The hardness and softening behavior of HAZ in Ti and Nb precipitation strengthened 600 MPa wheel steel

-

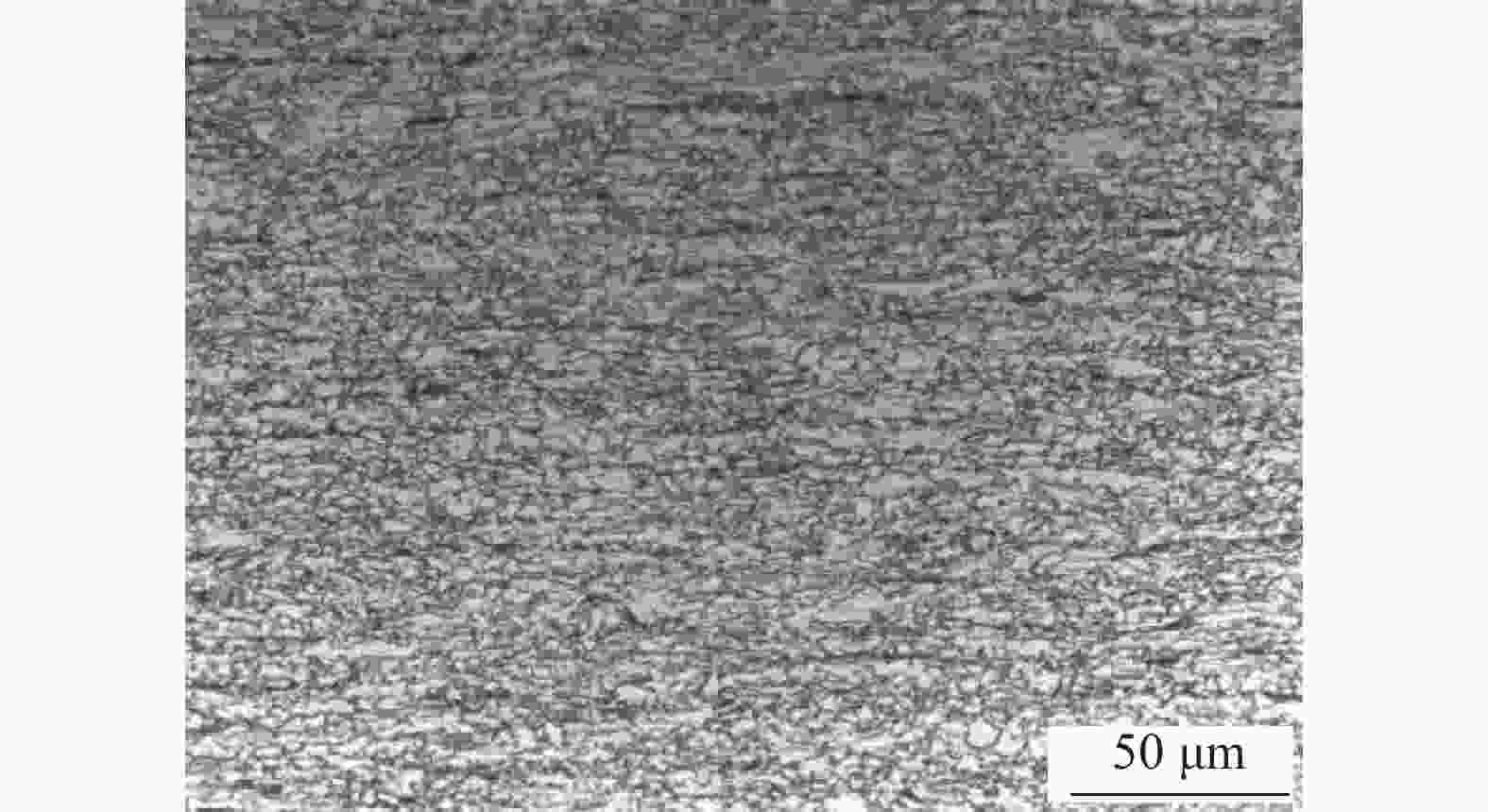

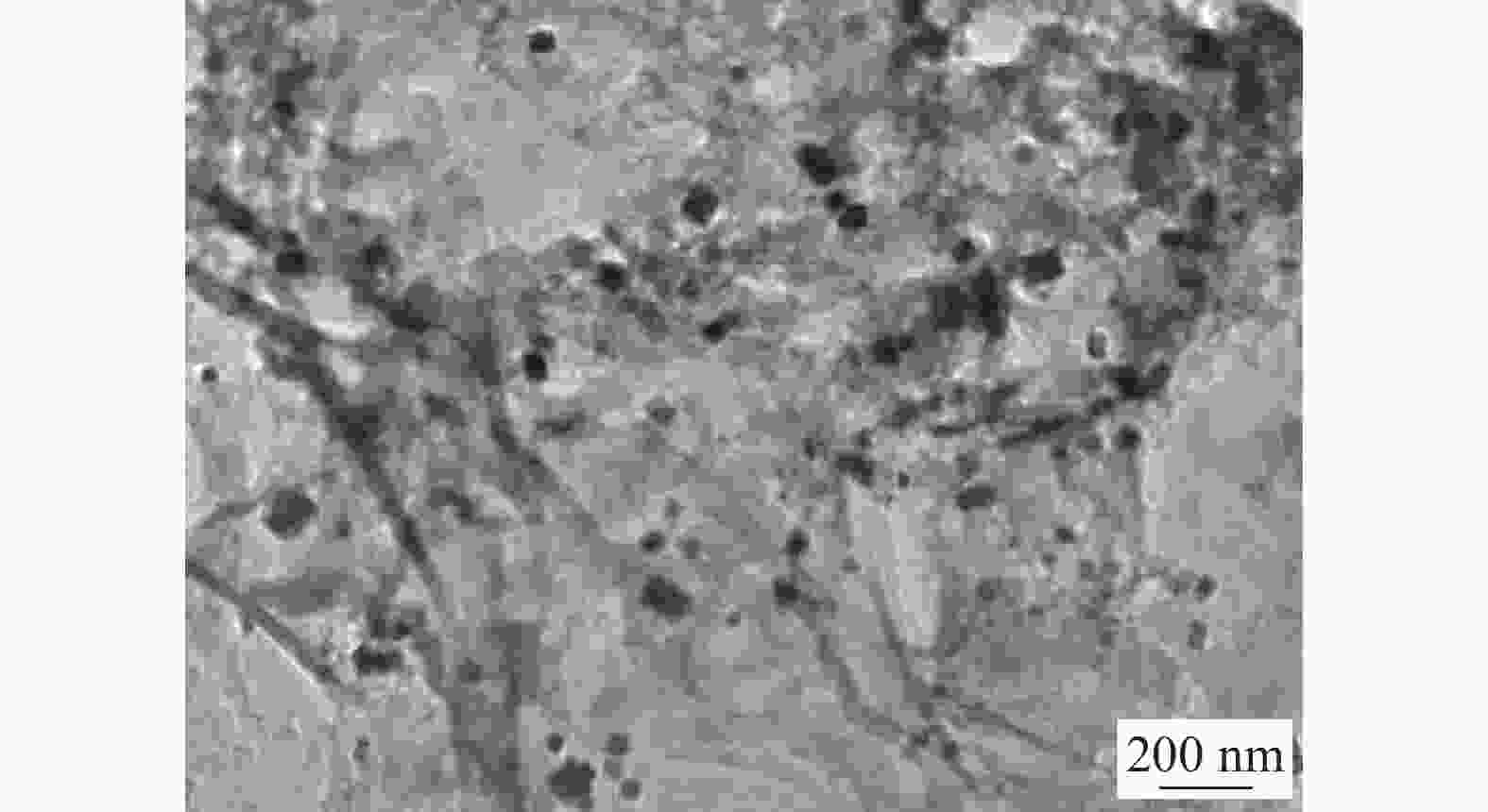

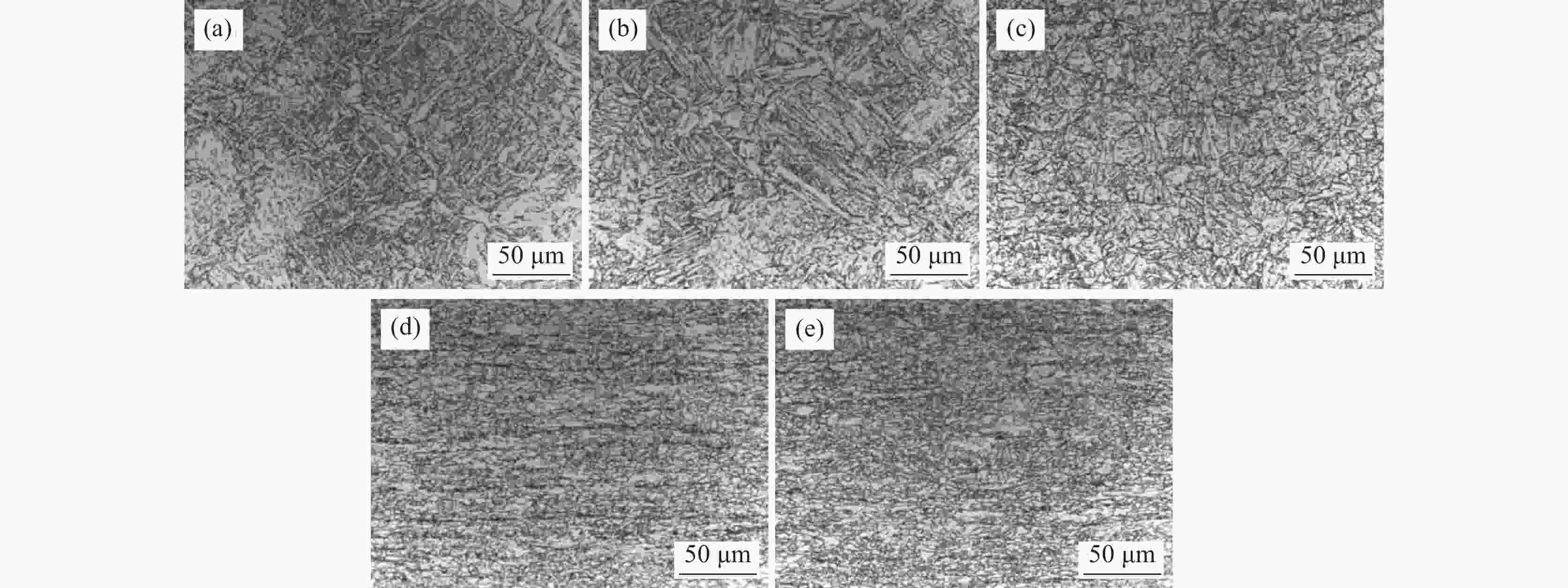

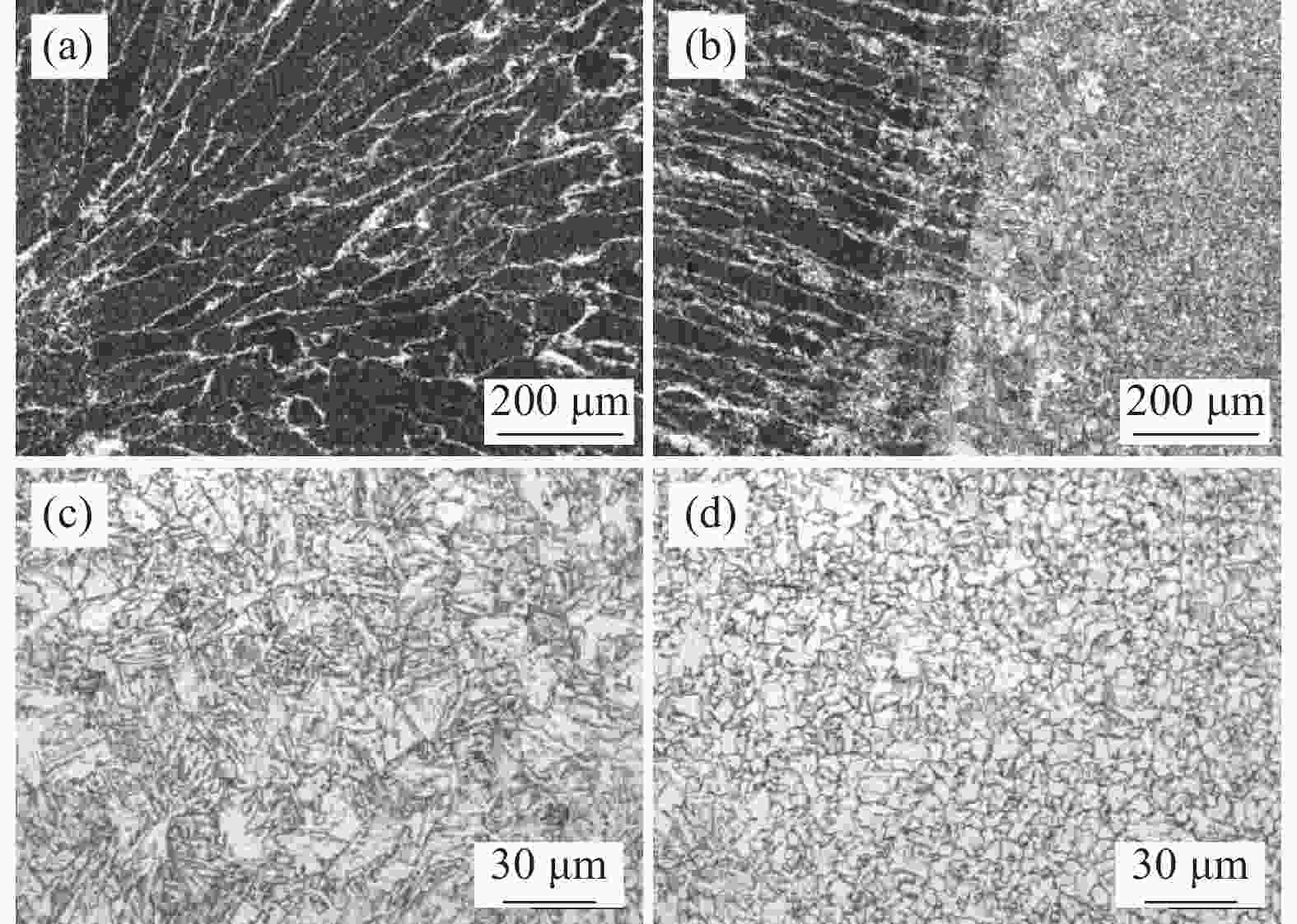

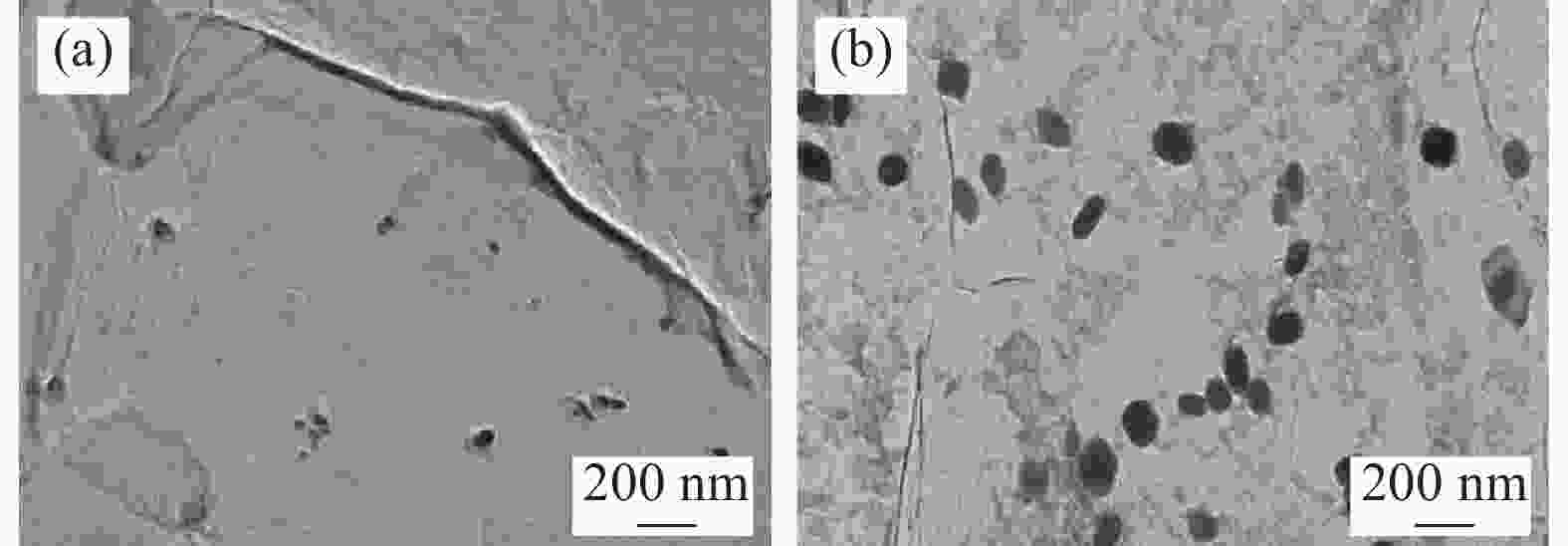

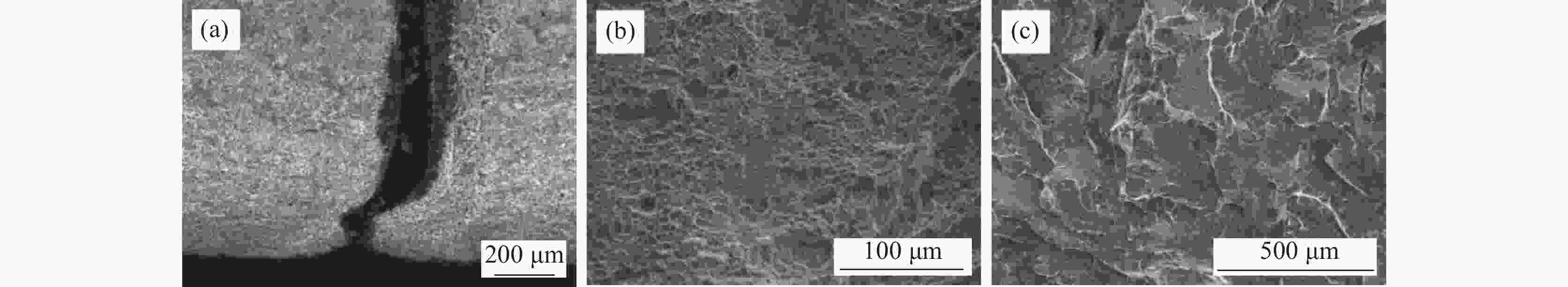

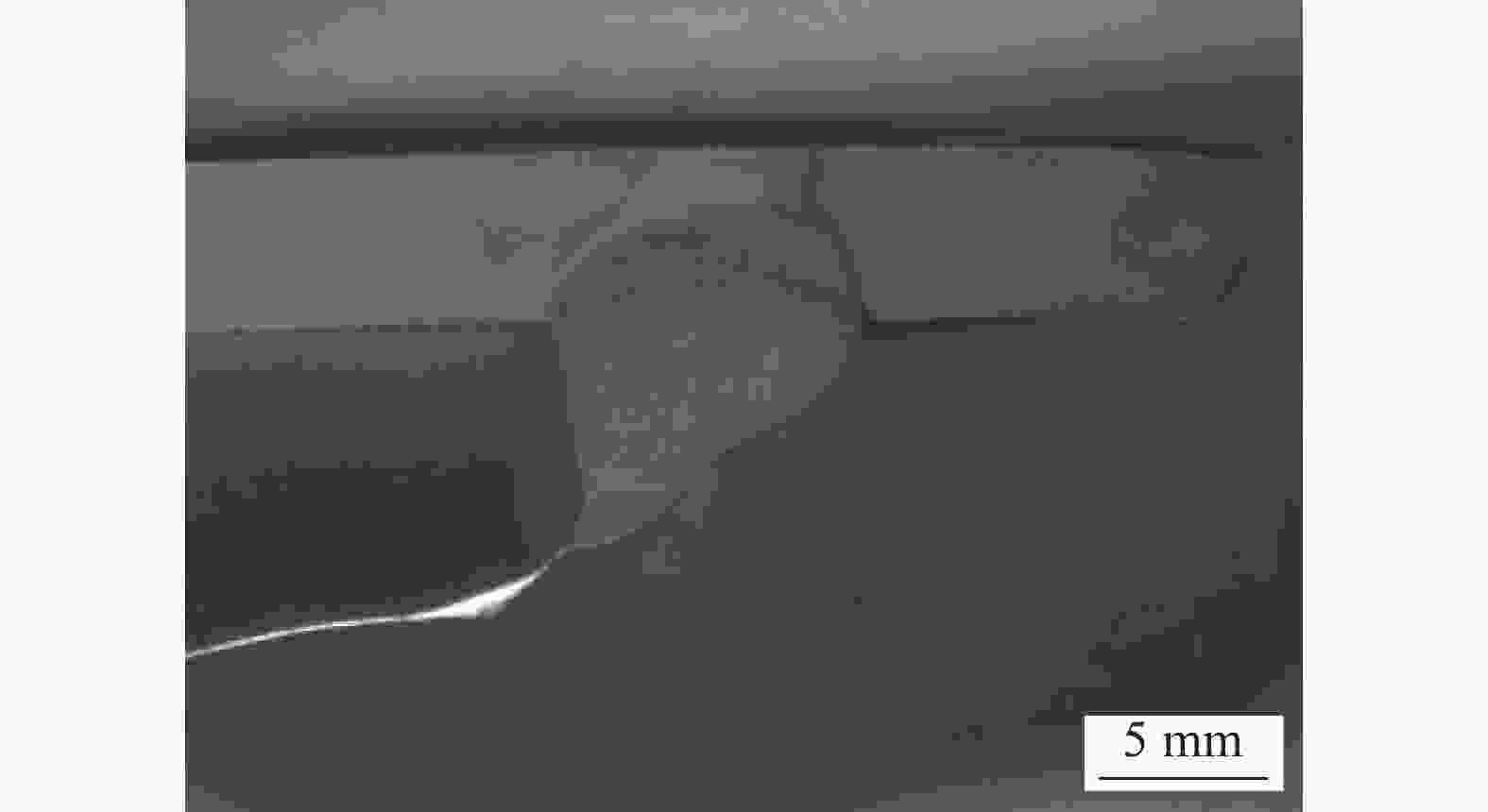

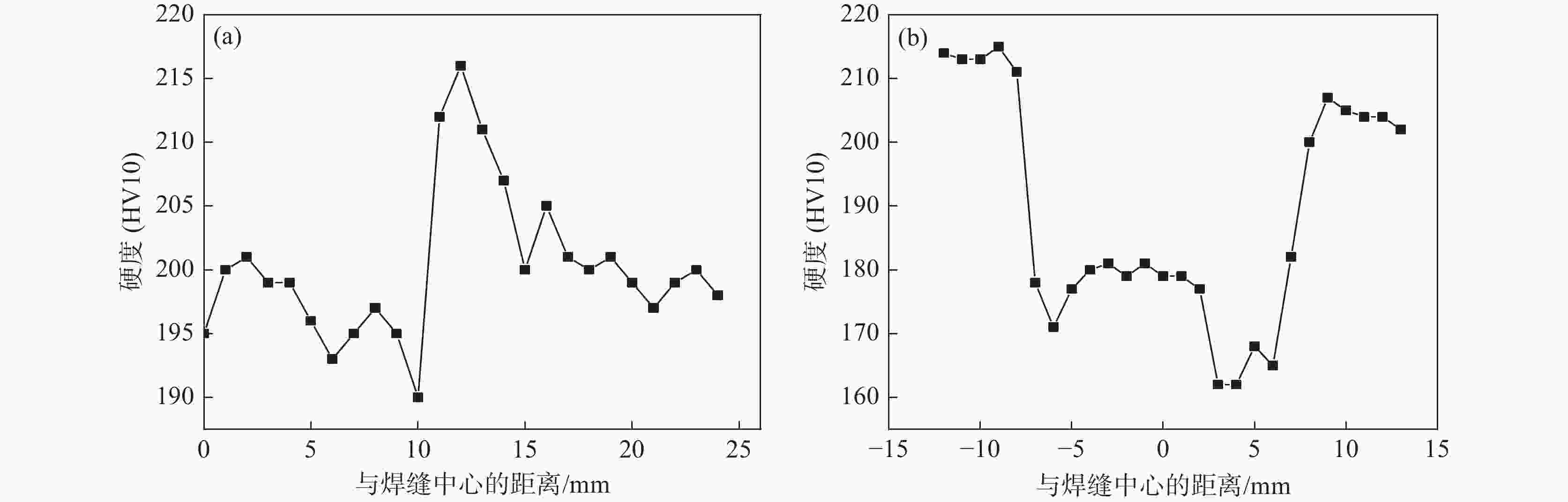

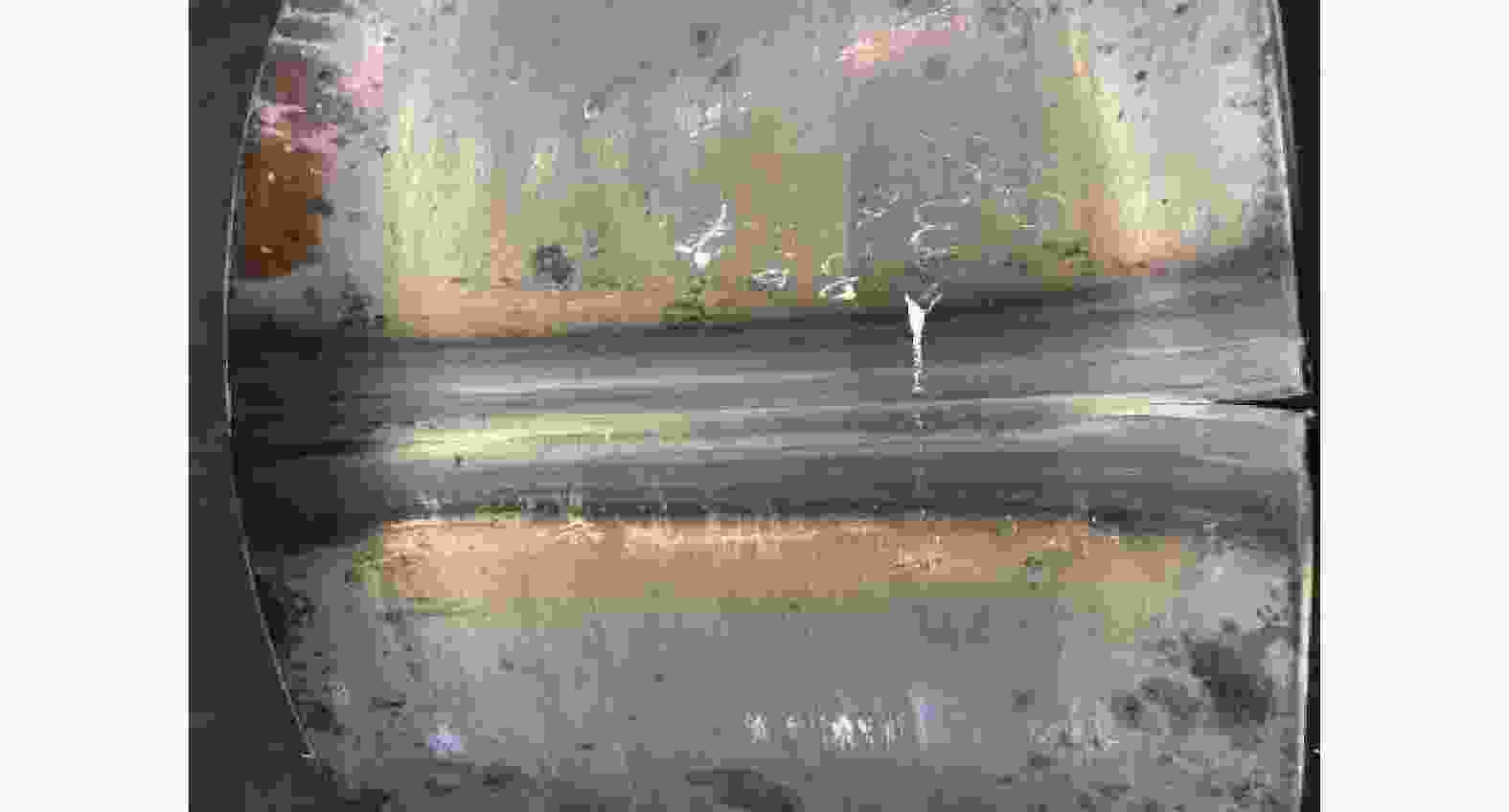

摘要: 采用连续闪光对焊技术,焊接600 MPa级Ti,Nb析出强化车轮钢,制造22.5×9.0车轮的轮辋。采用气体保护焊技术,焊接轮辋与轮辐的搭接接头。轮辋闪光对焊接头在扩口工序出现开裂、辊型工序出现减薄、扩张工序出现开裂,综合报废率37%。车轮径向疲劳试验80万转时,轮辋与轮辐搭接焊缝发生焊根部位的疲劳开裂。对车轮钢接头的断口、组织、硬度、析出相进行分析。结果表明,对焊接头硬度呈现“马鞍形”局部软化特征,搭接接头硬度呈现“盆地形”局部软化特征。热影响区中,过热区晶粒长大,20 nm以下第二相粒子大量溶解,正火区晶粒长大,20 nm以下第二相粒子消失伴随20 nm以上第二相粒子熟化,造成热影响区软化。Abstract: A 22.5 × 9.0 wheel rim made of Ti and Nb precipitation strengthened 600 MPa wheel steel was manufactured by continuous flash butt welding process to. The lap joint of rim and spoke was welded under gas shielded welding process. The flash butt welded joint of the rim cracked during the flaring process, thinned during rolling forming process and cracked during expansion process. Consequently, the comprehensive scrap rate was 37%. When the wheel was subjected to radial fatigue test for

800000 cycles, fatigue cracking occurred at the weld root of the lap between the rim and the spoke. The fracture, microstructure, hardness and precipitated phase of wheel steel joint were analyzed. The results show that the hardness of butt welded joints presents "saddle" local softening characteristics, and the hardness of lap joints presents "basin" local softening characteristics. In the CGHAZ the grains coarsen, while the second phase particles below 20 nm dissovle significantly. In the FGHAZ the grains grow, with the second phase particles below 20 nm disappear and particles above 20 nm coarsen, leading to softening behavior of HAZ. -

表 1 试验钢板化学成分及力学性能

Table 1. Chemical composition and mechanical properties of material investigated

w/% 屈服强度/MPa 抗拉强度/MPa 伸长率/% C Si Mn P S Nb+Ti Ceq 0.090 0.21 1.63 0.009 <0.002 0.075 0.368 570 630 25 注:Ceq=C+Mn/6+(Ni +Cu)/15+(Cr+Mo+V)/5 -

[1] Li Guangying, Zhou Jizhi. Development and application of a new generation high strength-plasticity steels[J]. Steel Rolling, 2011,28(1):1−10. (李光瀛, 周积智. 新一代高强塑性钢的开发与应用[J]. 轧钢, 2011,28(1):1−10.Li Guangying, Zhou Jizhi. Development and application of a new generation high strength- plasticity steels[J]. Steel Rolling, 2011, 28(1): 1-10. [2] Ma Mingtu, Shi M F. Advanced high strength steel and its applicationsin automobile industry[J]. Iron and Steel, 2004,(7):68−72. (马鸣图, Shi M F. 先进的高强度钢及其在汽车工业中的应用[J]. 钢铁, 2004,(7):68−72.Ma Mingtu, Shi M F. Advanced high strength steel and its applicationsin automobile industry[J]. Iron and Steel, 2004(7): 68 – 72. [3] Li Xing, e, Zhao Zhiyi, Xue Rundong, et al. Study on relationship between precipitated phases containing Ti and properties of high strength hot strip[J]. Iron and Steel, 2008,43(6):70−73. (李杏娥, 赵志毅, 薛润东, 等. Ti在热轧高强带钢中的析出相与性能关系的研究[J]. 钢铁, 2008,43(6):70−73.Li Xing, e, Zhao Zhiyi, Xue Rundong, et al. Study on relationship between precipitated phases containing Ti and properties of high strength hot strip[J]. Iron and Steel, 2008, 43(6): 70-73. [4] Dong Xianchun, Zhang Nan, Chen Yanqing, et al. The welded joint strength and analysis for HAZ softening behavior of high Ti and Nb precipitation strengthing high strength steel[J]. Transactions of the China Welding Institution, 2012,33(11):72−76. (董现春, 张楠, 陈延清, 等. 高Ti, Nb 析出强化高强钢接头强度及焊接热影响区软化行为分析[J]. 焊接学报, 2012,33(11):72−76.DongXianchun, ZhangNan, ChenYanqing, etal.TheweldedjointstrengthandanalysisforHAZsofteningbehaviorofhighTiandNbprecipitationstrengthinghighstrengthsteel[J]. Transactions oftheChinaWeldingInstitution, 2012, 33(11): 72-76. [5] Dong Xianchun, Liu Xinyao, Zhang Dawei, et al. Cracking analysis and process improvement of pulse preheating flash butt welded joint of dual phase wheel steel[J]. Welding & Joining, 2021,(5):41−46, 65-66. (董现春, 刘新垚, 张大伟, 等. 双相车轮钢脉动预热闪光对焊接头开裂分析及改进[J]. 焊接, 2021,(5):41−46, 65-66.Dong Xianchun, Liu Xinyao, Zhang Dawei, etal.Cracking analysis and process improvement of pulse preheating flash butt welded joint of dual phase wheel steel[J]. Welding & Joining, 2021 (5): 41-46, 65-66. [6] Zhao Hongli, Li Fayun, Luo Cheng, et al. Cracking analysis of antomabile rim flash butt welding[J]. Welding Technology, 2009,38(3):56−58. (赵红利, 李发云, 罗成, 等. 汽车辊型轮辋闪光对焊开裂报废分析[J]. 焊接技术, 2009,38(3):56−58.Zhao Hongli, Li Fayun, Luo Cheng, et al. Cracking analysis of antomabile rim flash butt welding[J]. Welding Technology, 2009, 38(3): 56-58. [7] 徐志欣. 590 MPa 级高强钢轮辋接头组织性能与失效分析[D]. 厦门: 华侨大学, 2017.Xu Zhixin. Joint structure and mechanicai properties of 590 MPa high strength steel antomabile rim[D]. Xiamen: Huaqiao University, 2017. [8] 郗晨瑶. RS590CL 钢闪光对焊接头微观组织及力学性能的研究[D]. 吉林: 吉林大学, 2016.Xi Chenyao. Study on microstructure and mechanical properties of flash butt welding joint of RS590CL steel[D]. Jinlin: Jishou University, 2016. [9] Zhang Nan, Dong Xianchun, Pan Hui, et al. Mechanical behavior of welded joint of a high Ti-Nb content microalloyed high-strength steel before and after drawing temper treatment[J]. Transactions of the China Welding Institution, 2015,36(5):93−98. (张楠, 董现春, 潘辉, 等. 高Ti-Nb系高强钢焊接接头回火前后的力学行为[J]. 焊接学报, 2015,36(5):93−98.Zhang Nan, Dong Xianchun, Pan Hui, etal. Mechanicalbehavior of welded jointof a highTi-Nbcontentmicroalloyedhighstrengthsteelbeforeandafterdrawingtempertreatment[J]. TransactionsoftheChinaWeldingInstitution, 2015, 36(5): 93-98. [10] Dong Xianchun, Zhang Nan, Chen Yanqing, et al. Microstructure and mechanical properties of welded joints of 800 MPa high strength steels with Ti and Nb precipitation strengthening[J]. Materials for Mechanical Engineering, 2014,38(11):21−25. (董现春, 张楠, 陈延清, 等. 800 MPa 级钛铌析出强化高强钢焊接接头的组织与力学性能[J]. 机械工程材料, 2014,38(11):21−25.Dong Xianchun, Zhang Nan, Chen Yanqing, etal. Microstructureand mechanical propertiesofweldedjointsof800 MPahigh strengthsteelswithTiandNbprecipitationstrengthening[J]. Materials forMechanicalEngineering, 2014, 38(11): 21-25. [11] Zhang Nan, Dong Xianchun, Xu Xiaoning, et al. Microstructure and property of welding joint with Ti-Nb microalloyed high-strength steel[J]. Transactions of Materials and Heat Treatment, 2014,35(6):115−120. (张楠, 董现春, 徐晓宁, 等. Ti-Nb 微合金化高强钢的焊接接头组织和性能[J]. 材料热处理学报, 2014,35(6):115−120.Zhang Nan, Dong Xianchun, Xu Xiaoning, etal. MicrostructureandpropertyofweldingjointwithTi-Nbmicroalloyedhighstrengthsteel[J]. TransactionsofMaterialsandHeatTreatment, 2014, 35(6): 115-120. [12] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006.Yong Qilong. Second phase in steel and iron materials [M]. Beijing: Metallurgical Industry Press, 2006. -

下载:

下载: