Research on short-process vanadium extraction technology from stone coal based on phosphate-assisted leaching

-

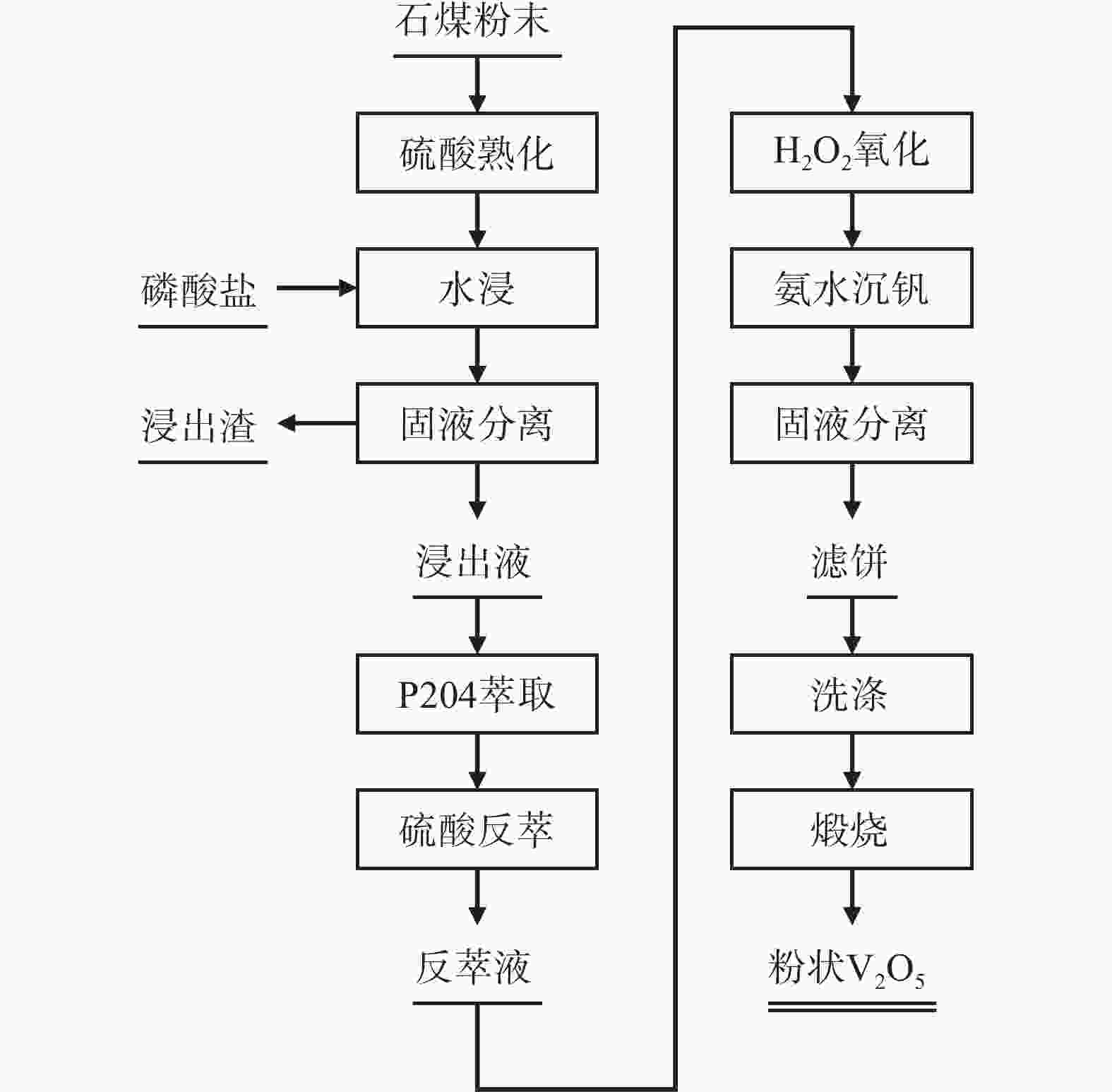

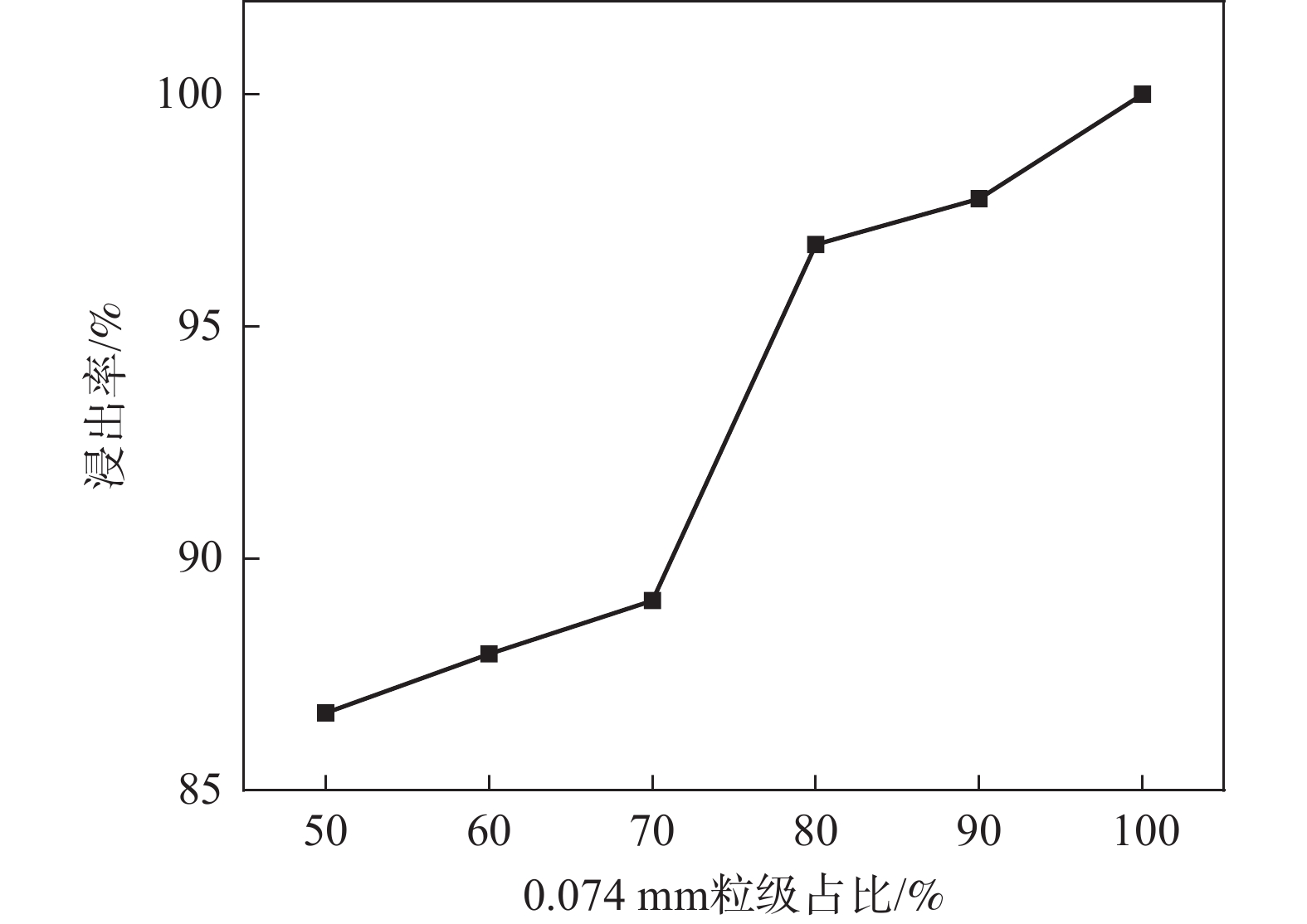

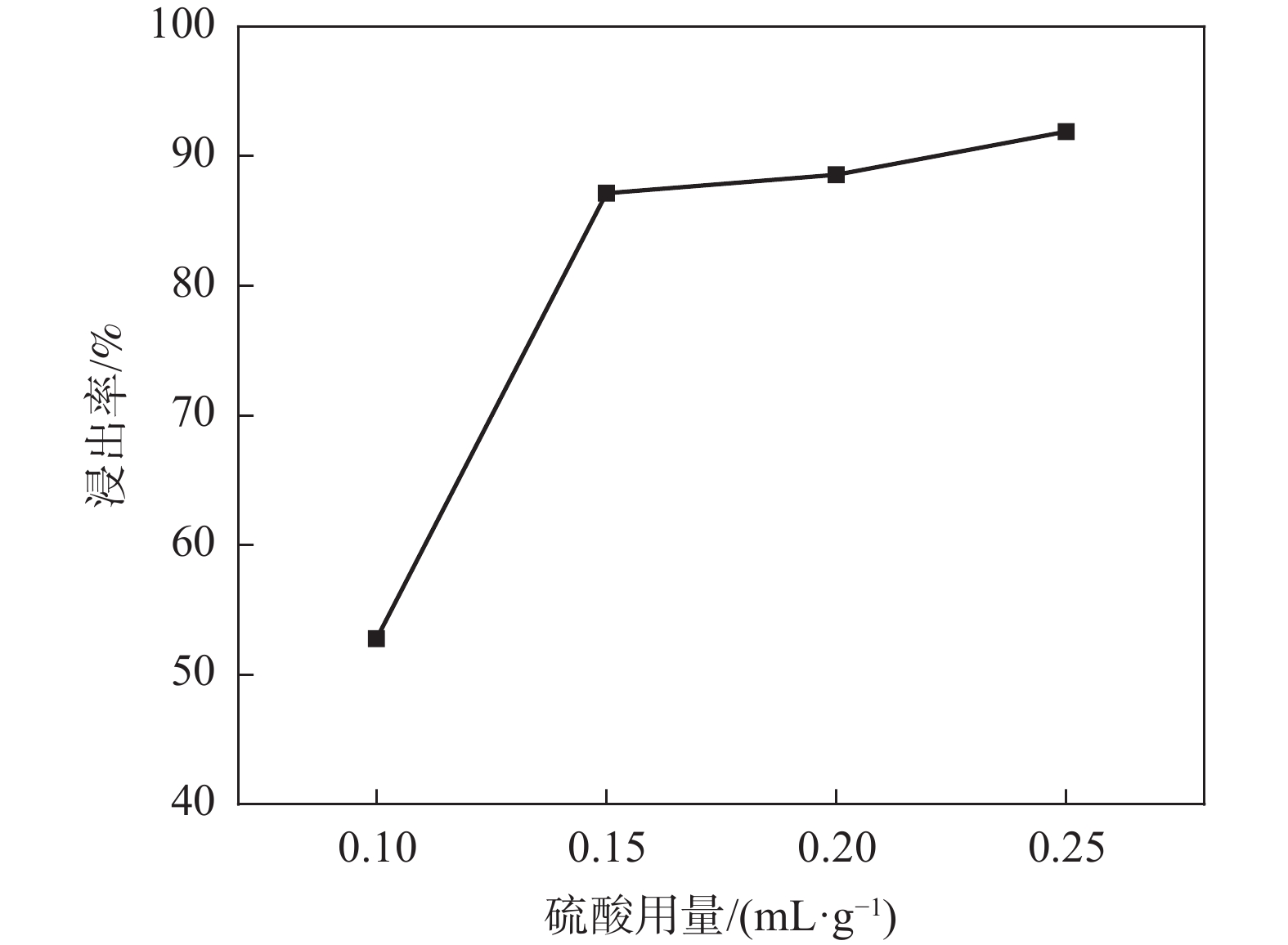

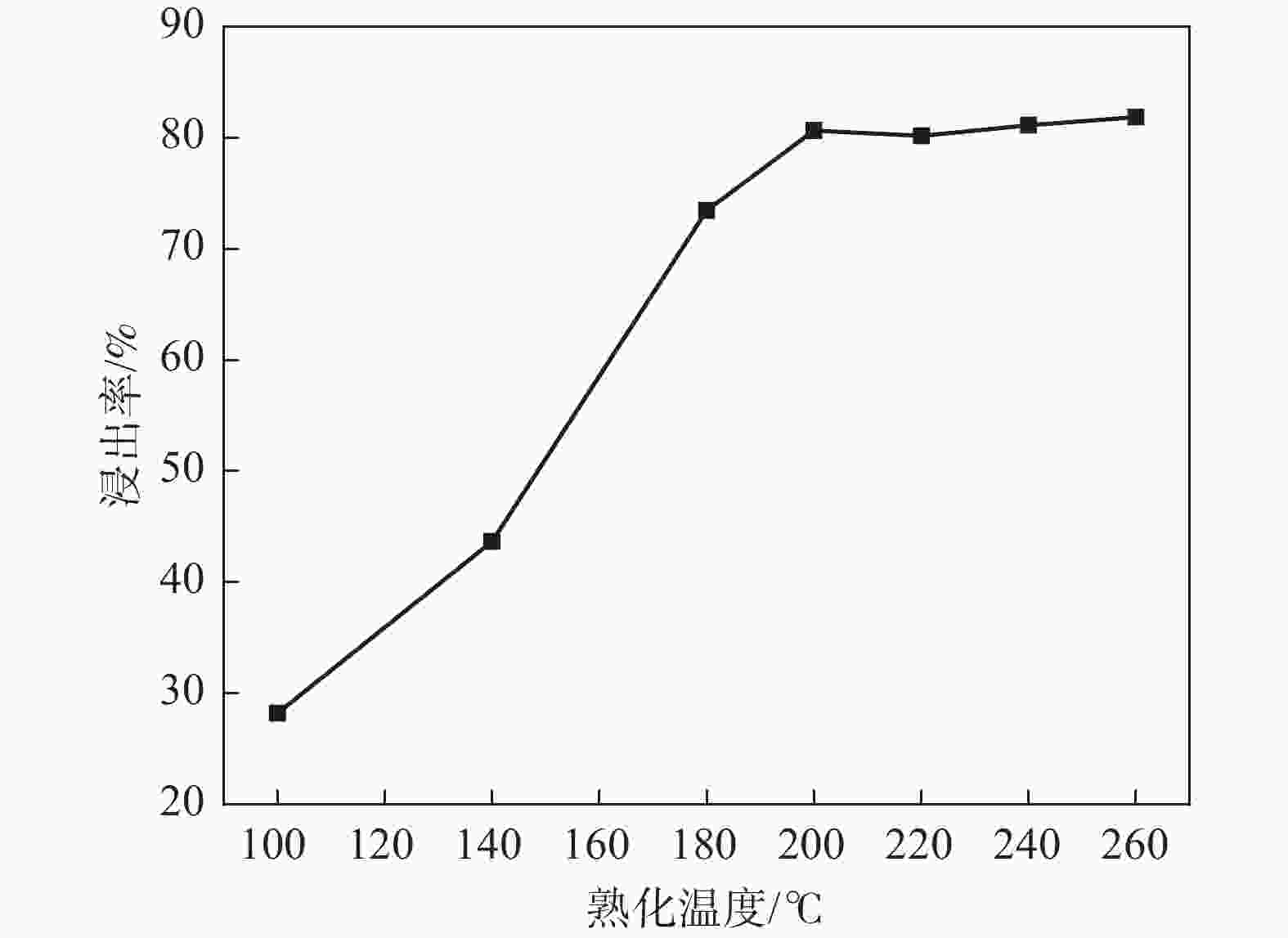

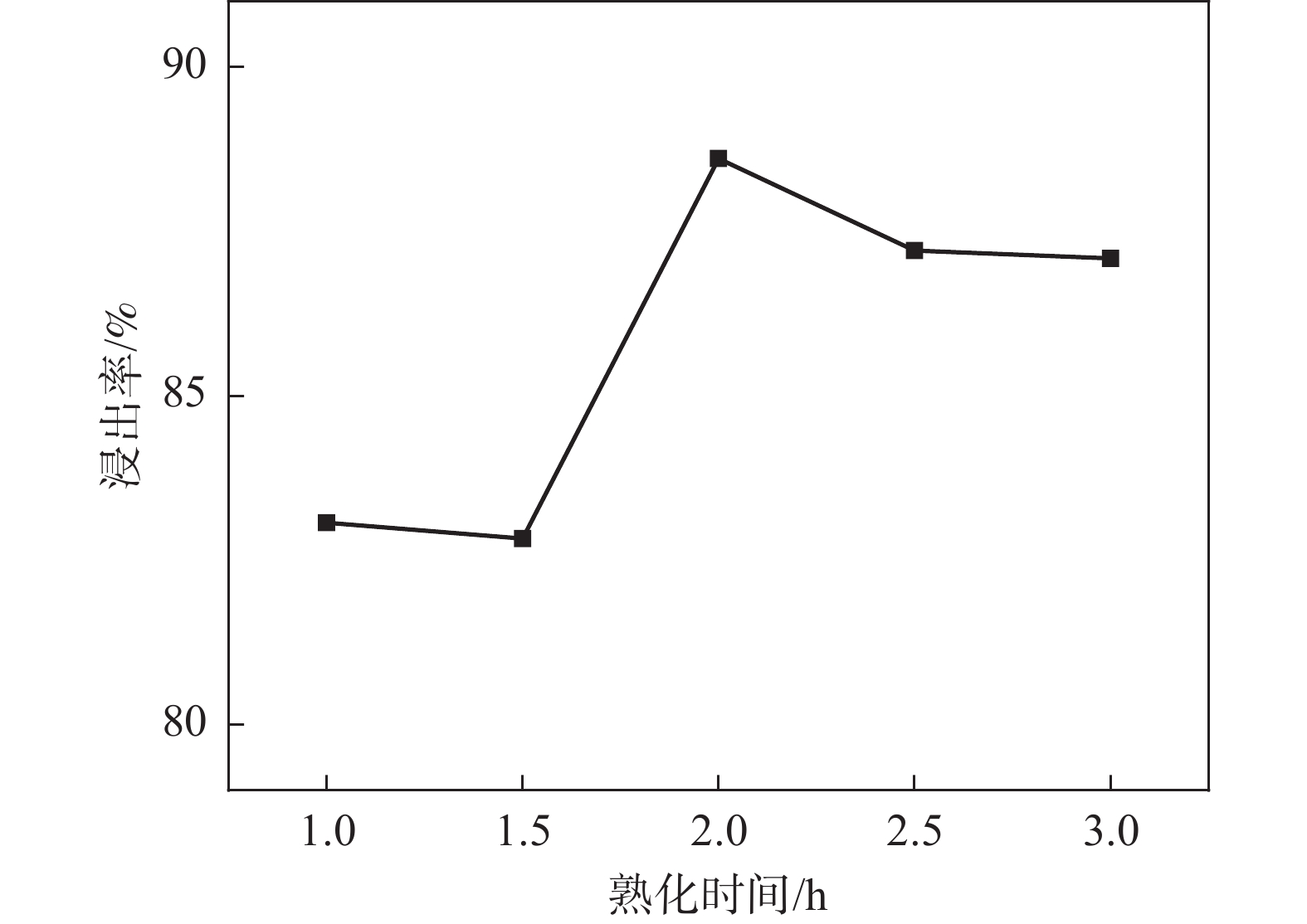

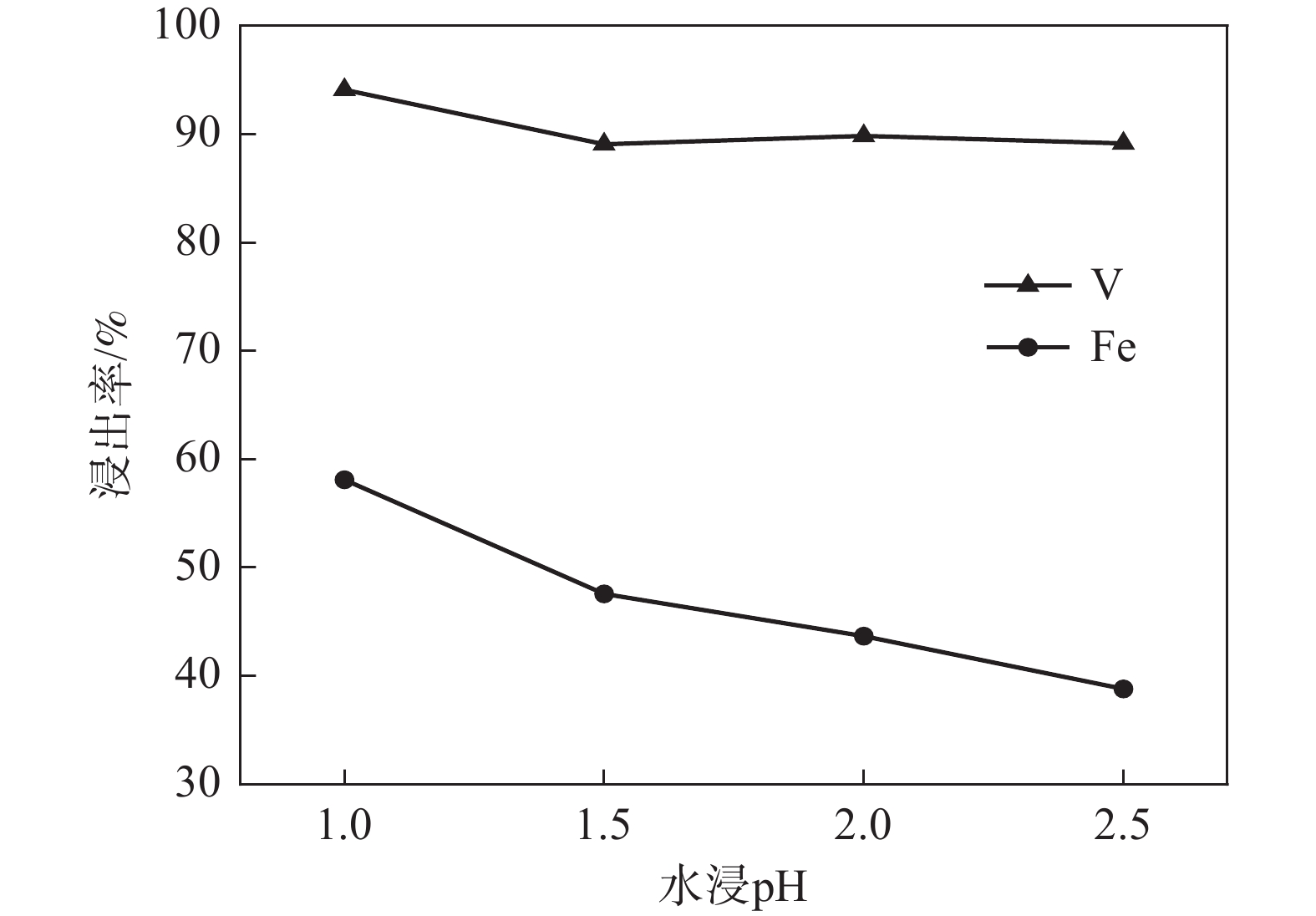

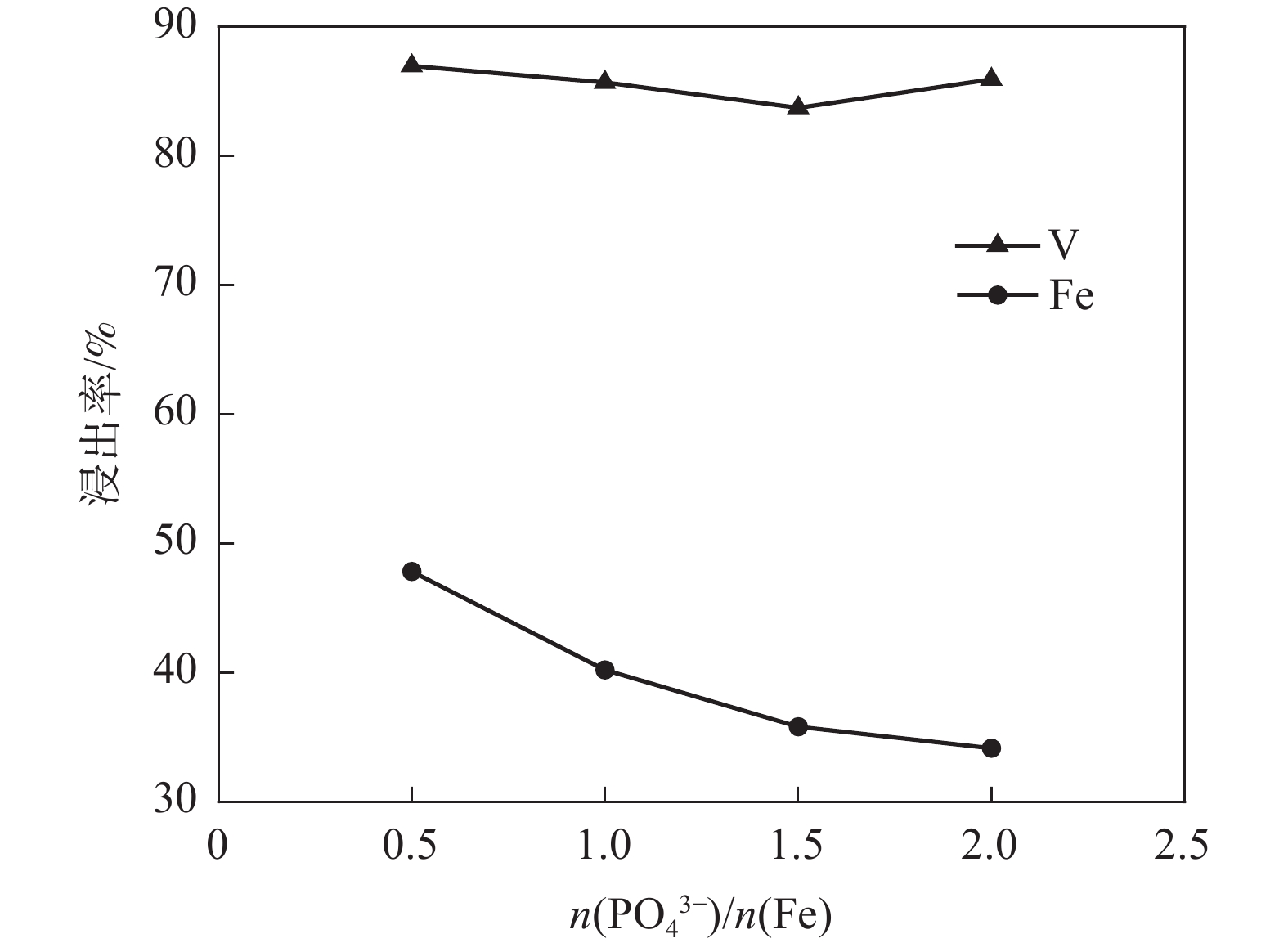

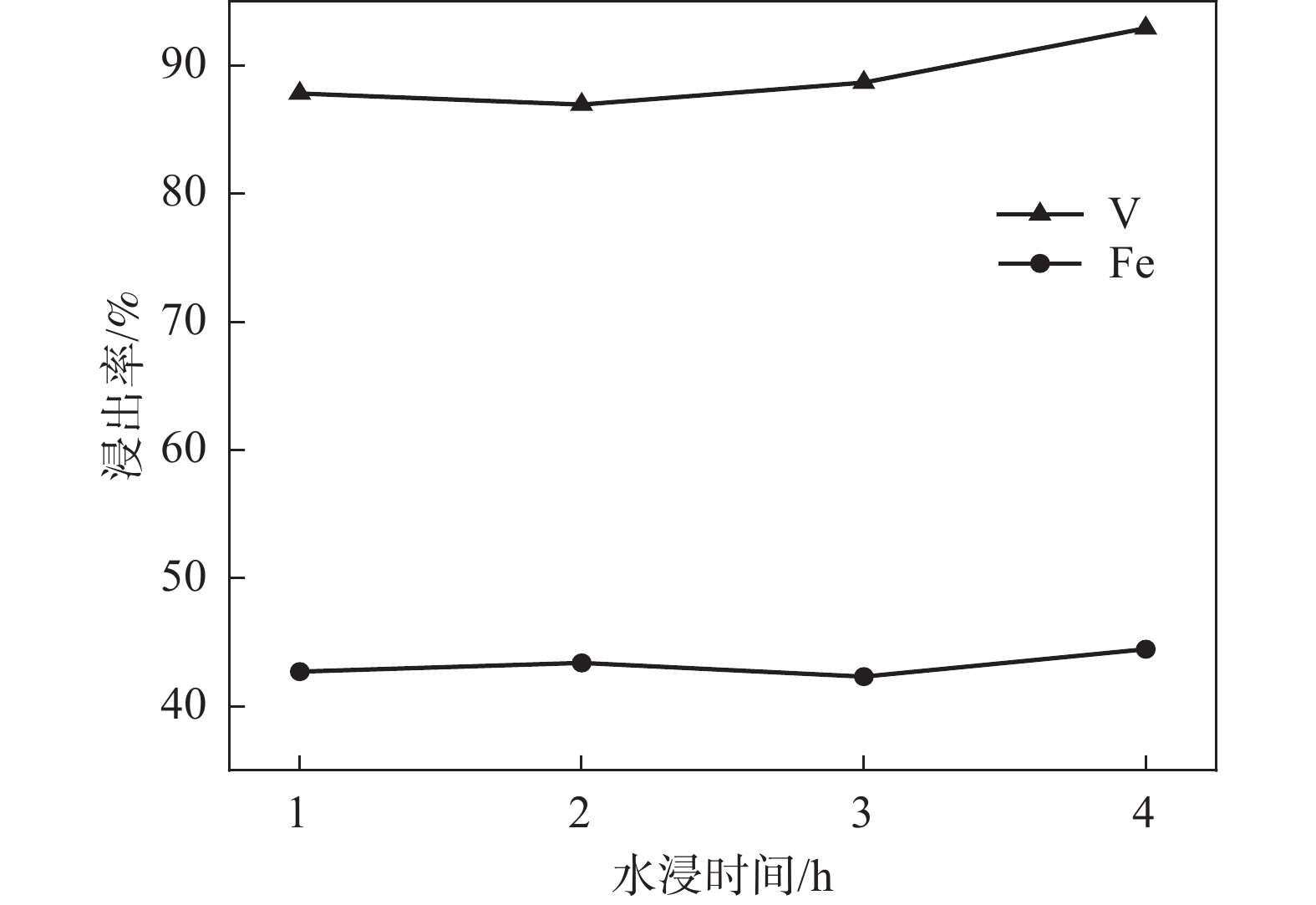

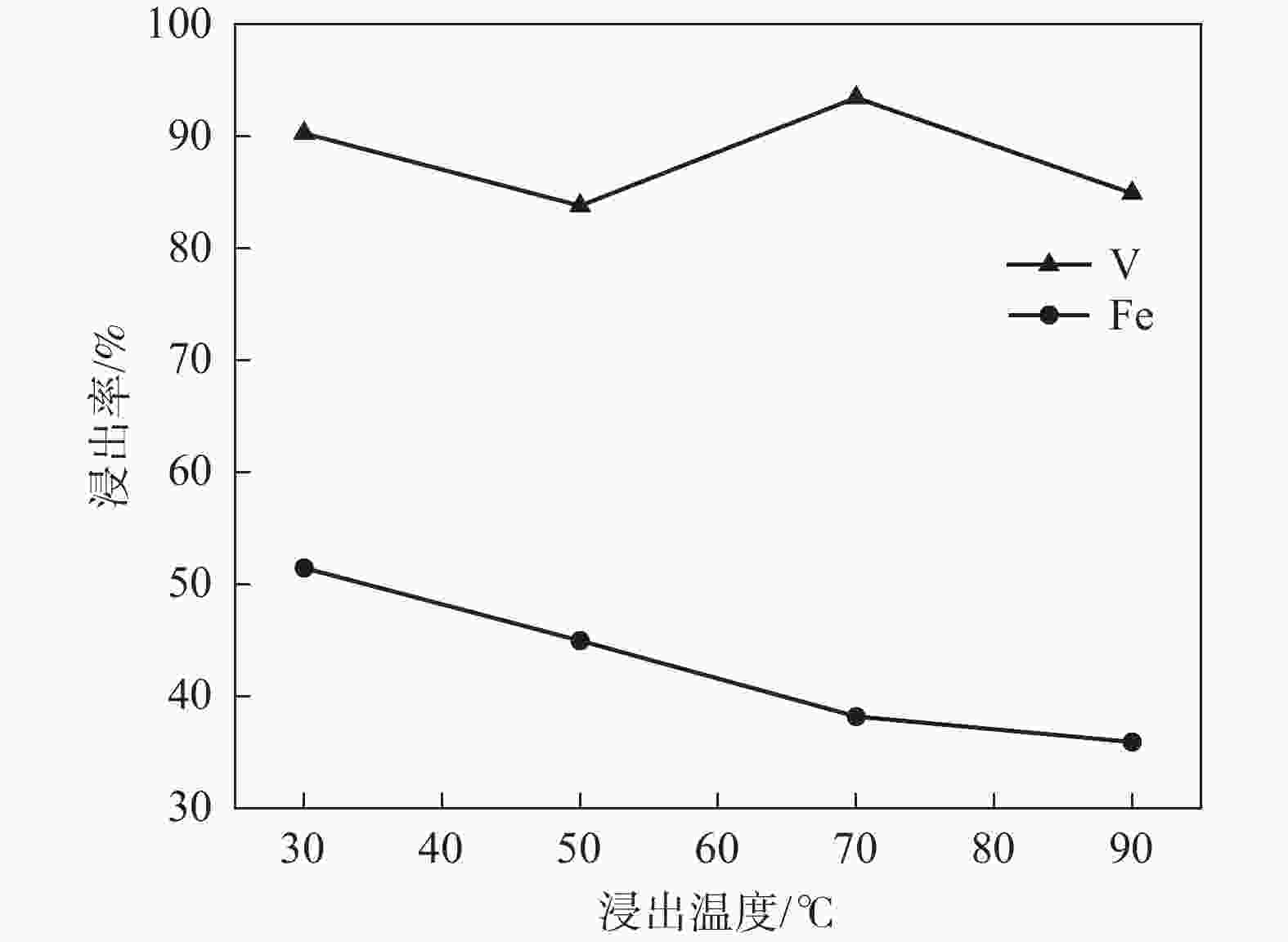

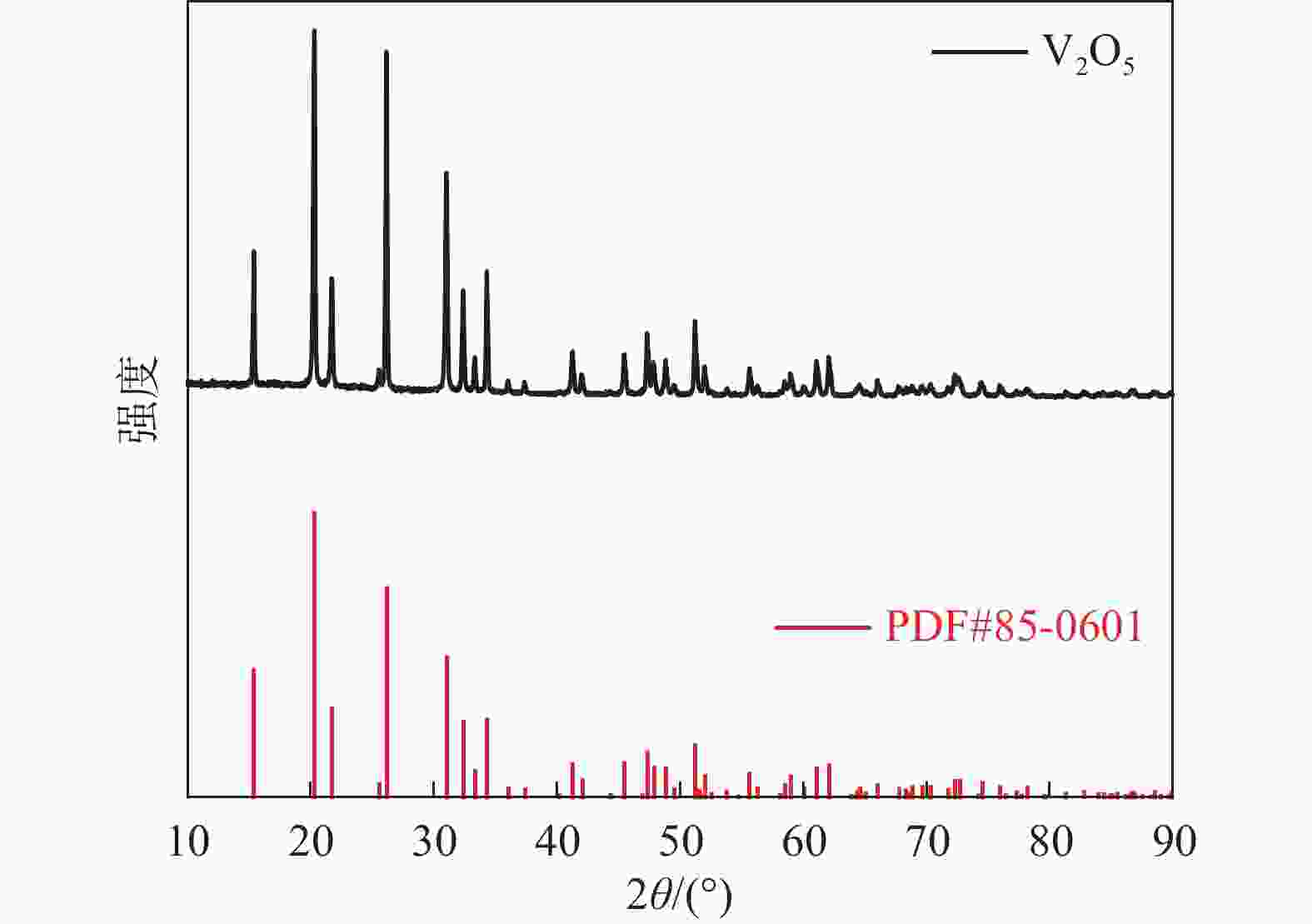

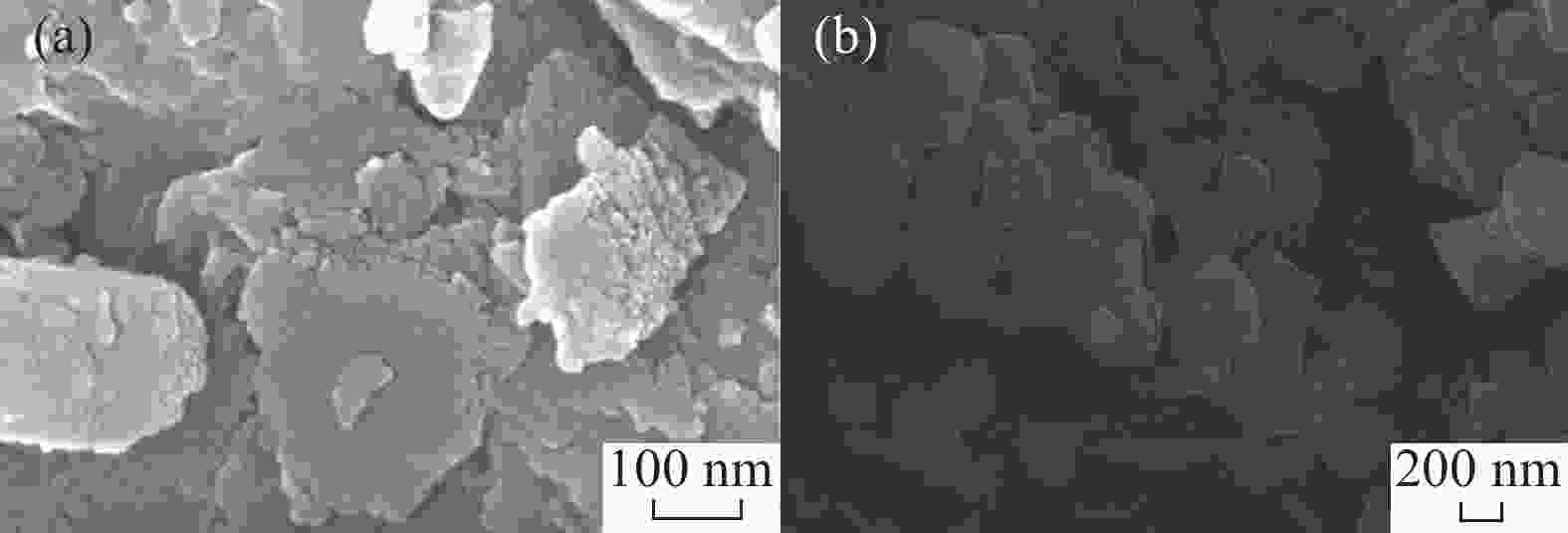

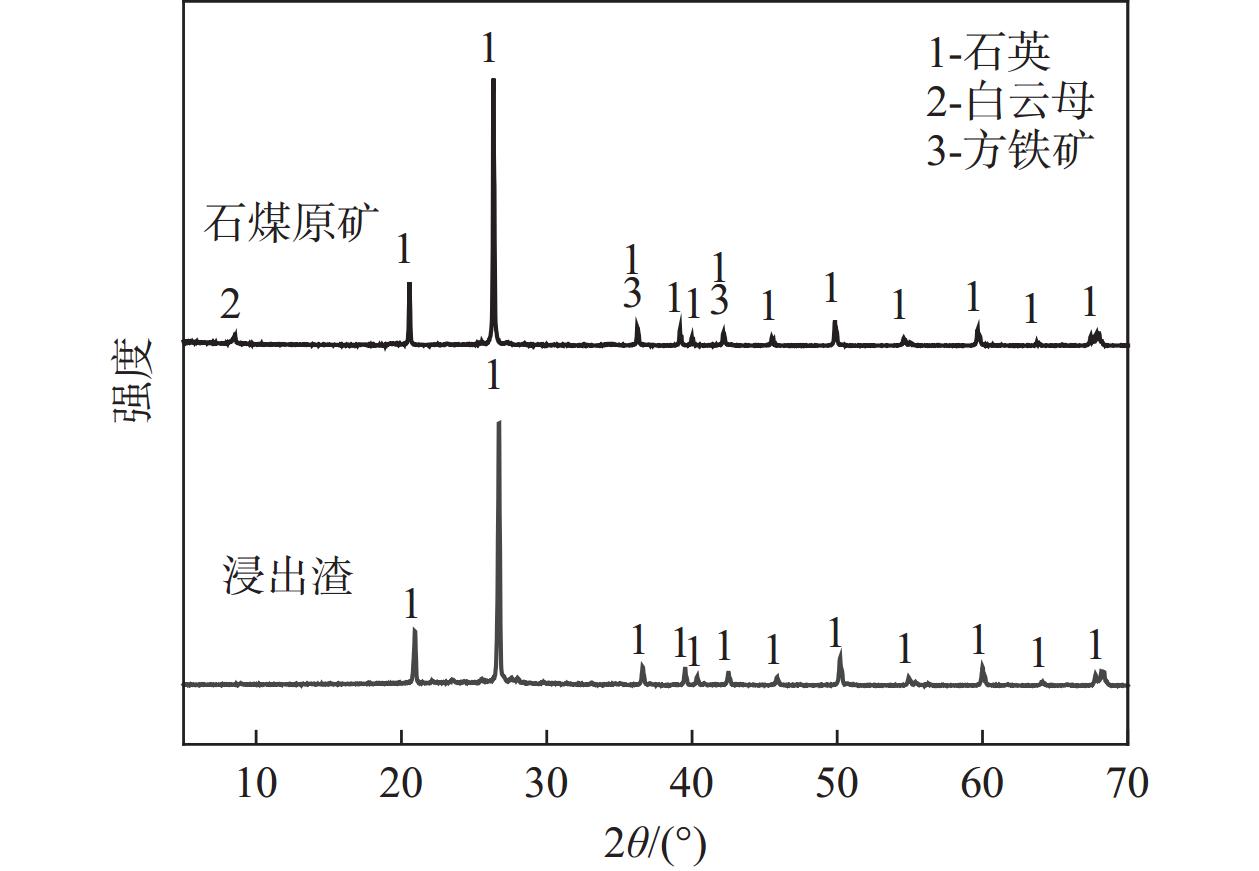

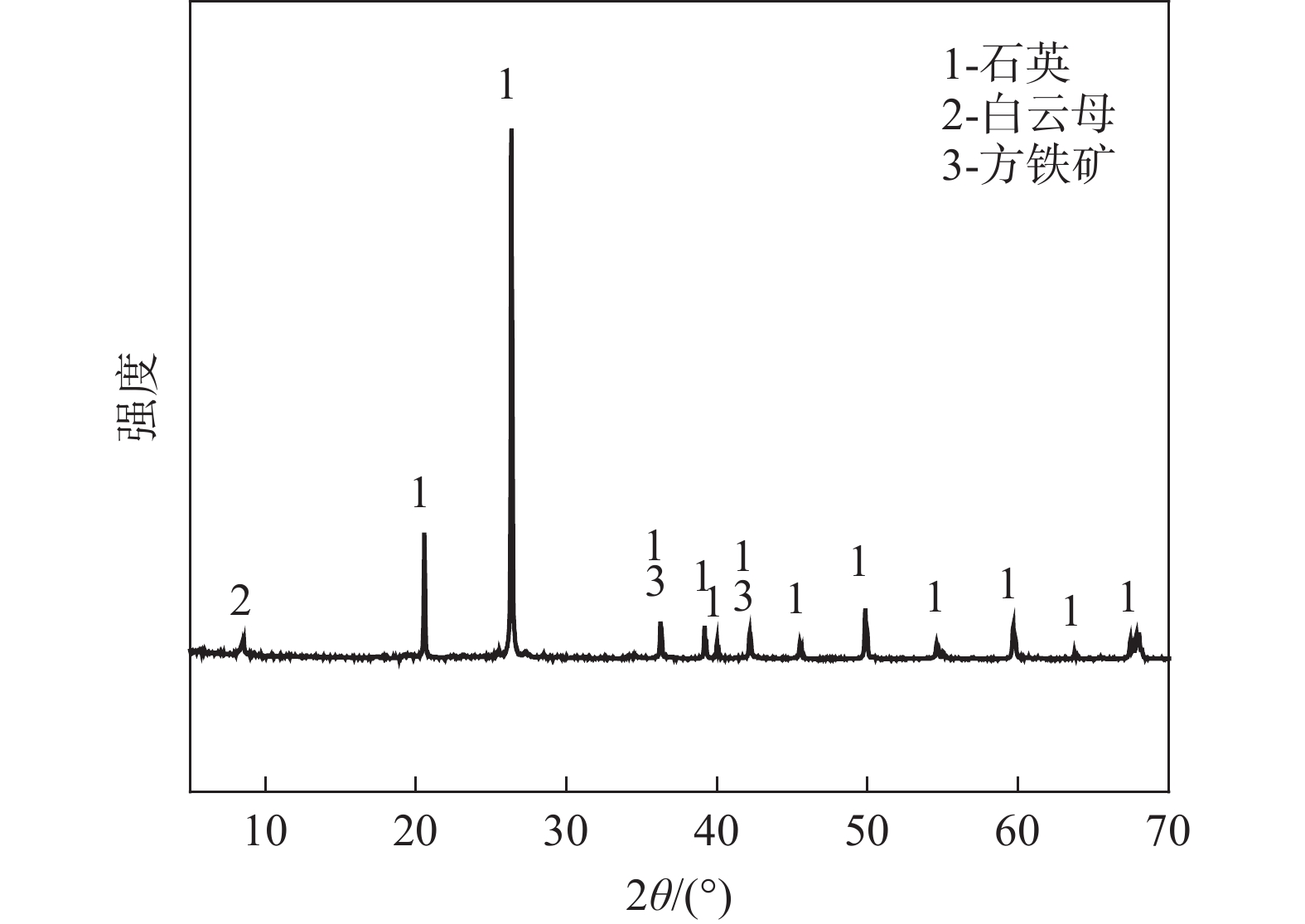

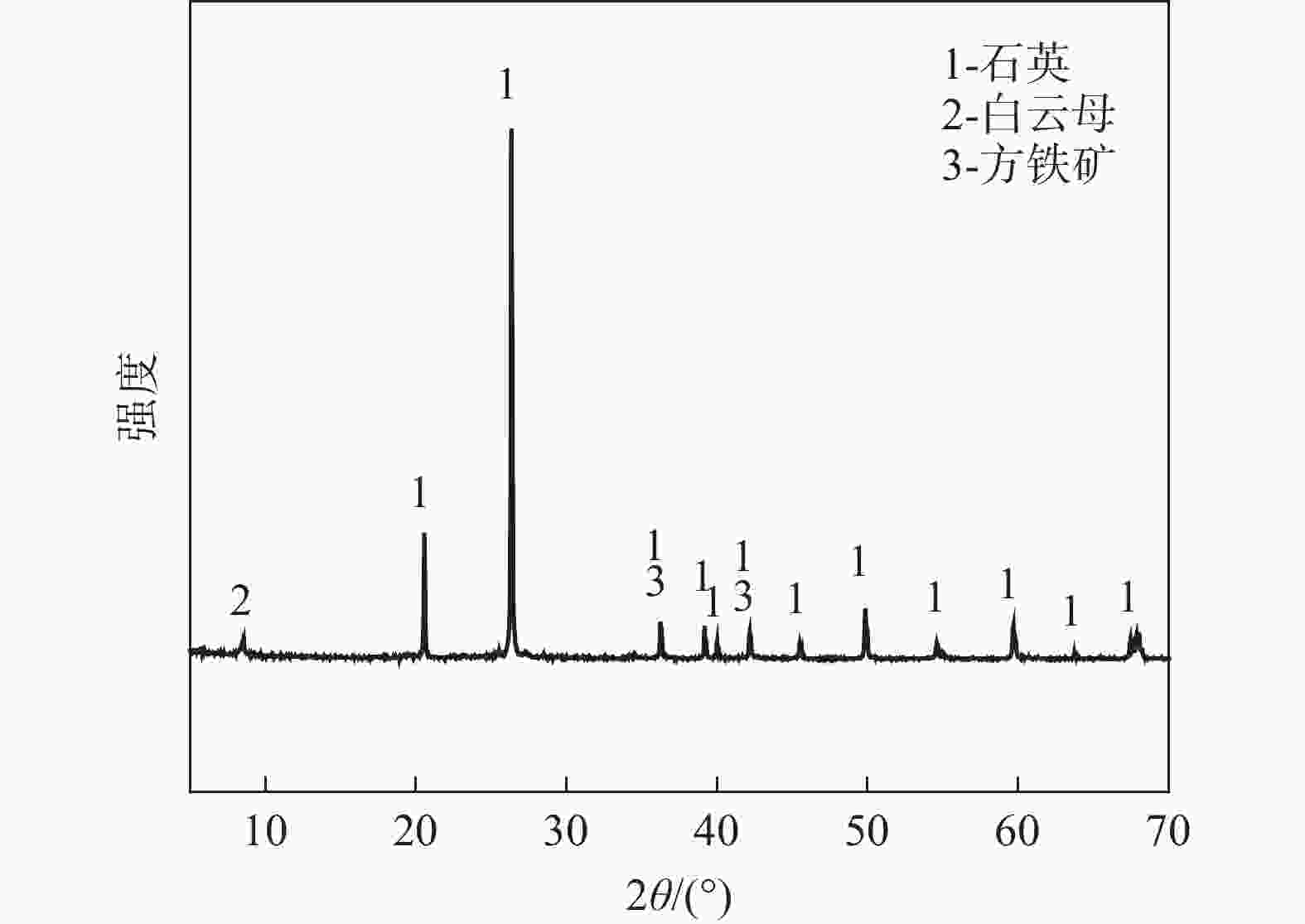

摘要: 针对湖北某石煤钒矿的矿相分析及传统处理流程,开发了一种磷酸盐辅助浸出的短流程提钒工艺,采用硫酸熟化—磷酸盐辅助浸出—溶剂萃取—氨水沉钒提钒工艺进行了提钒试验。研究了水浸pH、磷铁摩尔比、浸出时间、浸出温度对钒、铁浸出率的影响。结果表明,将粒度小于0.074 mm的原料在200 ℃和浓硫酸用量0.15 mL/g的条件下熟化2 h得到熟化样品,该熟化样品在水浸pH值2.5、磷铁摩尔比1.5:1、浸出时间1 h、浸出温度70 ℃的试验条件下,钒的浸出率可达93.44%,铁的浸出率为38.19%。采用P204萃取-硫酸反萃进行2段萃取-反萃,结合氨水沉钒工艺,成功制备出纯度大于99%的粉状五氧化二钒产品。该工艺提高了钒的浸出率,为石煤提钒提供了新的技术路线。Abstract: Aiming at the mineral phase analysis and traditional treatment process of a stone-coal vanadium mine in Hubei, a short-flow vanadium extraction process with phosphate-assisted leaching was developed. The vanadium extraction process using sulfuric acid curing - phosphate-assisted leaching - solvent extraction - vanadium precipitation using ammonia water was carried out for vanadium extraction experiments. The effects of water leaching pH, phosphorus-iron molar ratio, leaching time and temperature on the leaching rate of vanadium and iron were investigated, respectively. The results showed that the cured sample was obtained by curing the raw material with particle size less than 0.074 mm at 200 ℃ and the dosage of 0.15 mL/g of concentrated sulfuric acid for 2 h. The cured sample could leach up to 93.44% of vanadium and 38.19% of iron under the experimental conditions of aqueous leaching pH 2.5, phosphorus-iron molar ratio of 1.5:1, leaching time of 1 h, and leaching temperature of 70 ℃. A powdered vanadium pentoxide product with purity greater than 99% was successfully prepared by using P204 extraction and sulfuric acid stripping for 2-stage extraction and stripping, combined with ammonia vanadium precipitation process. This process improves the leaching rate of vanadium and provides a new technical route for vanadium extraction from stone coal.

-

表 1 原矿主要化学成分

Table 1. The main chemical composition of the raw ore

% V2O5 Fe2O3 Al2O3 SiO2 MgO K2O SO3 BaO P2O5 CaO Cr2O3 2.238 2.274 6.911 81.121 0.953 1.610 1.623 1.799 0.895 0.222 0.139 表 2 V2O5产品的化学成分

Table 2. Chemical composition of V2O5 product

% V2O5 SiO2 Fe2O3 P2O5 SO3 CaO MgO Na2O >99 0.031 0.060 0.050 0.119 0.009 0.002 0.018 -

[1] CHEN X X. Fundamental studies on the leaching and separation of V3+ from iron vanadate spinel minerals[D]. Beijing: University of Science and Technology Beijing, 2021. (陈学鑫. 钒铁尖晶石型精矿中V3+直接浸出分离的基础研究[D]. 北京:北京科技大学, 2021.CHEN X X. Fundamental studies on the leaching and separation of V3+ from iron vanadate spinel minerals[D]. Beijing: University of Science and Technology Beijing, 2021. [2] REN X Y. Application status and market prospects of rare metal vanadium[J]. Chinese Journal of Rare Metals, 2003(6):809-812. (任学佑. 稀有金属钒的应用现状及市场前景[J]. 稀有金属, 2003(6):809-812. doi: 10.3969/j.issn.0258-7076.2003.06.032REN X Y. Application status and market prospects of rare metal vanadium[J]. Chinese Journal of Rare Metals, 2003(6): 809-812. doi: 10.3969/j.issn.0258-7076.2003.06.032 [3] QU J W, MA N, HU Y F, et al. Current situation of vanadium resources and new process progress of vanadium extraction from the stone coal vanadium ore[J]. Multipurpose Utilization of Mineral Resources, 2025,46(1):194-199. (瞿金为, 马娜, 胡月芳, 等. 钒资源现状与石煤钒矿提钒新工艺进展[J]. 矿产综合利用, 2025,46(1):194-199. doi: 10.3969/j.issn.1000-6532.2025.01.026QU J W, MA N, HU Y F, et al. Current situation of vanadium resources and new process progress of vanadium extraction from the stone coal vanadium ore[J]. Multipurpose Utilization of Mineral Resources, 2025, 46(1): 194-199. doi: 10.3969/j.issn.1000-6532.2025.01.026 [4] GAO Y Z. Vanadium resources and it’s supply and demand situation in China[J]. China Mining Magazine, 2019,28(S2):5-10. (高永璋. 中国钒矿资源及供需形势分析[J]. 中国矿业, 2019,28(S2):5-10.GAO Y Z. Vanadium resources and it’s supply and demand situation in China[J]. China Mining Magazine, 2019, 28(S2): 5-10. [5] ZHANG Y M, BAO S X, LIU T, et al. Research status and prospect of vanadium extraction from stone coal in China[J]. Nonferrous Metals(Extractive Metallurgy), 2015(2):24-30. (张一敏, 包申旭, 刘涛, 等. 我国石煤提钒研究现状及发展[J]. 有色金属(冶炼部分), 2015(2):24-30.ZHANG Y M, BAO S X, LIU T, et al. Research status and prospect of vanadium extraction from stone coal in China[J]. Nonferrous Metals(Extractive Metallurgy), 2015(2): 24-30. [6] CHEN F, ZHANG Y M, HUANG J, et al. Effect of manganese dioxide on direct acid leaching of extracting vanadium from stone coal[J]. Chemical Industry and Engineering Progress, 2017,36(3):1126-1133. (陈放, 张一敏, 黄晶, 等. 二氧化锰对石煤提钒直接酸浸的影响[J]. 化工进展, 2017,36(3):1126-1133.CHEN F, ZHANG Y M, HUANG J, et al. Effect of manganese dioxide on direct acid leaching of extracting vanadium from stone coal[J]. Chemical Industry and Engineering Progress, 2017, 36(3): 1126-1133. [7] HU Y J, ZHANG Y M. Effect of calcium content on vanadium extraction from black shale by sodium roasting-water leaching[J]. Nonferrous Metals(Extractive Metallurgy), 2014(9):34-38, 46. (胡杨甲, 张一敏. 钙含量对含钒页岩钠盐焙烧—水浸提钒的影响[J]. 有色金属(冶炼部分), 2014(9):34-38, 46.HU Y J, ZHANG Y M. Effect of calcium content on vanadium extraction from black shale by sodium roasting-water leaching[J]. Nonferrous Metals(Extractive Metallurgy), 2014(9): 34-38, 46. [8] ZHANG X G, GAO Y B, XU Q, et al. Vanadic anhydride extracted from stone coal by calcified roast and NaOH leaching[J]. Applied Chemical Industry, 2013,42(6):1026-1028, 1032. (张晓刚, 高永波, 徐强, 等. 石煤钒矿钙化焙烧碱浸提钒工艺的实验研究[J]. 应用化工, 2013,42(6):1026-1028, 1032.ZHANG X G, GAO Y B, XU Q, et al. Vanadic anhydride extracted from stone coal by calcified roast and NaOH leaching[J]. Applied Chemical Industry, 2013, 42(6): 1026-1028, 1032. [9] LI C L, ZHOU X Y, WANG H, et al. Effect of oxidation on vanadium extraction from stone coal with calcified roasting[J]. Journal of Central South University(Science and Technology), 2011,42(1):7-10. (李昌林, 周向阳, 王辉, 等. 强化氧化对石煤钙化焙烧提钒的影响[J]. 中南大学学报(自然科学版), 2011,42(1):7-10.LI C L, ZHOU X Y, WANG H, et al. Effect of oxidation on vanadium extraction from stone coal with calcified roasting[J]. Journal of Central South University(Science and Technology), 2011, 42(1): 7-10. [10] YANG X L. Study on the vanadium extraction by roasting from high carbon vanadium-bearing shale by using composite additives[D]. Beijing: University of Science and Technology Beijing, 2018. (杨鑫龙. 高碳含钒页岩复合添加剂焙烧提钒研究[D]. 北京:北京科技大学, 2018.YANG X L. Study on the vanadium extraction by roasting from high carbon vanadium-bearing shale by using composite additives[D]. Beijing: University of Science and Technology Beijing, 2018. [11] WANG B, LIU T, ZHANG Y M, et al. Effect of composite additives on roasting of stone coal for vanadium extraction[J]. Nonferrous Metals(Extractive Metallurgy), 2017(3):31-35. (汪博, 刘涛, 张一敏, 等. 钙质复合添加剂对石煤提钒焙烧效果的影响[J]. 有色金属(冶炼部分), 2017(3):31-35.WANG B, LIU T, ZHANG Y M, et al. Effect of composite additives on roasting of stone coal for vanadium extraction[J]. Nonferrous Metals(Extractive Metallurgy), 2017(3): 31-35. [12] ZHANG C Q, SUN C Y, YIN W Z, et al. Study on extracting vanadium by no additive roasting-acid leaching from a illite-type vanadium-containing stone coal[J]. China Mining Magazine, 2018,27(12):106-111. (张成强, 孙传尧, 印万忠, 等. 伊利石型含钒石煤无添加剂焙烧-酸浸提钒工艺研究[J]. 中国矿业, 2018,27(12):106-111. doi: 10.12075/j.issn.1004-4051.2018.12.025ZHANG C Q, SUN C Y, YIN W Z, et al. Study on extracting vanadium by no additive roasting-acid leaching from a illite-type vanadium-containing stone coal[J]. China Mining Magazine, 2018, 27(12): 106-111. doi: 10.12075/j.issn.1004-4051.2018.12.025 [13] FU Z B, ZHANG L, ZHANG T, et al. Research on extraction vanadium from stone coal by no salt roasting and acid leaching process[J]. Ferro-Alloys, 2009,40(6):24-27. (付自碧, 张林, 张涛, 等. 石煤无盐焙烧—酸浸提钒工艺试验研究[J]. 铁合金, 2009,40(6):24-27. doi: 10.3969/j.issn.1001-1943.2009.06.006FU Z B, ZHANG L, ZHANG T, et al. Research on extraction vanadium from stone coal by no salt roasting and acid leaching process[J]. Ferro-Alloys, 2009, 40(6): 24-27. doi: 10.3969/j.issn.1001-1943.2009.06.006 [14] SHI S, WU J X, TIAN Z W, et al. Extraction of vanadium from a clay-type stone coal by direct acid leaching[J]. China Molybdenum Industry, 2025,49(1):46-50. (史松, 吴金鑫, 田战武, 等. 某粘土型石煤钒矿直接酸浸提钒研究[J]. 中国钼业, 2025,49(1):46-50.SHI S, WU J X, TIAN Z W, et al. Extraction of vanadium from a clay-type stone coal by direct acid leaching[J]. China Molybdenum Industry, 2025, 49(1): 46-50. [15] ZHANG Y, YE G H, LIANG X Y, et al. Research progress on the enhancement and activation of extracting vanadium by direct acid leaching from shale vanadium ore[J]. Iron Steel Vanadium Titanium, 2023,44(2):1-8, 33. (张云, 叶国华, 梁雪崟, 等. 页岩钒矿直接酸浸提钒的强化与活化研究进展[J]. 钢铁钒钛, 2023,44(2):1-8, 33.ZHANG Y, YE G H, LIANG X Y, et al. Research progress on the enhancement and activation of extracting vanadium by direct acid leaching from shale vanadium ore[J]. Iron Steel Vanadium Titanium, 2023, 44(2): 1-8, 33. -

下载:

下载: