Effect of recrystallization annealing on microstructures and properties of TA1 electron beam welded joint

-

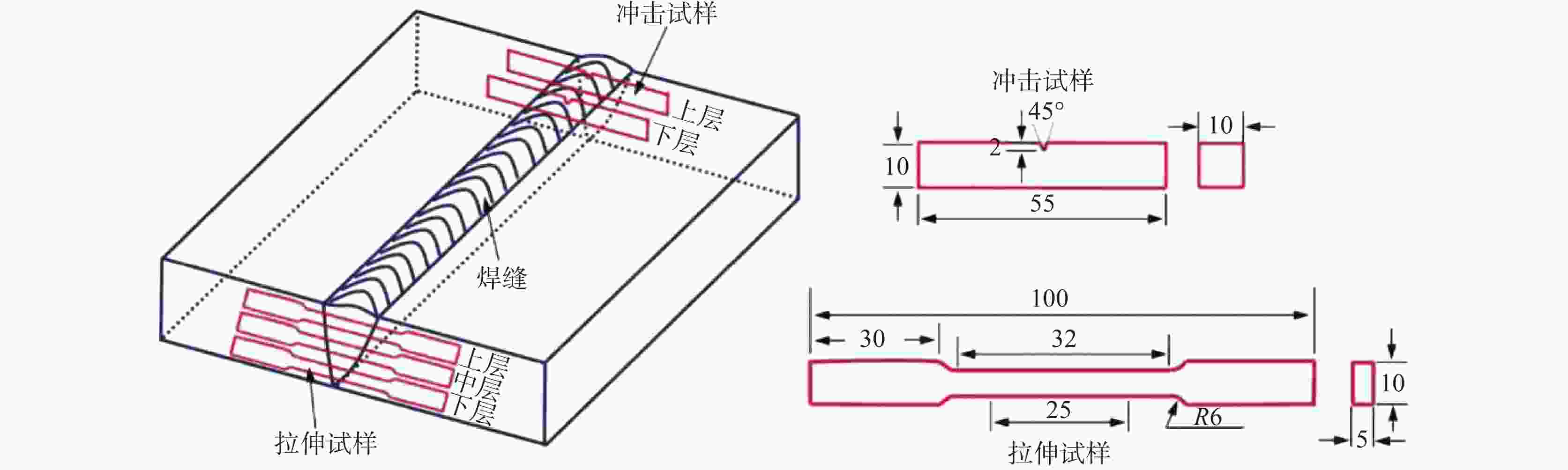

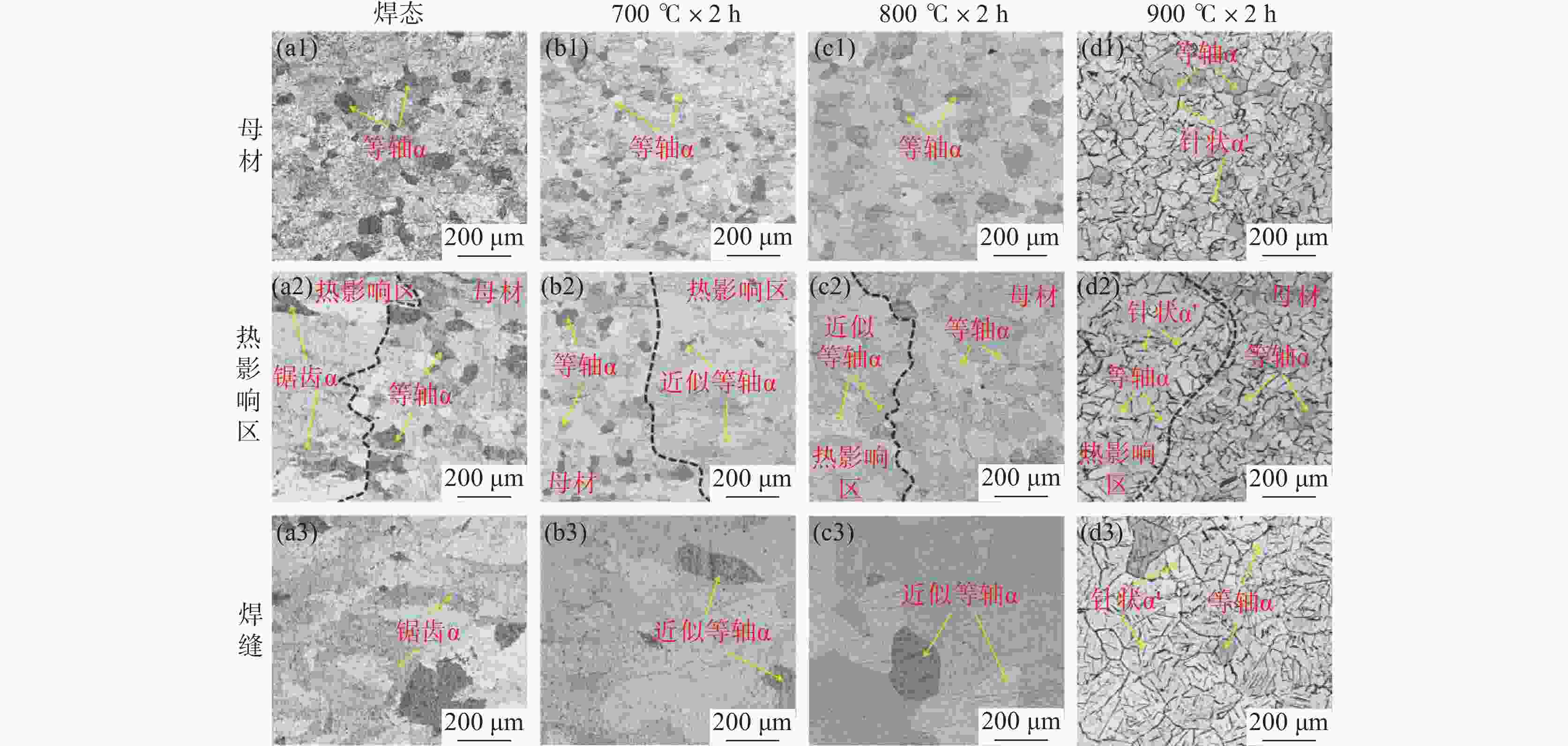

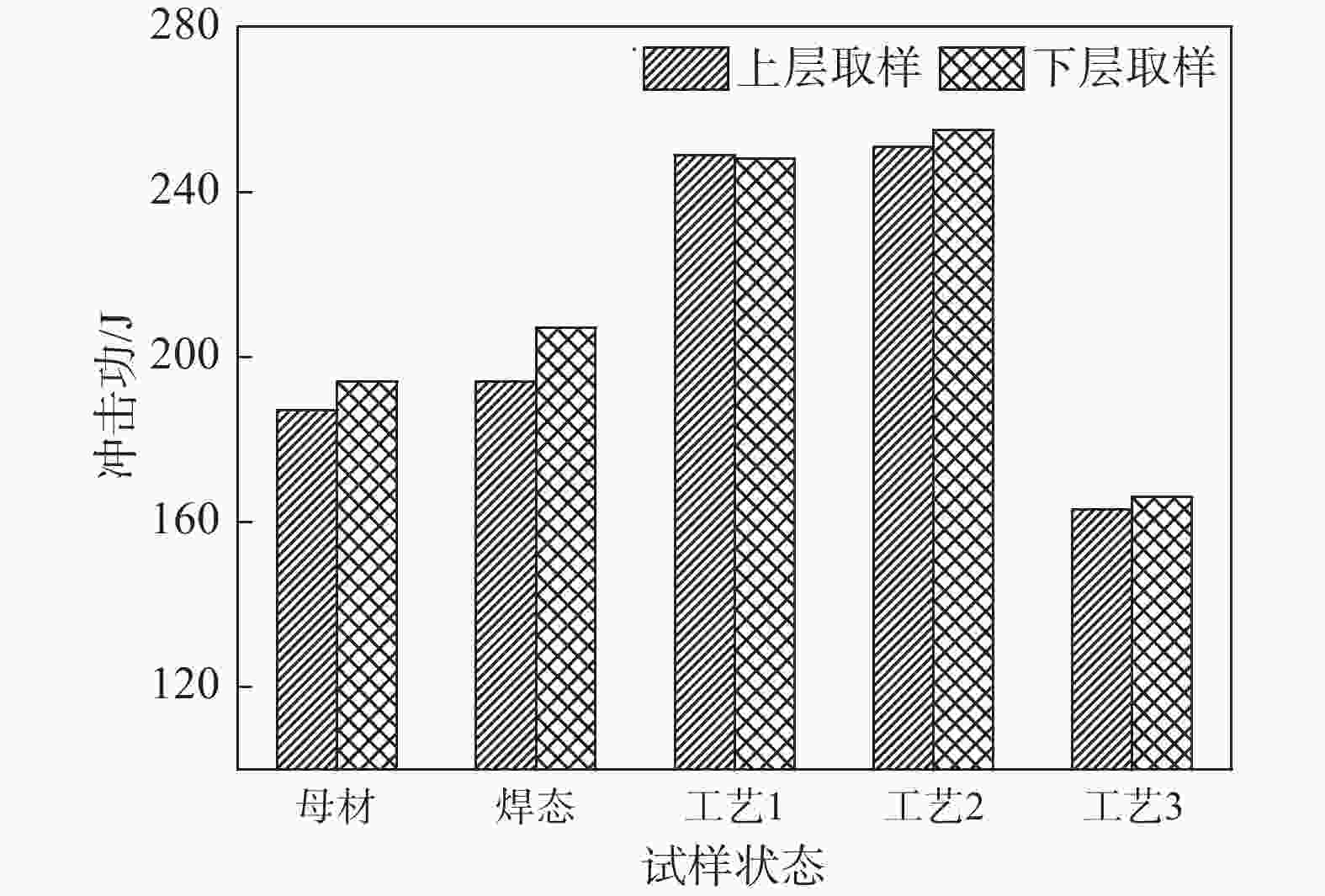

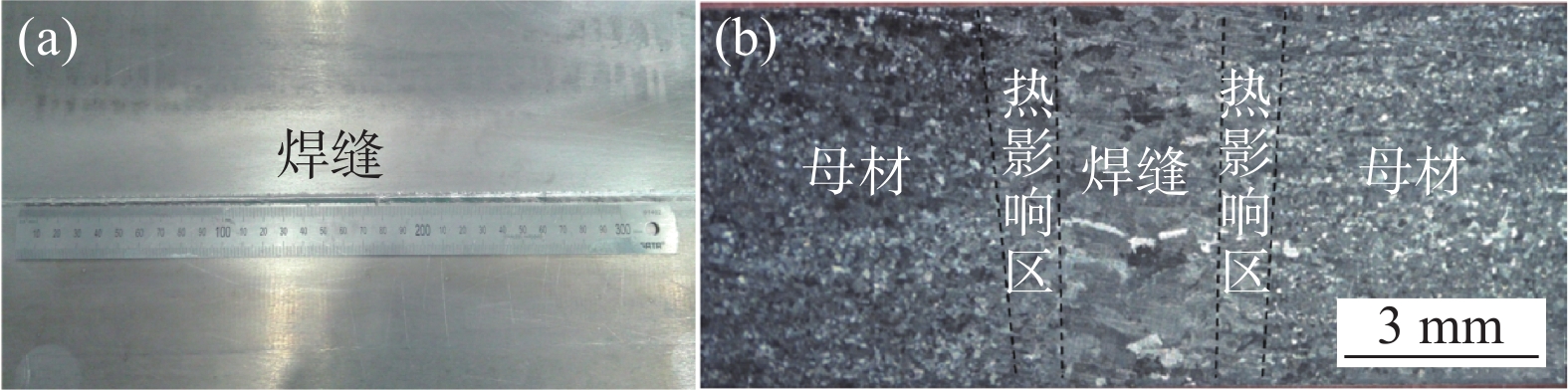

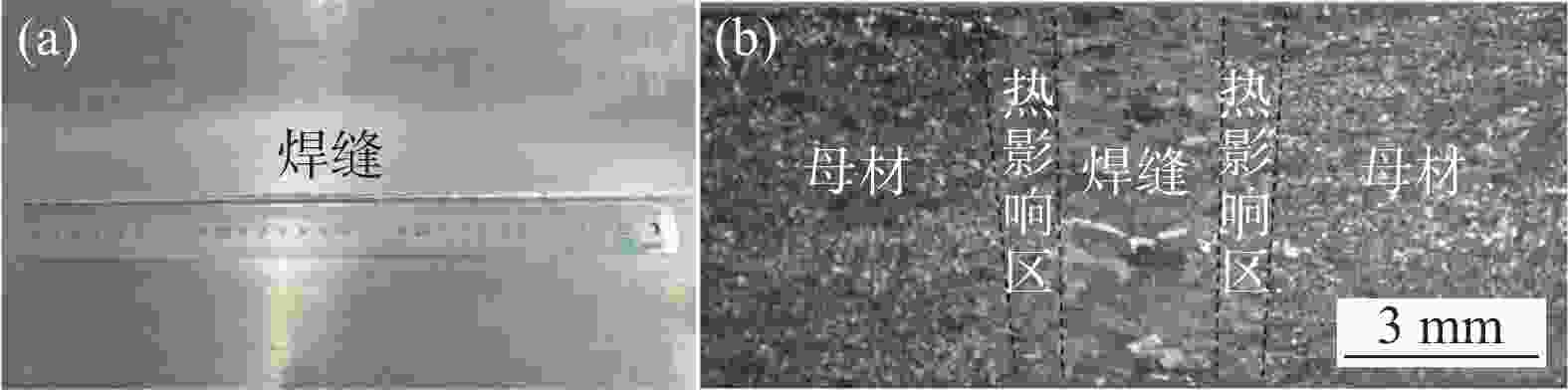

摘要: 对30 mm厚TA1真空电子束焊接试板开展了再结晶退火。通过对接头开展金相组织检验、拉伸、冲击试验,研究不同再结晶退火工艺对接头微观组织及力学性能的影响。结果表明:相较于组织为等轴α相的母材,高硬度锯齿α相和针状α'相的生成使对应的焊态下接头和900 ℃×2 h再结晶退火工艺下接头的屈服强度和抗拉强度提升,但随之而来的是接头塑性(即断后伸长率)和韧性(即冲击功)的大幅下降。母材具有的等轴α相以及700 ℃×2 h和800 ℃×2 h再结晶退火工艺下获得的近似等轴α相有利于提升韧性和塑性,使母材及对应工艺下的接头表现出了具有较高的塑性和韧性;800 ℃×2 h退火工艺下接头的强度与韧性获得最佳匹配。Abstract: Recrystallization annealing was performed on 30 mm thick TA1 plates with electron beam welding. Metallographic examination, tensile and impact tests were performed on the welded joint in order to study the effect of recrystallization annealing process on the microstructures and mechanical properties of the joints. The results show that the formation of high hardness serrated α phase and acicular α' phase increases the yield and tensile strength of the welded joint and the joint with 900 ℃ 2 h recrystallization annealing process, but the plasticity (i.e., elongation after fracture) and toughness (i.e., impact energy) of the joint decrease significantly. The equiaxed α phase of the base metal and the approximate equiaxed α phase obtained at 700 ℃ 2 h and 800 ℃ 2 h recrystallization annealing process are conducive to improving the ductility and toughness, thus the base metal and the joint under the corresponding process have higher ductility and toughness. The strength and toughness of the joint are best matched at the 800 ℃ 2 h annealing process.

-

表 1 焊接接头热处理工艺

Table 1. Heat treatment process of the welded joint

试验工艺 保温 冷却 温度/℃ 时间/h 方式 结束温度/ ℃ 母材 焊态 工艺1 700 2 随炉 100 工艺2 800 2 随炉 100 工艺3 900 2 随炉 100 -

[1] GAO X L, ZHANG L J, LIU J, et al. Effects of weld cross-section profiles and microstructure on properties of pulsed Nd: YAG laser welding of Ti6Al4V sheet[J]. International Journal of Advanced Manufacturing Technology, 2014,72(5-8):895-903. doi: 10.1007/s00170-014-5722-x [2] LI Y J, WU N, PUCHKOV P U. Application of advanced welding technology in aviation and aerospace industry[J]. Aeronautical Manufacturing Technology, 2010,53(9):43-47. (李亚江, 吴娜, PUCHKOV P U. 先进焊接技术在航空航天领域中的应用[J]. 航空制造技术, 2010,53(9):43-47. doi: 10.3969/j.issn.1671-833X.2010.09.005LI Y J, WU N, PUCHKOV P U. Application of advanced welding technology in aviation and aerospace industry[J]. Aeronautical Manufacturing Technology, 2010, 53(9): 43-47. doi: 10.3969/j.issn.1671-833X.2010.09.005 [3] SUN W J, WANG S L, CHEN Y H, et al. Development of advanced welding technologies for titanium alloys[J]. Aeronautical Manufacturing Technology, 2019,62(18):63-72. (孙文君, 王善林, 陈玉华, 等. 钛合金先进焊接技术研究现状[J]. 航空制造技术, 2019,62(18):63-72.SUN W J, WANG S L, CHEN Y H, et al. Development of advanced welding technologies for titanium alloys[J]. Aeronautical Manufacturing Technology, 2019, 62(18): 63-72. [4] ZHANG X Y, ZHAO Y Q, BAI C G. Titanium alloys and applications[M]. Beijing: Chemical Industry Press, 2005, 102. (张喜燕, 赵永庆, 白晨光. 钛合金及应用[M]. 北京: 化学工业出版社, 2005, 102.ZHANG X Y, ZHAO Y Q, BAI C G. Titanium alloys and applications[M]. Beijing: Chemical Industry Press, 2005, 102. [5] DUAN X G, JIANG H T, LIU J X, et al. Recrystallization process of commercial pure titanium cold rolled sheet[J]. Chinese Journal of Rare Metals, 2012,36(3):353-356. (段晓鸽, 江海涛, 刘继雄, 等. 工业纯钛TA2冷轧板再结晶过程的研究[J]. 稀有金属, 2012,36(3):353-356.DUAN X G, JIANG H T, LIU J X, et al. Recrystallization process of commercial pure titanium cold rolled sheet[J]. Chinese Journal of Rare Metals, 2012, 36(3): 353-356. [6] LI Z, SHI Y, LIU J, et al. Effect of laser welding parameters on microstructure and mechanical properties of commercial pure titanium[J]. Applied Laser, 2016,36(1):53-57. (李镇, 石岩, 刘佳, 等. 工艺参数对工业纯钛激光焊接接头组织性能的影响[J]. 应用激光, 2016,36(1):53-57.LI Z, SHI Y, LIU J, et al. Effect of laser welding parameters on microstructure and mechanical properties of commercial pure titanium[J]. Applied Laser, 2016, 36(1): 53-57. [7] SONG K, MAO X N, XIN S W, et al. Research progress on microstructure and properties of titanium alloy welded joints[J]. Materials Reports, 2018,32(S2):336-340. (宋凯, 毛小南, 辛社伟, 等. 钛合金焊接接头组织性能研究进展[J]. 材料导报, 2018,32(S2):336-340.SONG K, MAO X N, XIN S W, et al. Research progress on microstructure and properties of titanium alloy welded joints[J]. Materials Reports, 2018, 32(S2): 336-340. [8] LIU H, NAKATA K, YAMAMOTO N, et al. Mechanical properties and strengthening mechanisms in laser beam welds of pure titanium[J]. Science and Technology of Welding and Joining, 2011,16(7):581-585. doi: 10.1179/1362171811Y.0000000054 [9] LIAO Z Q, WANG Z P. Plasma welding of titanium alloy thick-plate[J]. Development and Application of Materials, 2005,20(04):27-28,37. (廖志谦, 王忠平. 钛合金厚板的等离子焊接[J]. 材料开发与应用, 2005,20(04):27-28,37. doi: 10.3969/j.issn.1003-1545.2005.04.008LIAO Z Q, WANG Z P. Plasma welding of titanium alloy thick-plate[J]. Development and Application of Materials, 2005, 20(04): 27-28,37. doi: 10.3969/j.issn.1003-1545.2005.04.008 [10] MERSON E, BRYDSON R, BROWM A. The effect of crystallographic orientation on the mechanical properties of titanium[J]. J. Phys. Conf. Ser., 2008(126):1-4. -

下载:

下载: