Progress in molecular dynamics simulation of NiTi shape memory alloys

-

摘要: 分子动力学技术作为一种精确高效的原子尺度材料微观结构和组织研究方法,在降低研发成本的同时,对试验研究具有指导意义,可在一定程度上弥补NiTi合金研究中因分析技术滞后而导致的试验数据不足和理论解释困难等问题。首先概述了NiTi合金的形状记忆效应和超弹性特性,介绍了分子动力学的基本原理和模拟NiTi合金的常用势函数,然后重点介绍了分子动力学模拟在研究NiTi 合金力学行为和相变方面的应用现状,包括晶粒尺寸、孔隙率、非晶相、Ni含量等因素对其性能的影响,凸显了分子动力学方法在研究NiTi形状记忆合金中的优势。使用分子动力学技术模拟不同参数对性能的影响,可指导试验研究,针对性地改进材料制备工艺,提高材料的形状记忆效应、超弹性和耐磨损性等性能,推动新型高性能NiTi合金材料的开发和应用。

-

关键词:

- NiTi形状记忆合金 /

- 力学行为 /

- 相变 /

- 分子动力学模拟

Abstract: Molecular dynamics (MD) serves as an indispensable tool for investigating the microstructure and organization of atomic-scale materials, providing invaluable guidance for experimental research while concurrently mitigating research costs. This technique effectively compensates for the paucity of experimental data and the intricacies of theoretical interpretation encountered in the study of NiTi alloys, which are constrained by the limitations of analytical technologies. This paper commenced by summarizing the shape memory effect and superelastic properties of NiTi alloys. Subsequently, the fundamental principles of molecular dynamics and the prevalent potential functions utilized for simulating NiTi alloys were delineated. The emphasis was placed on the application of MD simulation in the examination of the mechanical behavior and phase transitions of NiTi alloys. The influence of grain size, porosity, amorphous phase, and nickel content on the properties of NiTi shape memory alloys was elucidated, highlighting the advantages of MD methods in this research domain. The utilization of MD technology to simulate the impact of various parameters on material properties can facilitate experimental research, enhance the material preparation process, and bolster the shape memory effect, super elasticity, and wear resistance of the material. Consequently, this research endeavor facilitates the advancement and utilization of novel, high-performance NiTi alloy materials.-

Key words:

- NiTi shape memory alloy /

- mechanical behavior /

- phase change /

- molecular dynamics

-

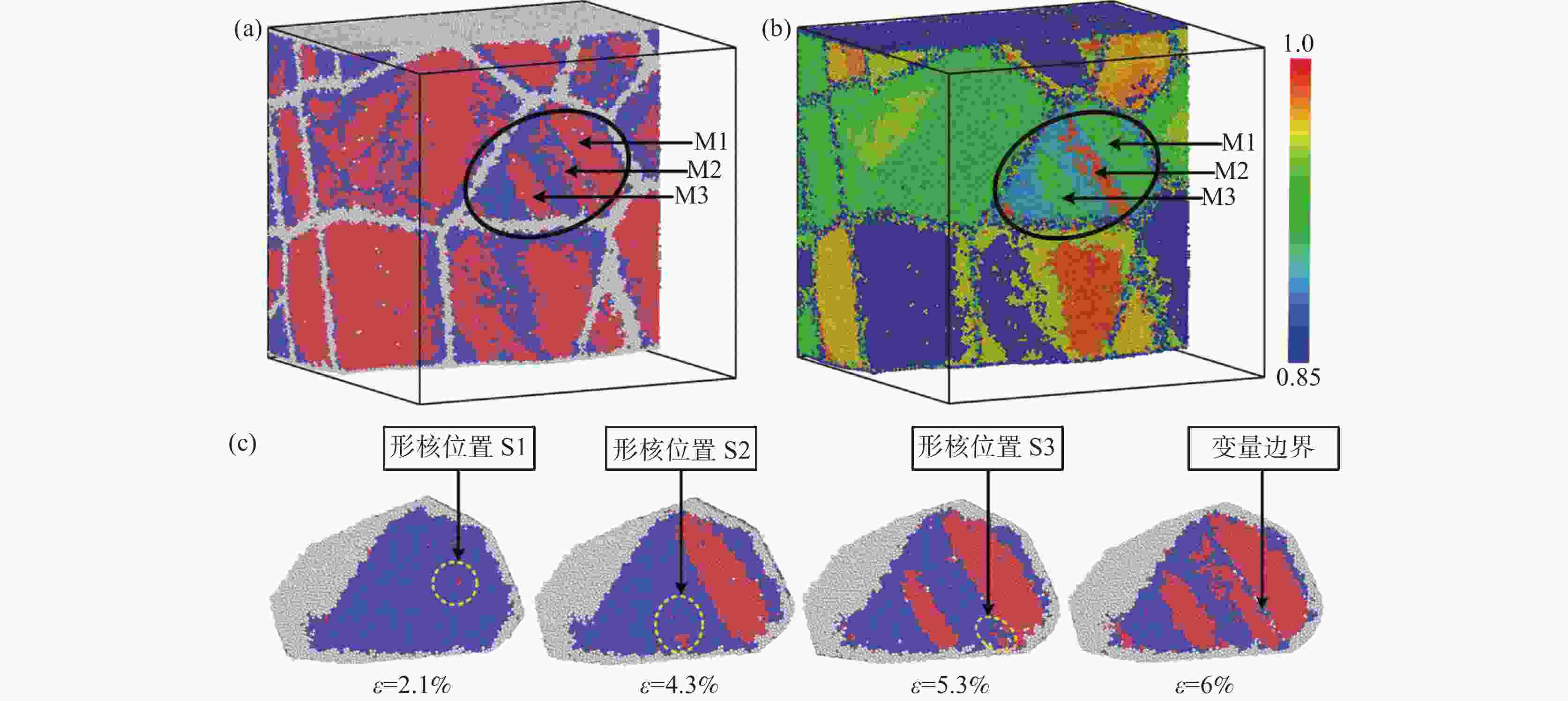

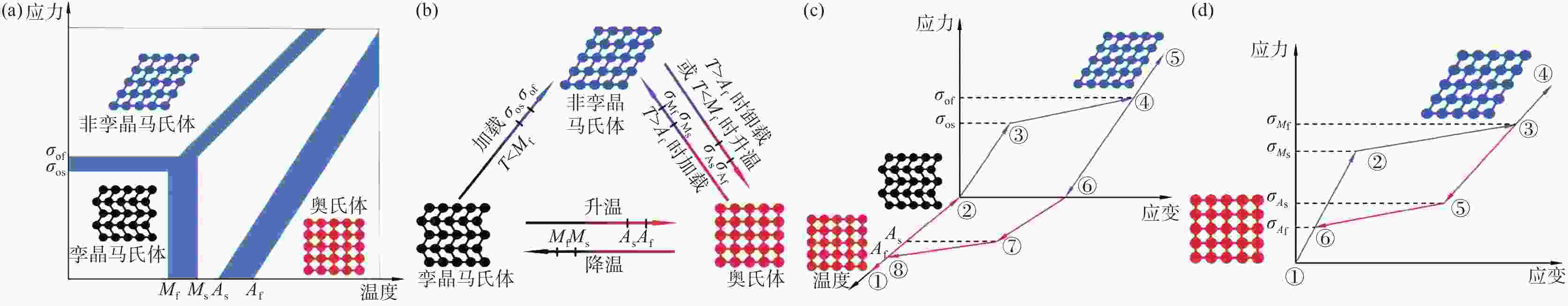

图 1 孪晶马氏体、非孪晶马氏体和奥氏体的(a)应力-温度相图,(b)相互转化关系,(c)OWSME的应力-应变-温度响应,(d)超弹性的应力-应变响应[21]

Figure 1. Twinned martensite, non-twinned martensite and austenite: (a) Stress-temperature phase diagram, (b) the mutual transformation relationship, (c) stress-strain-temperature response diagram of OWSME, (d) stress-strain response diagram of superelasticity[21]

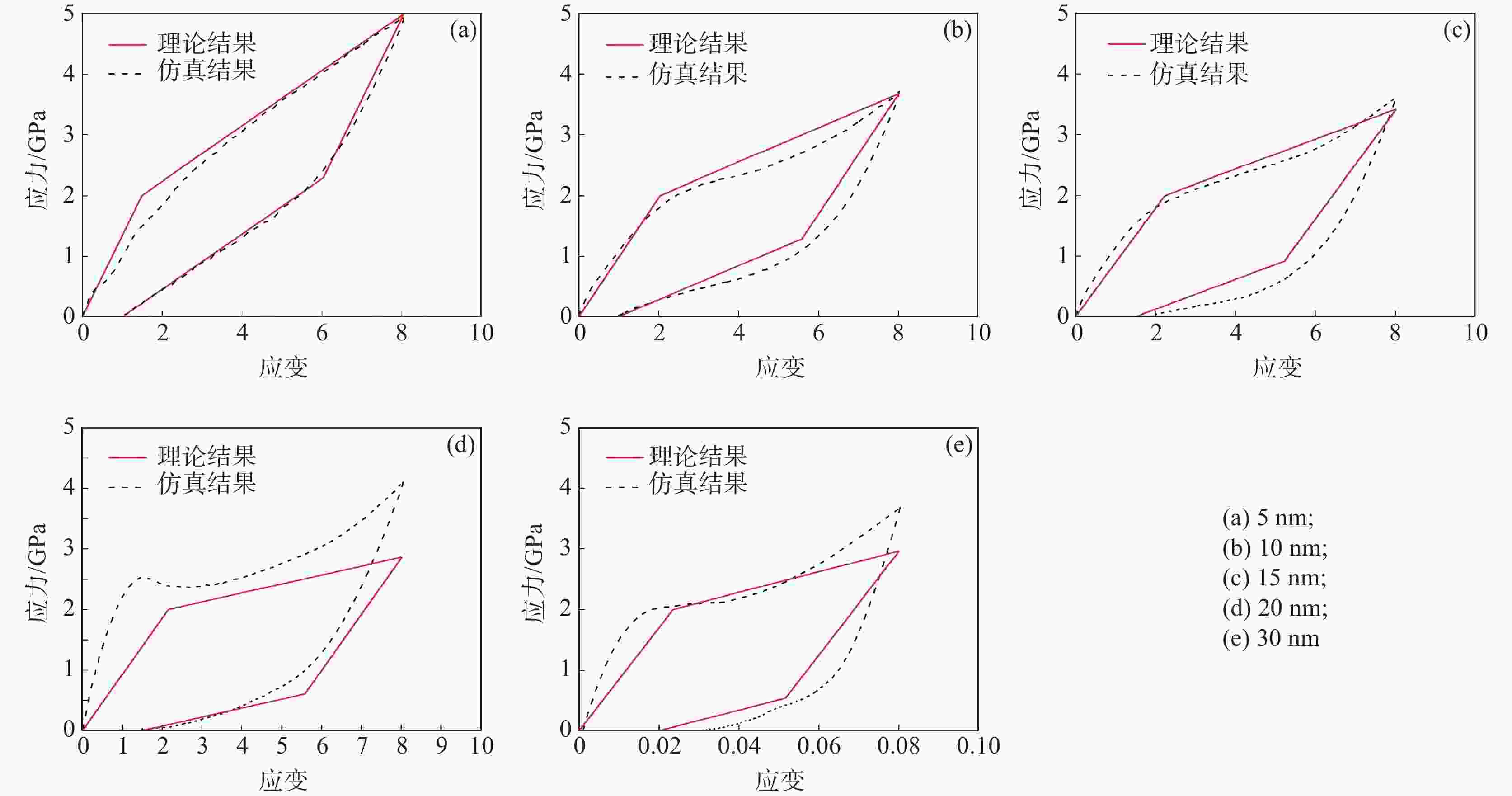

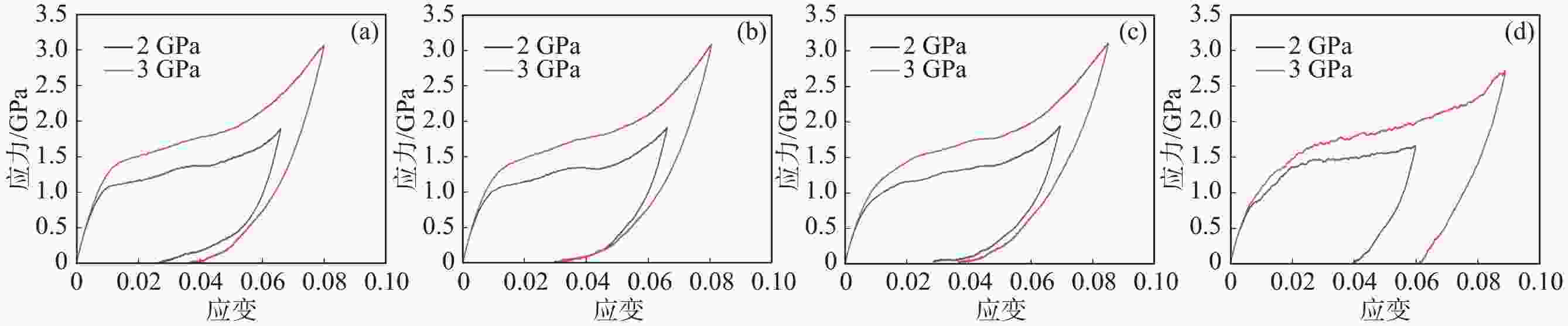

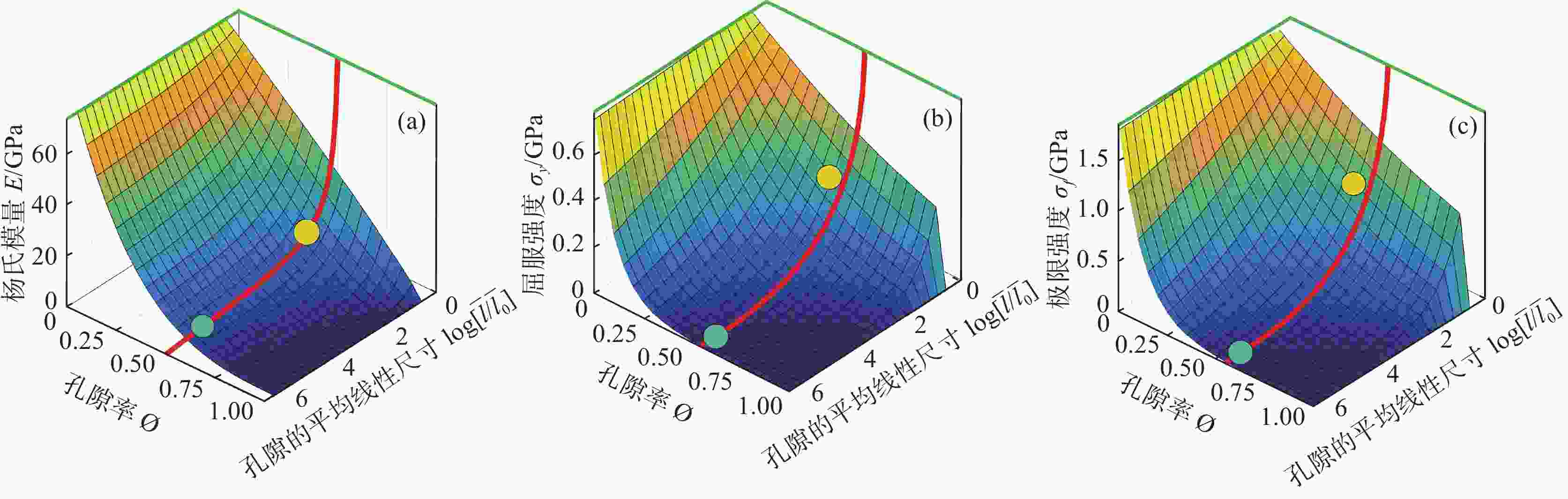

图 5 多孔NiTi的机械性能对约化平均线性孔径$ \mathrm{l}\mathrm{o}\mathrm{g}\left(\bar{l}/\bar{{l}_{0}}\right) $和孔隙率$ \varnothing $的依赖性[60]

红线表示在孔隙率为0.55时的切片,黄色圆圈表示孔隙率为0.55时具有纳米级孔隙的材料,绿色圆圈表示孔隙率为0.55时具有微米级孔隙的材料(a)杨氏模量E;(b)屈服强度$ {\sigma }_{y} $;(c)极限强度$ {\sigma }_{f} $

Figure 5. The mechanical properties of porous NiTi depend on the reduced mean linear pore size $ \mathrm{l}\mathrm{o}\mathrm{g}\left(\bar{l}/\bar{{l}_{0}}\right) $ and porosity $ \varnothing $ [60]

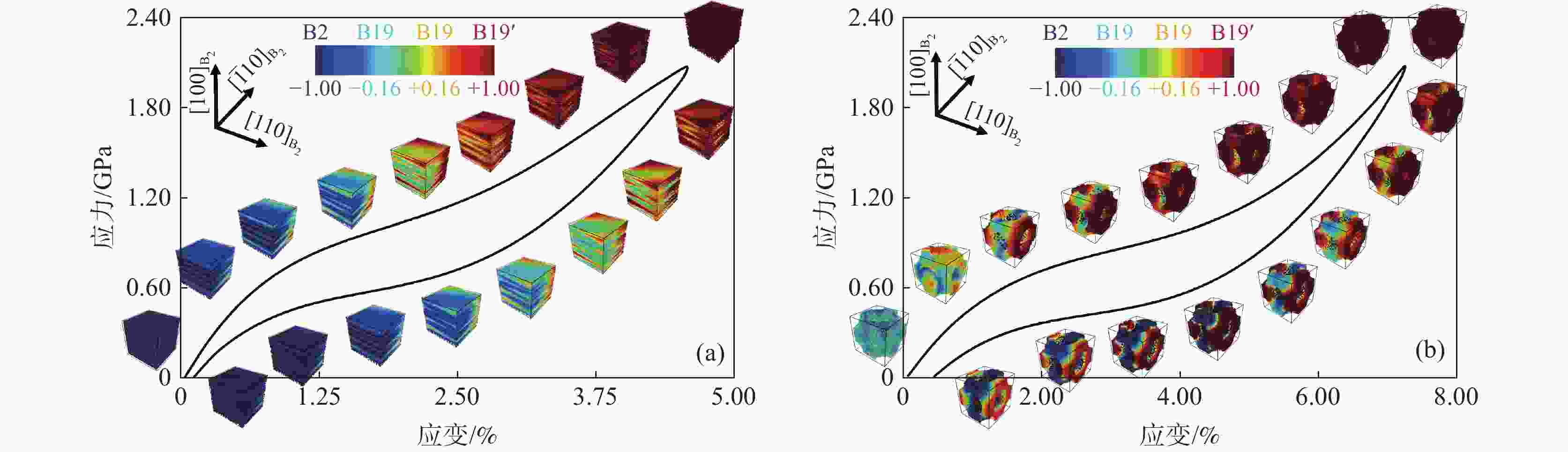

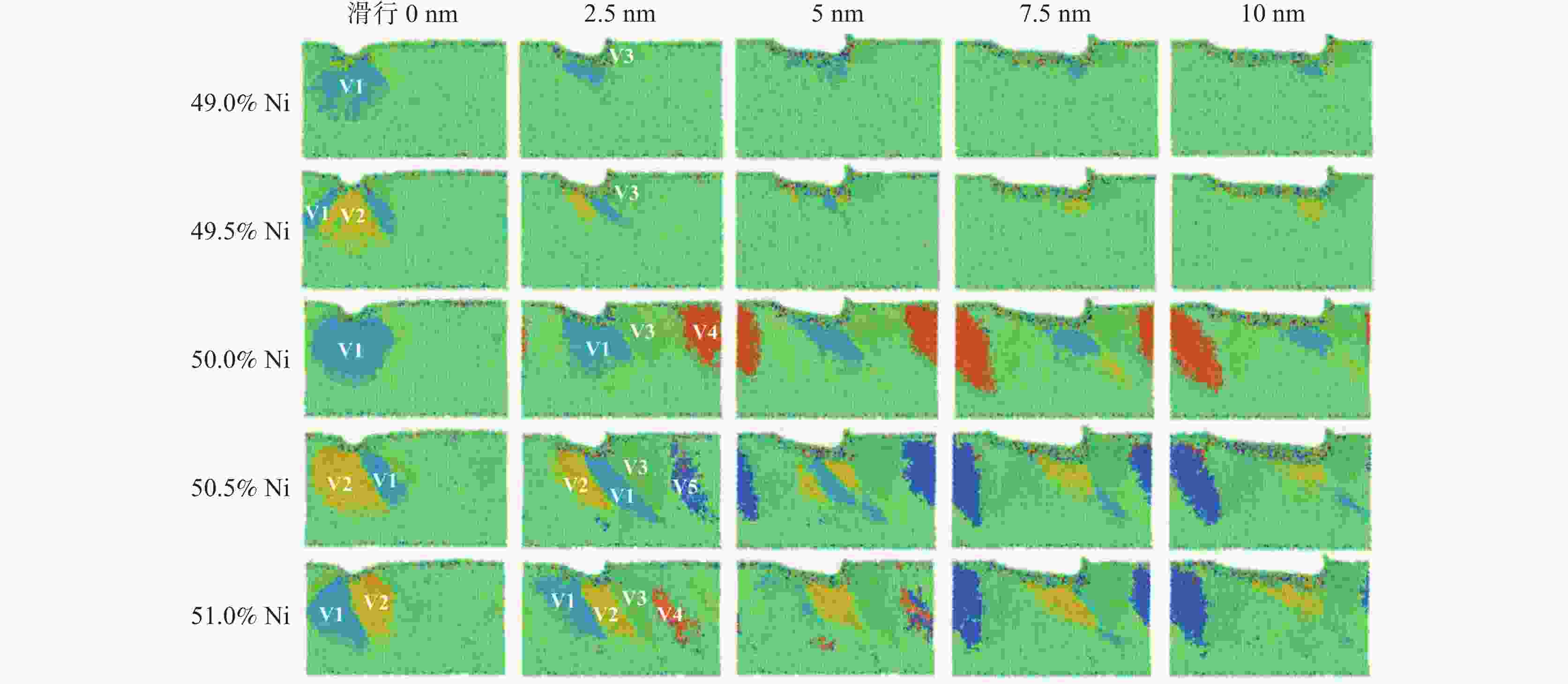

图 6 拉伸加载时PC模型(dave = 15 nm)中单个晶粒的相变行为:加载至6%应变时PC模型中的(a)相分布和 (b)取向分布(原子根据晶格取向着色);(c)所选晶粒中B19'马氏体的形核和生长过程

Figure 6. Phase transition behavior of individual grains in PC model (dave = 15 nm) under tensile loading: (a) phase distribution, (b) orientation distribution (atoms are colored according to lattice orientation) in the PC model when loaded to 6% strain and (c) growth of B19' martensite in selected grains

-

[1] SU M, SONG Y. Printable smart materials and devices: Strategies and applications[J]. Chemical Reviews, 2022,122(5):5144-5164. doi: 10.1021/acs.chemrev.1c00303 [2] ZHAO L C, CAI W, ZHENG Y F. Shape memory effect and superelasticity of alloys [M]. Beijing: National Defense Industry Press, 2002: 13-20. (赵连城, 蔡伟, 郑玉峰. 合金的形状记忆效应与超弹性[M]. 北京: 国防工业出版社, 2002: 13-20.ZHAO L C, CAI W, ZHENG Y F. Shape memory effect and superelasticity of alloys [M]. Beijing: National Defense Industry Press, 2002: 13-20. [3] TONG Y X, ZHENG Y F, LI L. Ultra-fine crystal titanium-nickel based shape memory alloy[M]. Beijing: Science Press, 2017: 123-127. (佟运祥, 郑玉峰, 李莉. 超细晶钛镍基形状记忆合金[M]. 北京: 科学出版社, 2017: 123-127.TONG Y X, ZHENG Y F, LI L. Ultra-fine crystal titanium-nickel based shape memory alloy[M]. Beijing: Science Press, 2017: 123-127. [4] TSUCHIYA K, INUZUKA M, TOMUS D, et al. Martensitic transformation in nanostructured TiNi shape memory alloy formed via severe plastic deformation[J]. Materials Science & Engineering A, Structural Materials : Properties, Microstructure and Processing, 2006, 438: 643-648. [5] BUEHLER W J, GILFRICH J V, WILEY R C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi[J]. Journal of Applied Physics, 1963,34(5):1475-1477. doi: 10.1063/1.1729603 [6] OTSUKA K, REN X. Physical metallurgy of Ti-Ni-based shape memory alloys[J]. Progress in Materials Science, 2005,50(5):511-678. doi: 10.1016/j.pmatsci.2004.10.001 [7] ZHAO W B. Material characteristics and medical application of nickel-titanium shape-memory alloy[J]. Journal of Clinical Rehabilitative Tissue Engineering Research, 2007,11(22):4376-4379. (赵维彪. 镍钛形状记忆合金的材料学特征与医学应用[J]. 中国组织工程研究与临床康复, 2007,11(22):4376-4379.ZHAO W B. Material characteristics and medical application of nickel-titanium shape-memory alloy[J]. Journal of Clinical Rehabilitative Tissue Engineering Research, 2007, 11(22): 4376-4379. [8] ALIPOUR S, TAROMIAN F, GHOMI E R, et al. Nitinol: From historical milestones to functional properties and biomedical applications//Proceedings of the Institution of Mechanical Engineers, Part H[J]. Journal of Engineering in Medicine, 2022,236(11):1595-1612. doi: 10.1177/09544119221123176 [9] PATEL S K, BEHERA B, SWAIN B, et al. A review on NiTi alloys for biomedical applications and their biocompatibility [C]// Materials Today : Proceedings. Elsevier Ltd, 2020, 33: 5548-5551. [10] MANI G, PORTER D, GROVE K, et al. Surface finishing of nitinol for implantable medical devices: A review[J]. Journal of Biomedical Materials Research. Part B, Applied Biomaterials, 2022,110(12):2763-2778. doi: 10.1002/jbm.b.35112 [11] DELLACORTE C. Ni-Ti alloys for aerospace bearing applications[C]//World Tribology Congress (WTC 2017). 2017 (GRC-E-DAA-TN42521). [12] PUENTE-CÓRDOVA J G, RENTERÍA-BALTIÉRREZ F Y, DIABB-ZAVALA J M, et al. Thermomechanical characterization and modeling of NiTi shape memory alloy coil spring[J]. Materials, 2023,16(10):3673. doi: 10.3390/ma16103673 [13] BIFFI C A, NESPOLI A, PREVITALI B, et al. Functional response of NiTi elements for smart micro-actuation applications: SMST 2013[J]. Journal of Materials Engineering and Performance, 2014,23(7):2351-2356. doi: 10.1007/s11665-014-0898-7 [14] LI G T, YU T Y, WU P, et al. Molecular dynamics simulation of NiTi shape memory alloys produced by laser powder bed fusion: Laser parameters on phase transformation behavior[J]. Materials, 2023,16(1):409. doi: 10.3390/ma16010409 [15] LIU B F, WANG Y Y, LI J C, et al. Surface effect on phase transformation of single crystal NiTi shape memory alloys studied by molecular dynamics simulation[J]. Advanced Engineering Materials, 2023,25(17):2300358. doi: 10.1002/adem.202300358 [16] CHEN J Y, HUO D H, KUMAR Y H. Molecular dynamics study of phase transformations in NiTi shape memory alloy embedded with precipitates[J]. Materials Research Express, 2021,8(10):106508. doi: 10.1088/2053-1591/ac2b57 [17] CHEN X, LIU T, LI R, et al. Molecular dynamics simulation on the shape memory effect and superelasticity in NiTi shape memory alloy[J]. Computational Materials Science, 2018,146:61-69. doi: 10.1016/j.commatsci.2018.01.026 [18] WANG B, KANG G C, WU W P, et al. Molecular dynamics simulations on nanocrystalline super-elastic NiTi shape memory alloy by addressing transformation ratchetting and its atomic mechanism[J]. International Journal of Plasticity, 2020,125:374-394. doi: 10.1016/j.ijplas.2019.10.009 [19] WANG M, JIANG S Y, SUN D, et al. Molecular dynamics simulation of mechanical behavior and phase transformation of nanocrystalline NiTi shape memory alloy with gradient structure[J]. Computational Materials Science, 2022,204:111186. doi: 10.1016/j.commatsci.2022.111186 [20] LIANG Y L. Investigation of plastic deformation mechanism and microstructure evolution of NiTiFe shape memory alloy during plane strain compression[D]. Harbin: Harbin Engineering University, 2018. (梁玉龙. 镍钛铁形状记忆合金平面应变塑性变形机理及微观结构演变研究[D]. 哈尔滨: 哈尔滨工程大学, 2018.LIANG Y L. Investigation of plastic deformation mechanism and microstructure evolution of NiTiFe shape memory alloy during plane strain compression[D]. Harbin: Harbin Engineering University, 2018. [21] YANG J N, HUANG B, GU X J, et al. A review of shape memory alloys: Mechanical behavior and application[J]. Chinese Journal of Solid Mechanics, 2021,42(4):345-375. (杨建楠, 黄彬, 谷小军, 等. 形状记忆合金力学行为与应用综述[J]. 固体力学学报, 2021,42(4):345-375.YANG J N, HUANG B, GU X J, et al. A review of shape memory alloys: Mechanical behavior and application[J]. Chinese Journal of Solid Mechanics, 2021, 42(4): 345-375. [22] ALDER B, WAINWRIGHT T. Phase transition for a hard sphere system[J]. J. Chem. Phys., 1957,27:1208-1209 . doi: 10.1063/1.1743957 [23] ALDER B, WAINWRIGHT T. Studies in molecular dynamics I: General method[J]. J. Chem. Phys., 1959,31:459-466 . doi: 10.1063/1.1730376 [24] RAHMAN A. Correlations in the motion of atoms in liquid argon[J]. Phys. Rev., 1964,136:405-411. [25] VERLET L. Computer “experiments” on classical fluids i: Thermodynamical properties of Lennard-Jones molecules[J]. Phys. Rev., 1967,159:98-103. doi: 10.1103/PhysRev.159.98 [26] SHIBUTA Y, SAKANE S, MIYOSHI E, et al. Heterogeneity in homogeneous nucleation from billion-atom molecular dynamics simulation of solidification of pure metal[J]. Nature Communications, 2017,8(1):1-10. doi: 10.1038/s41467-016-0009-6 [27] SHIBUTA Y, OHNO M, TAKAKI T. Advent of cross-scale modeling: High-performance computing of solidification and grain growth[J]. Advanced Theory and Simulations, 2018,1(9):1800065. doi: 10.1002/adts.201800065 [28] KMIECIK S, GRONT D, KOLINSKI M, et al. Coarse-Grained protein models and their applications[J]. Chemical Reviews, 2016,116(14):7898-7936. doi: 10.1021/acs.chemrev.6b00163 [29] EBINA H, FUKAHARA S, SHIBUTA Y. Accelerated molecular dynamics simulation of vacancy diffusion in substitutional alloy with collective variable-driven hyperdynamics[J]. Computational Materials Science, 2021,196:110577. doi: 10.1016/j.commatsci.2021.110577 [30] VOTER A F. Hyperdynamics: Accelerated molecular dynamics of infrequent events[J]. Physical Review Letters, 1997,78(20):3908-3911. doi: 10.1103/PhysRevLett.78.3908 [31] SORENSEN M R, VOTER A F. Temperature-accelerated dynamics for simulation of infrequent events[J]. Journal of Chemical Physics, 2000,112(21):9599-9606. doi: 10.1063/1.481576 [32] LAIO A, PARRINELLO M. Escaping free-energy minima[J]. Proceedings of the National Academy of Sciences - PNAS, 2002,99(20):12562-12566. doi: 10.1073/pnas.202427399 [33] ISHII A, OGATA S, KIMIZUKA H, et al. Adaptive-boost molecular dynamics simulation of carbon diffusion in iron[J]. Physical Review B: Condensed Matter and Materials Physics, 2012,85(6):064303. doi: 10.1103/PhysRevB.85.064303 [34] BAL K M, NEYTS E C. Merging metadynamics into hyperdynamics: Accelerated molecular simulations reaching time scales from microseconds to seconds[J]. Journal of Chemical Theory and Computation, 2015,11(10):4545-4554. doi: 10.1021/acs.jctc.5b00597 [35] BADAR M S, SHAMSI S, AHMED J, et al. Molecular dynamics simulations: Concept, methods, and applications[M]//Transdisciplinarity. Cham: Springer International Publishing, 2022: 131-151. [36] LEIMKUHLER B, MATTHEWS C. Molecular dynamics[J]. Interdisciplinary Applied Mathematics, 2015,39:443. [37] TUCKERMAN M E, MARTYNA G J. Understanding modern molecular dynamics: Techniques and applications[J]. Journal of Physical Chemistry B, 2000,104(2):159-178. doi: 10.1021/jp992433y [38] KANG H B, ZHANG Y W, YANG M. Molecular dynamics simulation of thermal conductivity of Cu-Ar nanofluid using EAM potential for Cu-Cu interactions[J]. Applied Physics A: Materials Science & Processing, 2011, 103(4): 1001-1008. [39] METYA A K, HENS A, SINGH J K. Molecular dynamics study of vapor-liquid equilibria and transport properties of sodium and lithium based on EAM potentials[J]. Fluid Phase Equilibria, 2012,313:16-24. doi: 10.1016/j.fluid.2011.08.026 [40] MUNAJI, SUDARNO, PURWANINGROOM D L, et al. Performance of EAM and MEAM potential for NiTi alloys: A comparative study[J]. IOP Conference Series: Materials Science and Engineering, 2017,180(1):12252. [41] XU W, KIM W K. Molecular dynamics simulation of the uniaxial tensile test of silicon nanowires using the MEAM potential[J]. Mechanics of Materials, 2019,137:103140. doi: 10.1016/j.mechmat.2019.103140 [42] TRĘDAK P, RUDNICKI W R, MAJEWSKI J A. Efficient implementation of the many-body reactive bond order (REBO) potential on GPU[J]. Journal of Computational Physics, 2016,321:556-570. doi: 10.1016/j.jcp.2016.05.061 [43] KHAN A, NAVID I, NOSHIN M, et al. Equilibrium molecular dynamics (MD) simulation study of thermal conductivity of graphene nanoribbon: A comparative study on MD potentials[J]. Electronics (Basel), 2015,4(4):1109-1124. [44] LIM J S. Dynamics of surfaces and interfaces: From first-principles modeling to machine-learning molecular dynamics[D]. Boston: Harvard University, 2022. [45] NOTTOLI M, MENNUCCI B, LIPPARINI F. Excited state born-oppenheimer molecular dynamics through coupling between time dependent DFT and AMOEBA[J]. Physical Chemistry Chemical Physics, 2020,22(35):19532-19541. doi: 10.1039/D0CP03688A [46] FINNIS M W, SINCLAIR J E. A simple empirical N-body potential for transition metals[J]. Philosophical Magazine A: Physics of Condensed Matter Defects and Mechanical Properties, 1984,50(1):45-55. [47] LAI W S, LIU B X. Lattice stability of some Ni-Ti alloy phases versus their chemical composition and disordering[J]. Journal of Physics: Condensed Matter, 2000,12(5):53-60. doi: 10.1088/0953-8984/12/5/101 [48] MUTTER D, NIELABA P. Simulation of the shape memory effect in a NiTi nano model system[J]. Journal of alloys and compounds, 2013,577:83-87. doi: 10.1016/j.jallcom.2012.01.095 [49] ZHONG Y, GALL K, ZHU T. Atomistic study of nanotwins in NiTi shape memory alloys[J]. Journal of Applied Physics, 2011,110(3):033532. doi: 10.1063/1.3621429 [50] KO W S, GRABOWSKI B, NEUGEBAUER J. Development and application of a Ni-Ti interatomic potential with high predictive accuracy of the martensitic phase transition[J]. Physical Review B, 2015,92:134107. doi: 10.1103/PhysRevB.92.134107 [51] WANG B. Study on super-elasticity degeneration mechanism of NiTi shape memory alloy by molecular dynamics simulations[D]. Chengdu: Southwest Jiaotong University, 2019. (王冰. NiTi形状记忆合金超弹性劣化机理的分子动力学模拟研究[D]. 成都: 西南交通大学, 2019.WANG B. Study on super-elasticity degeneration mechanism of NiTi shape memory alloy by molecular dynamics simulations[D]. Chengdu: Southwest Jiaotong University, 2019. [52] KIM Y M, LEE B J, BASKES M I. Modified embedded-atom method interatomic potentials for Ti and Zr[J]. Physical Review B, Condensed Matter and Materials Physics, 2006,74(1):014101. doi: 10.1103/PhysRevB.74.014101 [53] LEE B J. A modified embedded-atom method interatomic potential for the Fe-C system[J]. Acta Materialia, 2006,54(3):701-711. doi: 10.1016/j.actamat.2005.09.034 [54] KO W S, MAISEL S B, GRABOWSKI B, et al. Atomic scale processes of phase transformations in nanocrystalline NiTi shape-memory alloys[J]. Acta Materialia, 2017,123:90-101. doi: 10.1016/j.actamat.2016.10.019 [55] GUR S, FRANTIZSKONIS G N, MURALIDHARAN K. Atomistic simulation of shape memory effect (SME) and superelasticity (SE) in nano-porous NiTi shape memory alloy (SMA)[J]. Computational Materials Science, 2018,152:28-37. doi: 10.1016/j.commatsci.2018.05.031 [56] NIE K, LI M P, WU W P, et al. Grain size-dependent energy partition in phase transition of NiTi shape memory alloys studied by molecular dynamics simulation[J]. International Journal of Solids and Structures, 2021,221:31-41. doi: 10.1016/j.ijsolstr.2020.02.027 [57] LIU B F, LI Z F, DU C Z, et al. Molecular dynamics simulation of grain size effect on mechanism of twin martensite transformation of nanocrystalline NiTi shape memory alloys[J]. Computational Materials Science, 2022,210:111451. doi: 10.1016/j.commatsci.2022.111451 [58] LIU B F, LI Z F, LI W Z, et al. Molecular dynamics simulation of the porosity effect on transformation mechanism of nanocrystalline porous NiTi shape memory alloy[J]. Materials Today Communications, 2023,34:105320. doi: 10.1016/j.mtcomm.2023.105320 [59] LIU B F, WANG Y Y, WU W P. Effects of porosity and cyclic deformation on phase transformation of porous nanocrystalline NiTi shape memory alloy: An atomistic simulation[J]. Journal of Applied Physics, 2023,134(14):143102. doi: 10.1063/5.0167305 [60] GALIMZYANOV B N, NIKIFOROV G A, ANIKEEV S G, et al. A unified empirical equation for determining the mechanical properties of porous NiTi alloy: From nanoporosity to microporosity[J]. Crystals (Basel), 2023,13(12):1656. doi: 10.3390/cryst13121656 [61] KO W S, CHOI W S, XU G, et al. Dissecting functional degradation in NiTi shape memory alloys containing amorphous regions via atomistic simulations[J]. Acta Materialia, 2021,202:331-349. doi: 10.1016/j.actamat.2020.10.070 [62] WANG M, JIANG S Y, ZHANG Y Q, et al. Molecular dynamics investigation on mechanical behaviour and phase transition of nanocrystalline NiTi shape memory alloy containing amorphous surface[J]. Applied Surface Science, 2022,587:152871. doi: 10.1016/j.apsusc.2022.152871 [63] HUA P, XIA M L, ONUKI Y, et al. Nanocomposite NiTi shape memory alloy with high strength and fatigue resistance[J]. Nature Nanotechnology, 2021,16:409-413. doi: 10.1038/s41565-020-00837-5 [64] LI G T, YU T Y, ZHANG N, et al. The effect of Ni content on phase transformation behavior of NiTi alloys: An atomistic modeling study[J]. Computational Materials Science, 2022,215:111804. doi: 10.1016/j.commatsci.2022.111804 [65] LI G T, BAO J, YU T Y, et al. An atomistic study of effects of temperature and Ni element on the phase transition and wear behavior of NiTi shape memory alloy[J]. Tribology International, 2024,192:109309. doi: 10.1016/j.triboint.2024.109309 [66] WEN S F, LIU Y, ZHOU Y, et al. Effect of Ni content on the transformation behavior and mechanical property of NiTi shape memory alloys fabricated by laser powder bed fusion[J]. Optics and Laser Technology, 2021,134:106653. doi: 10.1016/j.optlastec.2020.106653 [67] CUI Y H, ZENG X G, XIAO J F, et al. Micro-damage evolution under intensive dynamic loading and its influence on constitutive and state equations for nanocrystalline NiTi alloy through molecular dynamics[J]. Journal of Applied Physics, 2022,131(17):174301. doi: 10.1063/5.0087504 [68] ATAOLLAHI S, MAHTABI M J. Effects of precipitate on the phase transformation of single-crystal NiTi alloy under thermal and mechanical loads: A molecular dynamics study[J]. Materials Today Communications, 2021,29:102859. doi: 10.1016/j.mtcomm.2021.102859 [69] ALIF MAHENDRA B N, ARIFEN R, MALYADI M, et al. Cooling times’ dependence on the glassy NiTi at extremely low temperatures: A result from rapid solidification using molecular dynamics simulations[J]. Journal of Physics: Conference Series, 2020,1428(1):12003. doi: 10.1088/1742-6596/1428/1/012003 -

下载:

下载: