Simulation study on granulation characteristics of blast furnace slag water jet

-

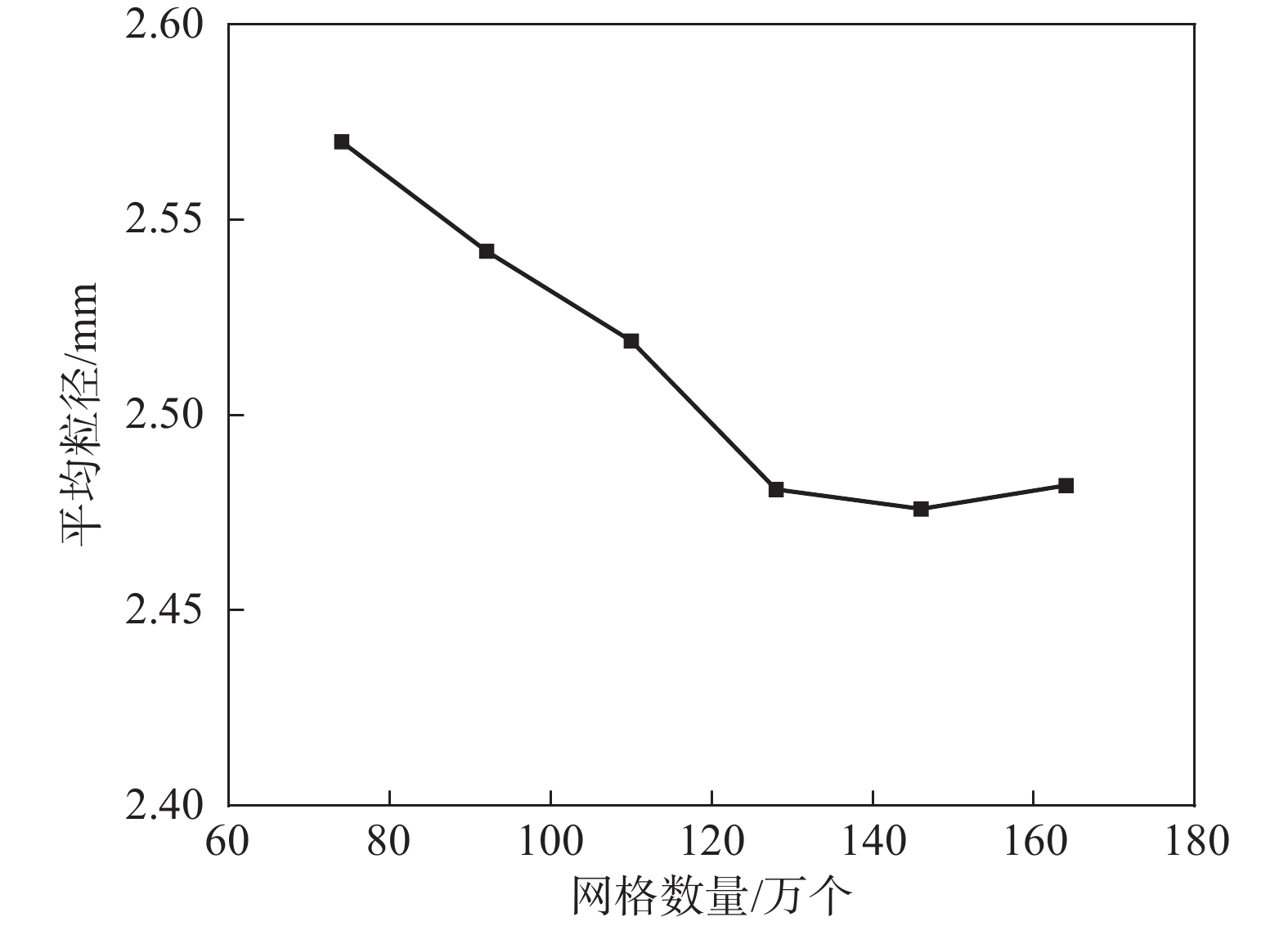

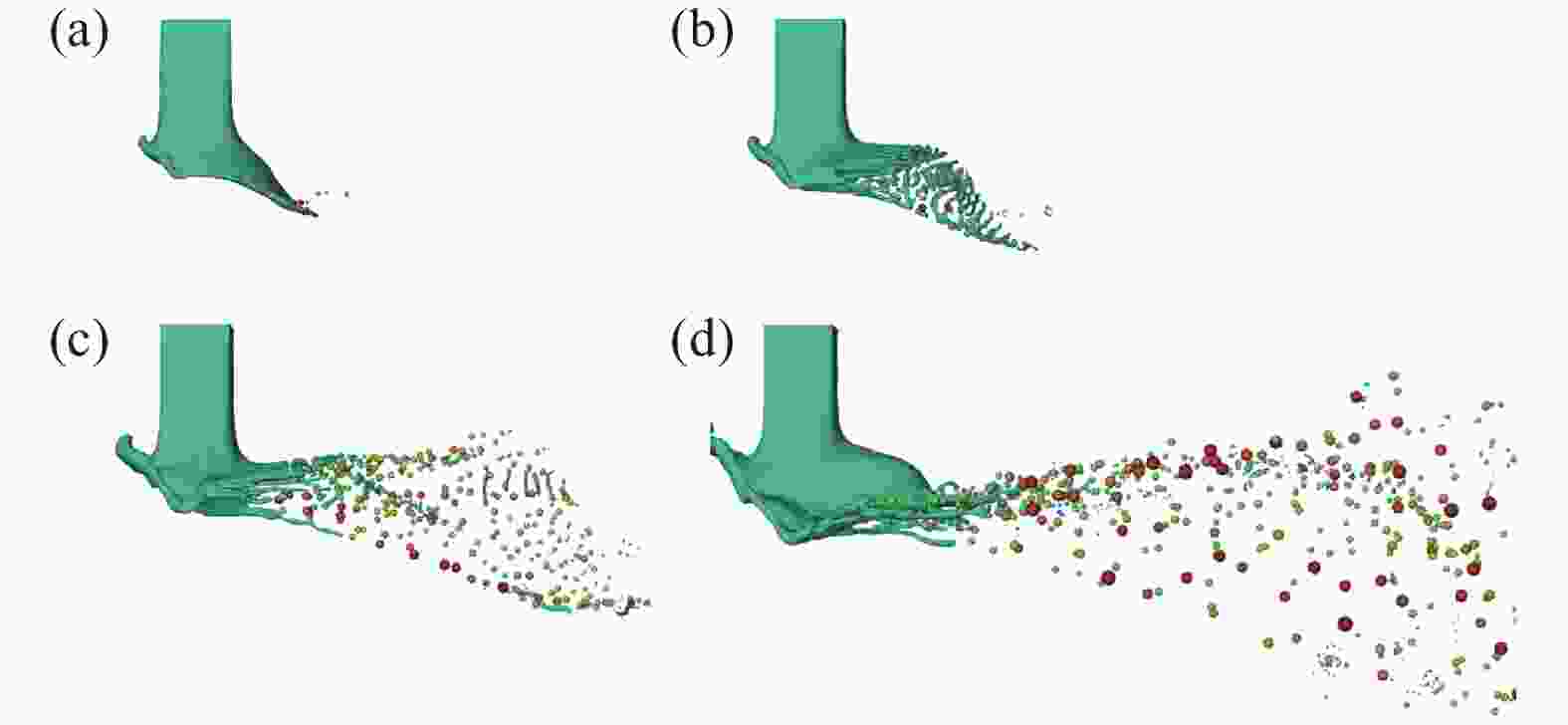

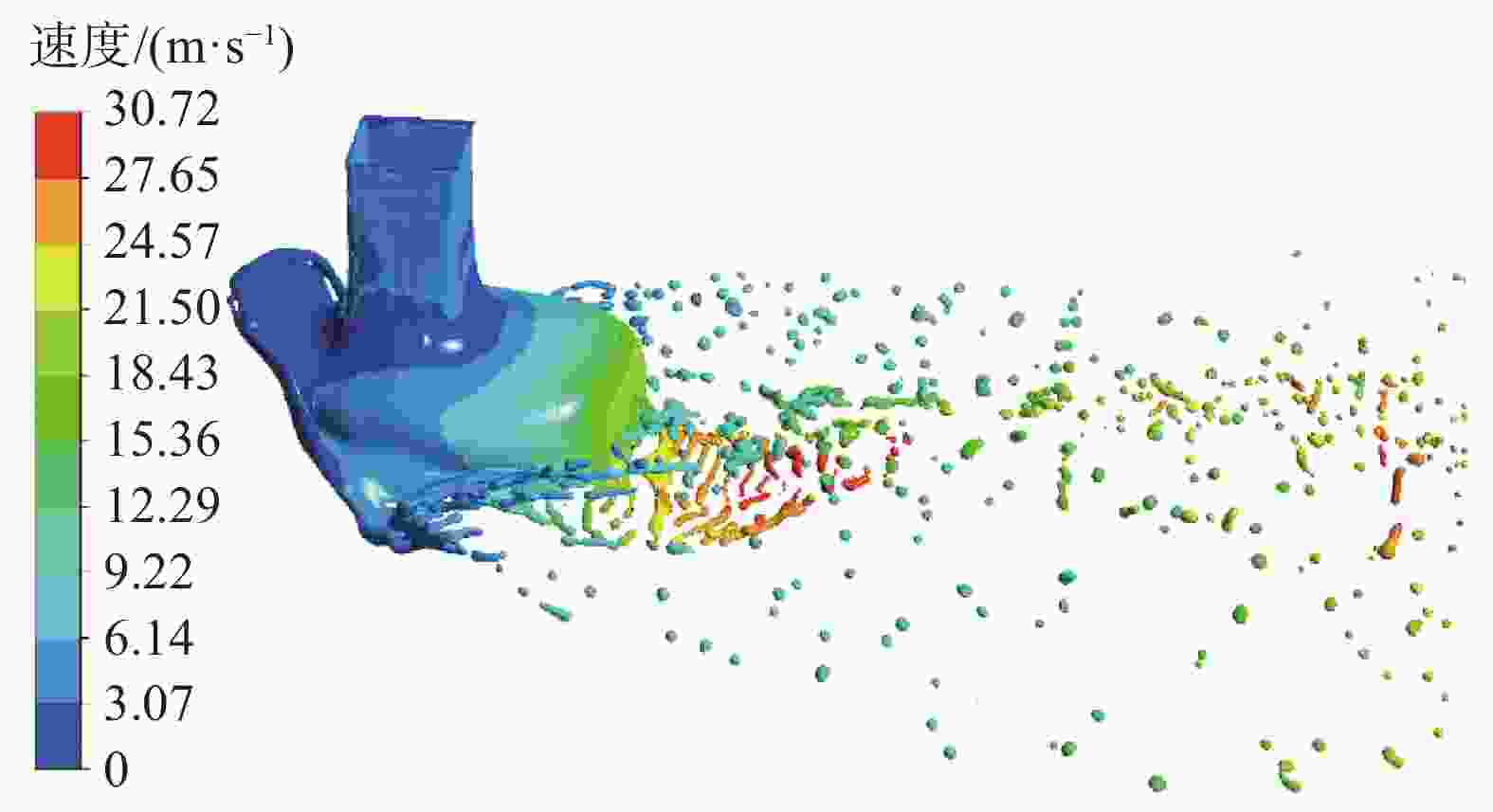

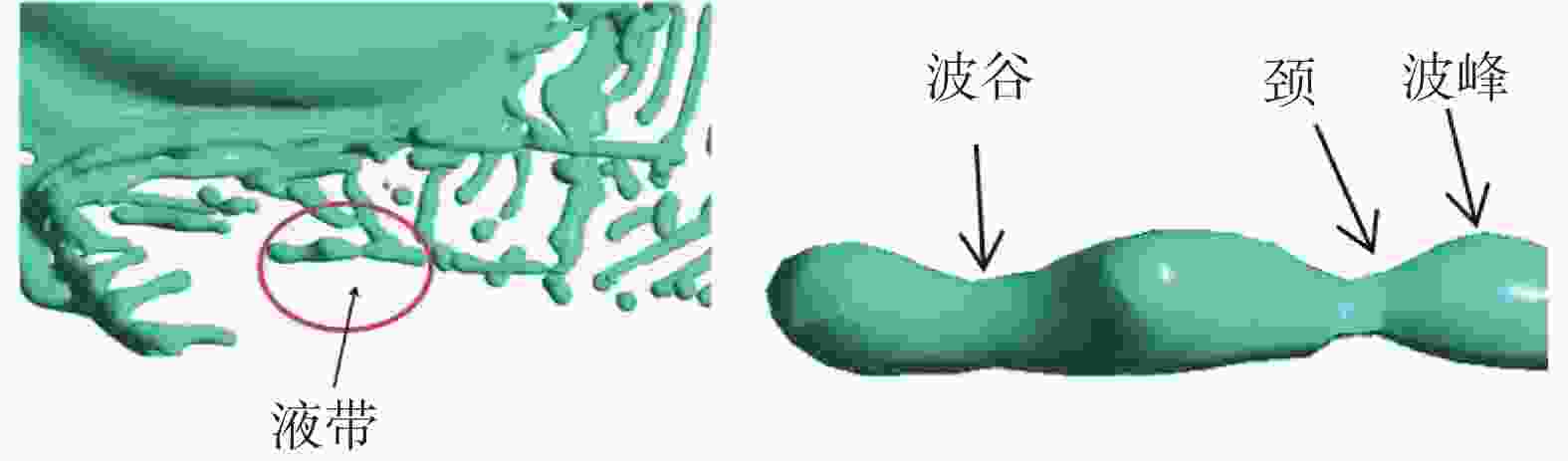

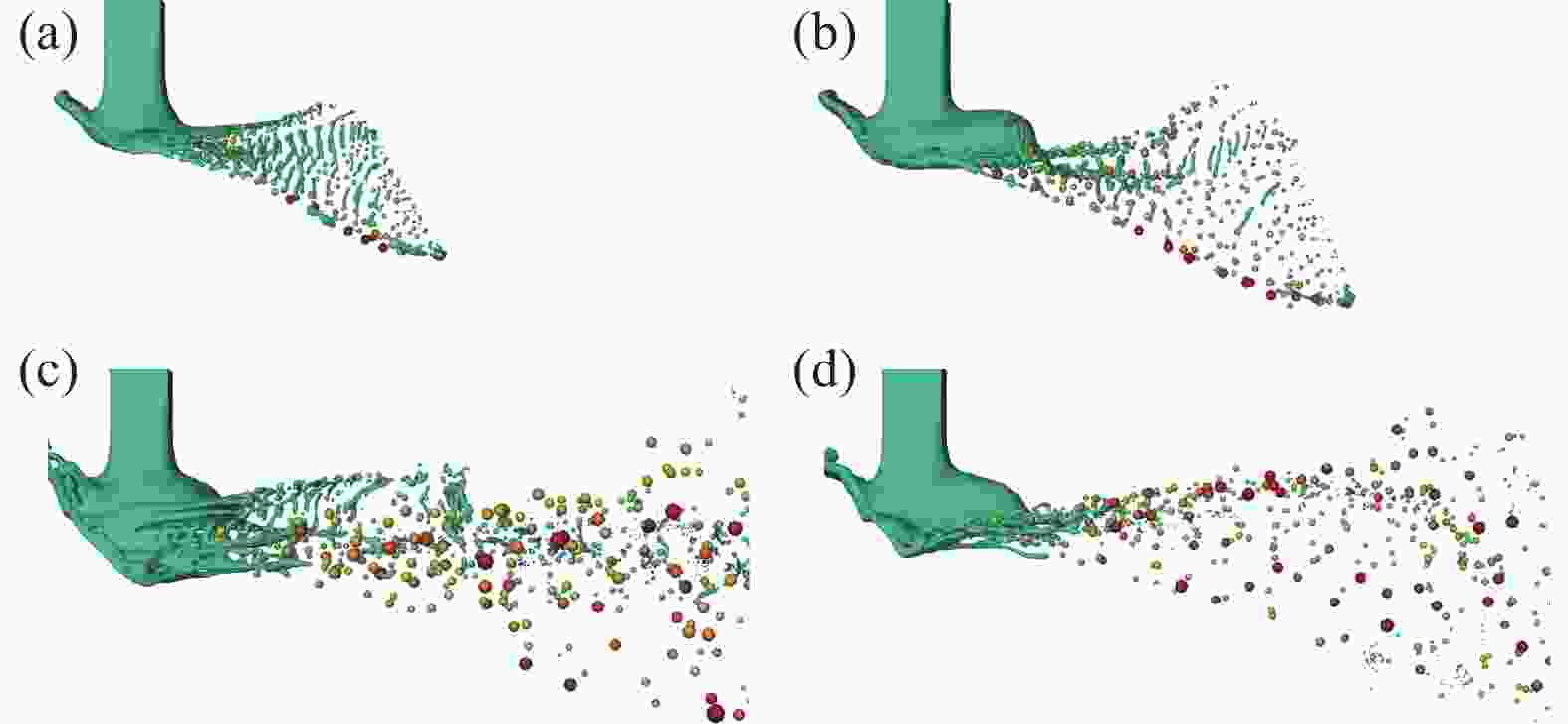

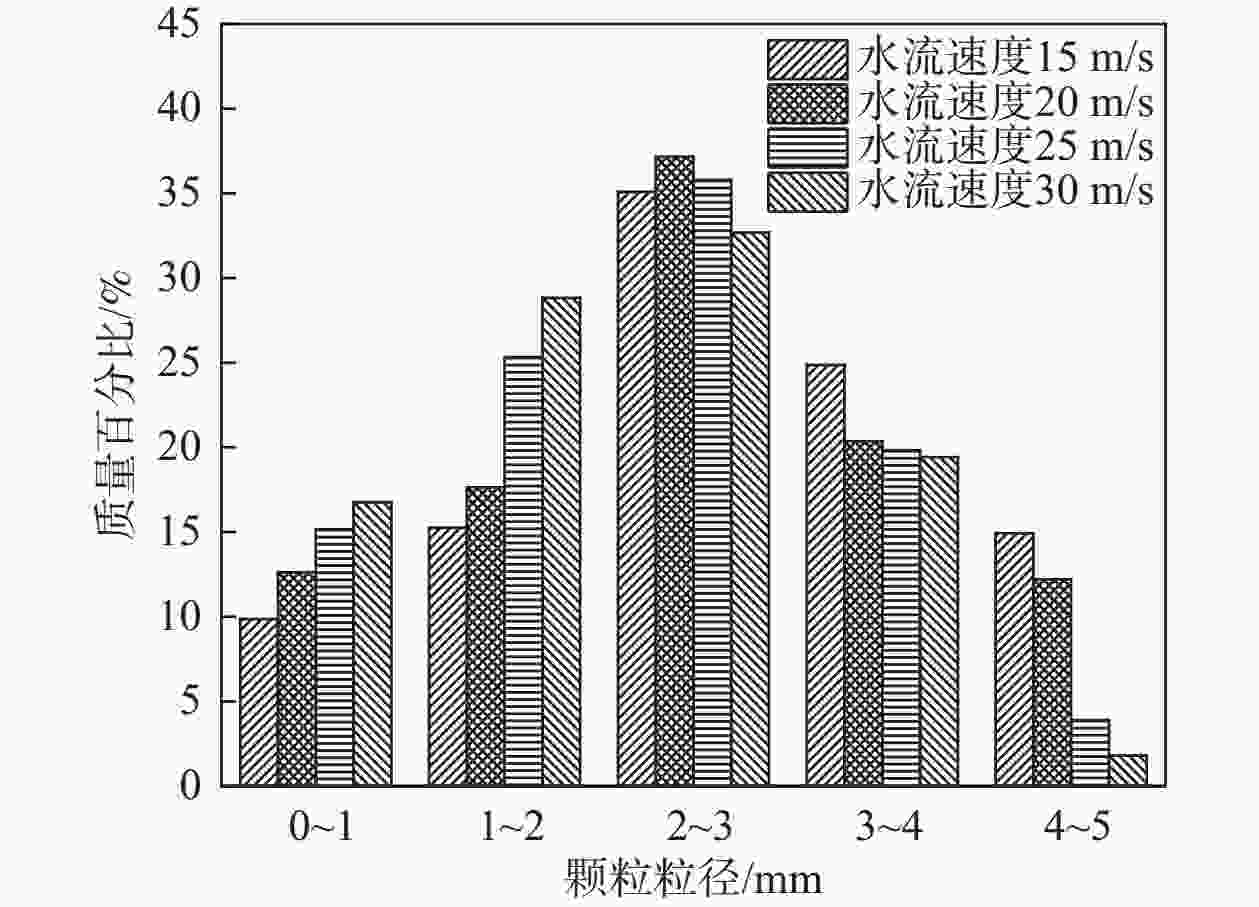

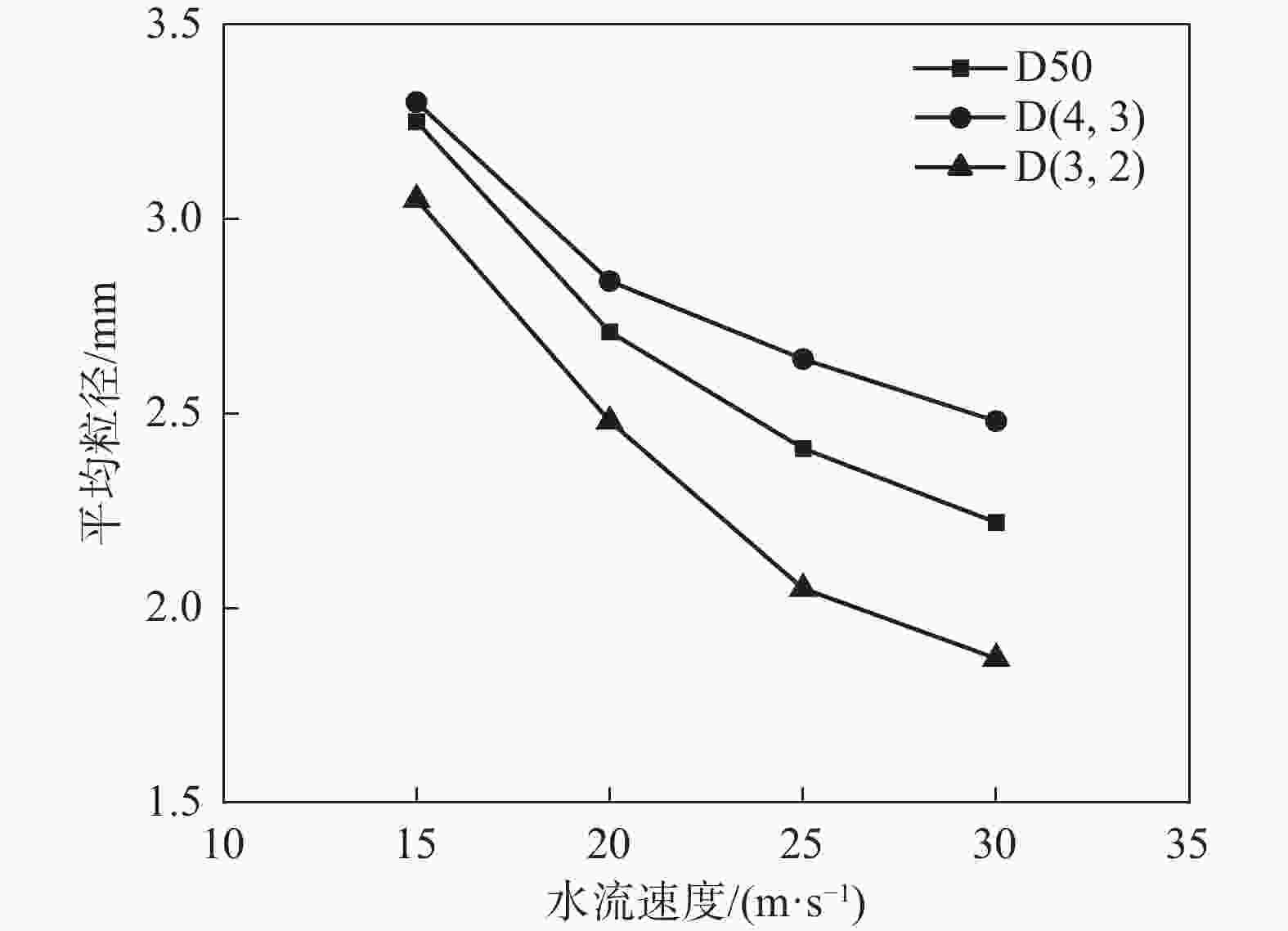

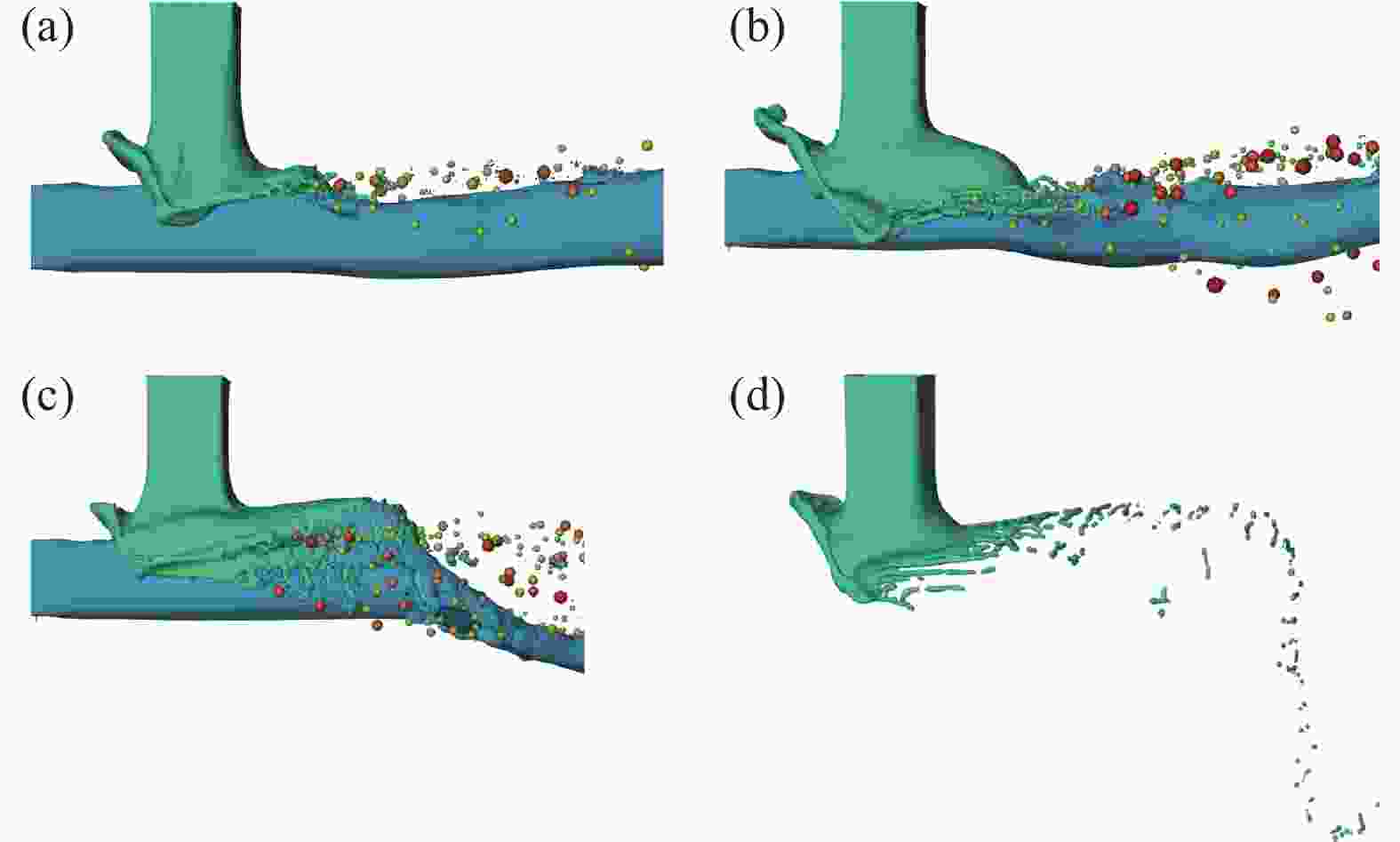

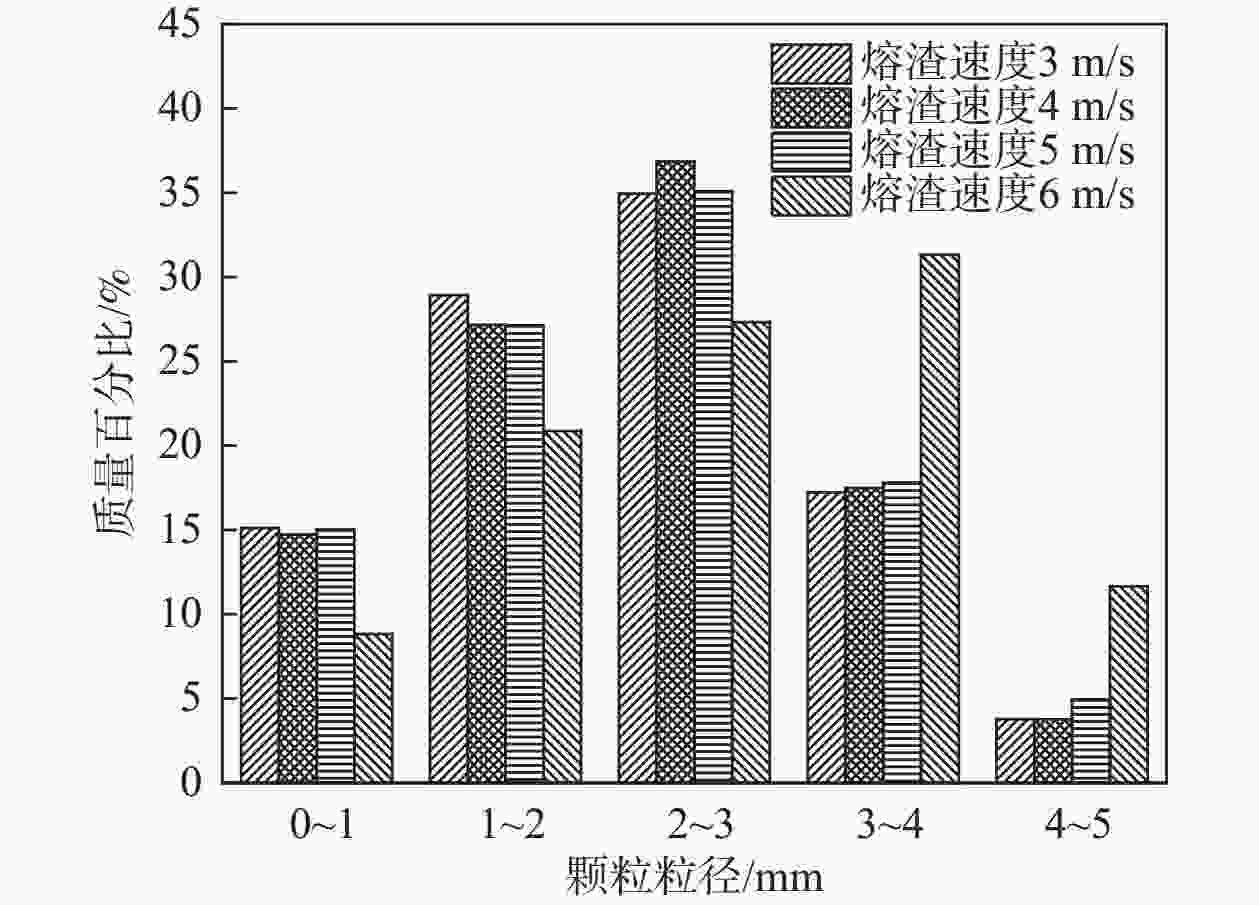

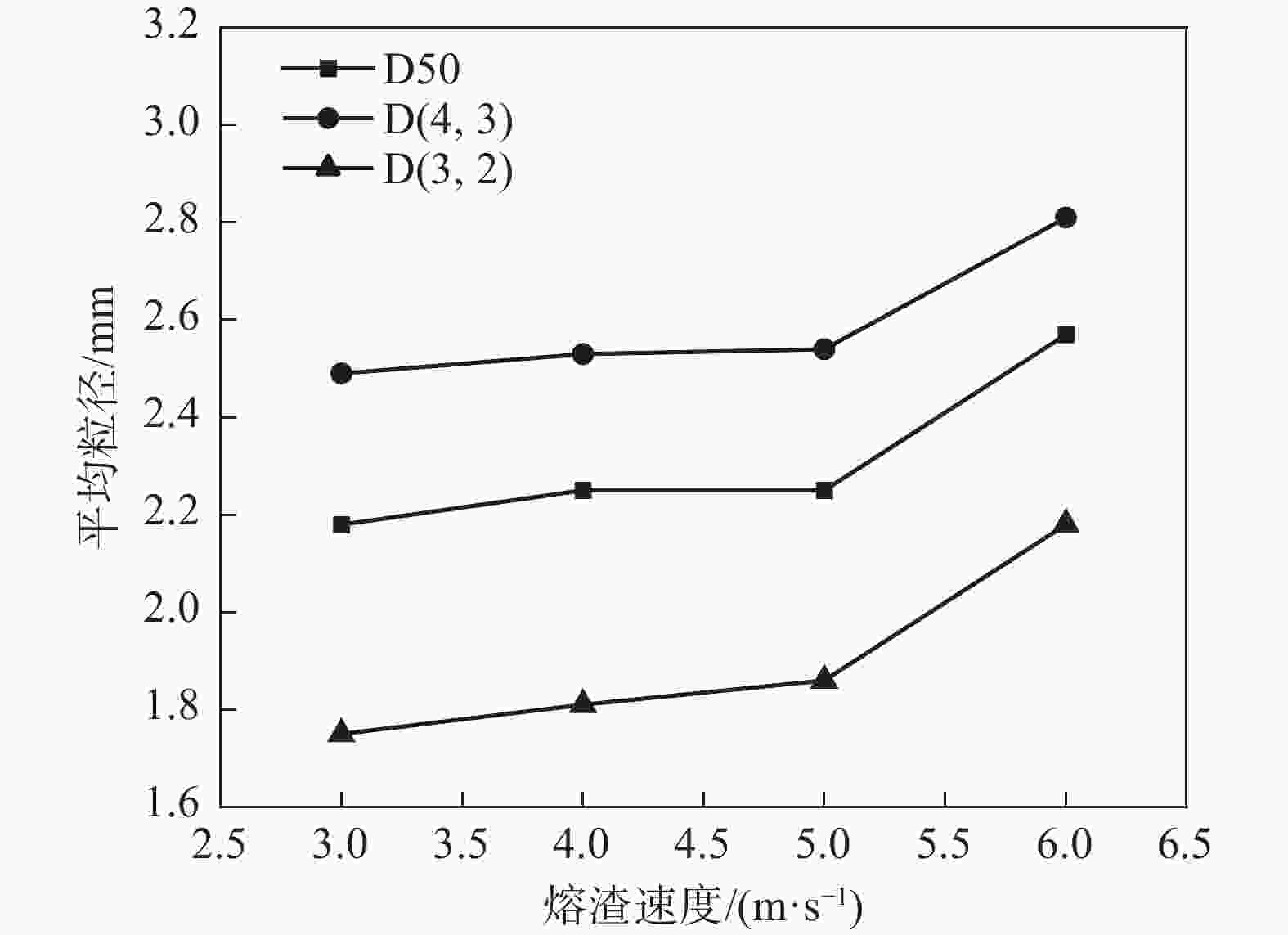

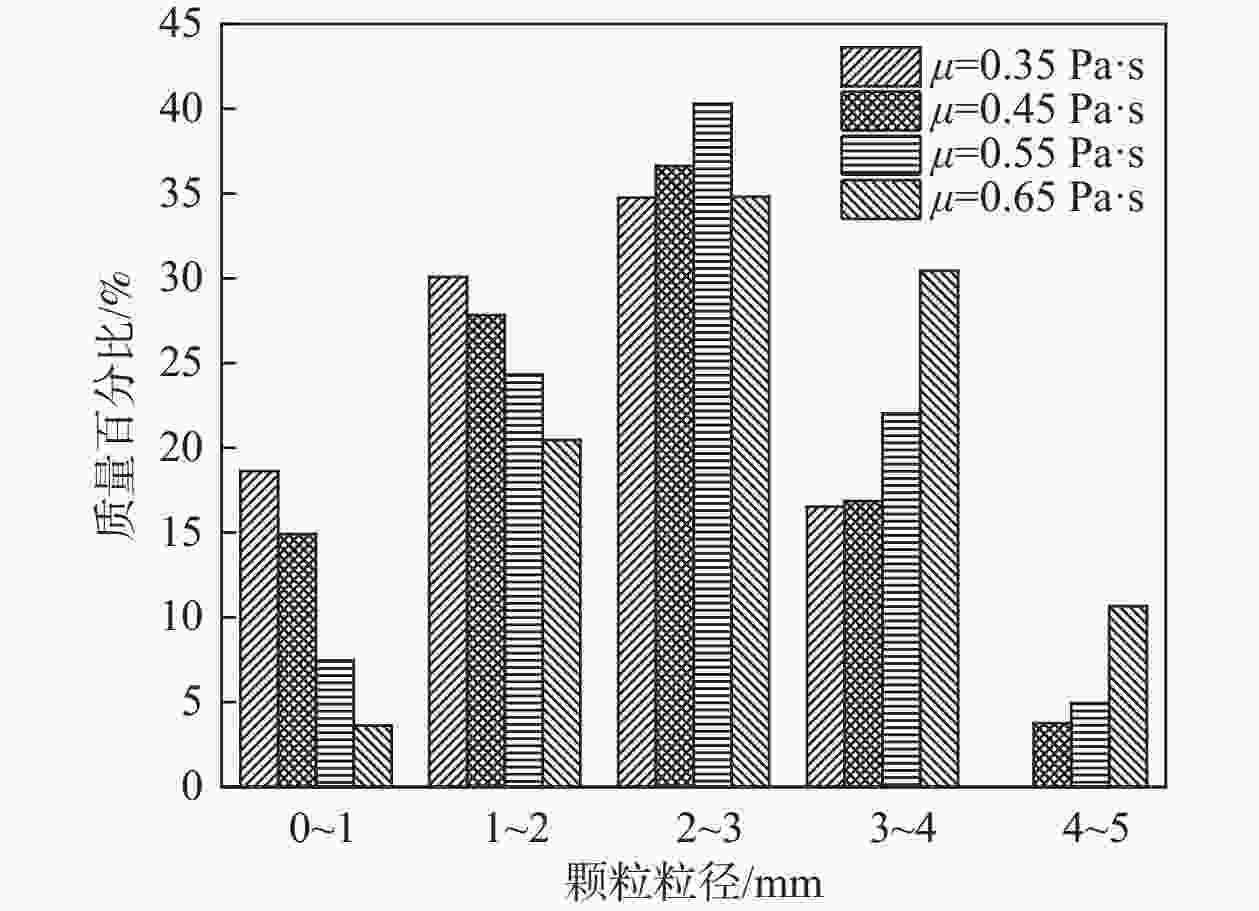

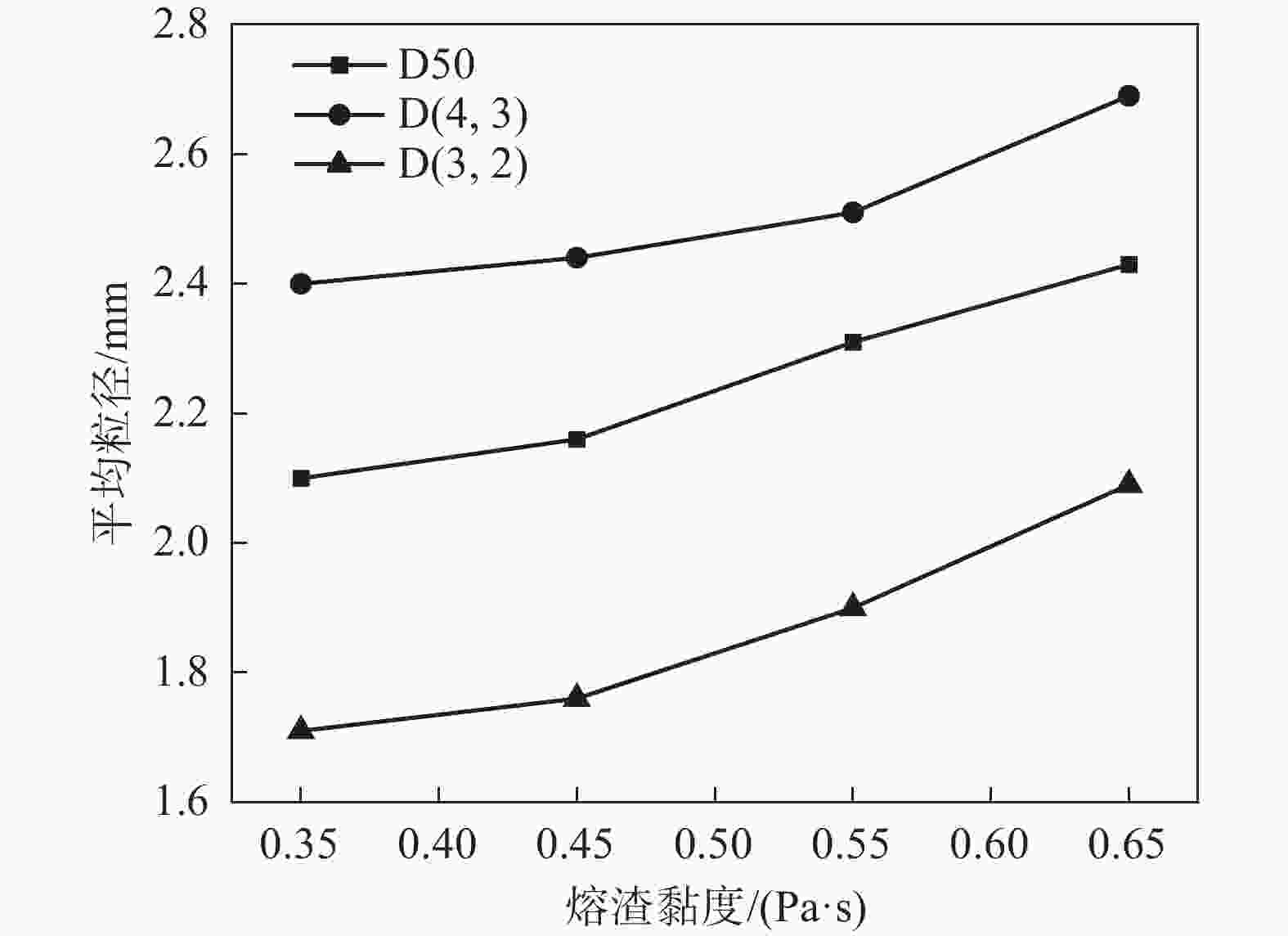

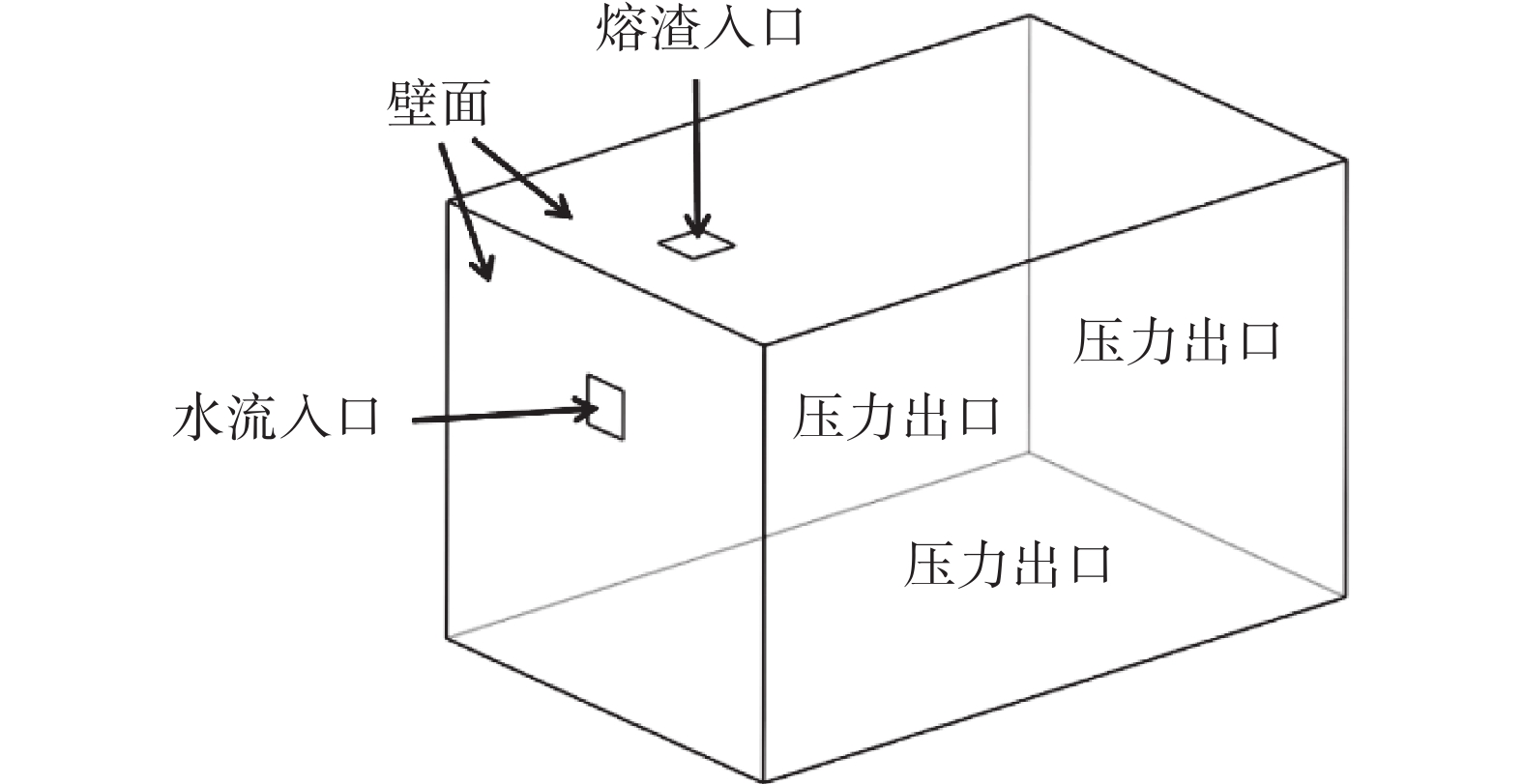

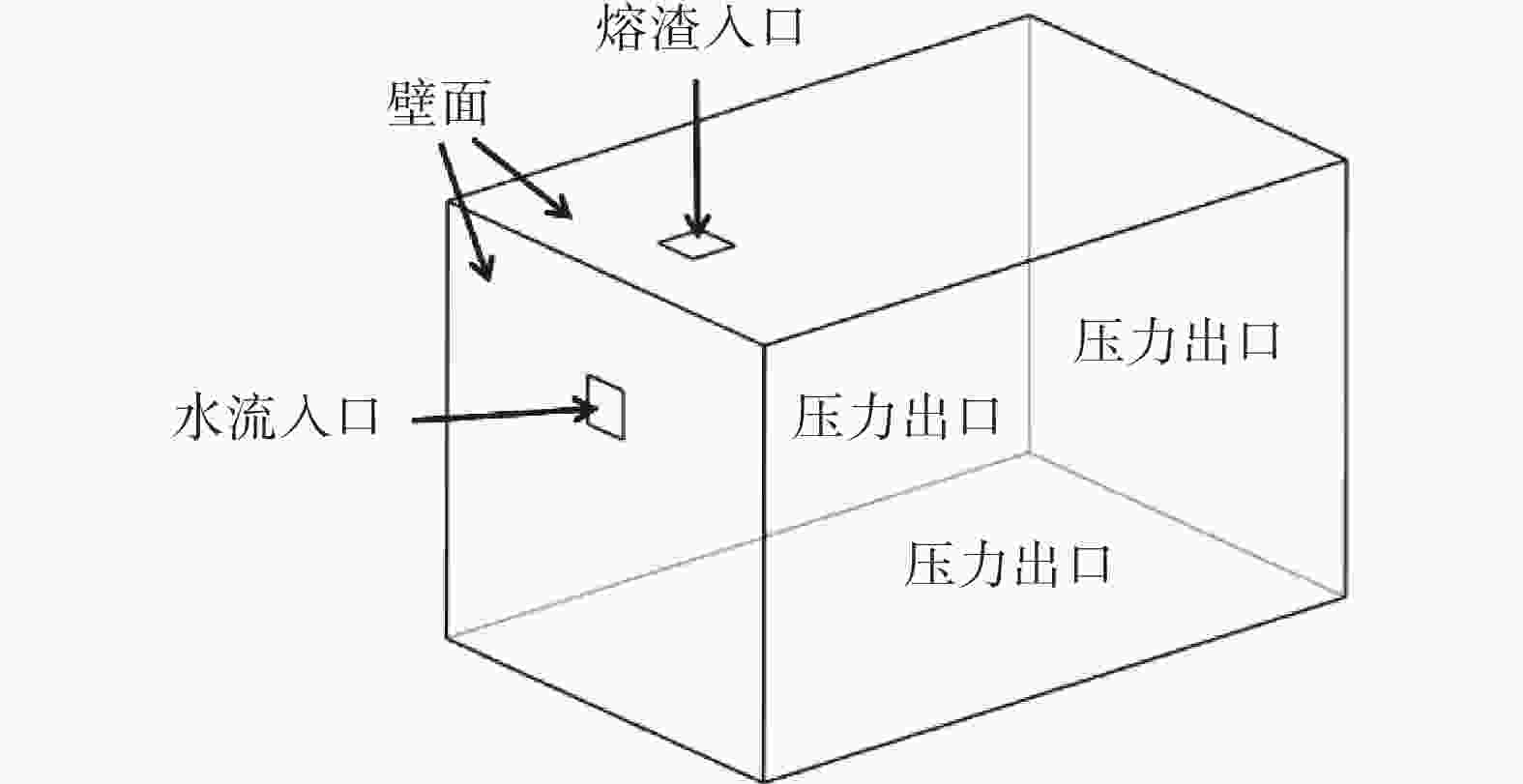

摘要: 鉴于常规的气淬粒化工艺可能存在的问题(如耗气量大等),拟采用水流作为粒化介质,开展高速水射流作用下熔渣粒化过程的数值模拟研究。研究利用VOF-to-DPM模型计算水射流熔渣粒化过程和熔渣粒径分布,并探究水流速度、熔渣速度、黏度等粒化条件对平均粒径等粒化结果的影响。结果表明:随着水流速度的增大,粒化后熔渣平均粒径减小,当水流速度达到30 m/s时,在所研究的参数条件下,基本不存在4 mm以上的大颗粒;当熔渣速度增加时,若水流厚度充足,对粒化效果和粒径分布影响很小;若水流厚度不足,则会出现未破碎熔渣直接下落的现象。为保证水流量充足,水渣比应达到2.2∶1;当熔渣黏度增加时,熔渣破碎效果变差,粒径分布和平均粒径明显增加。Abstract: Given the potential problems of the conventional gas quenching granulation process, such as the high gas consumption, this study intends to carry out a numerical simulation study of the slag granulation process under the action of high-speed water jet, using water flow as the granulation medium. The VOF-to-DPM model was used to calculate the granulation process and slag size distribution of water jet slag, and to explore the effects of water flow velocity, slag velocity, viscosity and other granulation process conditions on the average particle size and other granulation results. The results show that with the increase of water velocity, the average particle size of the slag after granulation decreases, and when the water velocity reaches 30 m/s, there are basically no large particles above 4 mm under the parameters studied. When the slag velocity increases, and the water flow thickness is sufficient, it has little influence on the granulation effect and particle size distribution. When the water flow thickness is insufficient, there will be a phenomenon of unbroken slag falling directly. In order to ensure that the water flow is sufficient, the water slag ratio should reach 2.2:1; when the slag viscosity increases, the slag crushing effect is getting worse, and the particle size distribution and average particle size increase significantly.

-

Key words:

- water jets /

- granulation /

- numerical simulation /

- slag /

- average particle size

-

表 1 模拟计算中气水渣物性参数

Table 1. Physical parameters of water slag in the simulation calculation

种类 密度/(kg·m−3) 黏度/(kg·m−1·s−1) 表面张力/(N·m−1) 高炉渣 2800 0.45 0.5 水 998.2 1.004×10−3 0.072 空气 1.225 1.7894 ×10−5 -

[1] TANG J H, YU J Y, MA B Y, et al. Research status of high value-added utilization of blast furnace slag[J]. Refractory & Lime, 2022,47(4):24-29. (汤鉴淮, 于敬雨, 马北越, 等. 高炉渣的高附加值利用研究现状[J]. 耐火与石灰, 2022,47(4):24-29. doi: 10.3969/j.issn.1673-7792.2022.4.gwnhcl202204006TANG J H, YU J Y, MA B Y, et al. Research status of high value-added utilization of blast furnace slag[J]. Refractory & Lime, 2022, 47(4): 24-29. doi: 10.3969/j.issn.1673-7792.2022.4.gwnhcl202204006 [2] ZHANG L S, LI H, ZHANG H X, et al. Comprehensive utilization and prospect of blast furnace slag[J]. Hot Working Technology, 2018,47(19):20-24. (张立生, 李慧, 张汉鑫, 等. 高炉渣的综合利用及展望[J]. 热加工工艺, 2018,47(19):20-24.ZHANG L S, LI H, ZHANG H X, et al. Comprehensive utilization and prospect of blast furnace slag[J]. Hot Working Technology, 2018, 47(19): 20-24. [3] WANG Z L. Research progress in centrifugal granulation of high temperature liquid slag[J]. Modern Chemical Research, 2023(4):25-27. (王治龙. 高温液态熔渣离心粒化研究进展[J]. 当代化工研究, 2023(4):25-27.WANG Z L. Research progress in centrifugal granulation of high temperature liquid slag[J]. Modern Chemical Research, 2023(4): 25-27. [4] XIAO Y L, HE F, XIE M Q, et al. Study on structure and properties of blast furnace slag[J]. Journal of Wuhan University of Technology, 2022,44(4):12-16. (肖永力, 何峰, 谢梦芹, 等. 高炉熔渣的结构与性质研究[J]. 武汉理工大学学报, 2022,44(4):12-16. doi: 10.3963/j.issn.1671-4431.2022.04.003XIAO Y L, HE F, XIE M Q, et al. Study on structure and properties of blast furnace slag[J]. Journal of Wuhan University of Technology, 2022, 44(4): 12-16. doi: 10.3963/j.issn.1671-4431.2022.04.003 [5] MA Y F. Current status and discussion of steel slag treatment technology[J]. Metallurgy and Materials, 2022,42(2):119-120. (马永富. 钢渣处理技术现况和探讨[J]. 冶金与材料, 2022,42(2):119-120. doi: 10.3969/j.issn.1674-5183.2022.02.060MA Y F. Current status and discussion of steel slag treatment technology[J]. Metallurgy and Materials, 2022, 42(2): 119-120. doi: 10.3969/j.issn.1674-5183.2022.02.060 [6] TAN F X, HUANG Y W. Preparation of copper and copper alloy powder by water atomization[J]. Metal Functional Materials, 2021,28(3):18-22. (谭芳香, 黄以伟. 水雾化法制备铜及铜合金粉[J]. 金属功能材料, 2021,28(3):18-22.TAN F X, HUANG Y W. Preparation of copper and copper alloy powder by water atomization[J]. Metal Functional Materials, 2021, 28(3): 18-22. [7] WANG Z B, LIU Y, ZHANG Y Z, et al. Experimental study on heat recovery of the process of gas blowing for blast slag[J]. Iron Steel Vanadium Titanium, 2018,39(4):93-98. (王子兵, 刘跃, 张玉柱, 等. 高炉熔渣气淬粒化热量回收试验研究[J]. 钢铁钒钛, 2018,39(4):93-98. doi: 10.7513/j.issn.1004-7638.2018.04.016WANG Z B, LIU Y, ZHANG Y Z, et al. Experimental study on heat recovery of the process of gas blowing for blast slag[J]. Iron Steel Vanadium Titanium, 2018, 39(4): 93-98. doi: 10.7513/j.issn.1004-7638.2018.04.016 [8] SUN R J, KANG Y, DING H L, et al. Influence of injection process parameters on granulation effect of blast furnace slag to beads[J]. Iron and Steel, 2024,59(7):159-168. (孙瑞靖, 康月, 丁洪玲, 等. 喷吹工艺参数对高炉渣粒化成珠效果的影响[J]. 钢铁, 2024,59(7):159-168.SUN R J, KANG Y, DING H L, et al. Influence of injection process parameters on granulation effect of blast furnace slag to beads[J]. Iron and Steel, 2024, 59(7): 159-168. [9] FANG W Y, WANG H, ZHU X, et al. Heat transfer characteristics of molten slag in rotary cup granulation process[J]. Iron and Steel, 2020,55(8):151-159. (方维扬, 王宏, 朱恂, 等. 转杯粒化工艺高温熔渣换热数值模拟[J]. 钢铁, 2020,55(8):151-159.FANG W Y, WANG H, ZHU X, et al. Heat transfer characteristics of molten slag in rotary cup granulation process[J]. Iron and Steel, 2020, 55(8): 151-159. [10] ZHANG B, CHENG P, LI Q L, et al. The crushing process of a transverse jet of a liquid under the action of an air film[J]. Acta Physica Sinica, 2021,70(5):230-241. (张彬, 成鹏, 李清廉, 等. 液体横向射流在气膜作用下的破碎过程[J]. 物理学报, 2021,70(5):230-241.ZHANG B, CHENG P, LI Q L, et al. The crushing process of a transverse jet of a liquid under the action of an air film[J]. Acta Physica Sinica, 2021, 70(5): 230-241. [11] SUN G T. Study on mechanical centrifugal granulation characteristics of blast furnace slag[D]. Qingdao: Qingdao University, 2020. (孙广彤. 高炉熔渣机械离心粒化特性研究[D]. 青岛:青岛大学, 2020.SUN G T. Study on mechanical centrifugal granulation characteristics of blast furnace slag[D]. Qingdao: Qingdao University, 2020. [12] JI H M. Research on key technologies of mechanical centrifugal granulation of blast furnace slag[D]. Qingdao: Qingdao University of Technology, 2019. (纪慧敏. 高炉熔渣机械离心粒化关键技术研究[D]. 青岛:青岛理工大学, 2019.JI H M. Research on key technologies of mechanical centrifugal granulation of blast furnace slag[D]. Qingdao: Qingdao University of Technology, 2019. [13] WU L, WU H F, WU Y D, et al. Discussion on development of heat recovery technology for high temperature molten slag[J]. Environmental Engineering, 2020,38(9):190-193, 88. (吴龙, 吴华峰, 吴跃东, 等. 高温熔渣热资源回收技术发展及探讨[J]. 环境工程, 2020,38(9):190-193, 88.WU L, WU H F, WU Y D, et al. Discussion on development of heat recovery technology for high temperature molten slag[J]. Environmental Engineering, 2020, 38(9): 190-193, 88. [14] BROUMAND M, AHMED M A, BIROUK M. Experimental investigation of spray characteristics of a liquid jet in a turbu lent subsonic gaseous crossflow[J]. Proceedings of the Combustion Institute, 2019,37(3):3237-3244. [15] WANG K, YI C J, HU F C, et al. Study on the flight and collision process of molten blast furnace slag[J]. Powder Metallurgy Technology, 2022,40(6):535-540, 548. (王凯, 仪垂杰, 胡凤超, 等. 高温液态熔渣飞行及碰撞过程研究[J]. 粉末冶金技术, 2022,40(6):535-540, 548.WANG K, YI C J, HU F C, et al. Study on the flight and collision process of molten blast furnace slag[J]. Powder Metallurgy Technology, 2022, 40(6): 535-540, 548. [16] WANG L L, ZHANG Y Z, KE H B, et al. Study on granulation performance of blast furnace slag by gas quenching[J]. Iron Steel Vanadium Titanium, 2020,41(4):82-86. (王丽丽, 张玉柱, 客海滨, 等. 气淬高炉熔渣粒化性能研究[J]. 钢铁钒钛, 2020,41(4):82-86.WANG L L, ZHANG Y Z, KE H B, et al. Study on granulation performance of blast furnace slag by gas quenching[J]. Iron Steel Vanadium Titanium, 2020, 41(4): 82-86. [17] WANG L L, ZHANG Y Z, KE H B, et al. Numerical simulation of molten slag film breakup during granulation process using air-quenching[J]. Journal of Materials and Metallurgy, 2020,19(2):87-93. (王丽丽, 张玉柱, 客海滨, 等. 气淬粒化工艺中熔渣液膜破碎数值模拟[J]. 材料与冶金学报, 2020,19(2):87-93.WANG L L, ZHANG Y Z, KE H B, et al. Numerical simulation of molten slag film breakup during granulation process using air-quenching[J]. Journal of Materials and Metallurgy, 2020, 19(2): 87-93. [18] GAO J, FENG Y H, FENG D L, et al. Centrifugal granulation of liquid slag by wind quenching[J]. Journal of Engineering Thermophysics, 2021,42(5):1288-1292. (高洁, 冯妍卉, 冯黛丽, 等. 风淬作用下液态熔渣的离心粒化[J]. 工程热物理学报, 2021,42(5):1288-1292.GAO J, FENG Y H, FENG D L, et al. Centrifugal granulation of liquid slag by wind quenching[J]. Journal of Engineering Thermophysics, 2021, 42(5): 1288-1292. [19] LIU X H, WEN Z, X Y L, et al. Analysis of slag granulation mechanism and crushing efficiency under gas quenching[J]. Journal of Northeastern University(Natural Science), 2023,44(10):1424-1430. (刘晓宏, 温治, 肖永力, 等. 气淬作用下熔渣粒化机理及破碎效果分析[J]. 东北大学学报(自然科学版), 2023,44(10):1424-1430. doi: 10.12068/j.issn.1005-3026.2023.10.008LIU X H, WEN Z, X Y L, et al. Analysis of slag granulation mechanism and crushing efficiency under gas quenching[J]. Journal of Northeastern University(Natural Science), 2023, 44(10): 1424-1430. doi: 10.12068/j.issn.1005-3026.2023.10.008 [20] LIU X H, WEN Z, DU Y H, et al. Study on liquid film breaking process of gas quenched granulated slag[J]. Journal of Central South University (Science and Technology), 2022,53(8):2851-2860. (刘晓宏, 温治, 杜宇航, 等. 气淬粒化熔渣液膜破碎过程研究[J]. 中南大学学报(自然科学版), 2022,53(8):2851-2860.LIU X H, WEN Z, DU Y H, et al. Study on liquid film breaking process of gas quenched granulated slag[J]. Journal of Central South University (Science and Technology), 2022, 53(8): 2851-2860. [21] SHAO C, KANG Y, XING H W, et al. Experimental and simulation on the granulation process of blast furnace slag[J]. Iron Steel Vanadium Titanium, 2024,45(1):104-114. (邵宸, 康月, 邢宏伟, 等. 高炉熔渣粒化工艺试验及其数值仿真研究分析[J]. 钢铁钒钛, 2024,45(1):104-114. doi: 10.7513/j.issn.1004-7638.2024.01.016SHAO C, KANG Y, XING H W, et al. Experimental and simulation on the granulation process of blast furnace slag[J]. Iron Steel Vanadium Titanium, 2024, 45(1): 104-114. doi: 10.7513/j.issn.1004-7638.2024.01.016 [22] ZHAO K, BAI X J, WANG D X, et al. Numerical simulation on pneumatic atomized water for granulation and heat recovery of molten slag [J/OL]. China Metallurgy, 1-15[2025-01-13]. (赵凯, 白晓军, 王殿新, 等. 气力雾化水用于高温熔渣粒化及热回收的数值模拟[J/OL]. 中国冶金, 1-15[2025-01-13].ZHAO K, BAI X J, WANG D X, et al. Numerical simulation on pneumatic atomized water for granulation and heat recovery of molten slag [J/OL]. China Metallurgy, 1-15[2025-01-13]. [23] LIU X H, WEN Z, DU Y H, et al. Numerical simulation of the slag granulation process in gas quenching under multi-influencing factors[J]. Iranian Journal of Science and Technology, Trans actions of Mechanical Engineering, 2023,47(4):1733-1745. doi: 10.1007/s40997-023-00640-2 [24] ZHANG X Y, XU N W, LI X M, et al. Numerical simulation of centrifugal granulation characteristics of slag optimized by auxiliary gas quenching winds[J]. The Chinese Journal of Process Engineering, 2024,24(5):523-532. (张馨艺, 徐宁文, 李小明, 等. 辅助气淬风优化熔渣离心粒化特性数值模拟[J]. 过程工程学报, 2024,24(5):523-532.ZHANG X Y, XU N W, LI X M, et al. Numerical simulation of centrifugal granulation characteristics of slag optimized by auxiliary gas quenching winds[J]. The Chinese Journal of Process Engineering, 2024, 24(5): 523-532. [25] LIAO B, ZHANG G F, WANG L H, et al. Deformation and breakup behaviors of drop in ambient liquid under impact[J]. Journal of Experimental in Fluid Mechanics, 2016,30(5):9-16. (廖斌, 张桂夫, 王鲁海, 等. 冲击作用下液滴在环境液体中的变形破碎行为[J]. 实验流体力学, 2016,30(5):9-16. doi: 10.11729/syltlx20160029LIAO B, ZHANG G F, WANG L H, et al. Deformation and breakup behaviors of drop in ambient liquid under impact[J]. Journal of Experimental in Fluid Mechanics, 2016, 30(5): 9-16. doi: 10.11729/syltlx20160029 [26] GUO J P, WANG Y B, BAI F Q, et al. Unstable breakup of a power-law liquid fuel jet in the presence of a gas crossflow[J]. Fuel, 2020,263:116606. doi: 10.1016/j.fuel.2019.116606 [27] LI B. Simulation study on gas quenching and granulation of modified blast furnace slag[D]. Tangshan: North China University of Science and Technology, 2022. (李兵. 调质高炉熔渣气淬粒化模拟研究[D]. 唐山:华北理工大学, 2022.LI B. Simulation study on gas quenching and granulation of modified blast furnace slag[D]. Tangshan: North China University of Science and Technology, 2022. [28] ZHANG B W. Study on multiphase flow and atomization characteristic in water atomization process[D]. Beijing: Beijing University of Civil Engineering and Architecture, 2023. (张博文. 水雾化过程多相流动及雾化规律探究[D]. 北京:北京建筑大学, 2023.ZHANG B W. Study on multiphase flow and atomization characteristic in water atomization process[D]. Beijing: Beijing University of Civil Engineering and Architecture, 2023. [29] KASHANJ S, KEBRIAEE A. The effects of different jet velocities and axial misalignment on the liquid sheet of two colliding jets[J]. Chemical Engineering Science, 2019,206:235-248. doi: 10.1016/j.ces.2019.05.015 [30] ZHANG Y, XU J, CHANG Q, et al. Bi-layer coarse-grained DPM of gas-solid systems with mesoscale heterogeneity re solved[J]. Chemical Engineering Science, 2022,263:118058. doi: 10.1016/j.ces.2022.118058 -

下载:

下载: