Effect of austenite grain size on intracrystalline ferrite nucleation in vanadium microalloyed steel

-

摘要:

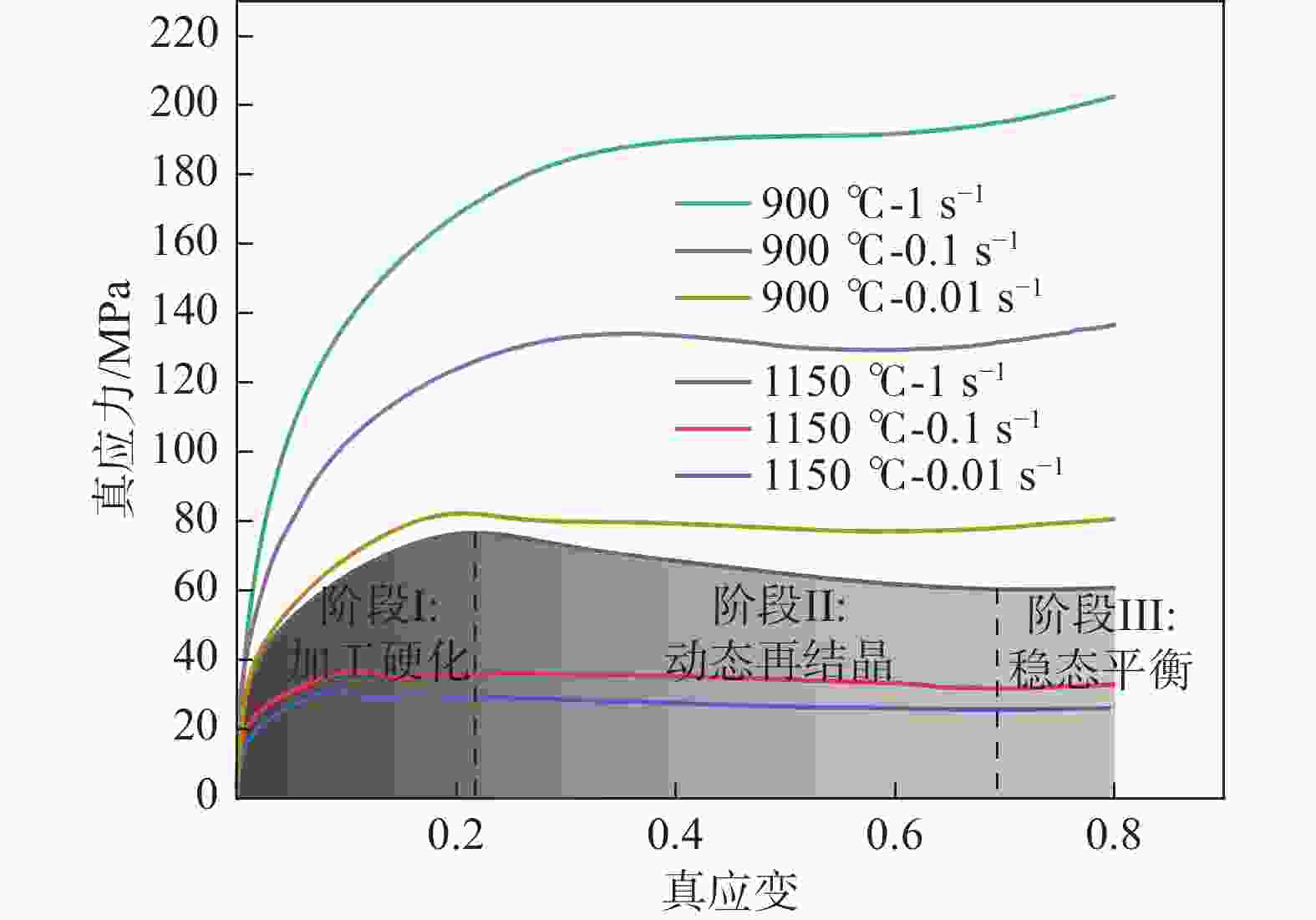

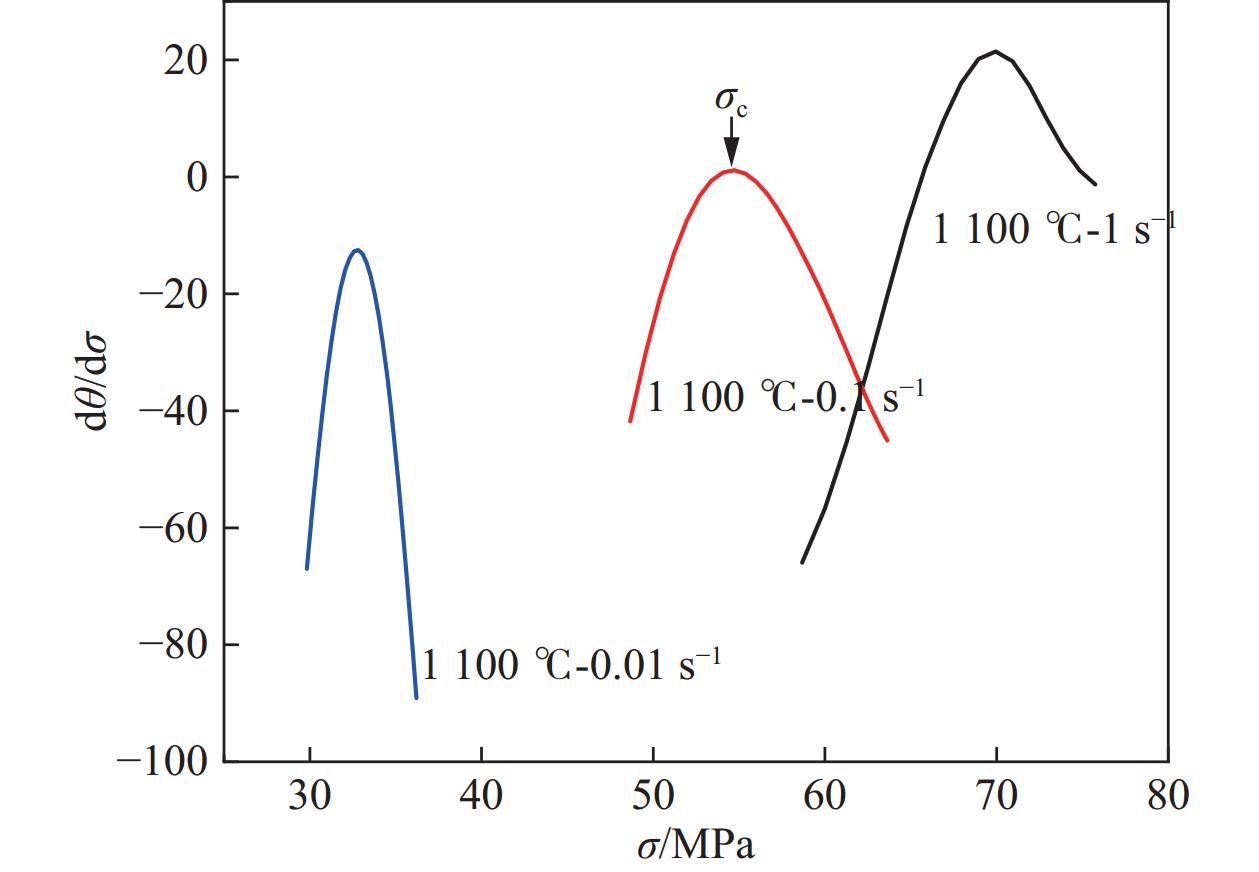

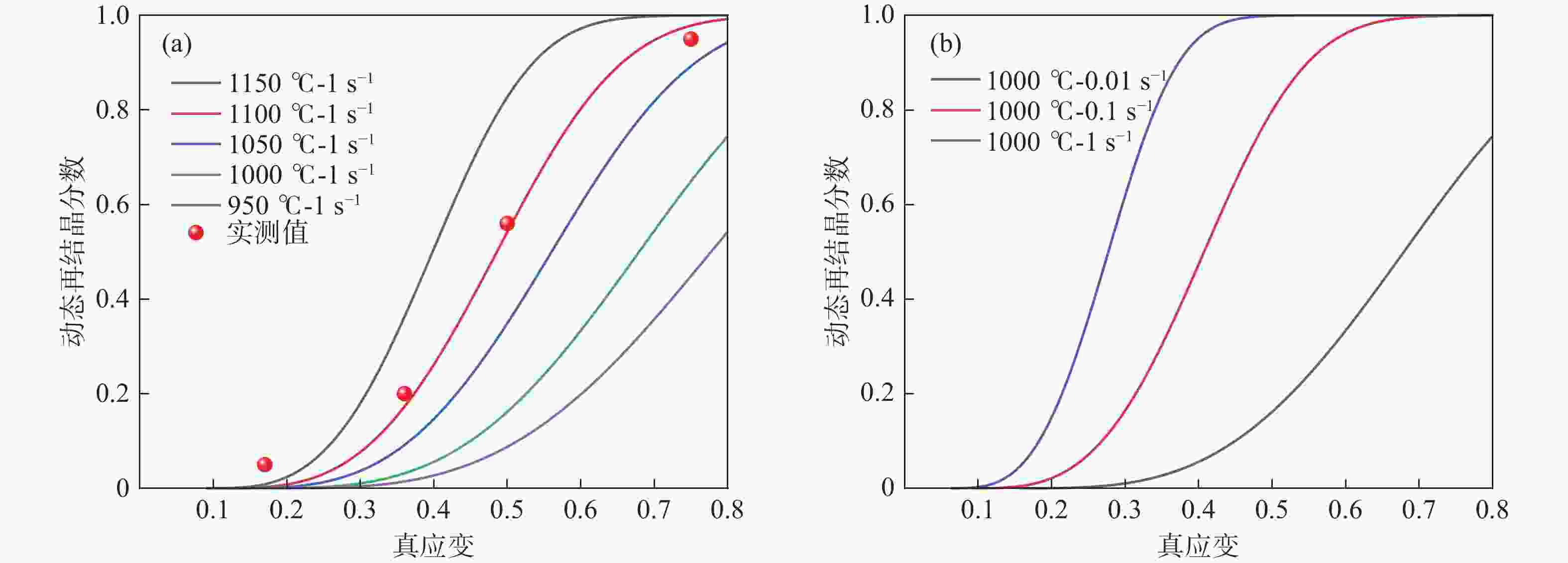

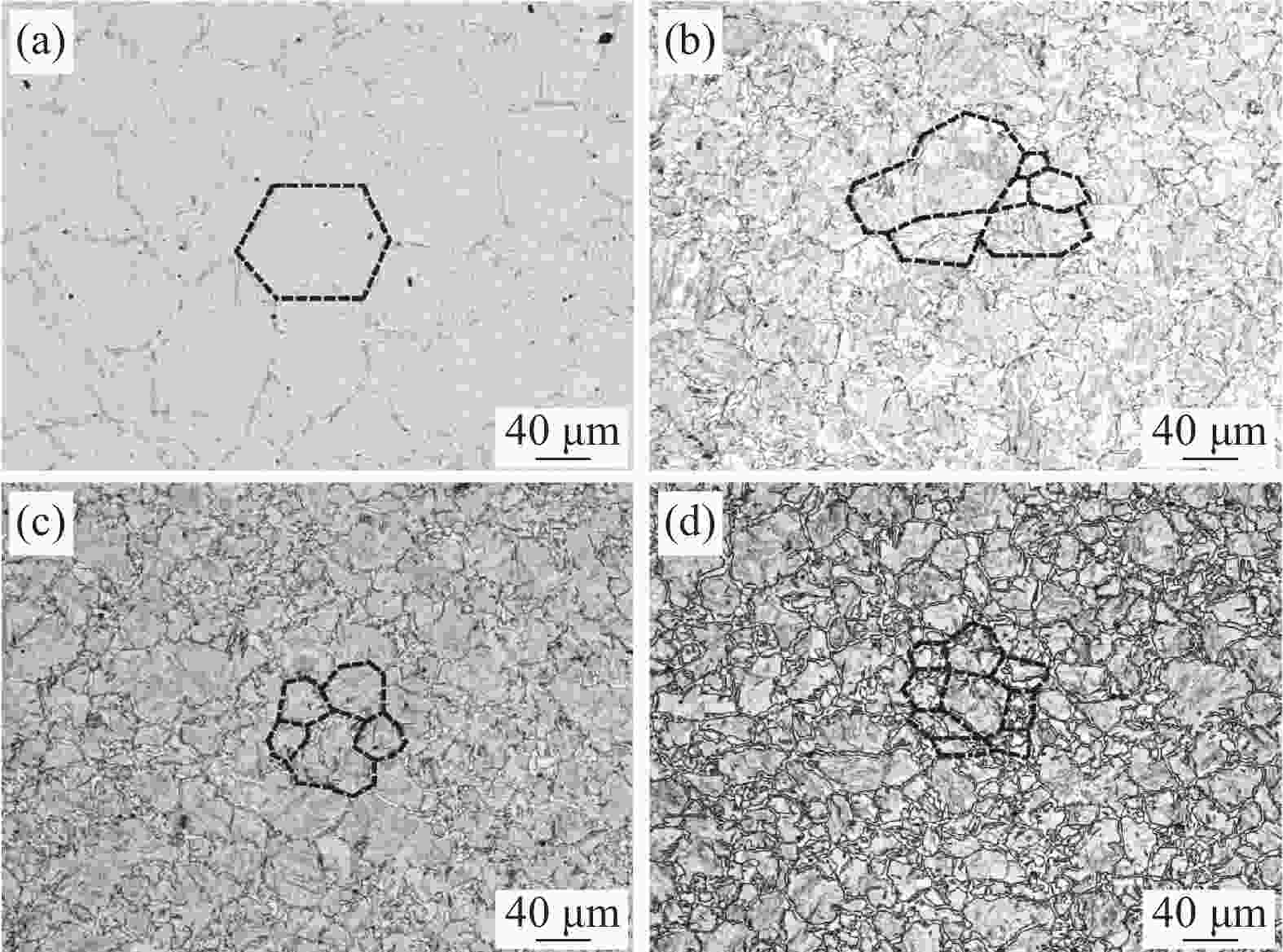

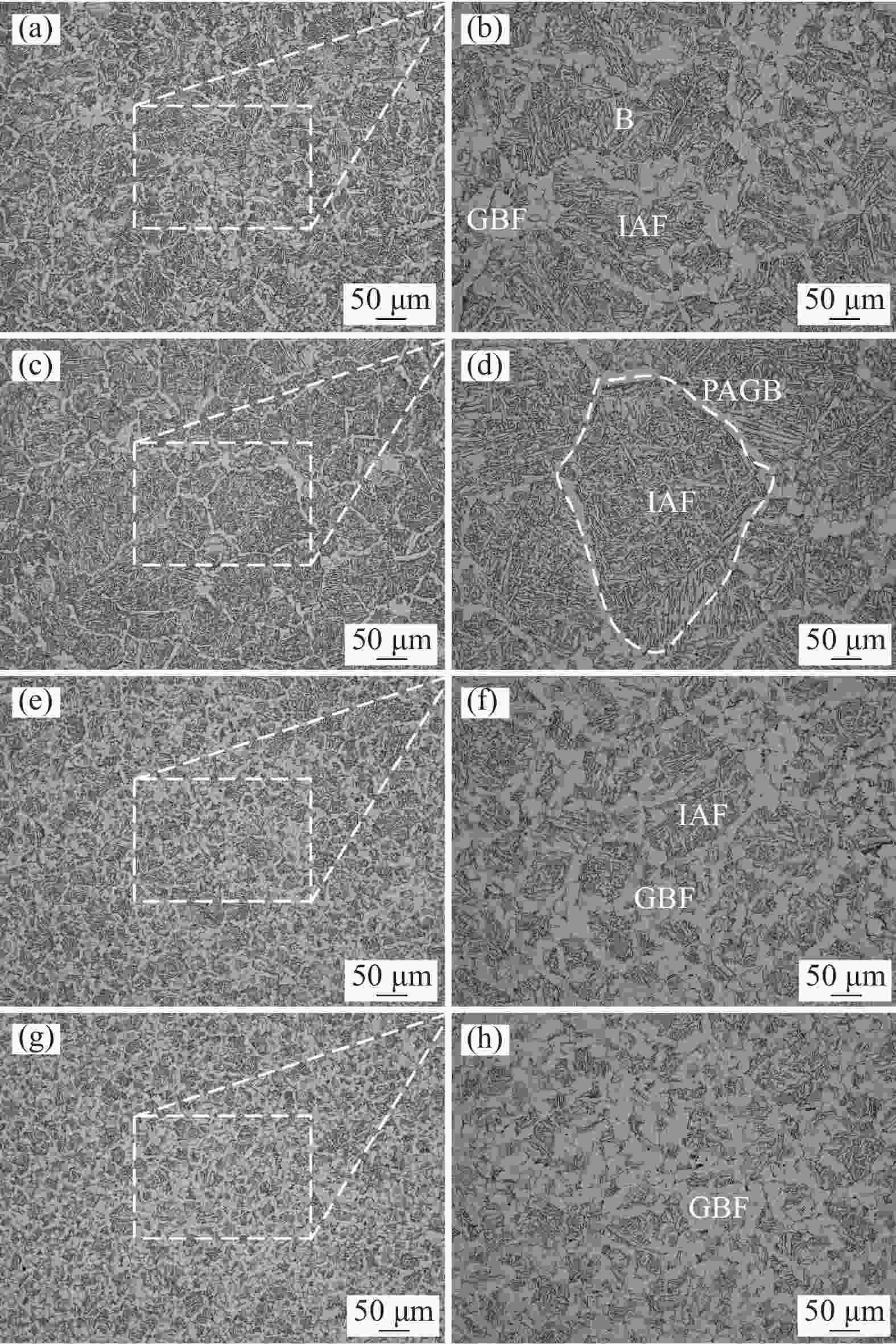

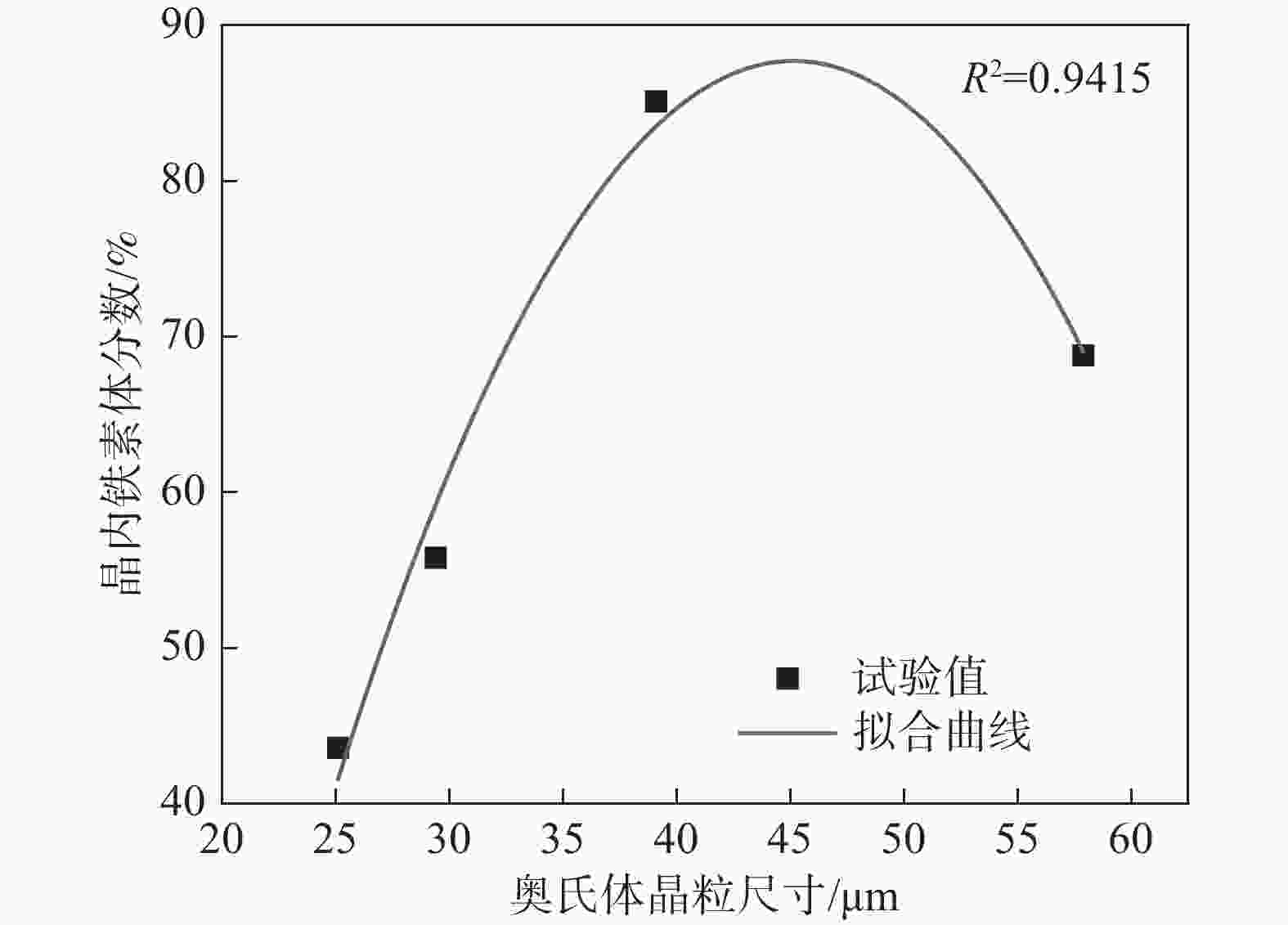

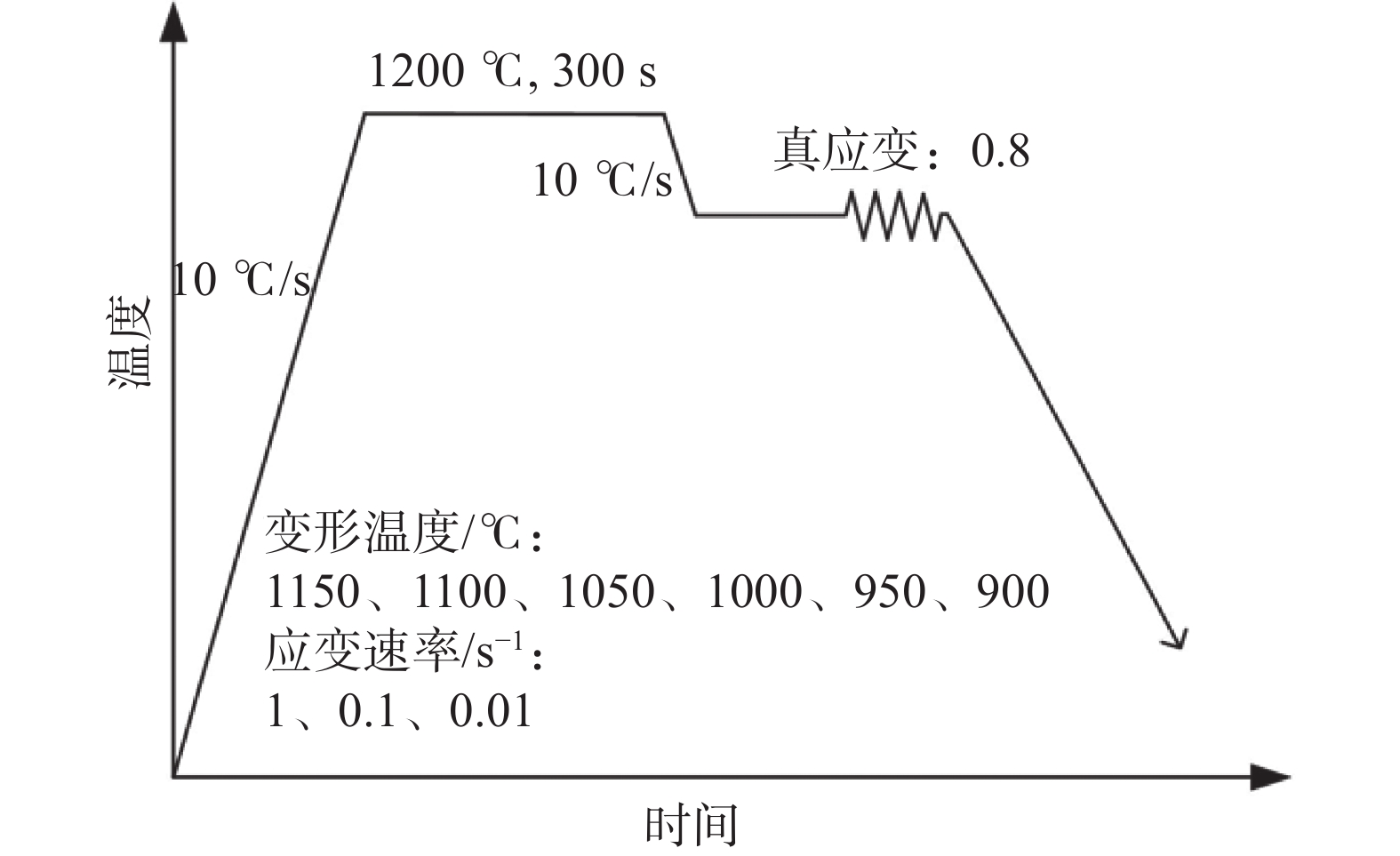

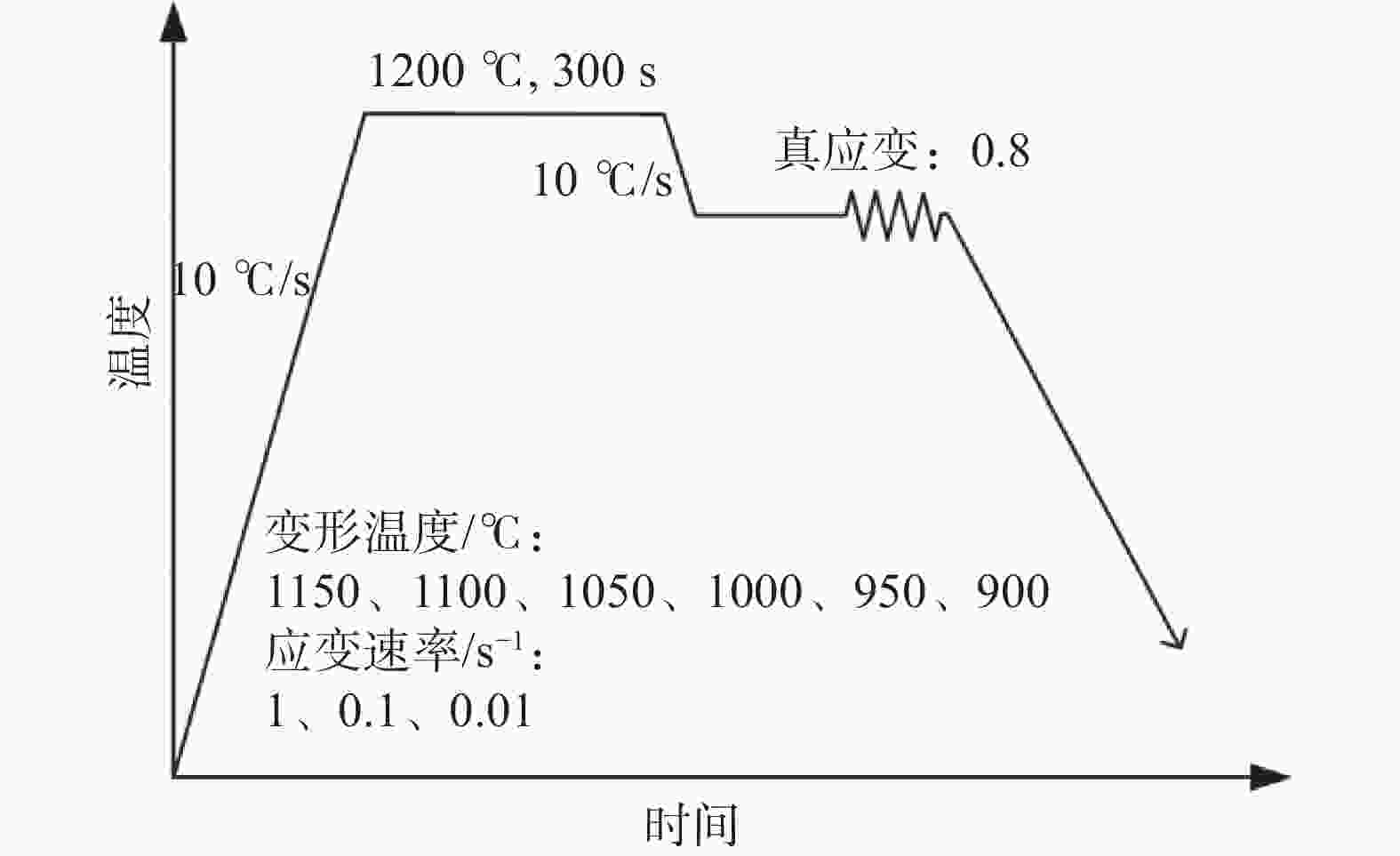

利用DIL805A/D变形热膨胀相变仪进行试验,建立了钒微合金钢不同变形温度和应变速率下的动态再结晶动力学模型,并通过组织分析与模型对比的方式研究了钒微合金钢晶内铁素体组织随动态再结晶晶粒尺寸的变化规律。结果表明:钒微合金钢的奥氏体动态再结晶晶粒尺寸对晶内铁素体相变具有一定影响,二者之间呈现抛物线关系。晶粒尺寸过大和较小均会造成晶界组织过度长大,不利于晶内铁素体组织形核。当奥氏体晶粒尺寸为40~50 μm时晶内铁素体形核能力最强,晶内组织细化效果明显。

Abstract:A dynamic recrystallization kinetics model of vanadium microalloyed steel at different deformation temperatures and strain rates was established using the DIL805A/D dilatometers for experiments. The variation of ferrite structure in vanadium microalloyed steel with dynamic recrystallization grain size was studied through microstructure analysis and model comparison. The results indicate that the dynamic recrystallization grain size of austenite in vanadium microalloyed steel has a certain impact on the transformation of intragranular ferrite, and there is a parabolic relationship between the two issues. Both large and small grain sizes can cause excessive growth of grain boundary structures, which is not conducive to the nucleation of intragranular ferrite structures. When the austenite grain size is 40-50 μm, the nucleation ability of intragranular ferrite is the strongest, and the refinement effect of intragranular structure is significant.

-

表 1 钒微合金钢的化学成分

Table 1. Chemical composition of V-microalloyed steel

% C Si Mn P S V N 0.175 0.613 1.57 0.024 0.026 0.107 0.006 -

[1] LLANOS L, PEREDA B, RODRIGUEZ-IBABE J M, et al. Effect of V microalloying in the hot working behavior of high Mn TWIP steels[J]. Iron Steel Vanadium Titanium, 2015,36(6):68-73, 93. (LLANOS L, PEREDA B, RODRIGUEZ-IBABE J M, 等. 钒微合金化对高锰TWIP钢热加工行为的影响[J]. 钢铁钒钛, 2015,36(6):68-73, 93.LLANOS L, PEREDA B, RODRIGUEZ-IBABE J M, et al. Effect of V microalloying in the hot working behavior of high Mn TWIP steels[J]. Iron Steel Vanadium Titanium, 2015, 36(6): 68-73, 93. [2] ISHIKAWA F, TAKAHASHI T, OCHI T. Intragranular ferrite nucleation in medium-carbon vanadium steels[J]. Metallurgical and Materials Transactions A, 1994,25(5):929-936. doi: 10.1007/BF02652268 [3] HU J, DU L, WANG J. Effect of V on intragranular ferrite nucleation of high Ti bearing steel[J]. Scripta Materialia, 2013,68:953-956. doi: 10.1016/j.scriptamat.2013.02.037 [4] ZHANG S, HATTORI N, ENOMOTO M, et al. Ferrite nucleation at ceramic/austenite interfaces[J]. ISIJ International, 1996,36(10):1301-1309. doi: 10.2355/isijinternational.36.1301 [5] HU J. Transformation of intragranular nucleation ferrite and microstructural nano-structuring of V microalloyed steel[D]. Shenyang: Northeastern University, 2014. (胡军. V 微合金钢晶内形核铁素体相变及微观组织纳米化[D]. 沈阳: 东北大学, 2014.HU J. Transformation of intragranular nucleation ferrite and microstructural nano-structuring of V microalloyed steel[D]. Shenyang: Northeastern University, 2014. [6] LIANG D M, ZHU Z Y, ZHOU L X, et al. Acicular ferrite and its heterogeneous nucleation mechanism in steels[J]. Heat Treatment of Metals, 2011,36(12):105-111. (梁冬梅, 朱远志, 周立新, 等. 钢中针状铁素体及其非均匀形核机制[J]. 金属热处理, 2011,36(12):105-111.LIANG D M, ZHU Z Y, ZHOU L X, et al. Acicular ferrite and its heterogeneous nucleation mechanism in steels[J]. Heat Treatment of Metals, 2011, 36(12): 105-111. [7] LI J W. Effect of austenitizing thermal treatment process on phase transformation of acicular ferrite induced by Ti-Mg oxide in low-carbon steel[D]. Shenyang: Northeastern University, 2021. (李家旺. 奥氏体化工艺对低碳钢中Ti-Mg氧化物诱导针状铁素体相变的影响[D]. 沈阳: 东北大学, 2021.LI J W. Effect of austenitizing thermal treatment process on phase transformation of acicular ferrite induced by Ti-Mg oxide in low-carbon steel[D]. Shenyang: Northeastern University, 2021. [8] LIU J, ZHANG K J, LU J S, et al. Strengthening mechanism and application of microalloying element vanadium in plates[J]. Sichuan Metallurgy, 2009,31(2):15-18. (刘健, 张开坚, 陆建生, 等. 微合金元素钒在钢板中的强化机理及应用[J]. 四川冶金, 2009,31(2):15-18.LIU J, ZHANG K J, LU J S, et al. Strengthening mechanism and application of microalloying element vanadium in plates[J]. Sichuan Metallurgy, 2009, 31(2): 15-18. [9] YIN G Q, HUANG Z Y, YANG C F, et al. Effects of nitrogen content and TMCP on microstructure and mechanical properties of V-N micro-alloying steel[J]. Heat Treatment of Metals, 2008,33(3):4-8. (尹桂全, 黄贞益, 杨才福, 等. 氮含量和TMCP对微合金V-N钢显微组织和力学性能的影响[J]. 金属热处理, 2008,33(3):4-8.YIN G Q, HUANG Z Y, YANG C F, et al. Effects of nitrogen content and TMCP on microstructure and mechanical properties of V-N micro-alloying steel[J]. Heat Treatment of Metals, 2008, 33(3): 4-8. [10] WAN X L, WU K M, NUNE K C, et al. In situ observation of acicular ferrite formation and grain refinement in simulated heat affected zone of high strength low alloy steel[J]. Science and Technology of Welding and Joining, 2015,20(3):254-263. doi: 10.1179/1362171815Y.0000000008 [11] LEE J L, PAN Y T. The formation of intragranular acicular ferrite in simulated heat-affected zone[J]. ISIJ International, 1995,35(8):1027-1033. doi: 10.2355/isijinternational.35.1027 [12] ZHOU X G, WANG X X, LI X, et al. Modeling of the dynamic recrystallization of Ti microalloyed high-strength steel[J]. Steel Research International, 2022,93(6):2100461. doi: 10.1002/srin.202100461 [13] POLIAK E I, JONAS J J. Initiation of dynamic recrystallization in constant strain rate hot deformation[J]. ISIJ International, 2003,43(5):684-691. doi: 10.2355/isijinternational.43.684 [14] WAHABI M, CABRERA J M, PRADO J M. Hot working of two AISI 304 steels: a comparative study[J]. Materials Science and Engineering A, 2003,343(1):116-125. [15] CHEN Q Y, ZHOU X G, LIU Z Y, et al. Microstructure and properties of Ti microalloyed automobile frame steel 510L[J]. Journal of Northeastern University (Natural Science Edition), 2018, 39(3): 339-344. (陈其源, 周晓光, 刘振宇, 等. Ti微合金化汽车大梁钢510L的组织性能[J]. 东北大学学报(自然科学版), 2018, 39(3): 339-344.CHEN Q Y, ZHOU X G, LIU Z Y, et al. Microstructure and properties of Ti microalloyed automobile frame steel 510L[J]. Journal of Northeastern University (Natural Science Edition), 2018, 39(3): 339-344. [16] BHADESHIA H K D H, EDMONDS D V. The mechanism of bainite formation in steels[J]. Acta Metallurgica, 1980,28(9):1265-1273. doi: 10.1016/0001-6160(80)90082-6 -

下载:

下载: