Comparison of the reducing activity of coke powder and semi-coke and its application in the carbonization process of Ti-bearing blast furnace slag

-

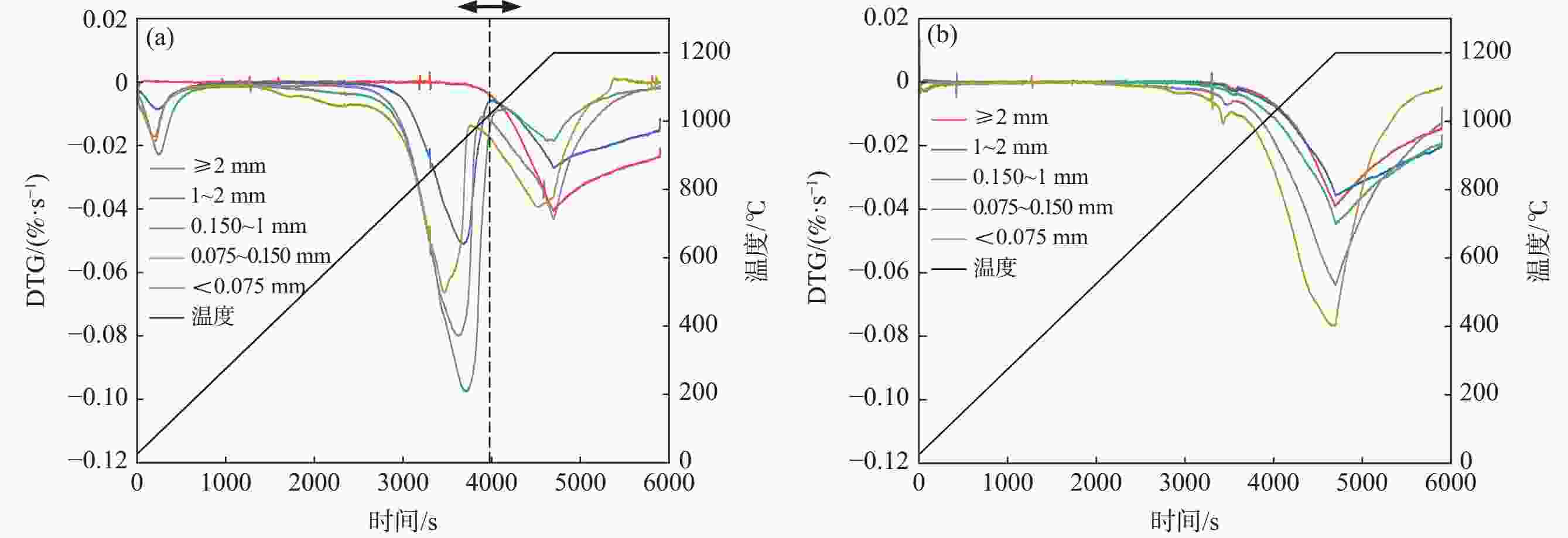

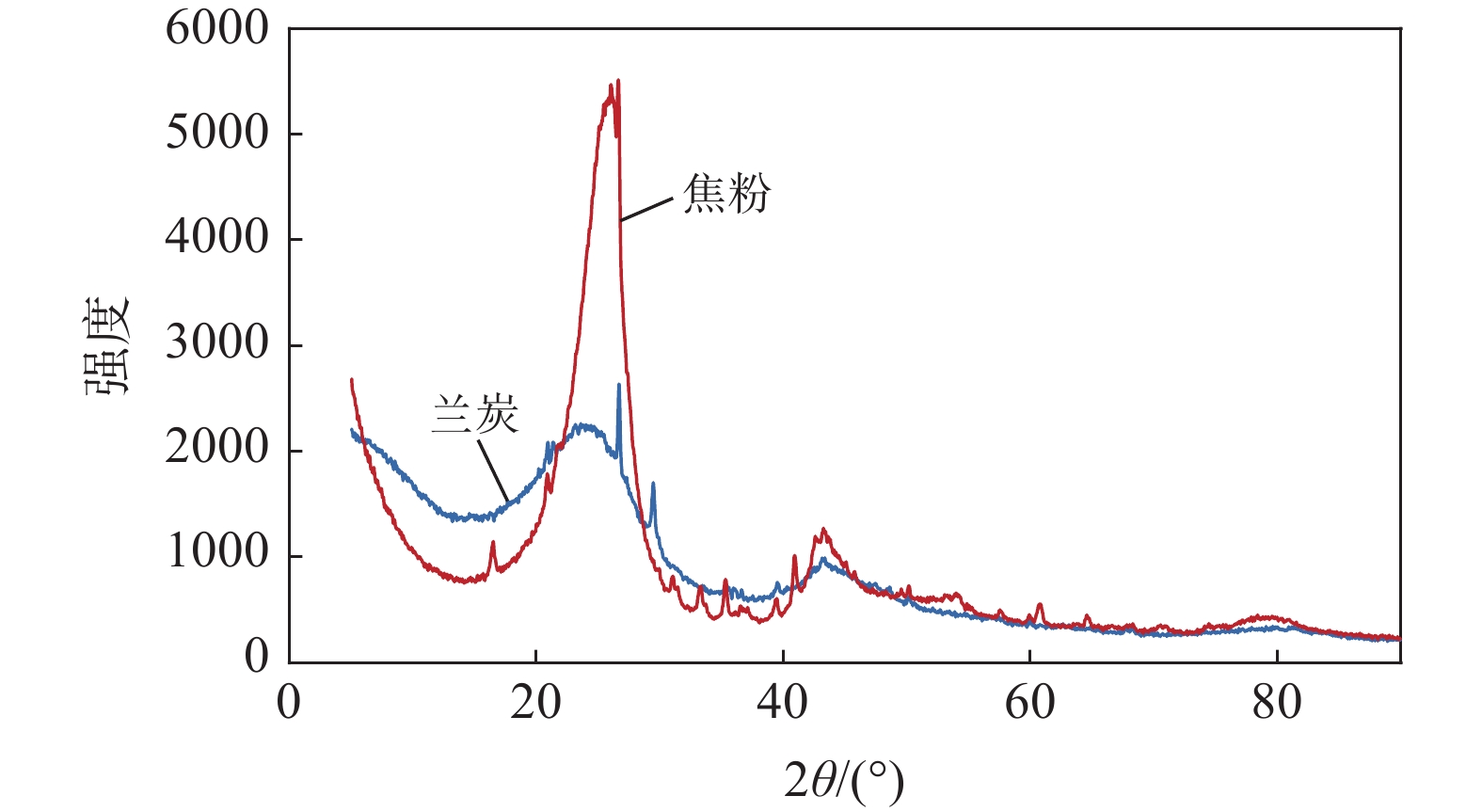

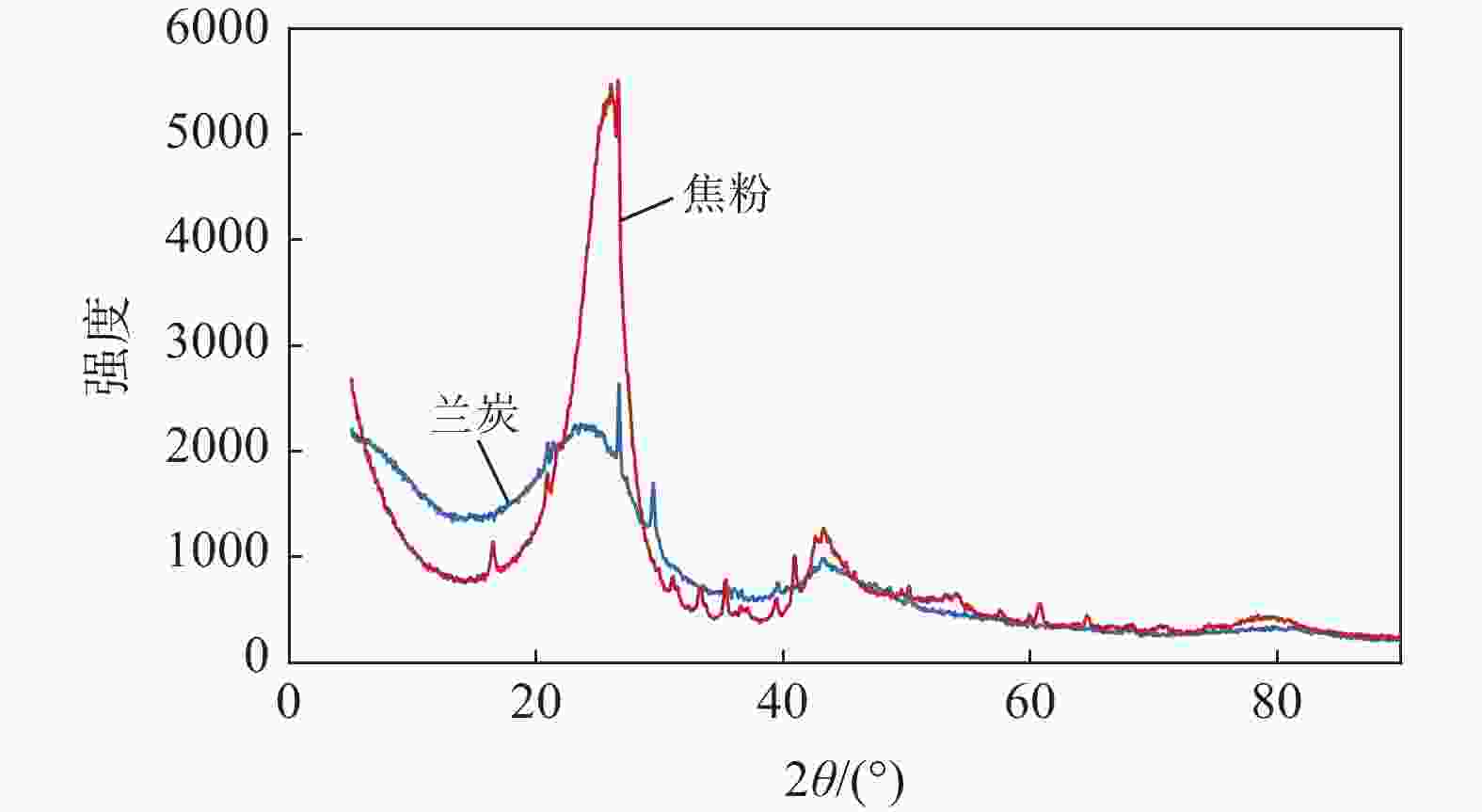

摘要: 在含钛高炉渣“高温碳化-低温氯化”提钛工艺中,高温碳化是关键且重要的工艺环节。高温碳化过程采用的碳质还原剂直接影响着该工序的成本和高炉渣中二氧化钛的碳化率,选取更加优质廉价的碳质还原剂是高温碳化工序提质降本的重要手段之一。研究选取兰炭和焦粉进行对比,通过研磨筛分获得不同粒径范围的碳质还原剂,并采用X-射线衍射仪、热重分析仪、比表面积分析仪等研究了兰炭和焦粉还原活性的差异,提出了与产线当前应用焦粉达到相同还原反应活性时兰炭对应的粒径控制范围,并进行了工业应用试验。结果表明,兰炭较焦粉石墨化度弱,在转化率0.3~0.8的范围内平均活化能低,粒径在0.150 mm以上比表面积大,导致兰炭反应活性高于焦粉。基于此提出了兰炭的粒径应在1~2 mm和0.150~1 mm的区间内进行协同控制,工业试验结果表明,按照此范围控制的兰炭应用于含钛高炉渣高温碳化过程,吨渣冶炼电耗和碳化率均与当前使用粒径分布的焦粉达到相同控制水平。Abstract: In the process of titanium extraction from Ti-bearing blast furnace slag by “high temperature carbonization and low temperature chlorination”, high temperature carbonization is very critical and important. The carbonaceous reducing agent used in the high temperature carbonization process directly affects the cost of the process and the carbonization rate of titanium dioxide in the blast furnace slag, so the selection of more high-quality and low-cost carbonaceous reducing agent is one of the important means to improve the quality and reduce the cost of high temperature carbonization process. In this study, semi-coke and coke powder with different particle size ranges were obtained by grinding and sieving as raw materials. By XRD, TGA, BET and other analytical methods, the difference of the reducing activity between semi-coke and coke powder was studied. The particle size of semi-coke corresponding to coke powder with the same reduction reaction activity was proposed, and the industrial application test was carried out. The results show that the graphitization degree of semi-coke is much lower than that of coke powder. In the range of conversion rate of 0.3~0.8, the average activation energy of semi-coke is lower than that of coke powder. When the particle size is more than 0.150 mm, the specific surface area of semi-coke is greater than that of coke powder, contributing to its higher reactivity than that of coke powder. Based on these, it is proposed that the particle size of semi-coke should be collaboratively controlled in the range of 1~2 mm and 0.150~1 mm. The industrial test results reveal that the power consumption per ton of slag and carbonization rate are the same as those of coke powder with particle size distribution currently used, when this above range-controlled semi-coke is applied to the high temperature carbonization process of Ti-bearing blast furnace slag.

-

表 1 高钛型高炉渣的典型化学成分

Table 1. Typical chemical composition of high-titanium blast furnace slag

% TiO2 Al2O3 MgO CaO SiO2 TFe V2O5 20.90~23.64 12.60~14.69 6.98~7.85 27.31~29.23 24.20~25.12 1.70~2.88 0.26~0.28 表 2 粒径筛分前焦粉和兰炭的主要成分

Table 2. The main components of coke powder and semi-coke

样品名称 成分/% 粒径分布/% 固定碳 灰分 挥发分 >2 mm 1~2 mm 0.15~1 mm 0.075~0.15 mm <0.075 mm 焦粉 85.44 13.17 1.19 3.47 4.69 31.51 22.47 37.86 兰炭 83.14 9.97 3.90 33.28 60.72 5.83 0.06 0.11 表 3 兰炭和焦粉石墨化度计算结果

Table 3. Graphitization degree of coke powder and semi-coke

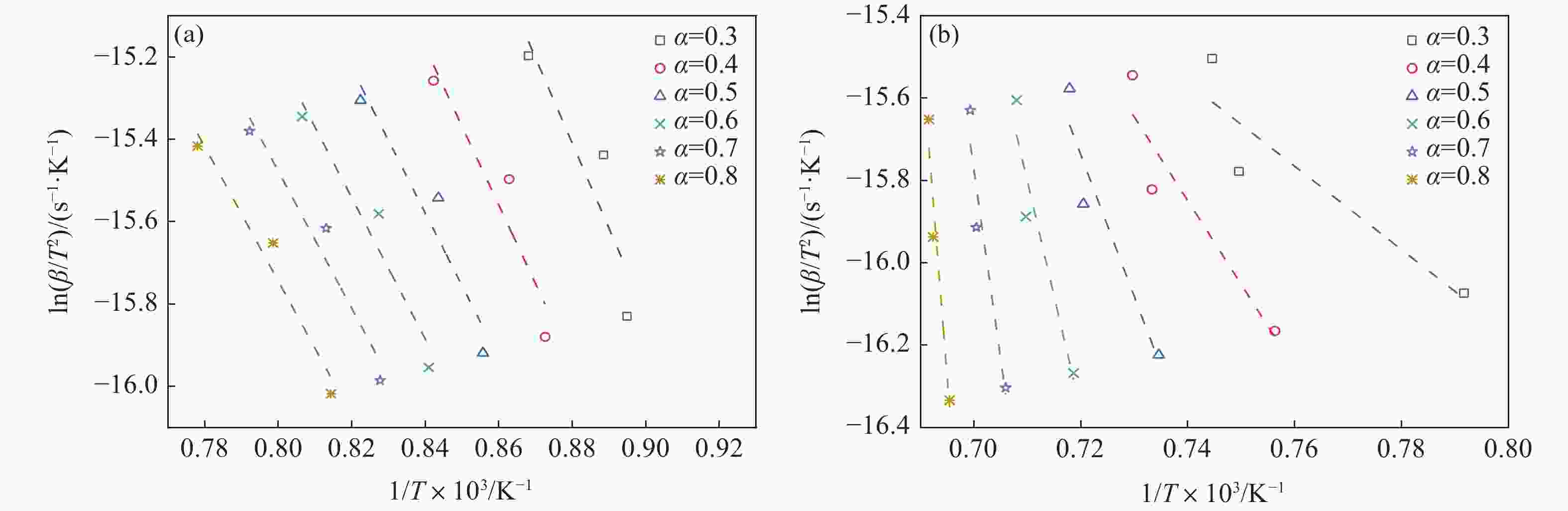

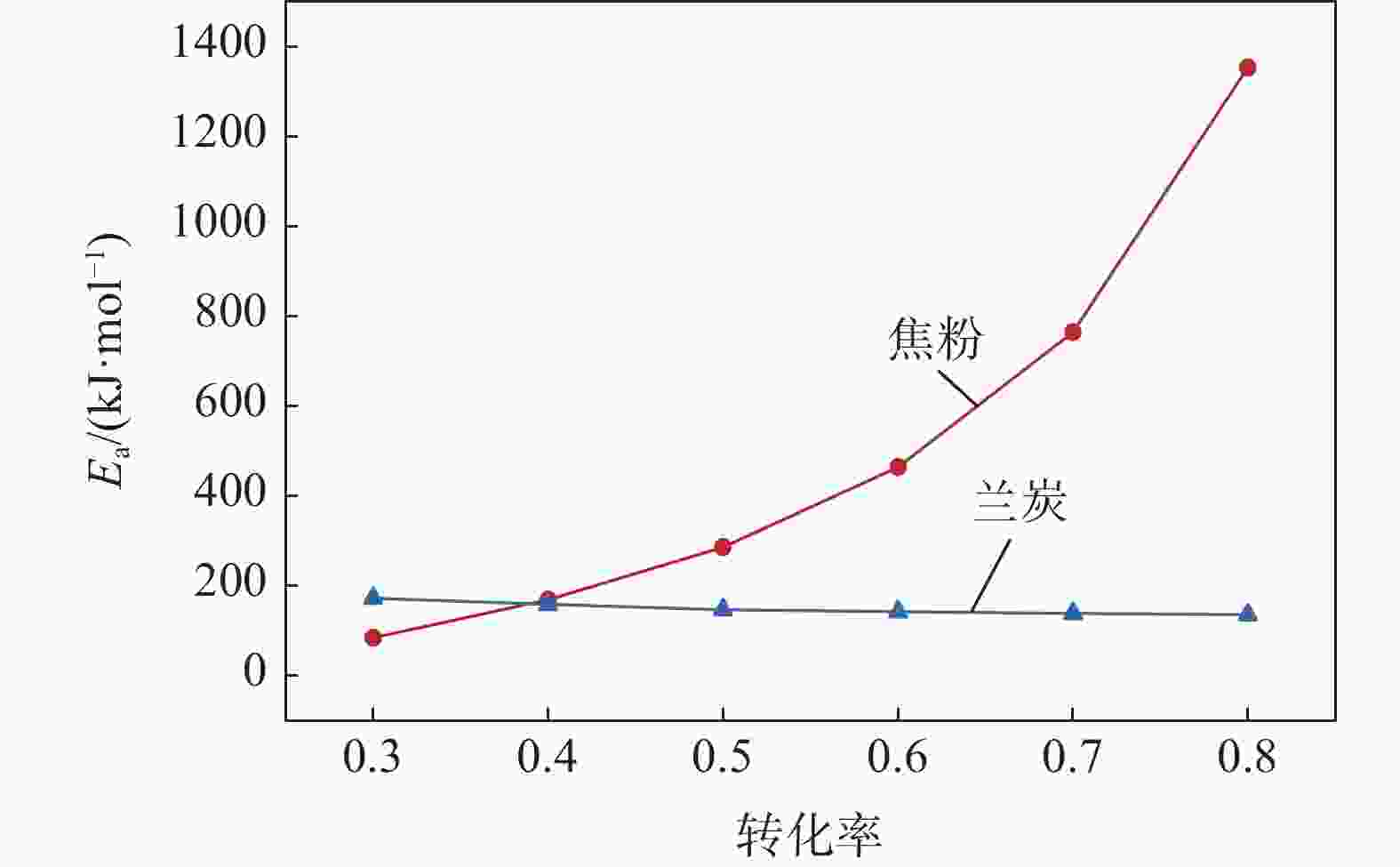

样品名称 2θ/(°) d002/nm g 兰炭 26.058 0.3417 0.2706 焦粉 26.342 0.3381 0.6915 表 4 兰炭在CO2气氛下的动力学求解结果

Table 4. Kinetic calculation results of semi-coke in CO2 atmosphere

转化率α 斜率k 截距b 活化能Ea/

(kJ·mol−1)指前因子A 相关系数R 0.3 −20.710 2.815 172.1829 188.341450 0.9195 0.4 −19.120 0.883 158.9637 25.185660 0.9445 0.5 −17.618 −0.780 146.4761 4.397609 0.9545 0.6 −17.151 −1.478 142.5934 2.129945 0.9692 0.7 −16.664 −2.146 138.5445 1.061084 0.9745 0.8 −16.318 −2.691 135.6679 0.602847 0.9799 平均 149.07 表 5 焦粉和CO2还原反应的动力学求解结果

Table 5. Kinetic solution results of coke powder in CO2 atmosphere

转化率α 斜率k 截距b 活化能Ea/

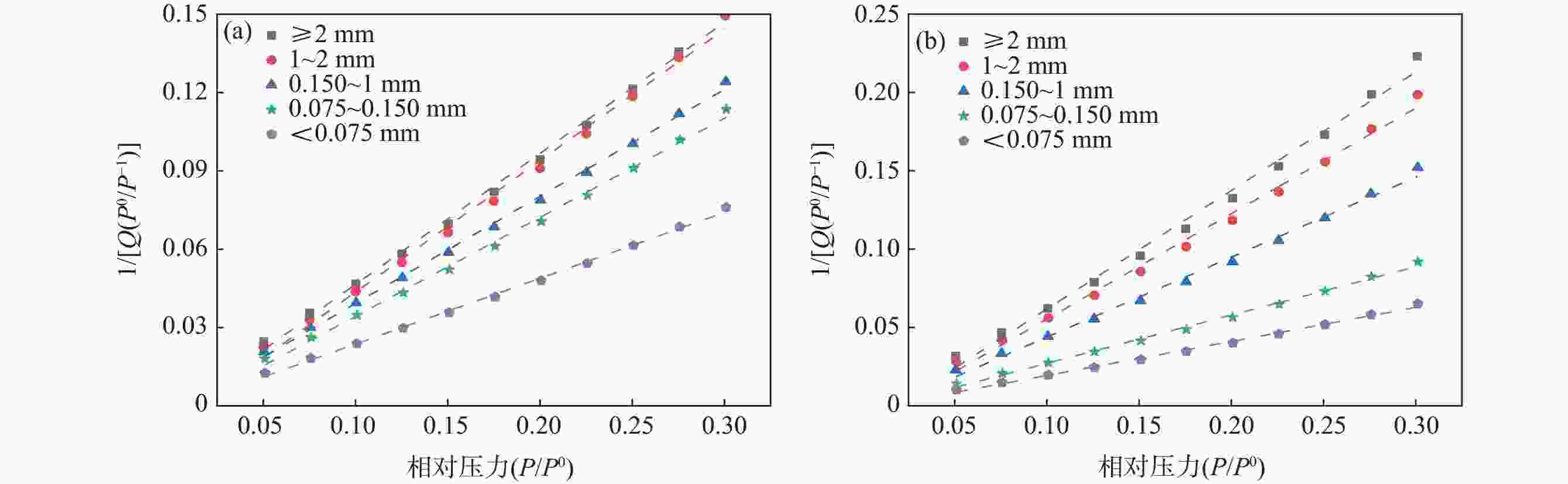

(kJ·mol−1)指前因子A 相关系数R 0.3 −10.134 −8.063 84.2541 0.001738 0.9195 0.4 −20.335 −0.801 169.0652 4.972801 0.9442 0.5 −34.393 9.025 285.9434 155685.45 0.9545 0.6 −55.791 23.809 463.8464 6.65×1011 0.9598 0.7 −91.952 48.591 764.4889 6.35×1022 0.9633 0.8 −162.740 96.828 1353.0204 9.99×1043 0.9729 平均 520.10 表 6 兰炭的BET表面积求解结果

Table 6. BET surface area calculation results of semi-coke

粒径区间

/mm斜率k 截距b 单层饱和气体吸附量Qm/(cm3·g−1) 比表面积SBET/(m2·g−1) 相关系数R ≥2.000 0.501750 − 0.003670 2.0077 8.7440 0.9986 1~2 0.503270 − 0.006758 2.0141 8.7716 0.9978 0.150~1 0.410177 − 0.001802 2.4487 10.6647 0.9991 0.075~0.150 0.379030 − 0.003601 2.6636 11.6006 0.9986 <0.075 0.252099 − 0.001549 3.9912 17.3825 0.9989 表 7 焦粉的BET表面积求解结果

Table 7. BET surface area calculation results of coke powder

粒径区间

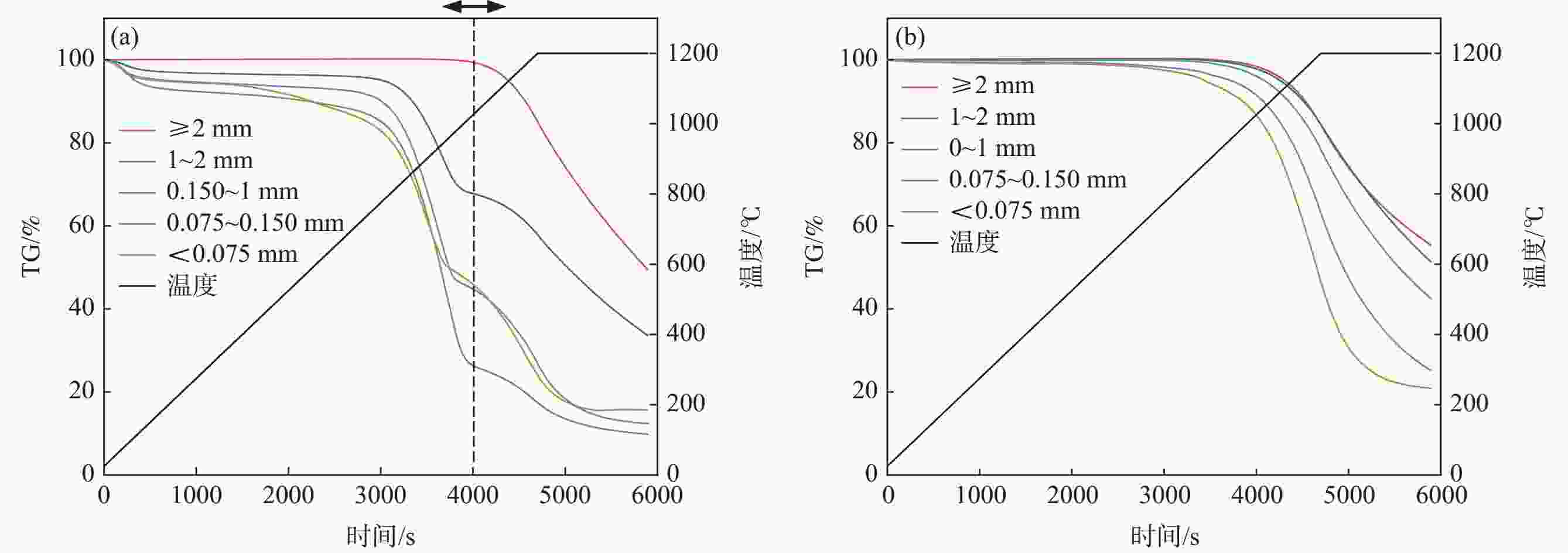

/mm斜率k 截距b 单层饱和气体吸附量Qm/(cm3·g−1) 比表面积SBET/(m2·g−1) 相关系数R ≥2 0.756079 − 0.013836 1.3473 5.8676 0.9965 1~2 0.672806 − 0.011914 1.5131 6.5899 0.9969 0.150~1 0.510554 − 0.007256 1.9869 8.6533 0.9974 0.075~0.150 0.308090 − 0.003710 3.2854 14.3084 0.9982 <0.075 0.217021 − 0.002348 4.6582 20.2876 0.9982 表 8 兰炭和焦粉的失重率与最大失重速率

Table 8. Weight loss and maximum weight loss rate of coke powder and semi-coke

粒径区

间/mm焦粉 兰炭 失重率/% 失重速

率/(%·s−1)失重率/% 失重速率-

Ⅰ/(%·s−1)失重速率-

Ⅱ/(%·s−1)≥2 44.68 0.039 46.27 0.041 1~2 48.80 0.036 66.43 0.051 0.027 0.150~1 57.63 0.044 89.31 0.100 0.018 0.075~0.150 74.83 0.064 87.63 0.080 0.044 <0.075 79.11 0.076 84.32 0.066 0.039 表 9 兰炭和焦粉在含钛高炉渣高温碳化过程的应用

Table 9. Application of semi-coke and coke powder in high temperature carbonization of Ti-bearing high furnace slag

编号 吨渣电耗/(kWh·t−1) 碳化率/% 焦粉 原兰炭 研磨筛分

后兰炭焦粉 原兰炭 研磨筛分

后兰炭1 845.82 886.69 814.75 87.12 85.82 87.39 2 826.81 904.77 852.49 86.30 85.69 86.23 3 860.55 874.45 843.06 86.54 85.13 87.66 4 869.25 855.05 845.70 87.35 84.82 86.47 5 834.28 836.47 840.28 87.64 85.78 88.04 6 842.20 837.67 832.87 86.92 85.96 87.92 7 850.25 861.88 840.44 88.10 86.13 87.88 8 832.87 874.12 842.20 87.67 85.74 87.67 9 835.38 840.34 834.92 86.38 86.25 87.89 10 836.53 861.56 835.25 86.60 86.86 86.71 11 841.90 864.89 821.53 87.42 86.14 87.21 12 828.90 857.01 835.38 88.13 85.98 86.62 13 848.62 854.29 834.28 87.42 84.77 86.89 14 814.44 871.92 865.65 87.63 86.92 87.40 15 847.88 918.49 852.63 86.88 85.84 87.09 标准差 13.20 22.45 11.97 0.57 0.59 0.56 均值 841.04 866.64 839.43 87.21 85.86 87.27 极差 54.81 82.02 50.90 1.83 2.15 1.81 备注:吨渣电耗为每批次加入高炉渣开始至碳化终点消耗的总电耗除以每批次加入的高炉渣量;碳化率为高炉渣中TiO2转变为TiC的比例。 -

[1] HAO B C, LI Z Y, JIA D F, et al. Comprehensive utilization of blast furnace slag containing titanium[J]. Multipurpose Utilization of Mineral Resources, 2020(6):1-2. (郝百川, 李子越, 贾东方, 等. 含钛高炉渣的综合利用[J]. 矿产综合利用, 2020(6):1-2.HAO B C, LI Z Y, JIA D F, et al. Comprehensive utilization of blast furnace slag containing titanium[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 1-2. [2] WANG J X, YUE D, WEN L Y, et al. Experimental characterization of chemical mineral composition and morphology of titanium in carbonized slag particles[J]. Journal of Materials Research and Technology, 2025,34:1571-1581. doi: 10.1016/j.jmrt.2024.12.175 [3] LONG Y, ZHANG X J, LI S L, et al. Study on influence factors of high temperature carbonization of Ti-bearing blast furnace slag for preparation of TiC[J]. Journal of Chongqing University of Technology( Natural Science), 2017,31(8):93-97,119. (龙雨, 张新建, 李书兰, 等. 含钛高炉渣高温碳化制备TiC影响因素研究[J]. 重庆理工大学学报(自然科学), 2017,31(8):93-97,119.LONG Y, ZHANG X J, LI S L, et al. Study on influence factors of high temperature carbonization of Ti-bearing blast furnace slag for preparation of TiC[J]. Journal of Chongqing University of Technology( Natural Science), 2017, 31(8): 93-97,119. [4] PENG Z F, ZHANG J L, BI C G, et al. Effect of coke powder and semi-coke on combustion characteristics of blast furnace blended coal[J]. Iron and Steel, 2019,54(12):10-18. (彭政富, 张建良, 毕传光, 等. 焦粉与兰炭对高炉混煤燃烧特性的影响[J]. 钢铁, 2019,54(12):10-18. doi: 10.13228/j.boyuan.issn0449-749x.20190076PENG Z F, ZHANG J L, BI C G, et al. Effect of coke powder and semi-coke on combustion characteristics of blast furnace blended coal[J]. Iron and Steel, 2019, 54(12): 10-18. doi: 10.13228/j.boyuan.issn0449-749x.20190076 [5] FU L L, SUN T, FANG J J, et al. Production test of blue carboon as fuel instead of pulverized coke in sintering process[J]. Henan Metallurgy, 2012,20(4):6-8,16. (付林林, 孙涛, 方俊杰, 等. 烧结过程用兰炭作为燃料替代焦粉的生产试验[J]. 河南冶金, 2012,20(4):6-8,16.FU L L, SUN T, FANG J J, et al. Production test of blue carboon as fuel instead of pulverized coke in sintering process[J]. Henan Metallurgy, 2012, 20(4): 6-8,16. [6] WANG X, ZHANG H Y, ZHAO J W, et al. Discussion on adding semi-coke to replace part of coke powder on all fine powder sintering process[J]. Xinjiang Iron and Steel, 2017(3):36-39. (王星, 张海燕, 赵金巍, 等. 全精粉烧结配加兰炭替代部分焦粉的探讨[J]. 新疆钢铁, 2017(3):36-39.WANG X, ZHANG H Y, ZHAO J W, et al. Discussion on adding semi-coke to replace part of coke powder on all fine powder sintering process[J]. Xinjiang Iron and Steel, 2017(3): 36-39. [7] LI S, ZHU Z Z, XU J, et al. Optimization and modification of semi-coke blending for conventional coke-making[J]. Iron and Steel, 2012,47(8):17-21. (李硕, 朱子宗, 徐军. 兰炭改性及配煤炼焦优化[J]. 钢铁, 2012,47(8):17-21.LI S, ZHU Z Z, XU J, et al. Optimization and modification of semi-coke blending for conventional coke-making[J]. Iron and Steel, 2012, 47(8): 17-21. [8] YANG S P, GUO S Q, ZHANG P H, et al. Influence of semi-coke used as sintering fuel on metallurgical properties of sinter[J]. Iron & Steel, 2016,51(9):6-11. (杨双平, 郭拴全, 张攀辉, 等. 兰炭作烧结燃料对烧结矿冶金性能的影响[J]. 钢铁, 2016,51(9):6-11.YANG S P, GUO S Q, ZHANG P H, et al. Influence of semi-coke used as sintering fuel on metallurgical properties of sinter[J]. Iron & Steel, 2016, 51(9): 6-11. [9] QIN L B, QIN W L, CHEN W S, et al. Experimental research on application of semi-coke instead of breeze in iron ore sintering[J]. Sintering and Pelletizing, 2023,48(4):95-102. (秦林波, 秦万里, 陈旺生, 等. 兰炭替代焦粉应用于铁矿烧结的试验研究[J]. 烧结球团, 2023,48(4):95-102.QIN L B, QIN W L, CHEN W S, et al. Experimental research on application of semi-coke instead of breeze in iron ore sintering[J]. Sintering and Pelletizing, 2023, 48(4): 95-102. [10] WANG H X, WU X X, WEI H N, et al. Research on property of semi-coke and its application in blast furnace injection technology [J]. Fuel & Chemical Processes 2024, 55 (2): 1-6. (王和喜, 吴枭雄, 魏会宁, 等. 兰炭特性及在高炉的应用研究进展[J]. 燃料与化工, 2024, 55 (2): 1-6.WANG H X, WU X X, WEI H N, et al. Research on property of semi-coke and its application in blast furnace injection technology [J]. Fuel & Chemical Processes 2024, 55 (2): 1-6. [11] HUANG J X, ZHAO Q E, LIU Y D, et al. A method for smelting Ti-bearing blast furnace slag with composite reducing agent[P]. China, CN202211141504.6, 2023.12. 15. (黄家旭, 赵青娥, 刘亚东, 等. 一种复合还原剂冶炼含钛高炉渣的方法[P]. 中国, CN202211141504.6, 2023.12. 15.HUANG J X, ZHAO Q E, LIU Y D, et al. A method for smelting Ti-bearing blast furnace slag with composite reducing agent[P]. China, CN202211141504.6, 2023.12. 15. [12] QIU S X, ZHANG S F, ZHOU X H, et al. Thermal behavior and organic functional structure of poplar-fat coal blends during co-pyrolysis[J]. Renewable Energy, 136 (2019): 308 - 316. [13] SHI Y, FAN Q M, LIU Z B, et al. Study on optimization method for calulation of graphitization degree of calcined petroleum coke[J]. Petroleum Processing ang Petrochemicals, 2022,53(4):89-94. (施洋, 范启明, 刘自宾, 等. 煅后石油焦石墨化度计算的修正方法研究[J]. 石油炼制与化工, 2022,53(4):89-94.SHI Y, FAN Q M, LIU Z B, et al. Study on optimization method for calulation of graphitization degree of calcined petroleum coke[J]. Petroleum Processing ang Petrochemicals, 2022, 53(4): 89-94. [14] ZHANG Y, DENG H J, LI M, et al. The evaluation of graphitization degree P1 M odeland M easurement of C/C composites[J]. Journal of Meterials Engineering, 2001(4):29-33. (张赟, 邓海金, 李明, 等. C/C复合材料石墨化度P1模型的表征及测定[J]. 材料工程, 2001(4):29-33. doi: 10.3969/j.issn.1001-4381.2001.04.008ZHANG Y, DENG H J, LI M, et al. The evaluation of graphitization degree P1 M odeland M easurement of C/C composites[J]. Journal of Meterials Engineering, 2001(4): 29-33. doi: 10.3969/j.issn.1001-4381.2001.04.008 [15] XU J L, YAN W, WU D J. Measuring the graphitization and crystallinity of carbon material by XRD peak separation method[J]. Journal of Wuhan University of Science and Technology, 2009,32(5):522-525. (许聚良, 鄢文, 吴大军. XRD分峰拟合法测定炭材料的石墨化度和结晶度[J]. 武汉科技大学学报, 2009,32(5):522-525.XU J L, YAN W, WU D J. Measuring the graphitization and crystallinity of carbon material by XRD peak separation method[J]. Journal of Wuhan University of Science and Technology, 2009, 32(5): 522-525. [16] DANG X E, TAGN C, LÜ J, et al. Exploratory study on graphitization of semi-coke powder[J]. Chinese Journal of Environmental Engineering, 2016,10(3):1438-1444. (党晓娥, 唐晨, 吕军, 等. 兰炭焦粉的石墨化探索性研究[J]. 环境工程学报, 2016,10(3):1438-1444.DANG X E, TAGN C, LÜ J, et al. Exploratory study on graphitization of semi-coke powder[J]. Chinese Journal of Environmental Engineering, 2016, 10(3): 1438-1444. [17] REN S S, WANG H, YANG S. Research progress in ruducing agents for producing industrial grade silicon[J]. Contemporary Chemical Industry, 2014,43(12):2627-2629, 2631. (任思帅, 王辉, 杨帅. 工业硅生产过程中还原剂研究进展[J]. 当代化工, 2014,43(12):2627-2629, 2631. doi: 10.3969/j.issn.1671-0460.2014.12.046REN S S, WANG H, YANG S. Research progress in ruducing agents for producing industrial grade silicon[J]. Contemporary Chemical Industry, 2014, 43(12): 2627-2629, 2631. doi: 10.3969/j.issn.1671-0460.2014.12.046 -

下载:

下载: