Analysis and selection of technical paths for recycling and utilization of waste vanadium catalysts

-

摘要: 在推进制造业绿色化发展过程中,废钒系催化剂的综合回收利用有着广阔的发展前景,是实现钒产业循环经济的迫切需求,探究低污染、低能耗、短流程、高效益、全回收、适于大规模运用的新工艺是废钒系催化剂回收利用技术的发展方向。通过分析现有废钒触媒和废钒钛系脱硝催化剂回收利用的主要方法、原理、途径及优缺点,可知目前研究工作的重点还是在降低工艺成本、简化工艺流程的前提下尽可能减少二次污染的产生,并进一步提高金属回收效率。机械预处理、先进的氧化工艺和选择性浸出等新技术值得进一步研究。基于承钢公司现有提钒钛工艺与设备,对废钒触媒和废钒钛系脱硝催化剂回收利用钒、钛等有价金属元素进行研究,并结合环保政策及建设成本等因素,提出了适宜的废钒系催化剂回收利用技术路线。Abstract: In order to promote the green development of manufacturing industry, the comprehensive recycling and utilization of waste vanadium catalysts has broad prospects, and is an urgent need to realize the circular economy of vanadium industry. Exploring a new process with low pollution, low energy consumption, short process, high efficiency, full recovery and suitable for large-scale application is the development direction of waste vanadium catalyst recycling and utilization. By analyzing the main methods, principles, approaches and advantages and disadvantages of the existing waste vanadium catalysts and waste vanadium titanium denitrification catalysts, it can be seen that the current research focus is to reduce the secondary pollution as much as possible and further improve the metal recovery efficiency under the premise of reducing the process cost and simplifying the process flow. New technologies such as mechanical pretreatment, advanced oxidation process and selective leaching are worthy of further study. Based on the existing technology and equipment of vanadium and titanium extraction in Cheng Iron and Steel Company, the recovery and utilization of valuable metal elements such as vanadium and titanium were studied in the waste vanadium catalyst and vanadium and titanium denitrification catalyst, and the appropriate technical route of recovery and utilization of vanadium and titanium catalysts was proposed in combination with environmental protection policy and construction cost.

-

表 1 废钒触媒回收利用技术对比

Table 1. Comparison of recycling and utilization technologies for waste vanadium catalysts

工艺 条件 浸出率/% 酸浸提钒法 还原酸浸[16] ① 98.5 还原酸浸[17] ② 98 直接酸浸[18] ③ 95 氧化酸浸[19] ④ 95.1 钠化焙烧-浸出提钒[22] ⑤ 95.2 碱浸提钒法 Na2CO3和NaHCO3混合浸出[25] ⑥ 89 两段逆流碱浸法[9] ⑦ 81.24~87.97 空白高温氧化-铵盐浸出法[26] ⑧ 91 注:由于各研究所采用的废钒触媒的物理性质、化学成分不尽相同,对比数据仅供参考。条件:①50 ℃,SO2/V=1.5 mol-equiv;②30 ℃,pH=1 H2SO4,0.01 mol/L Na2SO3;③80~85 ℃,S/L =2.5,硫酸:水=4.73:100;④50 ℃,0.5 mol/L H2SO4,0.1 mol/L H2O2;⑤废钒触媒粒度140 μm,氧化焙烧温度800 ℃,焙烧时间2 h;水浸pH值8~8.5,渣碱浸pH值12;⑥Na2CO3质量分数14.2%,NaHCO3质量分数15.3%,液固比3:1,固体物料中w(KClO3)0.9%,pH11~12,80~90 ℃,1 h;⑦一段:液固液比为1:4,80 ℃,45 min,终点pH值控制13 ~14;二段:加碱量为原料五氧化二钒含量的1.2~1.3倍,80 ℃,2 h,固液比1:4;⑧氧化温度850 ℃,氧化时间3 h,浸出温度72~75 ℃,浸出时间2 h。 表 2 废脱硝催化剂回收利用技术对比

Table 2. Comparison of recycling and utilization technologies for waste denitration catalysts

工艺 条件 钒浸出率/% 直接酸浸法 草酸浸出[34] Ⅰ 85 酒石酸浸出[36] Ⅱ 44 盐酸浸出[37] Ⅲ 98 直接碱浸法 常压碱浸[38] Ⅳ 92.94 加压碱浸[39] Ⅴ 91.5 高压碱浸[40] Ⅵ 50~60 高温碱熔法 钠化焙烧-水浸[41] Ⅶ 49.15 碳酸钠混合焙烧-稀硫酸浸出[42] Ⅷ 99.08 直接合金化法 铁钛合金[43] Ⅸ Ti-Al基合金[44-45] Ⅹ 注:由于各研究所采用的废脱硝催化剂的物理性质、化学成分不尽相同,对比数据仅供参考。条件:Ⅰ草酸浓度1.0 mol/L、固液比1/20 (g/mL)、反应温度 90 ℃、反应时间180 min ;Ⅱ酒石酸浓度为0.5 mol/L、浸取温度为100 ℃、液固比为10 mL/g、浸取时间为180 min;Ⅲ30 ℃,pH=1 H2SO4,0.01 mol/L Na2SO3;ⅣNaOH浓度为7.5 mol/L,温度为100 ℃;ⅤNaOH浓度为3 mol/L,温度250 ℃,固液比0.4;Ⅵ温度180~200 ℃,碱矿比0.6,液固比4;Ⅶ焙烧温度为900 ℃、焙烧时间为2 h、Na2CO3含量为30%;Ⅷ焙烧温度800 ℃、焙烧时间3 h、Na2CO3与催化剂的质量比1.2、硫酸浓度2%、液固比8、浸出温度80 ℃、浸出时间4 h;Ⅸ以金属铝作为还原剂将废脱硝催化剂中的二氧化钛还原为金属钛,并加入到铁液中制备铁钛合金;Ⅹ铝热还原-重熔精炼除杂工艺制备Ti-Al基合金,并添加不同含量的Cr元素,得到合金成分为Ti-~44%Al-(0.4%~0.9%)V-~2%W-3%Si-(0~3%)Cr。 表 3 废钒钛系脱硝催化剂钠化焙烧与加压碱浸提钒工艺对比

Table 3. Comparison of sodium roasting and pressurized alkaline leaching vanadium extraction processes for denitration catalysts

反应温度/ ℃ 钒浸出率/% 吨钒碱消耗量/t 环 保 投资成本 钠化焙烧工艺 850 50~52 60(Na2CO3) 废水难以循环利用,SO2、NH3、NO2气体排放 生产流程长,投资成本高 加压碱浸提钒工艺 160 71.39 3(NaOH) 可实现碱介质循环利用,无有害窑气排放 生产流程短,投资成本低 -

[1] Chen Donghui, Li Jiujiang, Zhao Beibei, et al. The green value outlined of strategic resources on vanadium[J]. World Nonferrous Metals, 2018(20):1−3. (陈东辉, 李九江, 赵备备, 等. 战略资源金属钒的绿色价值概述[J]. 世界有色金属, 2018(20):1−3. doi: 10.3969/j.issn.1002-5065.2018.20.001Chen Donghui, Li Jiujiang, Zhao Beibei, et al. The green value outlined of strategic resources on vanadium[J]. World Nonferrous Metals, 2018(20): 1−3. doi: 10.3969/j.issn.1002-5065.2018.20.001 [2] Yang Shaoli, Liu Guoqin, Chen Housheng. Vanadium and titanium materials[M]. Beijing: Metallurgical Industry Press, 2007: 10−11. (杨绍利, 刘国钦, 陈厚生. 钒钛材料[M]. 北京: 冶金工业出版社, 2007: 10−11.Yang Shaoli, Liu Guoqin, Chen Housheng. Vanadium and titanium materials[M]. Beijing: Metallurgical Industry Press, 2007: 10−11. [3] Wang Shuai, Guo Yufeng, Jiang Tao, et al. Comprehensive utilization and industrial development direction of vanadium-titanium magnetite[J]. China Metallurgy, 2016,26(10):40−44. (王帅, 郭宇峰, 姜涛, 等. 钒钛磁铁矿综合利用现状及工业化发展方向[J]. 中国冶金, 2016,26(10):40−44.Wang Shuai, Guo Yufeng, Jiang Tao, et al. Comprehensive utilization and industrial development direction of vanadium-titanium magnetite[J]. China Metallurgy, 2016, 26(10): 40−44. [4] Chang Fuzeng, Zhao Beibei, Li Lanjie, et al. Research status and prospect of vanadium extraction from vanadium titano-magnetite[J]. Iron Steel Vanadium Titanium, 2018,39(5):71−78. (常福增, 赵备备, 李兰杰, 等. 钒钛磁铁矿提钒技术研究现状与展望[J]. 钢铁钒钛, 2018,39(5):71−78.Chang Fuzeng, Zhao Beibei, Li Lanjie, et al. Research status and prospect of vanadium extraction from vanadium titano-magnetite[J]. Iron Steel Vanadium Titanium, 2018, 39(5): 71−78. [5] Li Lanjie, Chen Donghui, Bai Ruiguo, et al. Research progress of extraction technology for vanadium & chromium from vanadium slags[J]. Multipurpose Utilization of Mineral Resources, 2013(2):7−11. (李兰杰, 陈东辉, 白瑞国, 等. 钒渣中钒铬提取技术研究进展[J]. 矿产综合利用, 2013(2):7−11.Li Lanjie, Chen Donghui, Bai Ruiguo, et al. Research progress of extraction technology for vanadium & chromium from vanadium slags[J]. Multipurpose Utilization of Mineral Resources, 2013(2): 7−11. [6] Meng Wenbo, Yan Baijun. Effect of vanadium extraction from stone coal vanadium ore by reducing roasting-oxidiation leaching conditions on vanadium recovery rate[J]. China Metallurgy, 2018,28(5):28−32. (孟文博, 闫柏军. 还原焙烧-氧化浸出对石煤钒浸出率的影响[J]. 中国冶金, 2018,28(5):28−32.Meng Wenbo, Yan Baijun. Effect of vanadium extraction from stone coal vanadium ore by reducing roasting-oxidiation leaching conditions on vanadium recovery rate[J]. China Metallurgy, 2018, 28(5): 28−32. [7] Liu Tao, Ge Ling, Zhang Yimin. Advances and development trend in key technologies for all-vanadium redox flow battery[J]. China Metallurgy, 2023,33(4):1−8,133. (刘涛, 葛灵, 张一敏. 全钒液流电池关键技术进展与发展趋势[J]. 中国冶金, 2023,33(4):1−8,133.Liu Tao, Ge Ling, Zhang Yimin. Advances and development trend in key technologies for all-vanadium redox flow battery[J]. China Metallurgy, 2023, 33(4): 1−8,133. [8] Zhan Shuhua. Factors affecting the activity of vanadium catalysts[J]. Inner Mongolia Petrochemical Industry, 2012,38(5):40−41. (湛淑华. 影响钒触媒活性的因素[J]. 内蒙古石油化工, 2012,38(5):40−41.Zhan Shuhua. Factors affecting the activity of vanadium catalysts[J]. Inner Mongolia Petrochemical Industry, 2012, 38(5): 40−41. [9] Wei Jinke, Zhang Qiang, Li Yongguang, et al. Analysis on causation for deactivation of medium temperature denitration catalyst in sintering machine[J]. Hebei Metallurgy, 2021(12):75−79. (韦晋科, 张强, 李永光. 烧结机中温SCR脱硝催化剂失活原因分析[J]. 河北冶金, 2021(12):75−79.Wei Jinke, Zhang Qiang, Li Yongguang, et al. Analysis on causation for deactivation of medium temperature denitration catalyst in sintering machine[J]. Hebei Metallurgy, 2021(12): 75−79. [10] Chen Xinglong, Xiao Liansheng, Xu Jie, et al. Study on recovering vanadium and molybdenum from spent catalyst[J]. Mining and Metallurgical Engineering, 2004(3):47−49. (陈兴龙, 肖连生, 徐劼, 等. 从废石油催化剂中回收钒和钼的试验研究[J]. 矿冶工程, 2004(3):47−49.Chen Xinglong, Xiao Liansheng, Xu Jie, et al. Study on recovering vanadium and molybdenum from spent catalyst[J]. Mining and Metallurgical Engineering, 2004(3): 47−49. [11] Deng Juzhang. Recycling of waste vanadium catalyst[J]. Journal of Chemical Fertilizer Industry, 1990(4):40−41. (邓聚长. 废旧钒触媒的再生利用[J]. 化肥工业, 1990(4):40−41.Deng Juzhang. Recycling of waste vanadium catalyst[J]. Journal of Chemical Fertilizer Industry, 1990(4): 40−41. [12] Jiang Guoli, Jiang Fuhua, Shen Zhaoquan et al. Feasibility of recovery of vanadium pentoxide from waste vanadium catalyst[J]. Environmetal Science & Technology, 1990(2):13−14, 49. (蒋国礼, 蒋馥华, 申照全, 等. 从废钒触媒回收五氧化二钒的可行性[J]. 环境科学与技术, 1990(2):13−14, 49.Jiang Guoli, Jiang Fuhua, Shen Zhaoquan et al. Feasibility of recovery of vanadium pentoxide from waste vanadium catalyst[J]. Environmetal Science & Technology, 1990(2): 13−14, 49. [13] Liu Haipei. Research on resource utilization of waste vanadium and titanium denitrification catalyst[D]. Nanjing: Nanjing University of Technology, 2016. (刘海沛. 废弃钒钛脱硝催化剂资源化利用研究[D]. 南京: 南京工业大学, 2016.Liu Haipei. Research on resource utilization of waste vanadium and titanium denitrification catalyst[D]. Nanjing: Nanjing University of Technology, 2016. [14] Liu Haipei, Yan Wei, Li Zhong, et al. Study on the preparation of porcelain brick by waste denitration catalyst[J]. Environmental Engineering, 2017(s2):242−246. (刘海沛, 严巍, 李众, 等. 废弃脱硝催化剂制备瓷质砖的研究[J]. 环境工程, 2017(增刊2):242−246.Liu Haipei, Yan Wei, Li Zhong, et al. Study on the preparation of porcelain brick by waste denitration catalyst[J]. Environmental Engineering, 2017(s2): 242−246. [15] Liu Bin, Yu Shaoming, Zhang Ying, et al. Study on comprehensive recovery and utilization of waste vanadium catalyst[J]. Inorganic Chemicals Industry, 2012,44(11):57−59. (刘彬, 于少明, 张颍, 等. 废钒催化剂综合回收利用技术的研究[J]. 无机盐工业, 2012,44(11):57−59.Liu Bin, Yu Shaoming, Zhang Ying, et al. Study on comprehensive recovery and utilization of waste vanadium catalyst[J]. Inorganic Chemicals Industry, 2012, 44(11): 57−59. [16] Romanovskaia E, Romanovski V, Kwapinski W, et al. Selective recovery of vanadium pentoxide from spent catalysts of sulfuric acid production: Sustainable approach[J]. Hydrometallurgy, 2021,200:105568. doi: 10.1016/j.hydromet.2021.105568 [17] Nikiforova A, Kozhura O, Pasenko O. Leaching of vanadium by sulfur dioxide from spent catalysts for sulfuric acid production[J]. Hydrometallurgy, 2016,164:31−37. doi: 10.1016/j.hydromet.2016.05.004 [18] Zhang Ling. Study on recovery of vanadium pentoxide by precipitation of vanadium with acidic ammonium salt as catalyst[J]. Nonferrous Metals and Metallurgy, 2023,39(1):48−51, 34. (张玲. 废钒触媒酸性铵盐沉钒工艺回收五氧化二钒的研究[J]. 有色矿冶, 2023,39(1):48−51, 34.Zhang Ling. Study on recovery of vanadium pentoxide by precipitation of vanadium with acidic ammonium salt as catalyst[J]. Nonferrous Metals and Metallurgy, 2023, 39(1): 48−51, 34. [19] Erust C, Akcil A, Bedelova Z, et al. Recovery of vanadium from spent catalysts of sulfuric acid plant by using inorganic and organic acids: laboratory and semi-pilot tests[J]. Waste Management, 2016,49:455−461. doi: 10.1016/j.wasman.2015.12.002 [20] Hu Jianfeng. Research on new technology for extracting vanadium from waste vanadium catalyst[D]. Kunming: Kunming University of Science and Technology, 2006. (胡建锋. 从废钒触媒中提钒新工艺的研究[D]. 昆明: 昆明理工大学, 2006.Hu Jianfeng. Research on new technology for extracting vanadium from waste vanadium catalyst[D]. Kunming: Kunming University of Science and Technology, 2006. [21] Wang Xinwen, Lei Zhaomin, Duan Mingyou, et al. Experimental study of recovering refined vanadium pentoxide from waste vanadium catalyst[J]. Sulfuric Acid Industry, 1998(2):49−53, 59. (王新文, 雷兆敏, 段铭有, 等. 从废钒催化剂中回收精制五氧化二钒的试验研究[J]. 硫酸工业, 1998(2):49−53, 59.Wang Xinwen, Lei Zhaomin, Duan Mingyou, et al. Experimental study of recovering refined vanadium pentoxide from waste vanadium catalyst[J]. Sulfuric Acid Industry, 1998(2): 49−53, 59. [22] Liu Bin. Study on the technology of comprehensive recovery and utilization of waste vanadium catalyst[D]. Hefei: Hefei University of Technology, 2012. (刘彬. 废钒催化剂综合回收利用技术研究[D]. 合肥: 合肥工业大学, 2012.Liu Bin. Study on the technology of comprehensive recovery and utilization of waste vanadium catalyst[D]. Hefei: Hefei University of Technology, 2012. [23] Hao Xicai, Jing Zhongjian, Hu Binjie. Study on recovery of vanadium oxide from waste catalyst containing vanadium[J]. Inorganic Chemicals Industry, 2010,42(11):48−50. (郝喜才, 景中建, 胡斌杰. 从废钒催化剂中回收钒氧化物的研究[J]. 无机盐工业, 2010,42(11):48−50.Hao Xicai, Jing Zhongjian, Hu Binjie. Study on recovery of vanadium oxide from waste catalyst containing vanadium[J]. Inorganic Chemicals Industry, 2010, 42(11): 48−50. [24] Liu Bo, Tong Qingyun, Li Guoliang. Recovering of vanadium pentoxide from vanadic catalyzer waste by oxidizing roasting[J]. Journal of Sichuan University (Engineering Science Edition), 2002(2):112−115. (刘波, 童庆云, 李国良. 氧化焙烧法回收废钒触媒中的钒[J]. 四川大学学报(工程科学版), 2002(2):112−115.Liu Bo, Tong Qingyun, Li Guoliang. Recovering of vanadium pentoxide from vanadic catalyzer waste by oxidizing roasting[J]. Journal of Sichuan University (Engineering Science Edition), 2002(2): 112−115. [25] Jiang Fuhua, Zhang Ping. Experiment of recovering vanadium pentoxide from waste vanadium catalyst by trona leaching[J]. Sulfuric Acid Industry, 2000(4):28−30, 57. (蒋馥华, 张萍. 用天然碱浸法从废钒催化剂中回收五氧化二钒的试验[J]. 硫酸工业, 2000(4):28−30, 57. doi: 10.3969/j.issn.1002-1507.2000.04.008Jiang Fuhua, Zhang Ping. Experiment of recovering vanadium pentoxide from waste vanadium catalyst by trona leaching[J]. Sulfuric Acid Industry, 2000(4): 28−30, 57. doi: 10.3969/j.issn.1002-1507.2000.04.008 [26] Xu Biqiong. Research on abstracting V2O5 from spent vanadium catalyst[J]. Chemical Industry and Engineering Progress, 2002(3):200−202. (许碧琼. 从废钒触媒中回收钒氧化物[J]. 化工进展, 2002(3):200−202.Xu Biqiong. Research on abstracting V2O5 from spent vanadium catalyst[J]. Chemical Industry and Engineering Progress, 2002(3): 200−202. [27] Mo Yazhi, Huang Peizheng, Tang Jialin. Recovery of vanadium pentoxide from waste vanadium catalyst by ammonia leaching[J]. Guangxi Chemical Industry, 1992,21(2):2. (莫亚枝, 黄佩征, 唐家林. 氨性液浸出法回收废钒触媒中的五氧化二钒[J]. 广西化工, 1992,21(2):2.Mo Yazhi, Huang Peizheng, Tang Jialin. Recovery of vanadium pentoxide from waste vanadium catalyst by ammonia leaching[J]. Guangxi Chemical Industry, 1992, 21(2): 2. [28] Li Jianchi. Preparation of ammonium metavanadate from waste vanadium catalyst[J]. Shaanxi Chemical Industry, 1991(Z1):61. (李建池. 用废钒触媒制备偏钒酸铵[J]. 陕西化工, 1991(Z1):61.Li Jianchi. Preparation of ammonium metavanadate from waste vanadium catalyst[J]. Shaanxi Chemical Industry, 1991(Z1): 61. [29] Jiang Fuhua, Shen Zhaoquan. Study on recovery of vanadium pentoxide from waste vanadium catalyst[J]. Hubei Chemical Industry, 1991(1):27−29. (蒋馥华, 申照全. 废钒触媒中五氧化二钒的回收研究[J]. 湖北化工, 1991(1):27−29.Jiang Fuhua, Shen Zhaoquan. Study on recovery of vanadium pentoxide from waste vanadium catalyst[J]. Hubei Chemical Industry, 1991(1): 27−29. [30] Wang Baodong, Liu Zilin, Lin Dehai, et al. A review on recovery and utilization of spent V2O5-WO3/TiO2 catalyst[J]. Materials Reports, 2019, 35(15): 15001-15010. (王宝冬, 刘子林, 林德海, 等. 废钒-钛系脱硝催化剂回收利用策略与技术进展[J]. 材料导报, 2021, 35(15): 15001-15010.Wang Baodong, Liu Zilin, Lin Dehai, et al. A review on recovery and utilization of spent V2O5-WO3/TiO2 catalyst[J]. Materials Reports, 2019, 35(15): 15001-15010. [31] Shi Xiayi, Dong Yanping, Cui Yan. Analysis and comparison of sintering gas denitrification technology[J]. China Metallurgy, 2017,27(8):56−59. (史夏逸, 董艳苹, 崔岩. 烧结烟气脱硝技术分析及比较[J]. 中国冶金, 2017,27(8):56−59.Shi Xiayi, Dong Yanping, Cui Yan. Analysis and comparison of sintering gas denitrification technology[J]. China Metallurgy, 2017, 27(8): 56−59. [32] Li Qiang, Chen Tiejun, Li Qiyong, et al. Research progress on resource utilization of waste SCR denitration catalyst[J]. China Metallurgy, 2020,30(5):1−10. (李强, 陈铁军, 李奇勇, 等. 废弃SCR脱硝催化剂资源化利用研究进展[J]. 中国冶金, 2020,30(5):1−10.Li Qiang, Chen Tiejun, Li Qiyong, et al. Research progress on resource utilization of waste SCR denitration catalyst[J]. China Metallurgy, 2020, 30(5): 1−10. [33] Chen Fengqiao, Cui Chang, Qi Liqiang. Utilizing organic acids for V2O5 recovery from denitration catalyst alkaline inactivation[J]. Acta Chemologica Sinica, 2017,68(12):4717−4722. (陈凤桥, 崔畅, 齐立强. 碱失活SCR脱硝催化剂的有机酸回收[J]. 化工学报, 2017,68(12):4717−4722.Chen Fengqiao, Cui Chang, Qi Liqiang. Utilizing organic acids for V2O5 recovery from denitration catalyst alkaline inactivation[J]. Acta Chemologica Sinica, 2017, 68(12): 4717−4722. [34] Wu Wenfen. Basic research on recovery of vanadium, tungsten and carrier from spent denitrification catalyst[D]. Beijing: Institute of Process Engineering, Chinese Academy of Sciences, 2020. (武文粉. 废脱硝催化剂回收钒钨及载体循环利用过程基础研究[D]. 北京: 中国科学院过程工程研究所, 2020.Wu Wenfen. Basic research on recovery of vanadium, tungsten and carrier from spent denitrification catalyst[D]. Beijing: Institute of Process Engineering, Chinese Academy of Sciences, 2020. [35] An Jiakang, Wang Luzhu, Deng Lifeng, et al. Orthogonal experimental optimization of vanadium leaching rate from deactivated de NOx catalyst by organic acid[J]. Applied Chemical Industry, 2022, 51(6): 1555-1558. (安家康, 王露珠, 邓立锋, 等. 有机酸下失活脱硝催化剂钒浸出率的正交试验优化研究[J]. 应用化工, 2022, 51(6): 1555-1558.An Jiakang, Wang Luzhu, Deng Lifeng, et al. Orthogonal experimental optimization of vanadium leaching rate from deactivated de NOx catalyst by organic acid[J]. Applied Chemical Industry, 2022, 51(6): 1555-1558. [36] Zheng Yilin, Dai Shijin, Zhao Youcai, et al. Selective leaching of vanadium and tungsten from spent SCR catalyst using organic acids[J]. Environmental Protection of Chemical Industry, 2020,40(2):162−168. (郑怡琳, 戴世金, 赵由才, 等. 废SCR催化剂中钒和钨的有机酸浸出[J]. 化工环保, 2020,40(2):162−168. doi: 10.3969/j.issn.1006-1878.2020.02.009Zheng Yilin, Dai Shijin, Zhao Youcai, et al. Selective leaching of vanadium and tungsten from spent SCR catalyst using organic acids[J]. Environmental Protection of Chemical Industry, 2020, 40(2): 162−168. doi: 10.3969/j.issn.1006-1878.2020.02.009 [37] Li Licheng, Wang Lei, Zhao Xuejuan, et al. Comparison of effect of different acid treatments on vanadium extraction of waste deNOx catalyst[J]. The Chinese Journal of Nonferrous Metals, 2016,26(10):2230−2237. (李力成, 王磊, 赵学娟, 等. 几种酸在废弃脱硝催化剂中提钒效果的比较[J]. 中国有色金属学报, 2016,26(10):2230−2237.Li Licheng, Wang Lei, Zhao Xuejuan, et al. Comparison of effect of different acid treatments on vanadium extraction of waste deNOx catalyst[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(10): 2230−2237. [38] Tang Dingling, Song Hao, Liu Dingding, et al. Study on leaching kinetics of extracting vanadium and tungsten by sodium hydroxide from spent SCR catalyst[J]. Chinese Journal of Environmental Engineering, 2017,11(2):1093−1100. (唐丁玲, 宋浩, 刘丁丁, 等. 废弃脱硝催化剂碱浸提取钒和钨的浸出动力学研究[J]. 环境工程学报, 2017,11(2):1093−1100.Tang Dingling, Song Hao, Liu Dingding, et al. Study on leaching kinetics of extracting vanadium and tungsten by sodium hydroxide from spent SCR catalyst[J]. Chinese Journal of Environmental Engineering, 2017, 11(2): 1093−1100. [39] In-Hyeok C, Gyeonghye M, Jin-Young L, et al. Extraction of tungsten and vanadium from spent selective catalytic reduction (SCR) catalyst for stationary application by pressure leaching process[J]. Journal of Cleaner Production, 2018,197(1):163−169. [40] Li Xiaowen. Study on recovery of tungsten-vanadium by high pressure alkaline leaching of waste SCR catalyst[D]. Ganzhou: Jiangxi University of Science and Technology, 2020. (李小文. 废SCR催化剂高压碱浸回收钨钒的工艺研究[D]. 赣州: 江西理工大学, 2020.Li Xiaowen. Study on recovery of tungsten-vanadium by high pressure alkaline leaching of waste SCR catalyst[D]. Ganzhou: Jiangxi University of Science and Technology, 2020. [41] Zhou Kai, Lu Bin, Wang Sheng, et al. Research on recovery process of Ti, V and W in waste SCR denitration catalyst[J]. Electric Power Technology and Environmental Protection, 2019,35(4):8−13. (周凯, 陆斌, 王圣, 等. 废弃SCR脱硝催化剂中Ti、V、W元素回收工艺研究[J]. 电力科技与环保, 2019,35(4):8−13.Zhou Kai, Lu Bin, Wang Sheng, et al. Research on recovery process of Ti, V and W in waste SCR denitration catalyst[J]. Electric Power Technology and Environmental Protection, 2019, 35(4): 8−13. [42] Jia Yong, Ding Wanli, Ding Xilou, et al. The leaching of tungsten and vanadium from spent selective catalytic reduction catalyst[J]. Acta Scientiae Circumstantiae, 2016,36(10):3759−3764. (贾勇, 丁万丽, 丁希楼, 等. 废SCR脱硝催化剂中钨和钒的浸出试验研究[J]. 环境科学学报, 2016,36(10):3759−3764.Jia Yong, Ding Wanli, Ding Xilou, et al. The leaching of tungsten and vanadium from spent selective catalytic reduction catalyst[J]. Acta Scientiae Circumstantiae, 2016, 36(10): 3759−3764. [43] Chen Guangyu. Study on direct alloying of waste denitration catalyst[D]. Baotou: Inner Mongolia University of Science and Technology, 2019. (陈广玉. 废弃脱硝催化剂直接合金化研究[D]. 包头: 内蒙古科技大学, 2019.Chen Guangyu. Study on direct alloying of waste denitration catalyst[D]. Baotou: Inner Mongolia University of Science and Technology, 2019. [44] Piao Rongxun, Ma Lan, Yang Shaoli, et al. Experimental study on the preparation of Ti-Al based alloy by aluminothermic reduction-vacuum electromagnetic levitation refining of waste denitration catalyst[J]. Iron Steel Vanadium Titanium, 2019,40(3):39−45. (朴荣勋, 马兰, 杨绍利, 等. 废弃脱硝催化剂铝热还原-真空磁悬浮精炼制备钛铝基合金试验研究[J]. 钢铁钒钛, 2019,40(3):39−45.Piao Rongxun, Ma Lan, Yang Shaoli, et al. Experimental study on the preparation of Ti-Al based alloy by aluminothermic reduction-vacuum electromagnetic levitation refining of waste denitration catalyst[J]. Iron Steel Vanadium Titanium, 2019, 40(3): 39−45. [45] Piao Rongxun, Ma Lan, Yang Shaoli, et al. Experimental study on preparation of Cr-containing Ti-Al based alloys by aluminothermic reduction-remelting of waste SCR Ti-based denitration catalyst[J]. Iron Steel Vanadium Titanium, 2019,40(2):79−86. (朴荣勋, 马兰, 杨绍利, 等. 废SCR钛基脱硝催化剂铝热还原重熔制备含铬钛铝基合金的试验研究[J]. 钢铁钒钛, 2019,40(2):79−86.Piao Rongxun, Ma Lan, Yang Shaoli, et al. Experimental study on preparation of Cr-containing Ti-Al based alloys by aluminothermic reduction-remelting of waste SCR Ti-based denitration catalyst[J]. Iron Steel Vanadium Titanium, 2019, 40(2): 79−86. [46] Zhao Beibei, Li Lanjie, Liu Lin, et al. Study on vanadium extraction process of spent vanadium catalyst[J]. Multipurpose Utilization of Mineral Resources, 2019(6):80−83. (赵备备, 李兰杰, 柳林, 等. 废钒触媒提钒工艺研究[J]. 矿产综合利用, 2019(6):80−83.Zhao Beibei, Li Lanjie, Liu Lin, et al. Study on vanadium extraction process of spent vanadium catalyst[J]. Multipurpose Utilization of Mineral Resources, 2019(6): 80−83. [47] Zhang Zhenquan, Zhao Beibei, Li Lanjie, et al. Study on selective separation of vanadium, titanium and tungsten from spent SCR denitration catalyst[J]. Iron Steel Vanadium Titanium, 2021,42(1):24−31. (张振全, 赵备备, 李兰杰, 等. 废SCR脱硝催化剂钒、钛、钨选择性分离研究[J]. 钢铁钒钛, 2021,42(1):24−31. doi: 10.7513/j.issn.1004-7638.2021.01.004Zhang Zhenquan, Zhao Beibei, Li Lanjie, et al. Study on selective separation of vanadium, titanium and tungsten from spent SCR denitration catalyst[J]. Iron Steel Vanadium Titanium, 2021, 42(1): 24−31. doi: 10.7513/j.issn.1004-7638.2021.01.004 -

下载:

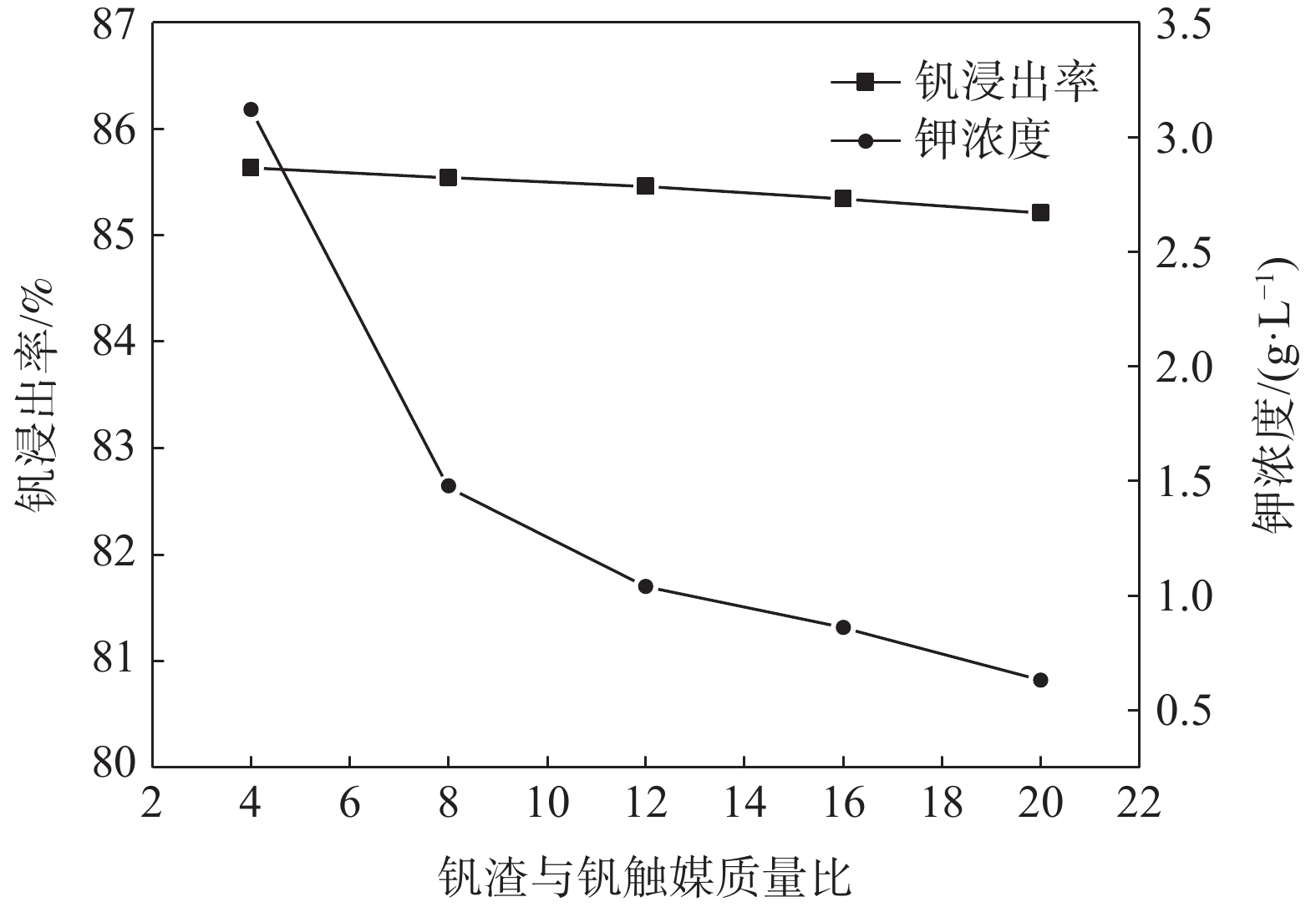

下载: