Research status and prospect of titanium alloys resistant to high temperature of 600 ℃ and above

-

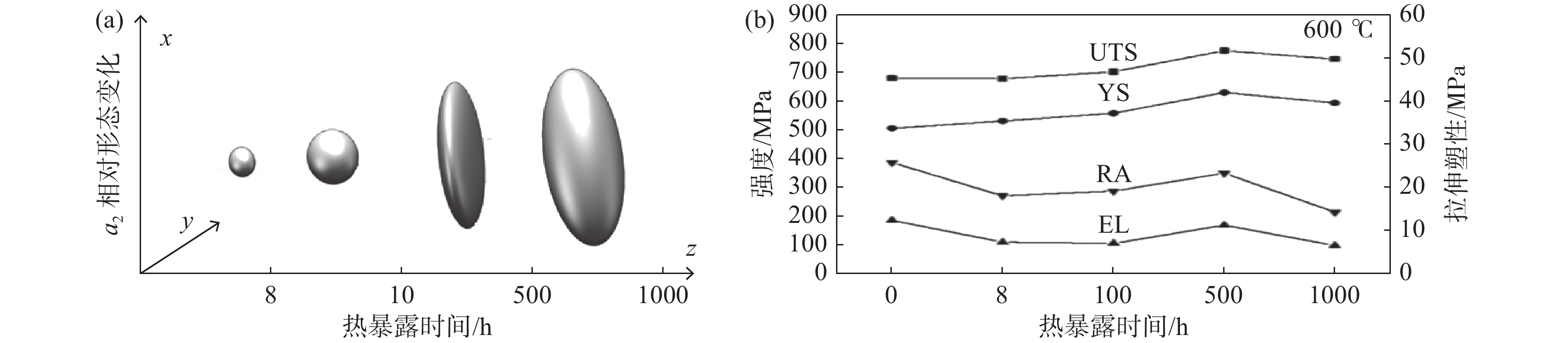

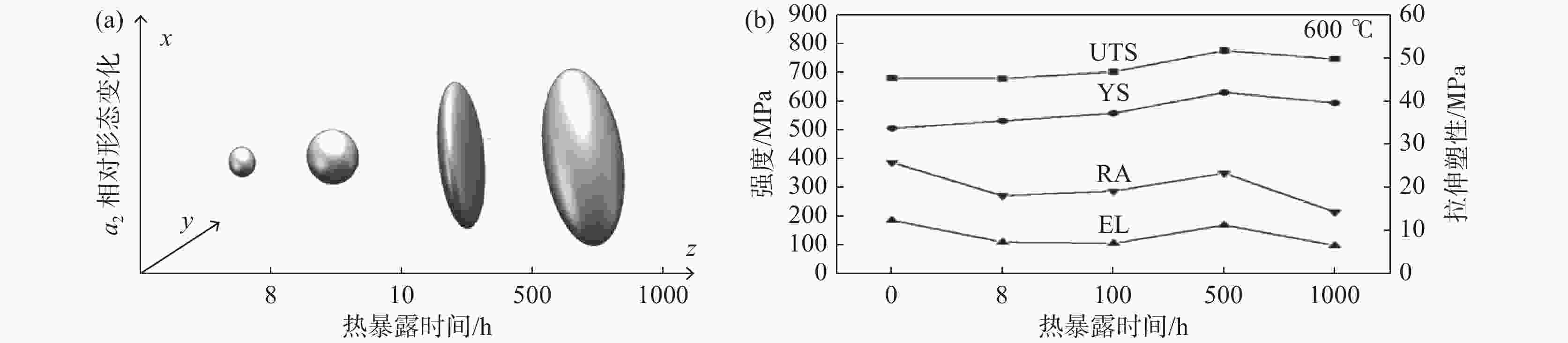

摘要: 概述了国内外耐600 ℃及以上高温钛合金的研究现状,在总结英国IMI834、美国Ti-1100、俄罗斯BT36、中国Ti60、TG6、Ti600、Ti65、Ti750等合金组成及性能的基础上,指出了制约高温钛合金发展的主要瓶颈,并针对目前的研究现状,提出了一些可供借鉴的解决办法。从提高高温钛合金的热稳定性、热强性和高温蠕变强度的角度对制备Ti基复合材料、优化合金成分、优化热加工工艺调控组织、控制α2相的尺寸、数量、体积分数和形态等方面进行了未来展望,为高性能高温钛合金的研制提供了理论基础和参考作用。Abstract: This paper reviews the development status of high-temperature titanium alloys resistant to 600 ℃ and above in domestic and foreign situations, and summarizes the composition and properties of IMI834 from UK, Ti-1100 from USA, BT36 from Russia and Ti60, TG6, Ti600, Ti65 and Ti750 from China. The main bottlenecks limiting the development of high-temperature titanium alloys are figured out, and some possible solutions are proposed for reference based on the current research status. In view of improving the thermal stability, thermal strength and high-temperature creeping strength of high-temperature titanium alloys, the future perspectives of preparing Ti-based composites, optimizing the alloy compositions and the thermal processing processes, controlling the size, number, volume fraction and morphology of the α2 phase and protecting the high-temperature oxide coating are prospected. This paper provides a theoretical basis and reference for the development of high performance high temperature titanium alloys.

-

Key words:

- high-temperature titanium alloy /

- thermal stability /

- thermal strength /

- creep strength

-

表 1 国内外部分典型高温钛合金化学成分和使用温度

Table 1. Chemical compositions and operating temperatures of some typical high temperature titanium alloys at home and abroad

国家 时间 合金牌号 服役温度/ ℃ 合金成分 美国 1954 TC4 300~350 Ti-6Al-4V 1988 Ti-1100 600 Ti-6Al-2.7Sn-4Zr-0.4Mo-0.45Si 英国 1984 IMI834 600 Ti-5.8Al-4Sn-3.5Zr-0.7Nb-0.5Mo-0.35Si-0.06C 俄罗斯 1992 BT36 600 Ti-6.2Al-2Sn-3.6Zr-0.7Mo-0.1Y-0.15Si-5W 中国 1994 Ti60 600 Ti-5.8Al-4.8Sn-2Zr-1Mo-0.35Si-0.85Nd 1994 Ti600 600 Ti-6Al-2.8Sn-4Zr-0.5Mo-0.4Si-0.1Y 2000 TG6 600 Ti-5.8Al-4.0Sn-4.0Zr-0.4Si-0.7Nb-1.5Ta-0.06C 2007 Ti65 650 Ti-5.9Al-4Sn-3.5Zr-0.3Mo-0.3Nb-2.0Ta-0.4Si-1W-0.05C 2009 Ti750 750 Ti-6Al-9Zr-1.21Nb-1.6W-0.3Si 表 2 国内外600 ℃及以上高温钛合金的基本特点

Table 2. Basic characteristics of 600 ℃ and above high temperature titanium alloys at home and abroad

合金牌号 密度/(g·m−3) β相转变温度/ ℃ 合金类型 Ti-1100 4.50 1015 近α型 IMI834 4.59 1005~1025 近α型 BT36 4.55 1035~1055 近α型 Ti60 4.50 1025 近α型 Ti600 4.50 1010 近α型 TG6 1050 近α型 Ti65 1050±15 近α型 Ti750 1000 近α型 表 3 国内外600 ℃及以上高温钛合金的力学性能

Table 3. Mechanical properties of 600 °C and above high temperature titanium alloys at home and abroad

合金

牌号室温拉伸性能 600 ℃拉伸性能 600 ℃蠕变性能 Rm/

MPaRp0.2/

MPaA/

%Z/

%Rm/

MPaRp0.2/

MPaA/

%Z/

%$ \varepsilon $/% $ \tau $/% Ti-1100 860 960 11 18 530 630 14 30 0.1 300 IMI834 960 1070 14 20 550 680 15 50 0.1 340 BT36 1080 10 15 640 0.2 335 Ti60 1030 1100 11 18 580 700 14 27 0.1 350 Ti600 1050 1068 11 13 615 745 16 31 0.06~0.1 350 TG6 940 1036 12.3 24.6 528 658 18.8 39.5 0.18 Ti65 1000 1094 12.5 12.8 545 655 23.0 46.5 0.14 -

[1] Li Miaoquan, Li Hong, Luo Jiao. Titanium alloy precision forging [M]. Beijing: Science Press, 2016. (李淼泉, 李宏, 罗皎. 钛合金精密锻造[M]. 北京: 科学出版社, 2016.Li Miaoquan, Li Hong, Luo Jiao. Titanium alloy precision forging [M]. Beijing: Science Press, 2016. [2] He Danqi, Shi Hao. Discussion on application of titanium alloy in aerospace field[J]. China High-tech Enterprises, 2016(27):50−51. (何丹琪, 石颢. 钛合金在航空航天领域中的应用探讨[J]. 中国高新技术企业, 2016(27):50−51. doi: 10.13535/j.cnki.11-4406/n.2016.27.023He Danqi, Shi Hao. Discussion on application of titanium alloy in aerospace field[J]. China High-tech Enterprises, 2016(27): 50−51. doi: 10.13535/j.cnki.11-4406/n.2016.27.023 [3] Tian Yongwu, Zhu Lele, Li Weidong, et al. Application and development of high temperature titanium alloy[J]. Hot Working Technology, 2020,49(8):17−20. (田永武, 朱乐乐, 李伟东, 等. 高温钛合金的应用及发展[J]. 热加工工艺, 2020,49(8):17−20. doi: 10.14158/j.cnki.1001-3814.20183380Tian Yongwu, Zhu Lele, Li Weidong, et al. Application and development of high temperature titanium alloy[J]. Hot Working Technology, 2020, 49(8): 17−20. doi: 10.14158/j.cnki.1001-3814.20183380 [4] Banerjee D, Williams J C. Perspectives on titanium science and technology[J]. Acta Materialia, 2013,61(3):844−879. doi: 10.1016/j.actamat.2012.10.043 [5] Liu Yingying, Chen Ziyong, Jin Tounan, et al. Development status and prospect of 600 ℃ high temperature titanium alloy[J]. Materials Review, 2018,32(11):1863−1869. (刘莹莹, 陈子勇, 金头男, 等. 600 ℃高温钛合金发展现状与展望[J]. 材料导报, 2018,32(11):1863−1869. doi: 10.11896/j.issn.1005-023X.2018.11.013Liu Yingying, Chen Ziyong, Jin Tounan, et al. Development status and prospect of 600 ℃ high temperature titanium alloy[J]. Materials Review, 2018, 32(11): 1863−1869. doi: 10.11896/j.issn.1005-023X.2018.11.013 [6] Chen Ziyong, Liu Yingying, Jin Yanfang, et al. Research status and progress of 650 ℃ resistant titanium alloy for aero-engine[J]. Aeronautical Manufacturing Technology, 2019,62(19):22−30. (陈子勇, 刘莹莹, 靳艳芳, 等. 航空发动机用耐650 ℃高温钛合金研究现状与进展[J]. 航空制造技术, 2019,62(19):22−30.Chen Ziyong, Liu Yingying, Jin Yanfang, et al. Research status and progress of 650 ℃ resistant titanium alloy for aero-engine[J]. Aeronautical Manufacturing Technology, 2019, 62(19): 22−30. [7] Zheng Zhuangzhuang. Study on thermal deformation behavior and microstructure properties of high temperature titanium alloy enhanced by nano Y2O3 [D]. Harbin: Harbin Institute of Technology, 2019. (郑壮壮. 纳米Y2O3增强高温钛合金热变形行为及板材组织性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.Zheng Zhuangzhuang. Study on thermal deformation behavior and microstructure properties of high temperature titanium alloy enhanced by nano Y2O3 [D]. Harbin: Harbin Institute of Technology, 2019. [8] He Chunyan, Zhang Lijun. Development and application of high temperature titanium alloys at home and abroad[J]. World Nonferrous Metals, 2016(1):21−25. (何春艳, 张利军. 国内外高温钛合金的发展与应用[J]. 世界有色金属, 2016(1):21−25.He Chunyan, Zhang Lijun. Development and application of high temperature titanium alloys at home and abroad[J]. World Nonferrous Metals, 2016(1): 21−25. [9] Huo Dongxing, Liang Jinglong, Li Hui, et al. Research and application progress of titanium alloy[J]. Casting Technology, 2016,37(10):2065−2066. (霍东兴, 梁精龙, 李慧, 等. 钛合金研究及应用进展[J]. 铸造技术, 2016,37(10):2065−2066. doi: 10.16410/j.issn1000-8365.2016.10.005Huo Dongxing, Liang Jinglong, Li Hui, et al. Research and application progress of titanium alloy[J]. Casting Technology, 2016, 37(10): 2065−2066. doi: 10.16410/j.issn1000-8365.2016.10.005 [10] Lütjering G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys[J]. Materials Science & Engineering: A, 1998,243(1/2):32−45. [11] Rosenberger A H, Madsen A, Ghonem H. Aging effects on the creep behavior of the near-alpha titanium alloy Ti-1100[J]. Journal of Materials Engineering and Performance, 1995,4(2):182−187. doi: 10.1007/BF02664112 [12] Wang Kaiting. Development and application of high temperature titanium alloys[J]. World Nonferrous Metals, 2021(14):21−22. (王恺婷. 高温钛合金的发展与应用[J]. 世界有色金属, 2021(14):21−22. doi: 10.3969/j.issn.1002-5065.2021.14.008Wang Kaiting. Development and application of high temperature titanium alloys[J]. World Nonferrous Metals, 2021(14): 21−22. doi: 10.3969/j.issn.1002-5065.2021.14.008 [13] Wang Qingjiang, Liu Jianrong, Yang Rui. Current situation and prospect of high temperature titanium alloys[J]. Journal of Aeronautical Materials, 2014,34(4):1−26. (王清江, 刘建荣, 杨锐. 高温钛合金的现状与前景[J]. 航空材料学报, 2014,34(4):1−26. doi: 10.11868/j.issn.1005-5053.2014.4.001Wang Qingjiang, Liu Jianrong, Yang Rui. Current situation and prospect of high temperature titanium alloys[J]. Journal of Aeronautical Materials, 2014, 34(4): 1−26. doi: 10.11868/j.issn.1005-5053.2014.4.001 [14] Singh N, Singh V. Effect of temperature on tensile properties of near-α alloy Ti metal 834[J]. Materials Science and Engineering: A, 2008,485(1-2):130−139. doi: 10.1016/j.msea.2007.07.064 [15] Li S, Deng T, Zhang Y, et al. Review on the creep resistance of high-temperature titanium alloy[J]. Transactions of the Indian Institute of Metals, 2021,74(2):215−222. doi: 10.1007/s12666-020-02137-x [16] Li Xin, Zhao Jun, Liu Shibing, et al. Research progress of high temperature titanium alloys for aviation [C]// Casting Branch of Chinese Mechanical Engineering Society Proceedings of China Foundry Week: Volume 2020. Hefei: Special Casting and Non-ferrous Alloys, 2020: 5-9. (李欣, 赵军, 刘时兵, 等. 航空用高温钛合金的研究进展[C]//中国机械工程学会铸造分会中国铸造活动周论文集: 2020年卷. 合肥: 特种铸造及有色合金, 2020: 5-9.Li Xin, Zhao Jun, Liu Shibing, et al. Research progress of high temperature titanium alloys for aviation [C]// Casting Branch of Chinese Mechanical Engineering Society Proceedings of China Foundry Week: Volume 2020. Hefei: Special Casting and Non-ferrous Alloys, 2020: 5-9. [17] Boyer R R. An overview on the use of titanium in the aerospace industry[J]. Materials Science and Engineering: A, 1996,213(1):103−114. [18] Cai Jianming, Li Zhenxi, Ma Jimin, et al. Research and development of 600 ℃ high temperature titanium alloy for aeroengine[J]. Materials Review, 2005(1):50−53. (蔡建明, 李臻熙, 马济民, 等. 航空发动机用600 ℃高温钛合金的研究与发展[J]. 材料导报, 2005(1):50−53.Cai Jianming, Li Zhenxi, Ma Jimin, et al. Research and development of 600 ℃ high temperature titanium alloy for aeroengine[J]. Materials Review, 2005(1): 50−53. [19] Cai Jianming, Hao Mengyi, Li Xueming, et al. Study on composition characteristics and microstructure of BT36 high temperature titanium alloy[J]. Materials Engineering, 2000(2):10−12. (蔡建明, 郝孟一, 李学明, 等. BT36高温钛合金的成分特点及组织研究[J]. 材料工程, 2000(2):10−12. doi: 10.3969/j.issn.1001-4381.2000.02.003Cai Jianming, Hao Mengyi, Li Xueming, et al. Study on composition characteristics and microstructure of BT36 high temperature titanium alloy[J]. Materials Engineering, 2000(2): 10−12. doi: 10.3969/j.issn.1001-4381.2000.02.003 [20] Gao Xiongxiong. Study on microstructure evolution of Ti60 titanium alloy during bimodal microstructure regulation [D]. Xi’an: Northwestern Polytechnical University, 2018. (高雄雄. Ti60钛合金双态组织调控过程中显微组织演变规律研究[D]. 西安: 西北工业大学, 2018.Gao Xiongxiong. Study on microstructure evolution of Ti60 titanium alloy during bimodal microstructure regulation [D]. Xi’an: Northwestern Polytechnical University, 2018. [21] Sun Meng. Ansteel group developed Ti60 high temperature titanium alloy[N]. China Metallurgical News, 2022-03-22. (孙萌. 鞍钢集团研制出Ti60高温钛合金[N]. 中国冶金报, 2022-03-22.Sun Meng. Ansteel group developed Ti60 high temperature titanium alloy[N]. China Metallurgical News, 2022-03-22. [22] Tang Haifang. Study on microstructure and high temperature properties of Ti600 alloy[D]. Shengyang: Northeastern University, 2010. (汤海芳. Ti600合金组织和高温性能的研究[D]. 沈阳: 东北大学, 2010.Tang Haifang. Study on microstructure and high temperature properties of Ti600 alloy[D]. Shengyang: Northeastern University, 2010. [23] Tang Haifang, Hong Quan, Zhao Yongqing, et al. Effect of rare earth element Y on microstructure and properties of Ti600 alloy[J]. Hot Working Technology, 2010,39(24):11−14. (汤海芳, 洪权, 赵永庆, 等. 稀土元素Y对Ti600合金组织和性能的影响[J]. 热加工工艺, 2010,39(24):11−14. doi: 10.14158/j.cnki.1001-3814.2010.24.013Tang Haifang, Hong Quan, Zhao Yongqing, et al. Effect of rare earth element Y on microstructure and properties of Ti600 alloy[J]. Hot Working Technology, 2010, 39(24): 11−14. doi: 10.14158/j.cnki.1001-3814.2010.24.013 [24] Duan Rui, Zhang Hua, Cai Jianming, et al. Effect of microstructure on creep behavior of near-α TG6 titanium alloy at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2010,20(S1):11−15. (段锐, 张华, 蔡建明, 等. 显微组织对近α型TG6钛合金高温蠕变变形行为的影响[J]. 中国有色金属学报, 2010,20(S1):11−15. doi: 10.19476/j.ysxb.1004.0609.2010.s1.003Duan Rui, Zhang Hua, Cai Jianming, et al. Effect of microstructure on creep behavior of near-α TG6 titanium alloy at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): 11−15. doi: 10.19476/j.ysxb.1004.0609.2010.s1.003 [25] Cai Jianming, Cao Chunxiao. Design and application prospect of a new generation of 600 ℃ high temperature titanium alloy materials[J]. Journal of Aeronautical Materials, 2014,34(4):27−36. (蔡建明, 曹春晓. 新一代600 ℃高温钛合金材料的合金设计及应用展望[J]. 航空材料学报, 2014,34(4):27−36.Cai Jianming, Cao Chunxiao. Design and application prospect of a new generation of 600 ℃ high temperature titanium alloy materials[J]. Journal of Aeronautical Materials, 2014, 34(4): 27−36. [26] Wu Xiyue, Chen Zhiyong, Cheng Chao, et al. Effect of heat treatment on microstructure, texture and tensile properties of Ti65 titanium alloy sheet[J]. Journal of Materials Research, 2019,33(10):785−793. (吴汐玥, 陈志勇, 程超, 等. 热处理对Ti65钛合金板材的显微组织、织构及拉伸性能的影响[J]. 材料研究学报, 2019,33(10):785−793. doi: 10.11901/1005.3093.2019.110Wu Xiyue, Chen Zhiyong, Cheng Chao, et al. Effect of heat treatment on microstructure, texture and tensile properties of Ti65 titanium alloy sheet[J]. Journal of Materials Research, 2019, 33(10): 785−793. doi: 10.11901/1005.3093.2019.110 [27] Yue Ke. Microstructure and key mechanical properties at high temperature of Ti65 alloy[D]. Hefei: University of Science and Technology of China, 2019. (岳颗. Ti65合金显微组织及关键高温力学性能[D]. 合肥: 中国科学技术大学, 2019.Yue Ke. Microstructure and key mechanical properties at high temperature of Ti65 alloy[D]. Hefei: University of Science and Technology of China, 2019. [28] Liu Jingyuan. Study on superplastic forming properties and microstructure evolution of Ti750 high temperature titanium alloy[D]. Harbin: Harbin Institute of Technology, 2011. (刘泾源. Ti750高温钛合金超塑成形性能及组织演变研究[D]. 哈尔滨: 哈尔滨工业大学, 2011.Liu Jingyuan. Study on superplastic forming properties and microstructure evolution of Ti750 high temperature titanium alloy[D]. Harbin: Harbin Institute of Technology, 2011. [29] Yao Gang, Fu Mingjie. Analysis of phase microstructure change during thermal process of TNW700 high temperature titanium alloy[J]. Materials Review, 2018,32(20):3584−3589. (姚罡, 付明杰. TNW700高温钛合金热过程中的相组织变化分析[J]. 材料导报, 2018,32(20):3584−3589. doi: 10.11896/j.issn.1005-023X.2018.20.016Yao Gang, Fu Mingjie. Analysis of phase microstructure change during thermal process of TNW700 high temperature titanium alloy[J]. Materials Review, 2018, 32(20): 3584−3589. doi: 10.11896/j.issn.1005-023X.2018.20.016 [30] Zeng Liying, Zhao Yongqing, Hong Quan, et al. Research and development of 600 ℃ high temperature titanium alloy[J]. Progress in Titanium Industry, 2012,29(5):1−5. (曾立英, 赵永庆, 洪权, 等. 600 ℃高温钛合金的研发[J]. 钛工业进展, 2012,29(5):1−5.Zeng Liying, Zhao Yongqing, Hong Quan, et al. Research and development of 600 ℃ high temperature titanium alloy[J]. Progress in Titanium Industry, 2012, 29(5): 1−5. [31] Wang S, Huang L J, Geng L, et al. Significantly enhanced creep resistance of low volume fraction in-situ TiBw/Ti6Al4V composites by architectured network reinforcements[J]. Scientific Reports, 2017,7(1):40823−40833. doi: 10.1038/srep40823 [32] Zhao Pengfei, Liu Yue, Tang Li, et al. Study on microstructure and mechanical properties of TC11 titanium matrix composites reinforced by sic particles[J]. Progress in Titanium Industry, 2021,38(6):31−36. (赵鹏飞, 刘跃, 唐莉, 等. 碳化硅颗粒增强TC11钛基复合材料的组织与力学性能研究[J]. 钛工业进展, 2021,38(6):31−36. doi: 10.11782/j.issn.1009-9964.2021.6.tgyjz202106007Zhao Pengfei, Liu Yue, Tang Li, et al. Study on microstructure and mechanical properties of TC11 titanium matrix composites reinforced by sic particles[J]. Progress in Titanium Industry, 2021, 38(6): 31−36. doi: 10.11782/j.issn.1009-9964.2021.6.tgyjz202106007 [33] Zhang Ruigang, Yang Qinghao, Liu Yue, et al. High temperature properties and microstructure of silicon carbide nanowires reinforced Ti60 composites[J]. Progress in Titanium Industry, 2021,38(5):14−18. (张瑞刚, 杨庆浩, 刘跃, 等. 碳化硅纳米线增强Ti60复合材料高温性能及显微组织研究[J]. 钛工业进展, 2021,38(5):14−18. doi: 10.13567/j.cnki.issn1009-9964.2021.05.006Zhang Ruigang, Yang Qinghao, Liu Yue, et al. High temperature properties and microstructure of silicon carbide nanowires reinforced Ti60 composites[J]. Progress in Titanium Industry, 2021, 38(5): 14−18. doi: 10.13567/j.cnki.issn1009-9964.2021.05.006 [34] Yu Lanlan, Mao Xiaonan, Zhao Yongqing, et al. New advances in particle-reinforced titanium matrix composites[J]. Rare Metals Express, 2006(4):1−5. (于兰兰, 毛小南, 赵永庆, 等. 颗粒增强钛基复合材料研究新进展[J]. 稀有金属快报, 2006(4):1−5.Yu Lanlan, Mao Xiaonan, Zhao Yongqing, et al. New advances in particle-reinforced titanium matrix composites[J]. Rare Metals Express, 2006(4): 1−5. [35] Zhao E, Sun S, Zhang Y. Recent advances in silicon containing high temperature titanium alloys[J]. Journal of Materials Research and Technology, 2021,14:3029−3042. doi: 10.1016/j.jmrt.2021.08.117 [36] Mishra H, Ghosal P, Nandy T K, et al. Influence of Fe and Ni on creep of near α-Ti alloy IMI834[J]. Materials Science and Engineering: A, 2005,399(1-2):222−231. doi: 10.1016/j.msea.2005.03.027 [37] Che Jinda, Jiang Beibei, Wang Qing, et al. Effect of trace elements (Hf/Ta/Nb) on oxidation resistance of near α-Ti alloy at high temperature[J]. Chinese Journal of Nonferrous Metals, 2016,26(10):2086−2092. (车晋达, 姜贝贝, 王清, 等. 微量元素(Hf/Ta/Nb)添加对近α-Ti合金高温抗氧化性能的影响[J]. 中国有色金属学报, 2016,26(10):2086−2092.Che Jinda, Jiang Beibei, Wang Qing, et al. Effect of trace elements (Hf/Ta/Nb) on oxidation resistance of near α-Ti alloy at high temperature[J]. Chinese Journal of Nonferrous Metals, 2016, 26(10): 2086−2092. [38] Gigliotti F X, Rowe R G, Deceased G E W. High strength oxidation resistant alpha titanium alloy: USA,4906436[P]. 1990-03-06. [39] Gao Xiongxiong. Study on microstructure evolution of Ti60 titanium alloy during duplexmicrostructure regulation[D]. Xi’an: Northwestern Polytechnical University, 2018. (高雄雄. Ti60钛合金双态组织调控过程中显微组织演变规律研究[D]. 西安: 西北工业大学, 2018.Gao Xiongxiong. Study on microstructure evolution of Ti60 titanium alloy during duplexmicrostructure regulation[D]. Xi’an: Northwestern Polytechnical University, 2018. [40] Ding Beibei, Li Bolong, Han Peng, et al. Effect of Nd on thermal stability of a near-α high temperature titanium alloy[J]. Hot Working Technology, 2011,40(18):4−7. (丁蓓蓓, 李伯龙, 韩鹏, 等. Nd对一种近α型高温钛合金热稳定性的影响[J]. 热加工工艺, 2011,40(18):4−7. doi: 10.3969/j.issn.1001-3814.2011.18.002Ding Beibei, Li Bolong, Han Peng, et al. Effect of Nd on thermal stability of a near-α high temperature titanium alloy[J]. Hot Working Technology, 2011, 40(18): 4−7. doi: 10.3969/j.issn.1001-3814.2011.18.002 [41] Wu Y, Guo Y, Xu G, et al. Effects of trace erbium addition on microstructure and mechanical properties of Ti6Al4V-xEr alloys[J]. Metals, 2019,9(6):628. doi: 10.3390/met9060628 [42] Deng T, Li S, Liang Y, et al. Effects of scandium and silicon addition on the microstructure and mechanical properties of Ti-6Al-4V alloy[J]. Journal of Materials Research and Technology, 2020,9(3):5676−5688. doi: 10.1016/j.jmrt.2020.03.092 [43] Tian Wei, Fu Yu, Zhong Yan, et al. Effect of forging process on microstructure and mechanical properties of TC17 titanium alloy[J]. Journal of Materials and Heat Treatment, 2016,37(9):57−61. (田伟, 伏宇, 钟燕, 等. 锻造工艺对TC17钛合金的显微组织和力学性能的影响[J]. 材料热处理学报, 2016,37(9):57−61.Tian Wei, Fu Yu, Zhong Yan, et al. Effect of forging process on microstructure and mechanical properties of TC17 titanium alloy[J]. Journal of Materials and Heat Treatment, 2016, 37(9): 57−61. [44] Balasundar I, Raghu T, Kashyap B P. Correlation between microstructural features and creep strain in a near-α titanium alloy processed in the α+β regime[J]. Materials Science & Engineering A, 2014,609:241−249. [45] Omprakash C M, Satyanarayana D V V, Kumar V. Effect of microstructure on creep and creep crack growth behaviour of titanium alloy[J]. Transactions of the Indian Institute of Metals, 2010,63:457−459. doi: 10.1007/s12666-010-0064-3 [46] Zhou Wei, Xin Shewei, Hong Quan, et al. Effect of solution cooling rate on microstructure and mechanical properties of short-time high temperature titanium alloy[J]. Rare Metals and Cemented Carbides, 2020,48(4):49−52. (周伟, 辛社伟, 洪权, 等. 固溶冷却速度对短时高温钛合金显微组织和力学性能的影响[J]. 稀有金属与硬质合金, 2020,48(4):49−52.Zhou Wei, Xin Shewei, Hong Quan, et al. Effect of solution cooling rate on microstructure and mechanical properties of short-time high temperature titanium alloy[J]. Rare Metals and Cemented Carbides, 2020, 48(4): 49−52. [47] Liu Qitong. Study on low-cycle fatigue properties of TC4ELI alloy with duplexmicrostructure[D]. Lanzhou: Lanzhou University of Technology, 2020. (刘栖桐. 双态组织TC4ELI合金低周疲劳性能研究[D]. 兰州: 兰州理工大学, 2020.Liu Qitong. Study on low-cycle fatigue properties of TC4ELI alloy with duplexmicrostructure[D]. Lanzhou: Lanzhou University of Technology, 2020. [48] Liu Qinghua, Hui Songxiao, Ye Wenjun, et al. Study on dynamic mechanical properties of TC4 ELI titanium alloy with different aicrostructure[J]. Rare Metals, 2012,36(4):517−522. (刘清华, 惠松骁, 叶文君, 等. 不同组织状态TC4 ELI钛合金动态力学性能研究[J]. 稀有金属, 2012,36(4):517−522.Liu Qinghua, Hui Songxiao, Ye Wenjun, et al. Study on dynamic mechanical properties of TC4 ELI titanium alloy with different aicrostructure[J]. Rare Metals, 2012, 36(4): 517−522. [49] Zhu Zhishou. Research and development of new high performance titanium alloy materials for aviation structures[J]. Aeronautical Science and Technology, 2012(1):5−9. (朱知寿. 航空结构用新型高性能钛合金材料技术研究与发展[J]. 航空科学技术, 2012(1):5−9.Zhu Zhishou. Research and development of new high performance titanium alloy materials for aviation structures[J]. Aeronautical Science and Technology, 2012(1): 5−9. [50] Xin Shewei, Hong Quan, Lu Yafeng, et al. Microstructure stability of high temperature Ti600 titanium alloy at 600 ℃[J]. Rare Metal Materials and Engineering, 2010,39(11):1918−1922. (辛社伟, 洪权, 卢亚锋, 等. Ti600高温钛合金600 ℃下组织稳定性研究[J]. 稀有金属材料与工程, 2010,39(11):1918−1922.Xin Shewei, Hong Quan, Lu Yafeng, et al. Microstructure stability of high temperature Ti600 titanium alloy at 600 ℃[J]. Rare Metal Materials and Engineering, 2010, 39(11): 1918−1922. [51] Li Dong, Wan Xiaojing. Study on thermal stability of titanium alloy Ⅲ: Thermal stability criterion and its application[J]. Acta Metallurgica Sinica, 1984(6):391−397. (李东, 万晓景. 钛合金热稳定性研究Ⅲ:热稳定性判据及其应用[J]. 金属学报, 1984(6):391−397.Li Dong, Wan Xiaojing. Study on thermal stability of titanium alloy Ⅲ: Thermal stability criterion and its application[J]. Acta Metallurgica Sinica, 1984(6): 391−397. [52] Madsen A, Ghonem H. Separating the effects of Ti3Al and silicide precipitates on the tensile and crack growth behavior at room temperature and 593 ℃ in a near-alpha titanium alloy[J]. On Academic, 1995,4(3):301−307. [53] Gysler A, Weissmann S. Effect of order in Ti3A1 particles and of temperature on the deformation behavior of age-hardened Ti-A1 alloys[J]. Material Science & Engineering, 1997,27(2):181−194. [54] Peng Na. Study on critical size effect of α2 phase in high temperature titanium alloy[D]. Shenyang: Shenyang University, 2007. (彭娜. 高温钛合金中α2相的临界尺寸效应研究[D]. 沈阳: 沈阳大学, 2007.Peng Na. Study on critical size effect of α2 phase in high temperature titanium alloy[D]. Shenyang: Shenyang University, 2007. [55] Zhang Jun, Li Dong. α2 Phase in high temperature titanium alloy[M]. Shenyang: Northeastern University Press, 2002. (张钧, 李东. 高温钛合金中的α2相[M]. 沈阳: 东北大学出版社, 2002.Zhang Jun, Li Dong. α2 Phase in high temperature titanium alloy[M]. Shenyang: Northeastern University Press, 2002. [56] Zhao Liang, Liu Jianrong, Wang Qingjiang, et al. Effect of precipitation on creep and durability of Ti60 titanium alloy[J]. Journal of Materials Research, 2009,23(1):1−5. (赵亮, 刘建荣, 王清江, 等. 析出相对Ti60钛合金蠕变和持久性能的影响[J]. 材料研究学报, 2009,23(1):1−5. doi: 10.3321/j.issn:1005-3093.2009.01.001Zhao Liang, Liu Jianrong, Wang Qingjiang, et al. Effect of precipitation on creep and durability of Ti60 titanium alloy[J]. Journal of Materials Research, 2009, 23(1): 1−5. doi: 10.3321/j.issn:1005-3093.2009.01.001 [57] Zhu Xuhui. Study on long-term microstructure stability of near-α high temperature titanium alloy Ti600[D]. Shenyang: Northeastern University, 2020. (朱旭晖. 近α型高温钛合金Ti600长期时效组织稳定性研究[D]. 沈阳: 东北大学, 2020.Zhu Xuhui. Study on long-term microstructure stability of near-α high temperature titanium alloy Ti600[D]. Shenyang: Northeastern University, 2020. [58] Li J, Cai J, Xu Y, et al. Influences of thermal exposure on the microstructural evolution and subsequent mechanical properties of a near-α high temperature titanium alloy[J]. Materials Science and Engineering: A, 2020,774:138934−138947. doi: 10.1016/j.msea.2020.138934 [59] Williams J C, Baggerly R G, Paton N E. Deformation behavior of HCP Ti-Al alloy single crystals[J]. Metallurgical and Materials Transactions A, 2002,33(3):837−850. doi: 10.1007/s11661-002-0153-y -

下载:

下载: