Research on the evolution of inclusions in 20CrMnTi gear steel and the improvement of steel liquid cleanliness

-

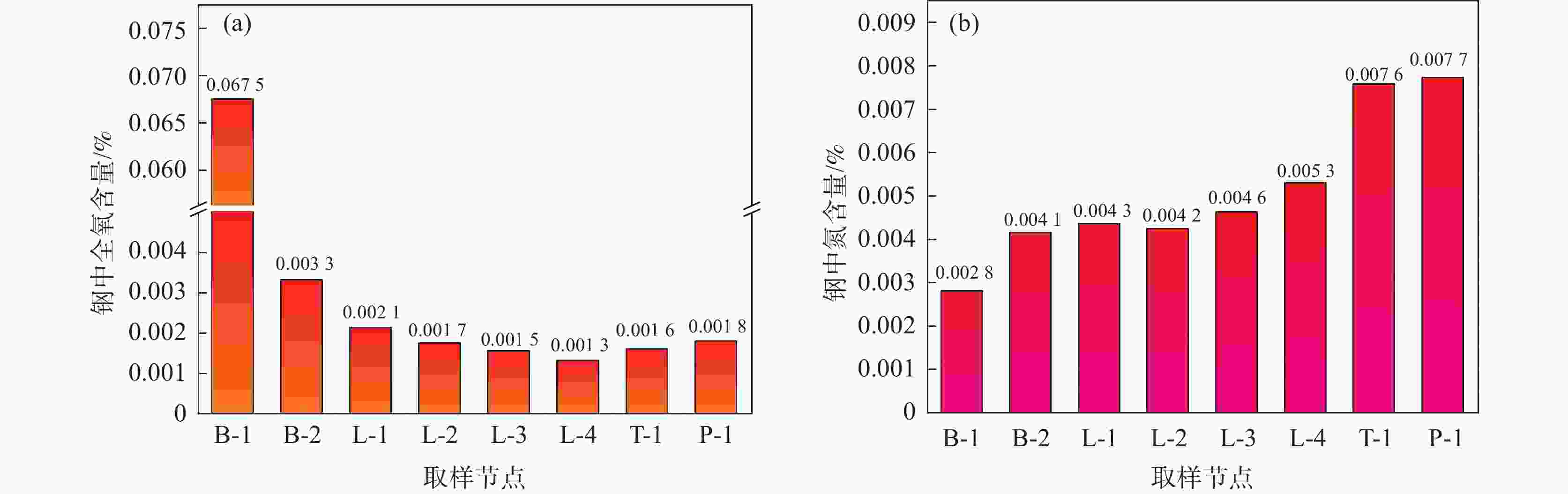

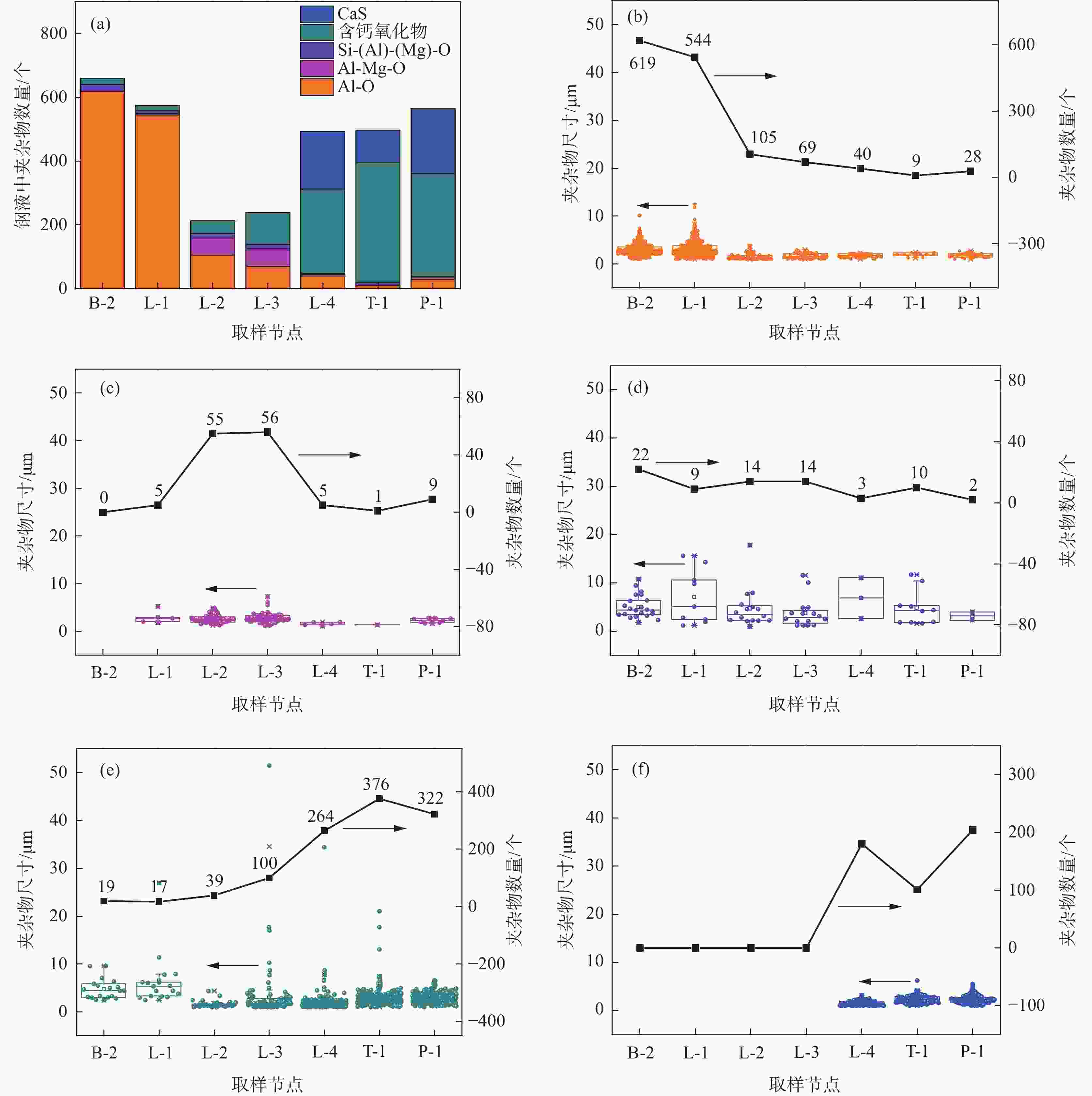

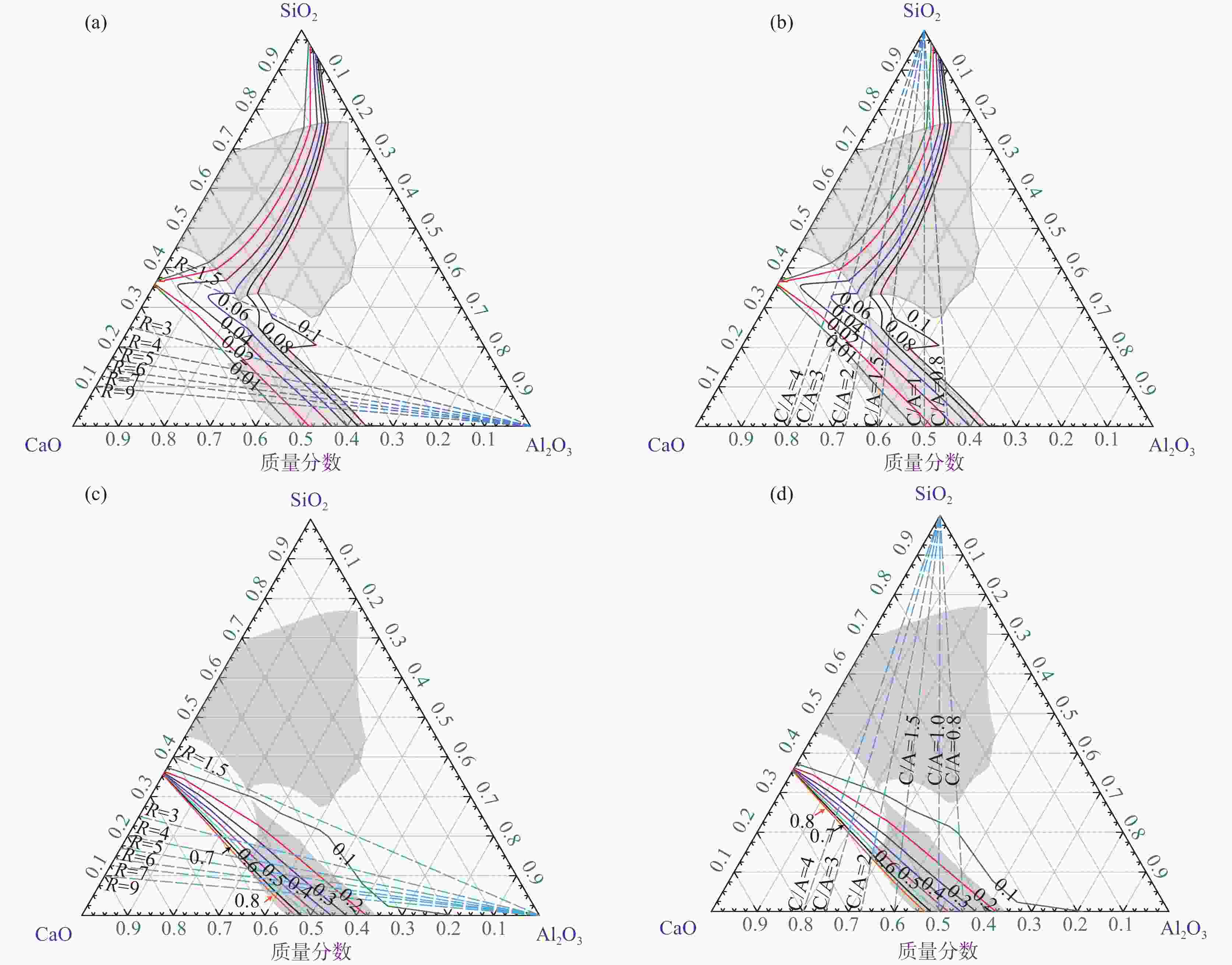

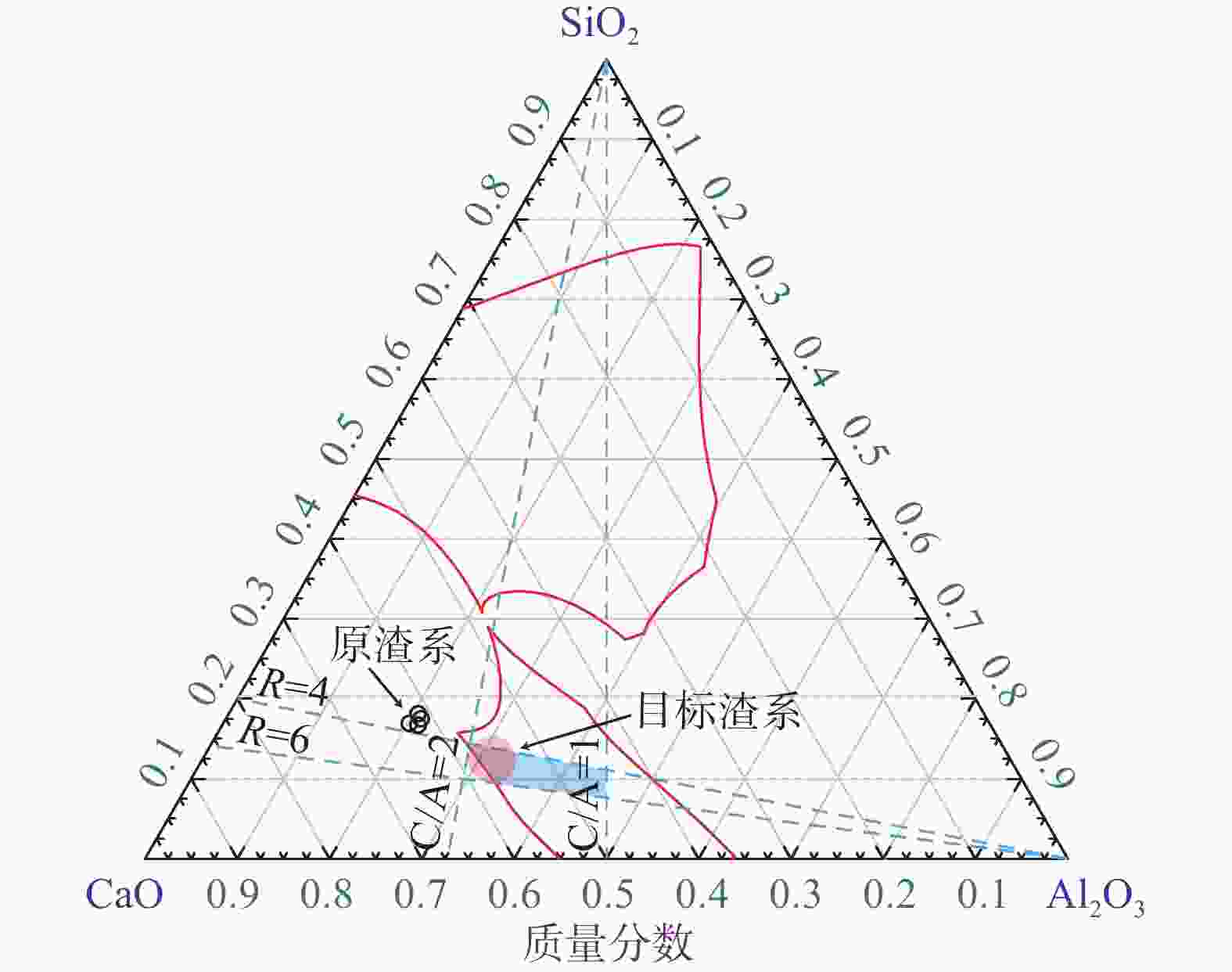

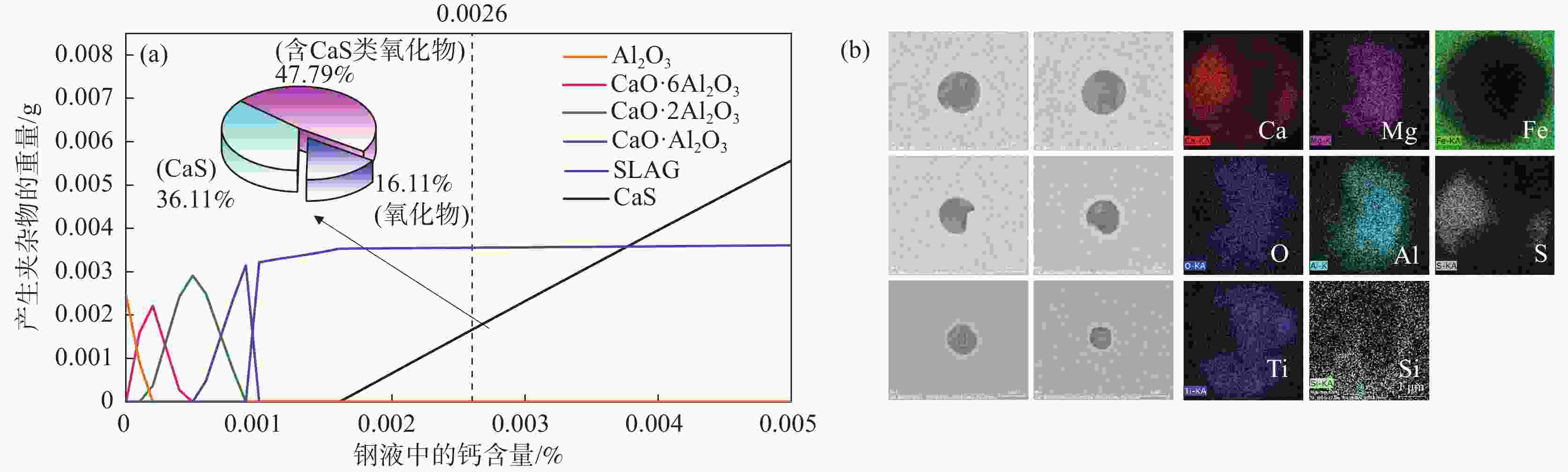

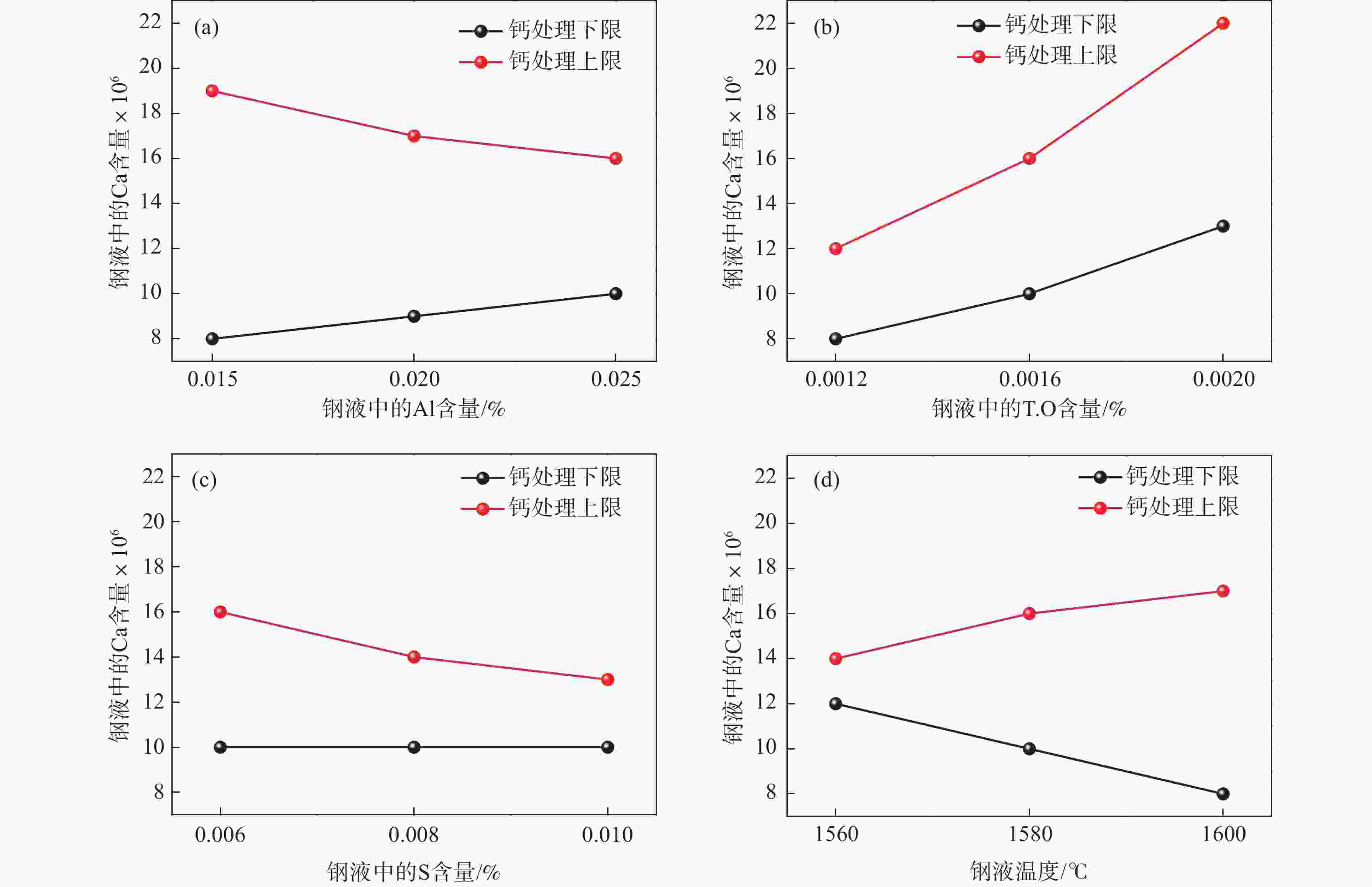

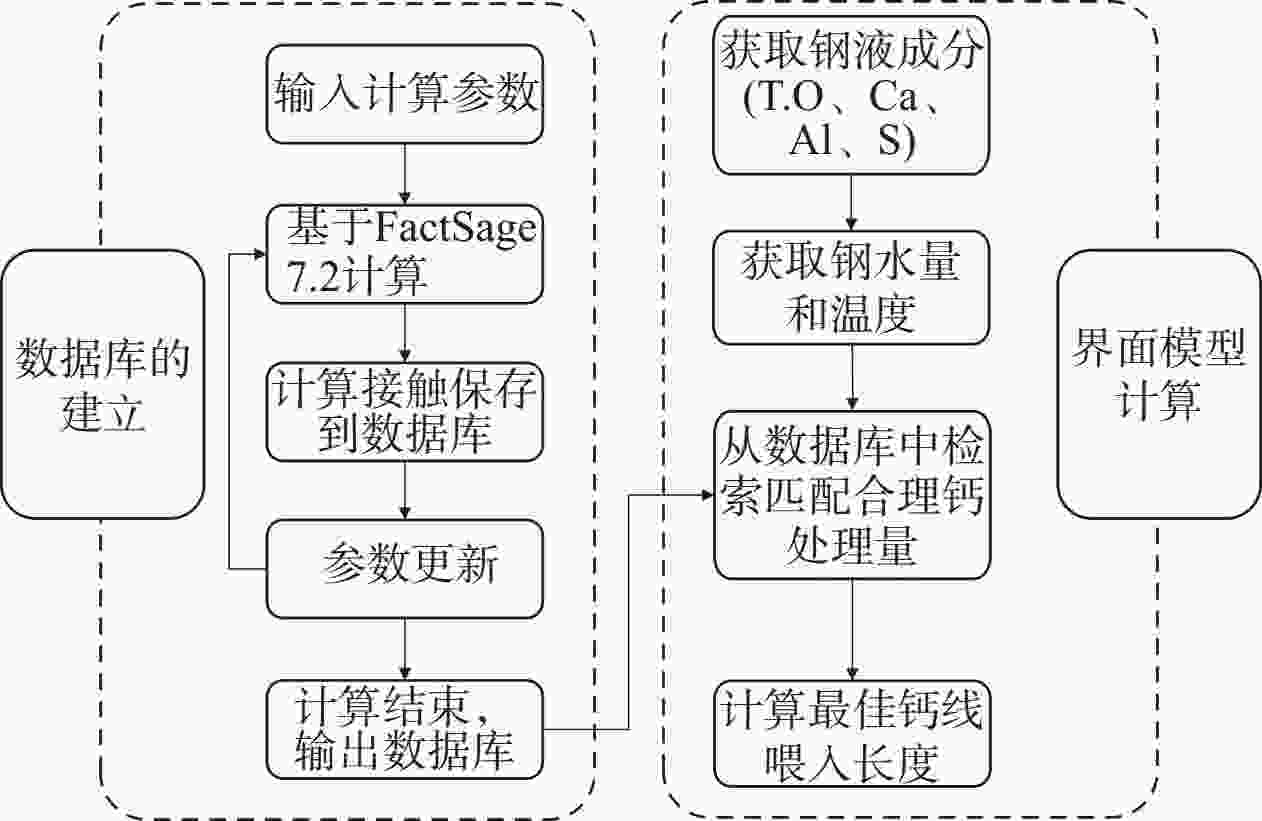

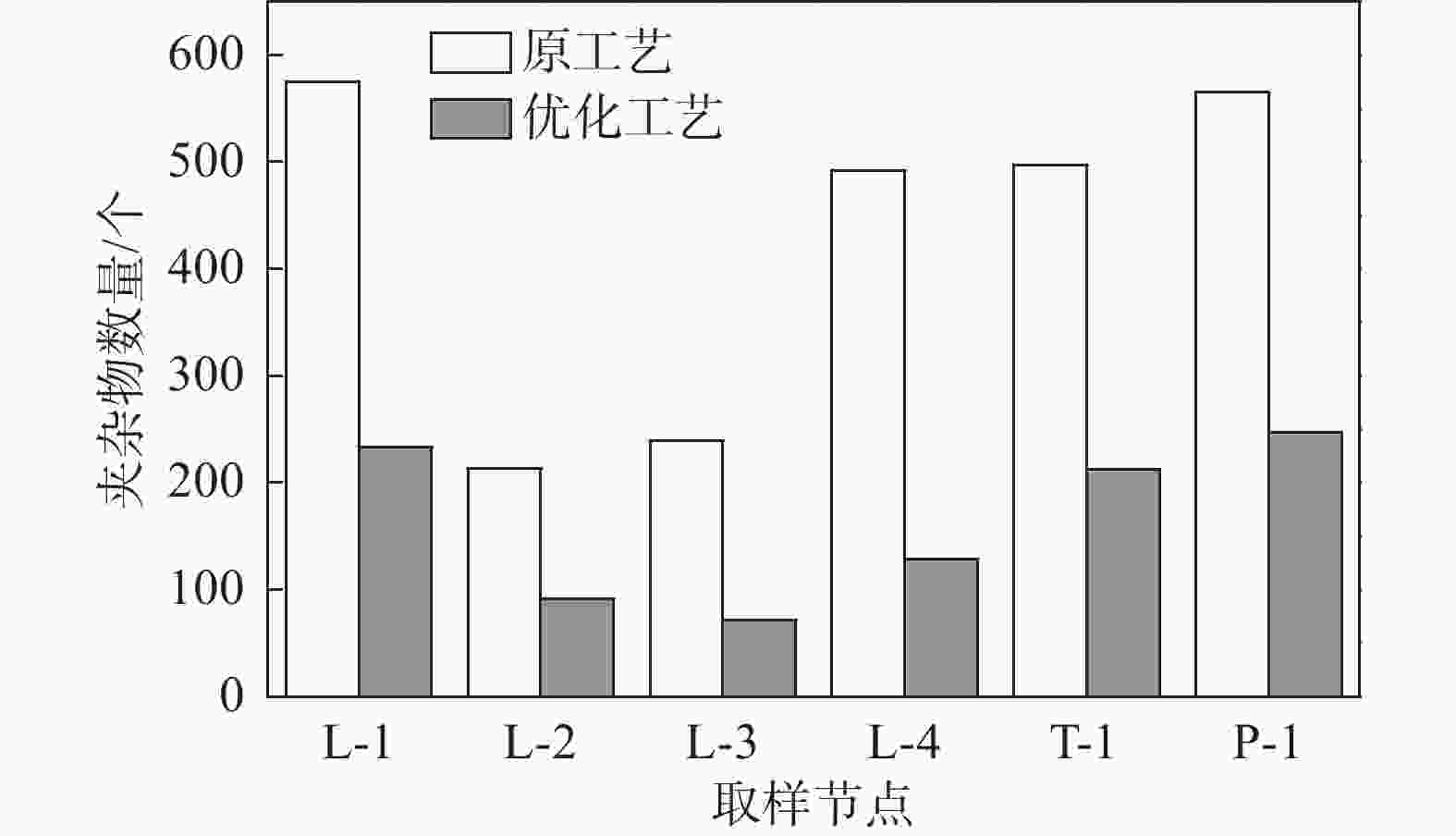

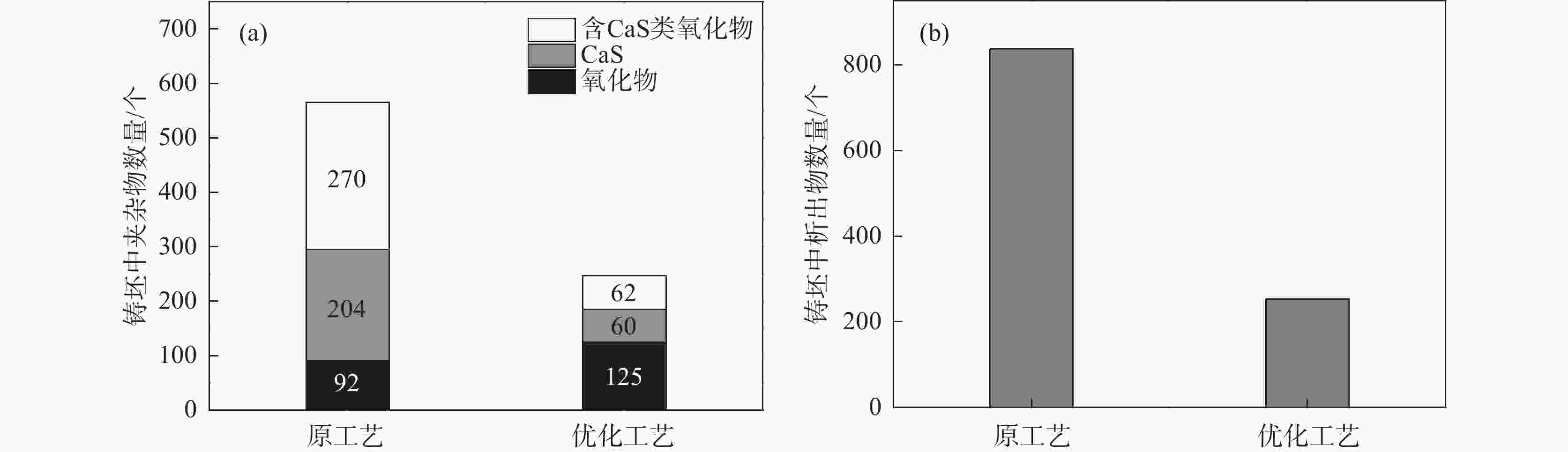

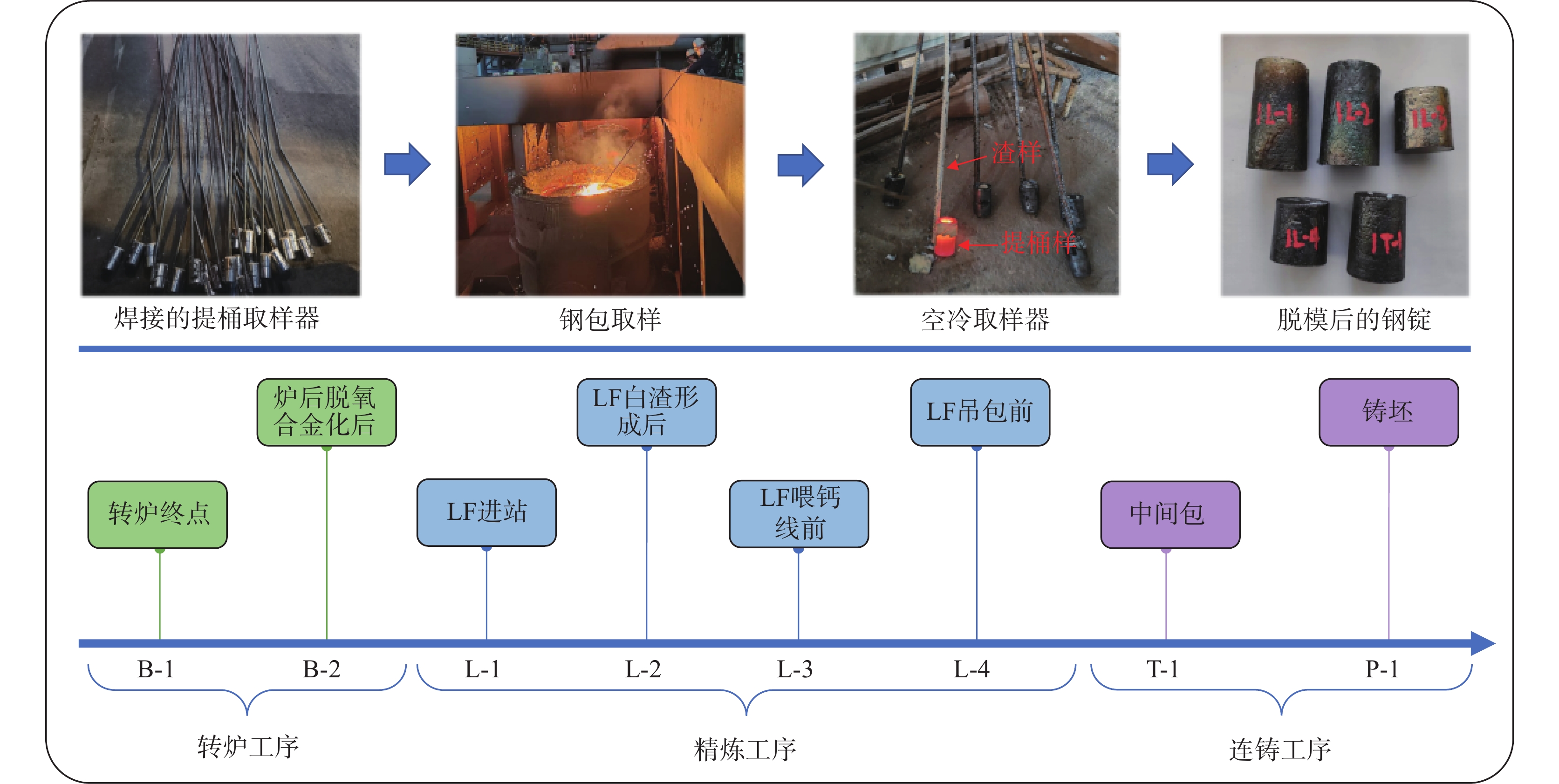

摘要: 以国内某厂20CrMnTi齿轮钢为研究对象,通过全流程取样分析了钢液洁净度提升的限制性环节,并提出以下两项优化措施:①基于FactSage7.2计算了精炼渣碱度和钙铝比对CaO和Al2O3活度的影响,综合考虑渣系的低温液相区,确定了目标精炼渣系范围:碱度=4~6,w(SiO2)=9%~13.5%,w(Al2O3)= 22.5%~31.5%,w(Fe2O3+MnO)<1%;②基于钙处理过量的现状,依托热力学数据库搭建了精准钙处理计算模型,并设计了人机交互界面。工业试验数据显示,在优化渣系和减少钙处理量的情况下,冶炼过程中的夹杂物数量显著减少,铸坯中夹杂物数量比原工艺降低56.3%。Abstract: In this work, taking a domestic factory’s 20CrMnTi gear steel as the research object, the limiting factors for improving the cleanliness of the steel liquid were analyzed through systematic sampling, and two optimization measures were proposed. Firstly, based on FactSage7.2, the effects of refining slag basicity and calcium aluminum ratio on CaO and Al2O3 activity were calculated. Taking into account the low-temperature liquid phase region of the slag system, the target refining slag system range was determined as follows: R=4-6, w (SiO2)=9%-13.5%, w (Al2O3)=22.5%-31.5%, and w (Fe2O3+MnO)<1%. Then, based on the current situation of excessive Ca-treatment, a thermodynamic database had been utilized to construct an accurate calculation model for Ca-treatment. Finally, the results of industrial experiments showed that with the optimization of the refining slag and the reduction of Ca-treatment, the number of inclusions in the smelting process significantly reduced, and the number of inclusions in the casting billet decreased by 56.3% compared to the original process.

-

Key words:

- 20CrMnTi /

- gear steel /

- improvement of cleanliness /

- optimization of slag system /

- Ca-treatment

-

表 1 20CrMnTi齿轮钢的化学成分

Table 1. Chemical Compositions of 20CrMnTi Gear Steel

% C Si Mn P S Cr Ti Al 标准 0.17~0.23 0.17~0.37 0.80~1.10 ≤0.03 ≤0.03 1.00~1.30 0.04~0.10 0.015~0.035 内控 0.18~0.20 0.19~0.26 0.87~0.93 ≤0.02 ≤0.02 1.02~1.08 0.05~0.08 0.020~0.030 表 2 精炼过程渣样化学成分

Table 2. Main components of refining process slag

% 节点 CaO SiO2 Al2O3 MgO Fe2O3 MnO R= CaO/ SiO2 LF进站时 54.85 16.08 18.36 5.29 1.41 0.92 3.41 LF白渣后 55.76 15.68 19.36 5.31 1.21 0.53 3.55 LF喂线前 56.68 15.11 19.21 5.01 0.92 0.15 3.75 LF吊包前 56.27 15.05 18.04 4.71 0.83 0.1 3.73 表 3 钢液化学成分和温度

Table 3. Chemical composition and temperature of molten steel

化学成分/% T/ ℃ C Si Mn P S O Al Fe 0.19 0.24 0.9 0.015 0.006 0.0015 0.015 1580 表 4 工艺优化前后渣样成分及钙线喂入量

Table 4. Compositions of slag samples and length of calcium wire added before and after process optimization

工艺 节点 化学成分/% 钙线喂入量/m CaO SiO2 Al2O3 MgO Fe2O3 MnO R= CaO/ SiO2 原工艺 LF进站渣 54.85 16.08 18.36 5.29 1.41 0.92 3.41 130 LF出站渣 56.27 15.05 18.04 4.71 0.83 0.1 3.73 新工艺 LF进站渣 54.16 9.55 27.59 3.84 1.70 1.44 5.67 80 LF出站渣 55.81 12.51 23.2 2.72 0.65 0.11 4.46 -

[1] LIN P. Smelting and producation quality study of high quality gear steel with BOF process[D]. Beijing: Beijing University of Science and Technology, 2010. (林平. 转炉生产高品质齿轮钢冶炼工艺与产品质量研究[D]. 东北大学, 2010.LIN P. Smelting and producation quality study of high quality gear steel with BOF process[D]. Beijing: Beijing University of Science and Technology, 2010. [2] ZHAO P L, HAN W X, YANG Z J, et al. Effect of inclusions on impact toughness of H-shaped steel for marine engineering[J]. China Metallurgy, 2020,30(2):74-78. (赵培林, 韩文习, 杨志杰, 等. 夹杂物对海工用H型钢冲击韧性影响及分析[J]. 中国冶金, 2020,30(2):74-78.ZHAO P L, HAN W X, YANG Z J, et al. Effect of inclusions on impact toughness of H-shaped steel for marine engineering[J]. China Metallurgy, 2020, 30(2): 74-78. [3] GUAN Z, SUN Y Q, LI L, et al. Effects of smelting process on fatigue performance of 15-5PH stainless steel[J]. Iron and Steel, 2020,55(1):72-80. (管真, 孙永庆, 李莉, 等. 冶炼工艺对15-5PH不锈钢疲劳性能的影响[J]. 钢铁, 2020,55(1):72-80.GUAN Z, SUN Y Q, LI L, et al. Effects of smelting process on fatigue performance of 15-5PH stainless steel[J]. Iron and Steel, 2020, 55(1): 72-80. [4] AN J, WANG Z, LI R X, et al. Cleanliness of automobile gear steel 8620RH[J]. China Metallurgy, 2016,26(9):33-37. (安杰, 王哲, 李润霞, 等. 汽车齿轮钢8620RH的洁净度[J]. 中国冶金, 2016,26(9):33-37.AN J, WANG Z, LI R X, et al. Cleanliness of automobile gear steel 8620RH[J]. China Metallurgy, 2016, 26(9): 33-37. [5] JU Y J, LÜ Z Y, XING L D, et al. Evolution analysis of inclusions in the whole process of 20CrMnTiH smelting[J]. Nonferrous Metals Science and Engineering, 2022,13(4):20-27. (巨银军, 吕子宇, 邢立东, 等. 20CrMnTiH冶炼全流程夹杂物演变分析[J]. 有色金属科学与工程, 2022,13(4):20-27.JU Y J, LÜ Z Y, XING L D, et al. Evolution analysis of inclusions in the whole process of 20CrMnTiH smelting[J]. Nonferrous Metals Science and Engineering, 2022, 13(4): 20-27. [6] ZHAO D W, BAO Y P, WANG M, et al. Composition optimization of LF refining slag in high cleanliness Al-killed steel[J]. Steelmaking, 2013,29(2):9-13. (赵东伟, 包燕平, 王敏, 等. 高洁净度铝镇静钢LF精炼渣成分优化[J]. 炼钢, 2013,29(2):9-13.ZHAO D W, BAO Y P, WANG M, et al. Composition optimization of LF refining slag in high cleanliness Al-killed steel[J]. Steelmaking, 2013, 29(2): 9-13. [7] LIU C S, HOU S W, LIU X Q, et al. Optimization of refining slag for 30CrlMolV steam turbine rotor steel[J]. Journal of Iron and Steel Research, 2022,34(10):1098-1107. (刘成松, 侯松威, 刘晓芹, 等. 30Cr1Mo1V汽轮机转子钢的精炼渣优化[J]. 钢铁研究学报, 2022,34(10):1098-1107.LIU C S, HOU S W, LIU X Q, et al. Optimization of refining slag for 30CrlMolV steam turbine rotor steel[J]. Journal of Iron and Steel Research, 2022, 34(10): 1098-1107. [8] ZHAO B, WU W, YANG F, et al. Thermodynamic analysis and performance optimization of refining slag containing lanthanum oxide[J]. China Metallurgy, 2023,33(7):31-39. (赵博, 吴伟, 杨峰, 等. 含氧化镧精炼渣的热力学分析及性能优化[J]. 中国冶金, 2023,33(7):31-39.ZHAO B, WU W, YANG F, et al. Thermodynamic analysis and performance optimization of refining slag containing lanthanum oxide[J]. China Metallurgy, 2023, 33(7): 31-39. [9] CHENG R J, QI Z, ZHANG H, et al. Optimization of refining slag of 20SiMn alloy structural steel[J]. Iron and Steel, 2023,58(1):100-107, 152. (成日金, 齐詹, 张华, 等. 20SiMn合金结构钢精炼渣系优化[J]. 钢铁, 2023,58(1):100-107, 152.CHENG R J, QI Z, ZHANG H, et al. Optimization of refining slag of 20SiMn alloy structural steel[J]. Iron and Steel, 2023, 58(1): 100-107, 152. [10] WANG X, WEI J, QIU S T, et al. Optimization of CaO/Al2O3 ratio in refining slag for 12Mn steel[J]. Iron Steel Vanadium Titanium, 2020,41(3):122-127. (王旭, 魏军, 仇圣桃, 等. 12Mn钢精炼渣CaO/Al2O3值优化[J]. 钢铁钒钛, 2020,41(3):122-127. doi: 10.7513/j.issn.1004-7638.2020.03.021WANG X, WEI J, QIU S T, et al. Optimization of CaO/Al2O3 ratio in refining slag for 12Mn steel[J]. Iron Steel Vanadium Titanium, 2020, 41(3): 122-127. doi: 10.7513/j.issn.1004-7638.2020.03.021 [11] XU G F, ZHANG X L, YANG S F, et al. Inclusion characterization in whole smelting process of 20CrMnTi gear steel[J]. China Metallurgy, 2020,30(11):23-28. (许国方, 张雪良, 杨树峰, 等. 20CrMnTi齿轮钢冶炼全流程的夹杂物分析[J]. 中国冶金, 2020,30(11):23-28.XU G F, ZHANG X L, YANG S F, et al. Inclusion characterization in whole smelting process of 20CrMnTi gear steel[J]. China Metallurgy, 2020, 30(11): 23-28. [12] WU H Q, LIN L, GU C. Optimization and industrial tests of LF refining slag for gear steel(8620H)[J]. China Metallurgy, 2016,26(8):32-38. (吴辉强, 林路, 顾超. 齿轮钢(8620H)精炼渣优化及工业试验[J]. 中国冶金, 2016,26(8):32-38.WU H Q, LIN L, GU C. Optimization and industrial tests of LF refining slag for gear steel(8620H)[J]. China Metallurgy, 2016, 26(8): 32-38. [13] LIN L, GU C, BAO Y P, et al. Optimization of LF refining slag of 20CrMnTi gear steel[J]. Steelmaking, 2017,33(2):15-19. (林路, 顾超, 包燕平, 等. 20CrMnTi齿轮钢LF精炼渣优化[J]. 炼钢, 2017,33(2):15-19.LIN L, GU C, BAO Y P, et al. Optimization of LF refining slag of 20CrMnTi gear steel[J]. Steelmaking, 2017, 33(2): 15-19. [14] LIU J, AN J, TIAN W Y, et al. Production practice on improving cleanliness of gear steel 8620RH[J]. Industrial Heating, 2023,52(12):7-10. (柳军, 安杰, 田万原, 等. 改善齿轮钢8620RH洁净度的生产实践[J]. 工业加热, 2023,52(12):7-10. doi: 10.3969/j.issn.1002-1639.2023.12.002LIU J, AN J, TIAN W Y, et al. Production practice on improving cleanliness of gear steel 8620RH[J]. Industrial Heating, 2023, 52(12): 7-10. doi: 10.3969/j.issn.1002-1639.2023.12.002 [15] ZENG Y X. Cleanness control of sulfur bearing gear steel 20CrMnTiH[J]. Iron and Steel, 2021,56(2):76-81. (曾耀先. 含硫齿轮钢20CrMnTiH洁净度控制[J]. 钢铁, 2021,56(2):76-81.ZENG Y X. Cleanness control of sulfur bearing gear steel 20CrMnTiH[J]. Iron and Steel, 2021, 56(2): 76-81. [16] JI S, ZHANG L F, LUO Y, et al. Effect of calcium treatment on nonmetallic inclusions in 20CrMnTiH gear steel[J]. Chinese Jounal of Engineering, 2021,43(6):825-834. (季莎, 张立峰, 罗艳, 等. 钙处理对20CrMnTiH齿轮钢中非金属夹杂物的影响[J]. 工程科学学报, 2021,43(6):825-834.JI S, ZHANG L F, LUO Y, et al. Effect of calcium treatment on nonmetallic inclusions in 20CrMnTiH gear steel[J]. Chinese Jounal of Engineering, 2021, 43(6): 825-834. [17] WU H J, LU P Y, YUE F, et al. Effect of calciumtreatment on sulfide inclusions in steel with medium sulphurcontent[J]. Journal of University of Science and Technology Beijing, 2014,36(S1):230-234. (吴华杰, 陆鹏雁, 岳峰, 等. 钙处理对中硫含量钢中硫化物形态影响的试验研究[J]. 北京科技大学学报, 2014,36(S1):230-234.WU H J, LU P Y, YUE F, et al. Effect of calciumtreatment on sulfide inclusions in steel with medium sulphurcontent[J]. Journal of University of Science and Technology Beijing, 2014, 36(S1): 230-234. [18] CAI X F, BAO Y P, LIN L. Evolution of inclusions during calcium treatment in liquid steel and its thermodynamic analysis[J]. Chinese Journal of Engineering, 2016,38(S1):32-36. (蔡小锋, 包燕平, 林路. 钙处理过程夹杂物演变及热力学分析[J]. 工程科学学报, 2016,38(S1):32-36.CAI X F, BAO Y P, LIN L. Evolution of inclusions during calcium treatment in liquid steel and its thermodynamic analysis[J]. Chinese Journal of Engineering, 2016, 38(S1): 32-36. [19] WANG H, LI J, SHI C B, et al. Evolution of inclusions in calcium-reated H13 die steel[J]. Chinese Journal of Engineering, 2018,40(S1):11-18. (王昊, 李晶, 史成斌, 等. 钙处理H13钢中夹杂物的转变[J]. 工程科学学报, 2018,40(S1):11-18.WANG H, LI J, SHI C B, et al. Evolution of inclusions in calcium-reated H13 die steel[J]. Chinese Journal of Engineering, 2018, 40(S1): 11-18. [20] BAI X, SUN Y, CHEN R, et al. Formation and thermodynamics of CaS-bearing inclusions during Ca treatment in oil casting steels[J]. International Journal of Minerals, Metallurgy and Materials, 2019,26:573-587. [21] GOLLAPALLI V, RAO M B V, KARAMCHED P S, et al. Modification of oxide inclusions in calcium-treated Al-killed high sulphur steels[J]. Ironmaking & Steelmaking, 2019,46(7):663-670. [22] ZHANG L F, LI F, FANG W. Thermodynamic investigation for the accurate calcium addition during calciumtreatment of molten steels[J]. Steelmaking, 2016,32(2):1-8. (张立峰, 李菲, 方文. 钢液钙处理过程中钙加入量精准计算的热力学研究[J]. 炼钢, 2016,32(2):1-8.ZHANG L F, LI F, FANG W. Thermodynamic investigation for the accurate calcium addition during calciumtreatment of molten steels[J]. Steelmaking, 2016, 32(2): 1-8. [23] LIU K L, LÜ M, SONG B M, et al. Q355B aluminum calming steel inclusion evolution and calcium treatment process optimization[J]. Iron and Steel, 2022,57(12):79-87. (刘坤龙, 吕明, 宋保民, 等. Q355B铝镇静钢夹杂物演变及钙处理工艺优化[J]. 钢铁, 2022,57(12):79-87.LIU K L, LÜ M, SONG B M, et al. Q355B aluminum calming steel inclusion evolution and calcium treatment process optimization[J]. Iron and Steel, 2022, 57(12): 79-87. [24] LONG H, QIU W S, LIU D, et al. Mechanism of ZrO2 containing nozzle clogging in continuous casting of calcium treated aluminum killed steel[J]. Continuous Casting, 2024(1):38-45. (龙鹄, 丘文生, 刘栋, 等. 钙处理铝镇静钢连铸锆质水口堵塞机理分析[J]. 连铸, 2024(1):38-45.LONG H, QIU W S, LIU D, et al. Mechanism of ZrO2 containing nozzle clogging in continuous casting of calcium treated aluminum killed steel[J]. Continuous Casting, 2024(1): 38-45. [25] JIA T, WANG W J, REN Y, et al. Effect of calcium addition amount on the modification of non-metallic inclusions in high-strength steel[J]. Continuous Casting, 2024, (3): 32-40. (贾涛, 王伟健, 任英, 等. 喂钙量对高强钢中非金属夹杂物的改性影响[J]. 连铸, 2024, (03): 32-40.JIA T, WANG W J, REN Y, et al. Effect of calcium addition amount on the modification of non-metallic inclusions in high-strength steel[J]. Continuous Casting, 2024, (3): 32-40. [26] WANG W J, YANG W, REN Y, et al. Development of the guidance software of precise calcium treatment and its application in special steel production[J]. Special Steel, 2023,44(6):25-30. (王伟健, 杨文, 任英, 等. 精准钙处理指导软件开发及在特殊钢生产中的应用[J]. 特殊钢, 2023,44(6):25-30.WANG W J, YANG W, REN Y, et al. Development of the guidance software of precise calcium treatment and its application in special steel production[J]. Special Steel, 2023, 44(6): 25-30. [27] LI X, WU H J, LIU W, et al. Practice and analysis of light calcium treatment of 55Cr3 aluminum deoxidized spring steel[J]. Special Steel, 2023,44(4):49-53 (李学, 吴华杰, 刘维, 等. 铝脱氧55Cr3弹簧钢轻钙处理的实践与分析[J]. 特殊钢, 2023,44(4):49-53.LI X, WU H J, LIU W, et al. Practice and analysis of light calcium treatment of 55Cr3 aluminum deoxidized spring steel[J]. Special Steel, 2023, 44(4): 49-53 [28] DENG Z Y, ZHU M Y. Discussion on calcium treatment technology for clean steel refining[J]. Iron and Steel, 2023,58(9):104-115, 147. (邓志银, 朱苗勇. 洁净钢精炼钙处理技术探析[J]. 钢铁, 2023,58(9):104-115, 147.DENG Z Y, ZHU M Y. Discussion on calcium treatment technology for clean steel refining[J]. Iron and Steel, 2023, 58(9): 104-115, 147. [29] ZHANG Y Q, CHENG G G, Li Y, et al. Characteristics and distribution of sulfide in calciumtreated resulfurized steel at home and abroad[J]. China Metallurgy, 2023,33(2):65-72. (张友祺, 成国光, 李尧, 等. 国内外钙处理含硫钢中硫化物的特征和分布[J]. 中国冶金, 2023,33(2):65-72.ZHANG Y Q, CHENG G G, Li Y, et al. Characteristics and distribution of sulfide in calciumtreated resulfurized steel at home and abroad[J]. China Metallurgy, 2023, 33(2): 65-72. -

下载:

下载: