| [1] |

Yeh J W, Chen S K, Lin S J, et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004,6:299−303. doi: 10.1002/adem.200300567

|

| [2] |

George E P, Raabe D, Ritchie R O. High-entropy alloys[J]. Nature Reviews Materials, 2019,4:515−534.

|

| [3] |

乔珺威. 面心立方结构高熵合金[M]. 北京: 冶金工业出版社, 2021.Qiao Junwei. High entropy alloy with face-centered cubic structure [M].Beijing: Metallurgical Industry Press, 2021.

|

| [4] |

王龙. 高熵合金涂层的微结构与耐腐蚀性能研究[D]. 自贡: 四川理工学院, 2015.Wang Long. Study on microstructure and corrosion resistance of high entropy alloy coatings[D]. Zigong: Sichuan University of Science and Technology, 2015.

|

| [5] |

鲁一荻, 张骁勇, 侯硕. 高熵合金的发展及工业应用展望[J]. 稀有金属材料与工程, 2021, 50(1): 333-341.Lu Yidi, Zhang Xiaoyong, Hou Shuo, et al. Development and industrial application prospect of high entropy alloys[J]. Rare Metal Materials and Engineering, 2021, 50(1): 333-341.

|

| [6] |

张荣, 祁文军, 张爽. AlxCoCrFeNi拉伸力学性能的分子动力学模拟[J]. 钢铁钒钛, 2022, 43(6): 173-179.Zhang Rong, Qi Wenjun, Zhang Shuang. Molecular dynamics simulation of tensile mechanical properties of AlxCoCrFeNi[J], Iron Steel Vanadium Titanium, 2022,43(6):173-179.

|

| [7] |

Zhao Haichao, Qiao Yulin, Liang Xiubing, et al. Research progress and prospect of lightweight high entropy alloys[J]. Rare Metal Materials and Engineering, 2020,49(4):1457−1468. (赵海朝, 乔玉林, 梁秀兵, 等. 轻质高熵合金的研究进展与展望[J]. 稀有金属材料与工程, 2020,49(4):1457−1468.Zhao Haichao, Qiao Yulin, Liang Xiubing et al. Research progress and prospect of Lightweight High Entropy Alloys [J]. Rare Metal Materials and Engineering, 2020, 49(04): 1457-1468.

|

| [8] |

Csikor F F, Motz C, Weygand D, et al. Dislocation avalanches, strain bursts, and the problem of plastic forming at the micrometer scale[J]. Science, 2017,318:251−254.

|

| [9] |

Xie K, Sirestha S, Cao Y, et al. The effect of pre-existing defects on the strength and deformation behavior of a-Fe nanopillars[J]. Acta Materialia, 2013,61:439−452. doi: 10.1016/j.actamat.2012.09.022

|

| [10] |

Zhang J Y, Lei S Y, Liu Y, et al. Length scale-dependent deformation behavior of nanolayered Cu/Zr micropillars[J]. Acta Materialia, 2012,(60):1610−1622.

|

| [11] |

Zhang J Y, Liu G, Lei S Y, et al. Transition from homogeneous-like to shear-band deformation in nanolayered crystalline Cu/amorphous Cu–Zr micropillars: Intrinsic vs. extrinsic size effect[J]. Acta Materialia, 2012,(60):7183−7196.

|

| [12] |

Yu Zou, Soumyadipta Maiti, Walter Steurer, et al. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropyalloy[J]. Acta Materialia, 2014,65:85−97. doi: 10.1016/j.actamat.2013.11.049

|

| [13] |

Indranil Basu, Vaclav Ocelík, Jeff Th M, et al. Size dependent plasticity and damage response in multiphase body centered cubic high entropy alloys[J]. Acta Materialia, 2018,150:104−116. doi: 10.1016/j.actamat.2018.03.015

|

| [14] |

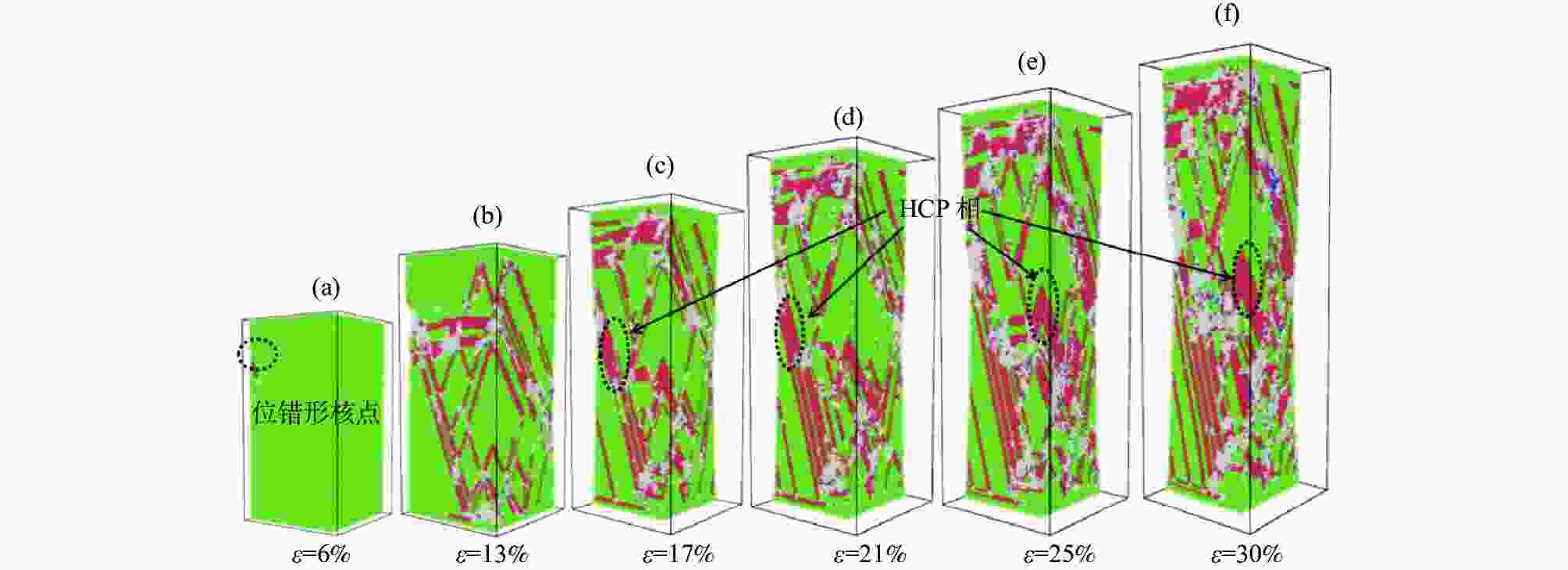

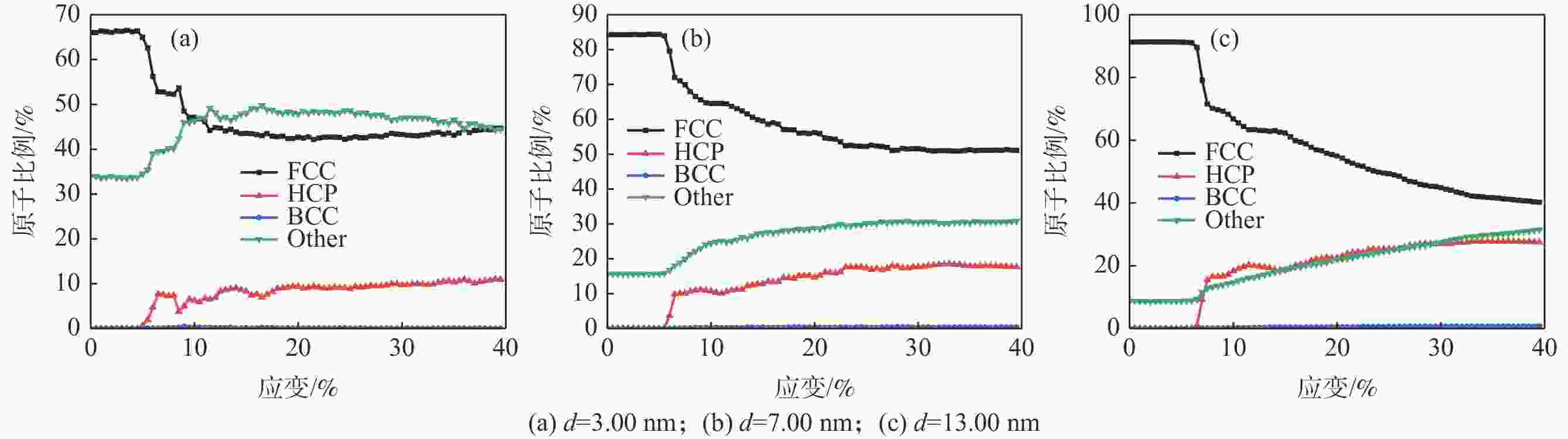

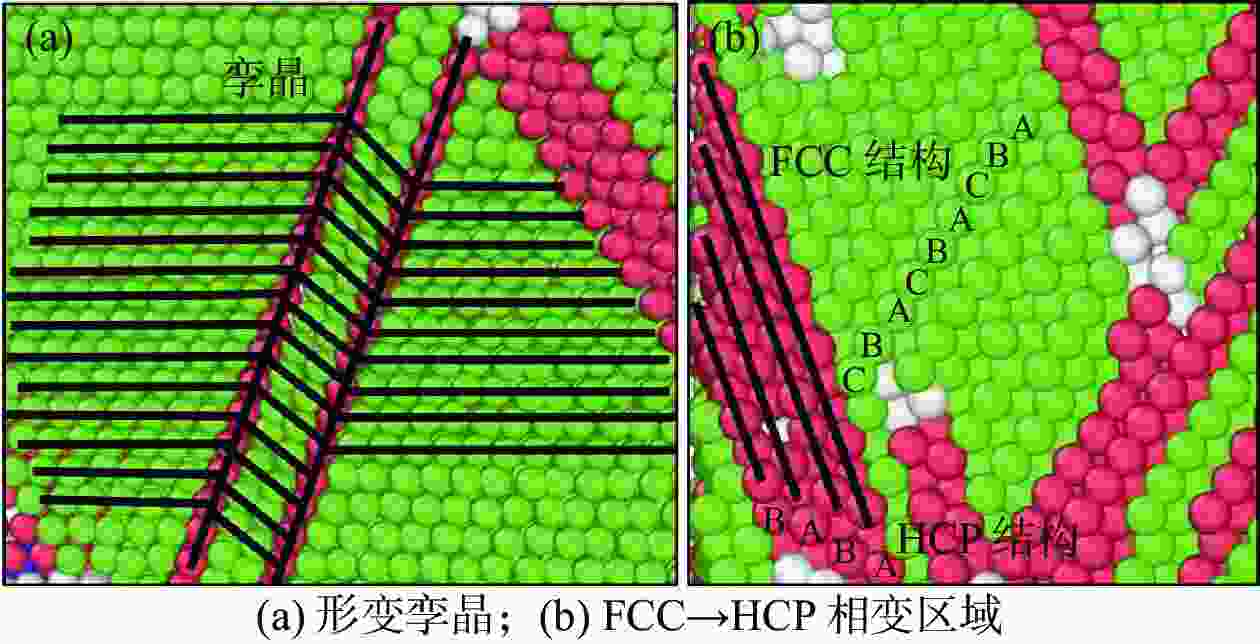

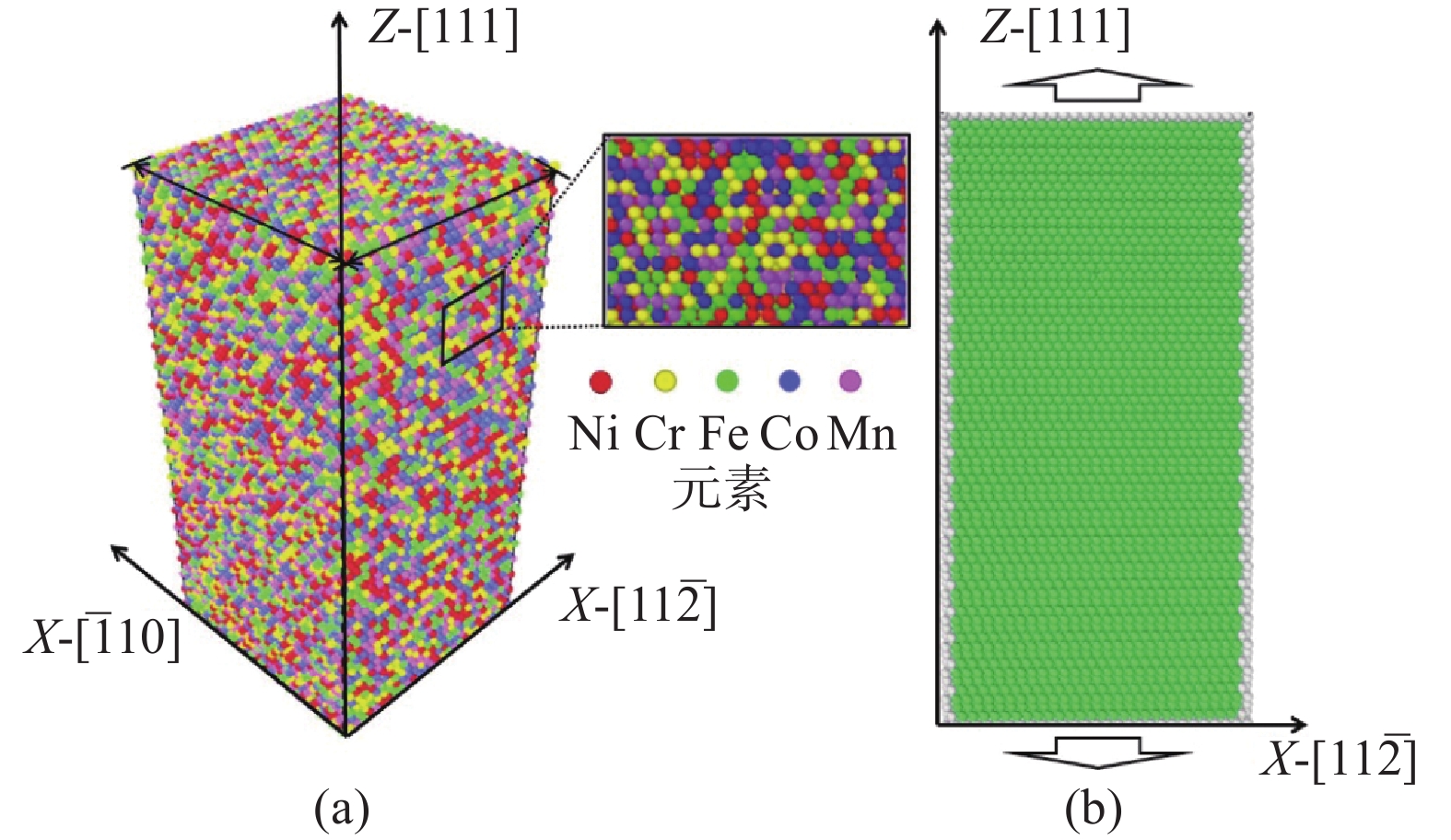

An Minrong, Li Silan, Su Mengjia. Molecular dynamics simulation of size-dependent plastic deformation mechanism of CoCrFeNiMn crystal/amorphous biphase high entropy alloy[J]. Acta Physica Sinica, 2022,(24):146−157. (安敏荣, 李思澜, 宿梦嘉. 尺寸依赖的CoCrFeNiMn晶体/非晶双相高熵合金塑性变形机制的分子动力学模拟研究[J]. 物理学报, 2022,(24):146−157. doi: 10.7498/aps.71.20221368An Minrong, Li Silan, Su Mengjia. Molecular dynamics simulation of size-dependent plastic deformation mechanism of CoCrFeNiMn crystal/amorphous biphase high entropy alloy. Acta Physica Sinica. doi: 10.7498/aps.71.20221368.

|

| [15] |

Xiao L L, Zheng Z Q, Guo S W, et al. Ultra-strong nanostructured CrMnFeCoNi high entropy alloys[J]. Materials and Design, 2020,194:108895. doi: 10.1016/j.matdes.2020.108895

|

| [16] |

Ji W, Wu M S. Nanoscale origin of the crystalline-to-amorphous phase transformation and damage tolerance of Cantor alloys at cryogenic temperatures[J]. Acta Materialia, 2022,226:117639. doi: 10.1016/j.actamat.2022.117639

|

| [17] |

Zhao S, Li Z, Zhu C, et al. Amorphization in extreme deformation of the CrMnFeCoNi high-entropy alloy[J]. Science Advance, 2021,7:eabb3108.

|

| [18] |

Li J, Bai Z, Max Powers. et al. Deformation mechanisms in crystalline-amorphous high-entropy composite multilayers[J]. Materials Science & Engineering A, 2022, 848: 143144.

|

| [19] |

Ren J, Sun J, Xiao L, et al. Size-dependent of compression yield strength and deformation mechanism in titanium single-crystal nanopillars orientated [0001] and [11-20][J]. Materials Science & Engineering A, 2014,615:22−28.

|

| [20] |

Shuichi Nosé. A unified formulation of the constant temperature molecular dynamics methods[J]. The Journal of Chemical Physics, 1984, 81: 511.

|

| [21] |

Won-Mi Choi, Yong Hee Jo, Seok Su Sohn, et al. Understanding the physical metallurgy of the CoCrFeMnNi high-entropy alloy: an atomistic simulation study[J]. NPJ Computational Materials, 2018,4:1. doi: 10.1038/s41524-017-0060-9

|

| [22] |

Utt D, Lee S, Xing Y, et al. The origin of jerky dislocation motion in high-entropy alloys[J]. Nature Communications, 2022,13:4777. doi: 10.1038/s41467-022-32134-1

|

| [23] |

Hayakawa S, Xu H. Temperature-dependent mechanisms of dislocation-twin boundary interactions in Ni-based equiatomic alloys[J]. Acta Materialia, 2021,211:116886. doi: 10.1016/j.actamat.2021.116886

|

| [24] |

Plimpton S, Fast parallel algorithms for short-range molecular dynamics[J].Journal of Computational Physics, 1995, 117: 1-19.

|

| [25] |

Stukowski A. Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool [J].Modelling and Simulation in Materials Science and Engineering, 2009, 18: 015012.

|

| [26] |

Faken D, Jónsson H. Systematic analysis of local atomic structure combined with 3D computer graphics [J]. Computational Materials Science, 1994, 2: 279-286.

|

| [27] |

Li J, Chen H, Feng H, et al. Microstructure evolution and deformation mechanism of amorphous/crystalline high-entropy-alloy composites[J]. Journal of Materials Science & Technology, 2020,54:14−19.

|

| [28] |

Shen Tianzhan, Song Haiyang, An Minrong. Molecular dynamics simulation of the effect of twin boundary on mechanical behavior of Cr26Mn20Fe20Co20Ni14 high entropy alloy[J]. Acta Physica Sinica, 2021,70(18):186201. (申天展, 宋海洋, 安敏荣. 孪晶界对Cr26Mn20Fe20Co20Ni14高熵合金力学行为影响的分子动力学模拟[J]. 物理学报, 2021,70(18):186201. doi: 10.7498/aps.70.20210324Shen Tianzhan, Song Haiyang, An MinRong. Molecular dynamics simulation of the effect of twin boundary on mechanical behavior of Cr26Mn20Fe20Co20Ni14 high entropy alloy[J]. Acta Physica Sinica, 2021, 70(18): 186201. doi: 10.7498/aps.70.20210324

|

| [29] |

Qi Y M, Zhao M, Feng M L. Molecular simulation of microstructure evolution and plastic deformation of nanocrystalline CoCrFeMnNi high-entropy alloy under tension and compression[J]. Journal of Alloys and Compounds, 2021,851:156923. doi: 10.1016/j.jallcom.2020.156923

|

| [30] |

Fang Q H, Chen Y, Li J, et al. Probing the phase transformation and dislocation evolution in dual-phase high-entropy alloys[J]. International Journal of Plasticity, 2019,114:161−173. doi: 10.1016/j.ijplas.2018.10.014

|

| [31] |

Chowdhury P, Canadinc D, Sehitoglu H. On deformation behavior of Fe-Mn based structural alloys[J]. Materials Science and Engineering R, 2017, 122: 1-28.

|

下载:

下载: