Research status and prospects of reduction and upgrading technology of converter steel slag under the Dual-Carbon background

-

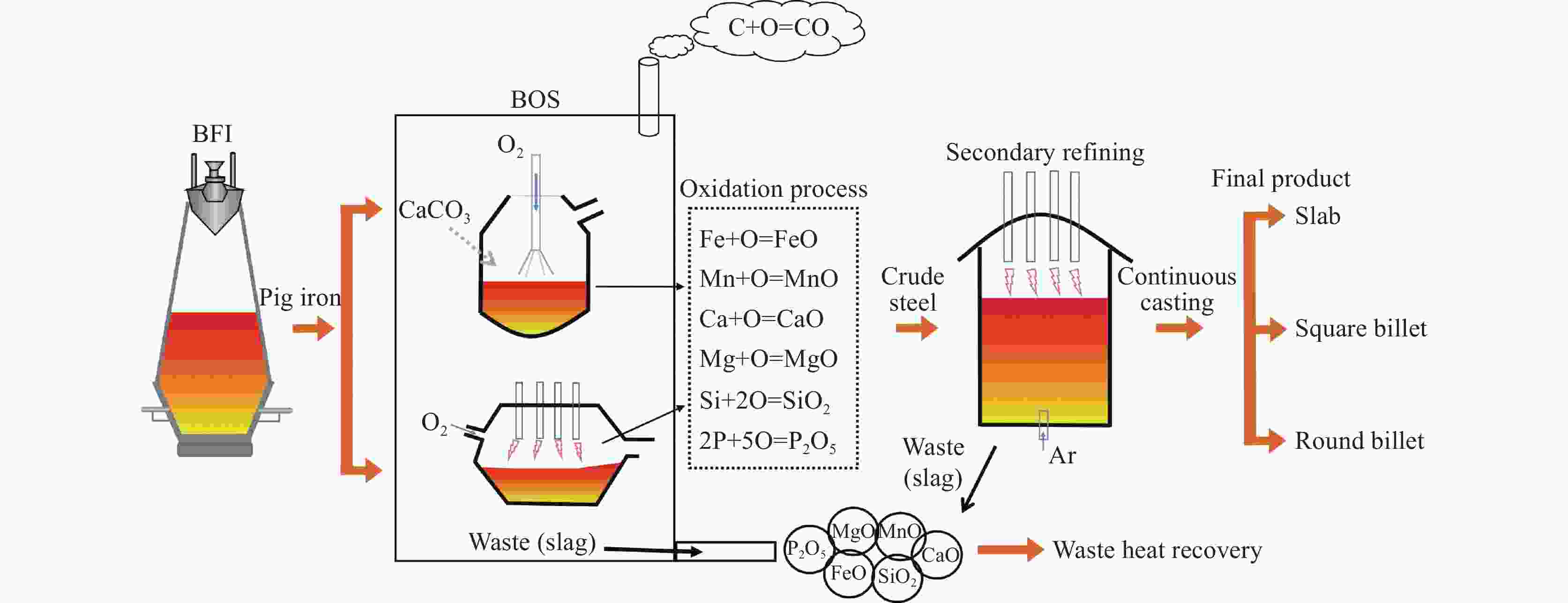

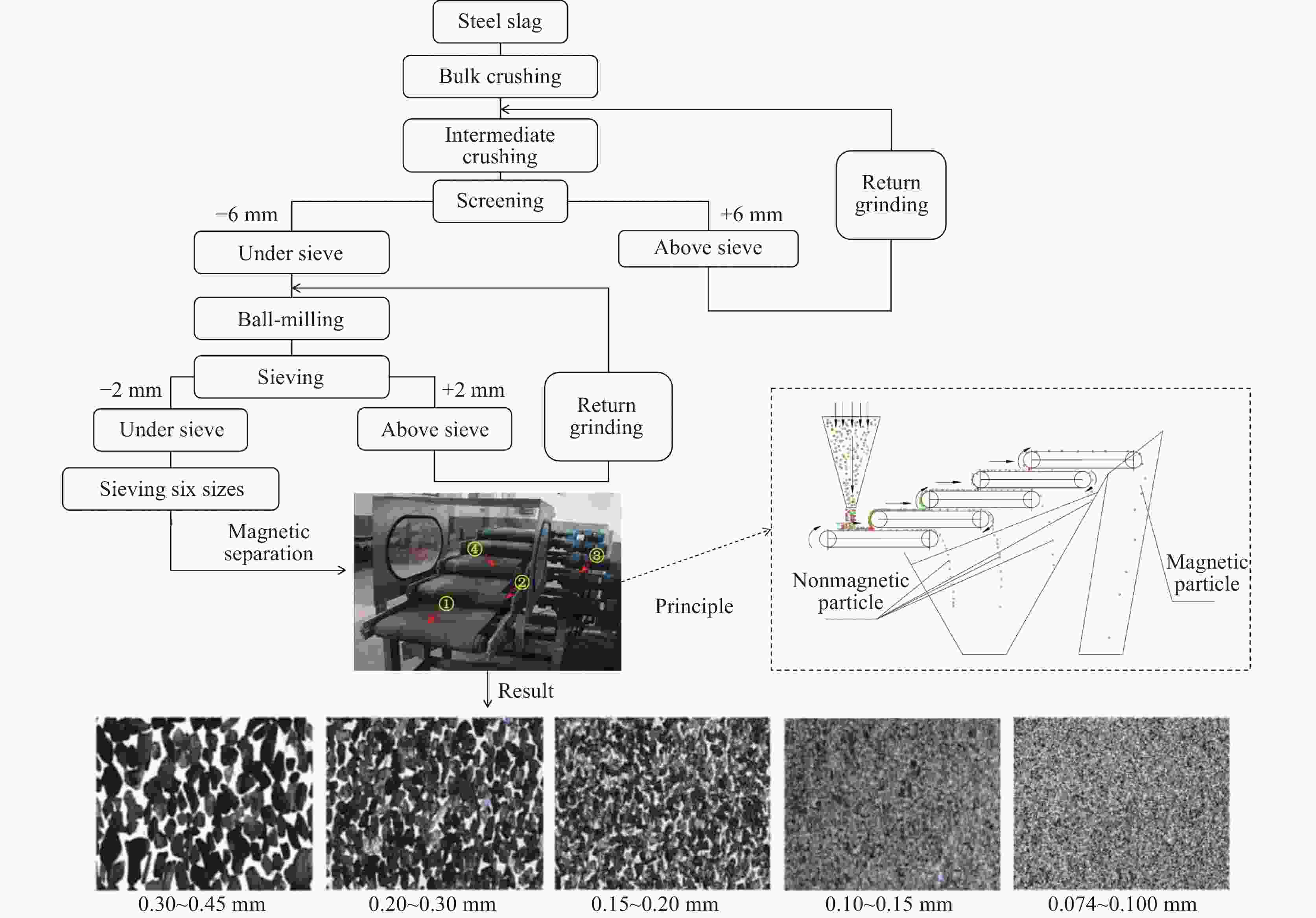

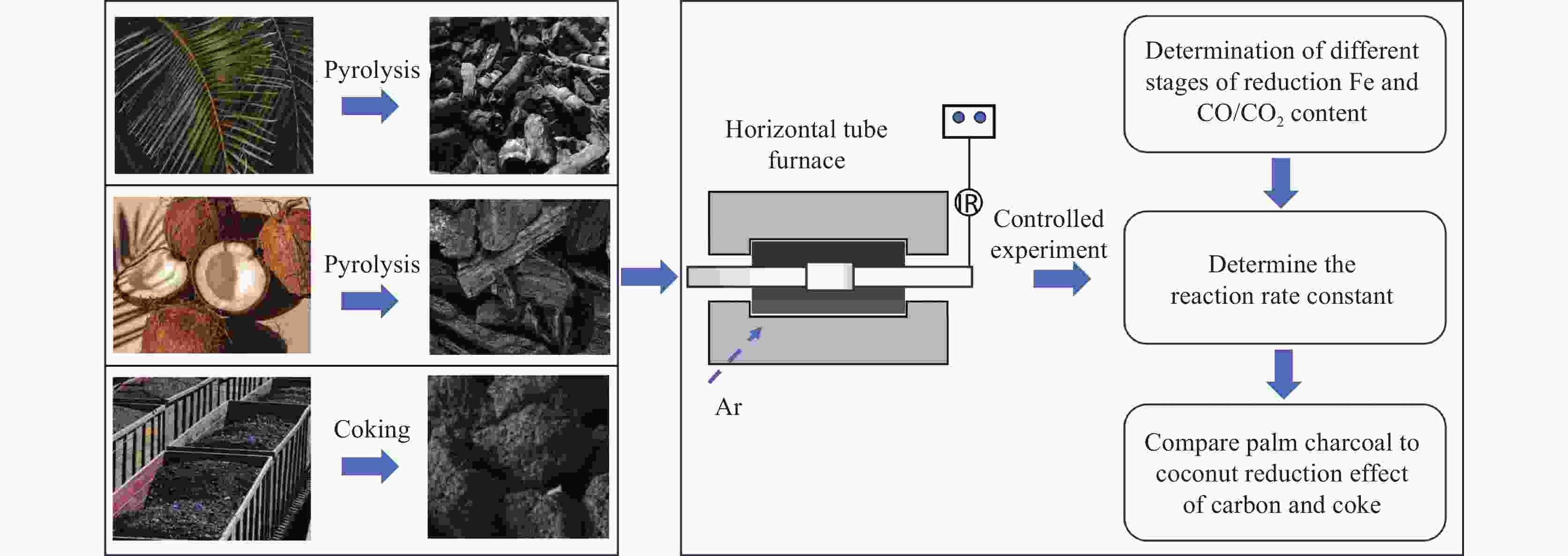

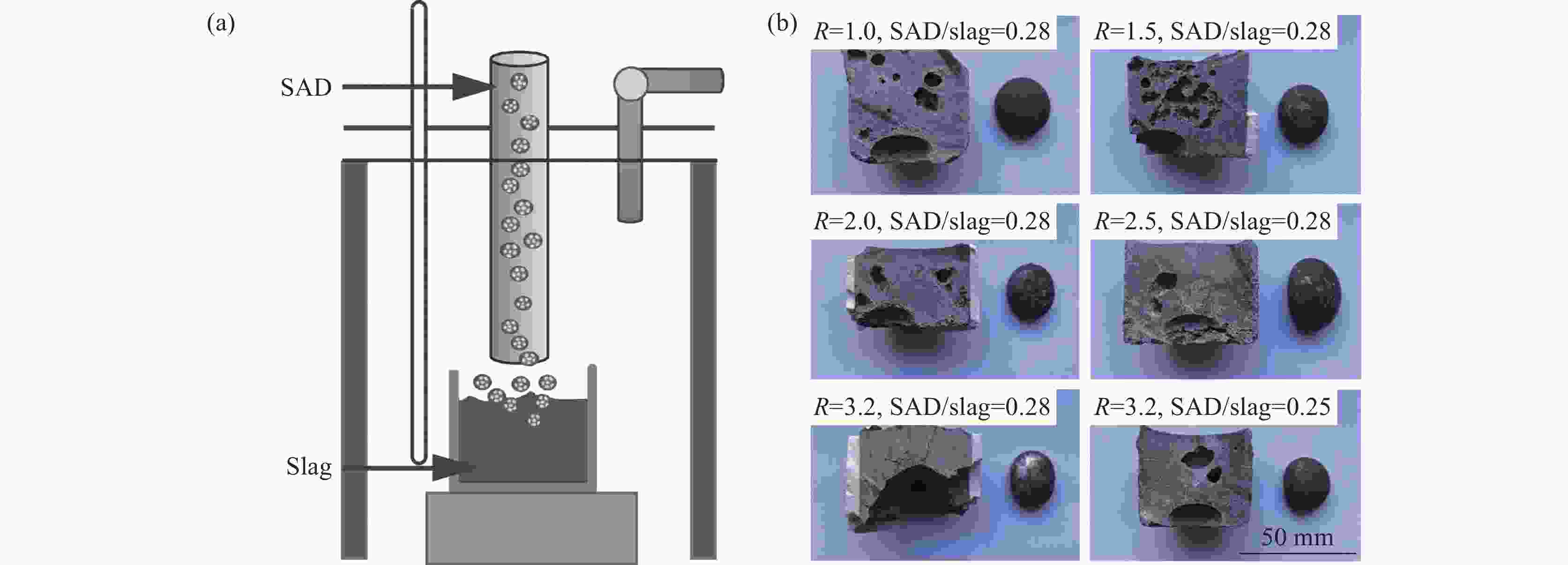

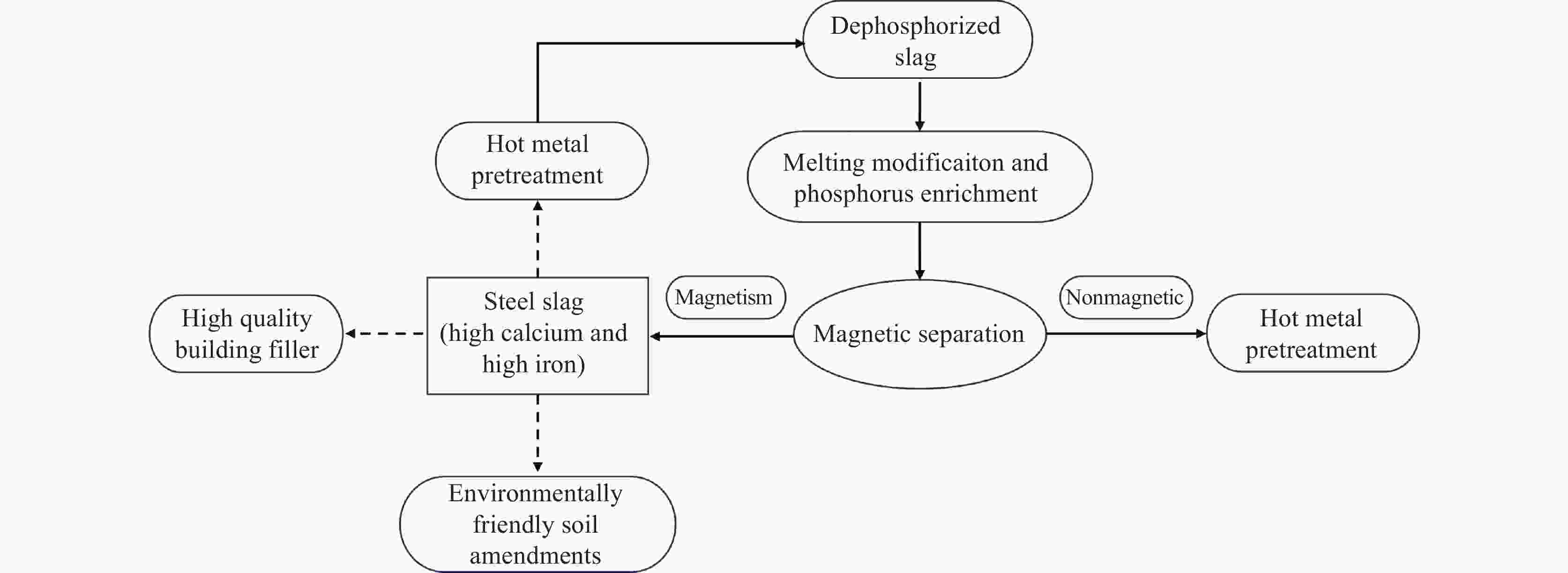

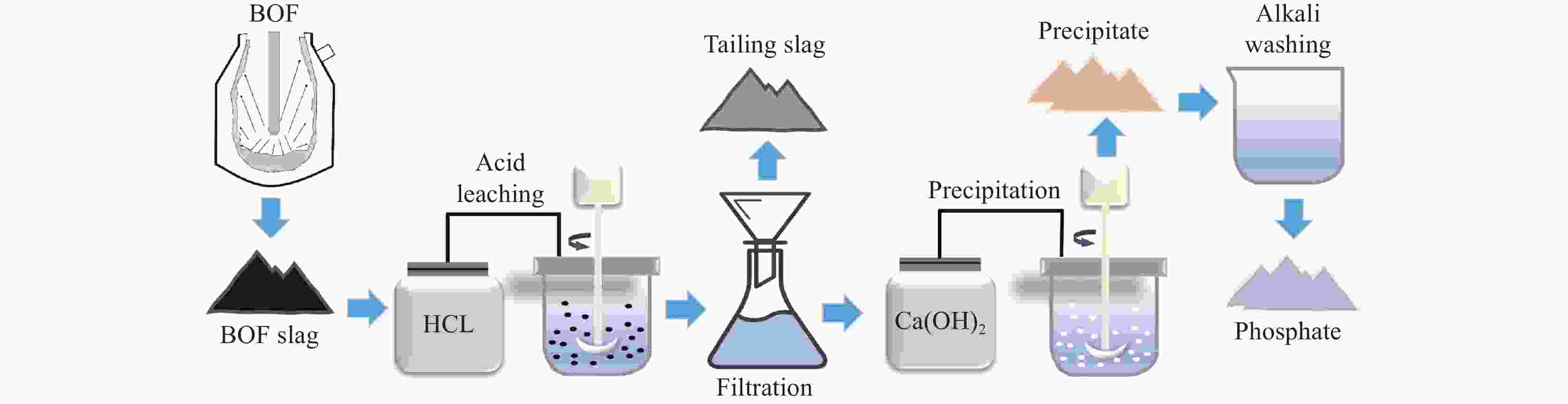

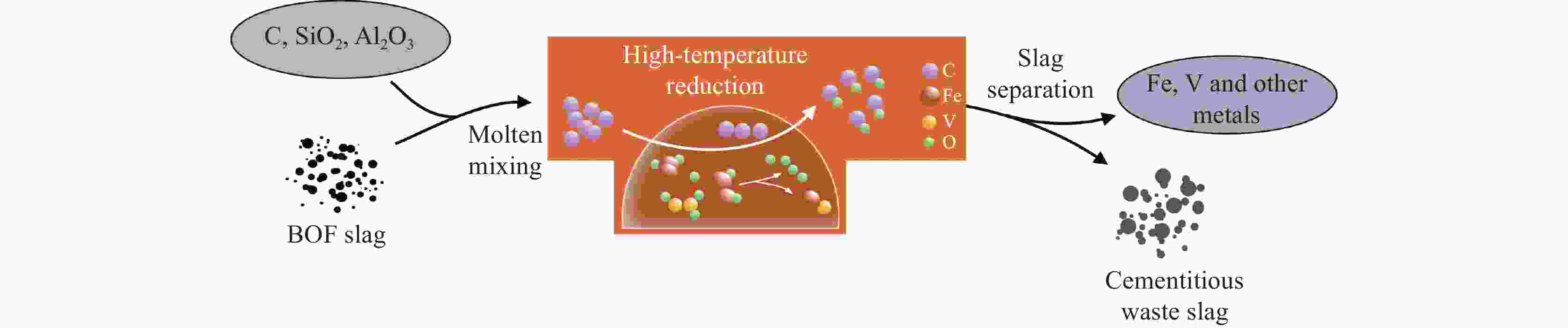

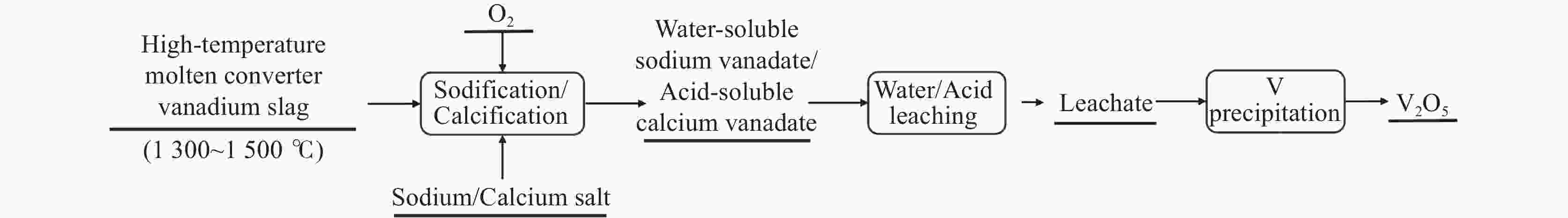

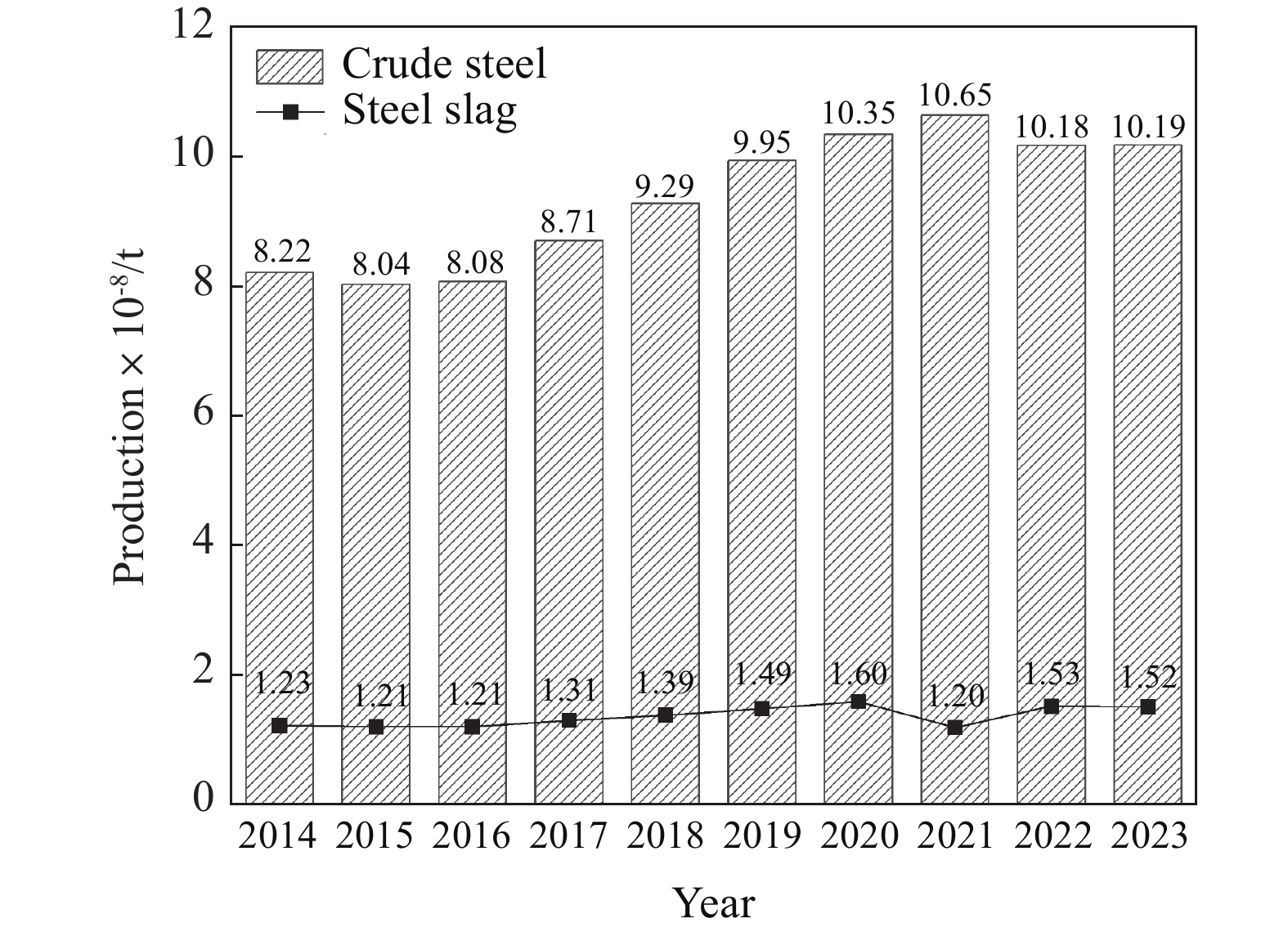

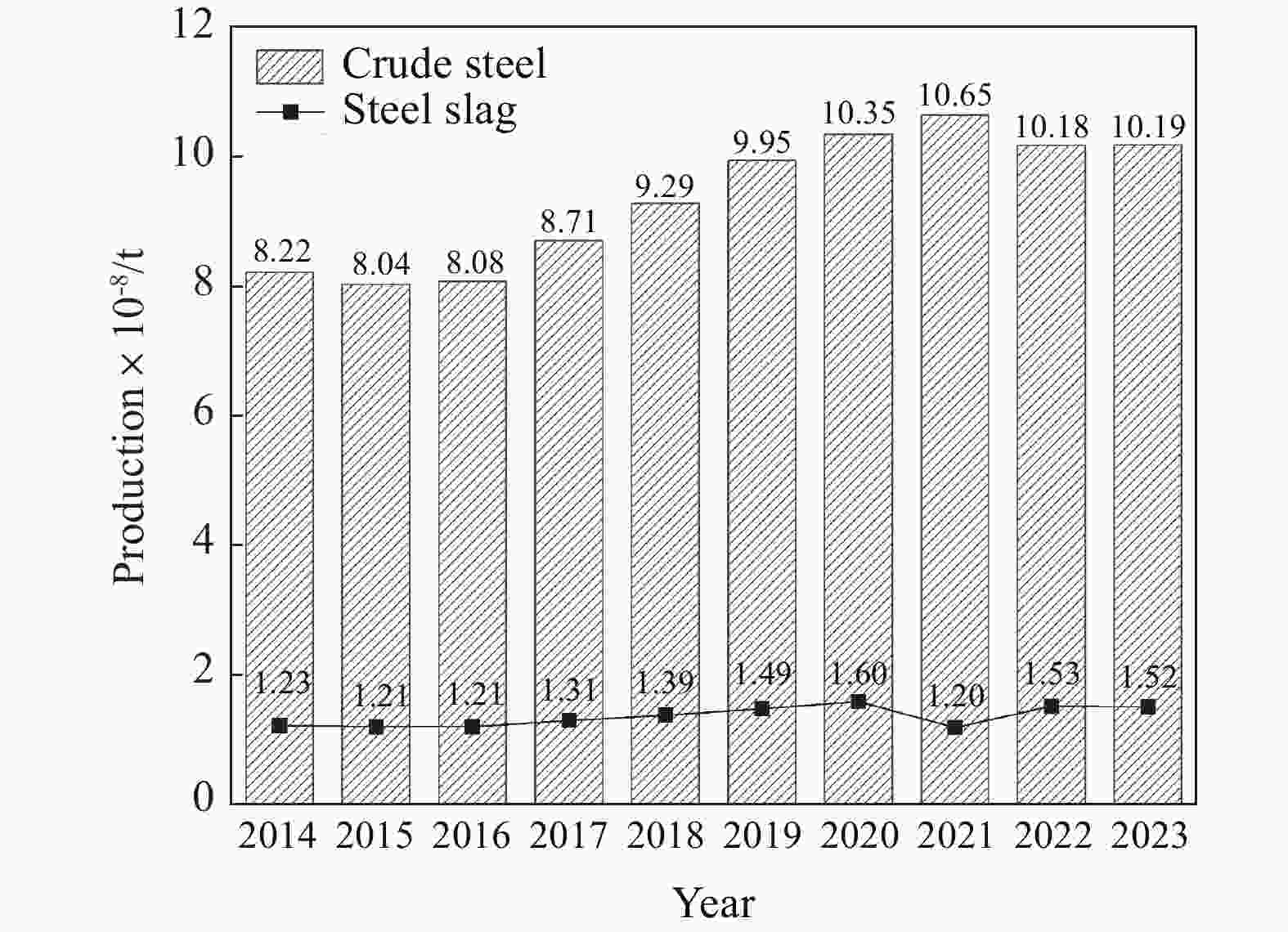

摘要: 钢铁行业作为高能耗、高碳排放领域,其降碳路径对实现“双碳”目标至关重要。转炉钢渣富含Fe、P、V等有价元素且携带高热值余热,其高效利用是钢铁行业降本增效的关键。系统解析了转炉渣的产排特征与多相组成,综述分选法、碳热还原、熔融还原等提铁技术,熔融改质与湿法酸浸提磷工艺,以及钒、锰等合金元素的高温还原与湿法提取路径,同时探讨了高能级钢渣余热回收技术进展。研究表明:现有技术虽已实现工业化应用,但仍面临能量损耗高(余热利用率仅30%)、元素提取效率低、环境二次污染等问题。提出,未来应聚焦复合还原体系构建、有机/无机酸协同浸出、熔融改质-余热回收耦合等方向,为钢铁工业节能减排提供了关键技术支撑。Abstract: As a high-energy consumption and high-carbon emission sector, the steel industry’s carbon reduction pathway plays a crucial role in achieving the“Dual-Carbon”goals. The converter steel slag is rich in valuable elements like Fe, P and V, and carries high-calorific waste heat, and its efficient ultilization is the key for reducing costs and increasing efficiency in steel industry. This paper systematically analyzes the production and discharge characteristics and multiphase composition of converter slag, comprehensively reviews iron extraction technologies including sorting methods, carbothermic reduction, and molten reduction, phosphorus recovery processes such as molten modification and wet acid leaching, as well as explores high-temperature reduction and hydrometallurgical extraction pathways of vanadium, manganese and other alloy elements. It also discusses technological advancements in high-grade slag waste heat recovery. Research shows that although the existing technologies have been industrialized, they still face problems such as high energy loss (merely 30% waste heat utilization rate), low elemental extraction efficiency, and secondary environmental pollution. The study proposes that in the future, the focus should be on the construction of composite reduction systems, the development of synergistic organic/inorganic acid leaching processes, and the coupling molten modification with waste heat recovery, which provides key technological support for energy conservation and emission reduction in the steel industry.

-

表 1 转炉渣的组成

Table 1. Composition of converter slag

% CaO FeO/Fe2O3 SiO2 MgO MnO Al2O3 P2O5 Others 47.5 23.8 14.3 7.1 3.6 2.4 1.2 0.1 表 2 转炉渣还原提质研究进展

Table 2. Research progress on reduction and quality improvement of converter slag

Converter slag reduction and upgrading Technology Reference Reduction and iron recovery from converter slag Separation method [10-13] Carbothermic reduction method [14-20] Molten reduction method [21-22] Reduction and phosphorus recovery from converter slag Molten conditioning method [23-26] Hydrometallurgical acid leaching method [27-30] Reduction and vanadium recovery from converter slag High-temperature reduction method [31-33] Roasting and acid leaching method [34-38] Reduction and extraction of other alloy elements Carbothermic reduction method [39-40] Solvent extraction method [41-42] Waste heat recovery Heat supply and power generation [43-44] Multi-stage waste heat recovery [45] Catalytic pyrolysis [46] 表 3 最佳反应条件区间

Table 3. Optimal reaction condition interval

Factor Initial

FeOx/%R Temperature/℃ Reaction

time/minInterval range 15~30 1.0~3.0 1500 ~1550 40~60 -

[1] YIN R Y. Essence and common law of a process-oriented manufacturing process[J]. Iron & Steel, 2023,58(2):1-7. (殷瑞钰. 流程型制造流程的本质与共性规律[J]. 钢铁, 2023,58(2):1-7.YIN R Y. Essence and common law of a process-oriented manufacturing process[J]. Iron & Steel, 2023, 58(2): 1-7. [2] HORII K, TSUTSUMI N, KATO T, et al. Overview of iron/steel slag application and development of new utilization technologies[J]. Nippon Steel & Sumitomo Metal Technical Report, 2015,109(109):5. [3] CUI X Y, NA X Z. Technologies and prospects for resource utilization of steel slag[J]. China Metallurgy, 2024,34(10):16-25. (崔心宇, 那贤昭. 钢渣资源化技术及展望[J]. 中国冶金, 2024,34(10):16-25.CUI X Y, NA X Z. Technologies and prospects for resource utilization of steel slag[J]. China Metallurgy, 2024, 34(10): 16-25. [4] ZHANG X, CHEN J, JIANG J, et al. The potential utilization of slag generated from iron and steelmaking industries: A review[J]. Environ Geochem Health, 2020,42:1321. doi: 10.1007/s10653-019-00419-y [5] SHANGGUAN F Q, LIU Z D, YIN R Y. Study on implementation path of “carbon peak” and “carbon neutrality” in steel industry in China[J]. China Metallurgy, 2021,31(9):15-20. (上官方钦, 刘正东, 殷瑞钰. 钢铁行业“碳达峰”“碳中和”实施路径研究[J]. 中国冶金, 2021,31(9):15-20.SHANGGUAN F Q, LIU Z D, YIN R Y. Study on implementation path of “carbon peak” and “carbon neutrality” in steel industry in China[J]. China Metallurgy, 2021, 31(9): 15-20. [6] ZHAO J H, YAN P Y, WANG D M. Research on mineral characteristics of converter steel slag and its comprehensive utilization of internal and external recycle[J]. Journal of Cleaner Production, 2017,156:50. doi: 10.1016/j.jclepro.2017.04.029 [7] YANG G, LI D J, LI B Y, et al. Development of key unit technology with high scrap ratio in converter steelmaking[C]// Chinese Society of Metals. Proceedings of the 14th China Iron and Steel Annual Conference-4. Steelmaking and continuous casting. State Key Laboratory of Metal Material for Marine Equipment and Application, Ansteel Iron & Steel Research Institutes; 2023: 5. (杨光, 李德军, 李博洋, 等. 转炉高废钢比冶炼的关键单元技术进展[C]//中国金属学会. 第十四届中国钢铁年会论文集—4. 炼钢与连铸. 海洋装备用金属材料及其应用国家重点实验室;鞍钢集团钢铁研究院;2023: 5.YANG G, LI D J, LI B Y, et al. Development of key unit technology with high scrap ratio in converter steelmaking[C]// Chinese Society of Metals. Proceedings of the 14th China Iron and Steel Annual Conference-4. Steelmaking and continuous casting. State Key Laboratory of Metal Material for Marine Equipment and Application, Ansteel Iron & Steel Research Institutes; 2023: 5. [8] HAO Y D, WANG H G, WU L, et al. Summary and prospect of steel slag treatment technology at the “double carbon” goal[J]. Multipurpose Utilization of Mineral Resources, 2024,45(6):67-73. (郝以党, 王会刚, 吴龙, 等. 双碳目标下钢渣处理技术综述及展望[J]. 矿产综合利用, 2024,45(6):67-73. doi: 10.3969/j.issn.1000-6532.2024.06.011HAO Y D, WANG H G, WU L, et al. Summary and prospect of steel slag treatment technology at the “double carbon” goal[J]. Multipurpose Utilization of Mineral Resources, 2024, 45(6): 67-73. doi: 10.3969/j.issn.1000-6532.2024.06.011 [9] TONG S, LI C X, WANG S H, et al. Evaluation of dephosphorization and energy saving and emission reduction of molten iron by converter gasification dephosphorization slag[J]. Steelmaking, 2023,39(4):88-92. (佟帅, 李晨晓, 王书桓, 等. 转炉气化脱磷渣用于铁水脱磷及节能减排评估研究[J]. 炼钢, 2023,39(4):88-92.TONG S, LI C X, WANG S H, et al. Evaluation of dephosphorization and energy saving and emission reduction of molten iron by converter gasification dephosphorization slag[J]. Steelmaking, 2023, 39(4): 88-92. [10] CHANG S Q. Collaborative modification and resource blastfurnace slag and utilization of converter slag[D]. Inner Mongolia: Inner Mongolia University of Science and Technology, 2023. (常仕琦. 高炉渣与转炉渣协同改质及资源化利用[D]. 内蒙古:内蒙古科技大学, 2023.CHANG S Q. Collaborative modification and resource blastfurnace slag and utilization of converter slag[D]. Inner Mongolia: Inner Mongolia University of Science and Technology, 2023. [11] WANG L, BU X Z, CHEN W, et al. Experimental research on magnetic separation and recovery of converter steel slag[J]. Mining Research and Development, 2022,42(11):48-53. (王亮, 卜显忠, 陈伟, 等. 转炉钢渣磁选回收试验研究[J]. 矿业研究与开发, 2022,42(11):48-53.WANG L, BU X Z, CHEN W, et al. Experimental research on magnetic separation and recovery of converter steel slag[J]. Mining Research and Development, 2022, 42(11): 48-53. [12] ZHAO J, HU W, NI W, et al. The effect of removing hard-to-grind minerals from steel slag on efficient grinding and hydration activity[J]. Journal of Sustainable Metallurgy, 2023,9(3):1315-1328. doi: 10.1007/s40831-023-00728-8 [13] SHI L C, WANG N S, CHENG G. Dry magnetic separation technology for the recovery of iron minerals in fine-grained steel slag[J]. Engineering Review, 2020: 7-16. [14] GAO F. Changes of RO phase and kinetics of iron oxide at high temperature in the process of steel slag reduction reconstruction[D]. Guangzhou: South China University of Technology, 2016. (高凡. 钢渣还原重构过程中RO相变化及铁氧化物高温还原动力学研究[D]. 广州: 华南理工大学, 2016.GAO F. Changes of RO phase and kinetics of iron oxide at high temperature in the process of steel slag reduction reconstruction[D]. Guangzhou: South China University of Technology, 2016. [15] LI Y. Basic research on smelting reduction and recovery of Fe and P from steel slag in converter[D]. Shenyang: Northeastern University, 2011. (李勇. 转炉钢渣熔融还原同时回收Fe、P的基础研究[D]. 沈阳: 东北大学, 2011.LI Y. Basic research on smelting reduction and recovery of Fe and P from steel slag in converter[D]. Shenyang: Northeastern University, 2011. [16] SHI X Y. Research on kinetics of converter slag carbothermic reduction process under microwave field[D]. Tangshan: Hebei United University, 2013. (石鑫越. 微波碳热还原转炉渣脱磷动力学研究[D]. 唐山:河北联合大学, 2013.SHI X Y. Research on kinetics of converter slag carbothermic reduction process under microwave field[D]. Tangshan: Hebei United University, 2013. [17] HE S, LIN L, LIU Y Q, et al. Recovery of valuable elements from molten modified phosphorous steel slag by carbothermic reduction[J]. Iron & Steel, 2022,57(6):167. (何赛, 林路, 刘亚琴, 等. 熔融改质含磷钢渣碳热还原回收有价元素试验[J]. 钢铁, 2022,57(6):167.HE S, LIN L, LIU Y Q, et al. Recovery of valuable elements from molten modified phosphorous steel slag by carbothermic reduction[J]. Iron & Steel, 2022, 57(6): 167. [18] ZHANG B, LUO G, HAO S, et al. Thermodynamic simulation and computational study of the carbothermal reduction of converter steel slag[J]. JOM, 2024: 1-9. [19] ZHANG B K, LUO G P, HAO S, et al. Optimization of steel slag carbothermal reduction process conditions[J]. Journal of Iron and Steel Research, 2024,36(6):794-805. (张博康, 罗果萍, 郝帅, 等. 钢渣碳热还原工艺条件优化研究[J]. 钢铁研究学报, 2024,36(6):794-805.ZHANG B K, LUO G P, HAO S, et al. Optimization of steel slag carbothermal reduction process conditions[J]. Journal of Iron and Steel Research, 2024, 36(6): 794-805. [20] YUNOS N F M, NAJMI N H, MUNUSAMY S R R, et al. Effect of high temperature on reduction-controlling reaction rate of agricultural waste chars and coke with steelmaking slag[J]. Journal of Thermal Analysis and Calorimetry, 2019, 138: 175-183. [21] XU L, LI X, LIU Y, et al. Recovery of low phosphorus iron from steel slag using secondary aluminum dross as the reductant[J]. Journal of Environmental Chemical Engineering, 2023,11(5):110973. doi: 10.1016/j.jece.2023.110973 [22] GUO H, YIN S, YU Q, et al. Iron recovery and active residue production from Basic Oxygen Furnace(BOF)slag for supplementary cementitious materials[J]. Resources, Conservation and Recycling, 2018,129:209. doi: 10.1016/j.resconrec.2017.10.027 [23] ZHOU C G, CHEN Q G, AI L Q, et al. Dephosphorization behavior by low temperature gasification of converter slag[J]. Iron & Steel, 2022,57(11):64-76. (周朝刚, 陈庆功, 艾立群, 等. 转炉熔渣低温气化脱磷行为[J]. 钢铁, 2022,57(11):64-76.ZHOU C G, CHEN Q G, AI L Q, et al. Dephosphorization behavior by low temperature gasification of converter slag[J]. Iron & Steel, 2022, 57(11): 64-76. [24] LI G X. Study on selective enrichment and separation of iron and phosphoruselements in phosphorus-containing converter slag[D]. Zhenjiang: Jiangsu University, 2022. (李果轩. 含磷转炉渣中铁、磷元素选择性富集与分离研究[D]. 镇江:江苏大学, 2022.LI G X. Study on selective enrichment and separation of iron and phosphoruselements in phosphorus-containing converter slag[D]. Zhenjiang: Jiangsu University, 2022. [25] LIN L, BAO Y P, WANG M, et al. Influence of titania modification on phosphorus enrichment in P-bearing steelmaking slag[J]. Chinese Journal of Engineering, 2014,36(8):1013. (林路, 包燕平, 王敏, 等. 二氧化钛改质对含磷转炉渣中磷富集行为的影响[J]. 北京科技大学学报, 2014,36(8):1013.LIN L, BAO Y P, WANG M, et al. Influence of titania modification on phosphorus enrichment in P-bearing steelmaking slag[J]. Chinese Journal of Engineering, 2014, 36(8): 1013. [26] WANG Z, SUN Y, SRIDHAR S, et al. Effect of Al2O3 on the viscosity and structure of CaO-SiO2-MgO-Al2O3-FetO slags[J]. Metallurgical and Materials Transactions B, 2015,46:537-541. doi: 10.1007/s11663-015-0303-4 [27] ZHOU C, LI J, CHEN Q, et al. Leaching behavior and microstructure of phosphorus in converter slag[J]. Journal of Iron and Steel Research International, 2024: 1-15. [28] DU C, ZHANG Y, YU W. A method for high value-added utilization of BOF slag: Towards slag recycling and phosphorus recovery[J]. Process Safety and Environmental Protection, 2024,190:586-597. [29] SHIGERU S, IOKA D, HAYASHI T, et al. Recovery of phosphate from unused resources[J]. Phosphorus Research Bulletin, 2011,25:18. doi: 10.3363/prb.25.18 [30] IWAMA T, INOUE R, NAKASE K, et al. Separation of phosphorus from phosphorus-concentrated steelmaking slag[J]. ISIJ International, 2024,64(5):785-794. doi: 10.2355/isijinternational.ISIJINT-2023-495 [31] DING M. Utilization of vanadium extraction from vanadium-bearing steel slag[C]//IOP Conference Series: Earth and Environmental Science. IOP Publishing, 2021, 631(1): 012056. [32] LIU W, FANG Y B, KE J J. Overview of comprehensive utilization research on chemical metallurgy from Panzhihua mineral resources by Chinese Academy of Sciences[J]. Journal of Engineering Studies, 2021,13(4):381-391. (刘伟, 方一兵, 柯家骏. 中国科学院对攀枝花钒钛磁铁矿综合利用之化工冶金研究回顾[J]. 工程研究-跨学科视野中的工程, 2021,13(4):381-391. doi: 10.3724/SP.J.1224.2021.00381LIU W, FANG Y B, KE J J. Overview of comprehensive utilization research on chemical metallurgy from Panzhihua mineral resources by Chinese Academy of Sciences[J]. Journal of Engineering Studies, 2021, 13(4): 381-391. doi: 10.3724/SP.J.1224.2021.00381 [33] WU E H, ZHU R, YANG S L, et al. Experimental and thermodynamic study on reduction of carbon-containing pellet of vanadium tailings smelted by electric arc furnace[J]. Iron Steel Vanadium Titanium, 2015,36(5):40-46. (吴恩辉, 朱荣, 杨绍利, 等. 提钒尾渣含碳球团电弧炉熔融还原热力学分析与试验[J]. 钢铁钒钛, 2015,36(5):40-46. doi: 10.7513/j.issn.1004-7638.2015.05.009WU E H, ZHU R, YANG S L, et al. Experimental and thermodynamic study on reduction of carbon-containing pellet of vanadium tailings smelted by electric arc furnace[J]. Iron Steel Vanadium Titanium, 2015, 36(5): 40-46. doi: 10.7513/j.issn.1004-7638.2015.05.009 [34] LI K, SONG W C, ZHENG Q, et al. Vanadium extraction by acid leaching after calcification of molten vanadium slag[J]. Iron Steel Vanadium Titanium, 2013,34(5):15-18, 22. (李昆, 宋文臣, 郑权, 等. 熔融态钒渣氧化钙化后酸浸研究[J]. 钢铁钒钛, 2013,34(5):15-18, 22. doi: 10.7513/j.issn.1004-7638.2013.05.003LI K, SONG W C, ZHENG Q, et al. Vanadium extraction by acid leaching after calcification of molten vanadium slag[J]. Iron Steel Vanadium Titanium, 2013, 34(5): 15-18, 22. doi: 10.7513/j.issn.1004-7638.2013.05.003 [35] SONG W C, LI H. A new process for vanadium extraction from molten vanadium slag by direct oxidation and sodium activating method[J]. Iron Steel Vanadium Titanium, 2012,33(6):1-5. (宋文臣, 李宏. 熔融钒渣直接氧化钠化提钒新工艺研究[J]. 钢铁钒钛, 2012,33(6):1-5. doi: 10.7513/j.issn.1004-7638.2012.06.001SONG W C, LI H. A new process for vanadium extraction from molten vanadium slag by direct oxidation and sodium activating method[J]. Iron Steel Vanadium Titanium, 2012, 33(6): 1-5. doi: 10.7513/j.issn.1004-7638.2012.06.001 [36] ATTAH M, HILDOR F, YILMAZ D, et al. Vanadium recovery from steel converter slag utilised as an oxygen carrier in oxygen carrier aided combustion (OCAC)[J]. Journal of Cleaner Production, 2021,293:126159. doi: 10.1016/j.jclepro.2021.126159 [37] XIANG J, HUANG Q, LÜ X, et al. Effect of mechanical activation treatment on the recovery of vanadium from converter slag[J]. Metallurgical and Materials Transactions B, 2017,48:2759-2767. doi: 10.1007/s11663-017-1033-6 [38] XIANG J, HUANG Q, LÜ X, et al. Multistage utilization process for the gradient-recovery of V, Fe, and Ti from vanadium-bearing converter slag[J]. Journal of hazardous materials, 2017,336:1-7. doi: 10.1016/j.jhazmat.2017.04.060 [39] SHIN D J, GAO X, UEDA S, et al. Separation of phosphorus and manganese from steelmaking slag by selective reduction[J]. Metallurgical and Materials Transactions B, 2019,50:1248-1259. doi: 10.1007/s11663-019-01556-6 [40] WU Z J, JIANG B F, LIU W M, et al. Selective recovery of valuable components from converter steel slag for preparing multidoped FePO4[J]. Industrial & engineering chemistry research, 2011,50(24):13778-13788. [41] RASHID W T. Extraction of manganese element from electric arc furnace steel slag (EAFS) by liquid-liquid extraction (LLE) method[J]. Journal of Engineering, 2022, 28(6). [42] KIM S J, SUZUKI J, GAO X, et al. A kinetic model to simulate the reaction between slag and matte for the production of ferromanganese alloy from steelmaking slag[J]. Journal of Sustainable Metallurgy, 2016,2:141-151. doi: 10.1007/s40831-016-0042-z [43] GUO X, YAN Y. Research on waste heat recovery and recycling of hot steel slag[J]. Resources Economization & Environmental Protection, 2024(08):36-39. (郭新, 闫燚. 热态钢渣余热回收与循环利用研究[J]. 资源节约与环保, 2024(08):36-39. doi: 10.3969/j.issn.1673-2251.2024.08.009GUO X, YAN Y. Research on waste heat recovery and recycling of hot steel slag[J]. Resources Economization & Environmental Protection, 2024(08): 36-39. doi: 10.3969/j.issn.1673-2251.2024.08.009 [44] ZHAO X Z, YU H M. The theory analysis and practice of heat recovery utilization in converter steel-slag treatment process[J]. Xinjiang Iron and Steel, 2015(4):42-44. (赵旭章, 俞海明. 转炉钢渣热能回收利用的理论分析和实践[J]. 新疆钢铁, 2015(4):42-44. doi: 10.3969/j.issn.1672-4224.2015.04.019ZHAO X Z, YU H M. The theory analysis and practice of heat recovery utilization in converter steel-slag treatment process[J]. Xinjiang Iron and Steel, 2015(4): 42-44. doi: 10.3969/j.issn.1672-4224.2015.04.019 [45] CHEN W, WANG M, LIU L, et al. Three-stage method energy–mass coupling high-efficiency utilization process of high-temperature molten steel slag[J]. Metallurgical and Materials Transactions B, 2021,52(5):3004-3015. doi: 10.1007/s11663-021-02213-7 [46] LI P, ZHANG X, WANG J, et al. Process characteristics of catalytic thermochemical conversion of oily sludge with addition of steel slag towards energy and iron recovery[J]. Journal of Environmental Chemical Engineering, 2020,8(4):103911. doi: 10.1016/j.jece.2020.103911 -

下载:

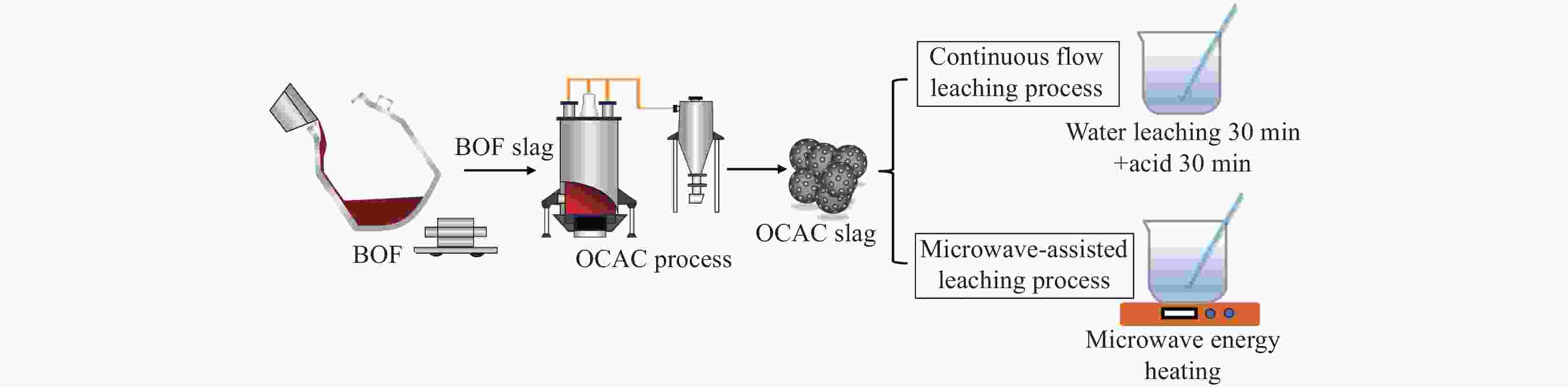

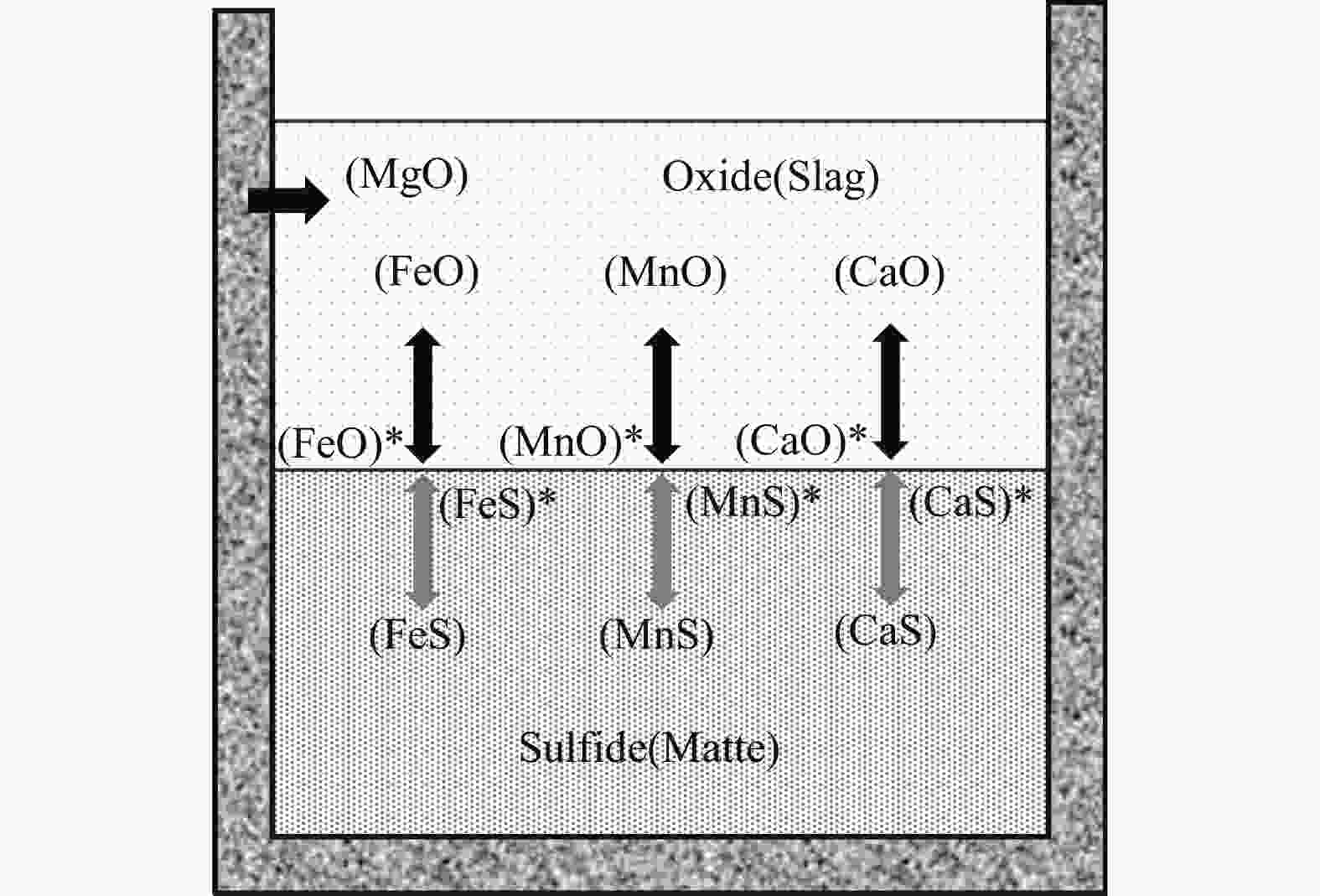

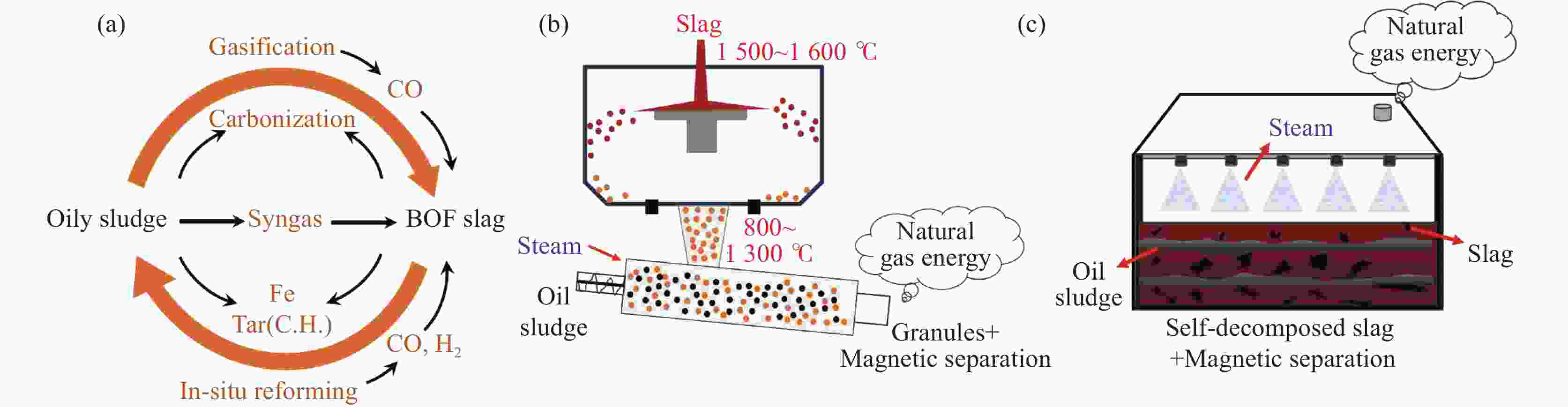

下载: