Study on process mineralogy of a titanium concentrate from Panzhihua

-

摘要:

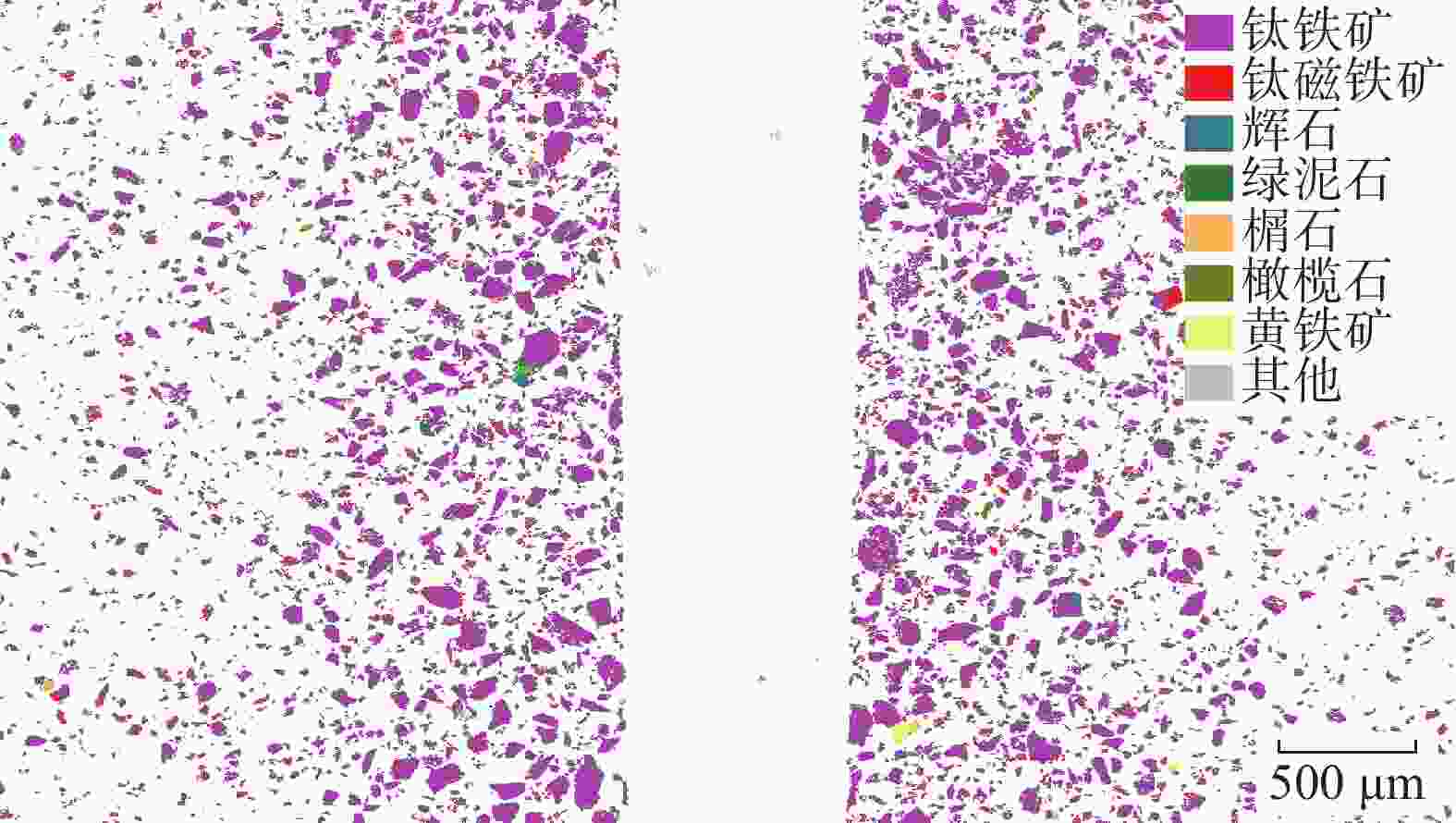

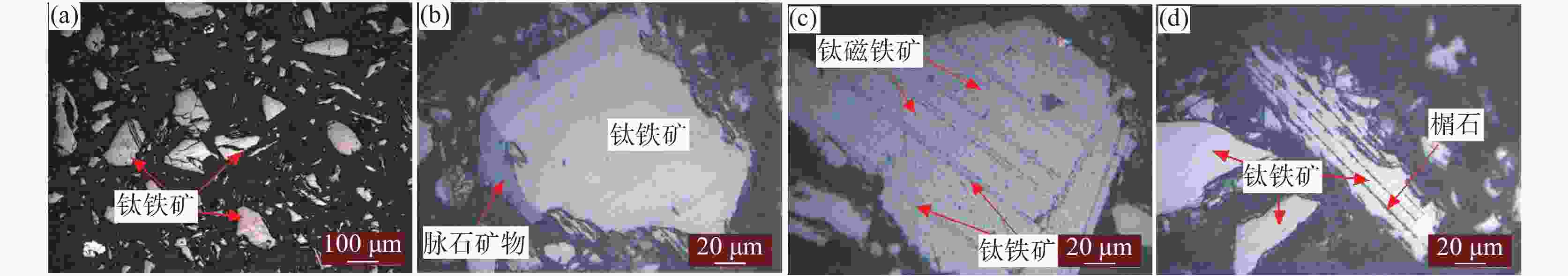

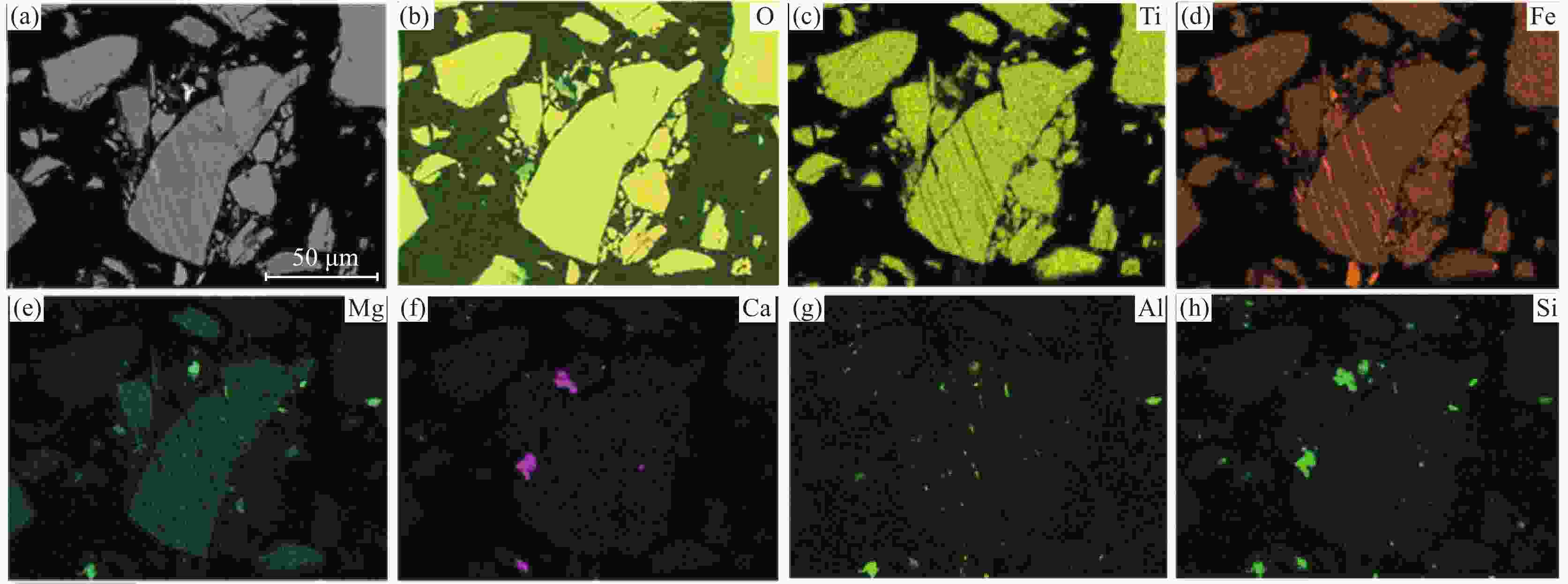

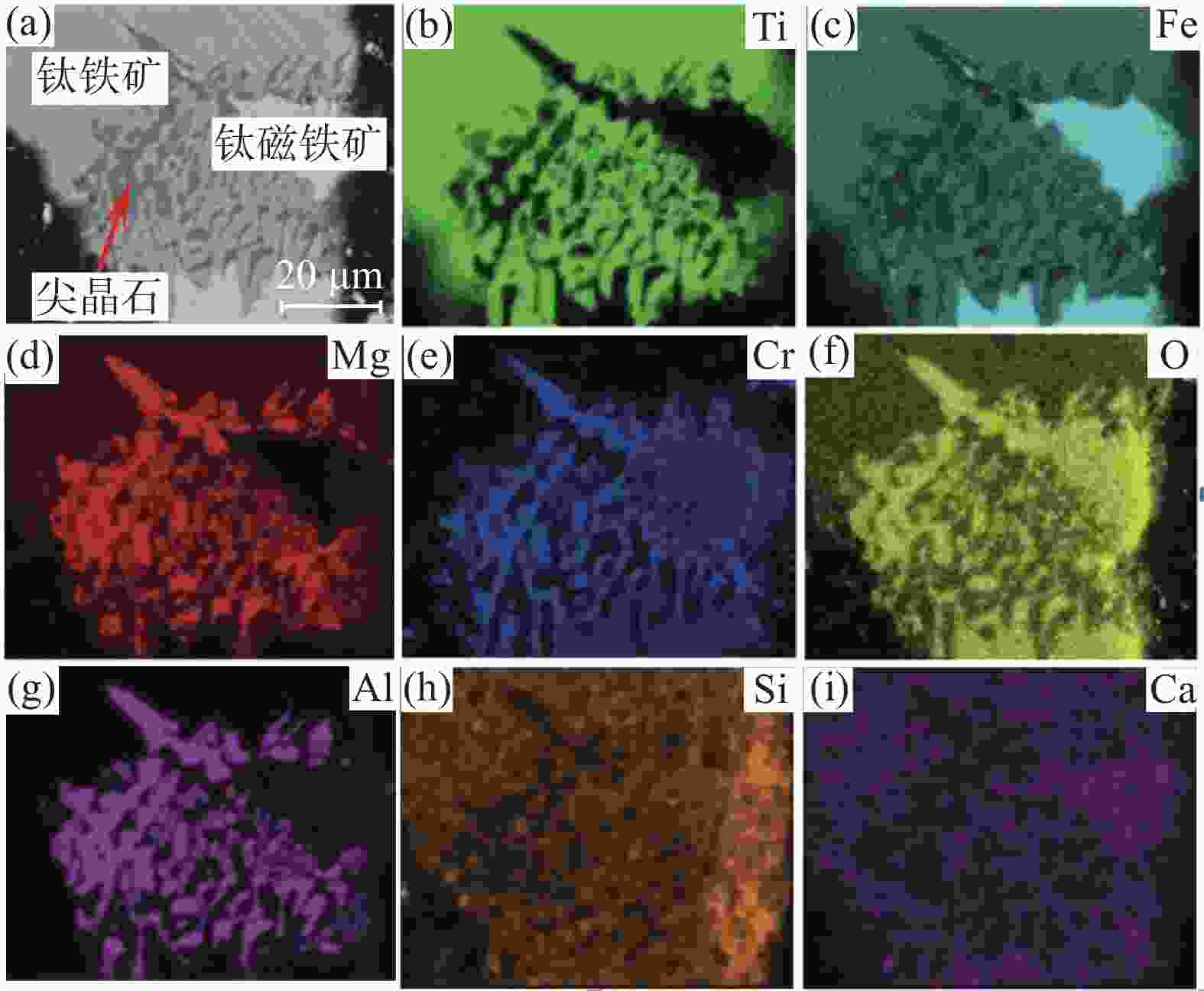

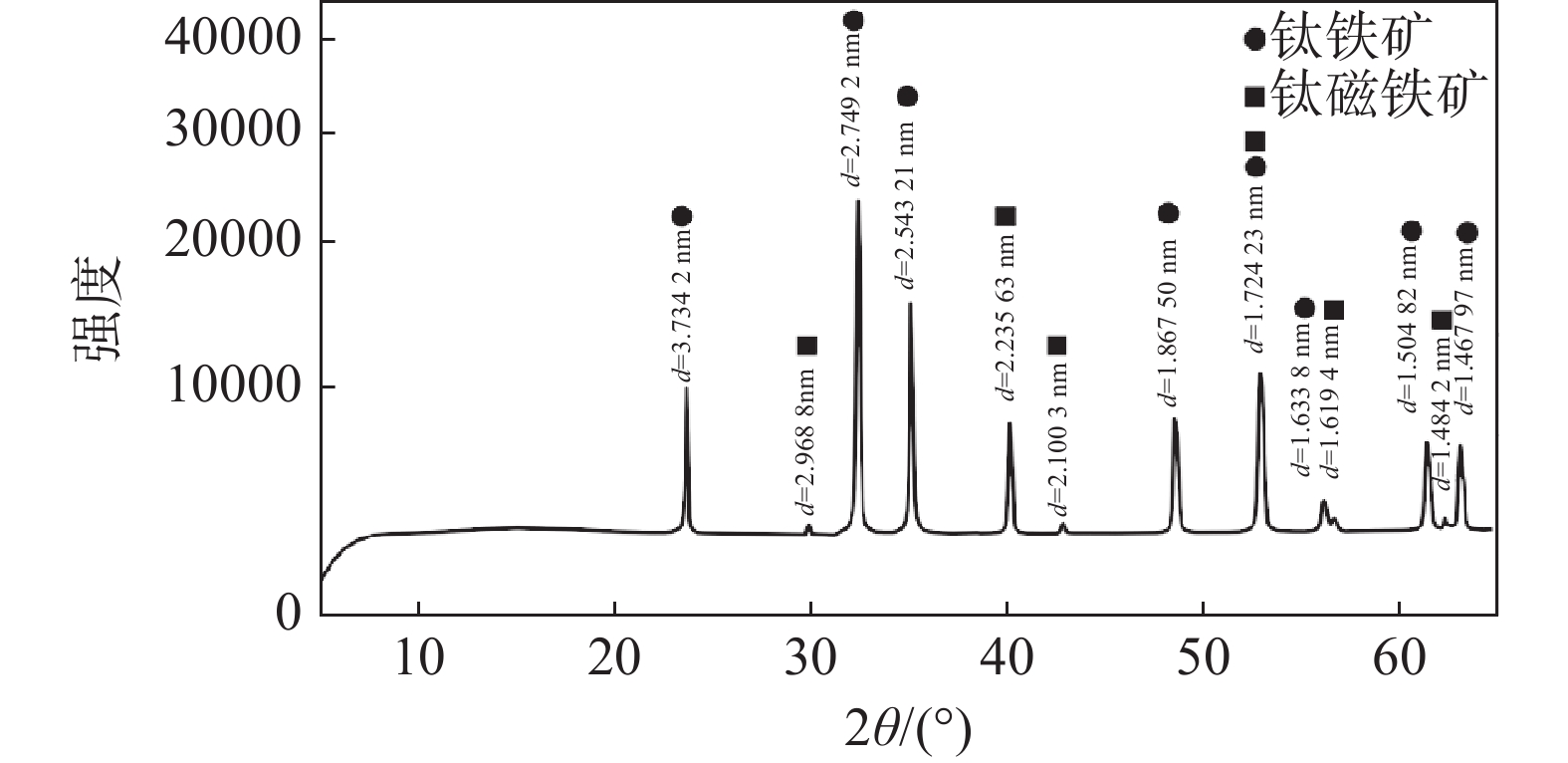

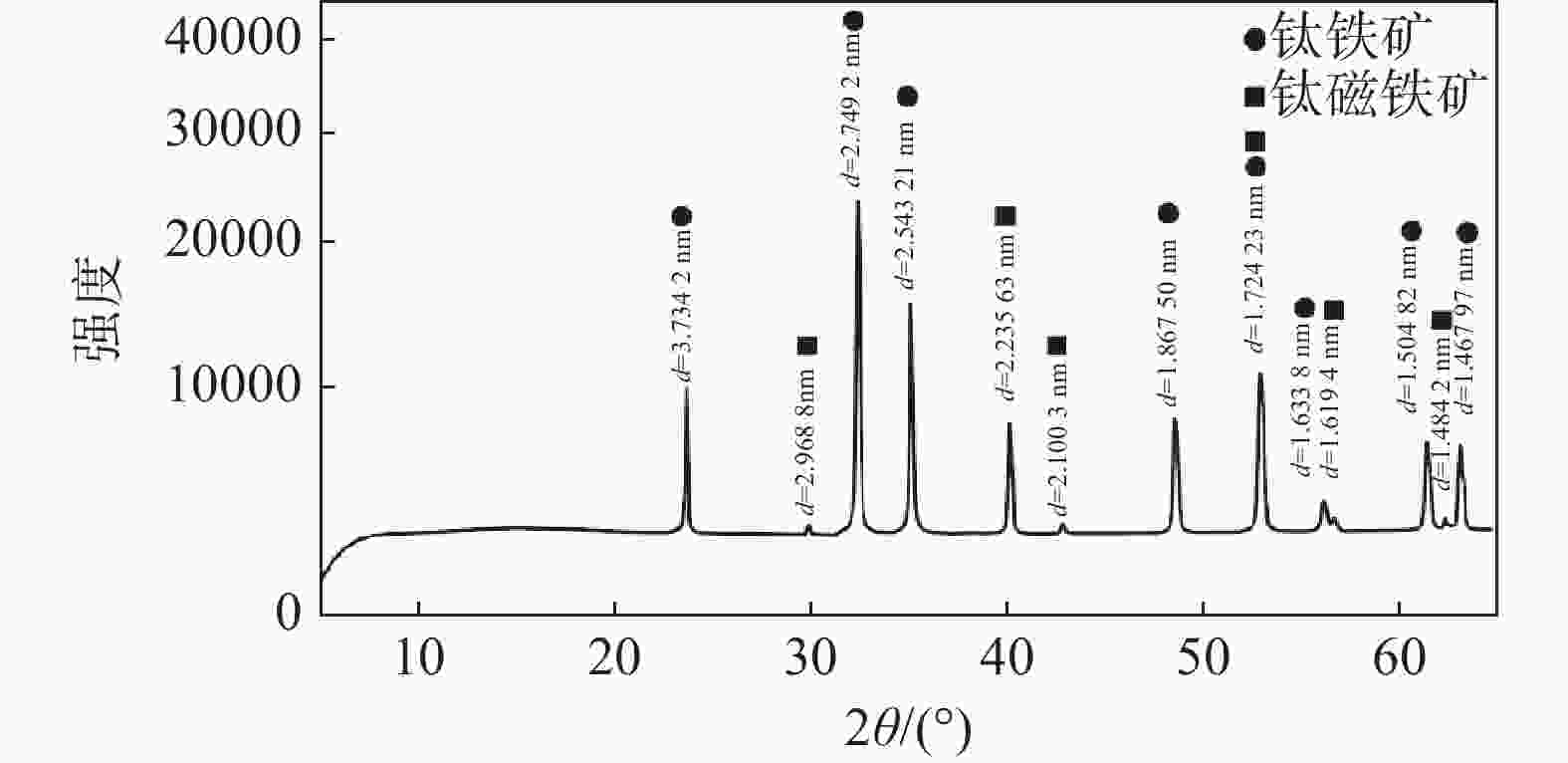

以攀枝花某钛精矿为例,通过化学多元素分析、AMICS矿物自动分析、电子探针分析、X射线衍射分析、扫描电镜分析和光学显微镜鉴定等手段开展详细的工艺矿物学研究,查明该钛精矿中TiO2含量为48.03%,TFe含量为33.93%,另含少量MgO、SiO2、Al2O3、CaO等杂质组分;主要矿物为钛铁矿(91.00%),次要矿物为钛磁铁矿(1.41%),以及少量黄铁矿(0.35%),另外含有少量辉石、绿泥石、榍石、橄榄石等脉石矿物(7.24%);钛元素主要以独立矿物相形式赋存于钛铁矿、榍石中,分布率分别为99.50%、0.35%;其次以类质同象形式赋存于钛磁铁矿中,分布率为0.12%;确定该钛精矿TiO2理论品位为52.09%。研究认为钛精矿中的部分钛铁矿与钛磁铁矿以固溶体分离结构紧密连生产出,通过传统的选矿手段难以有效分离剔除;钛精矿中存在少量含镁、钙、硅、铝等杂质元素的脉石矿物,这些是钛精矿品位难以提高的主要原因,应探索优化钛精矿精选工艺流程及药剂制度,有效剔除钛精矿中的脉石矿物,从而提高钛精矿品位,降低杂质含量。

Abstract:This study focused on a specific case - titanium concentrate from Panzhihua. Detailed process mineralogy research was conducted using chemical element analysis, AMICS, EPMA, XRD, SEM and optical microscope identification. The research reveals that the ilmenite concentrate contains 48.03% TiO2 and 33.93% TFe, along with small amounts of impurity components such as MgO, SiO2, Al2O3 and CaO. The primary mineral present is ilmenite (91.00%), followed by titanomagnetite (1.41%), with a small percentage (7.59%) consisting of gangue minerals including pyroxene, chlorite, titanite and olivine. The titanium element primarily exists in the form of independent mineral phases in ilmenite and titanite, with distribution rates of 99.50% and 0.35%, respectively. It also occurs as isomorphism in titanomagnetite, with a distribution rate of 0.12%. The theoretical TiO2 grade of the titanium concentrate has been determined to be 52.09%. It is believed that part of the ilmenite and titanomagnetite in the titanium concentrate are formed by solid solution separation structures, which are difficult to effectively separate and eliminate using traditional beneficiation methods. Additionally, there are small amounts of gangue minerals containing impurity elements such as magnesium, calcium, silicon, and aluminum present in the titanium concentrate. These reasons render it challenging to enhance the grade of titanium concentrate. We ought to explore and optimize the beneficiation process for the purpose of effectively eliminating the gangue minerals within the titanium concentrate, thereby upgrading the grade of titanium concentrate and reducing the impurity content.

-

表 1 钛精矿化学成分

Table 1. Chemical element analysis of Ti concentrate

% TiO2 TFe FeO SiO2 Al2O3 CaO MgO 48.03 33.93 38.26 1.50 0.57 0.50 3.12 表 2 钛精矿矿物组成分析结果

Table 2. Mineral compositions of Ti concentrate

% 钛铁矿 钛磁铁矿 硫化物

(黄铁矿等)脉石矿物 合计 辉石 绿泥石 榍石 角闪石 尖晶石 橄榄石 其它 91.00 1.41 0.35 1.10 1.40 0.40 0.35 0.05 1.00 2.94 100.00 表 3 钛精矿粒度分布范围

Table 3. Particle size composition of titanium concentrate

粒度/μm 钛铁矿/% 钛磁铁矿/% 绿泥石/% 筛上 累积分布 筛上 累积分布 筛上 累积分布 89.19 0 100 75 3.71 96.29 63.07 0 96.29 0 100 53.03 1.61 94.68 4.88 95.12 44.6 0 100 0 94.68 5.14 89.98 37.5 3.78 96.22 2.86 91.82 8.53 81.44 31.53 2.79 93.43 4.6 87.22 5.93 75.51 26.52 3.79 89.64 0.92 86.3 8.2 67.31 22.3 7.76 81.88 2.44 83.86 9.79 57.52 18.75 8.01 73.87 4.46 79.4 8.02 49.5 15.77 10.08 63.79 5.25 74.14 9.29 40.21 13.26 15.81 47.97 8.97 65.18 10.26 29.95 11.15 13.65 34.32 9.81 55.37 10.71 19.24 9.38 10.65 23.67 13.73 41.64 6.72 12.53 7.88 10.22 13.45 11.14 30.49 5.78 6.75 6.63 5.89 7.56 11.5 18.99 3.38 3.38 5.57 3.58 3.98 7.68 11.31 1.62 1.76 表 4 钛铁矿、钛磁铁矿单体解离度分析结果

Table 4. Dissociation degree of ilmenite and titanomagnetite monomer

矿物名称 单体解

离度/%连生体/% 金红石 钙钛矿 钛铁矿 钛磁铁矿 黄铁矿 含Cr磁铁矿 橄榄石 绿泥石 榍石 角闪石 尖晶石 辉石 钛铁矿 96.58 0.04 0.09 0.00 1.6 0.05 0.01 0.02 0.64 0.55 0.15 0.06 0.12 钛磁铁矿 57.75 0.02 0.06 40.41 0.00 0.16 0.13 0.07 0.78 0.25 0.08 0.03 0.19 表 5 钛铁矿微区电子探针分析结果

Table 5. EPMA analysis results of ilmenite

% 序号 TiO2 FeO MgO CaO Al2O3 SiO2 V2O3 Na2O K2O P2O5 Total 1 53.60 42.09 3.51 0.00 0.01 0.00 0.14 0.00 0.01 0.00 99.37 2 52.46 42.71 4.36 0.03 0.02 0.03 0.08 0.00 0.01 0.00 99.70 3 51.61 45.03 2.95 0.03 0.01 0.01 0.00 0.00 0.00 0.02 99.66 4 51.83 44.93 2.85 0.00 0.00 0.02 0.21 0.01 0.00 0.00 99.86 5 56.28 35.62 8.02 0.00 0.00 0.00 0.07 0.03 0.01 0.00 100.05 6 50.86 48.00 0.07 0.00 0.00 0.00 0.00 0.05 0.00 0.00 98.99 7 52.37 47.28 0.09 0.01 0.00 0.00 0.00 0.02 0.00 0.00 99.77 8 52.05 47.23 0.08 0.00 0.00 0.02 0.32 0.02 0.00 0.00 99.73 9 50.53 48.91 0.02 0.02 0.03 0.00 0.00 0.02 0.00 0.01 99.55 10 49.33 50.17 0.07 0.04 0.05 0.00 0.22 0.00 0.01 0.01 99.90 平均值 52.09 45.20 2.20 0.01 0.01 0.01 0.11 0.01 0.00 0.00 99.66 表 6 其他矿物的能谱微区数据

Table 6. Energy spectrum analysis results of other minerals

% 矿物 TiO2 FeO TFe MgO CaO Al2O3 SiO2 Cr2O3 ZnO Na2O K2O 钛磁铁矿 4.02 92.60 72.02 3.38 辉石 7.01 5.45 15.94 24.65 4.99 47.41 尖晶石 11.92 21.20 16.48 13.41 46.29 6.30 0.88 绿泥石 4.56 3.55 33.21 33.74 28.50 榍石 41.18 0.94 0.73 30.10 1.05 26.73 角闪石 2.76 6.12 4.76 18.58 14.16 16.96 37.86 3.02 0.56 橄榄石 27.15 21.12 38.04 34.81 表 7 钛精矿中Fe、Ti、Mg元素平衡配分计算

Table 7. Equilibrium partition calculation table of chemical elements such as Fe, Ti, Mg in the sample

% 矿物

名称矿物

含量TFe TiO2 MgO 含量 金属量 分布率 含量 金属量 分布率 含量 金属量 分布率 钛铁矿 91.00 35.16 31.996 95.45 52.09 47.402 99.50 2.20 2.002 64.70 钛磁铁矿 1.41 72.02 1.015 3.03 4.02 0.057 0.12 0.00 0.000 0.00 辉石 1.10 5.45 0.060 0.18 0.00 0.000 0.00 15.94 0.175 5.67 绿泥石 1.40 3.55 0.050 0.15 0.00 0.000 0.00 33.21 0.465 15.03 榍石 0.40 0.73 0.003 0.01 41.18 0.165 0.35 0.00 0.000 0.00 尖晶石 0.05 16.49 0.008 0.02 11.92 0.006 0.01 13.41 0.007 0.22 角闪石 0.35 4.76 0.017 0.05 2.76 0.010 0.02 18.58 0.065 2.10 黄铁矿 0.35 45.76 0.160 0.48 0.00 0.000 0.00 0.00 0.000 0.00 橄榄石 1.00 21.12 0.211 0.63 0.00 0.000 0.00 38.04 0.380 12.29 其它矿物 2.94 合计 100.00 33.520 100.00 47.639 100.00 3.094 100.00 钛精矿品位 33.93 48.03 3.12 平衡系数(k) 98.79 99.19 99.18 表 8 钛精矿中Ca、Si、Al元素平衡配分计算

Table 8. Equilibrium partition calculation table of chemical elements such as Ca, Si, Al in the sample

% 矿物

名称矿物

含量CaO SiO2 Al2O3 含量 金属量 分布率 含量 金属量 分布率 含量 金属量 分布率 钛铁矿 91.00 0.01 0.009 1.80 0.01 0.009 0.60 0.01 0.009 1.46 钛磁铁矿 1.41 4.02 0.057 11.18 0.00 0.000 0.00 0.00 0.000 0.00 辉石 1.10 24.65 0.271 53.49 47.41 0.522 34.37 4.99 0.055 8.81 绿泥石 1.40 0.00 0.000 0.00 28.50 0.399 26.30 33.74 0.472 75.81 榍石 0.40 30.10 0.120 23.75 26.73 0.107 7.05 1.05 0.004 0.67 尖晶石 0.00 0.000 0.00 0.00 0.000 0.00 46.29 0.023 3.71 角闪石 0.35 14.16 0.050 9.78 37.86 0.133 8.73 16.96 0.059 9.53 黄铁矿 0.35 0.00 0.000 0.00 0.00 0.000 0.00 0.00 0.000 0.00 橄榄石 1.00 0.00 0.000 0.00 34.81 0.348 22.94 0.00 0.000 0.00 其它矿物 2.94 合计 100.00 0.507 100.00 1.517 100.00 0.623 100.00 钛精矿品位 0.50 1.50 0.57 平衡系数(k) 101.38 101.14 109.31 -

[1] CHENG D. Institute of comprehensive utilization of minerals, China Geological Survey Bureau. Panxi vanadium titanium magnetite resources and comprehensive utilization technology [M]. Beijing: Metallurgical Industry Press, 2015: 1-12. (中国地质科学院矿产综合利用研究所. 攀西钒钛磁铁矿资源及综合利用技术[M]. 北京: 冶金工业出版社, 2015: 1-12.CHENG D. Institute of comprehensive utilization of minerals, China Geological Survey Bureau. Panxi vanadium titanium magnetite resources and comprehensive utilization technology [M]. Beijing: Metallurgical Industry Press, 2015: 1-12. [2] LI X Y, ZHOU M G. Process mineralogy research on the titanium concentrate from a mining field Panxi region[J]. Multipurpose Utilization of Mineral Resources, 2009(1):24-27. (李潇雨, 周满赓. 西部某矿区钛精矿工艺矿物学研究[J]. 矿产综合利用, 2009(1):24-27. doi: 10.3969/j.issn.1000-6532.2009.01.007LI X Y, ZHOU M G. Process mineralogy research on the titanium concentrate from a mining field Panxi region[J]. Multipurpose Utilization of Mineral Resources, 2009(1): 24-27. doi: 10.3969/j.issn.1000-6532.2009.01.007 [3] CHONG X X, LUAN W L, WANG F X, et al. Overview of global titanium resources status and titanium consumption trend in China[J]. Conservation and Utilization of Mineral Resources, 2020,40(2):162-170. (崇霄霄, 栾文楼, 王丰翔, 等. 全球钛资源现状概述及我国钛消费趋势[J]. 矿产保护与利用, 2020,40(2):162-170.CHONG X X, LUAN W L, WANG F X, et al. Overview of global titanium resources status and titanium consumption trend in China[J]. Conservation and Utilization of Mineral Resources, 2020, 40(2): 162-170. [4] LI Z, CHEN C X. Development status of global titanium resources industry[J]. Acta Geoscientica Sinica, 2021,42(2):245-250. (李政, 陈从喜. 全球钛资源行业发展现状[J]. 地球学报, 2021,42(2):245-250. doi: 10.3975/cagsb.2020.102001LI Z, CHEN C X. Development status of global titanium resources industry[J]. Acta Geoscientica Sinica, 2021, 42(2): 245-250. doi: 10.3975/cagsb.2020.102001 [5] DING R F, ZHANG D W, QIN Z R, et al. Analysis of resource security and supply under the rapid development of titanium industry in China[J]. China Steel Focus, 2023(22):43-51. (丁瑞锋, 张大伟, 秦子然, 等. 我国钛产业高速发展下的资源安全保供分析[J]. 冶金管理, 2023(22):43-51.DING R F, ZHANG D W, QIN Z R, et al. Analysis of resource security and supply under the rapid development of titanium industry in China[J]. China Steel Focus, 2023(22): 43-51. [6] WANG Y L, WANG S, XU B J, et al. Study on process mineralogy of a vanadium and titanium iron concentrate[J]. Modern Mining, 2023,39(7):153-156,161. (王云龙, 王帅, 徐宝金, 等. 某含钒钛铁精矿工艺矿物学研究[J]. 现代矿业, 2023,39(7):153-156,161. doi: 10.3969/j.issn.1674-6082.2023.07.037WANG Y L, WANG S, XU B J, et al. Study on process mineralogy of a vanadium and titanium iron concentrate[J]. Modern Mining, 2023, 39(7): 153-156,161. doi: 10.3969/j.issn.1674-6082.2023.07.037 [7] LIU Z X. Research and industrial practice on improving quality and reducing[J]. Iron Steel Vanadium Titanium, 2022,43(3):104-110. (刘志雄. 白马钒钛磁铁矿提质降杂研究及工业实践[J]. 钢铁钒钛, 2022,43(3):104-110. doi: 10.7513/j.issn.1004-7638.2022.03.017LIU Z X. Research and industrial practice on improving quality and reducing[J]. Iron Steel Vanadium Titanium, 2022, 43(3): 104-110. doi: 10.7513/j.issn.1004-7638.2022.03.017 [8] ZHAO X F. The influence of related mineral composition of vanadium titanomagnetite on the quality of titanium concentrate[J]. Multipurpose Utilization of Mineral Resources, 1983(3):96-99. (赵新奋. 钒钛磁铁矿有关矿物成份对钛精矿质量的影响[J]. 矿产综合利用, 1983(3):96-99.ZHAO X F. The influence of related mineral composition of vanadium titanomagnetite on the quality of titanium concentrate[J]. Multipurpose Utilization of Mineral Resources, 1983(3): 96-99. -

下载:

下载: