Influence of pre-strain and heat treatment on subsequent deformation behavior of Ti6321 titanium alloy

-

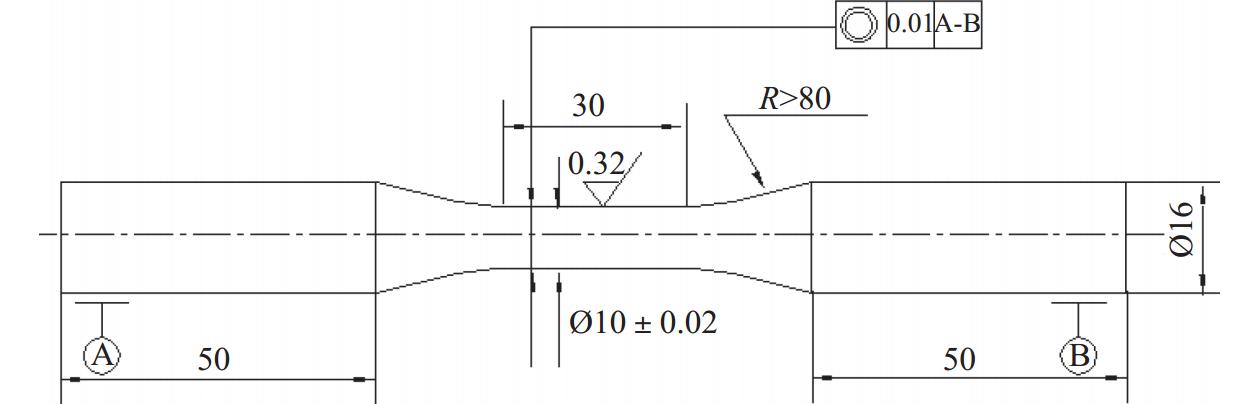

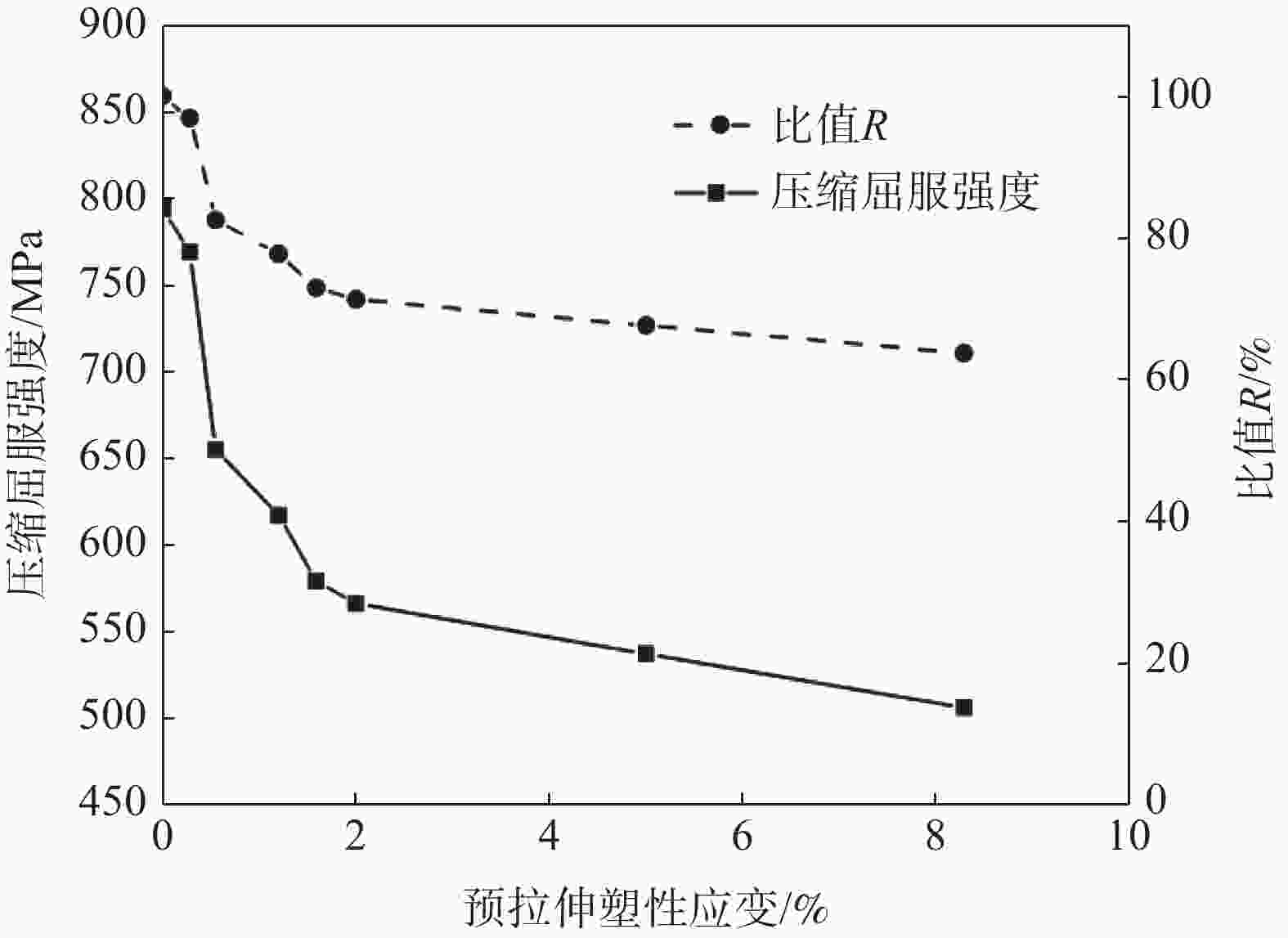

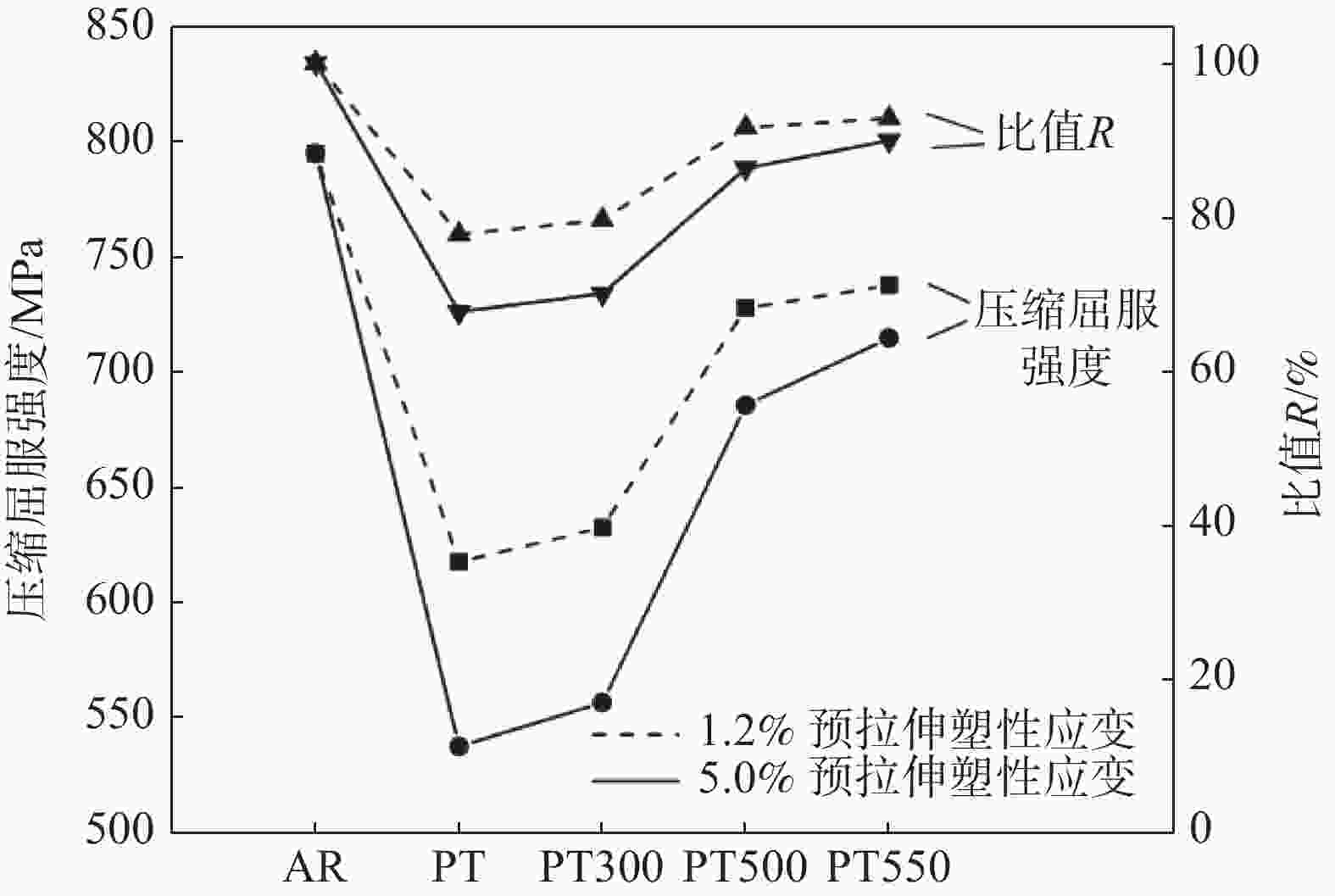

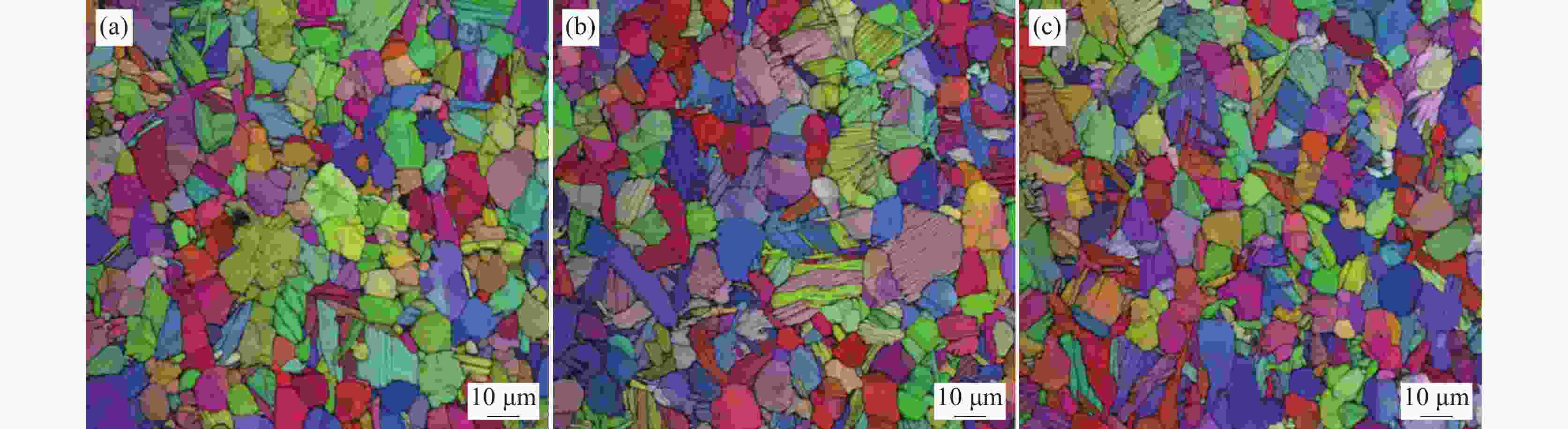

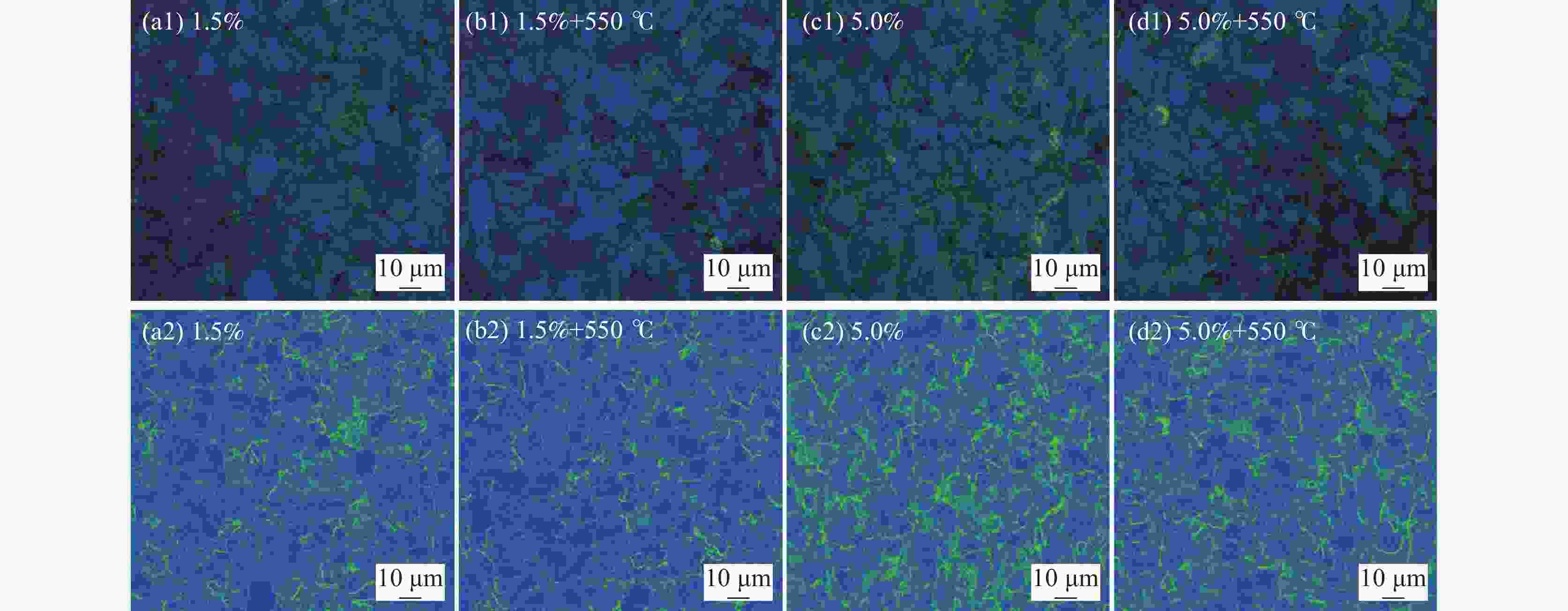

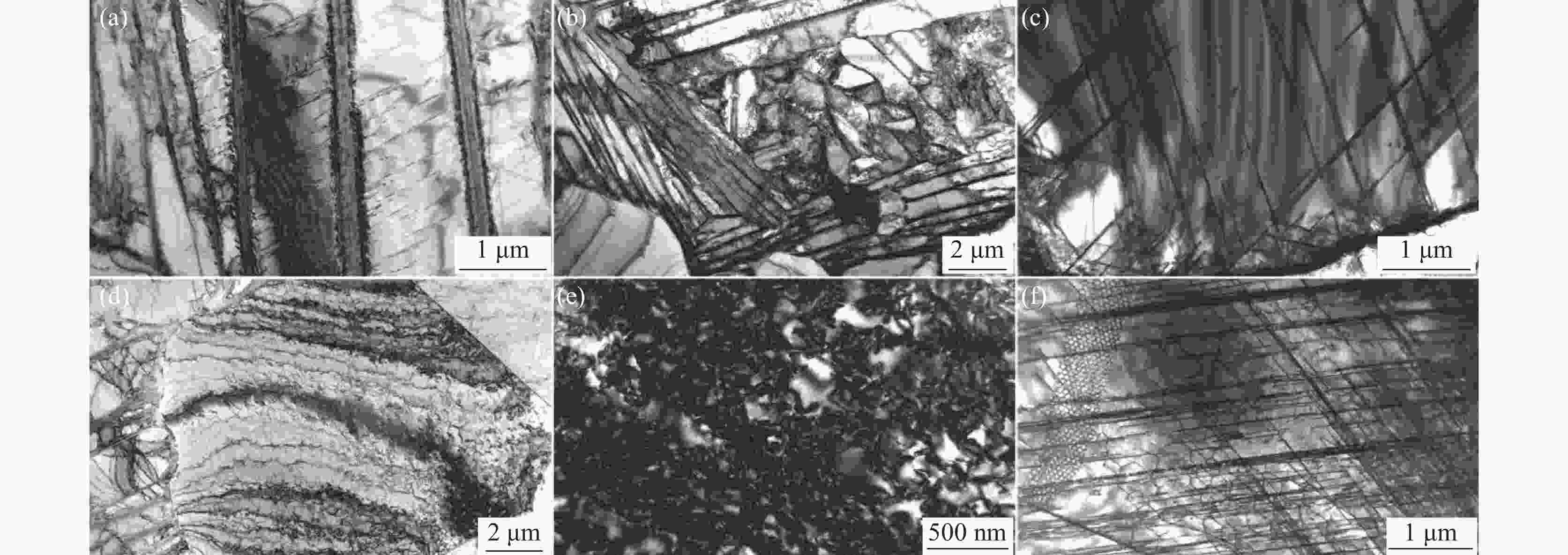

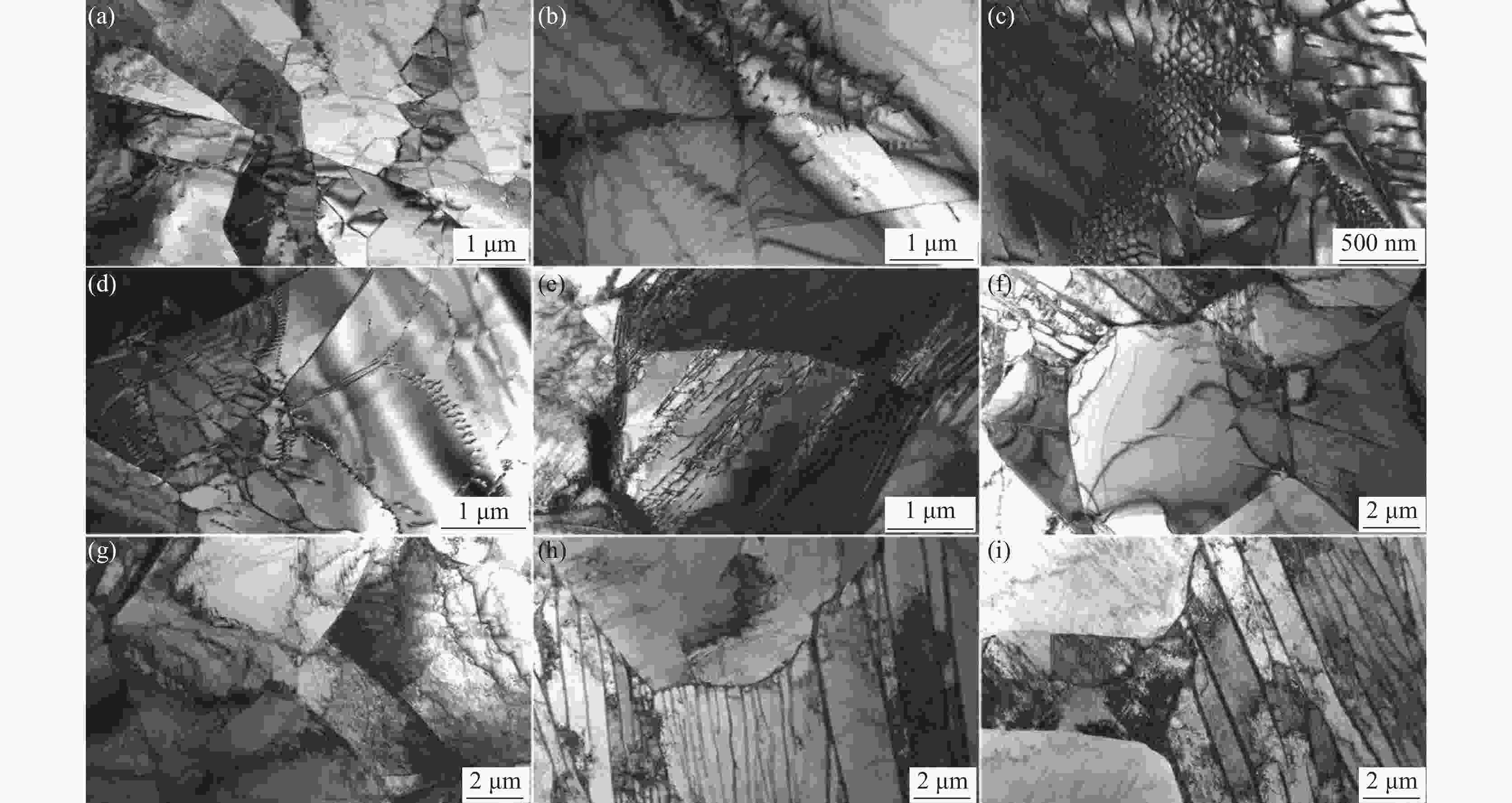

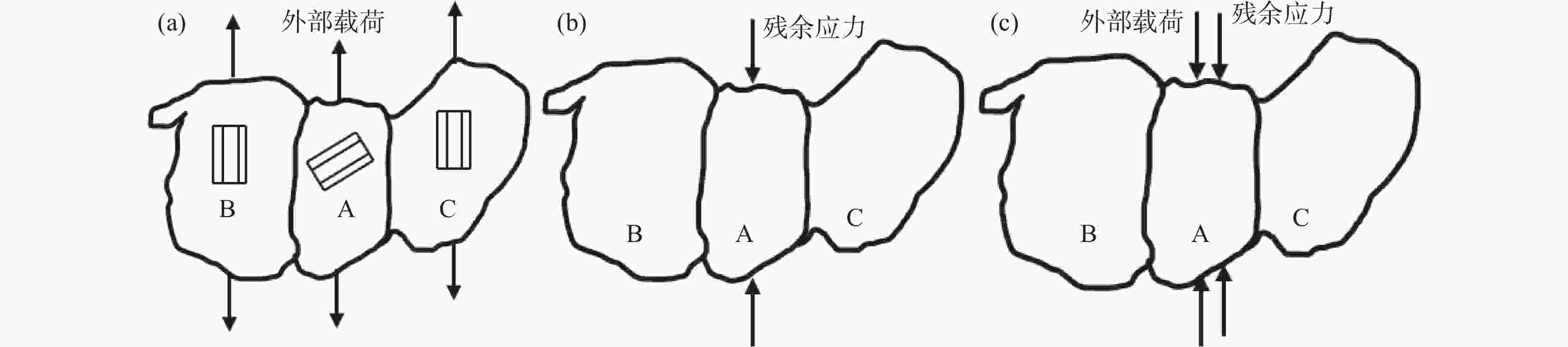

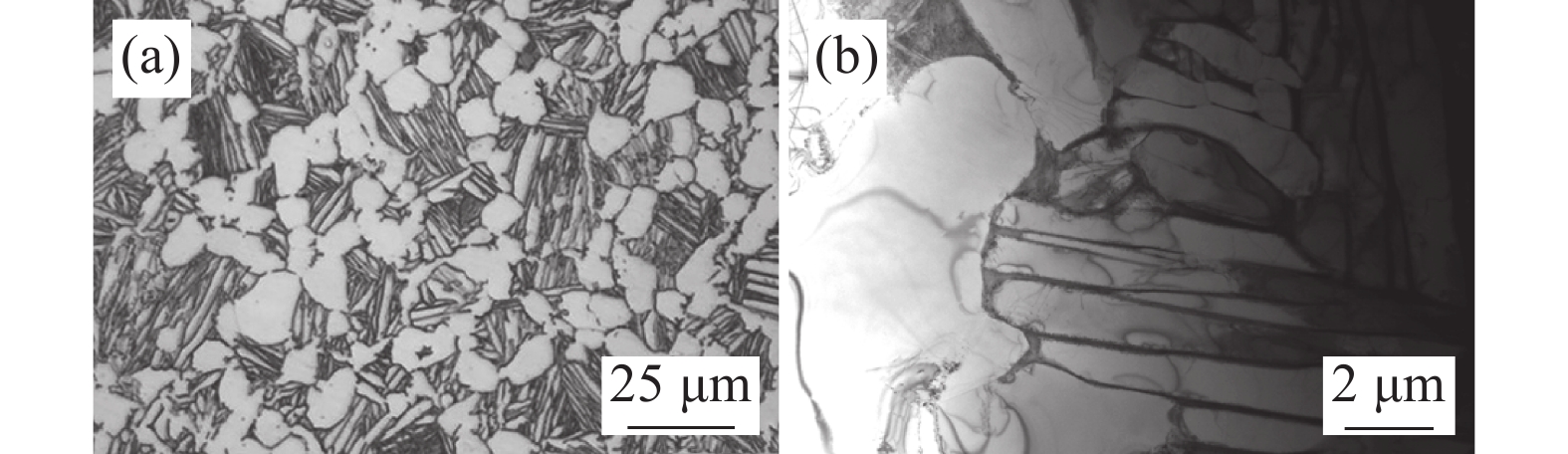

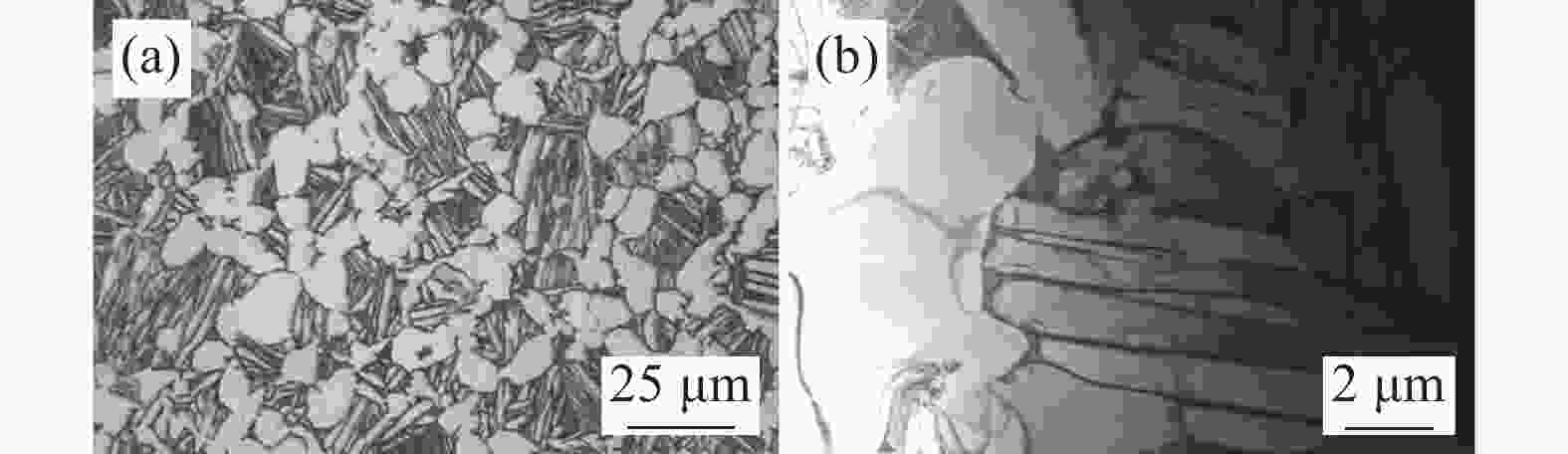

摘要: 对Ti6321合金进行预拉伸,研究预变形对其后续变形行为的影响;另外对预变形后Ti6321合金进行热处理,并与未处理预变形Ti6321进行了对比分析。结果表明,试样经过预拉伸后,其压缩屈服强度降低,降低幅度随着预拉伸塑性应变量的增大先增大后趋于稳定。预拉伸试样经热处理后再反向加载,其压缩屈服强度得到一定程度恢复,且高于未经热处理预拉伸试样的压缩屈服强度,压缩屈服强度回复幅度随着热处理温度升高而增大。Ti6321合金产生包申格效应的机制为微区非均匀塑性变形过程中残余应力的长程效应与位错运动过程中阻力变化的短程效应共同作用的结果,且前者为主要原因。预变形试样在热处理保温过程中位错组态发生变化,形成亚晶等使位错密度减小、位错塞积程度降低;另一方面高温下位错发生攀移,进而产生应力松弛,晶粒间的附加应力降低,微区残余应力减小,二者共同作用下使预变形态Ti6321合金反向承载能力得到回复,包申格效应减弱。Abstract: Pre-tension and heat treatment were performed on the Ti6321 alloy, and their effects on subsequent deformation behavior were investigated and compared. The results show that the compressive yield strength of the specimen decreases after pre-tension, and the decrease amplitude increases first and then tends to be stable with the increase of pre-tensile plastic strain. The compressive yield strength of the pre-tensile specimen is restored to a certain extent after heat treatment and then reverse loading, and it is higher than that of the pre-tensile specimen without heat treatment. The recovery amplitude of the compressive yield strength increases with the increase of heat treatment temperature. The mechanism of Bauschinger effect in Ti6321 alloy is the result of the long-range effect of residual stress in the process of micro-zone heterogeneous plastic deformation and the short-range effect of resistance change in the process of dislocation movement, and the former is the main reason. The dislocation configuration of the pre-deformed specimen changes during the heat treatment process, and the formation of subgrains reduces the dislocation density and the degree of dislocation pile-up. On the other hand, the dislocation climbs at high temperature, which leads to stress relaxation, the additional stress between grains decreases, and the residual stress in the micro-area decreases. Under the combined action of the two, the reverse bearing capacity of the pre-deformed Ti6321 alloy is restored, and the Bauschinger effect is weakened.

-

Key words:

- Ti6321 alloy /

- pre-tension /

- heat treatment /

- Bauschinger effect

-

表 1 Ti6321合金板材化学成分

Table 1. Chemical composition of Ti6321 alloy plate

% Ti Al Nb Zr Mo N H C O Fe Si Bal. 6.22 2.50 2.03 1.02 <0.005 0.0016 <0.01 0.081 0.029 0.024 表 2 不同预应变后Ti6321合金的压缩屈服强度

Table 2. Compressive yield strength of the Ti6321 alloy with different pre-tensile plastic strain

试样 预拉伸塑性应变/% 压缩屈服强度/MPa 1 0 794 2 0.28 769 3 0.55 655 4 1.20 617 5 1.59 579 6 2.00 566 7 5.00 537 8 8.29 506 表 3 预拉伸+热处理后Ti6321合金测试结果

Table 3. Compressive properties of pre-tensile plastic strain Ti6321 alloy after heat treatment

预拉伸塑性应变/% 热处理温度/℃ 压缩屈服强度/MPa 比值R/% 0 794 100 1.2 617 77.7 1.2 300 632 79.6 1.2 500 727 91.6 1.2 550 737 92.8 5.0 537 67.6 5.0 300 556 70.0 5.0 500 685 86.3 5.0 550 714 89.9 -

[1] GORYNIN I V. Titanium alloy for marine application[J]. Materials Science and Engineering A, 1999,263(2):112-116. doi: 10.1016/S0921-5093(98)01180-0 [2] SCHUTZ R W, SCATURRO M R. An overview of current and candidate titanium alloy application on U. S. navy surface ships[J]. Naval Engineers Journal, 1991(5):175-191. [3] ORYSHCHENKO A S, GORYNIN I V, LEONOV V P, et al. Marine titanium alloys: present and future[J]. Inorganic materials: applied research, 2015,6(6):571-579. doi: 10.1134/S2075113315060106 [4] YU X Y, JI H T, ZHANG H, et al. Experimental and numerical investigation on the bauschinger effect during cold forming of TC4ELI alloy[J]. International Journal of Material Forming, 2022,15(2):1-10. [5] YIN Y C, ZHANG S F, XU Y L, et al. Influence of pre-strain on deformation behavior of TC4ELI titanium alloy[J]. Development and Application of Materials, 2023,38(1):66-72. (尹艳超, 张帅锋, 许亚利, 等. 预应变对TC4ELI钛合金变形行为的影响[J]. 材料开发与应用, 2023,38(1):66-72.YIN Y C, ZHANG S F, XU Y L, et al. Influence of pre-strain on deformation behavior of TC4ELI titanium alloy[J]. Development and Application of Materials, 2023, 38(1): 66-72. [6] HEMEN R. The bauschinger effect in 6-6-2 titanium alloy and its influence on advanced artillery projectiles[R]. Watertown: U. S. Army Materials Technology Laboratory, 1989. [7] DAI Q, WANG F, ZHANG J, et al. Effect of pre-strain on failure assessment of titanium pressure vessel with crack[J]. Rare Metal Materials and Engineering, 2020,49(10):3301-3308. [8] MAYKUTH D J. Residual stresses, stress relief, and annealing of titanium and titanium alloys[R]. Ohio: U. S. Air Force Materials Laboratory, 1968. [9] RAE W, RAHIMI S. Effect of stress relaxation on the evolution of residual stress during heat treatment of Ti-6Al-4V[C]. The 14th World Conference on Titanium. 2019. [10] CAVALLARO J L. Ti-6Al-2Cb-1Ta-0.8Mo titanium alloy as a structural material for marine applications[R]. Annapolis: U. S. Navy Marine Engineer Laboratory, 1967. [11] CHEN H B, LIU T M, LU L W, et al. Influence of pre-strain and heat treatment on subsequent deformation behavior of extruded AZ31 Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2015(11):3604-3610. [12] WANG R F, DENG W P, NIU J C, et al. Effect of plastic deformation and stress relief heat treatment on microstructure and properties of 10CrNi5MoV steel plate[J]. Development and Application of Materials, 2019,34(5):16-21,26. (王任甫, 邓晚平, 牛继承, 等. 塑性变形及消应力热处理对10CrNi5MoV钢性能与组织的影响[J]. 材料开发与应用, 2019,34(5):16-21,26.WANG R F, DENG W P, NIU J C, et al. Effect of plastic deformation and stress relief heat treatment on microstructure and properties of 10CrNi5MoV steel plate[J]. Development and Application of Materials, 2019, 34(5): 16-21,26. [13] PEIRS J, VERLEYSEN P, DEGRIECK J. Study of the dynamic bauschinger effect in Ti6Al4V by torsion experiments[J]. The European Physical Journal Conferences, 2012,26:01023. doi: 10.1051/epjconf/20122601023 [14] PEIRS J, VERLEYSEN P, VERBEKEN K, et al. High strain rate torsion and bauschinger tests on Ti6Al4V[J]. Materials Science Forum, 2012,706-709:774-779. doi: 10.4028/www.scientific.net/MSF.706-709.774 [15] YU X Y, ZHANG B W. Investigation on bauschinger effect of TC4ELI titanium alloy based on experiment[J]. Die and Mould Industry, 2021,47(9):6-8. (于翔宇, 张博文. TC4 ELI钛合金包申格效应试验研究[J]. 模具工业, 2021,47(9):6-8.YU X Y, ZHANG B W. Investigation on bauschinger effect of TC4ELI titanium alloy based on experiment[J]. Die and Mould Industry, 2021, 47(9): 6-8. [16] FANG Z G, LIU B, LI G M, et al. Requirement and development analysis of warship equipment materials system[J]. Materials China, 2014(7):385-393. (方志刚, 刘斌, 李国明, 等. 舰船装备材料体系发展与需求分析[J]. 中国材料进展, 2014(7):385-393.FANG Z G, LIU B, LI G M, et al. Requirement and development analysis of warship equipment materials system[J]. Materials China, 2014(7): 385-393. [17] MAMUN A A, MOAT R J, KELLEHER J, et al. Origin of the bauschinger effect in a polycrystalline material[J]. Materials Science and Engineering A, 2017,707:576-584. doi: 10.1016/j.msea.2017.09.091 [18] STOLTZ R E, PELLOUX R M. The Bauschinger effect in precipitation strengthened aluminum alloys[J]. Metallurgical Transactions A, 1976,7(8):1295-1306. doi: 10.1007/BF02658814 [19] WANG Y F, LI C, LING X Y, et al. An overview on the bauschinger effect in metallic materials[J]. China Nuclear Science and Technology Report, 2002(0):410-423. (王延峰, 李聪, 凌绪玉等. 金属材料的包申格效应综述[J]. 中国核科技报告, 2002(0):410-423.WANG Y F, LI C, LING X Y, et al. An overview on the bauschinger effect in metallic materials[J]. China Nuclear Science and Technology Report, 2002(0): 410-423. [20] MACEWEN S R, ELLS C E, WOO O T. The bauschinger effect in Zircaloy-2[J]. Journal of Nuclear Materials, 1981,101:336-349. doi: 10.1016/0022-3115(81)90175-6 [21] IBRAHIM K, HUSEYIN S, CHUMLYAKOV Y I, et al. The effect of twinning and slip on the bauschinger effect of hadfield steel single crystals[J]. Metallurgiacl Transactions, 2001, 32A: 695-706. [22] GERD L, JAMES C, WILLIAMS. Titanium[M]. Berlin: Springer-Verlag. 2007. [23] WILLIAMS J C, BAGGERLY R G, PATOU N E. Deformation behavior of HCP Ti-Al alloy single crystals[J]. Metallurgical and Materials Transactions A, 2002,33:837-850. [24] YU W X, LÜ Y F, LI S K, et al. Mechanism of the anisotropy of yield ratio in TA5 titanium alloy plates[J]. Materials Science and Engineering A, 2015,639:314-319. doi: 10.1016/j.msea.2015.04.083 [25] AMBARD A, GUÉTAZ L, LOUCHET F, et al. Role of interphases in the deformation mechanisms of an α/β titanium alloy at 20 K[J]. Materials Science and Engineering A, 2001, 319: 404-408. [26] AKHTAR A. Basal slip and twinning in α-titanium single crystals[J]. Metallurgical and Materials Transactions A, 1975,6:1105-1113. doi: 10.1007/BF02661366 [27] ZULFIKAR H A K, WANG Z R. Bauschinger effect in a modified Zr-2.5wt% Nb pressure tube material[J]. Materials Science and Engineering A: 1993, 171(1-2): 55-63 [28] WANG Z Q, ALEXANDRU D S, MA D, et al. Stress relaxation behavior and mechanisms in Ti-6Al-4V determined via in situ neutron diffraction: application to additive manufacturing[J]. Materials Science and Engineering A, 2017,7:585-592. [29] HUANG Z, YUAN W H, ZHU J J. Low temperature stress relaxation and morphology evolution of Ti-6.5Al-2Zr-1Mo-1V titanium alloys[J]. Rare Metal Materials and Engineering, 2002,51(1):83-91. -

下载:

下载: