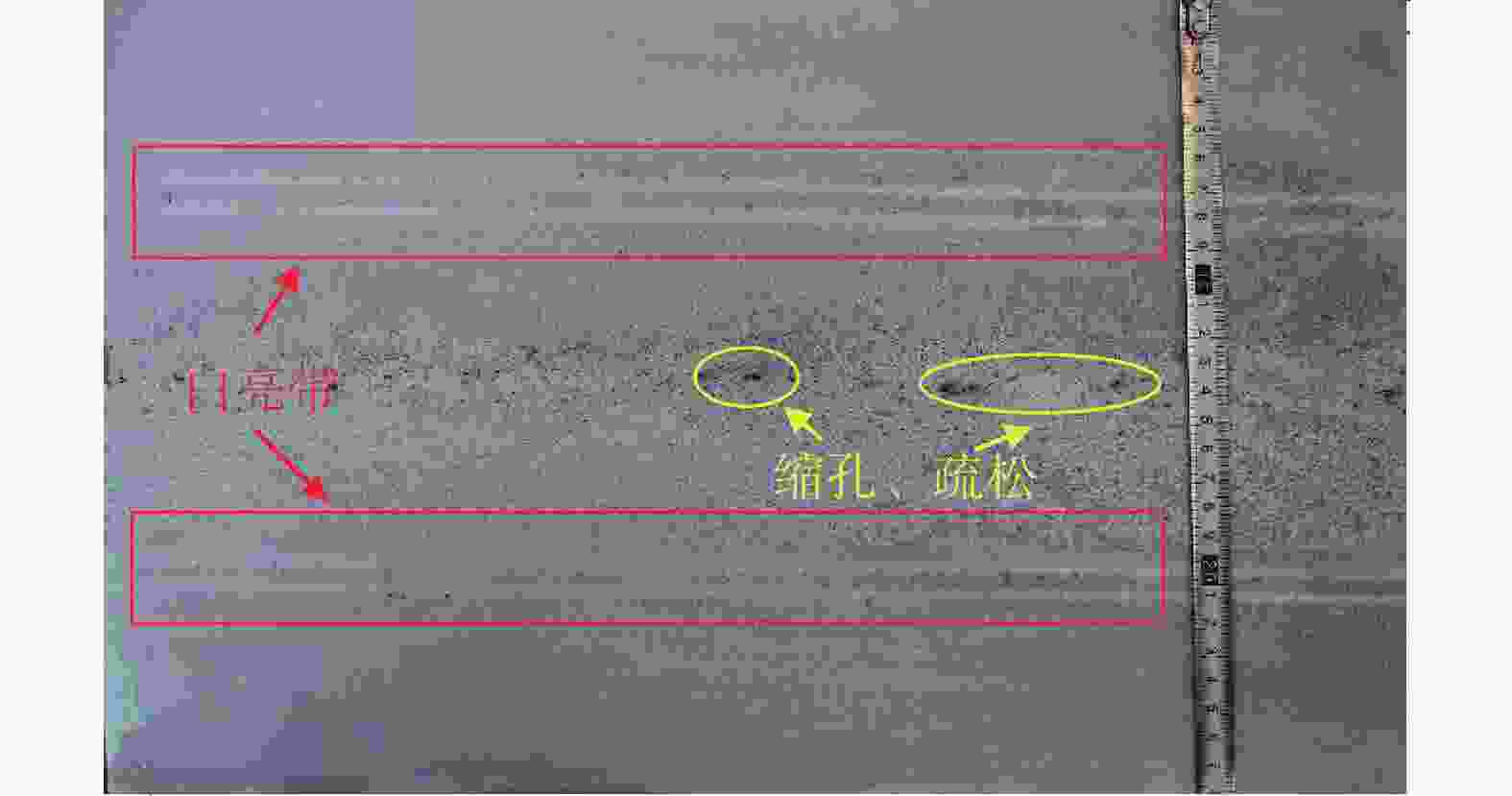

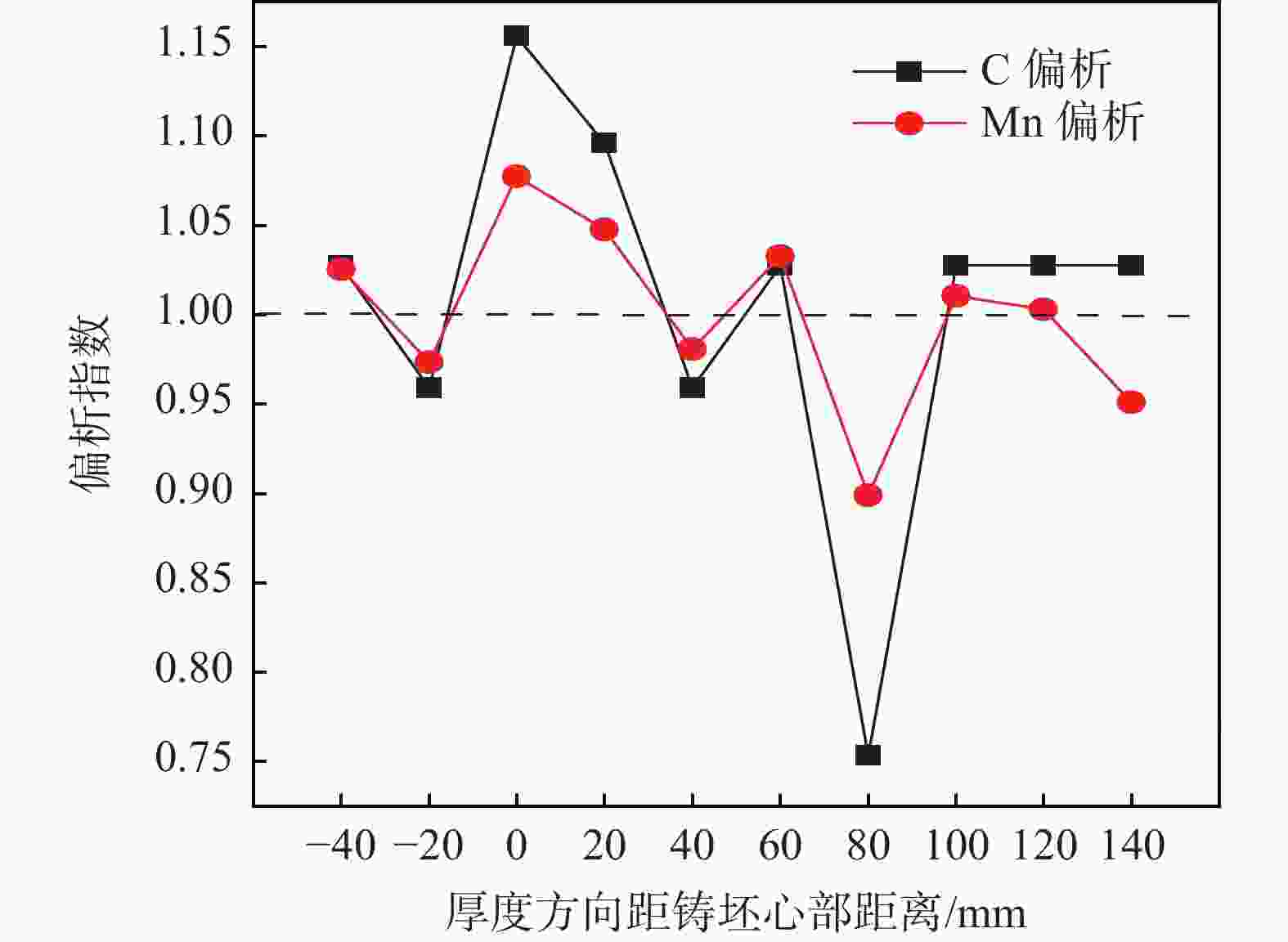

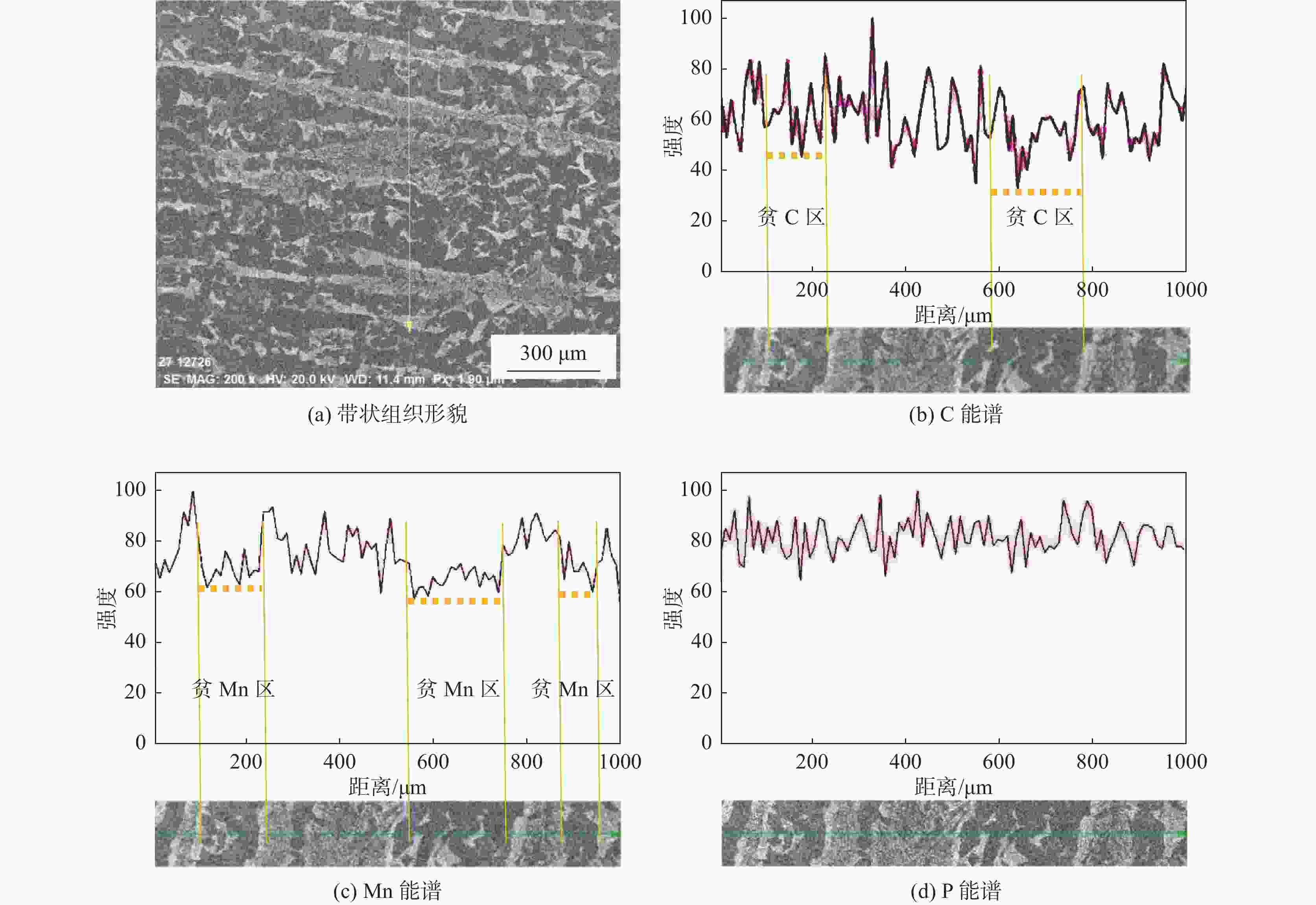

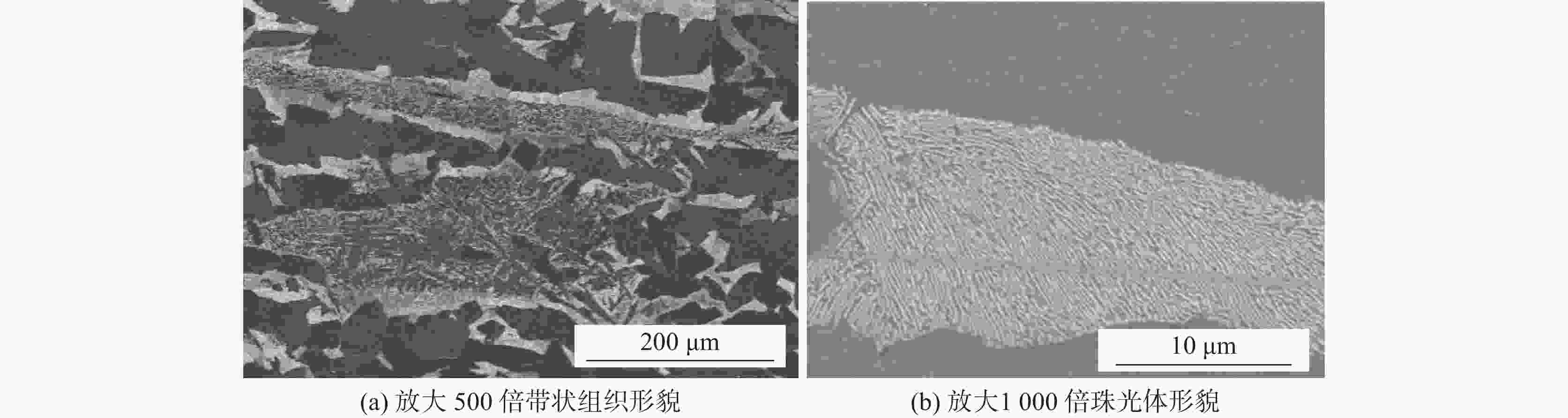

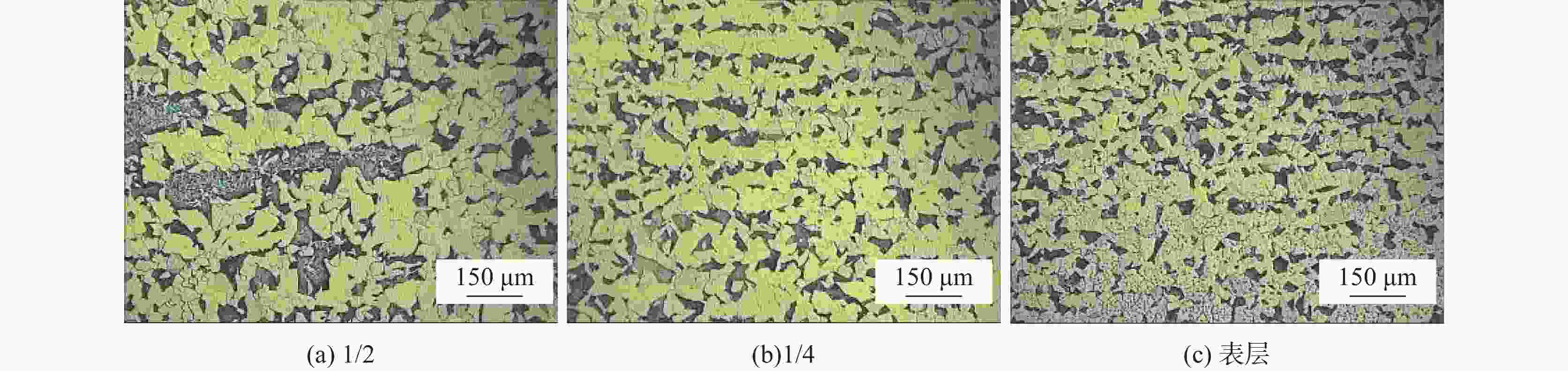

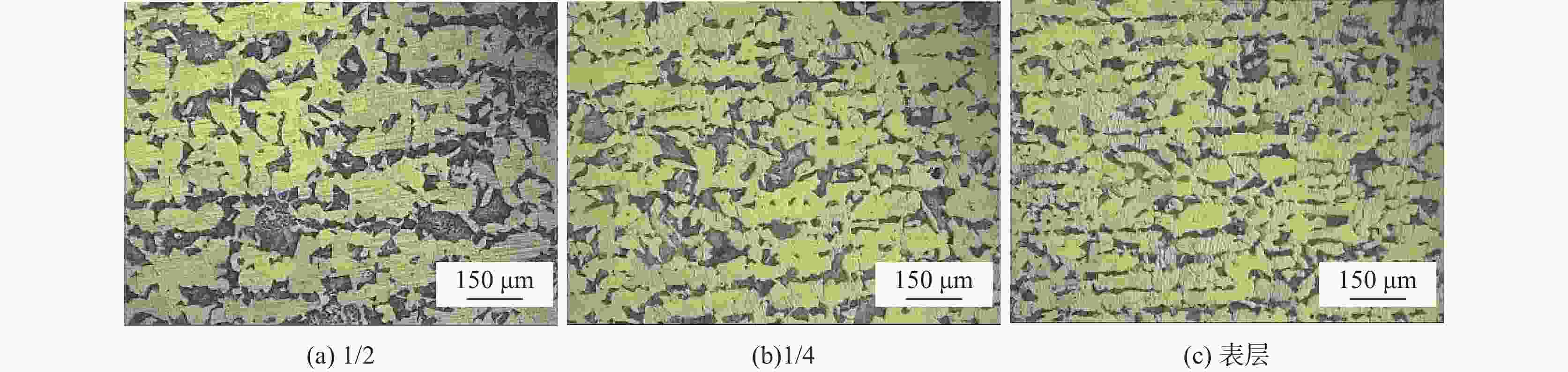

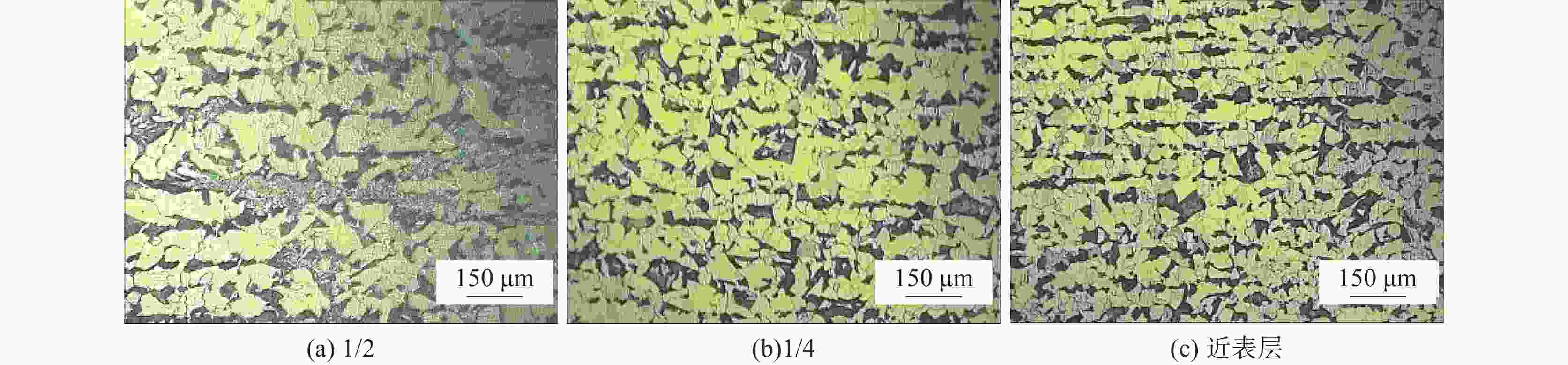

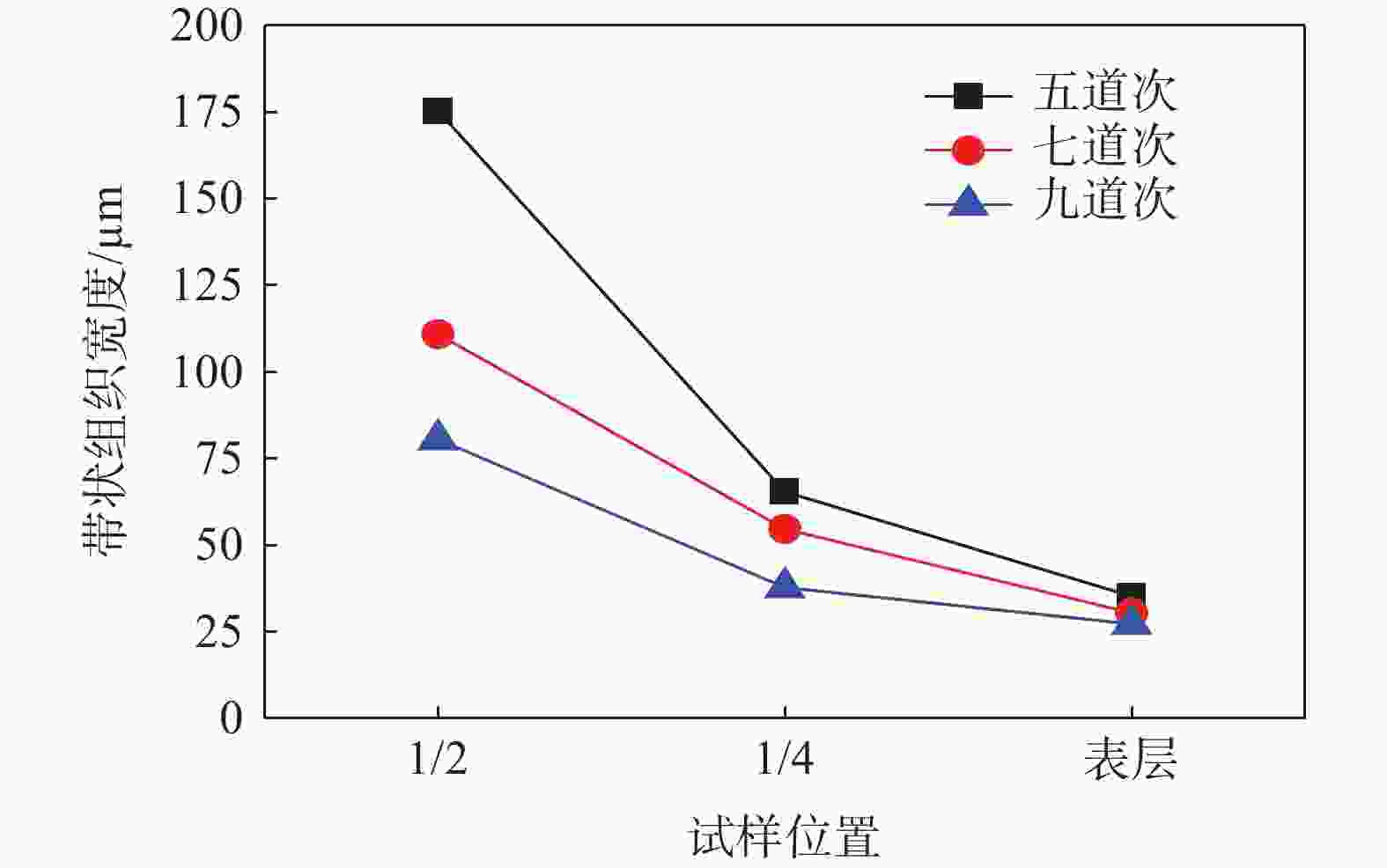

摘要: 低碳微合金钢在轧制过程中经常出现带状组织缺陷,对产品质量和使用性能都有着重要的影响。以某厂Q345热轧板坯为研究对象,通过对元素偏析,轧件热轧过程不同轧制道次、不同位置带状组织演变行为进行分析,结果表明,枝晶间溶质元素偏析是导致带状组织形成的本质原因。同时发现不同轧制道次和不同位置轧材,带状组织尺寸有着明显差异。不同轧制道次,相同位置的带状组织,压下率越大,带状组织越细小,压下率为50%时,中心带状组织宽度约为175 μm;压下率为67%时,中心带状组织宽度约为75 μm。相同轧制道次下,不同轧件位置的带状组织比较,可以发现厚度中心位置带状组织最为粗大,表面处最为细小。Abstract: Banded structure defects often appear in low carbon microalloyed steels during rolling process, which have a great impact on the product quality and service properties. In this study, Q345 hot-rolled slab in a plant was selected as the research object, and the evolution of the banded structure in different rolling passes and positions during hot rolling was analyzed. The results show that the segregation of solute elements between dendrites is the essential reason for the formation of banded structure. At the same time, it is found that there are significant differences in the banded structure size of rolled products at different rolling passes and positions. For the banded structure at the same position in different rolling passes, the larger the reduction rate is, the smaller the banded structure is. When the reduction rate is 50%, the width of the central banded structure is about 175 μm. When the reduction rate is 67%, the width of the central banded tissue is about 75 μm. Under the same rolling pass, the comparison of banded structure at different rolling positions can be made. It is found that the banded structure at half-thickness is the largest, compared to the smallest band observed at the surface.

-

Key words:

- low carbon microalloyed steel /

- hot rolling /

- banded structure /

- reduction /

- evolution behavior

-

表 1 Q345主要化学成分

Table 1. Main chemical composition of Q345

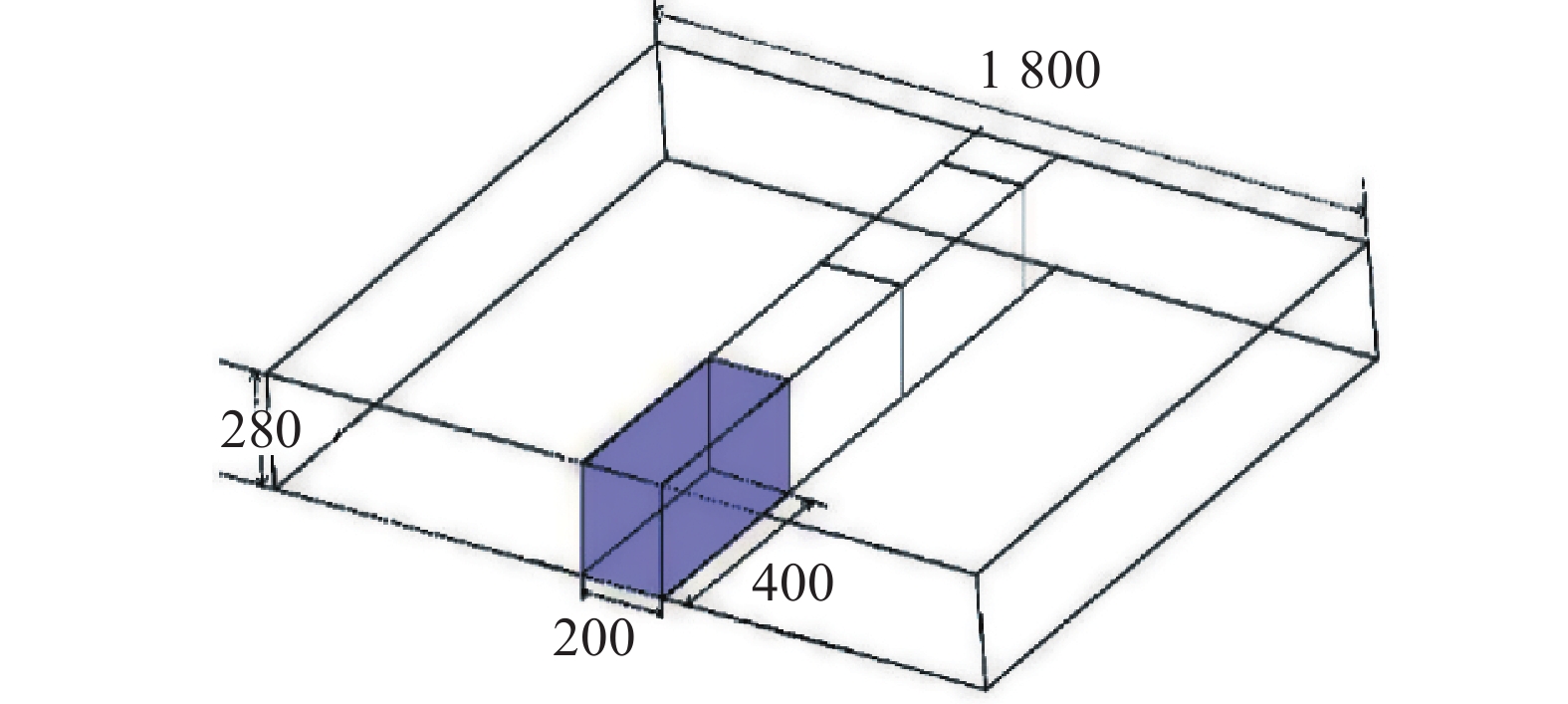

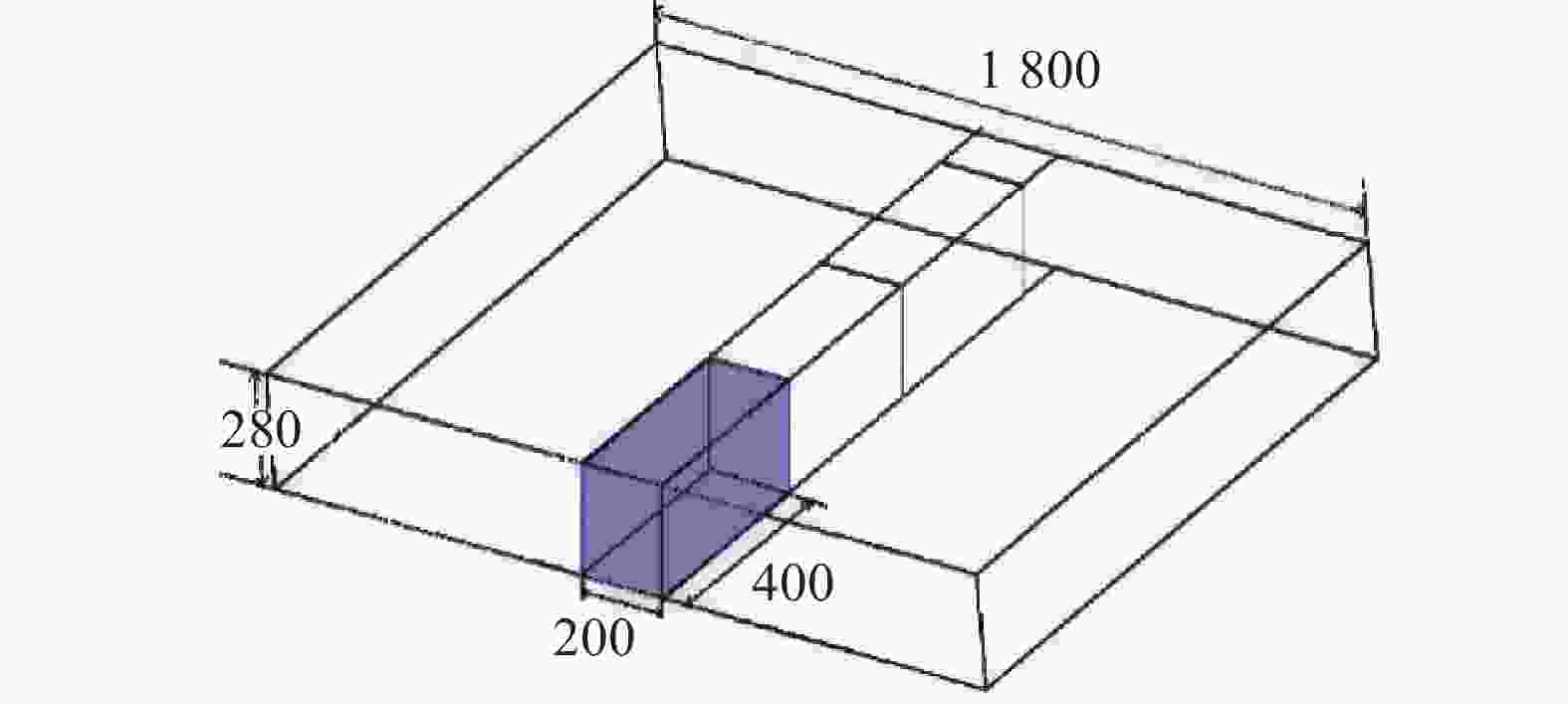

% C Si Mn P S V Nb Ti N 0.14 0.20 1.40 0.014 0.006 0.028 0.025 0.02 0.007 表 2 轧制工艺参数

Table 2. Rolling process parameters

轧制道次 厚度/mm 道次压下率/% 总压下率/% 压缩比 0 280.0 0.0 0.0 0.00 1 247.5 11.6 11.6 1.13 2 216.0 12.7 22.8 1.29 3 186.6 13.6 33.3 1.50 4 161.0 13.7 42.5 1.74 5 140.4 12.8 50.0 2.00 6 124.7 11.2 55.5 2.25 7 111.9 10.3 60.0 2.51 8 100.0 10.6 64.3 2.80 9 92.1 7.9 67.1 3.00 -

[1] Uthaisangsuk V, Muenstermann S, Prahl U, et al. A study of microcrack formation in multiphase steel using representative volume element and damage mechanics[J]. Computational Materals Science, 2011,50(4):1225−1232. doi: 10.1016/j.commatsci.2010.08.007 [2] Ji Yuan, Min Yunfeng, Li Pengshan, et al. Ribbon structure in steel and its research status[J]. Chinese Metallurgy, 2016,26(4):1−9. (纪元, 闵云峰, 李鹏善, 等. 钢中带状组织及其研究现状[J]. 中国冶金, 2016,26(4):1−9.Ji Yuan, Min Yunfeng, Li Pengshan, et al. Ribbon structure in steel and its research status[J]. Chinese Metallurgy, 2016, 26(4): 1-9. [3] Verhoeven J D. A review of microsegregation induced banding phenomena in steels[J]. Journal of Materials Engineering and Performance, 2000,9(3):286−296. doi: 10.1361/105994900770345935 [4] Karimi Y, Nedjad S H, Miyamoto G, et al. Banding effects on the process of grain refinement by cold deformation and recrystallization of acicular C-Mn steel[J]. Materials Science Engineering A, 2017,697(7):1−7. [5] Grange R A. Effect of microstructural banding in steel[J]. Metallurgical and Materials Transaction A, 1971,2(2):417−426. doi: 10.1007/BF02663328 [6] Zaefferer S, Ohlert J, Bleck W. A study of microstructure, transformation mechanisms and correlation between microstructure and mechanical properties of a low alloyed TRIP steel[J]. Acta Materialia, 2004,52(9):2765−2778. doi: 10.1016/j.actamat.2004.02.044 [7] Krizan D, Spiradek H K, Pichler A. Relationship between microstructure and mechanical properties in Nb-V microalloyed TRIP steel[J]. Materials Science and Technology, 2015,31(6):661−668. doi: 10.1179/1743284714Y.0000000637 [8] Krauss G. Solidification, segregation, and banding in carbon and alloy steel[J]. Metallurgical and Materials Transaction B, 2003,34(6):781−792. doi: 10.1007/s11663-003-0084-z [9] Gao Xiao, Yang Renjie, Li Yingjie, et al. Effect of strip group on mechanical properties of Q345E steel[J]. Large Castings and Forgings, 2016,(2):29−31. (高潇, 杨仁杰, 李英杰, 等. 带状组组对Q345E钢力学性能的影响[J]. 大型铸锻件, 2016,(2):29−31.Gao Xiao, Yang Renjie, Li Yingjie, et al. Effect of strip group on mechanical properties of Q345 E steel[J]. Large Castings and Forgings, 2016, 2: 29-31. [10] Wang Zhiyi, Le Kexiang. Q345B causes of delamination defects in medium and thick steel plates[J]. Physical and Chemical Testing: Physical Fascicles, 2009,45(10):613−616. (王智轶, 乐可襄. Q345B中厚钢板分层缺陷的形成原因[J]. 理化检验:物理分册, 2009,45(10):613−616.Wang Zhiyi, Le Kexiang. Q345 B causes of delamination defects in medium and thick steel plates[J]. Physical and Chemical Testing: Physical Fascicles, 2009, 45(10): 613-616. [11] Shi Kewei, Lu Hongxing, Han Yong, et al. Experimental study on the influence of continuous casting cooling strength on the banded structure grade of steel[J]. Continuous Casting, 2015,40(5):42−44. (石可伟, 卢洪星, 韩勇, 等. 连铸冷却强度对钢材带状组织级别影响的试验研究[J]. 连铸, 2015,40(5):42−44.Shi Kewei, Lu Hongxing, Han Yong, et al. Experimental study on the influence of continuous casting cooling strength on the banded structure grade of steel[J]. Continuous Casting, 2015, 40(5): 42-44. [12] Zhang Yanling, Liu Haiying, Ruan Xiaojiang, et al. Segregation behavior of alloy elements in medium and low carbon gear steels and its effect on banded structure[J]. Journal of Beijing University of Science and Technology, 2009,31(S1):199−206. (张延玲, 刘海英, 阮小江, 等. 中低碳齿轮钢中合金元素的偏析行为及其对带状组织的影响[J]. 北京科技大学学报, 2009,31(S1):199−206.Zhang Yanling, Liu Haiying, Ruan Xiaojiang, et al. Segregation behavior of alloy elements in medium and low carbon gear steels and its effect on banded structure[J]. Journal of Beijing University of Science and Technology, 2009, 31(S1): 199-206. [13] Ji Yuzhong. Control practice of strip structure of 25CrMo4 gear steel produced by continuous casting and rolling[J]. Shandong Metallurgy, 2022,44(4):54−56. (纪玉忠. 连铸连轧生产25CrMo4齿轮钢带状组织的控制实践[J]. 山东冶金, 2022,44(4):54−56.Ji Yuzhong. Control practice of strip structure of 25 CrMo4 gear steel produced by continuous casting and rolling[J]. Shandong Metallurgy, 2022, 44(4): 54-56. [14] Wang Jie, Dang Shu, e, Fan Zijing, et al. Tissue homogenization of 17CrNiMo6 gear steel[J]. Metal Heat Treatment, 2022,47(11):126−133. (王杰, 党淑娥, 范子靖, 等. 17CrNiMo6齿轮钢的组织均匀化[J]. 金属热处理, 2022,47(11):126−133.Wang Jie, Dang Shue, Fan Zijing, et al. Tissue homogenization of 17 CrNiMo6 gear steel [J]. Metal Heat Treatment, 2022, 47(11): 126-133. [15] Wen Hongquan, Wu Cunyou, Zhou Yueming. Study on solute redistribution and macroscopic segregation during solidification process of carbon steel continuous casting billet[J]. Baosteel Technology, 2019,(4):45−49. (温宏权, 吴存有, 周月明. 碳钢连铸坯凝固过程溶质再分配及宏观偏析的研究[J]. 宝钢技术, 2019,(4):45−49.Wen Hongquan, Wu Cunyou, Zhou Yueming. Study on solute redistribution and macroscopic segregation during solidification process of carbon steel continuous casting billet [J]. Baosteel Technology , 2019(4): 45-49. [16] Chen Jixiong, Liu Weihang, Peng Xiaofeng. Formation reason and process improvement of banded structure in microstructure of Q345B thick steel plate[J]. Physical Testing and Chemical Analysis(Part A:Physical Testing), 2021,57(5):18−20, 26. (陈继雄, 刘卫航, 彭晓枫. Q345B厚钢板显微组织中带状组织的形成原因及工艺改进[J]. 理化检验(物理分册), 2021,57(5):18−20, 26.Chen Jixiong, Liu Weihang, Peng Xiaofeng. Formation reason and process improvement of banded structure in microstructure of Q345 B thick steel plate[J]. Physical Testing and Chemical Analysis(Part A: Physical Testing), 2021, 57(5): 18-20, 26. [17] Huo Xiangdong, Hou Liang, Li Liejun, et al. Recrystallization law of titanium microalloyed high-strength steel[J]. Journal of Materials Heat Treatment, 2017,38(4):119−125. (霍向东, 侯亮, 李烈军, 等. 钛微合金化高强钢的再结晶规律[J]. 材料热处理学报, 2017,38(4):119−125.Huo Xiangdong, Hou Liang, Li Liejun, et al. Recrystallization law of titanium microalloyed high-strength steel[J]. Journal of Materials Heat Treatment, 2017, 38(4): 119-125. [18] Xie Xinghua, Yao Zekun, Ning Yongquan, et al. Dynamic recrystallization and grain refinement of FGH4096 alloy[J]. Journal of Aeronautical Materials, 2011,31(1):20−24. (谢兴华, 姚泽坤, 宁永权, 等. FGH4096合金的动态再结晶与晶粒细化研究[J]. 航空材料学报, 2011,31(1):20−24. doi: 10.3969/j.issn.1005-5053.2011.1.004Xie Xinghua, Yao Zekun, Ning Yongquan, et al. Dynamic recrystallization and grain refinement of FGH4096 alloy[J]. Journal of Aeronautical Materials, 2011, 31(1): 20-24. doi: 10.3969/j.issn.1005-5053.2011.1.004 [19] Ma Cainü, Gao Xueyun, Hu Zhiyu, et al. Effect of rolling deformation on grain refinement of 0.05C-2.8Mn-4.2Ni-2Al-1.2Mo-1.9Cu of F-M duplex steel[J]. Special Steel, 2022,43(3):91−94. (马才女, 高雪云, 呼陟宇, 等. 轧制变形对F-M双相钢0.05C-2.8Mn-4.2Ni-2Al-1.2Mo-1.9Cu晶粒细化的影响[J]. 特殊钢, 2022,43(3):91−94. doi: 10.3969/j.issn.1003-8620.2022.03.020Ma Cainv, Gao Xueyun, Hu Zhiyu, et al. Effect of rolling deformation on grain refinement of 0.05 C-2.8 Mn-4.2 Ni-2 Al-1.2 Mo-1.9 Cu of F-M duplex steel[J]. Special Steel, 2022, 43(3): 91-94. doi: 10.3969/j.issn.1003-8620.2022.03.020 -

下载:

下载: